Automatic assembling machine for female joint of television signal line

A technology for TV signal and female connector is applied in the field of automatic assembly machine for TV signal line female connector, which can solve the problems of low productivity, poor qualification rate and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

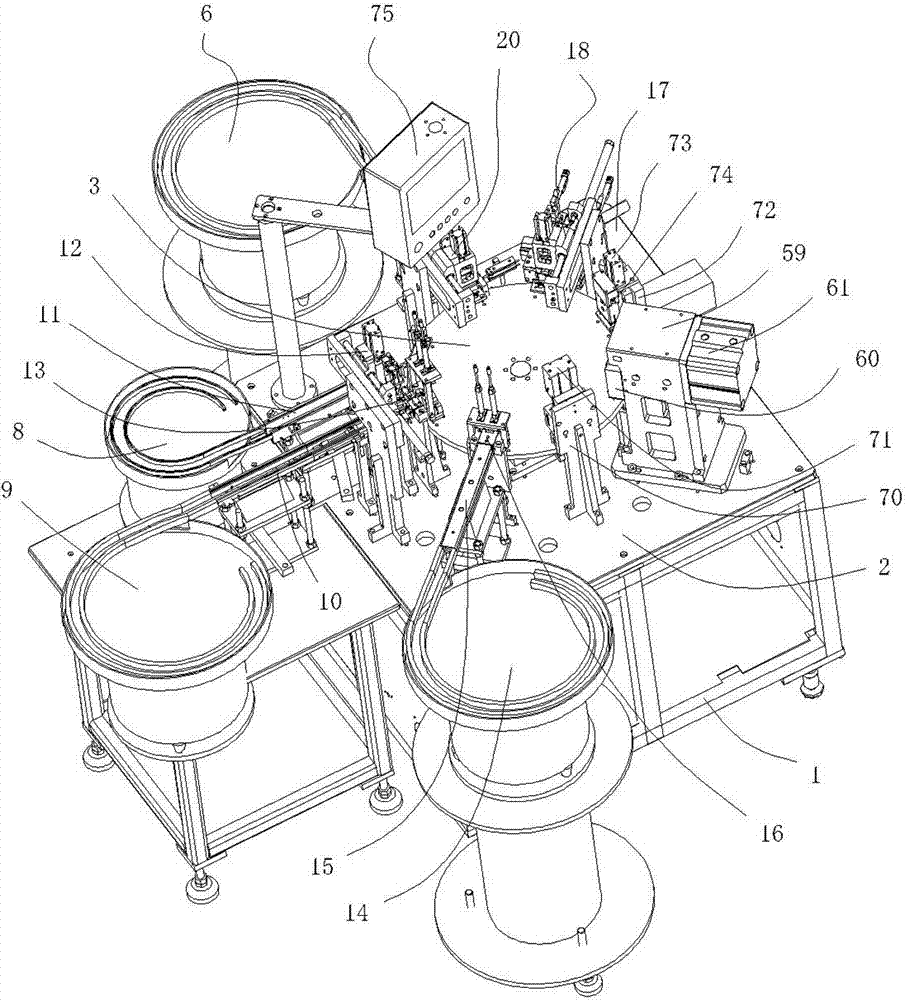

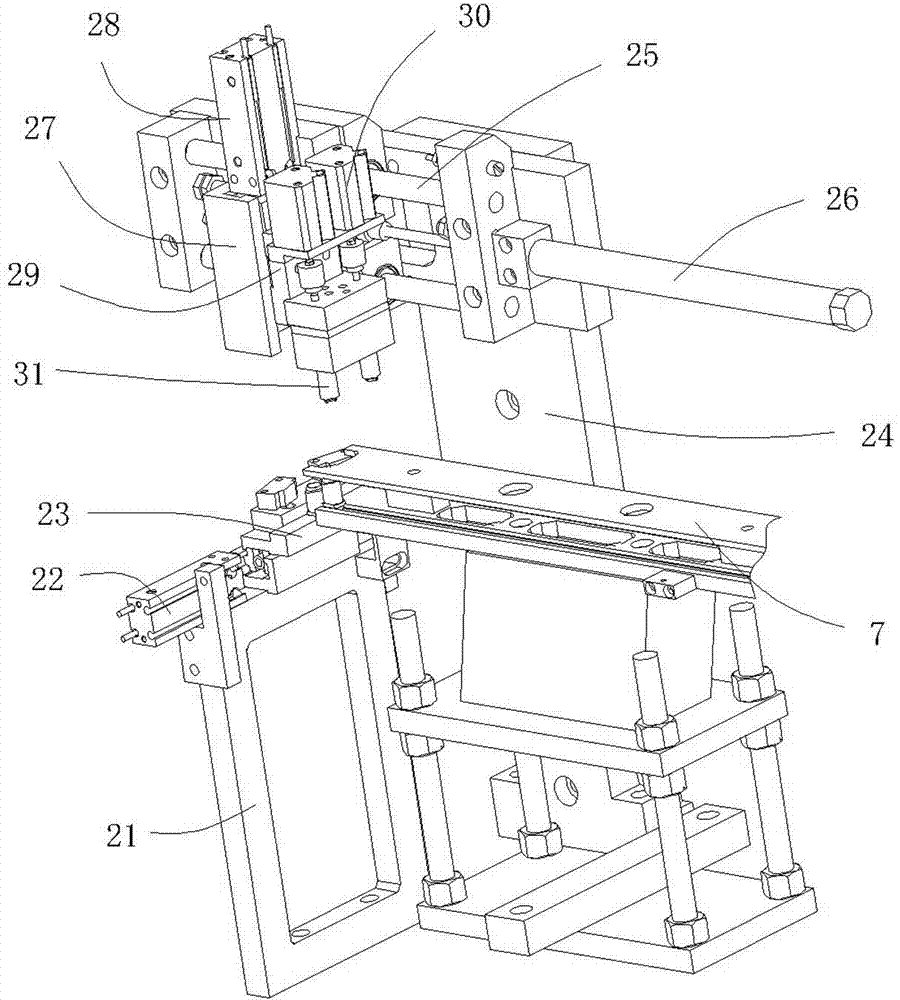

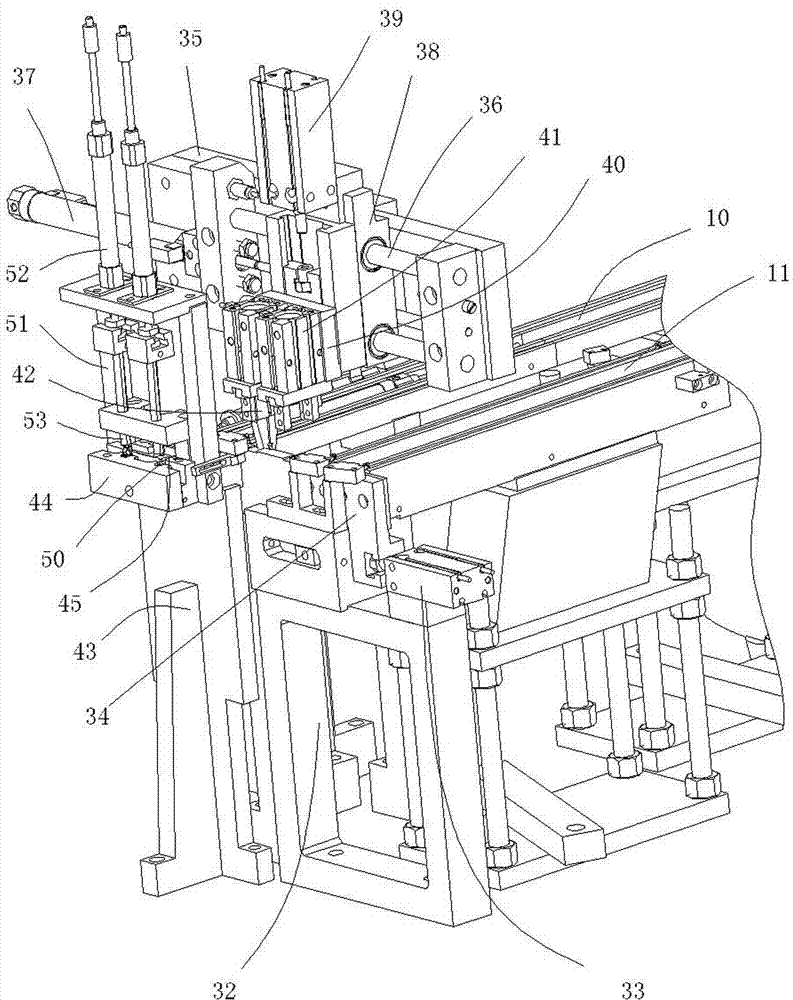

[0045] refer to Figure 1~Figure 7 , an automatic assembly machine for female connectors of television signal lines, comprising a frame 1, a workbench 2 is provided on the frame, a multi-station turntable 3 is arranged on the workbench, and the multi-station turntable is driven by an indexing drive mechanism Thereby rotating, a plurality of positioning molds 4 are evenly distributed on the multi-station turntable, and positioning grooves 5 matching the shell are recessed on the positioning molds;

[0046]The upper part of the multi-station turntable 3 is evenly distributed in turn with an upper casing station, an upper semi-finished product station, an upper insulating sleeve station, a riveting station, and a blanking station. The indexing positions of the multi-station turntable 3 are respectively It corresponds to the upper casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com