Electromagnetic shielding film and preparation method thereof

A technology of electromagnetic shielding film and shielding layer, which is applied in the fields of magnetic field/electric field shielding, chemical instruments and methods, electrical components, etc., and can solve problems such as the electromagnetic wave reflection effect does not have the electromagnetic wave absorption function, the shielding effect is not ideal, and the structure of the shielding film is single. , to achieve the effect of facilitating industrial promotion and application, improving electromagnetic shielding efficiency, and enhancing electromagnetic shielding function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

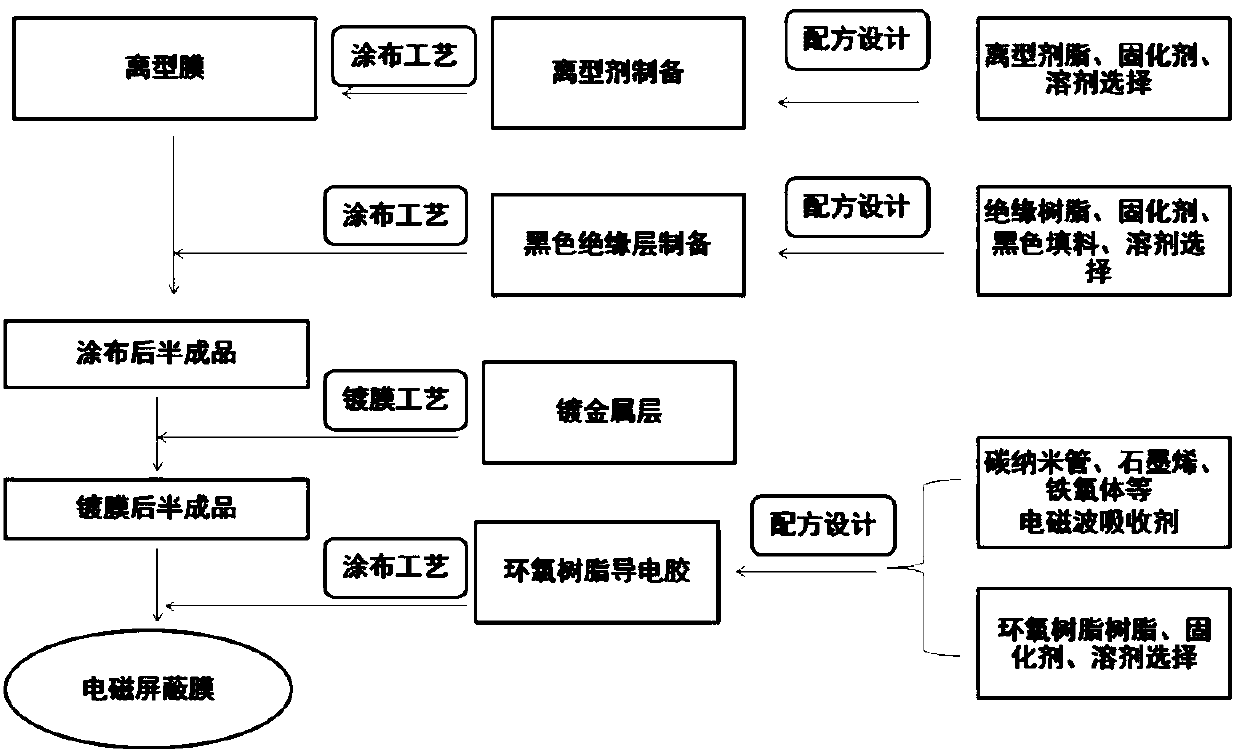

[0043] A kind of electromagnetic shielding film, its structure is as figure 1 As shown, the preparation process is as follows figure 2 shown, including the following steps:

[0044] (1) Prepare a release film layer, the raw materials include 45% release agent grease, 5% curing agent, and 50% solvent;

[0045] (2) The insulating layer and black insulating layer are prepared by 23% insulating resin, 4% curing agent, 0.5% accelerator, 8% filler and 7.8% flame retardant, and the insulating layer is coated on the release film by coating process layer, and then coat a black insulating layer on the other side of the insulating layer, and then plate copper on the other side of the black insulating layer through a coating process to form a metal layer with a thickness of 100 nanometers to obtain a semi-finished product;

[0046] (3) Prepare conductive glue with 12% epoxy resin and 65% conductive powder, and apply conductive glue on the metal layer;

[0047] (4) On the other side of...

Embodiment 2

[0049] A kind of electromagnetic shielding film, raw material and preparation method are as follows:

[0050] (1) Prepare a release film layer, the raw materials include 45% release agent grease, 5% curing agent, and 50% solvent;

[0051] (2) The insulating layer and black insulating layer are prepared by 23% insulating resin, 4% curing agent, 0.5% accelerator, 8% filler and 7.8% flame retardant, and the insulating layer is coated on the release film by coating process layer, and then coat a black insulating layer on the other side of the insulating layer, and then plate copper on the other side of the black insulating layer through a coating process to form a metal layer with a thickness of 200nm to obtain a semi-finished product;

[0052] (3) Prepare conductive glue with 12% epoxy resin, 65% conductive powder and 1% carbon nanotube, and coat the conductive glue on the metal layer;

[0053] (4) On the other side of the conductive adhesive, a shielding film is prepared throug...

Embodiment 3

[0055] A kind of electromagnetic shielding film, raw material and preparation method are as follows:

[0056] (1) Prepare a release film layer, the raw materials include 40% release agent grease, 3.8% curing agent, and 56.2% solvent;

[0057] (2) The insulating layer and black insulating layer are prepared by 30% insulating resin, 6% curing agent, 0.8% accelerator, 5% filler and 8% flame retardant, and the insulating layer is coated on the release film by coating process layer, and then coat a black insulating layer on the other side of the insulating layer, and then plate copper on the other side of the black insulating layer through a coating process to form a metal layer with a thickness of 150nm to obtain a semi-finished product;

[0058] (3) Prepare conductive glue with 17% epoxy resin, 55% conductive powder and 1% graphene, and coat the conductive glue on the metal layer;

[0059] (4) On the other side of the conductive adhesive, a shielding film is prepared through a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com