Automatic oil pot assembly detection production line

An automatic assembly and production line technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., to achieve the effect of reducing labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

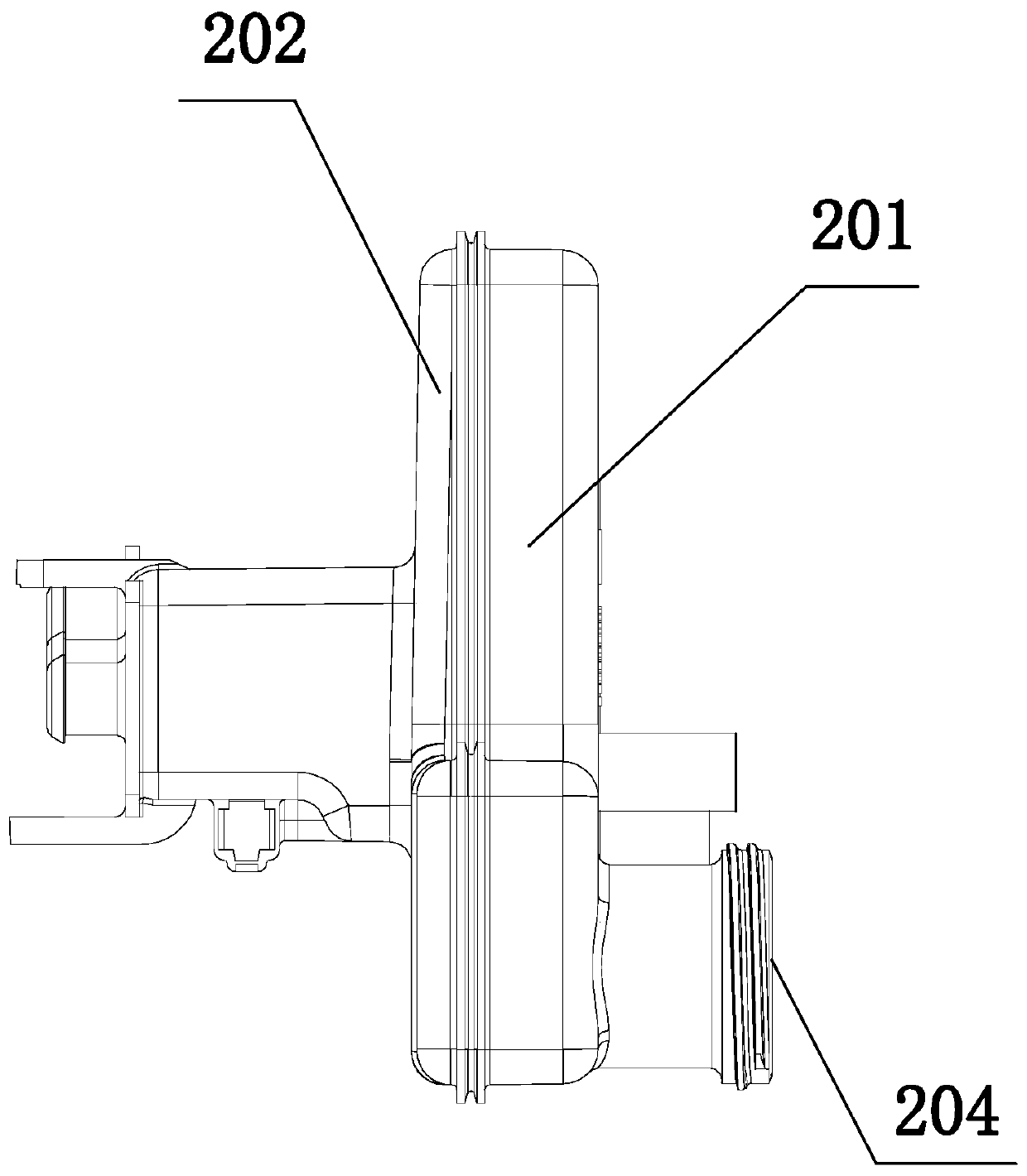

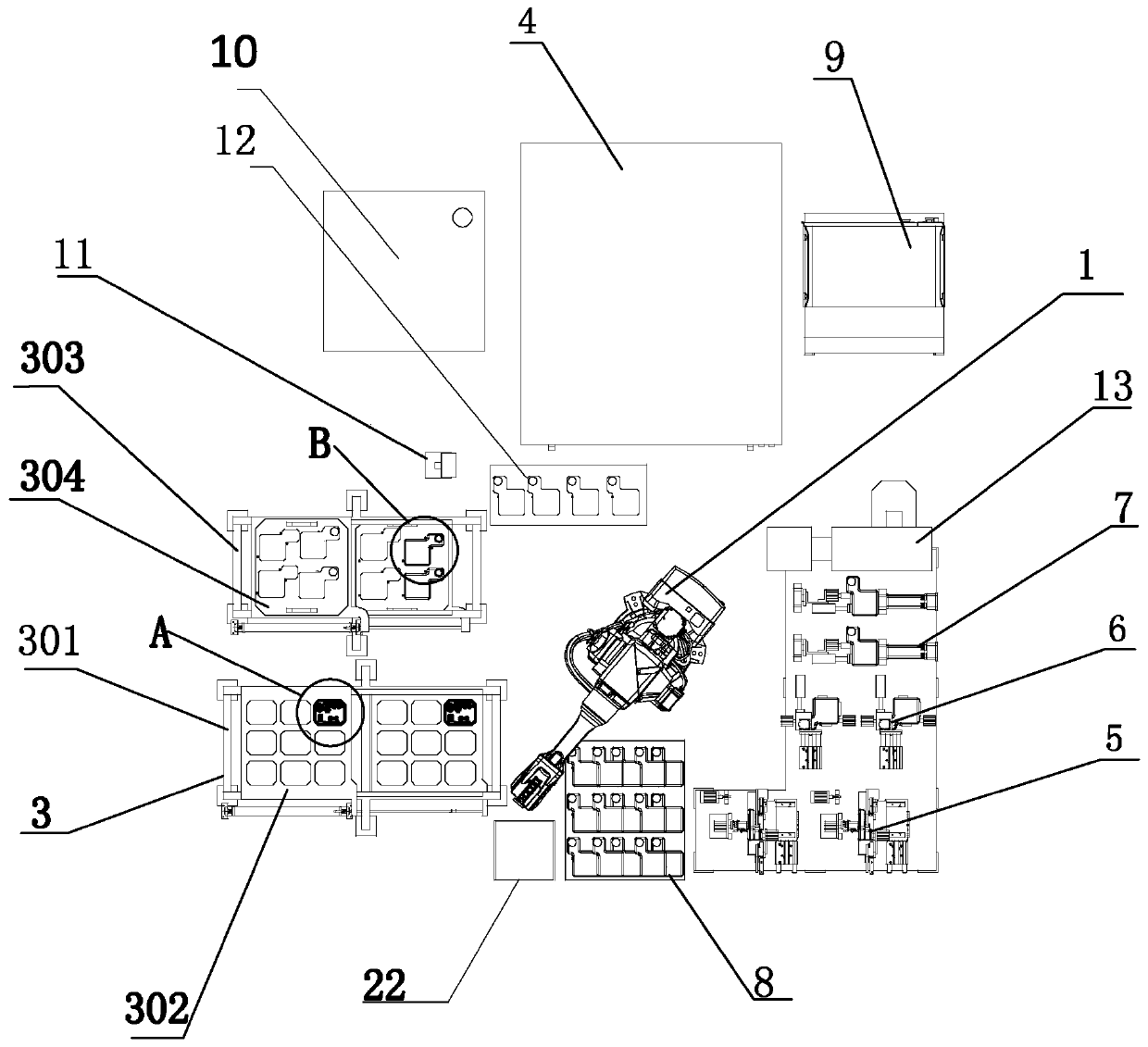

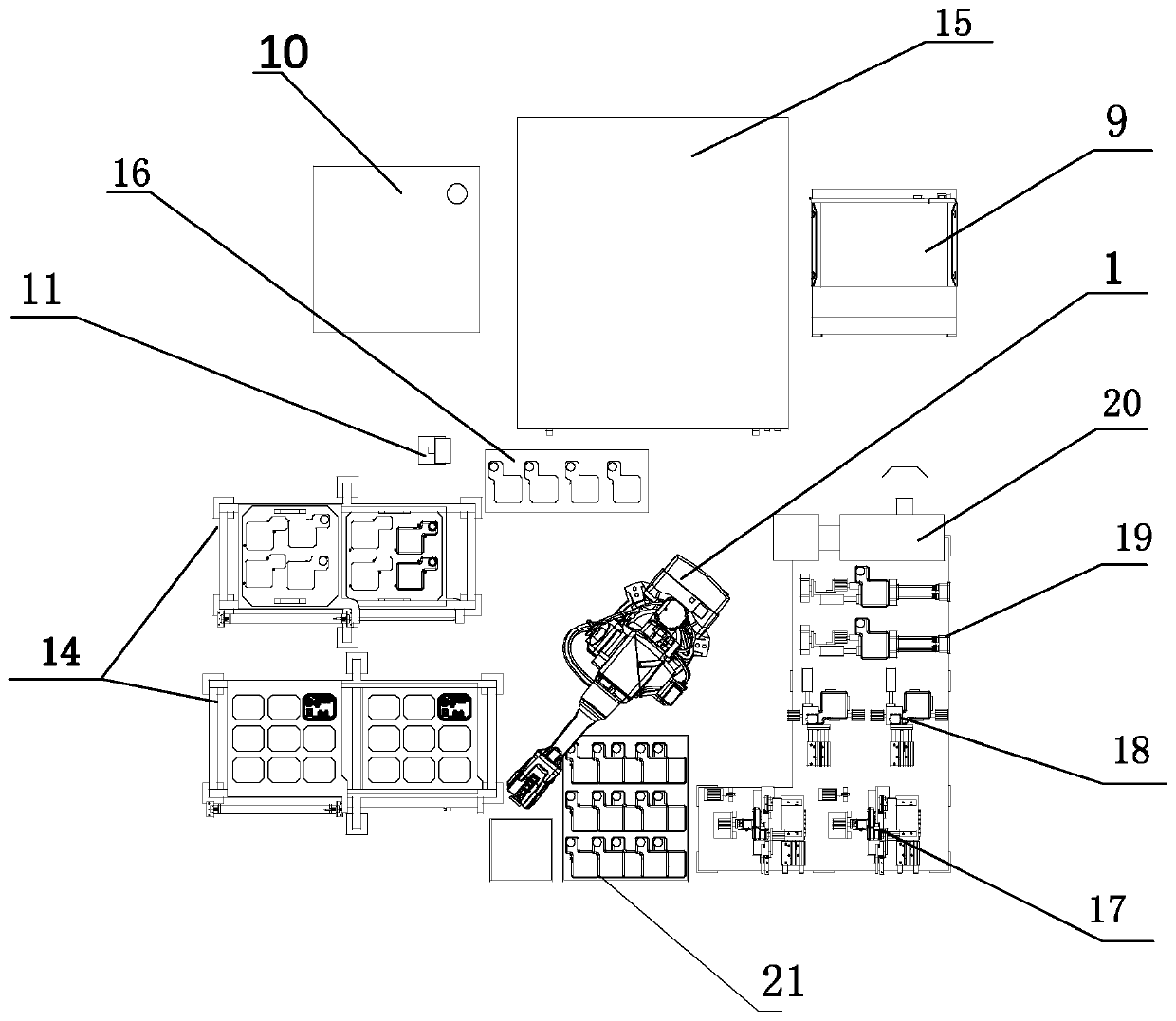

[0043] like Figure 1 to Figure 11 As shown, the oil pot 2 is automatically assembled and tested on the production line, and the oil pot 2 includes an upper cover body 201, a lower cover body 202, a sensor 203, an oil filling port 204, an oil filling port filter screen 205 and a float 206;

[0044] Including robot system 1, feeding system 3, servo welding machine 4, 2 air tightness testing machines 5, 2 sensors 203 pulling force testing machine 6, 2 turning on-off testing machines 7; the product robot system 1 It is arranged in the middle of the production line, the feeding system 3 is arranged on the left side of the robot system 1, the servo welding machine 4 is arranged behind the robot system 1, and the air tightness detection mechanism 5 and the sensor 203 are tested for pulling force. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com