Groove type pipe joint seal ring-free leakage testing device for firefighting

A test device, a groove-type technology, applied in the field of fire-fighting groove-type pipe joint without sealing ring leakage test device, can solve the problems of low detection quality and efficiency, many interference factors, high labor intensity, etc., and achieve detection automation , Simple structure, detection quality and efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

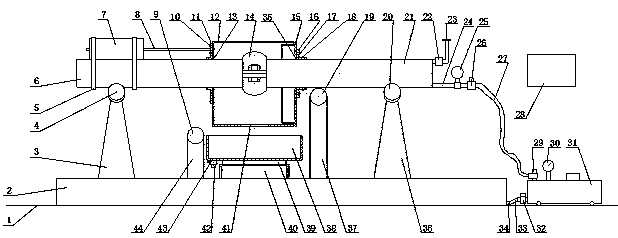

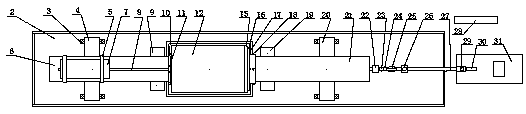

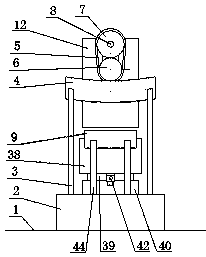

[0020] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a circulating water tank 2 placed on the ground 1, and the circulating water tank 2 is sequentially installed with a bracket A3 with a concave bar A4 on the top, a bracket B37 with a cross bar A19 on the top, and a concave bar at the top. The bracket C36 of the bar B20, the left end closed tube 6 is arranged on the concave bar A4, the right tube 21 is set on the cross bar A19 and the concave bar B20, and there is no sealing ring groove installed between the left end closed tube 6 and the right tube 21 Type pipe joint sample 14; the water collection chamber composed of the moving end 12 of the water collection chamber and the fixed end 15 of the water collection chamber is set on the periphery of the groove type pipe joint sample 14 without sealing ring, and the right pipe 21 passes through the flange 16 is fixed with the fixed end 15 of the water collection chamber, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com