Self-adhesive conductive silicone rubber electromagnetic shielding material

An electromagnetic shielding material, conductive silicon technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems affecting the shielding effect of products, poor assembly of electromagnetic sealing rings, etc., to eliminate poor electromagnetic sealing, The electromagnetic shielding effect is good and the labor cost is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

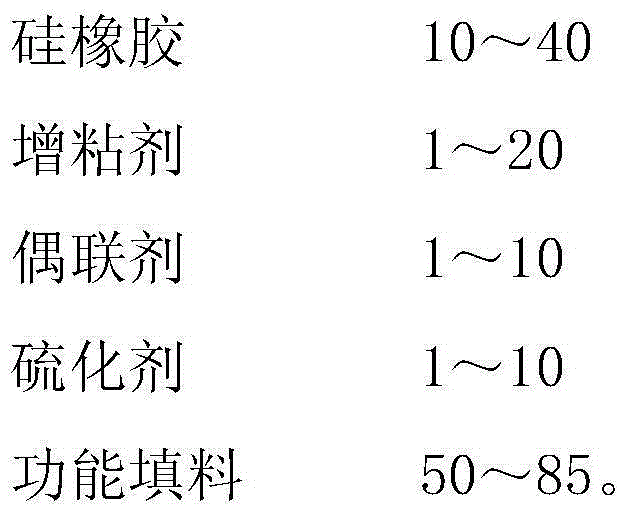

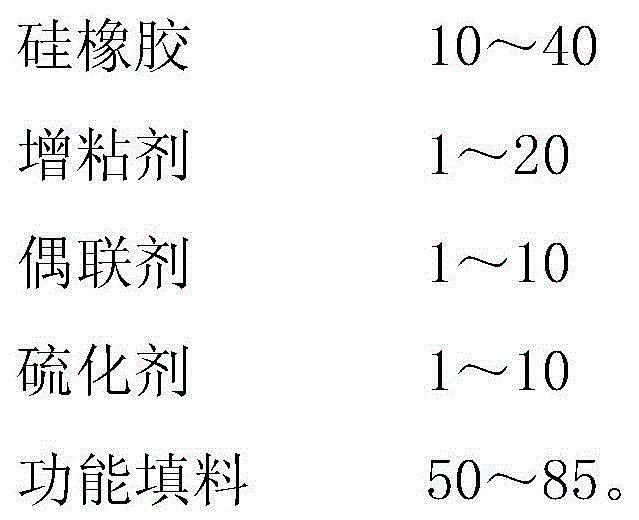

Method used

Image

Examples

Embodiment 1

[0016] Get the conductive carbon black powder that weight is 7kg, the nickel-coated graphite powder of 12kg, the trimethyl borate of 0.4kg, the methyl vinyl silicone rubber of 0.4kg silane coupling agent A-151, 13kg mixes 30 minutes, after double Add 0.5 kg of bis-2-4 vulcanizing agent on the roller mill and knead for 20 minutes to form the self-adhesive conductive silicone rubber electromagnetic shielding material of the present invention, and then press the electromagnetic shielding material on a flat vulcanizer to form a sealing strip with a diameter of 100 mm. Install the sealing strip between the upper and lower metal cover plates, cover the cover plate, pre-press with a force of 30kgf, and then put it in an oven at 160°C for 15 minutes to vulcanize, so that the two layers of metal cover plates are firmly bonded.

[0017] After testing, the resistivity of the self-adhesive conductive silicone rubber electromagnetic shielding material is 0.5Ω*cm, and the bonding force of th...

Embodiment 2

[0019] Get the silver powder that weight is 10kg, the nickel-coated graphite powder of 10kg, the tricyclic derivative of silicon nitrogen of 1kg, the methylvinyl silicone rubber of 0.5kg silane coupling agent A-171, 10kg add on the two-roll mill 0.5kg of hydrogen-containing silicone oil with a hydrogen content of 0.36%, and 0.05kg of a Pt catalyst with a double-headed Pt content of 3000ppm were opened for 20 minutes, and the composite material was pressed into a sealing strip with a diameter of 100mm on a flat vulcanizer. Install the sealing strip in the middle of the upper and lower metal cover plates, cover the cover plate, pre-press with a force of 30kgf, and then put it in an oven at 120°C for 15 minutes for vulcanization.

[0020] After testing, the resistivity of the conductive rubber mixture is 0.05Ω*cm, and the bonding strength of the upper and lower metal cover plates is greater than 4MPa. The adhesive force and resistivity of the sample remained unchanged after 1000 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com