Multifunctional equipment used for glass bottle

A technology of multi-functional equipment, glass bottles, applied in the direction of sorting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

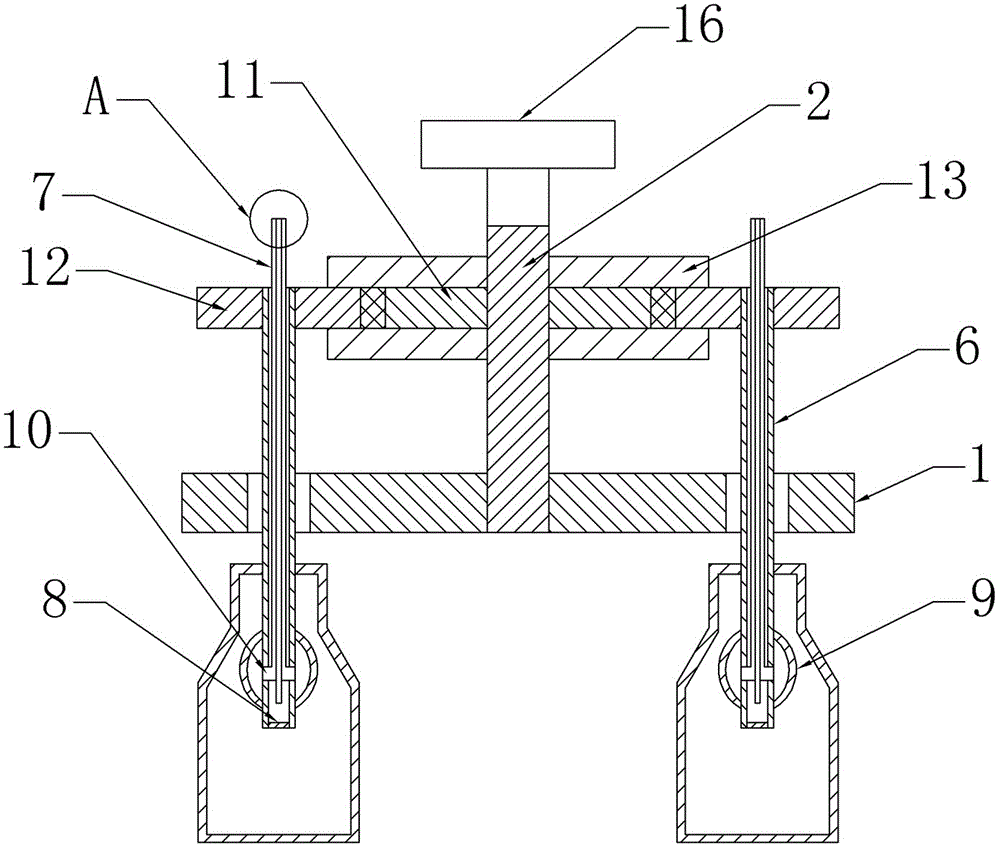

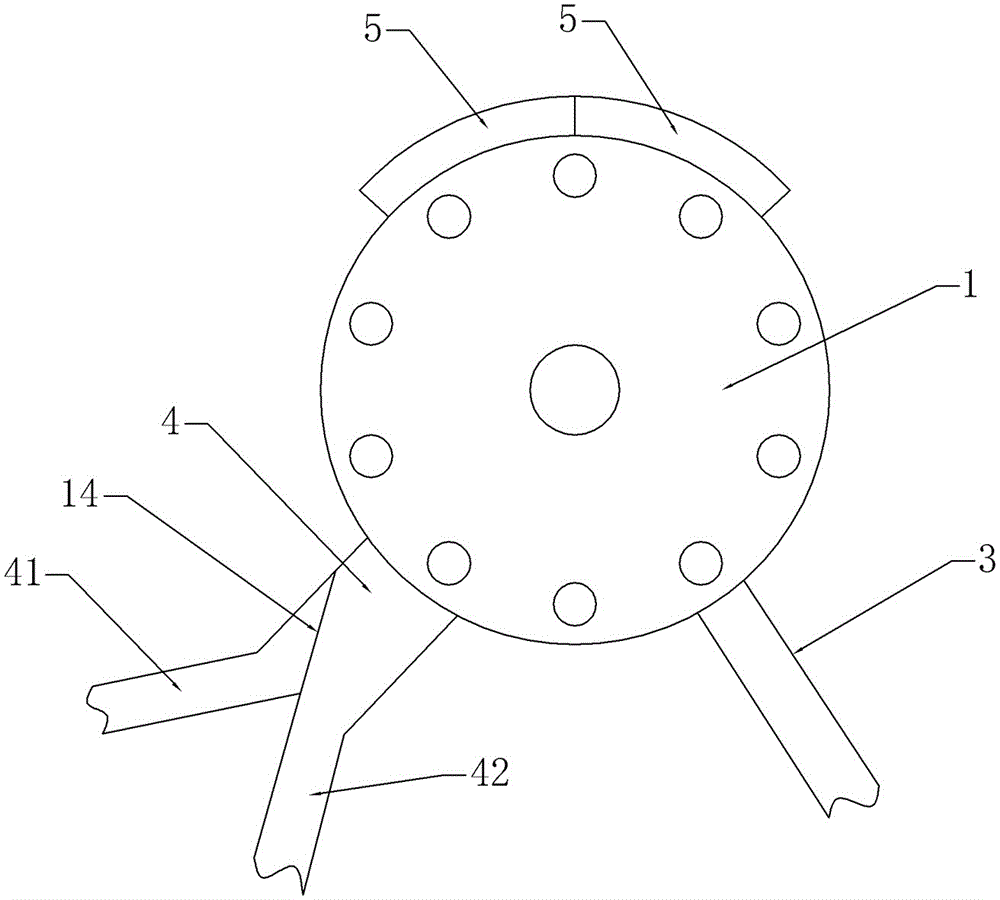

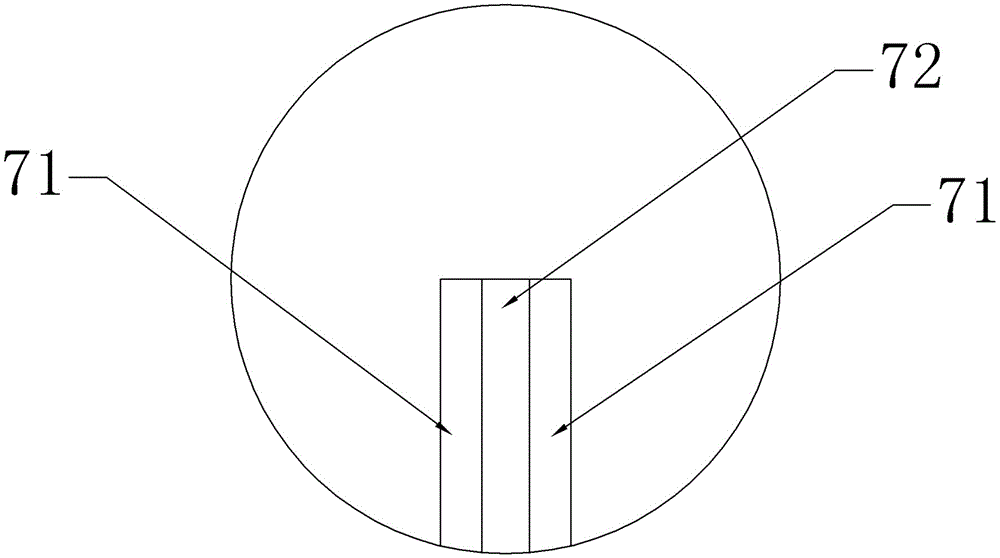

[0024] The reference signs in the drawings of the description include: turntable 1, rotating shaft 2, feed channel 3, discharge channel 4, genuine product channel 41, defective product channel 42, camera device 5, fixed cylinder 6, water inlet pipe 7, secondary pipe 71, cleaning pipe 72, water pressure control valve 8, small water bag 9, outlet hole 10, first gear 11, second gear 12, positioning plate 13, adjusting plate 14, groove 15, lifting mechanism 16.

[0025] This example figure 1 and figure 2 As shown, the multi-functional equipment used for glass bottles has a rotating shaft 2 in the center of the turntable 1 with an interference fit. The upper end of the rotating shaft 2 is fixedly connected to the rotating motor. The upper end of the rotating motor is connected to a lifting mechanism 16. for hydraulic presses. The middle part of the rotating shaft 2 has an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com