Flexible electromagnetic shielding film material with bionic multilayer structure capable of being regulated into isolation structure and preparation method of flexible electromagnetic shielding film material

An electromagnetic shielding material and electromagnetic shielding film technology, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of secondary or multiple processing, electromagnetic shielding performance degradation, irreparable repair or recycling, etc., to improve electromagnetic shielding Effectiveness, high-efficiency electromagnetic shielding performance, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

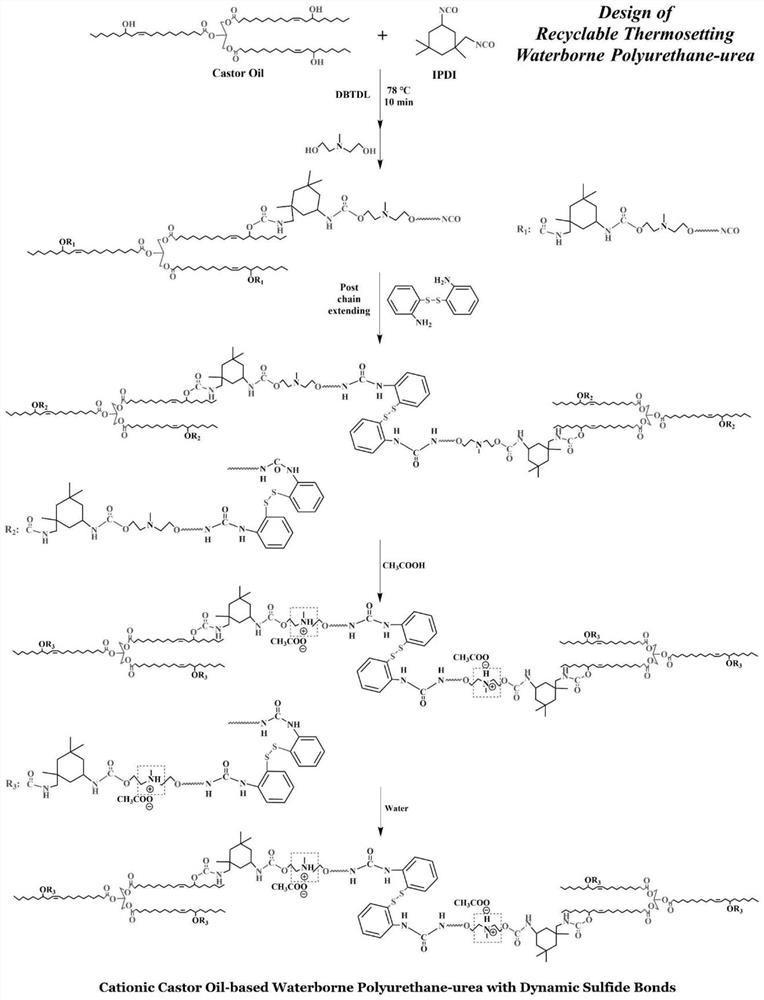

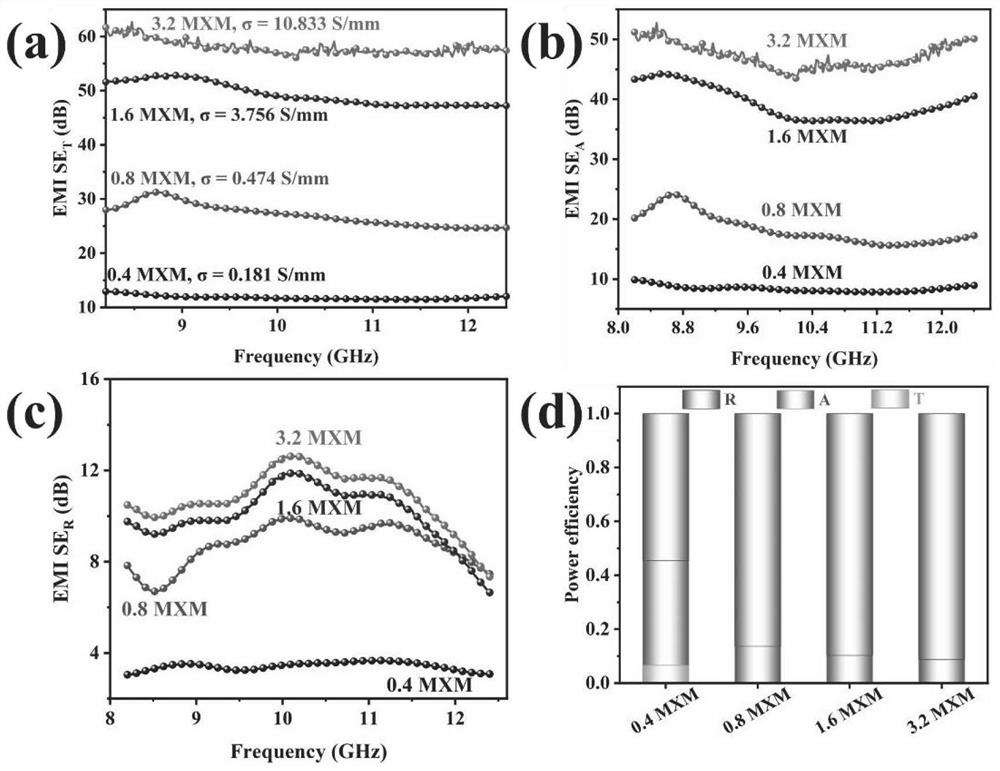

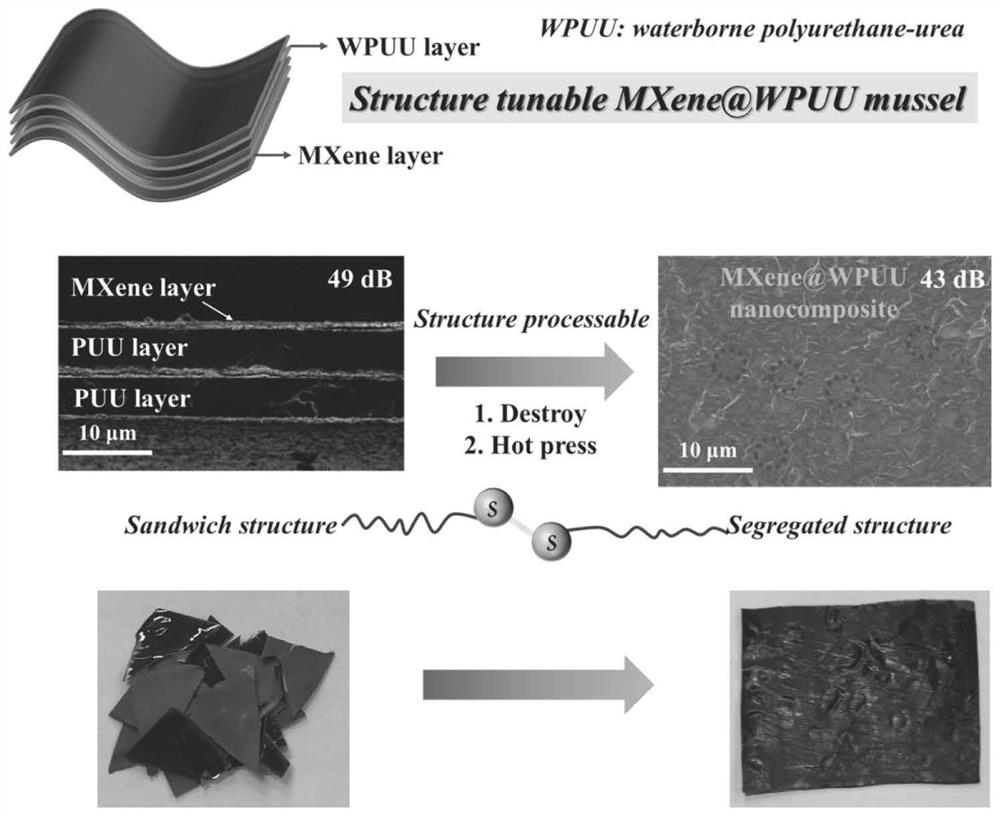

[0035] The bionic structure-adjustable electromagnetic shielding film of this implementation is made of castor oil-based water-based polyurethane (see the preparation process in figure 1 ), solvent water and electromagnetic shielding filler as raw materials, the electromagnetic shielding film prepared by the method of vacuum filtration; specifically prepared according to the following steps:

[0036] Step 1: Use liquid-phase chemical etching to prepare titanium carbide nanosheets, ultrasonically disperse to prepare an aqueous dispersion of titanium carbide, and prepare a concentration of 1 wt% to obtain an electromagnetic shielding nanofiller dispersion for use; the mass of titanium carbide used is 0.02 g, 0.04 g and 0.06 g.

[0037] Step 2: prepare a responsive castor oil-based water-based polyurethane, dilute with deionized water to a concentration of 2 wt %, and obtain a polymer dispersion for use.

[0038] Step 3: Add the two raw material components obtained in steps 1 an...

Embodiment 2

[0042] The biomimetic structure adjustable electromagnetic shielding film of this implementation is an electromagnetic shielding film prepared by vacuum filtration using castor oil-based water-based polyurethane, solvent water, and electromagnetic shielding filler as raw materials; the specific preparation is as follows:

[0043] Step 1: Use ultrasonic dispersion for 24 hours to prepare an aqueous dispersion of carbon nanotubes with a concentration of 1 wt% to obtain an electromagnetic shielding nanofiller dispersion for use; the mass usage of carbon nanotubes is 0.02g, 0.04g and 0.06g respectively.

[0044] Step 2: prepare a responsive castor oil-based water-based polyurethane, dilute with deionized water to a concentration of 2 wt %, and obtain a polymer dispersion for use.

[0045] Step 3: Add the two raw material components obtained in steps 1 and 2 into the vacuum suction filtration device alternately, and filter under vacuum conditions for 6 hours to form a total of five ...

Embodiment 3

[0049] The bionic structure adjustable electromagnetic shielding film of this implementation is an electromagnetic shielding film prepared by the method of vacuum sand core suction filtration using castor oil-based water-based polyurethane as the polymer base material, solvent water and electromagnetic shielding filler as raw materials; the specific steps are as follows. preparation:

[0050] Step 1: Use ultrasonic dispersion for 24 hours to prepare an aqueous dispersion of graphene, with a concentration of 1 wt%, to obtain an electromagnetic shielding nanofiller dispersion for use; the mass of graphene used is 0.02g, 0.04g and 0.06g, respectively.

[0051] Step 2: prepare a responsive castor oil-based water-based polyurethane, dilute with deionized water to a concentration of 2 wt %, and obtain a polymer dispersion for use.

[0052] Step 3: The two raw material components obtained in steps 1 and 2 are added alternately to the vacuum suction filtration device, and suction filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com