Longitudinally-adjustable connecting rod with cylinder-piston unit with rotational locking

An anti-rotation, connecting rod technology, applied to the second connecting rod, the connecting rod of the joint, can solve the problems of expensive cylinder hole sealing and high production cost, and achieve the effect of minimizing the remaining gap and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

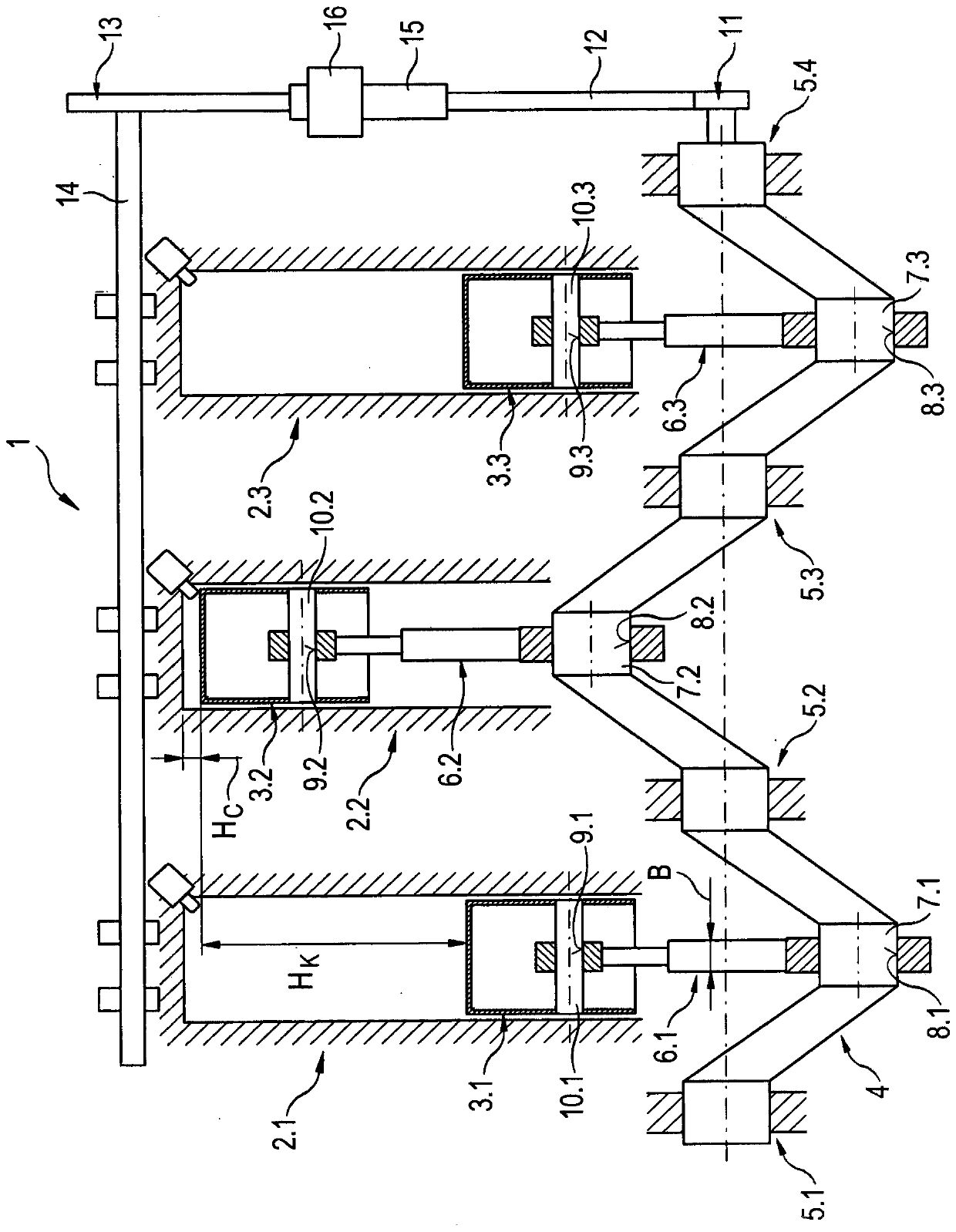

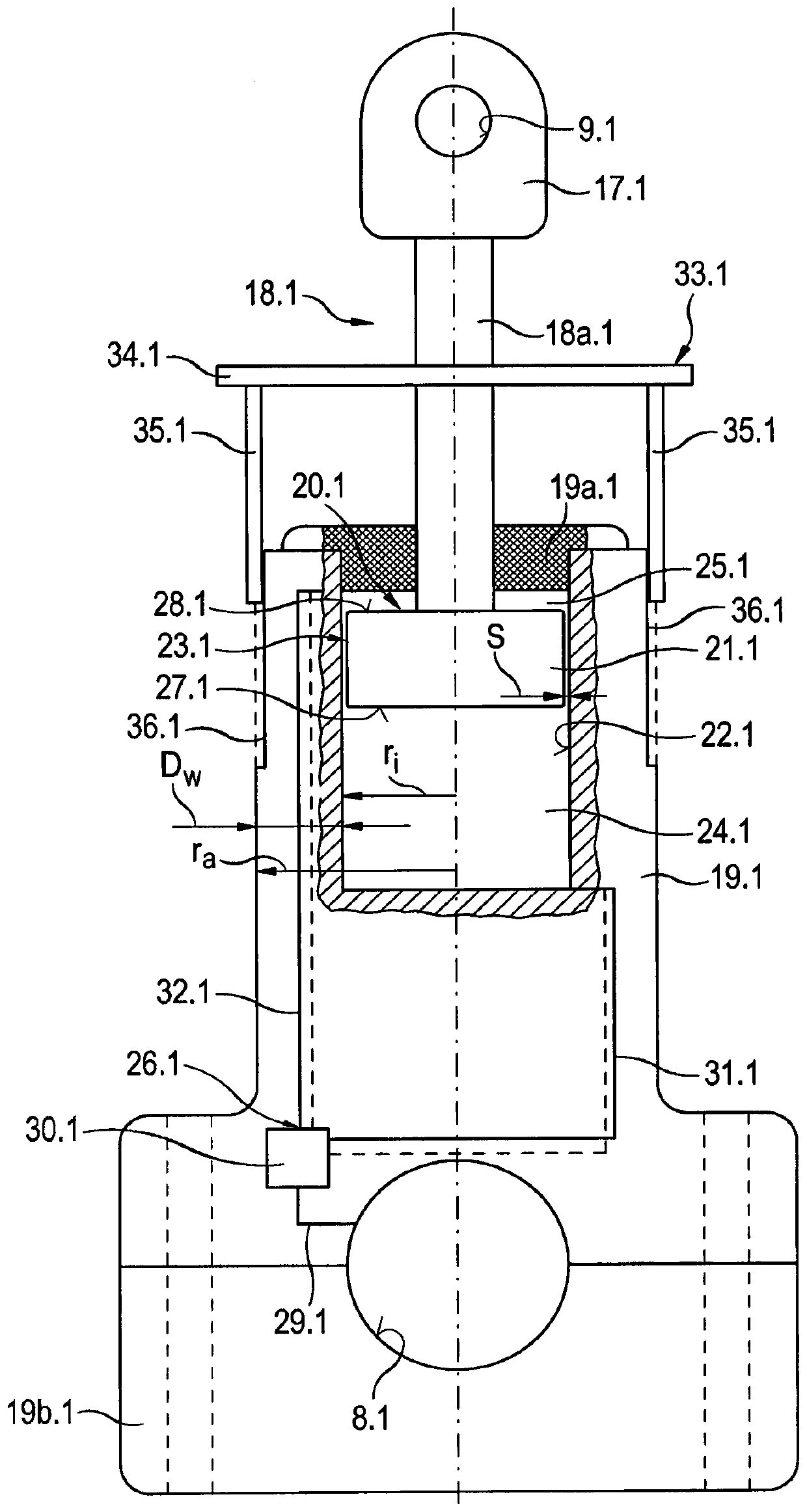

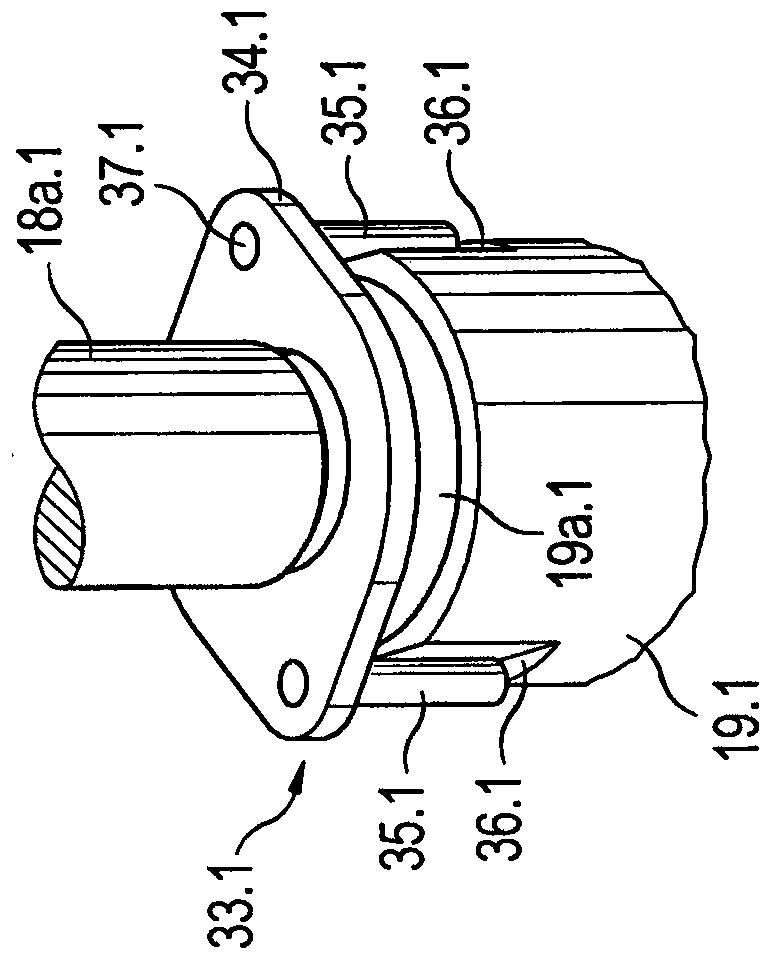

[0042] exist figure 1An internal combustion engine (gasoline engine) 1 is schematically illustrated in . The internal combustion engine 1 has three cylinders 2.1, 2.2 and 2.3, in each cylinder a reciprocating piston 3.1, 3.2, 3.3 moves up and down. Furthermore, the internal combustion engine 1 includes a crankshaft 4 which is rotatably mounted via crankshaft bearings 5.1, 5.2, 5.3, 5.4. Crankshaft 4 is connected to associated reciprocating pistons 3.1, 3.2 and 3.3 via connecting rods 6.1, 6.2 and 6.3, respectively. For each connecting rod 6.1, 6.2 and 6.3, the crankshaft 4 has an eccentrically arranged crankshaft journal 7.1, 7.2 and 7.3. The large connecting rod eyelets 8.1, 8.2 and 8.3 of the connecting rods 6.1, 6.2, 6.3 are respectively supported on the associated crankshaft journals 7.1, 7.2 and 7.3. The small connecting rod eyelets 9.1, 9.2 and 9.3 of the connecting rods 6.1, 6.2, 6.3 are respectively supported on the piston pins 10.1, 10.2 and 10.3 and are thus pivot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com