Bearing cover packaging system and control method of bearing cover packaging system

A technology of packaging system and control method, which is applied in the field of bearing packaging equipment and its control system, can solve the problems of inaccessible materials, inventory control of materials, wrong parts of bearing caps, placement of missing parts, etc., so as to prevent unsalable products , Guarantee quality and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical means and creative features realized by the present invention easy to understand, the present invention will be further elaborated below.

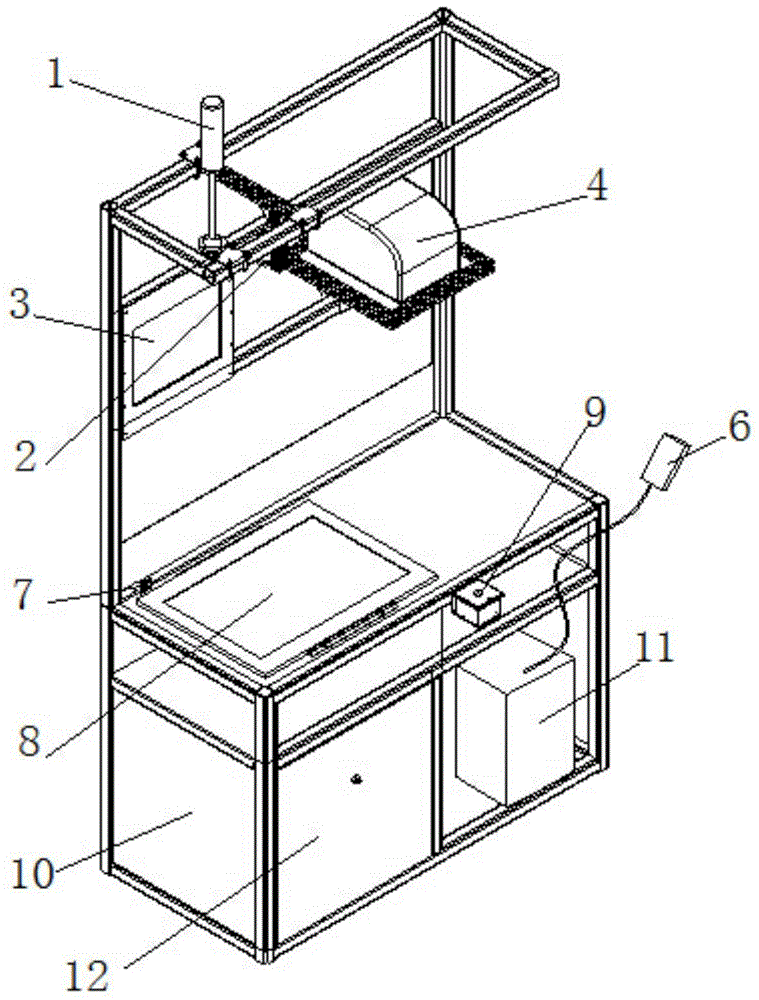

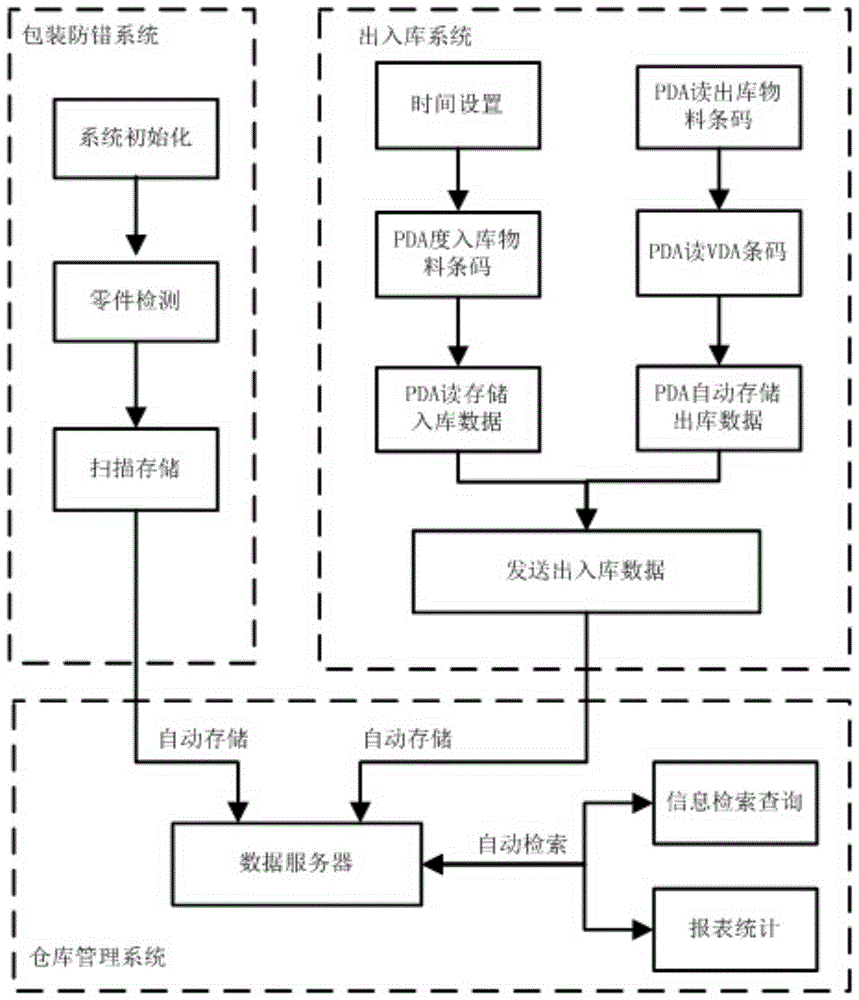

[0046] Such as Figure 1 to Figure 4 As shown, a bearing cover packaging system includes a workbench (12), a packaging error prevention system, a storage system and a warehouse management system.

[0047] In the packaging process, the blister tray is used to fix the bearing cap, the material box is used to pack the blister tray, and the material tray is used to place the material box.

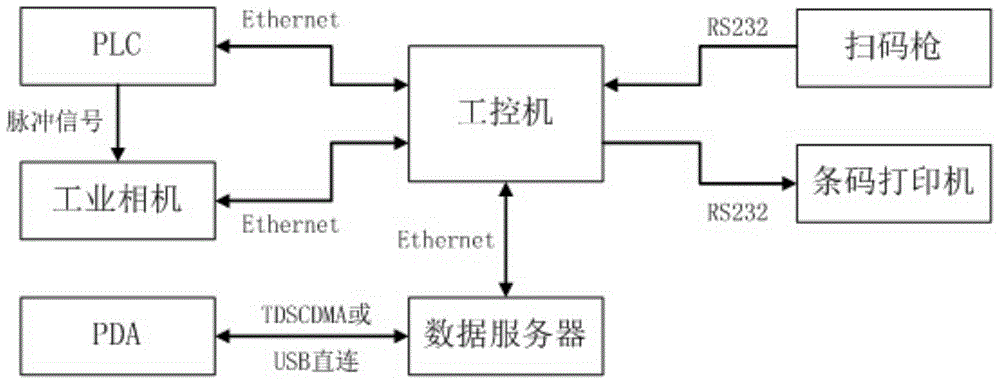

[0048] Such as figure 1 , the workbench (12) is used to install and fix all hardware devices, the lower left part of the workbench (12) is equipped with an electric control box (10), and the electric control box (10) is equipped with a PLC and an industrial computer, The hardware interface of the industrial computer includes at least three RJ45 interfaces and two RS232 interfaces. The lower right part of the workbenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com