Electric machinery rotor automatic press-fitting machine

A technology of motor rotors and press-fitting machines, which is applied in the direction of electromechanical devices, electric components, and manufacturing motor generators, etc., and can solve problems such as multi-manual operations, low stability of assembly quality, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

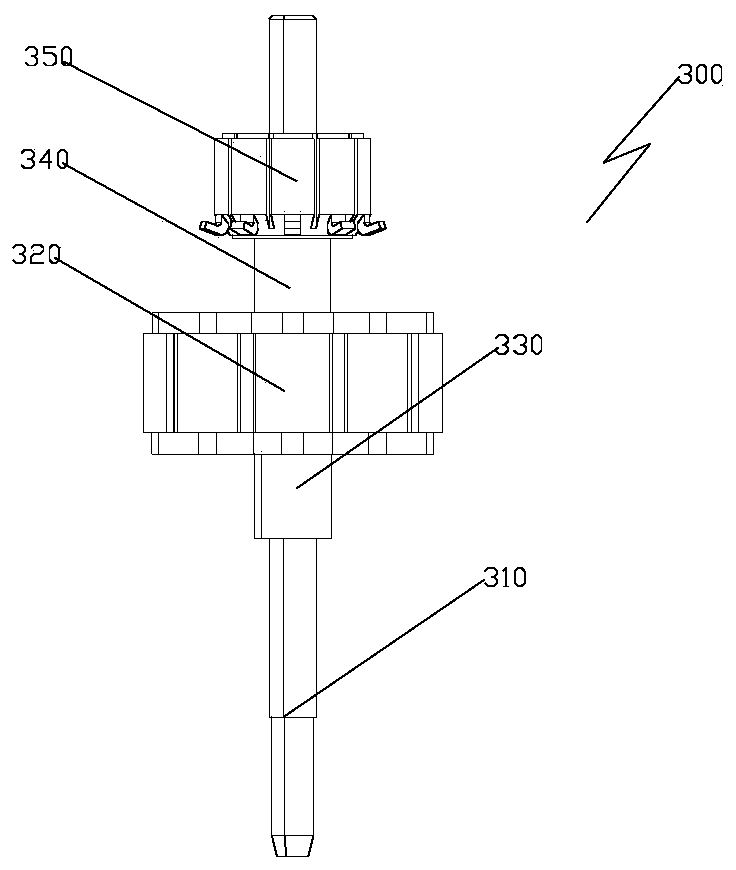

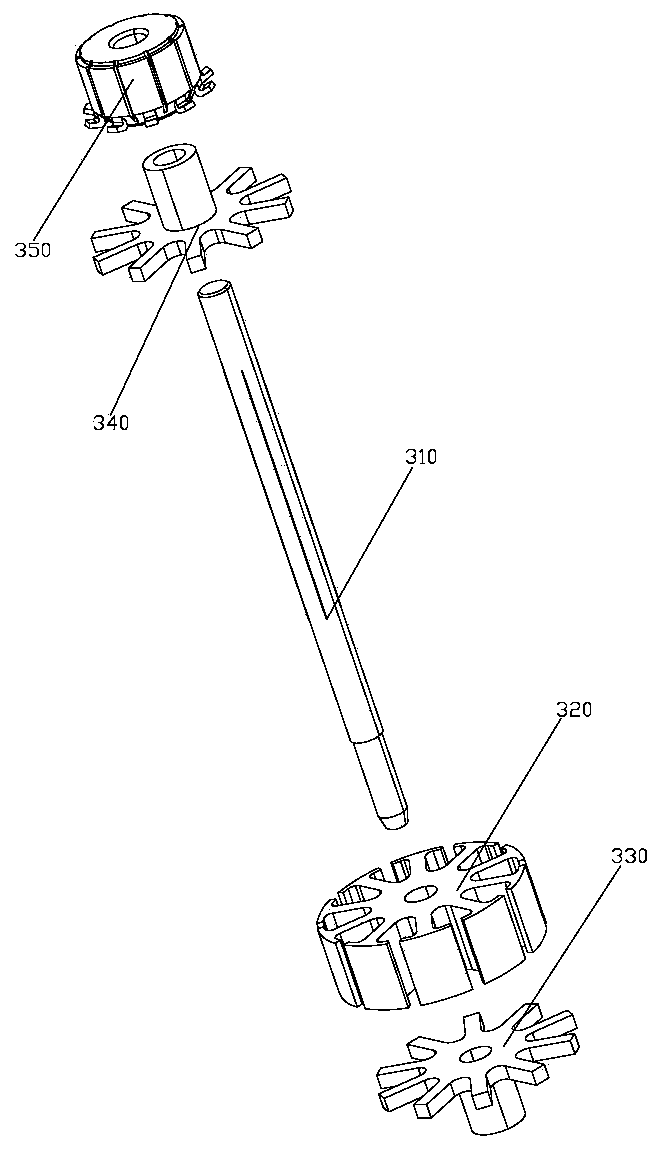

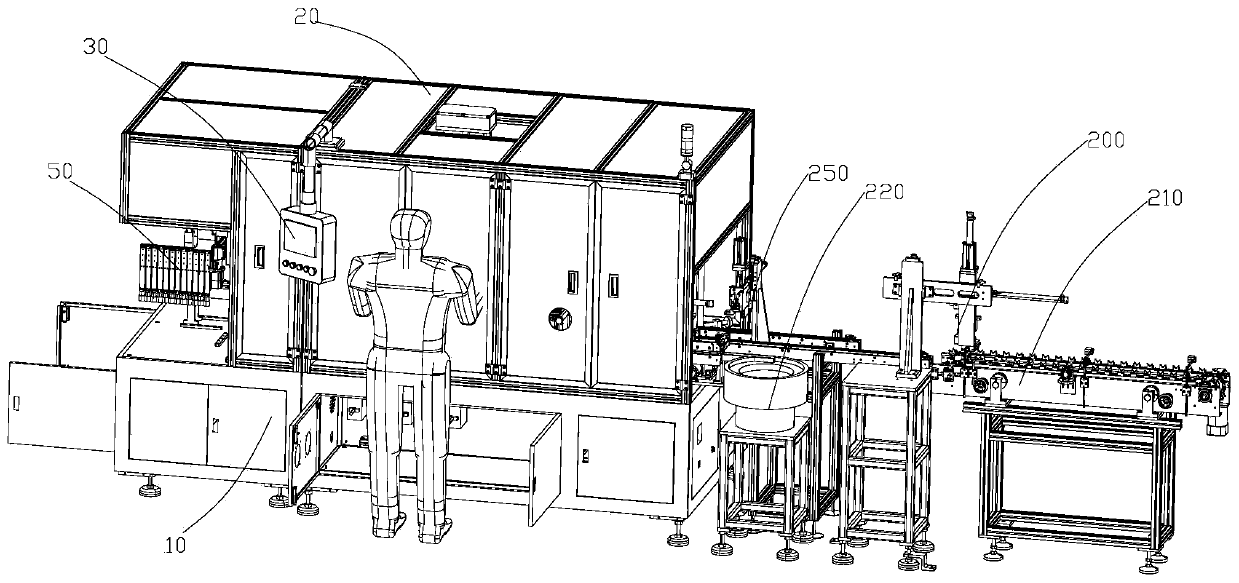

[0059] Such as Figure 3-8 As shown, the embodiment of the present invention provides an automatic motor rotor pressing machine, including a frame 10 and an iron core conveying device 40, a limited displacement conveying platform 70, a rotating worktable 120, and a blanking device provided along the length direction of the frame 10. The transmission device 210 is provided with an iron core feeding device 50 on the front end of the iron core transmission device 40, and a mandrel insertion station is provided at the front end of the limited displacement conveying platform 70, corresponding to both sides of the mandrel insertion station A mandrel feeding device 90 and a mandrel inserting device 60 are correspondingly provided, an automatic discharging device 80 is provided corresponding to the limited displacement conveying channel of the limited displacement conveying platform 70, and a mandrel is provided at the rear end of the limited displacement conveying platform 70 The press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com