Patents

Literature

349 results about "Gudgeon pin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In internal combustion engines, the gudgeon pin (UK, wrist pin US) connects the piston to the connecting rod, and provides a bearing for the connecting rod to pivot upon as the piston moves. In very early engine designs, including those driven by steam, and many very large stationary or marine engines, the gudgeon pin is located in a sliding crosshead that connects to the piston via a rod. A gudgeon is a pivot or journal. The origin of the word gudgeon is the Middle English word gojoun, which originated from the Middle French word goujon. Its first known use was in the 15th century.

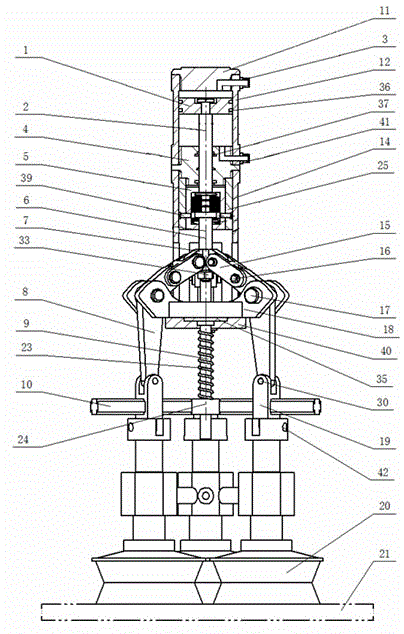

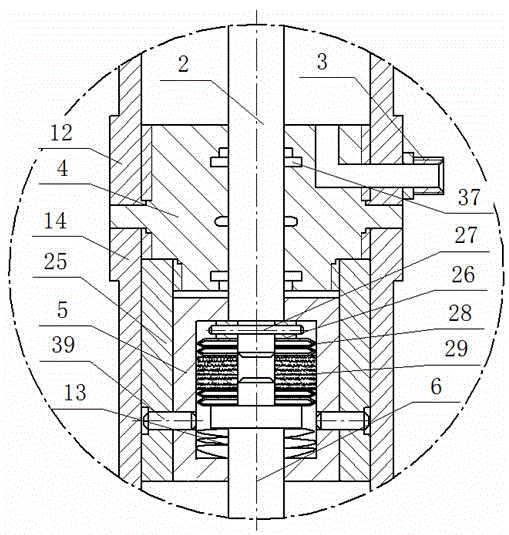

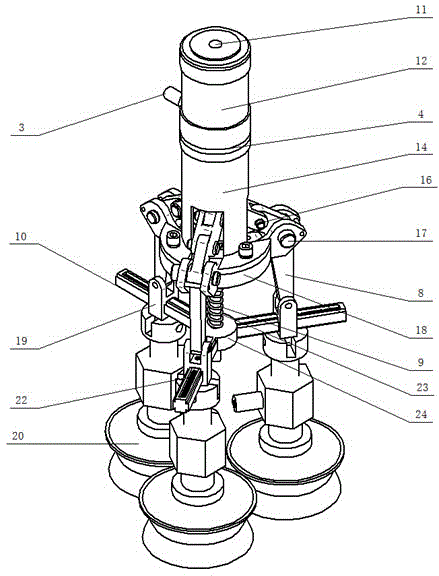

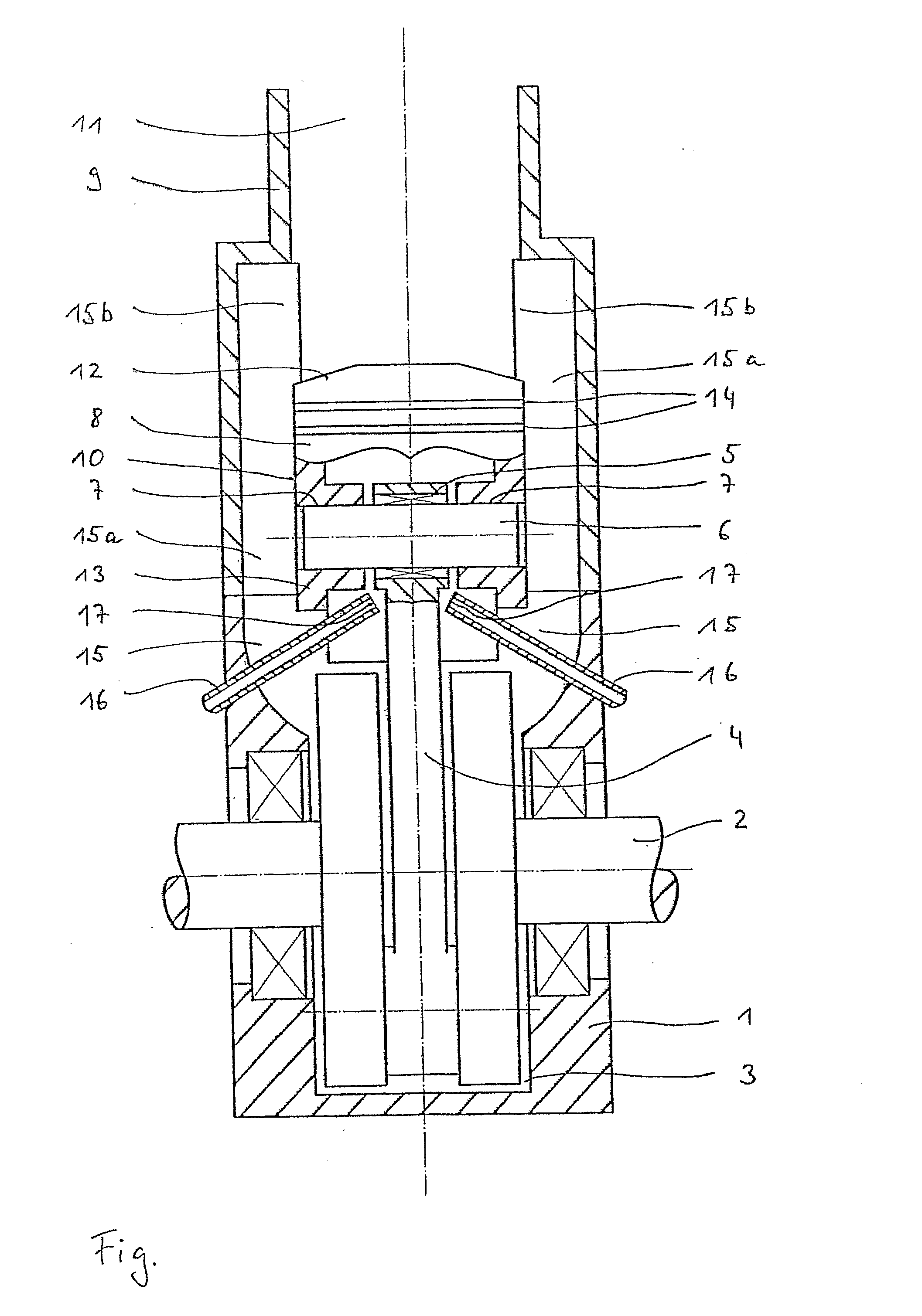

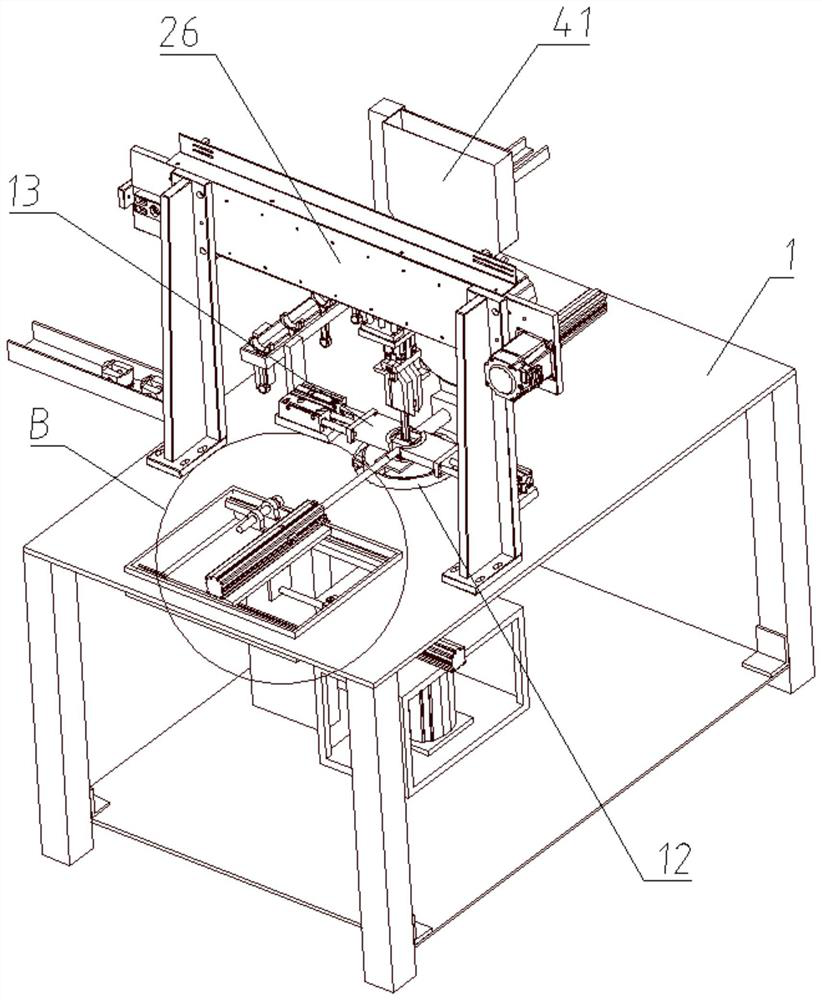

Vacuum chuck manipulator paw

The invention discloses a vacuum chuck manipulator paw which comprises a piston, a piston rod, a pipe connector I, a front cylinder cover, a sleeve, a push-pull rod, a push-pull rod head, more than three knuckles, a connecting rod, a chuck sliding groove, a rear cylinder cover, a cylinder, a relaxation spring, a connecting seat, a hinge, a hinge shaft, a knuckle shaft, a mounting seat, a movable hand rack, a vacuum chuck, a return spring, a spring, a connecting ring, a sleeve connecting seat, a piston rod fixing plate, a piston pin, a disc spring slice group, a friction plate, a movable hand rack pin, a spring stopper, a stopper locking nut, a piston nut, a pressing plate, a sealing ring, a seal ring, a connecting rod fixing plate and a pipe connector II. When the cylinder charges air or discharges air, the push-pull rod is driven to move downwards or upwards, the manipulator paw opens or shrinks, the return spring is compressed or rebounds along with the manipulator paw, so that the chuck horizontally slides on an X plane and a Y plane and vertically moves in a Z direction and is matched with an external big arm to move, blocks with different sizes can be caught and taken, and the requirements of actual production are met.

Owner:KUNMING UNIV OF SCI & TECH

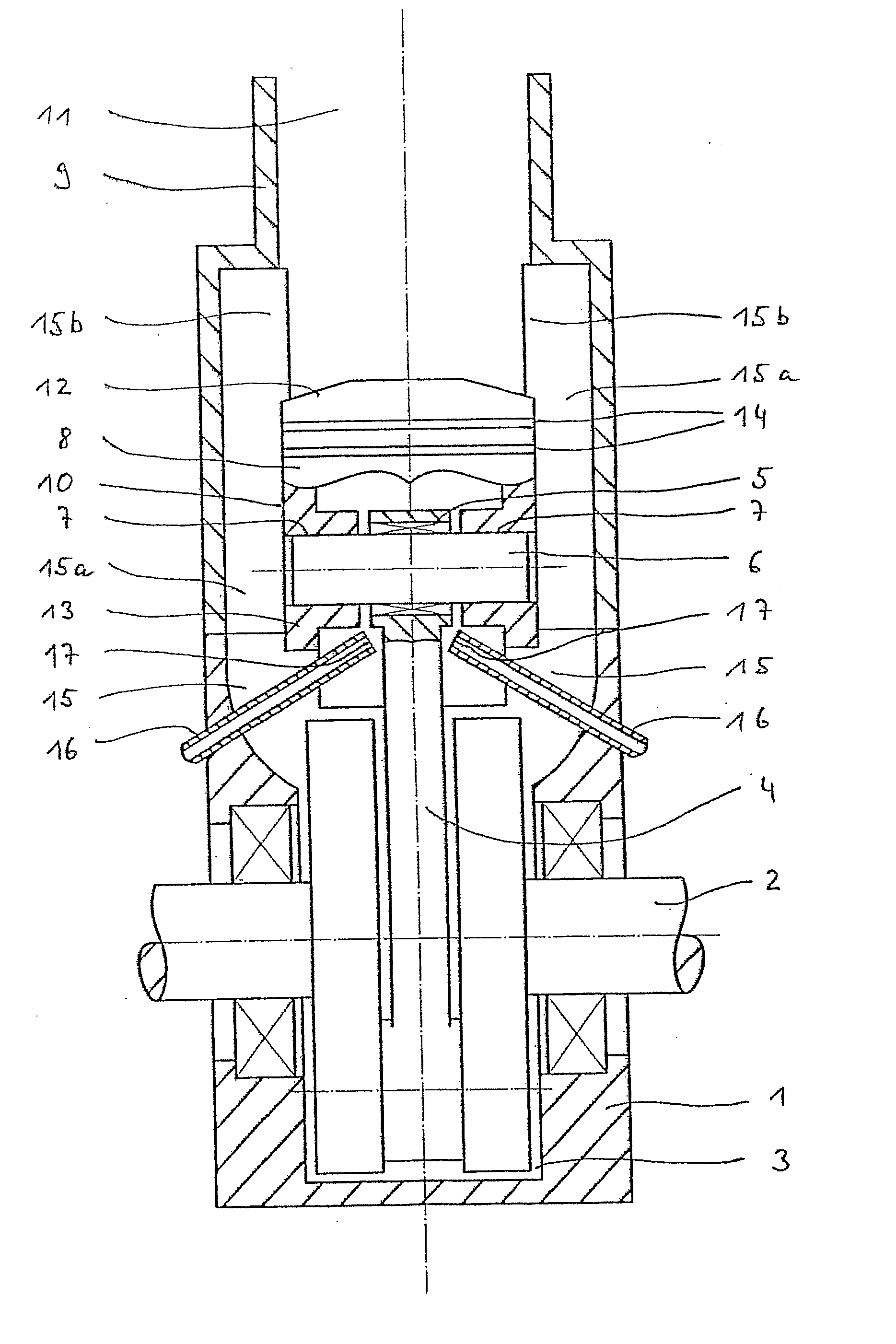

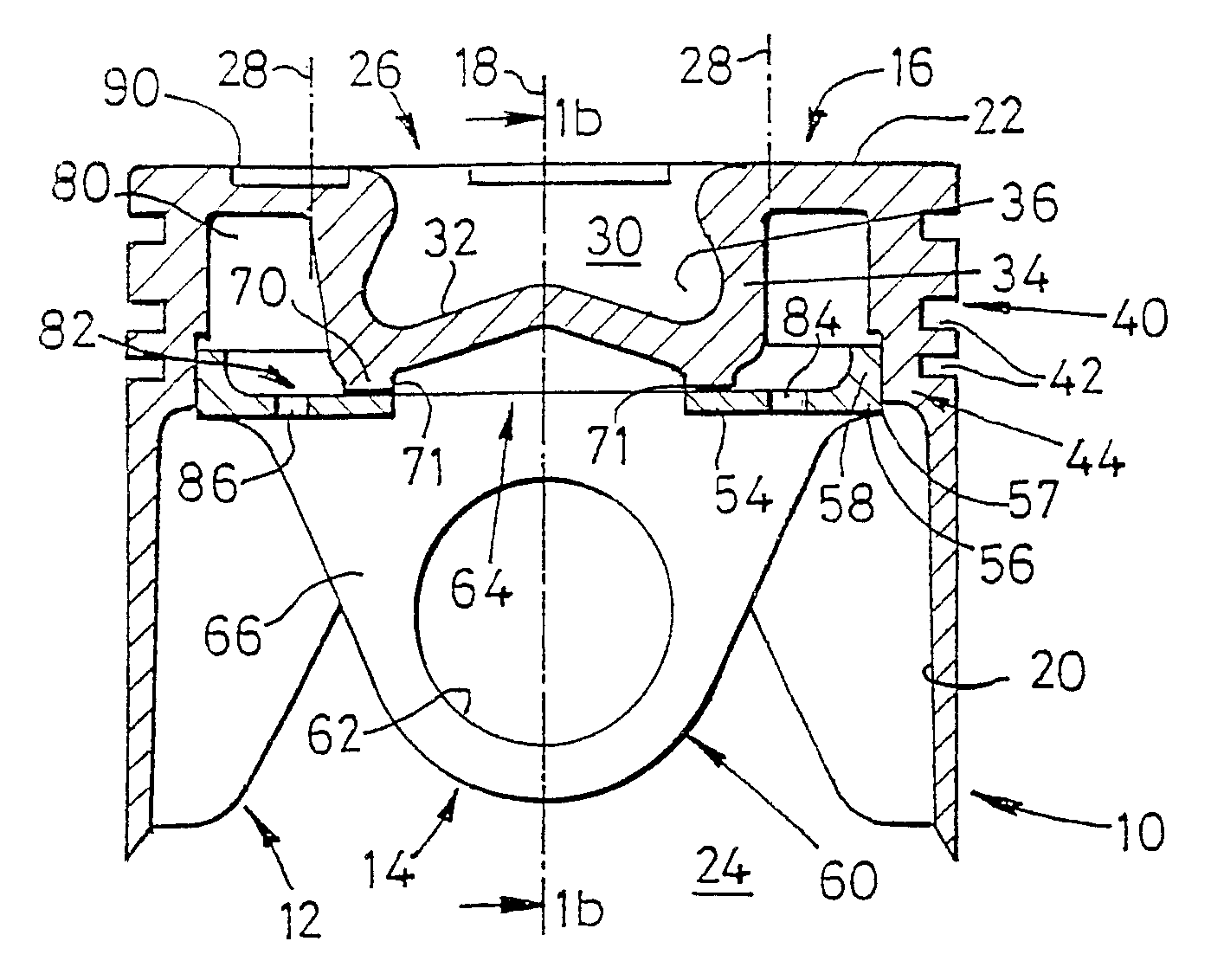

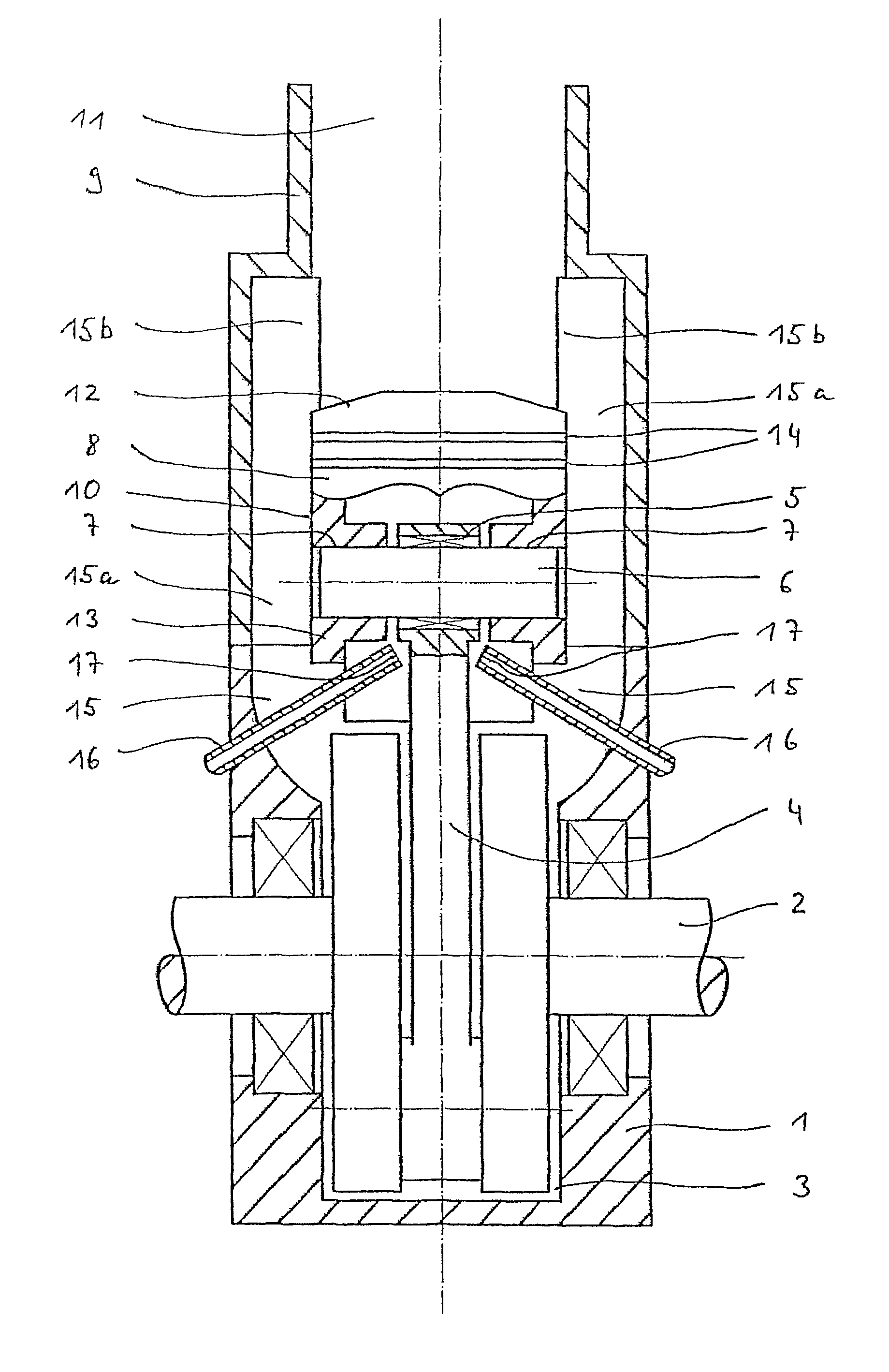

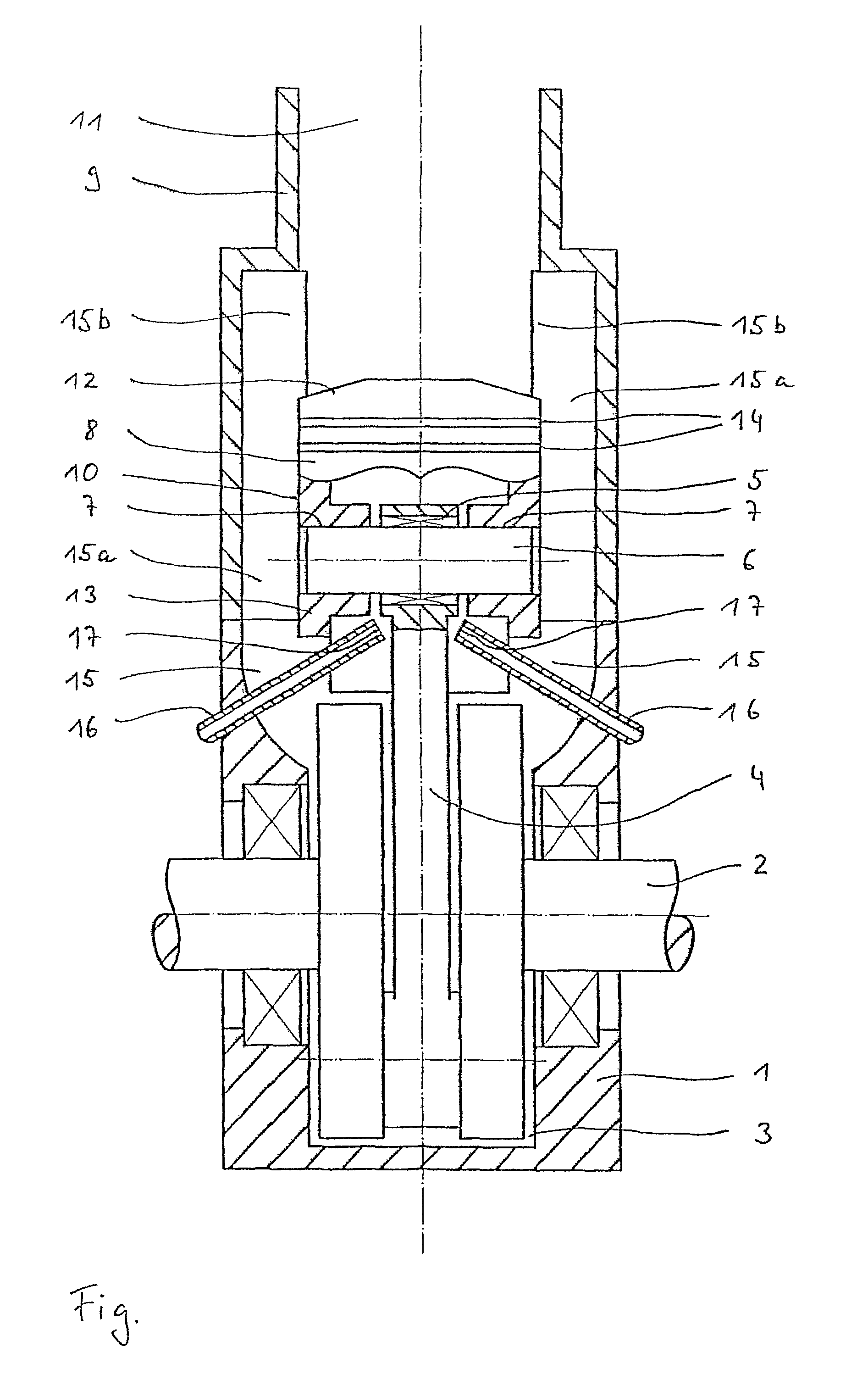

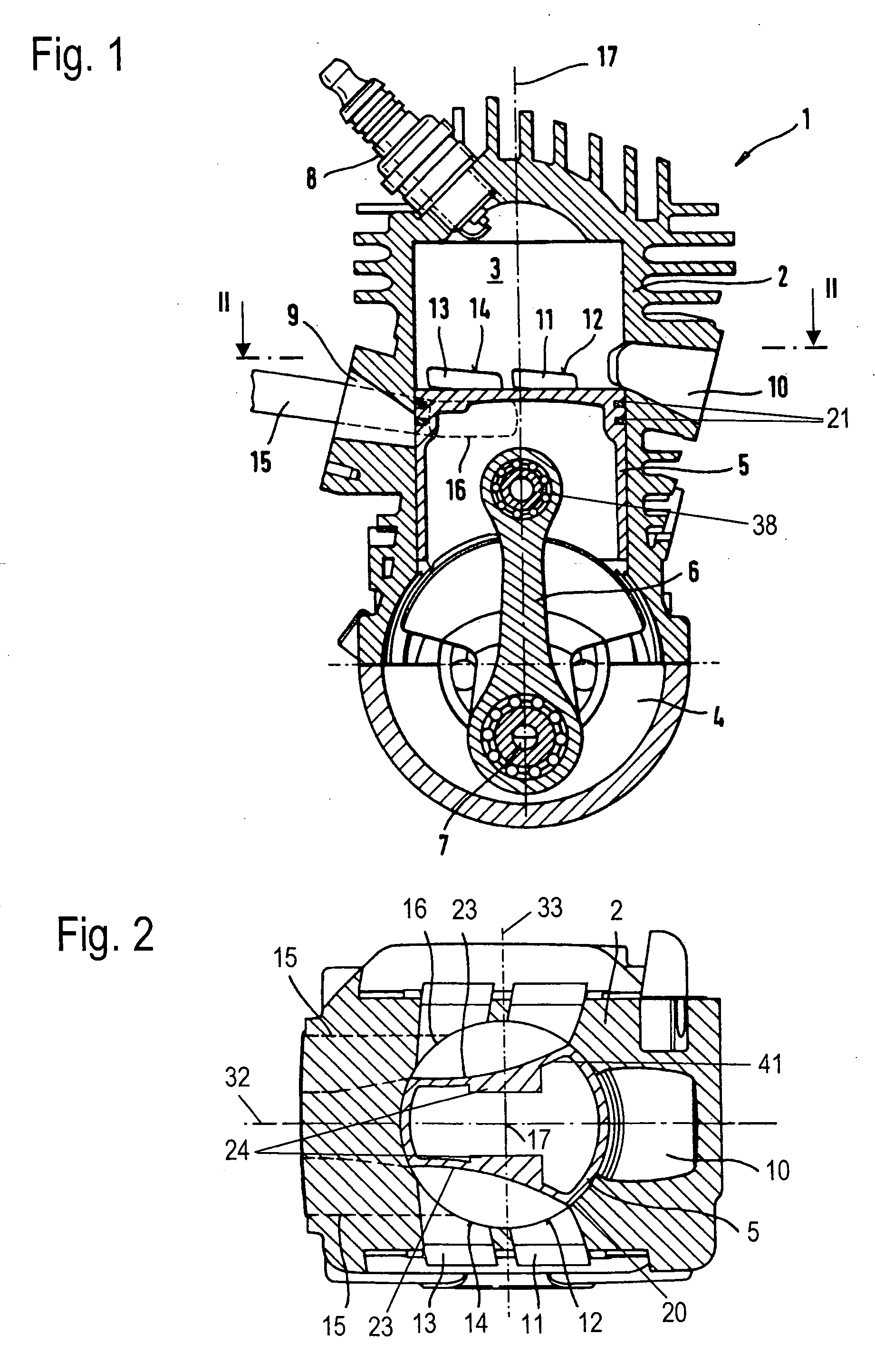

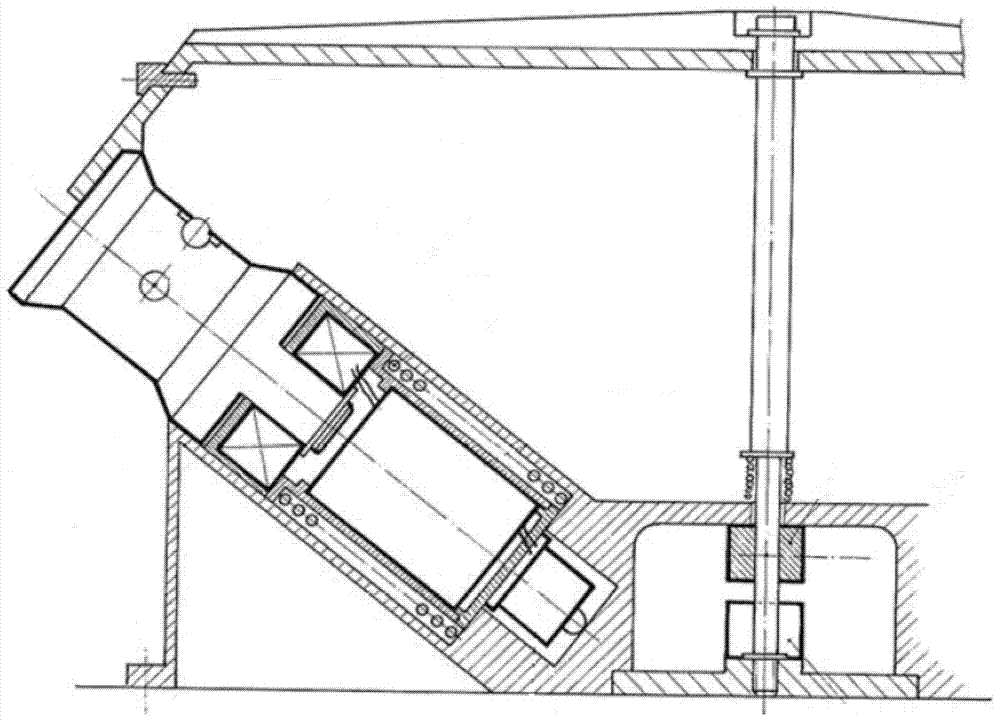

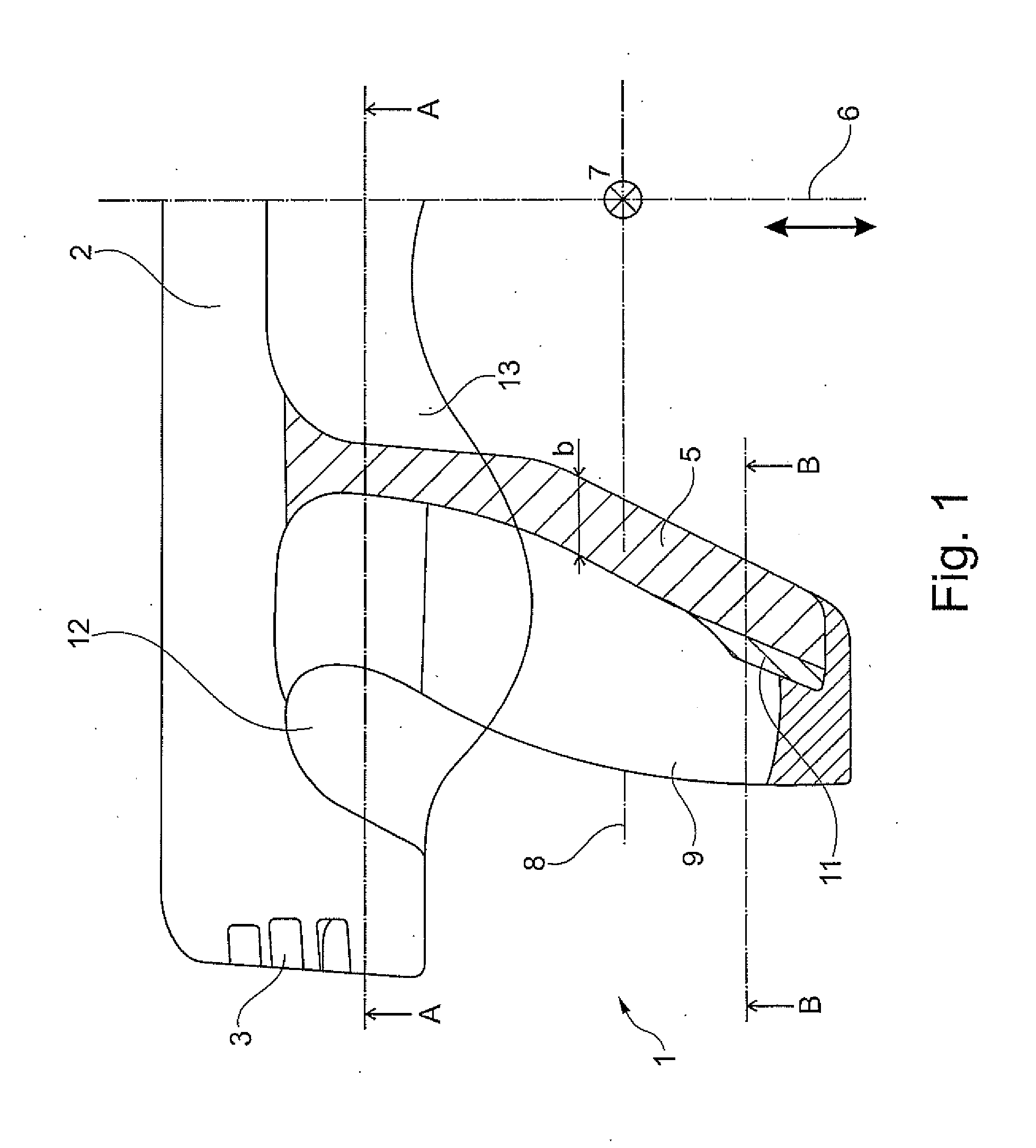

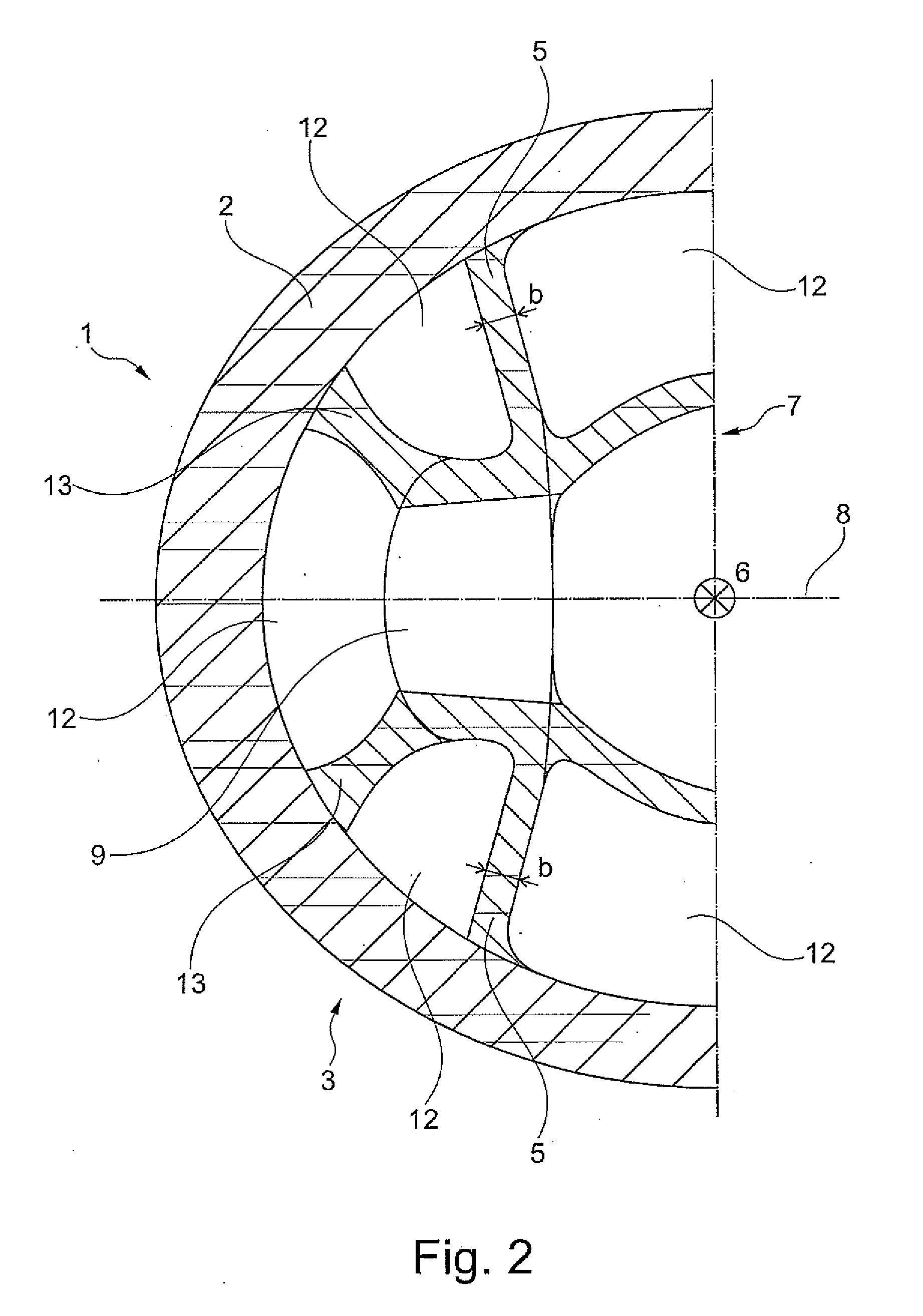

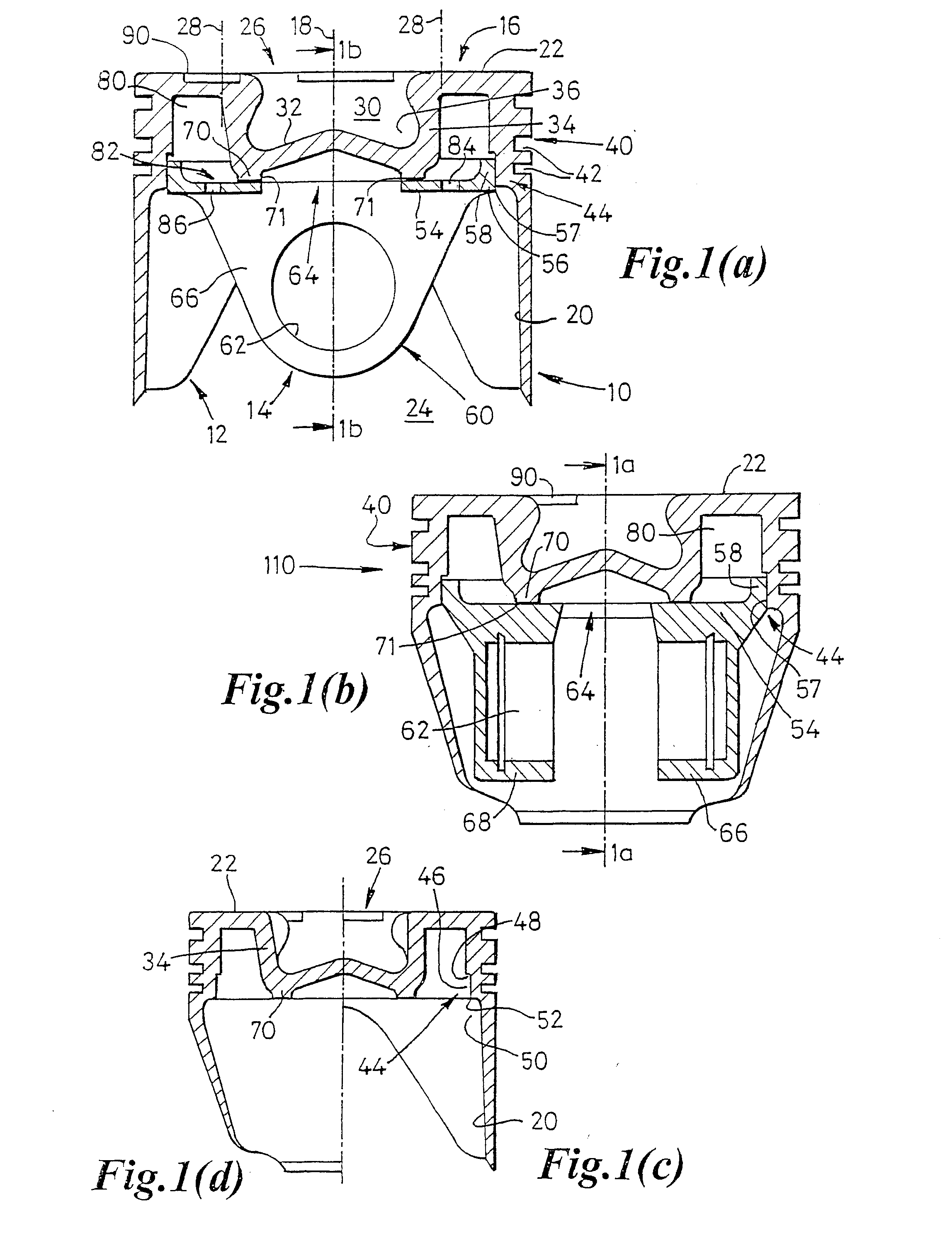

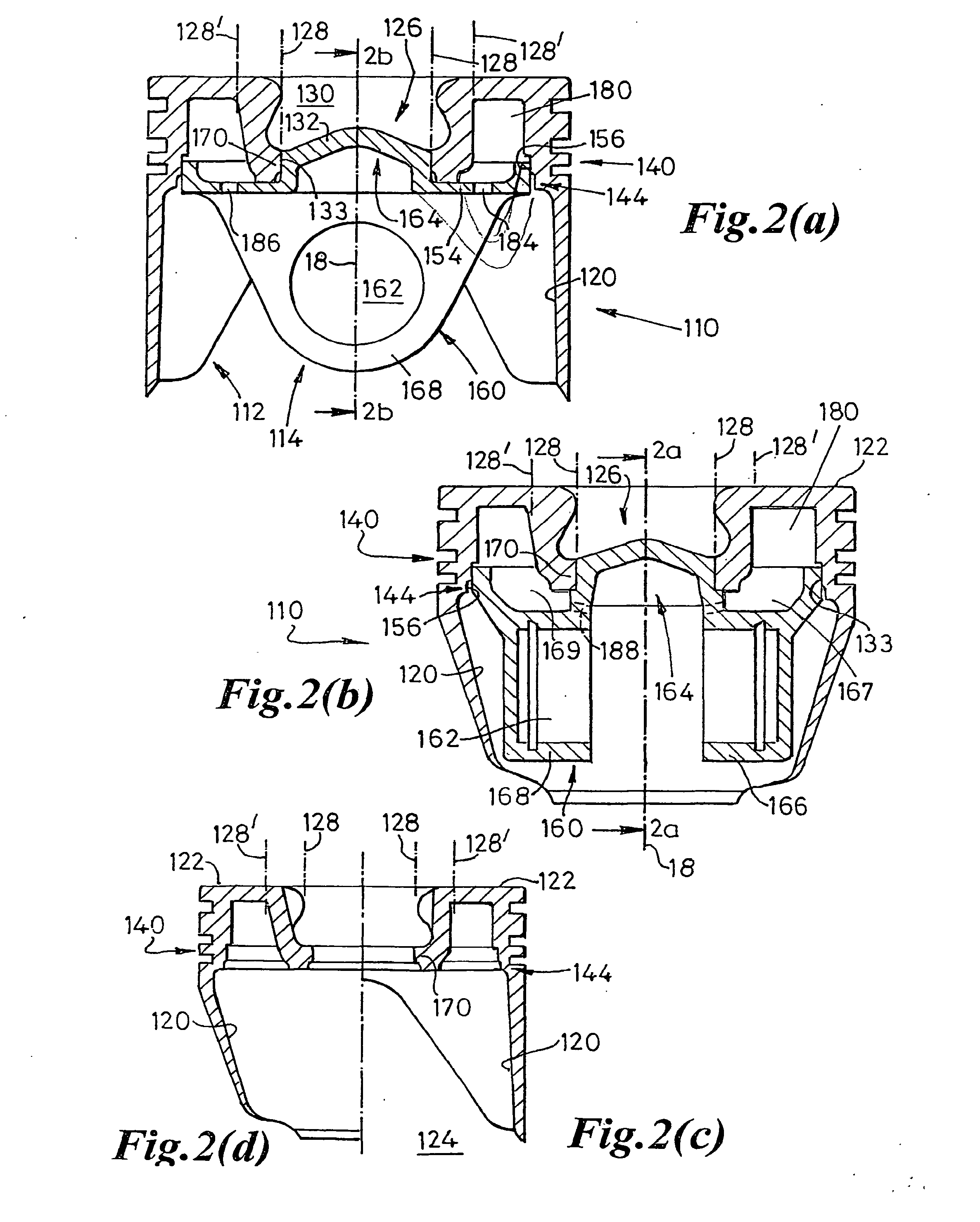

Oil Supply For An Internal Combustion Engine

InactiveUS20080035101A1Improving oil supplyReliable functionLiquid coolingLubrication of auxillariesReciprocating motionInternal combustion engine

The invention relates to an oil supply for an internal combustion engine, comprising an oil supply device for the supply of oil to a piston, reciprocating in a cylinder. The oil supply device is embodied such that at least at a point at which the piston is in the region of bottom dead centre, oil is introduced directly into a region below the piston, by means of the oil supply device, in particular, beneath the piston crown and within the piston skirt. The oil supply device thus comprises at least one tube element, extending into a region beneath the piston crown. The tube element terminates as close as possible to a gudgeon pin, when the piston is at bottom dead centre. A targeted lubrication of the mechanically and thermally highly loaded gudgeon pin can thus be guaranteed. It is also possible by means of the oil supply to supply transfer ports of a two-stroke engine with oil, counteracting a tendency to coke up.

Owner:WACKER NEUSON SE

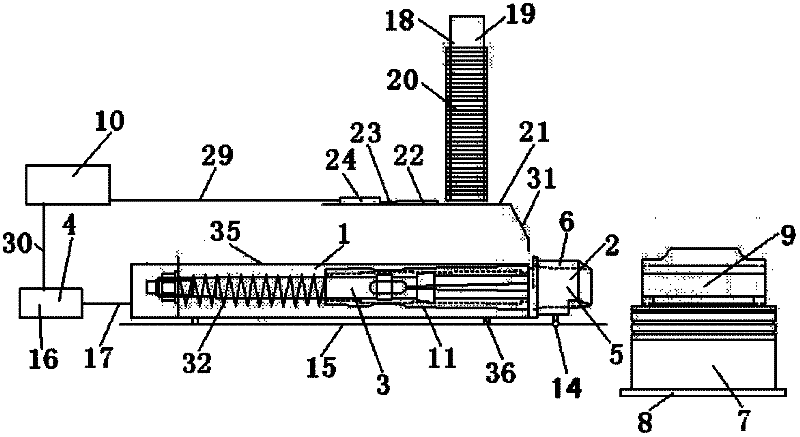

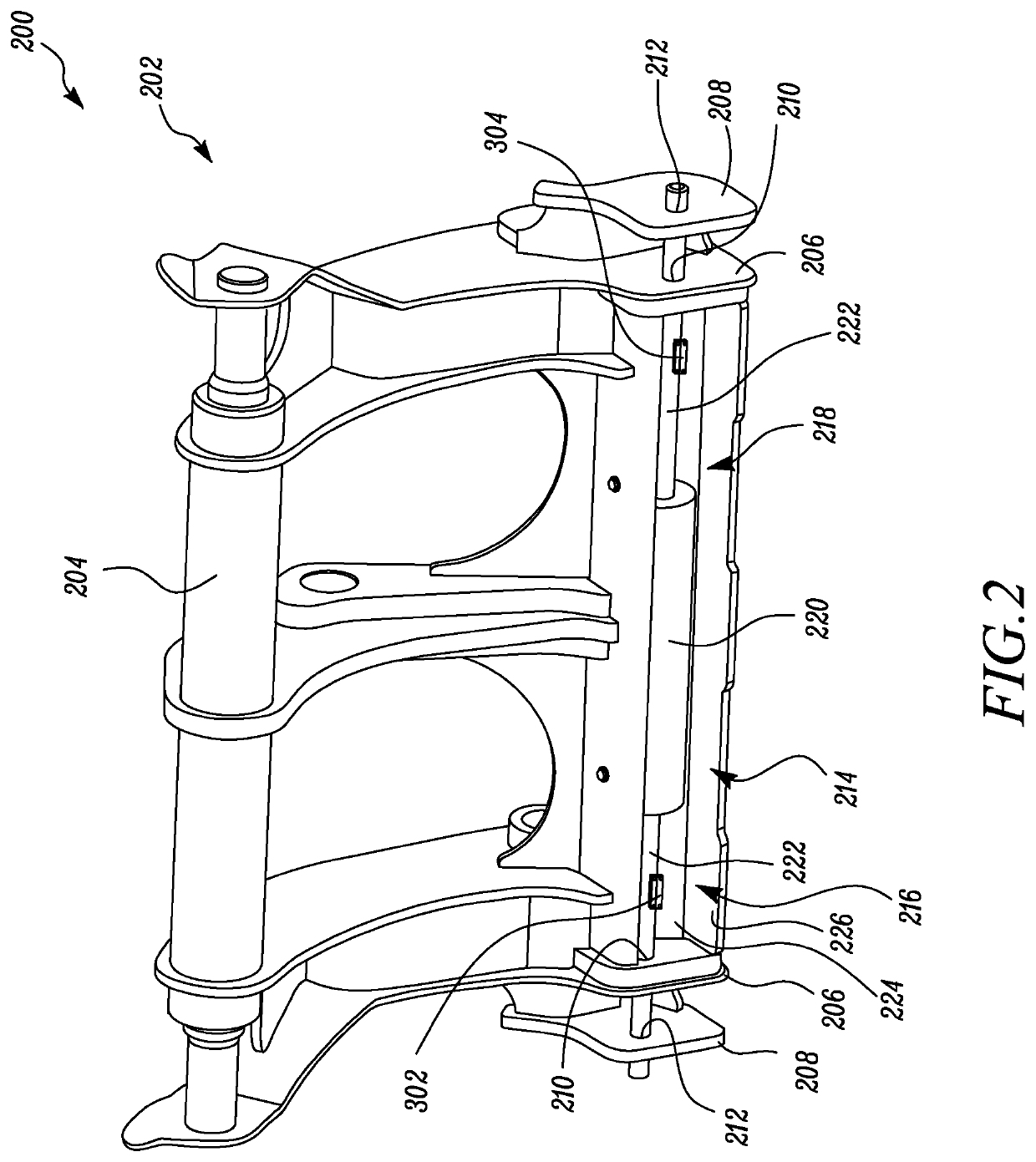

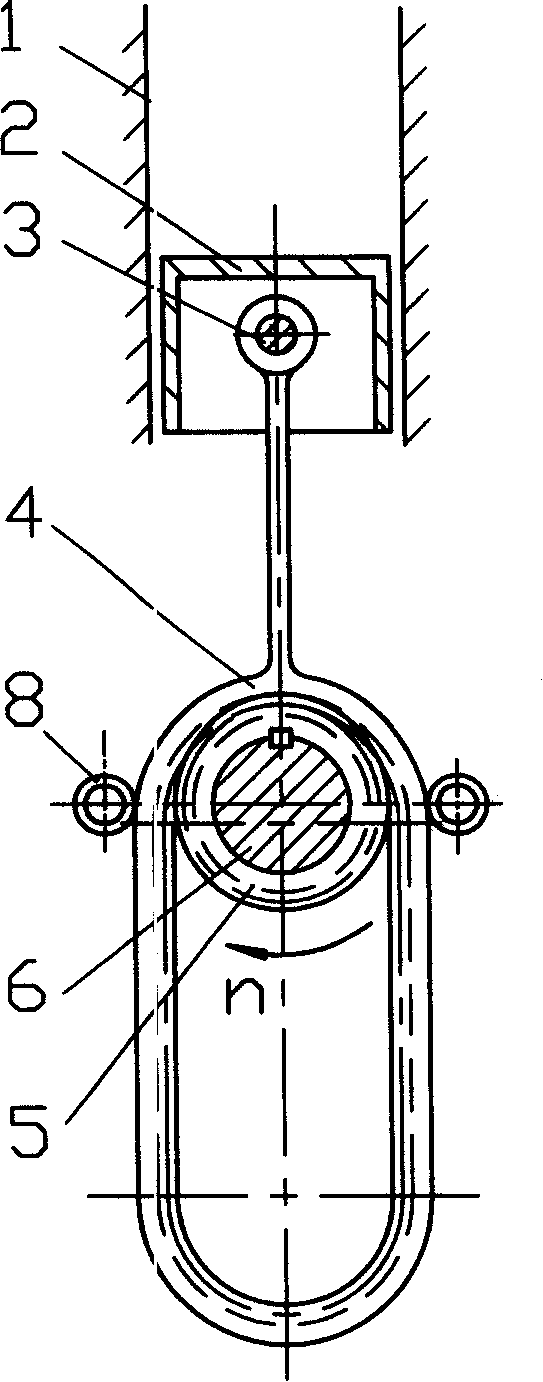

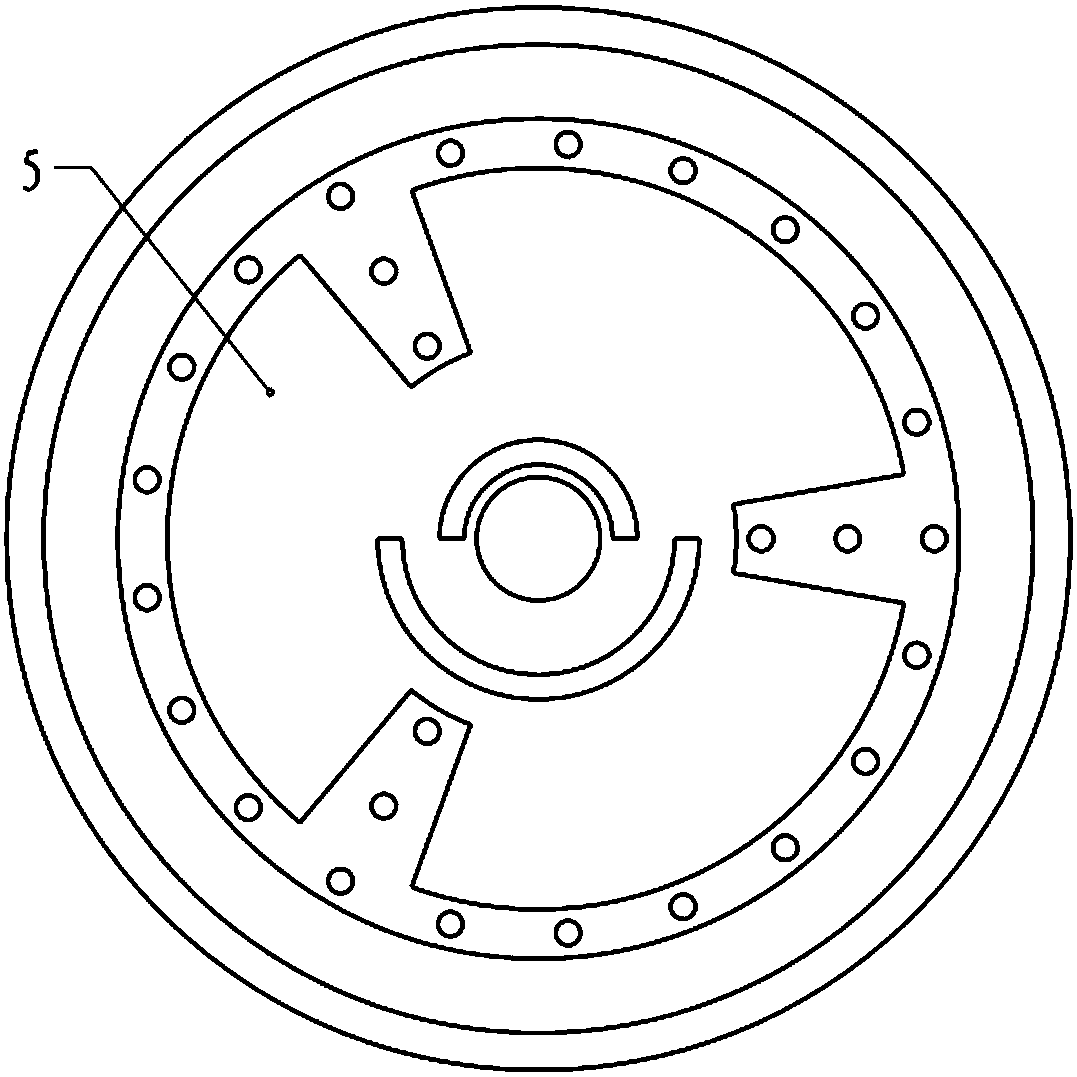

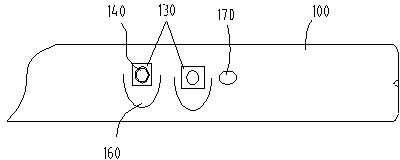

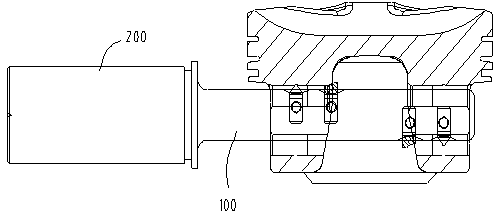

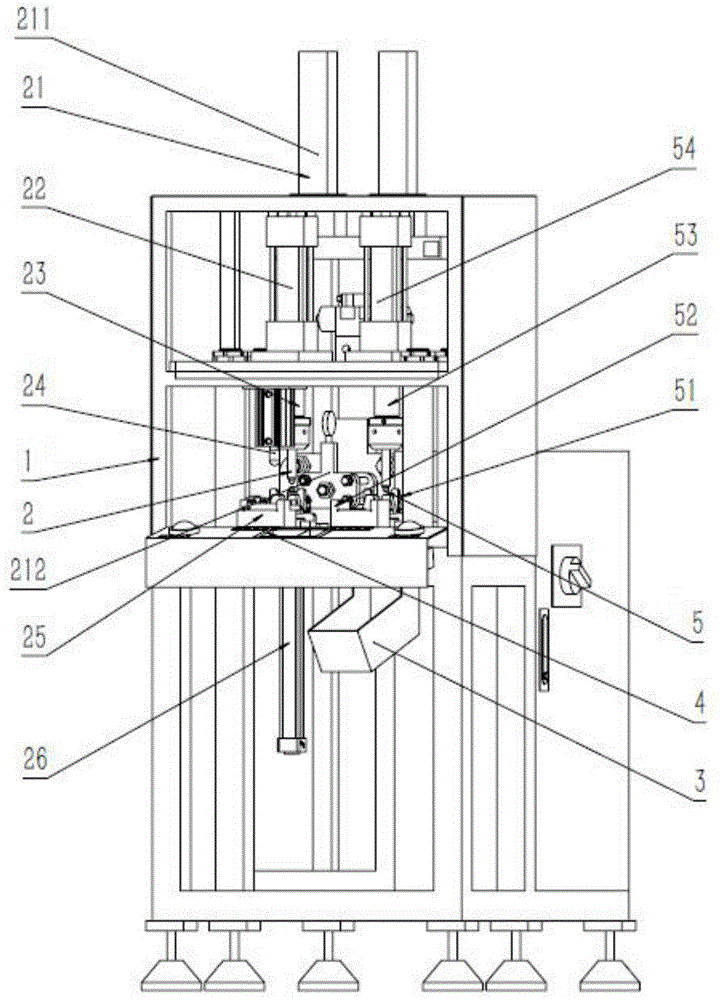

Assembly mechanism for clamp ring of engine gudgeon pin

InactiveCN102407440AAvoid the risk of easy collapse and injuryAutomate assemblyMetal working apparatusFixed frameEngineering

The invention provides an assembly mechanism for a clamp ring of an engine gudgeon pin. A press mounting guide pillar (3) is of a rod-like structure; one end of the press mounting guide pillar (3) is connected with a telescopic rod member (4); a clamp ring press head (2) is set into a hollow cylindrical structure; a press head cavity (5) is arranged in the middle of the clamp ring press head (2); an open slot (6) is arranged at the upper end of the clamp ring press head (2); the telescopic rod member (4) can penetrate through the clamp ring press head (2); a fixing frame (8) for fixing a piston (7) is arranged at the front end of the clamp ring press head (2); when the piston (7) is fixed on the fixing frame (8), a piston pin hole (9) and the press mounting guide pillar (3) are positioned on the same straight line; the press mounting guide pillar (3) can extend forwards to the interior of the piston pin hole (9); and a press mounting device (1) is connected with a controller (10) for controlling the press mounting device (1) to work. According to the assembly mechanism for the clamp ring of the engine gudgeon pin, which is provided by the invention, the risk that the clamp ring is easily bounded to injure people during manual assembly can be avoided and the function of protecting assemble workers is achieved.

Owner:RUIZHAN TONGLING TECH

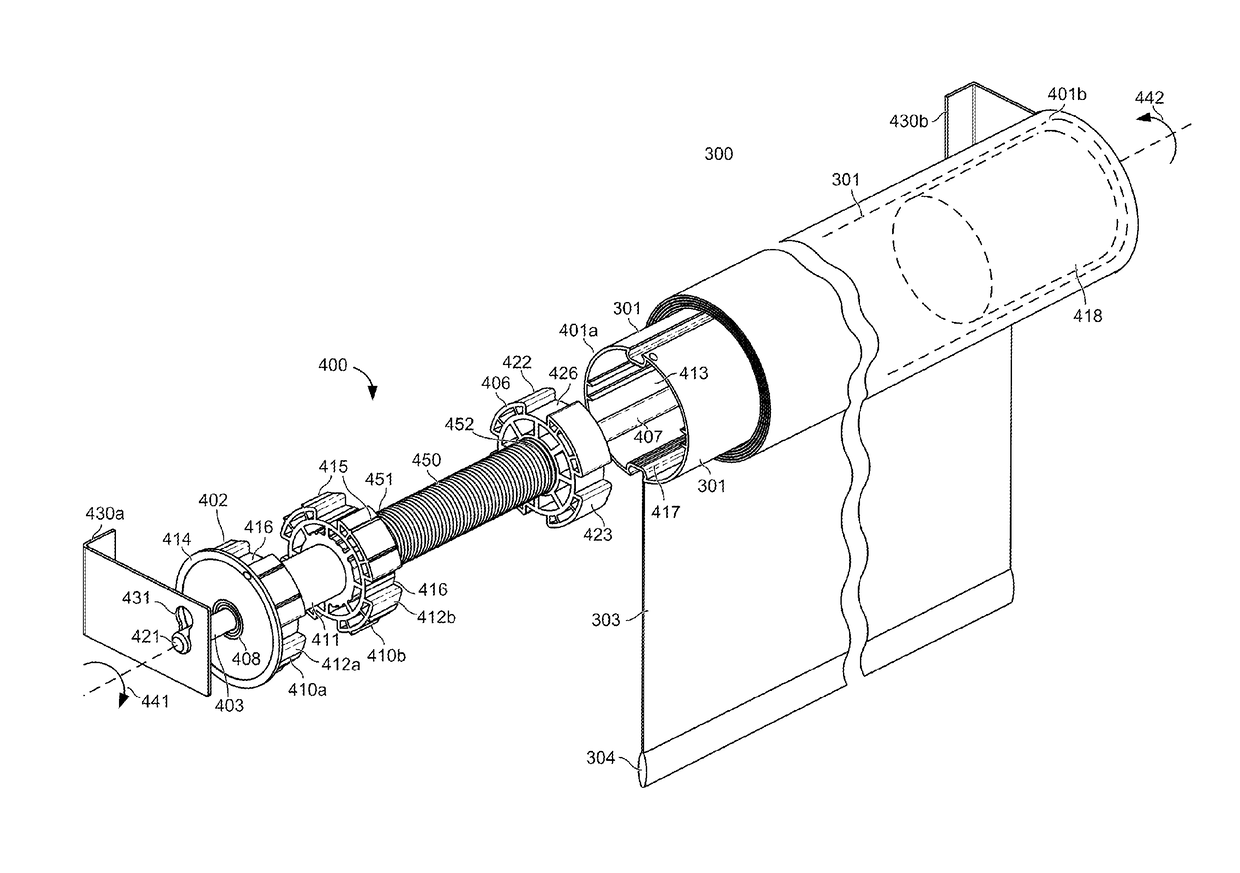

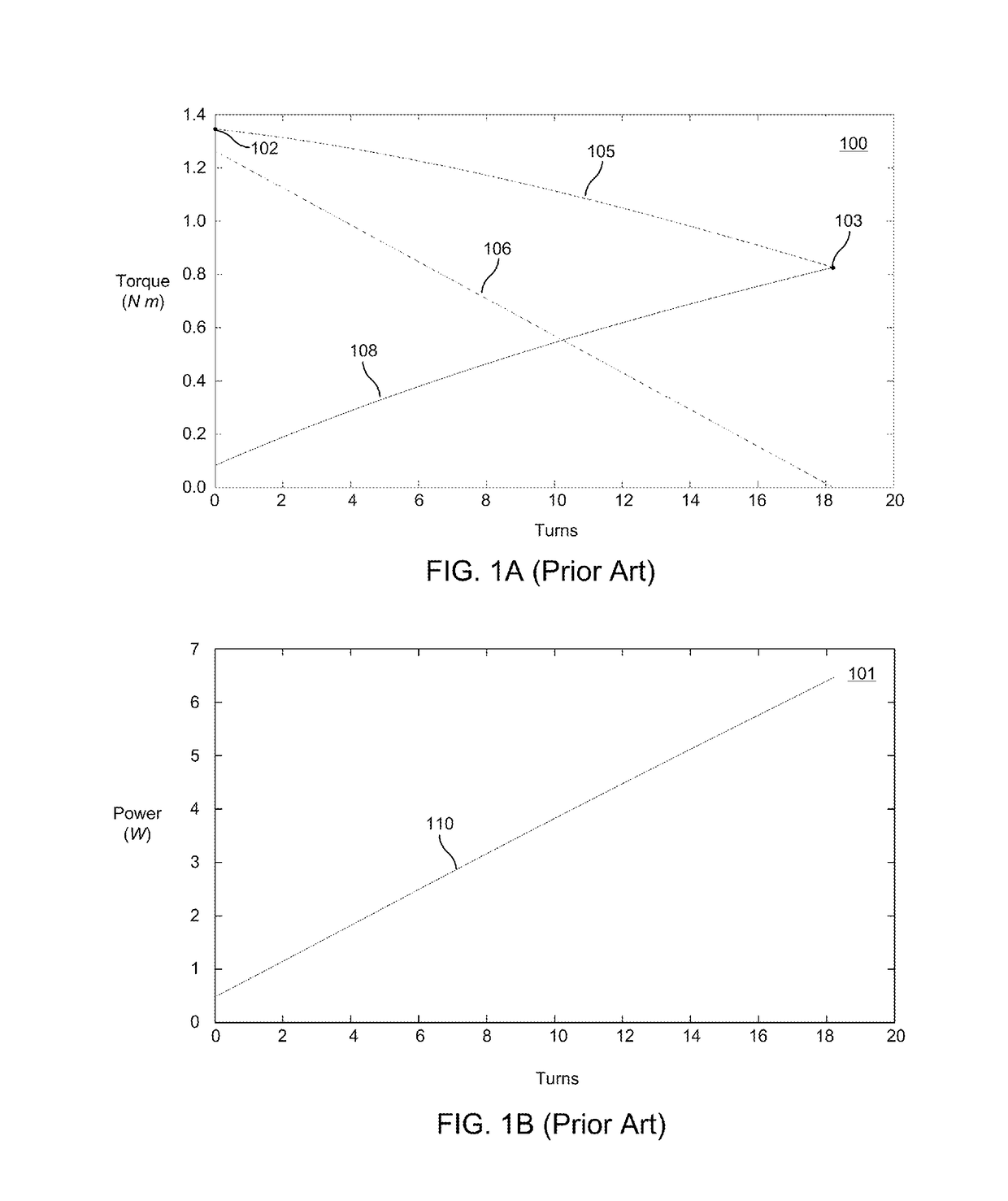

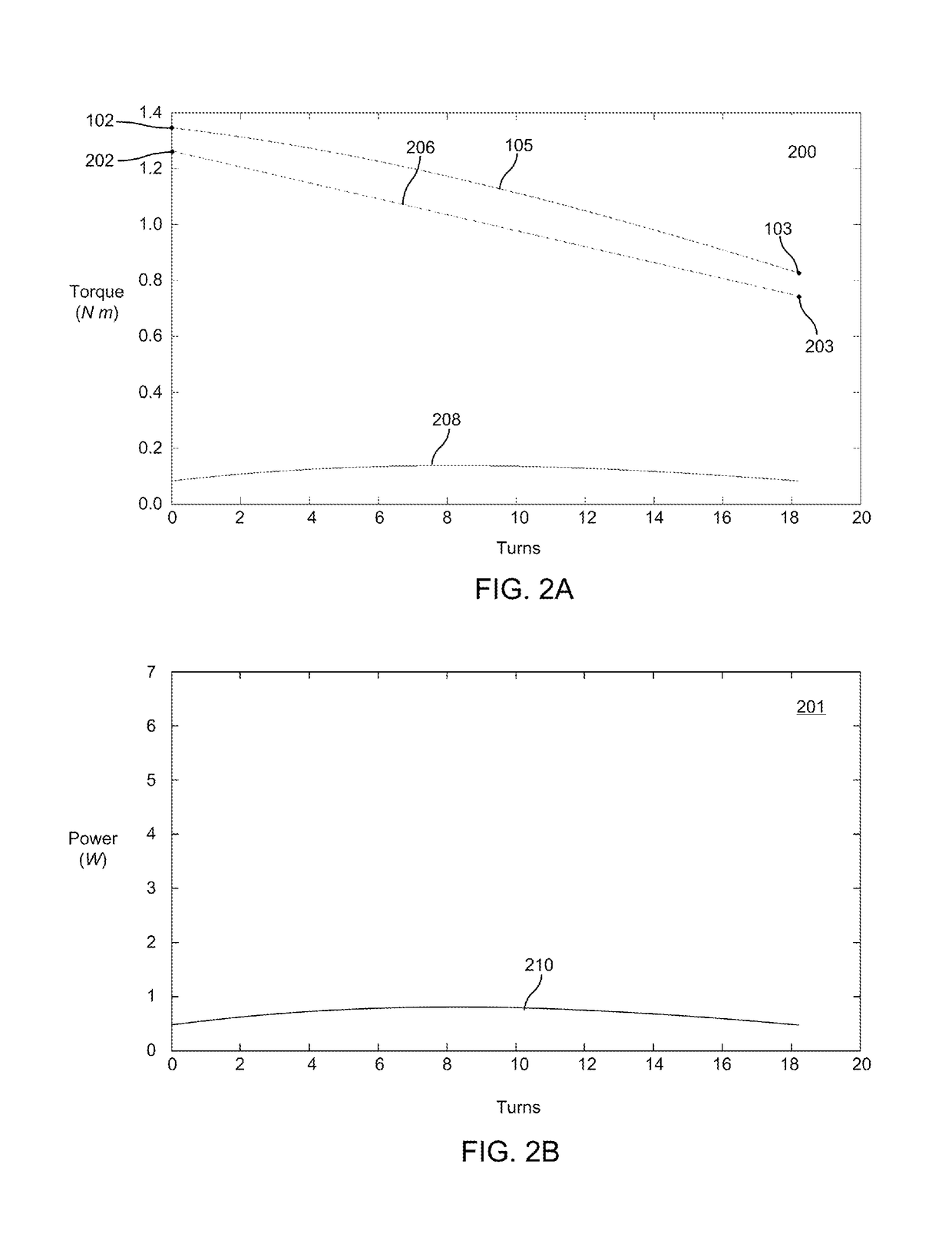

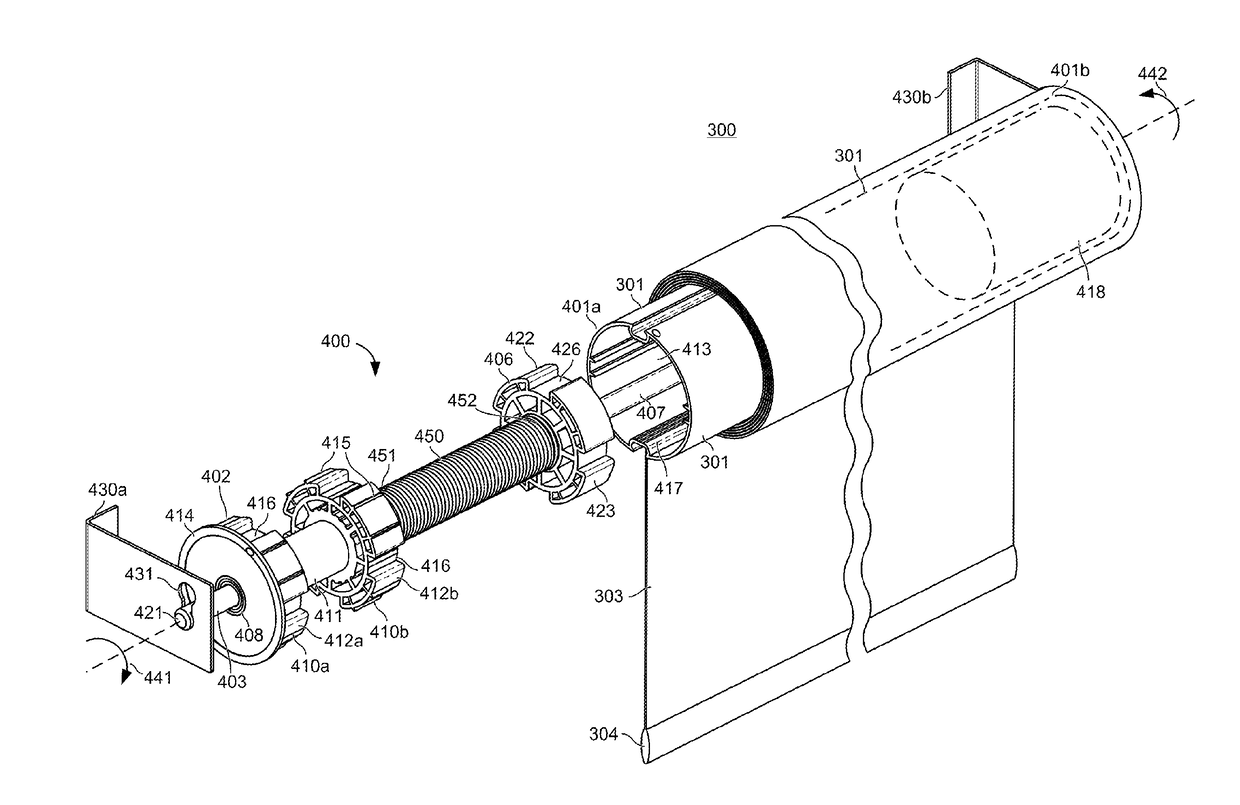

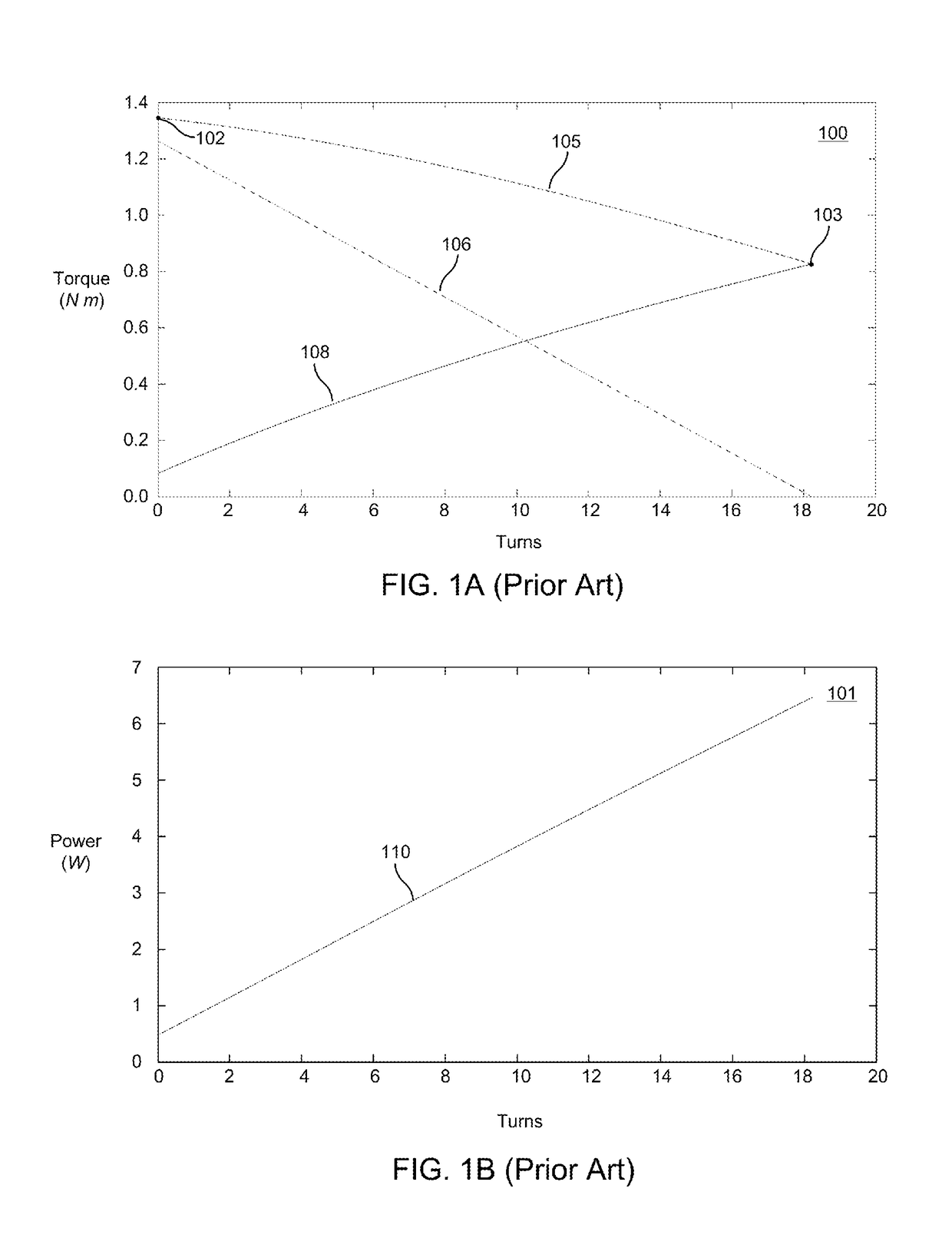

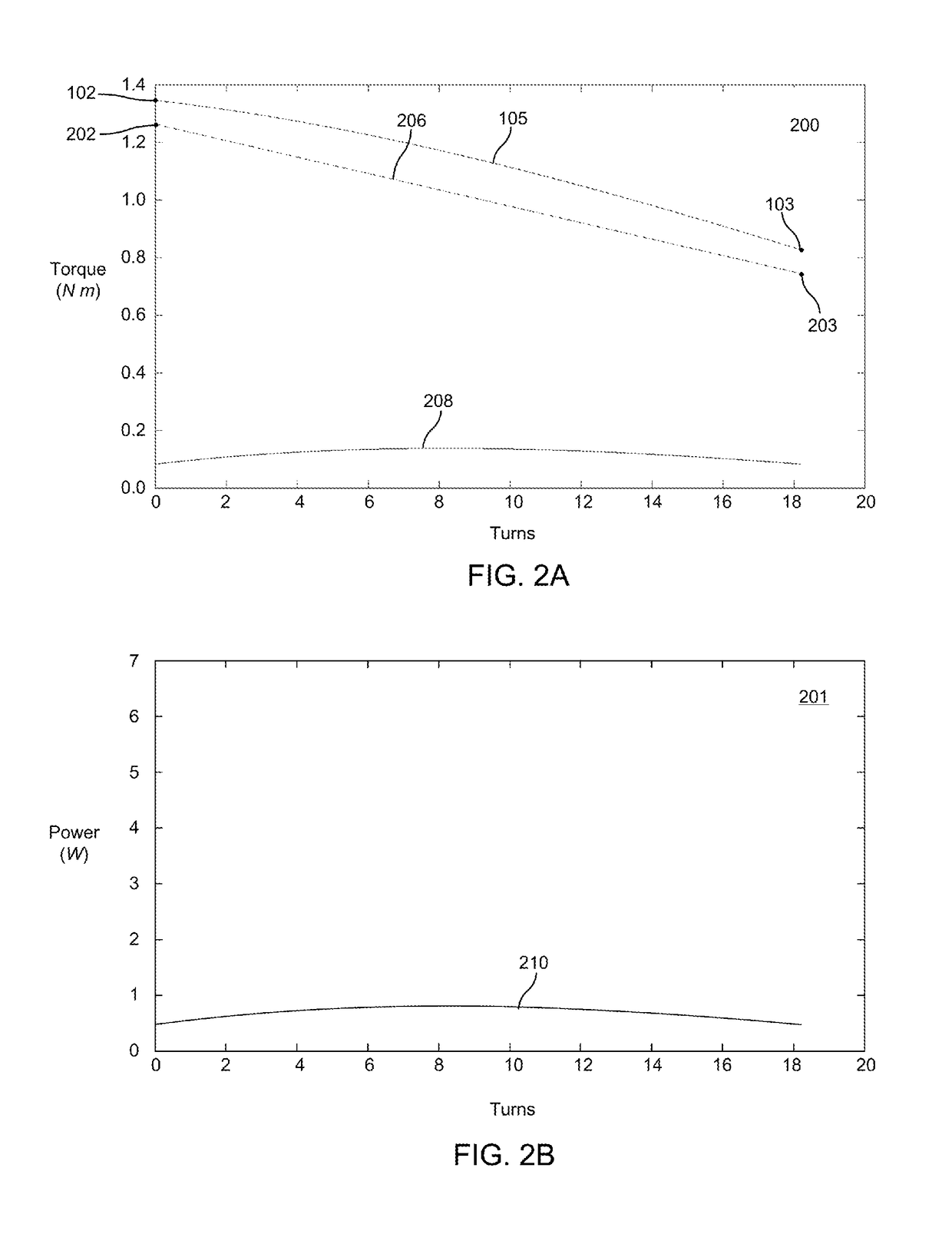

Roller shade with a pretensioned spring and method for pretensioning the spring

ActiveUS20170067289A1Reduce torque loadLight protection screensPivotal connectionsMechanical engineeringGudgeon pin

A roller shade is disclosed having a counterbalancing assembly with an optimally pretensioned spring that lowers the torque load on the motor of the roller shade throughout the rolling up or rolling down cycles. The roller shade comprises a roller tube, a gudgeon pin having a first stop, a gudgeon body having a through bore and rotatably connected about the gudgeon pin and operably connected to the roller tube, a limit nut operably connected to the gudgeon body and adapted to axially travel along the gudgeon pin within the through bore, a spring, a first spring carrier connected to the first end of the spring and operably connected to the gudgeon pin, and a second spring carrier connected to the second end of the spring and operably connected to the roller tube. The spring is pretensioned and the limit nut abuts the first stop thereby locking the pretension. Rotation of the roller tube to roll down the shade further tensions the spring, and rotation of the roller tube to roll up the shade releases the tension in the spring.

Owner:CRESTRON ELECTRONICS

Engine piston and manufacture

An engine piston is manufactured by assembling an outer shell, comprising a crown and tubular side wall in which a ring groove region and skirt are defined, with a plate-like mounting member and bonding them together by brazing or welding. The mounting member is located within the tubular side wall displaced axially from the crown and is bonded near, but displaced radially from, its centre to the crown and at its periphery to the side wall at the end of the ring groove region. The mounting member carries gudgeon pin boss means facing away from the crown. The outer shell is formed by extrusion or the like that permits minimal wall thickness and the bonded structure is of light weight but great strength and stiffness, particularly in the ring groove region. A combustion bowl formed in the crown facilitates bonding to the mounting member and defines with the mounting member an annular cooling chamber adjacent the ring groove region and crown.

Owner:FEDERAL MOGUL TECH LTD

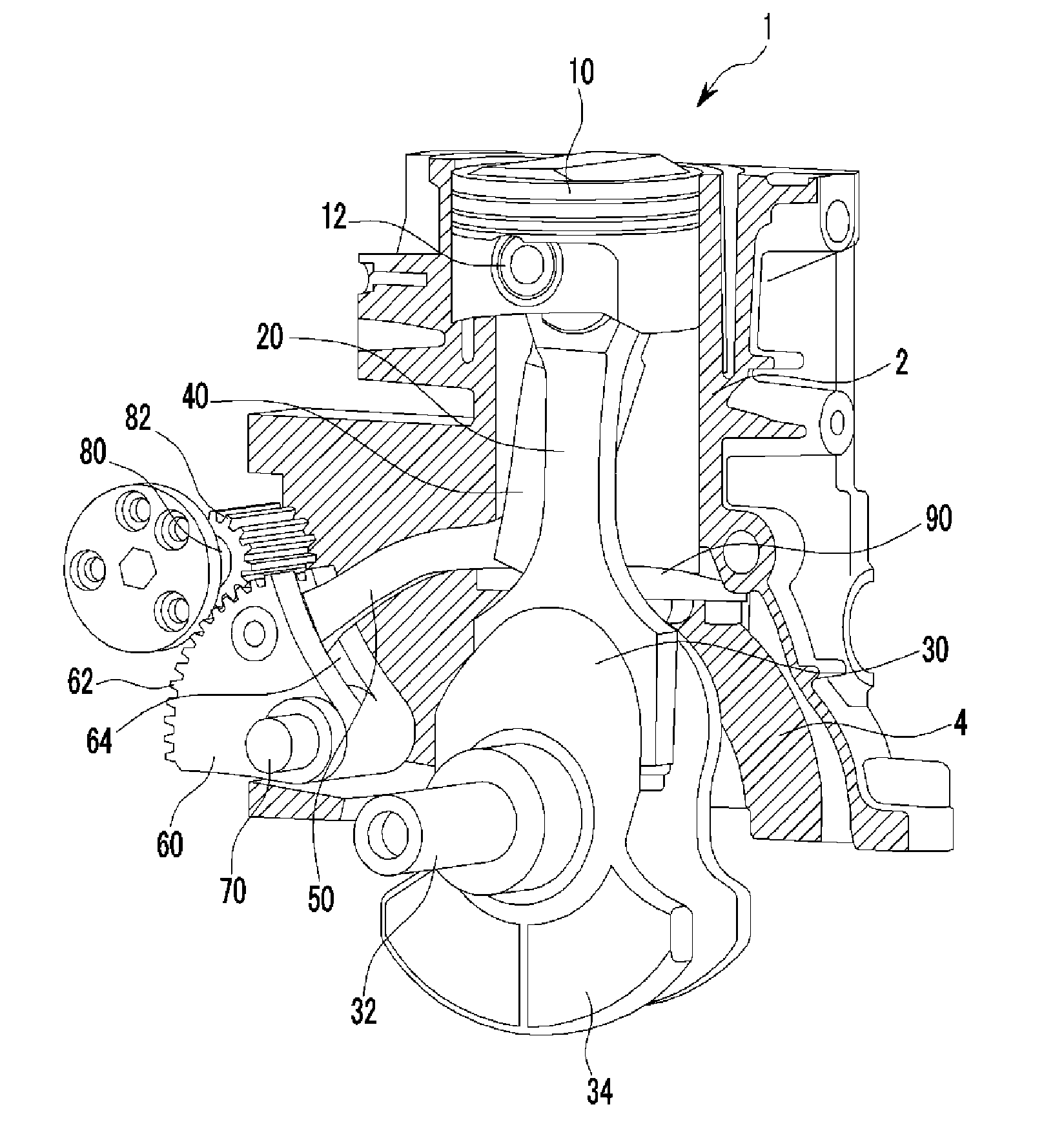

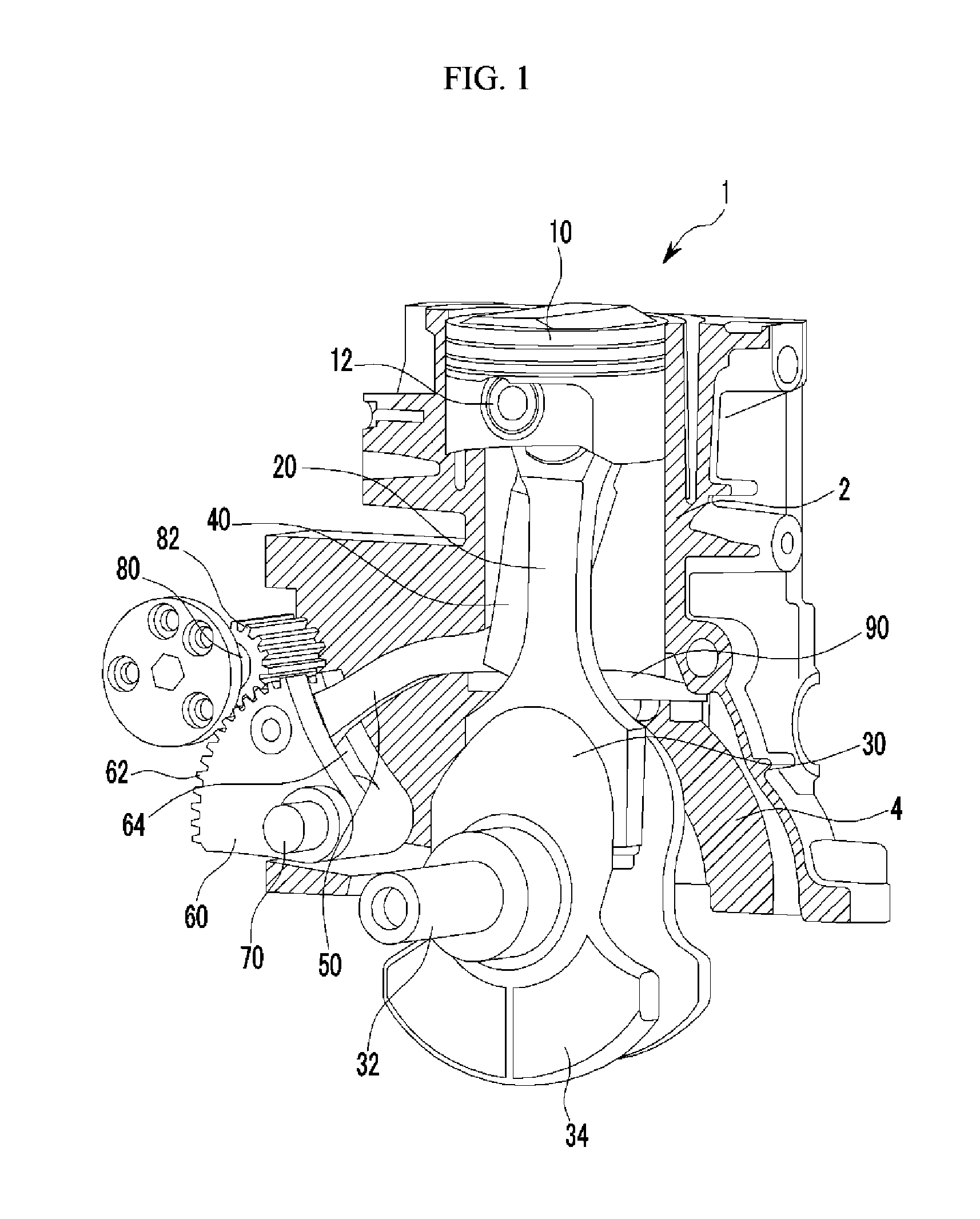

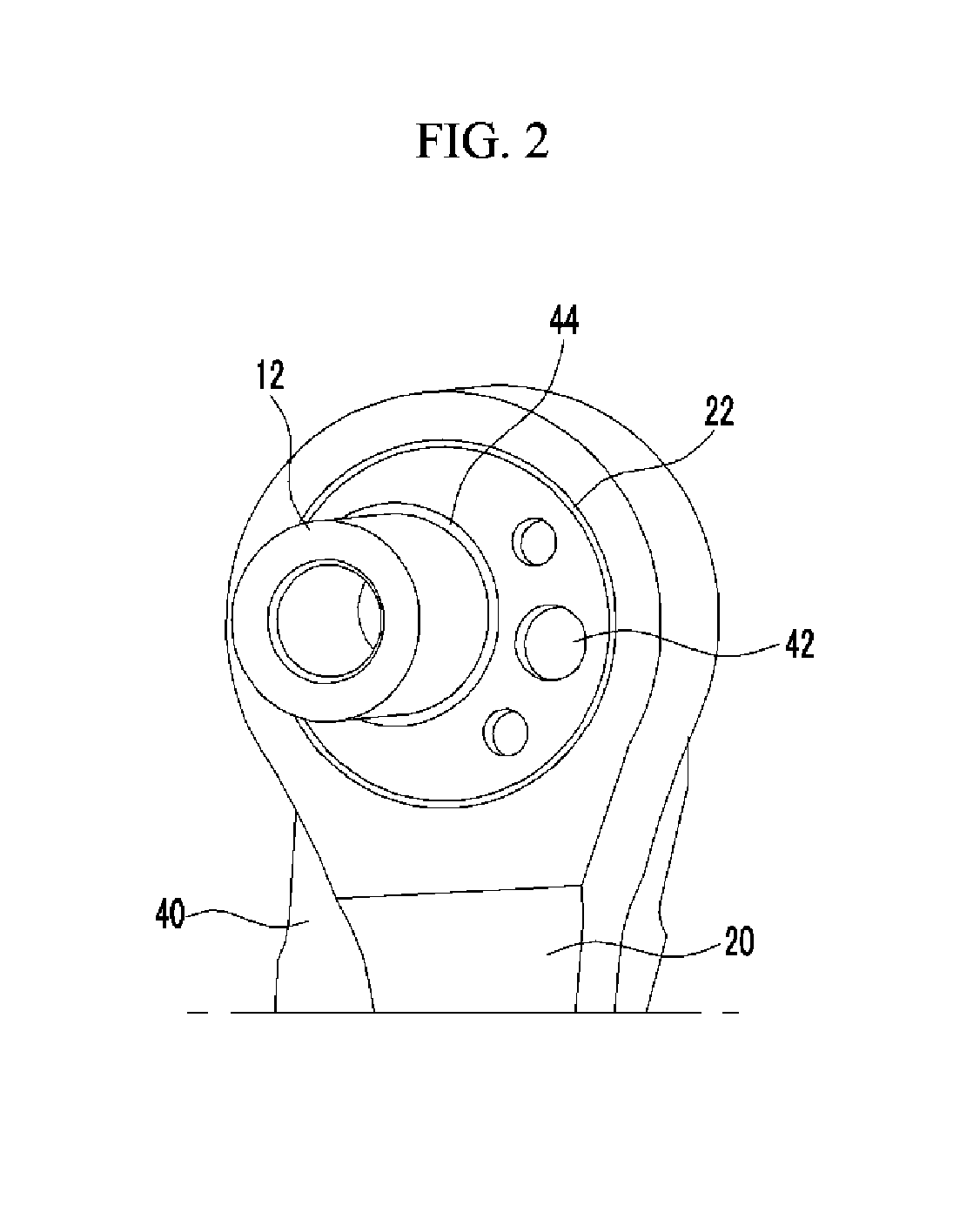

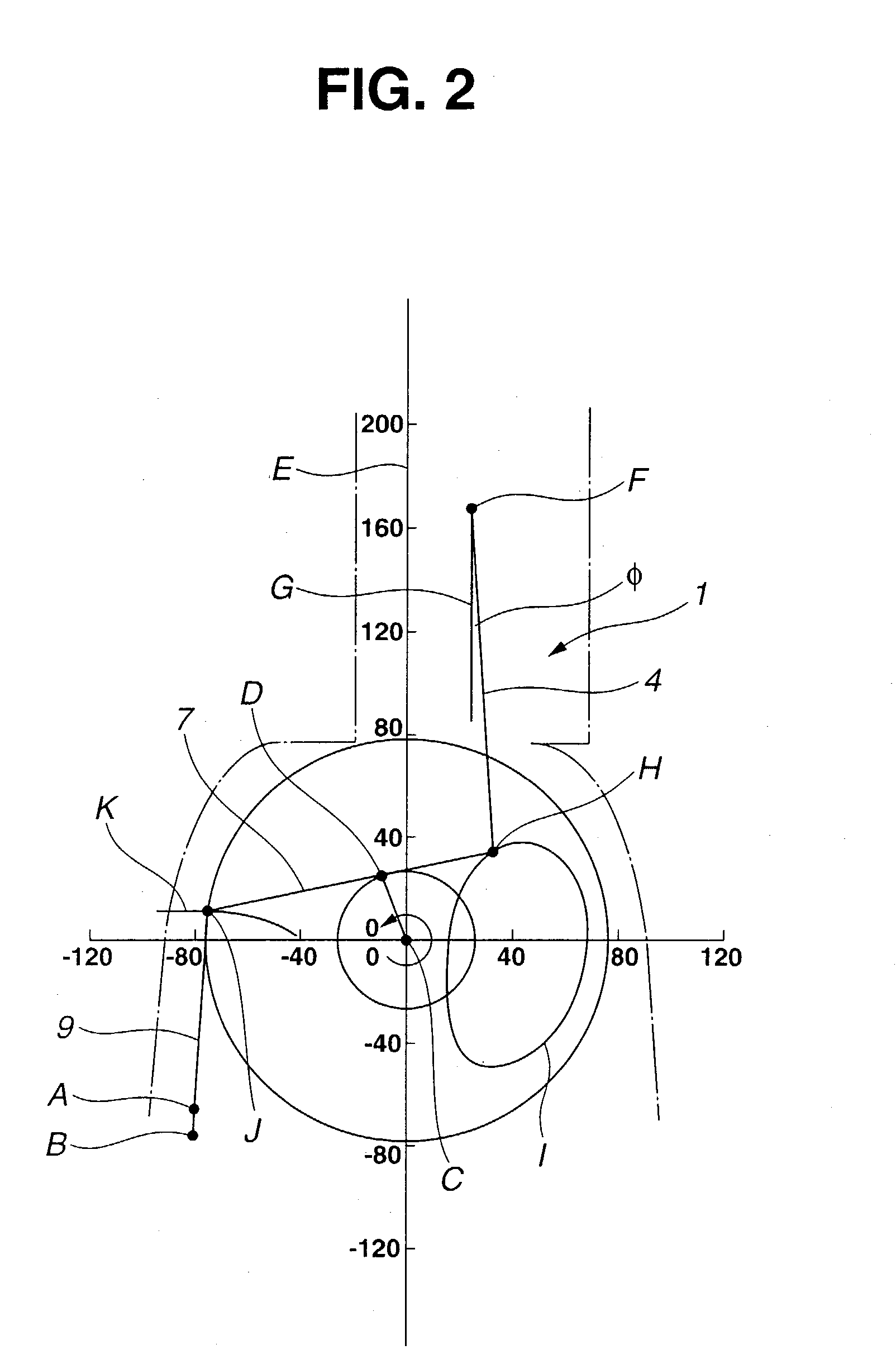

Variable compression ratio apparatus

InactiveUS20120125297A1Minimize forceMinimizing combustion forceEngine controllersMachines/enginesCombustionCrankshaft

A variable compression ratio apparatus for an engine receiving combustion force of an air-fuel mixture from a piston and rotating a crankshaft, and for changing compression ratio of the air-fuel mixture. The apparatus may include a connecting rod including one end with a mounting hole and an other end eccentrically and rotatably connected to the crankshaft, an eccentric link including one end connected to an eccentric bearing concentrically and rotatably mounted in the mounting hole, a piston pin eccentrically and rotatably mounted in the eccentric bearing, a variable link including one end rotatably connected to an other end of the eccentric link, a variable gear link pivoting with respect to a fixed shaft and formed of first gear teeth at an exterior circumference, an external circumferential portion rotatably connected to an other end of the variable link, a control shaft including second gear teeth engaged to the first gear teeth and rotating to pivot the variable gear link, and a guide bar, together with the connecting rod, limiting horizontal movement of the eccentric link.

Owner:HYUNDAI MOTOR CO LTD

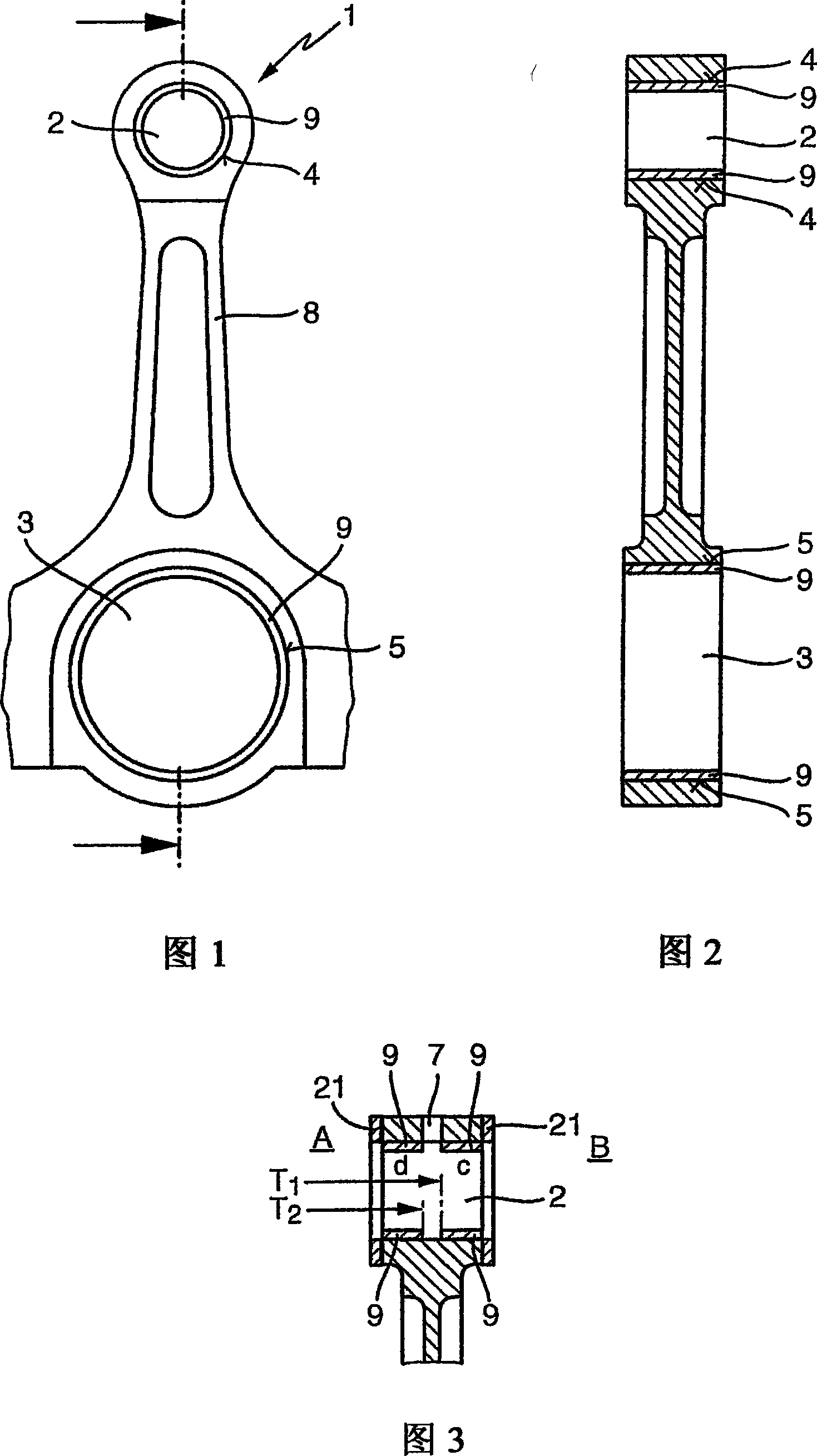

Connecting rod for a combustion engine and method for coating the plain bearing surfaces thereof

ActiveCN101094731AImprove surface qualityLimited depthConnecting rod bearingsShaftsCombustionInternal combustion engine

Disclosed is a connecting rod for a combustion engine, comprising a small connecting-rod eye that is provided with a plain bearing surface and is used for accommodating a piston pin, and a large connecting-rod eye which is provided with a plain bearing surface and embraces a crankshaft journal. In order to very effectively and inexpensively prevent the piston pin and the crankshaft journal of said connecting rod from jamming and wearing off, a self-lubricating coating made of a thermally cured resin which contains embedded solid lubricant particles is applied directly to at least one of the plain bearing surfaces by means of rotary atomization.

Owner:MAHLE INT GMBH

Roller shade with a pretensioned spring and method for pretensioning the spring

ActiveUS20170107760A1Reduce torque loadLight protection screensPivotal connectionsEngineeringMechanical engineering

A roller shade is disclosed having a counterbalancing assembly with an optimally pretensioned spring that lowers the torque load on the motor of the roller shade throughout the rolling up or rolling down cycles. The roller shade comprises a roller tube, a gudgeon pin having a first stop, a gudgeon body having a through bore and rotatably connected about the gudgeon pin and operably connected to the roller tube, a limit nut operably connected to the gudgeon body and adapted to axially travel along the gudgeon pin within the through bore, a spring, a first spring carrier connected to the first end of the spring and operably connected to the gudgeon pin, and a second spring carrier connected to the second end of the spring and operably connected to the roller tube. The spring is pretensioned and the limit nut abuts the first stop thereby locking the pretension. Rotation of the roller tube to roll down the shade further tensions the spring, and rotation of the roller tube to roll up the shade releases the tension in the spring.

Owner:CRESTRON ELECTRONICS

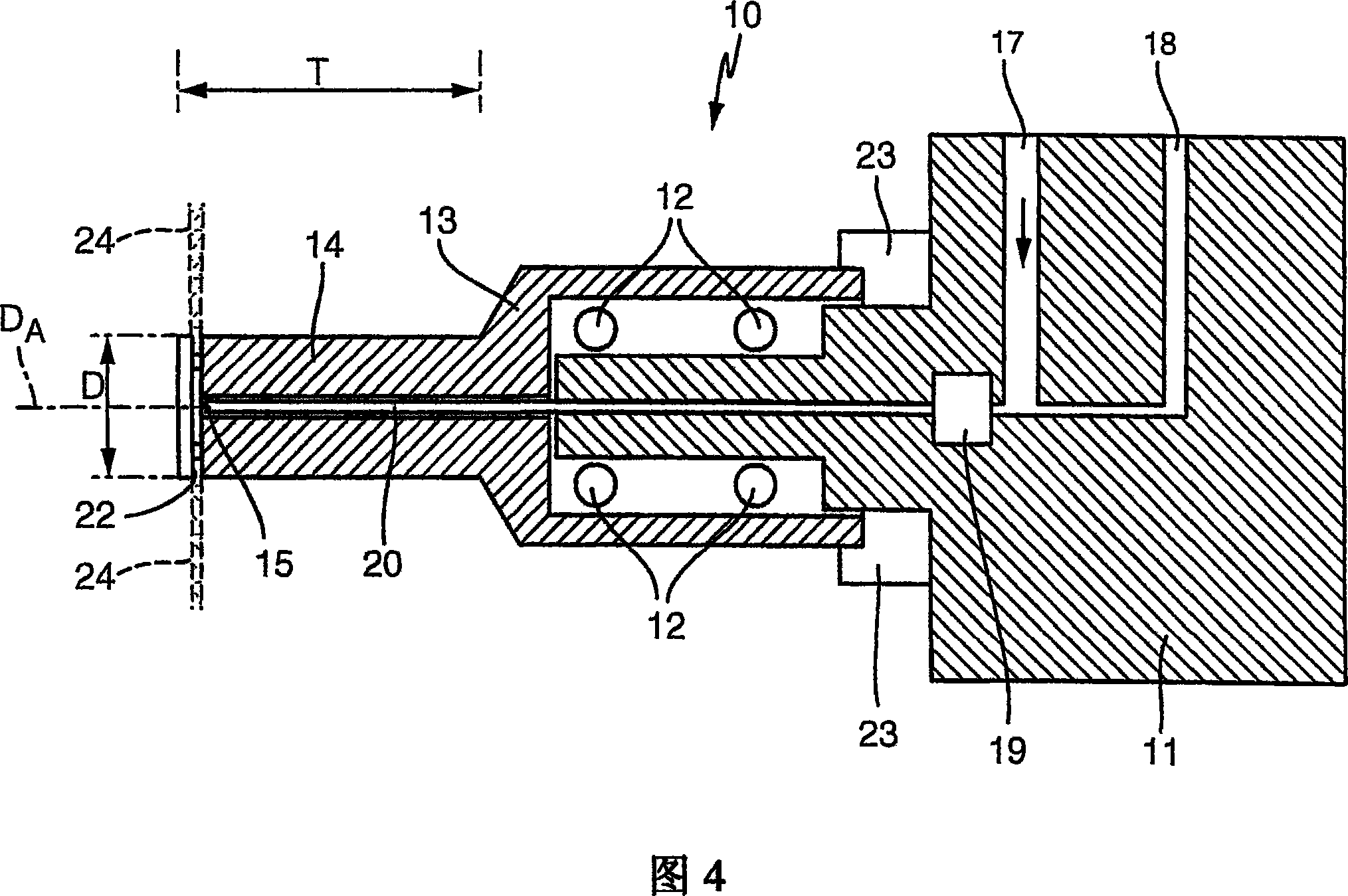

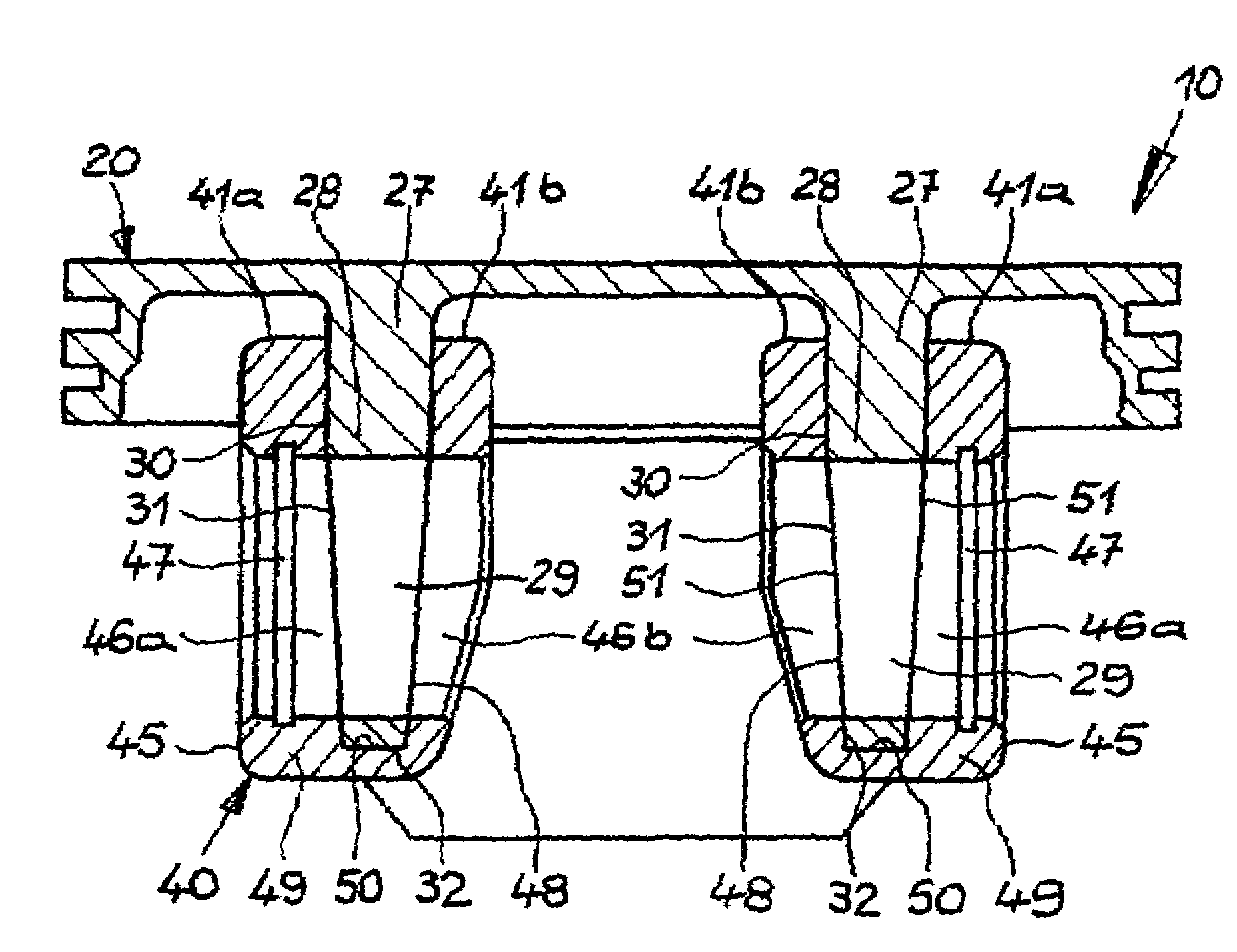

Oil supply for an internal combustion engine

InactiveUS7753024B2Increase supplyReliable functionDrip lubricationLiquid coolingReciprocating motionInternal combustion engine

The invention relates to an oil supply for an internal combustion engine, comprising an oil supply device for the supply of oil to a piston, reciprocating in a cylinder. The oil supply device is embodied such that at least at a point at which the piston is in the region of bottom dead centre, oil is introduced directly into a region below the piston, by means of the oil supply device, in particular, beneath the piston crown and within the piston skirt. The oil supply device thus comprises at least one tube element, extending into a region beneath the piston crown. The tube element terminates as close as possible to a gudgeon pin, when the piston is at bottom dead center. A targeted lubrication of the mechanically and thermally highly loaded gudgeon pin can thus be guaranteed. It is also possible by means of the oil supply to supply transfer ports of a two-stroke engine with oil, counteracting a tendency to coke up.

Owner:WACKER NEUSON SE

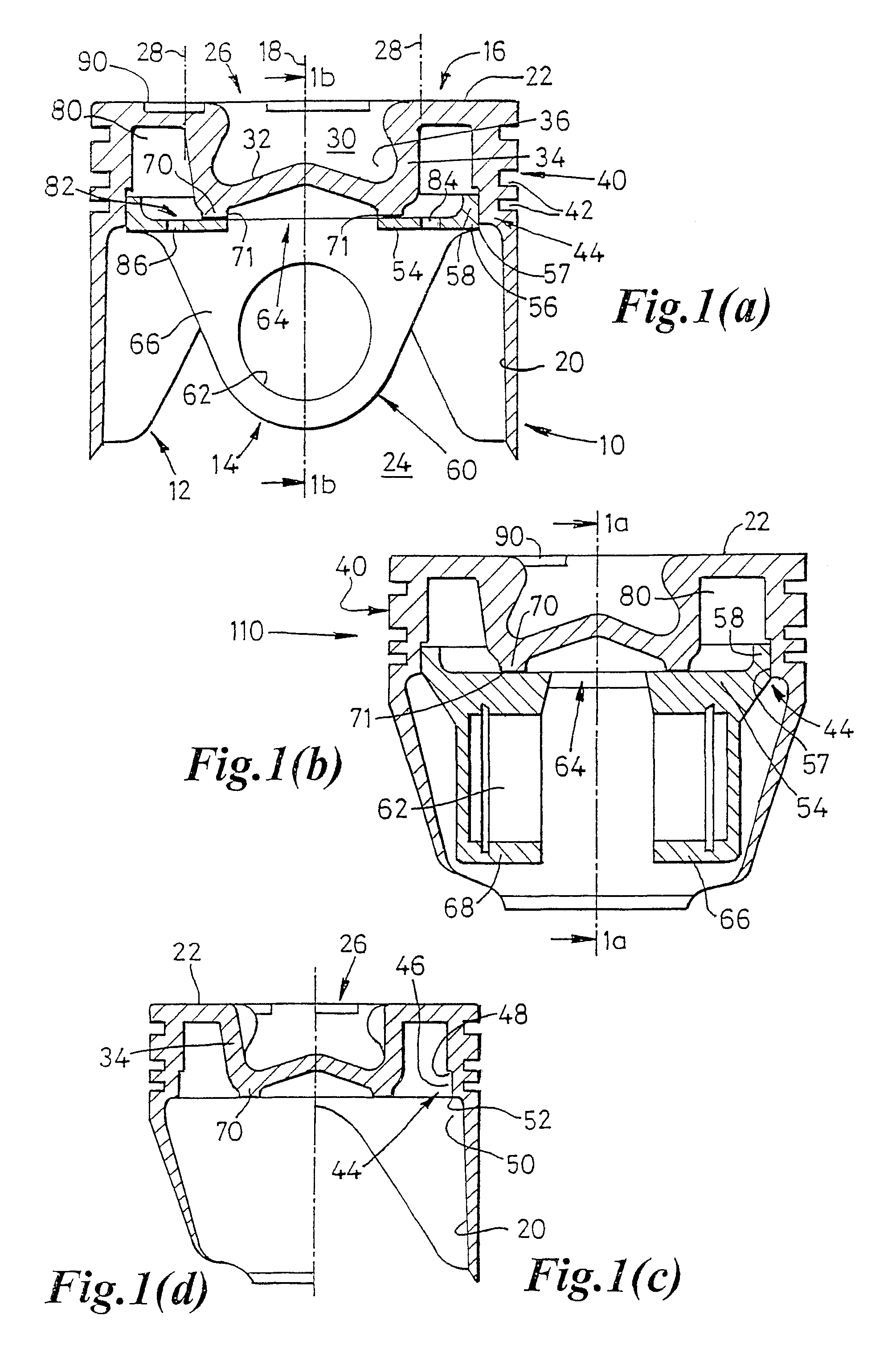

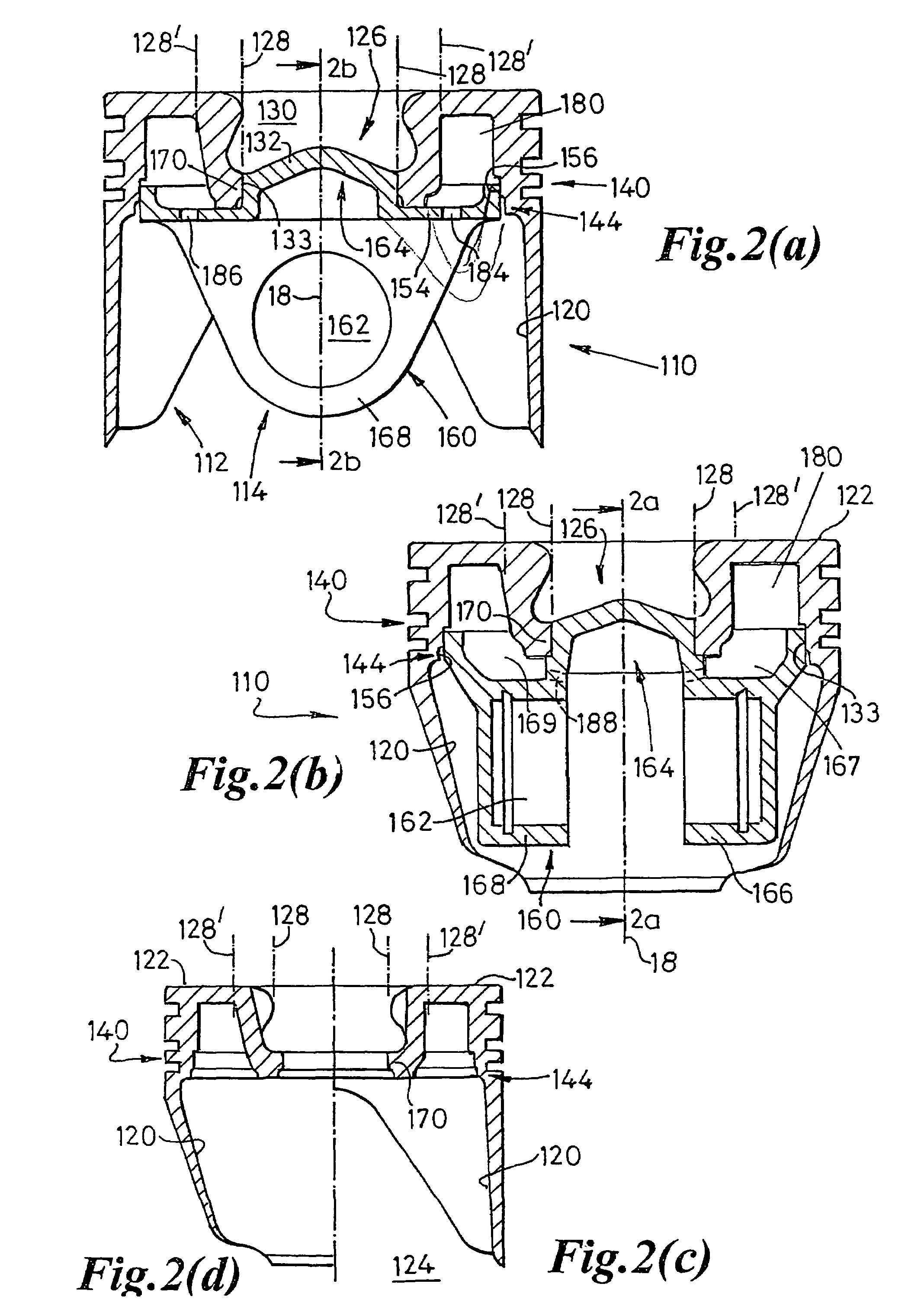

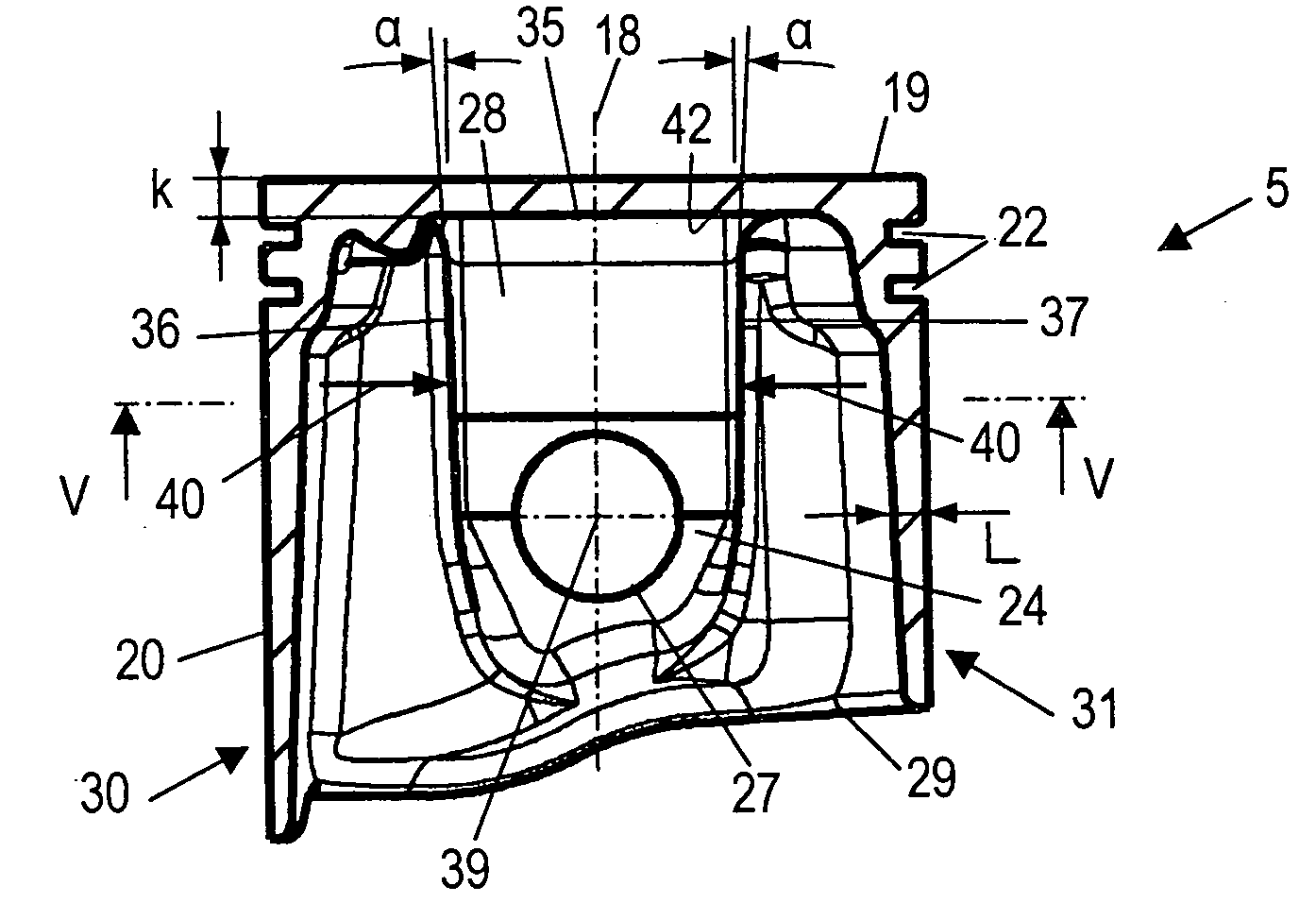

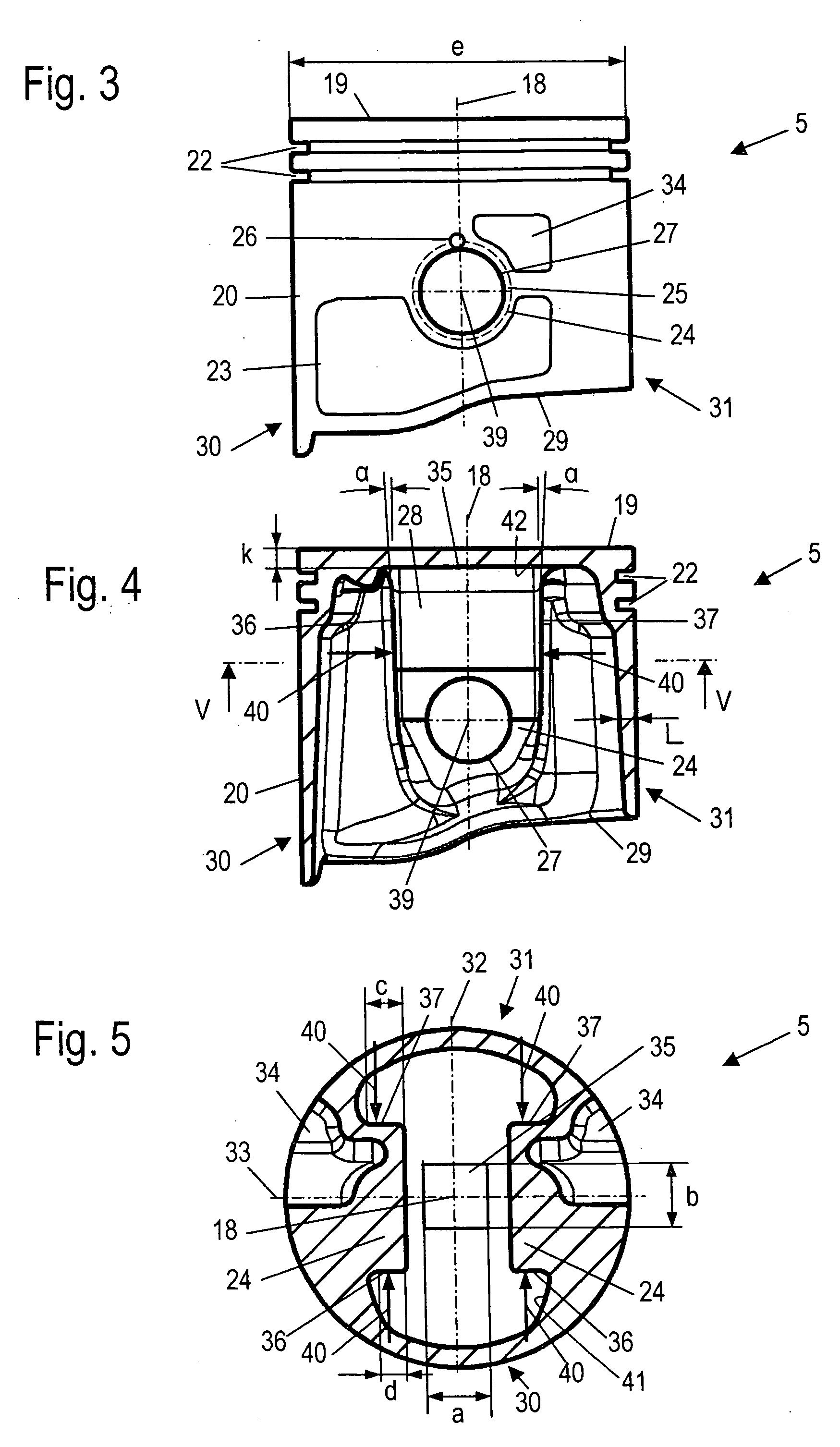

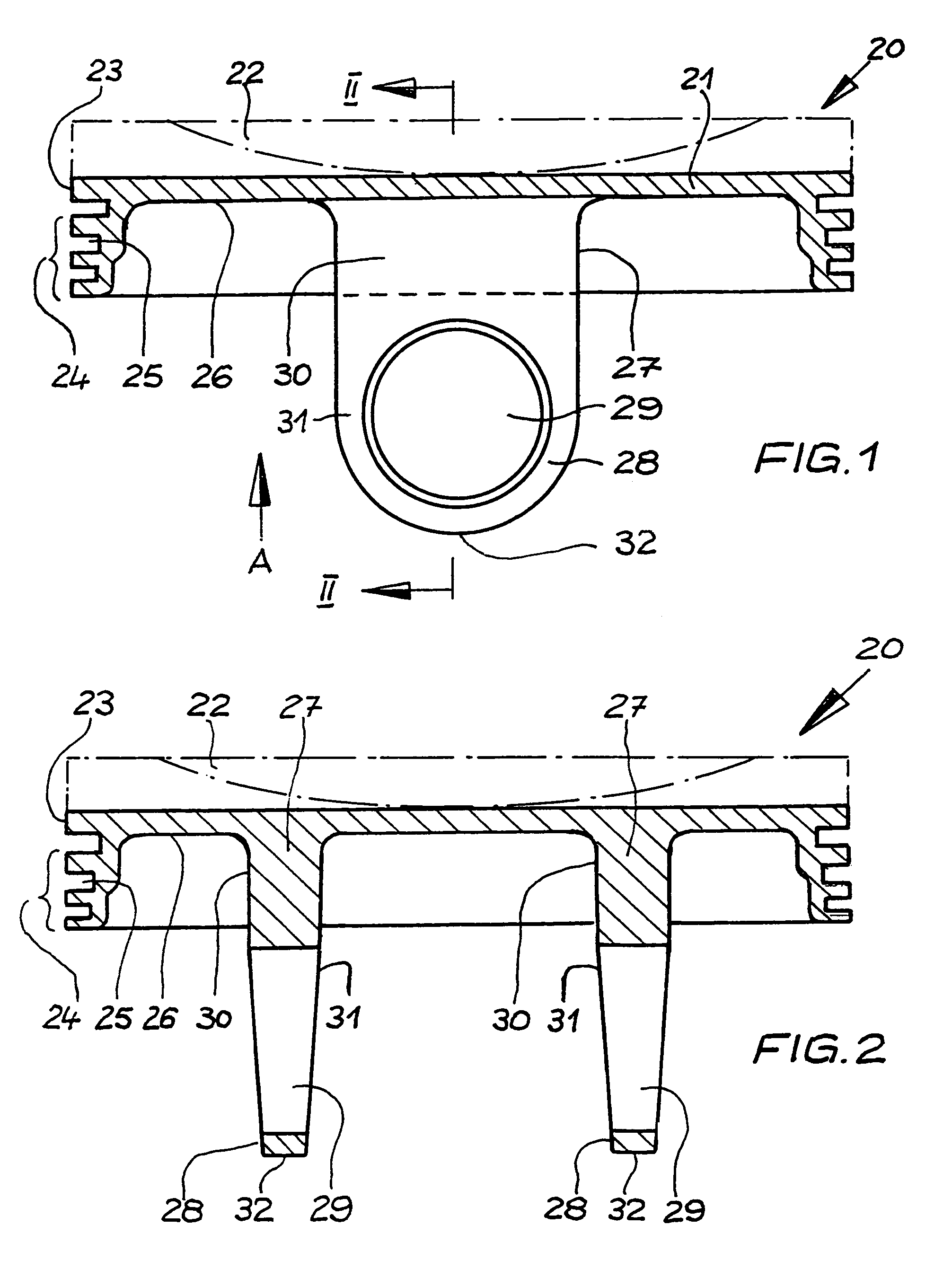

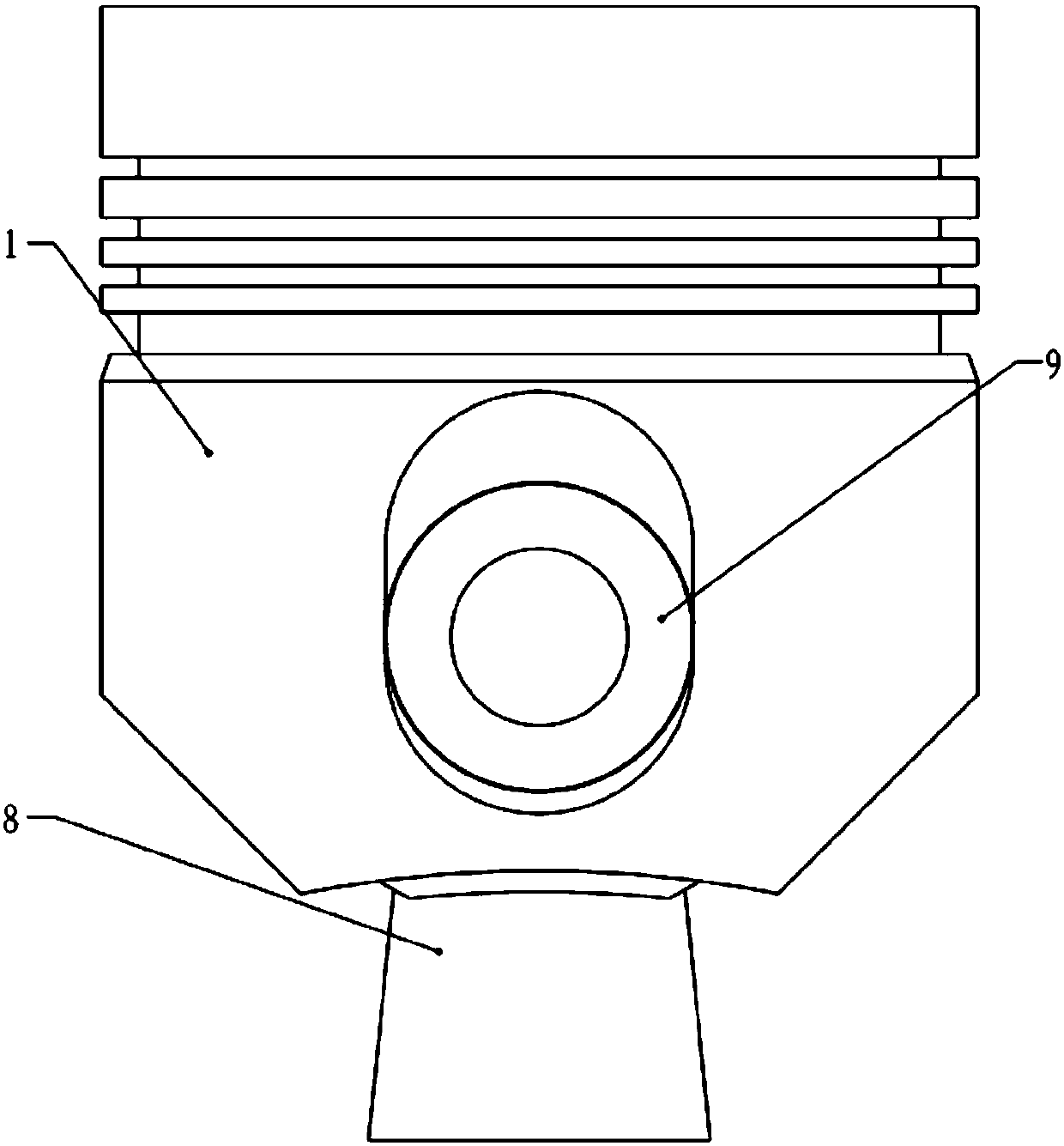

Piston for a two-stroke engine and a method of making the same

InactiveUS20070113734A1Improve accuracyHigh precision machiningInternal combustion piston enginesPlungersThermodynamicsMechanical engineering

A piston (5) for a two-stroke engine (1) has a piston base (19) and at least one piston pin boss (24). The piston pin boss (24) has a bore for accommodating a piston pin. At the piston pin boss (24), two mutually opposite-lying planar clamping surfaces (36, 37) are formed. The piston (5) is produced in a pressure die cast process and is thereafter clamped at the clamping surfaces (36, 37) and a stop surface (35). In this clamping state, all machining operations of the piston (5) can be carried out so that a high dimensional stability of the piston (5) results.

Owner:ANDREAS STIHL AG & CO KG

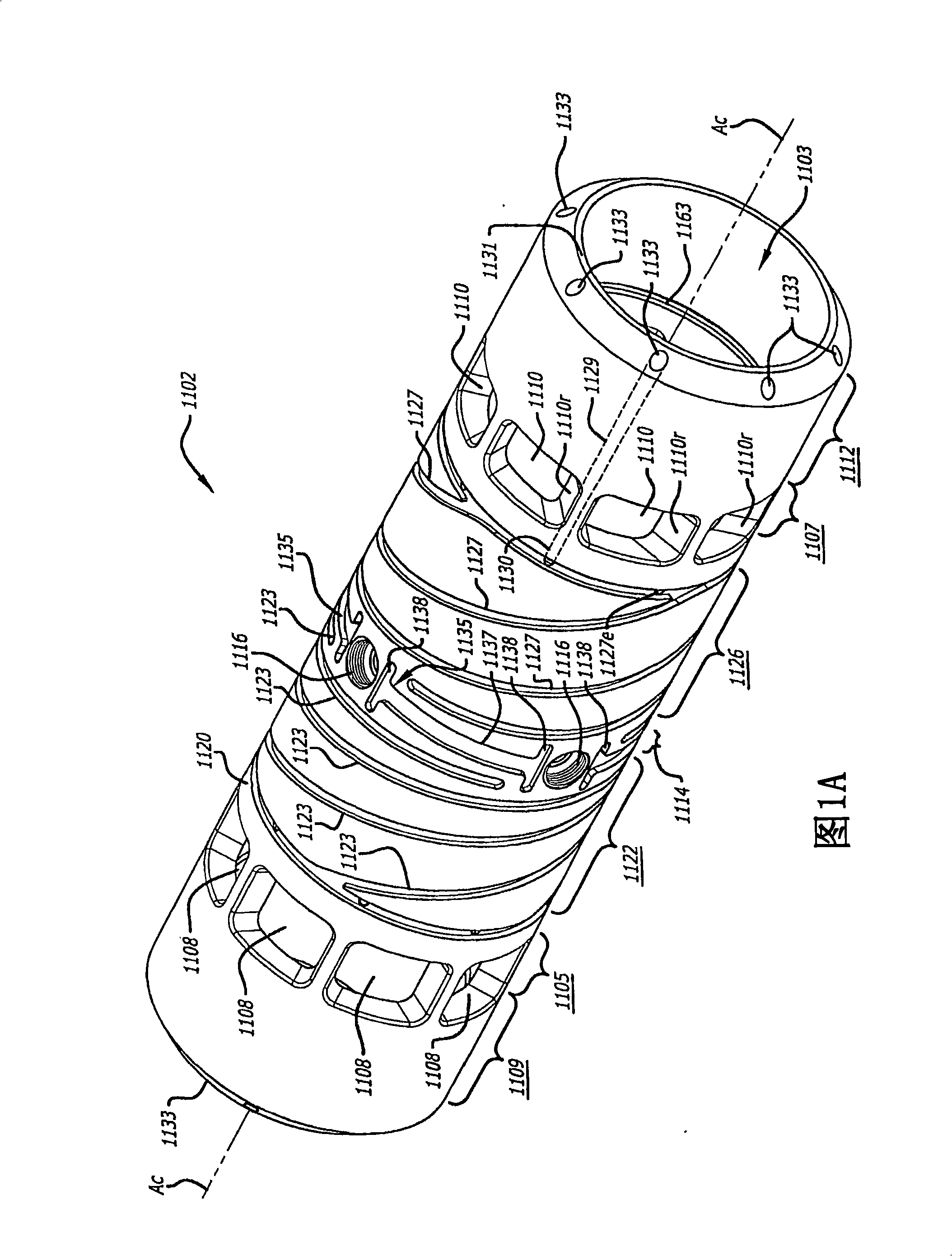

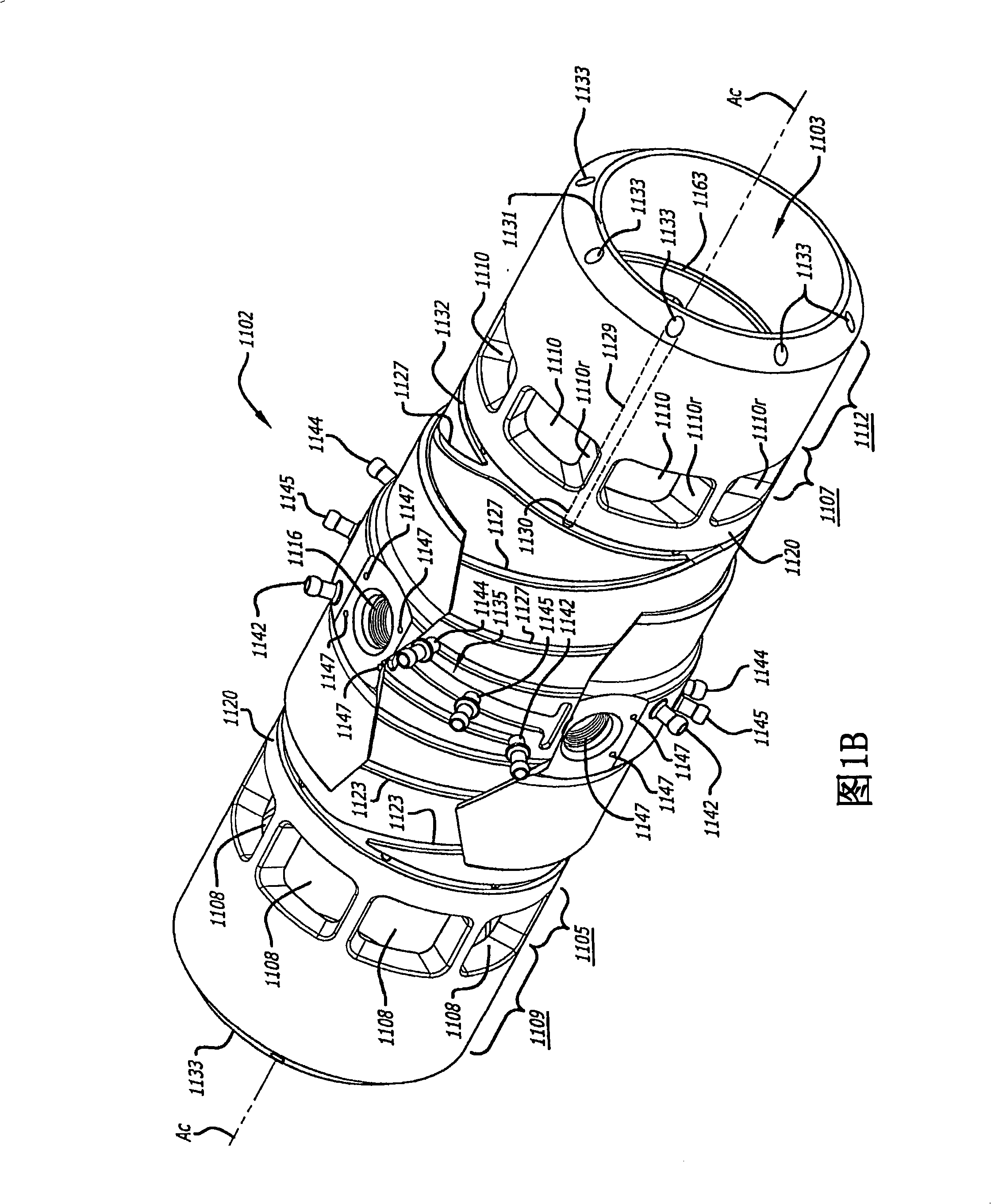

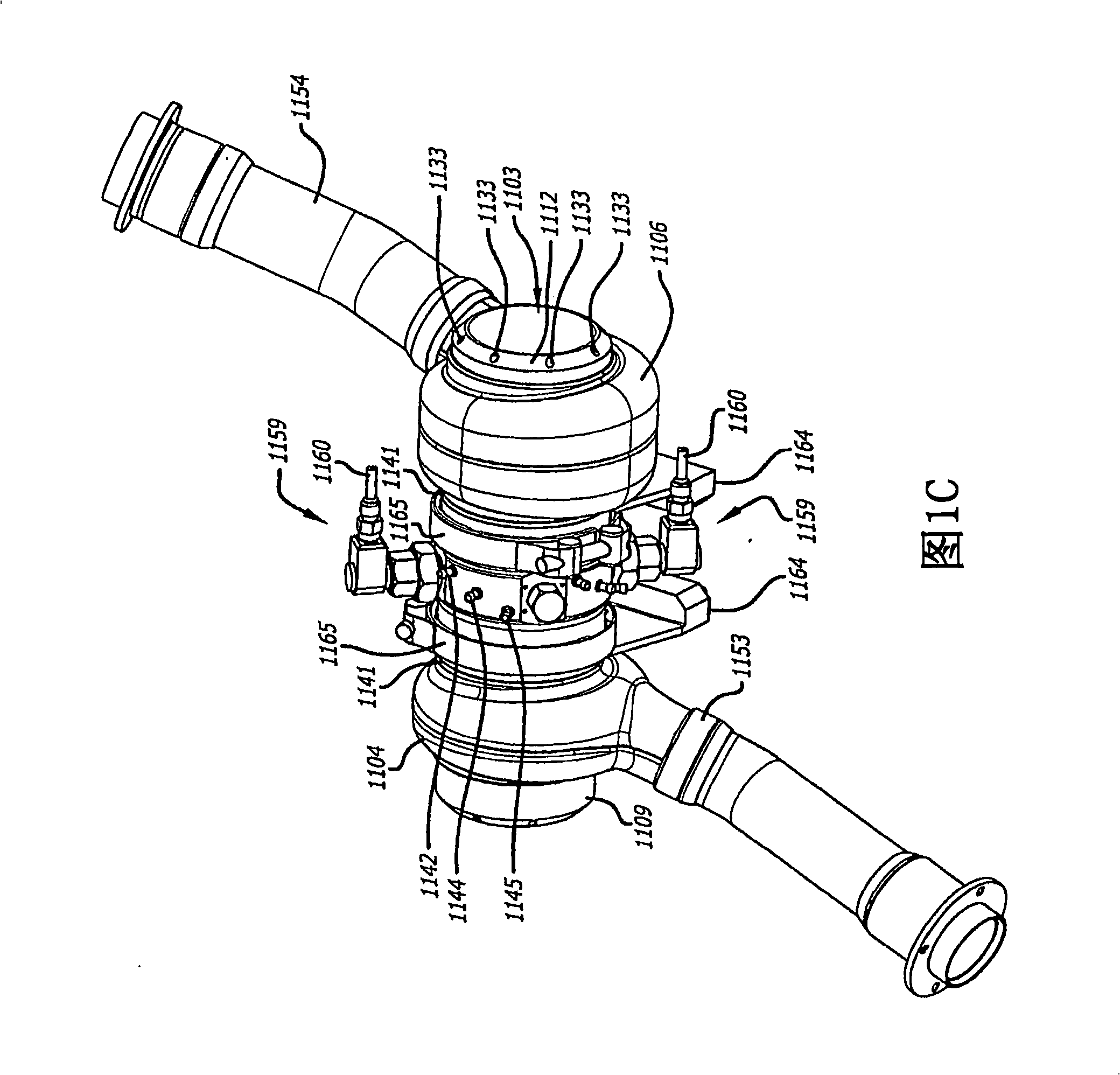

Opposed piston engine

A two-cycle, opposed piston engine with side-mounted crankshafts and cylinders isolated from mechanical stresses of the engine includes tailored cooling of cylinders and symmetrical cooling of the interior surfaces of piston crowns. Each opposed piston includes a compliant member that permits movement of an axially-centered rod mounted in the piston in order to maintain axial alignment with the bore of a cylinder in which the piston is disposed during engine operation. A single wristpin is disposed externally of the piston to connect the piston with connecting rods that run between the piston and the crankshafts.

Owner:ACHATES POWERS INC

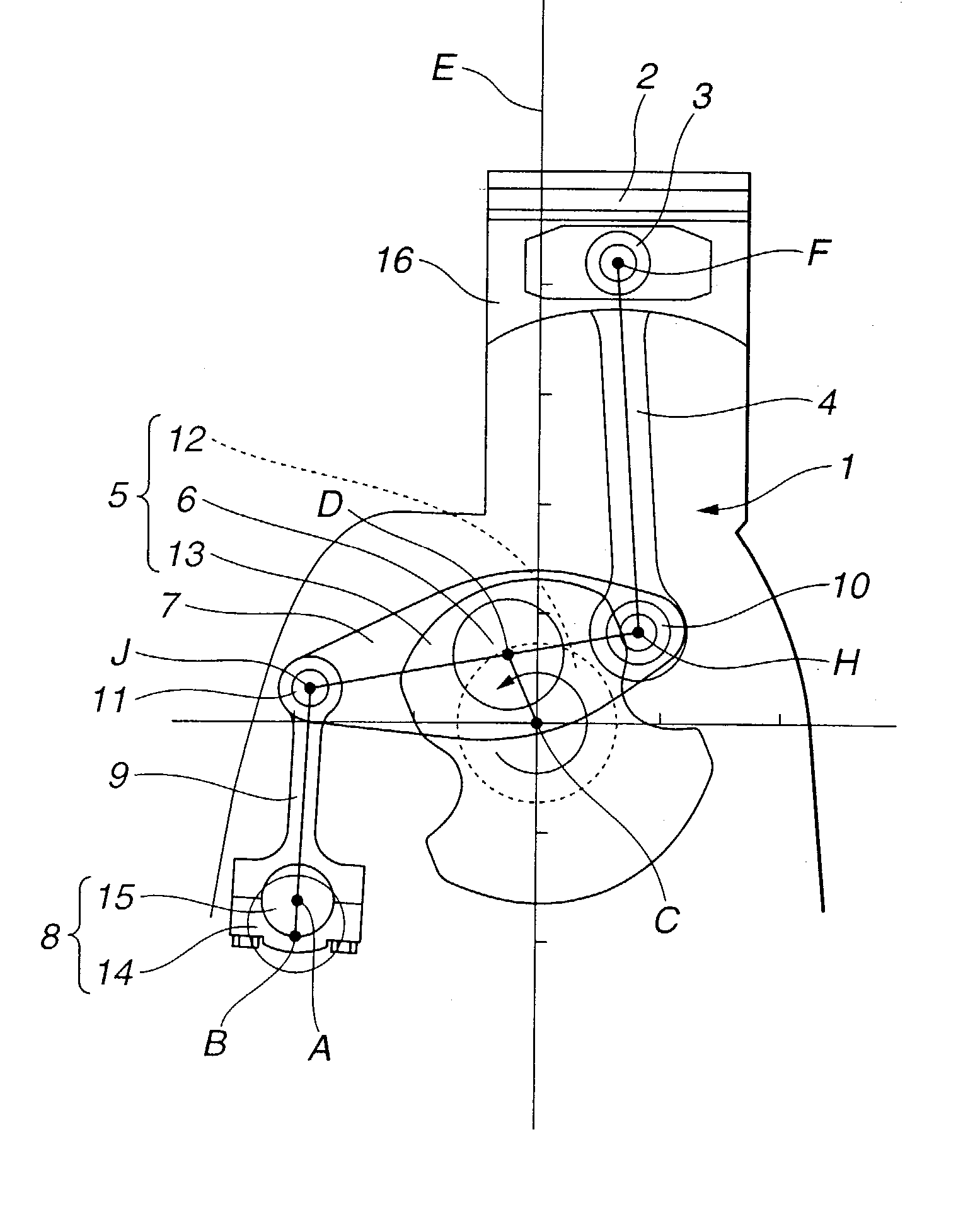

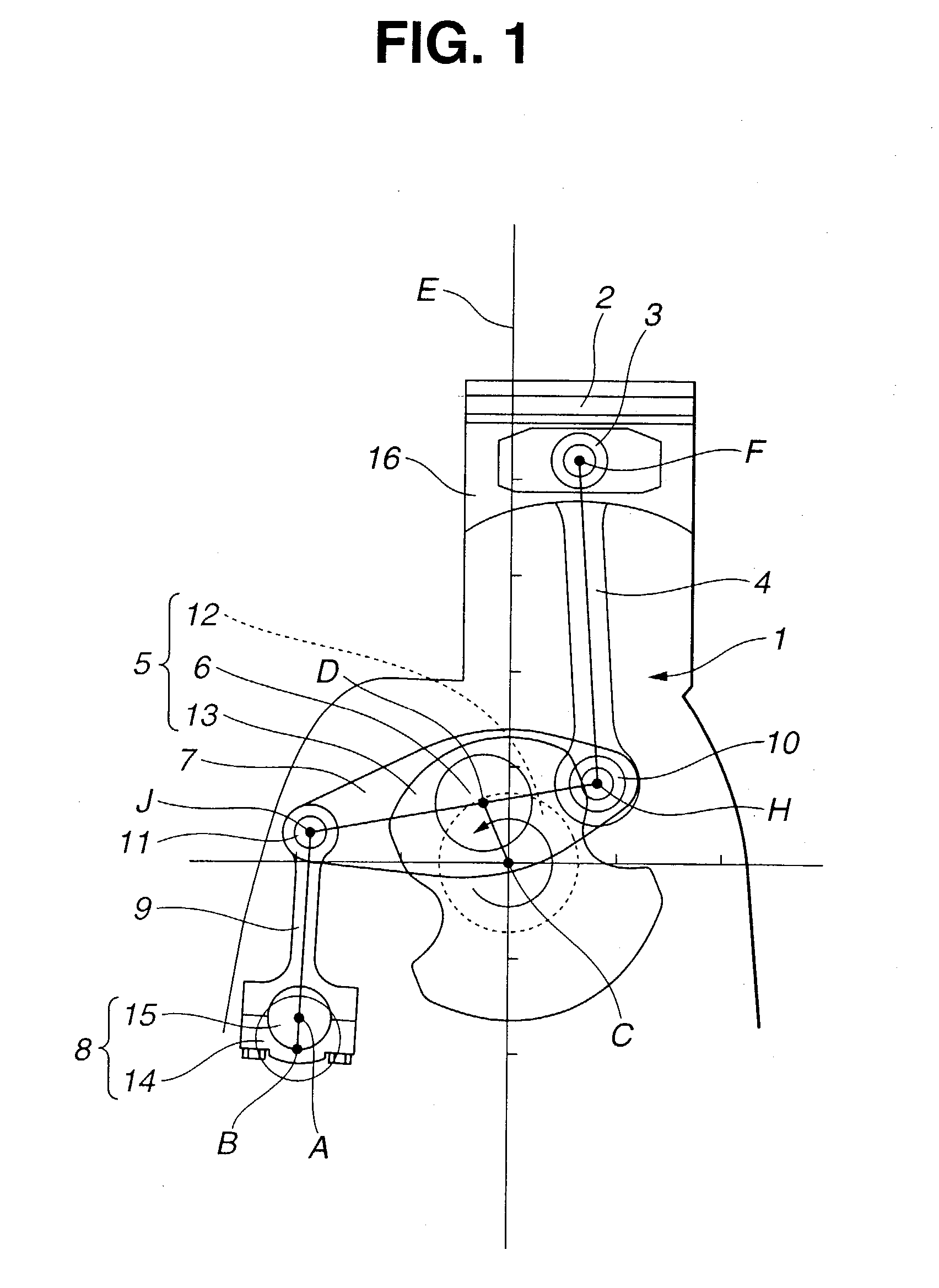

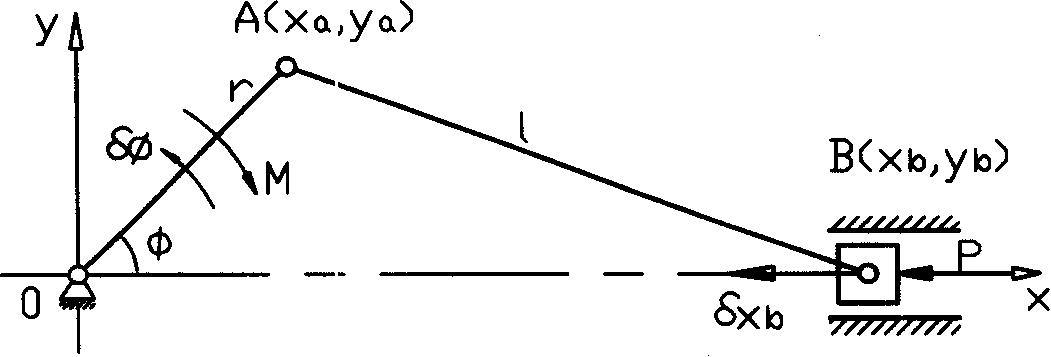

Link mechanism of reciprocating internal combustion engine

A link mechanism of an engine includes: an upper link having a first end connected to a piston pin of a piston; a lower link connected to the upper link via an upper pin having a center, the lower link being connected to a crank pin of a crank shaft; a control shaft extending substantially in parallel with the crank shaft, the control shaft having a rotational center; and a control link including: a first end swingably connected to the control shaft, and a second end connected to the lower link. In a process of the center of the upper pin moving nearer to the axial line of the piston pin, the center of the control pin moves in the upward direction, thus inclining the lower link and allowing the center of the upper pin and the center of the piston pin to move in the downward direction.

Owner:NISSAN MOTOR CO LTD

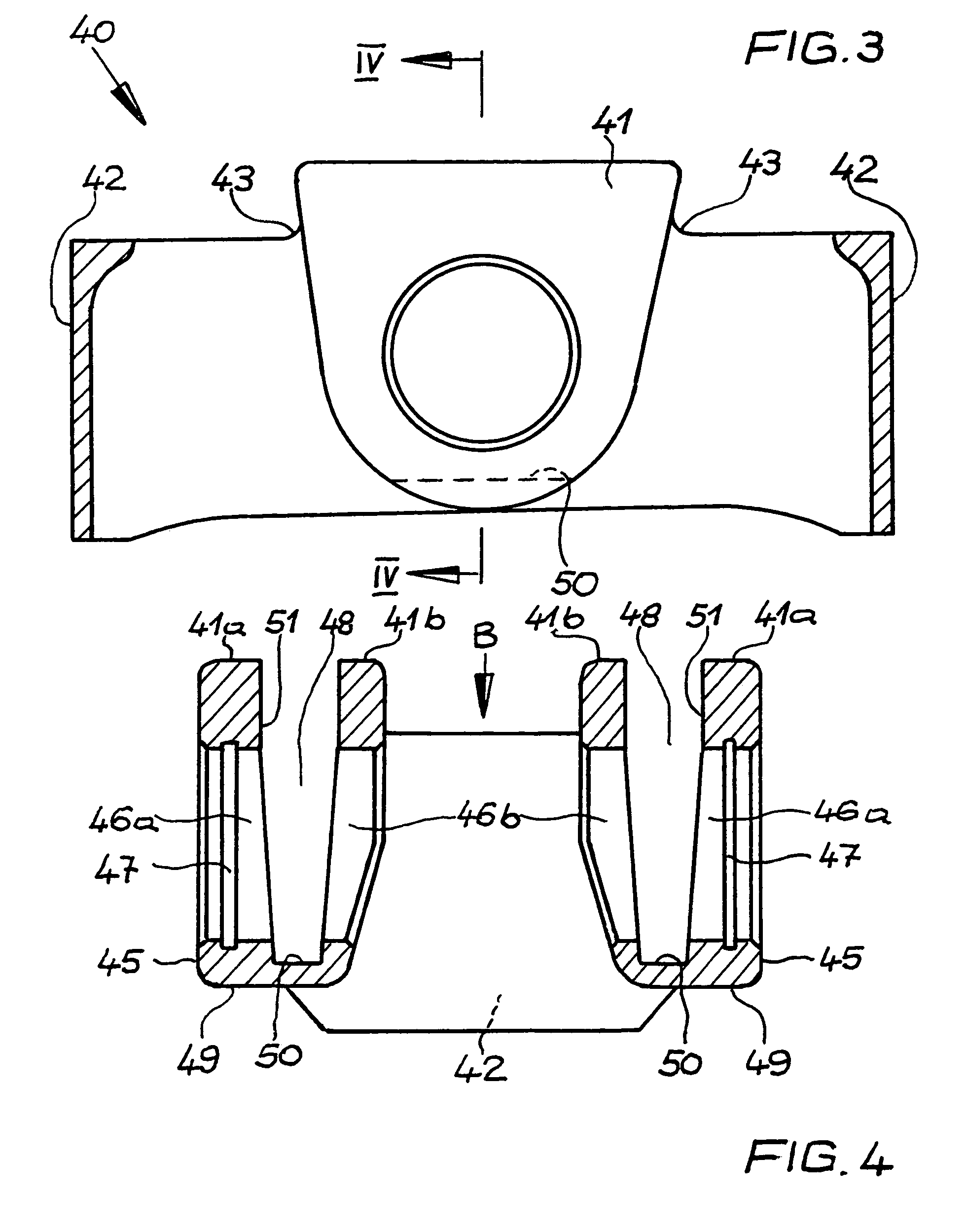

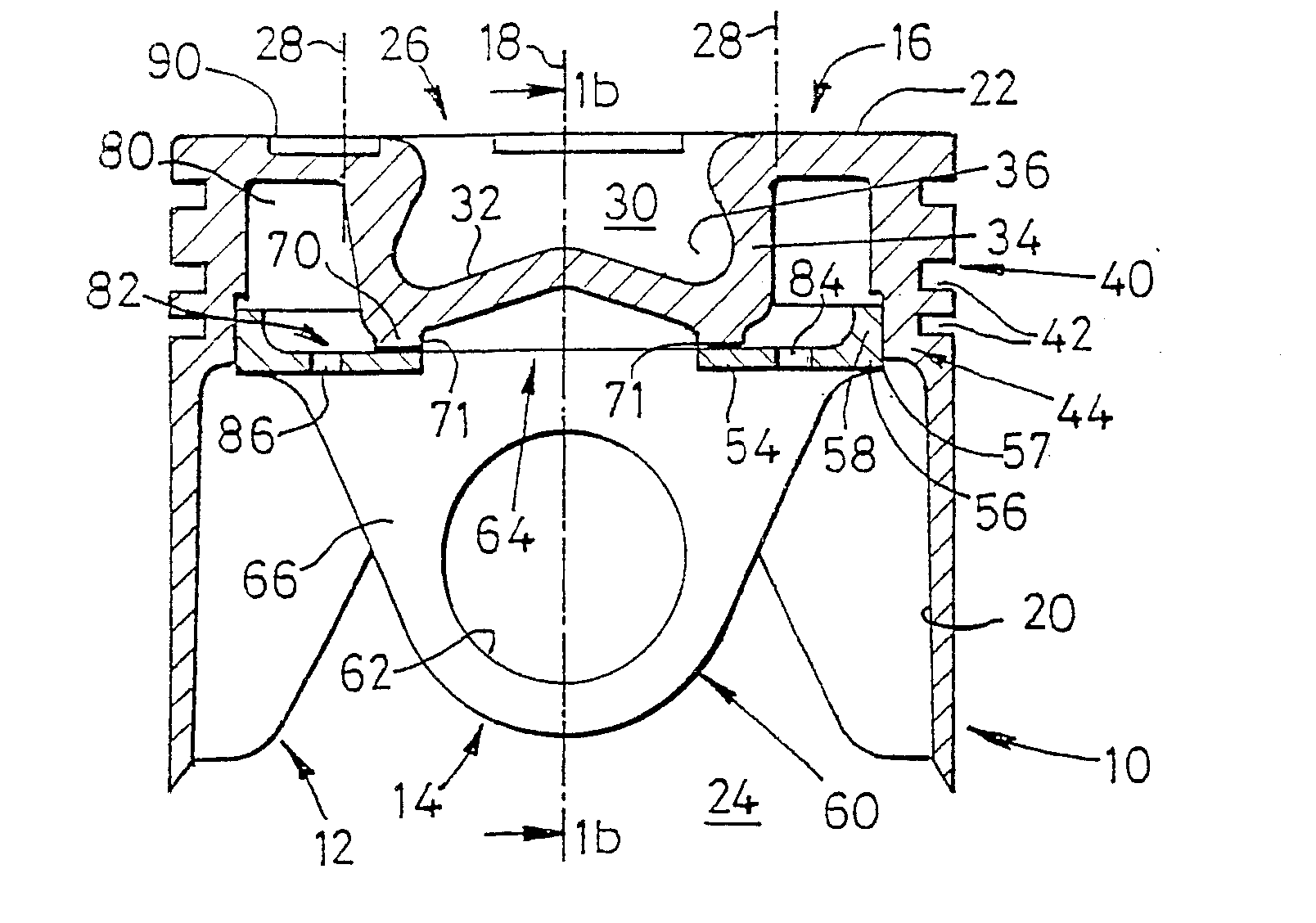

Two-part piston for an internal combustion engine

ActiveUS7210399B2Easy to assembleReduce weightPlungersMachines/enginesInternal combustion engineGudgeon pin

A two-part piston for an internal combustion engine has a piston head and a piston skirt. The piston head has a piston crown on the underside of which at least two boss lands, each provided with a head boss and a head boss hole are connected. The piston skirt has at least two boss bodies, each provided with a skirt boss and a skirt boss hole. When the head and skirt are joined, the head boss holes and skirt boss holes are flush in relation to each other for accommodating a gudgeon pin. Each boss body has a recess in which the corresponding boss land is accommodated with the associated head boss so that the head boss hole and skirt boss hole are aligned flush relative to each other.

Owner:MAHLE TECH +1

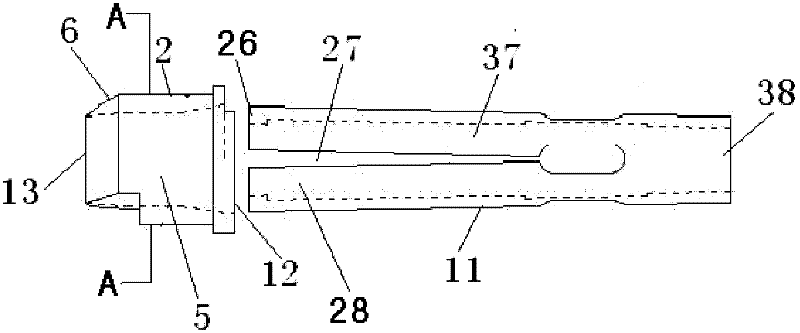

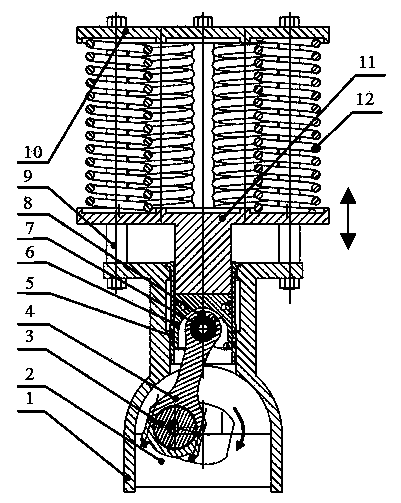

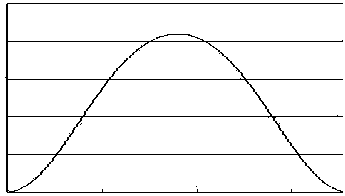

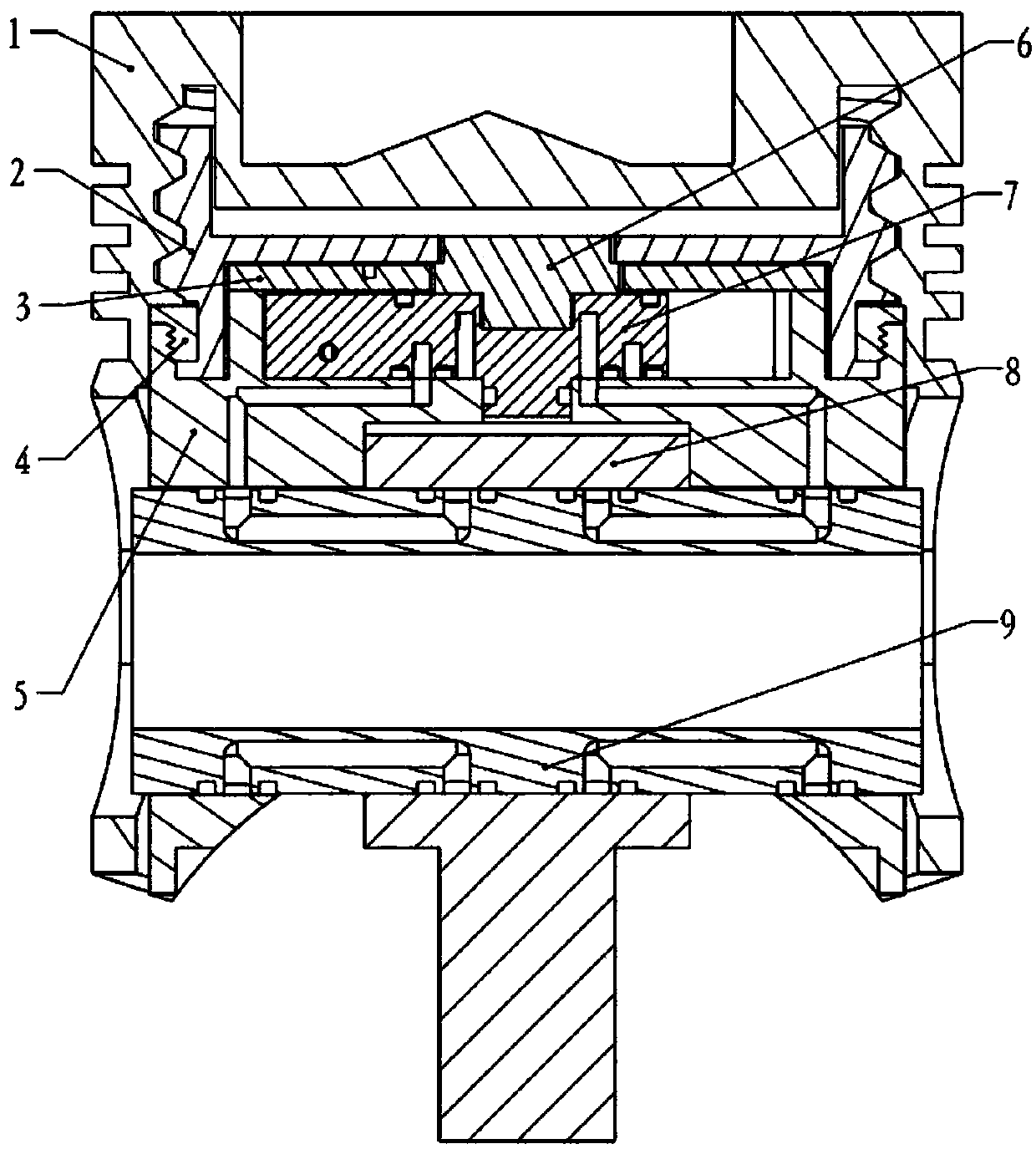

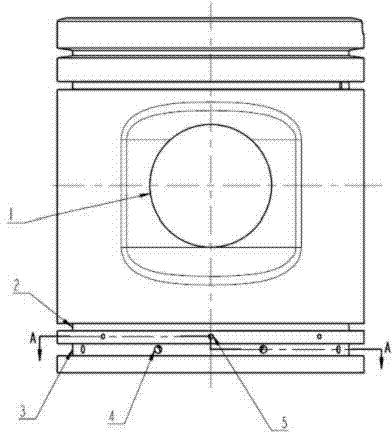

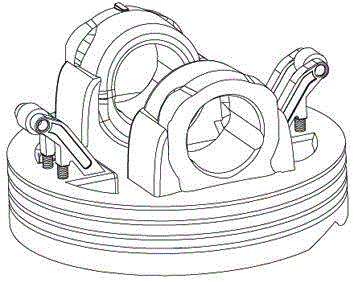

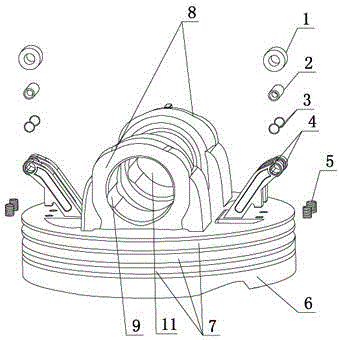

Friction wearing part test apparatus for connecting rod small end bushing of engine

ActiveCN103994880AShort screening cycleSimple structureMachine part testingReciprocating motionEngineering

The invention relates to a friction wearing part test apparatus for a connecting rod small end bushing of an engine. The apparatus comprises a body (1), a bearing cover (2), a crankshaft (3), a connecting rod (4), a cylinder sleeve (5), a test piston (6), a piston pin (7) and a small end bushing (8). The crankshaft (3) performs rotary motion in a bearing structure composed of the body (1) and the bearing cover (2). The crankshaft (3) and the connecting rod (4) are connected, the connecting rod (4) is connected with the test piston (6) through the piston pin (7), the contact portion of the connecting rod (4) and the piston pin (7) is provided with the small end bushing (8), and the rotary motion of the crankshaft (3) drives the test piston (8) to perform up-and-down motion in the cylinder sleeve (5). The apparatus further comprises a support rod (9), a spring limiting disc (10), a motion disc (11) and a spring set (12). Compared to a whole machine test, the apparatus can reduce the cost for endurance testing of a connecting rod small end bushing.

Owner:CHINA NORTH ENGINE INST TIANJIN

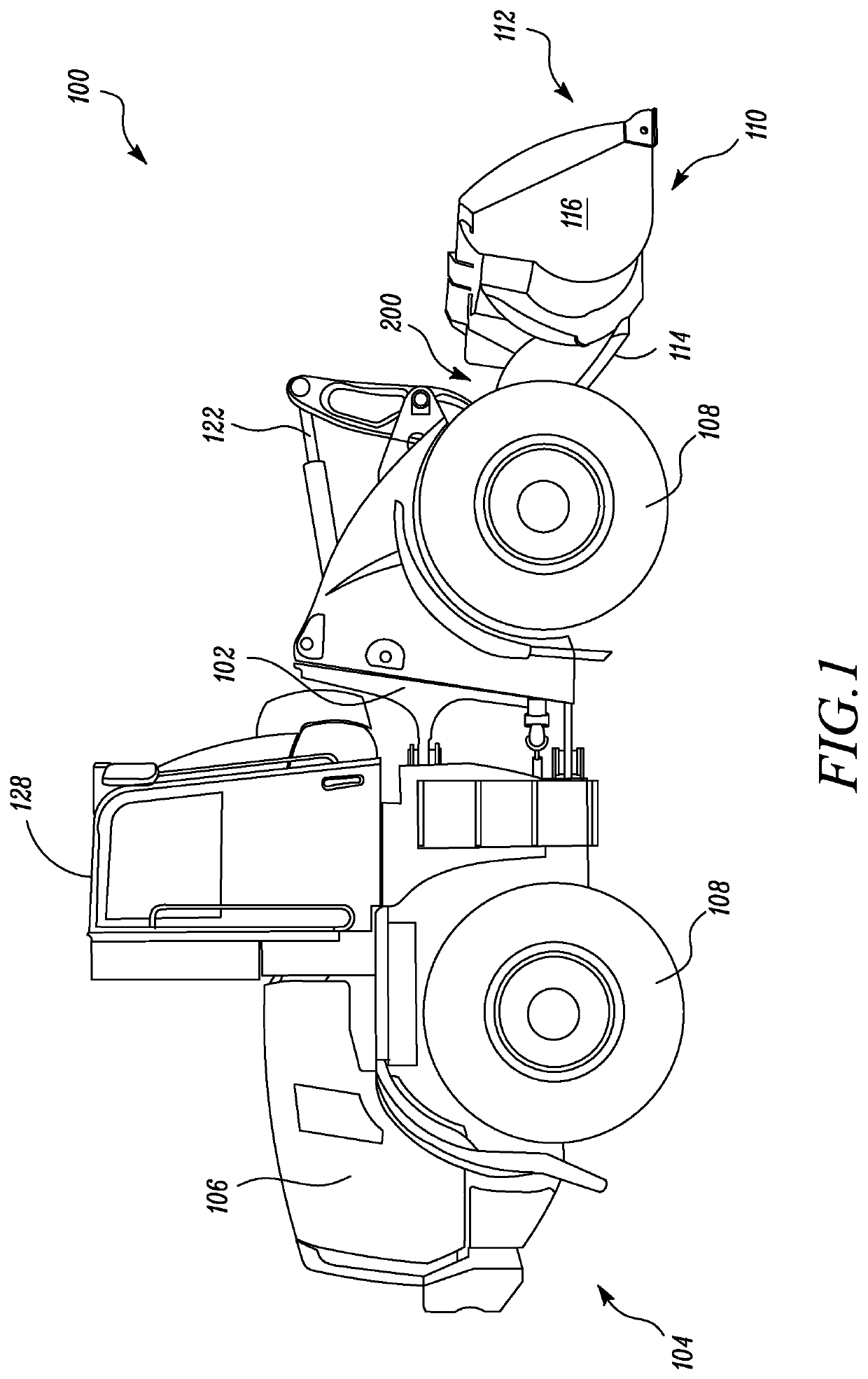

Indication system for a quick coupler assembly

ActiveUS10711429B2Mechanical machines/dredgersFluid-pressure actuatorsEngineeringMechanical engineering

An indication system associated with a coupler assembly includes a sensing element affixed to the coupler assembly, and an indicator assembly coupled to the sensing element. The sensing element is arranged and positioned proximate to a hydraulic assembly of the coupler assembly. The sensing element is configured to generate a signal indicative of an extension of a piston pin of the hydraulic assembly. The indicator assembly is configured to receive the signal indicative of the extension of the piston pin, and determine if the piston pin is in an extended state based on the received signal.

Owner:CATEPILLAR SARL

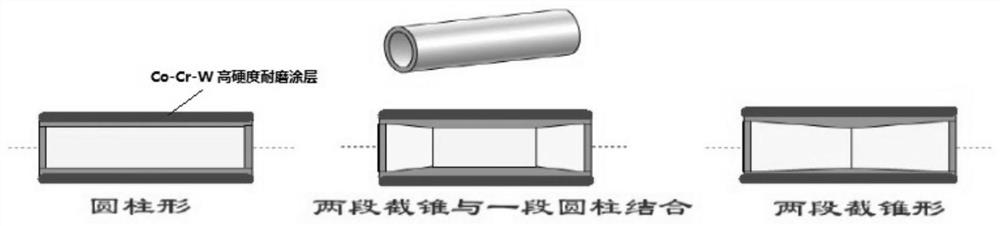

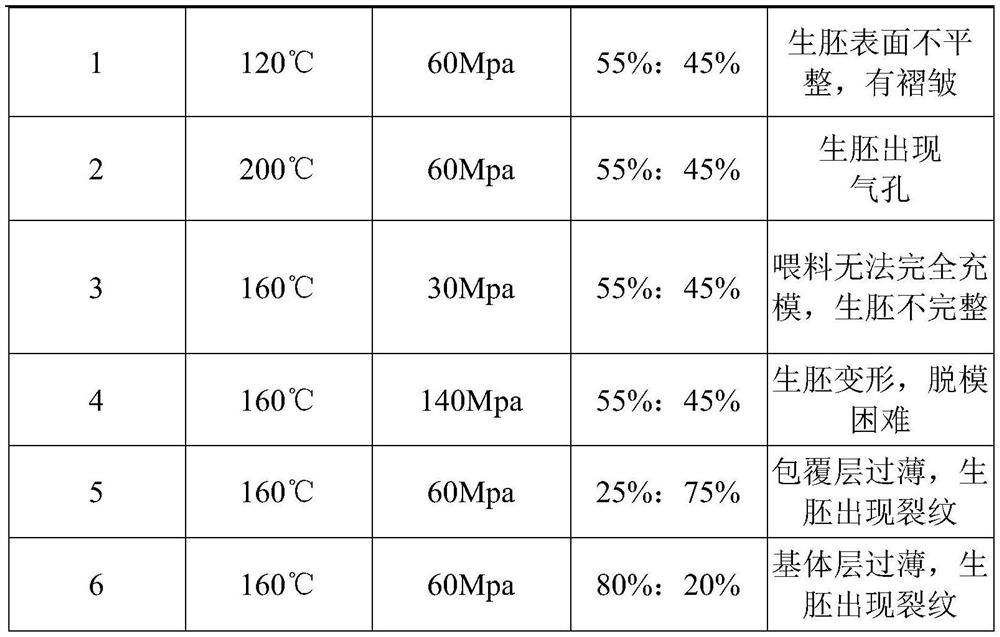

High-hardness wear-resistant piston pin and preparation method thereof

The invention discloses a high-hardness wear-resistant piston pin and a preparation method thereof. The preparation method comprises the following steps of firstly, respectively mixing matrix material powder and Co-Cr-W alloy powder with a binder, and performing granulation to obtain a matrix material feed and a high-hardness wear-resistant coating material feed; then, sequentially injecting the matrix material feed and the Co-Cr-W alloy coating material feed into a mold cavity by using an injection molding technology to obtain a product green body; removing the binder in the green body through catalytic debinding and thermal debinding processes; and finally, performing co-sintering densification to obtain the Co-Cr-W series high-hardness wear-resistant piston pin. The process is simple, the bonding performance of a coating layer and a matrix is good, and the piston pin has the characteristics of high hardness and wear resistance.

Owner:湖南英捷高科技有限责任公司

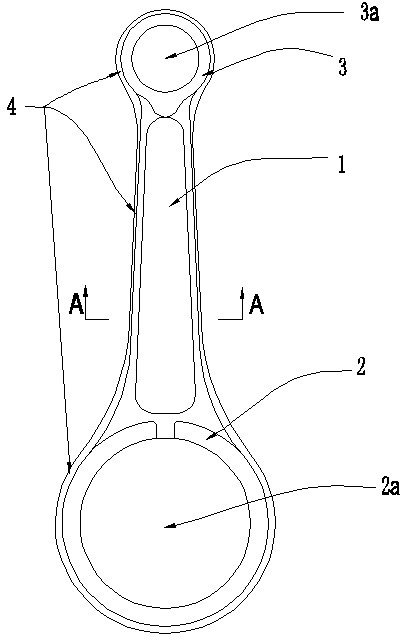

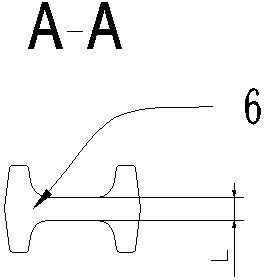

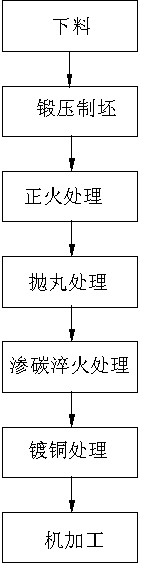

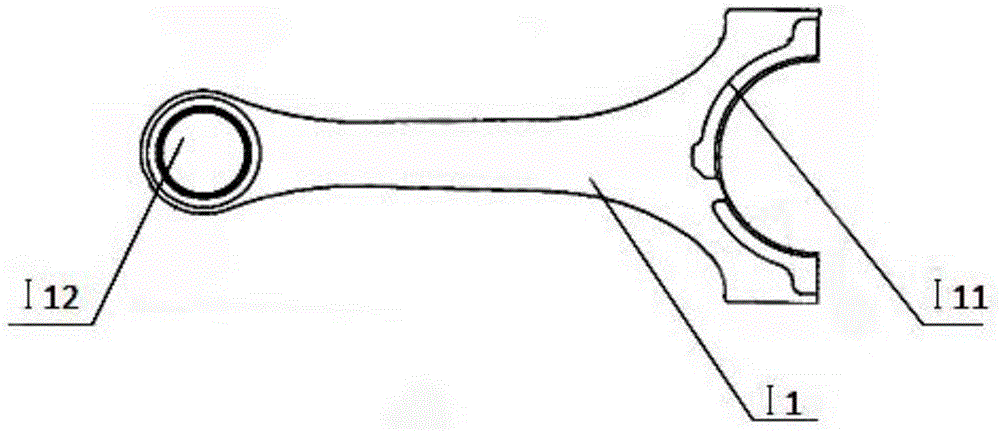

A kind of motorcycle engine connecting rod and its manufacturing process

InactiveCN102287441ADelay the oxidation processReduce the chance of occurrenceConnecting rodsCopper platingSurface oxidation

The invention discloses a motorcycle engine connecting rod and its manufacturing process. The engine connecting rod has a rod body, a large head and a small head are respectively arranged at two ends of the rod body, and a crank pin mounting hole is arranged on the large head. A piston pin installation hole is provided on the small head, and a copper layer is plated on the surface of the shaft, the large head and the small head, and the thickness L of the copper layer is 0.05mm-0.09mm. The manufacturing process of the engine connecting rod is: 1) blanking; 2) forging blank; 3) normalizing treatment; 4) shot blasting treatment; 5) carburizing and quenching treatment; 6) copper plating treatment; 7) machining out Crank pin mounting holes and piston pin mounting holes. The invention delays the surface oxidation process of the connecting rod by increasing the copper plating treatment, reduces the chance of cracks, and improves the service life of the invention; it has the characteristics of easy realization, low cost, long life and light weight.

Owner:CHONGQING NEW FEELING MOTORCYCLE

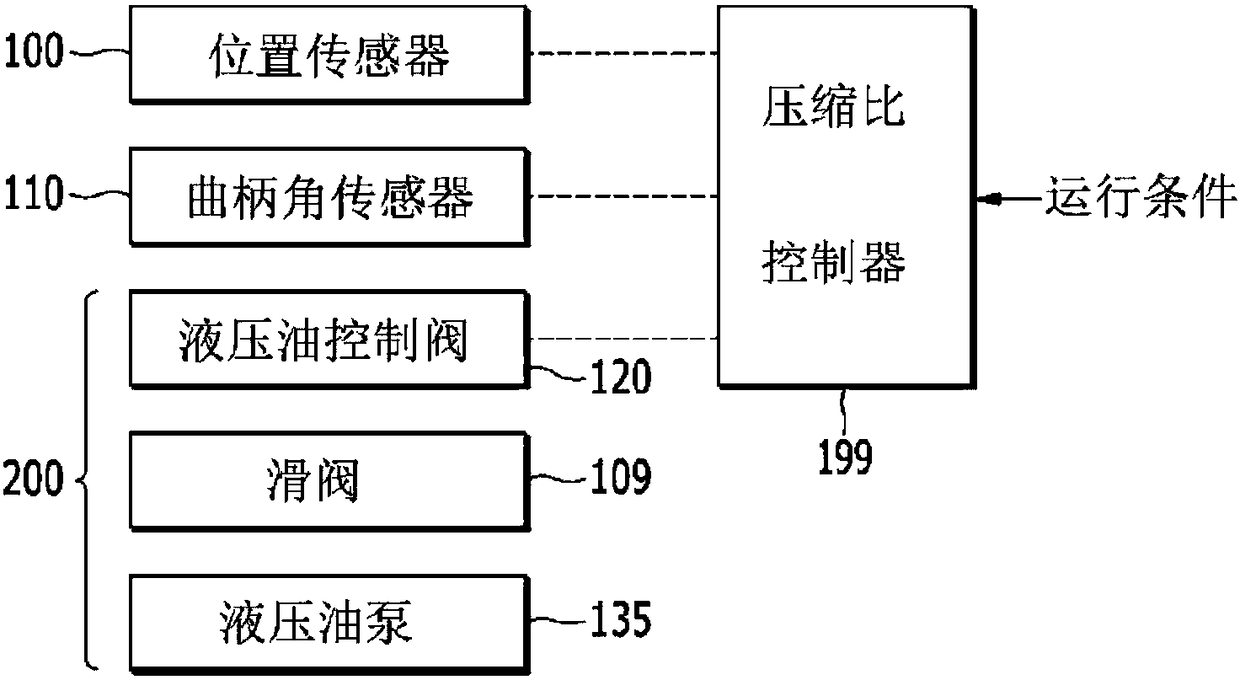

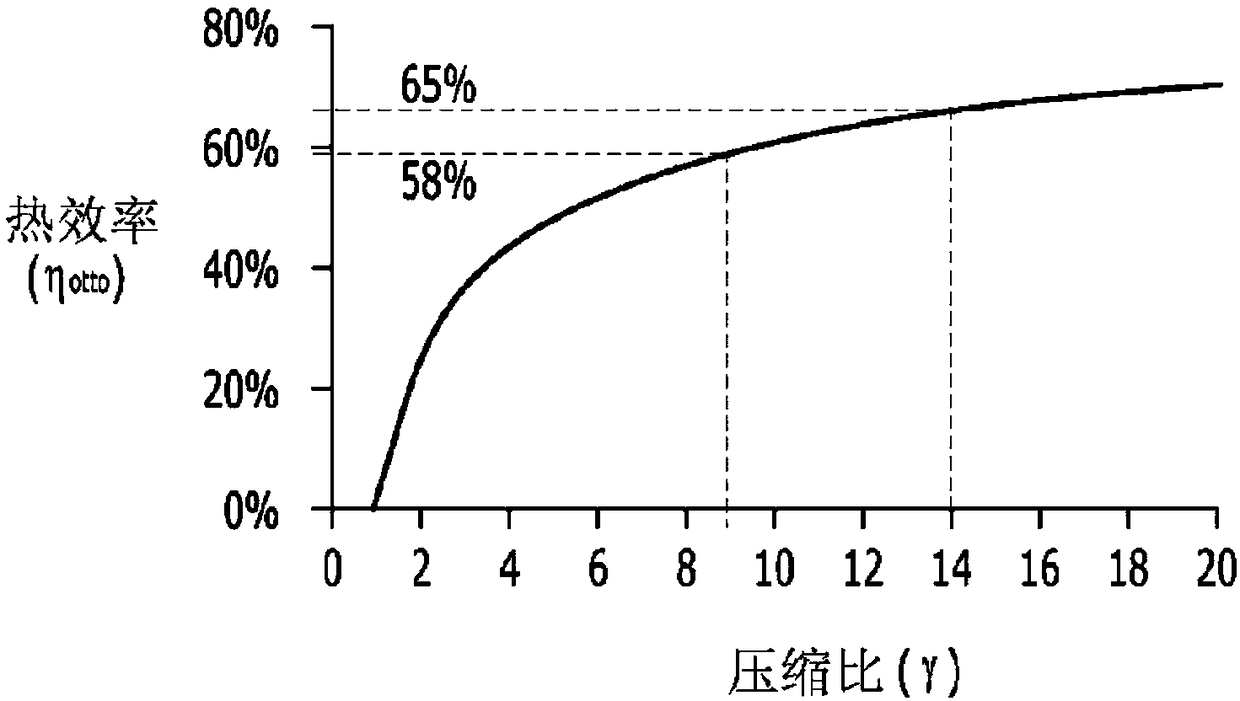

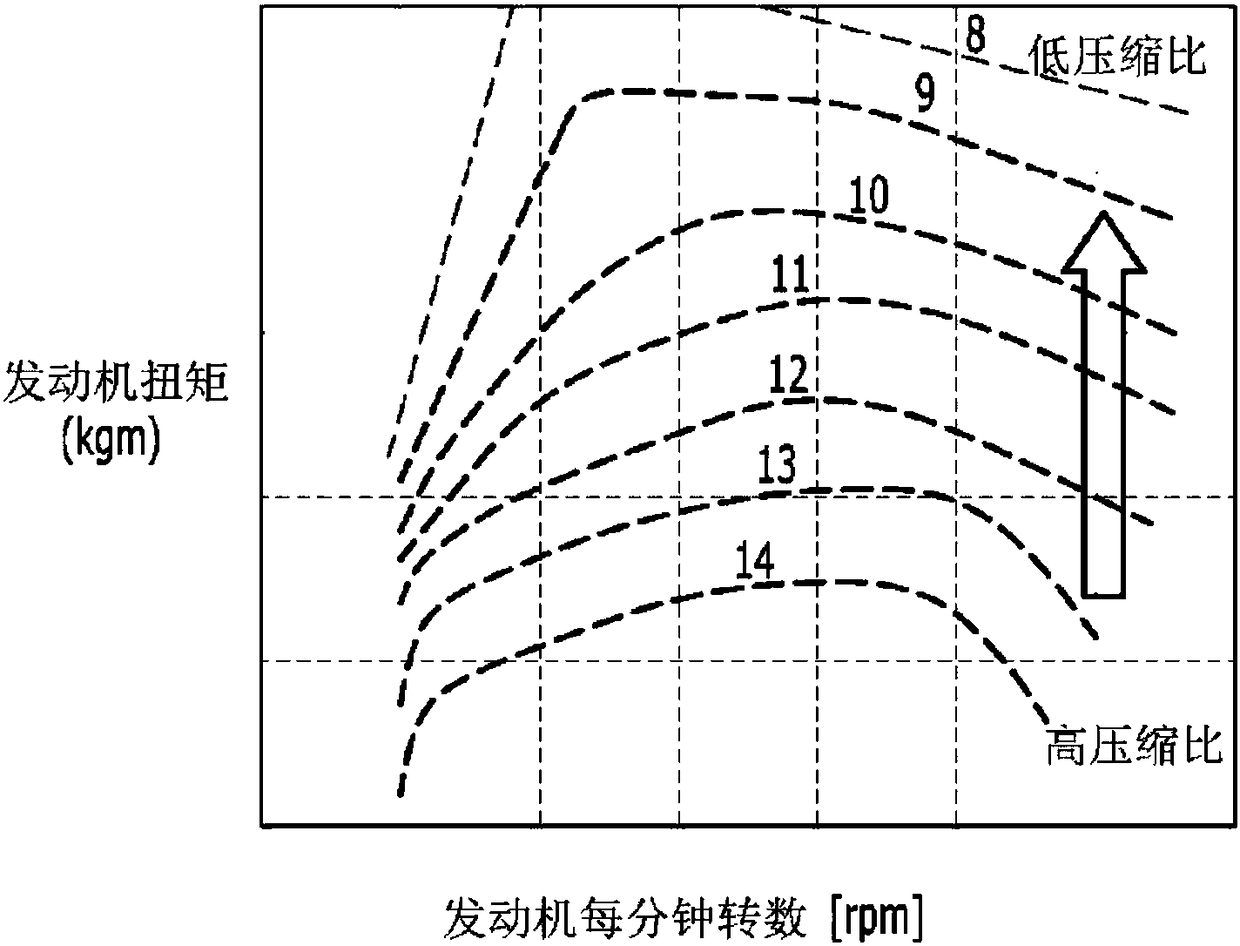

Variable compression ratio device and control method thereof

InactiveCN109404142AImprove efficiencyReduce consumptionInternal-combustion engine testingCrankshaftsCamHydraulic fluid

A variable compression ratio device and a control method thereof are provided. The device includes a connecting rod connected to a piston in a cylinder and an eccentric cam interposed between a pistonpin and the connecting rod. The eccentric cam moves the piston vertically to vary a compression ratio according to an eccentric cam rotation position. A hydraulic controller adjusts hydraulic fluid supplied to first and second chambers formed between the eccentric cam and the connecting rod. The first chamber rotates the eccentric cam in one direction by supplied hydraulic fluid. The second chamber rotates the eccentric cam in another direction by the supplied hydraulic fluid. A position sensor senses a piston position. A compression ratio controller calculates a target compression ratio according to an operating condition of an engine, calculates a current compression ratio based on the piston, and adjusts the eccentric cam rotation position using an oil control valve.

Owner:HYUNDAI MOTOR CO LTD +1

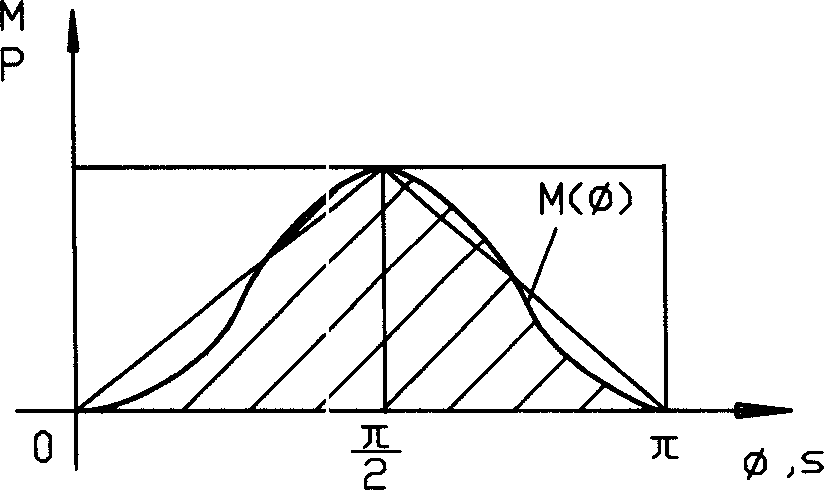

Non-round annular wheel crankless engines

InactiveCN101158316AEliminate work lossIncrease conversion rateMachines/enginesTime delaysWork cycle

The invention provides a piston-typed engine without crankshaft, moment dead point, or time delay ignition, mainly comprising a cylinder body, a piston, a piston pin, a non-round internal gear, a mainshaft gear, a mainshaft, a cam, a cam roller, etc. When the piston supplies work, the piston pushes the non-round internal gear to move and pushes the mainshaft gear engaged with the non-round internal gear to rotate, and the power is output from the mainshaft; meanwhile, the other mainshaft gears are driven to drive respective non-round gear engaged with the mainshaft gear to move, in order to implement the working cycles of each cylinder of sucking, pressing, bursting, and discharging. As the thrust force of the non-round internal gear is always tangent to a reference circle of the mainshaft gear and the torque is not changed with the rotation angle of the mainshaft gear, the output torque of the mainshaft is improved to the most extent, the torque of the crankshaft is avoided to be changed with the rotation angle of the crankshaft, the work loss caused by moment dead point and time delay ignition are avoided; the conversion rate of the power can theoretically reach 100%; the output torque, the output power of the mainshaft and the power performance of the engine are greatly improved, and the fuel consumption and pollution discharge are reduced by more than a half.

Owner:张连奎

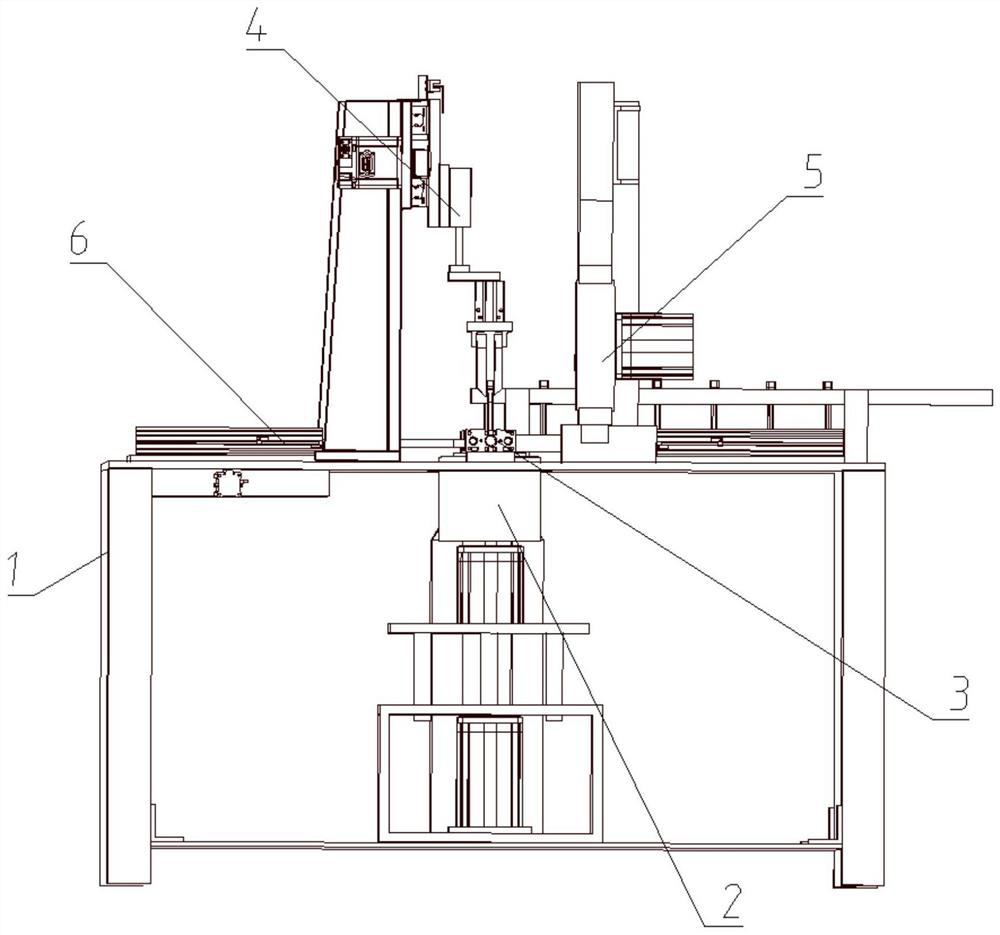

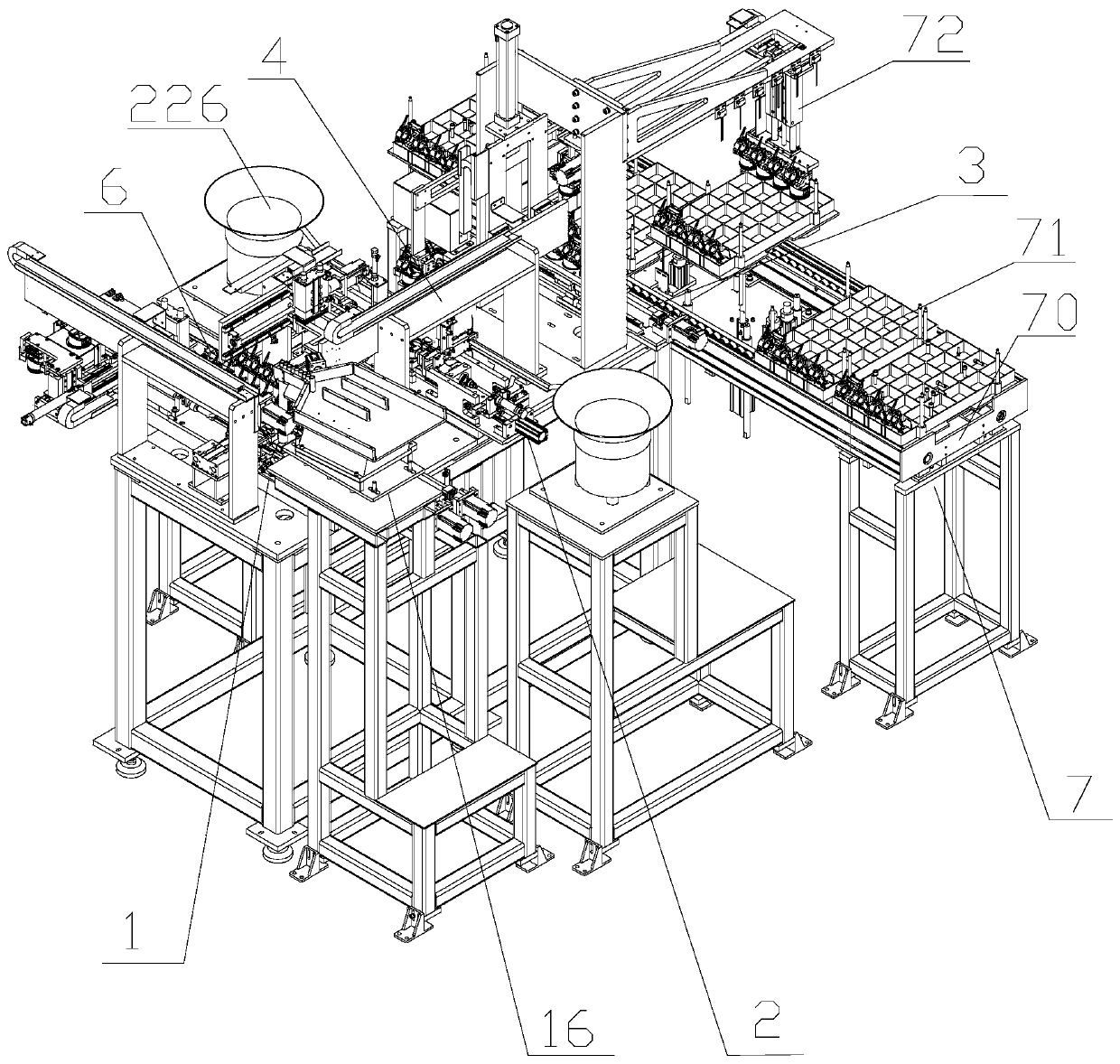

Automatic piston assembling robot and method

ActiveCN112935797AImplement automatic assemblyAssembly machinesMetal working apparatusEngineeringMachine

The invention provides an automatic piston assembling robot. A piston comprises a piston head, a piston rod and a piston pin, a first connecting hole is formed in the piston head, a second connecting hole is formed in the piston rod, the piston pin is inserted into the first connecting hole and the second connecting hole so that the piston rod can be hinged to the piston head. The robot comprises a machine frame, wherein the machine frame comprises a horizontally-placed mounting plate and a plurality of supporting legs arranged on the lower surface of the mounting plate, and the supporting legs support the mounting plate; a piston head feeding mechanism which is arranged on the machine frame and used for feeding a piston head to be assembled to an assembly station; a piston rod feeding mechanism which is arranged on the machine frame and used for feeding a piston rod to be assembled to the assembly station, inserting the end, provided with a second connecting hole, of the piston rod into the piston head located at the assembly station and aligning the first connecting hole with the second connecting hole; and a piston pin feeding mechanism which is arranged on the machine frame and used for feeding a piston pin to the assembly station and inserting the piston pin into the first connecting hole and the second connecting hole located in the assembly station. The robot can achieve automatic assembly of the piston.

Owner:BINZHOU UNIV

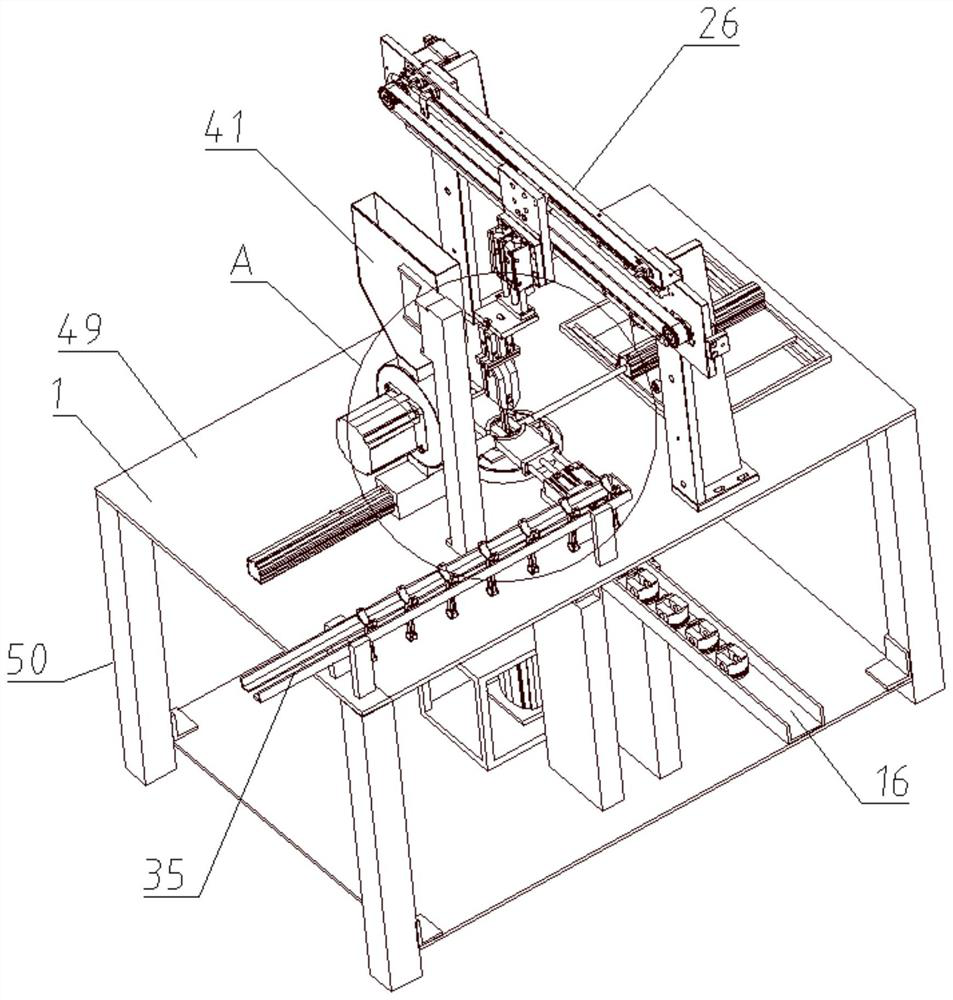

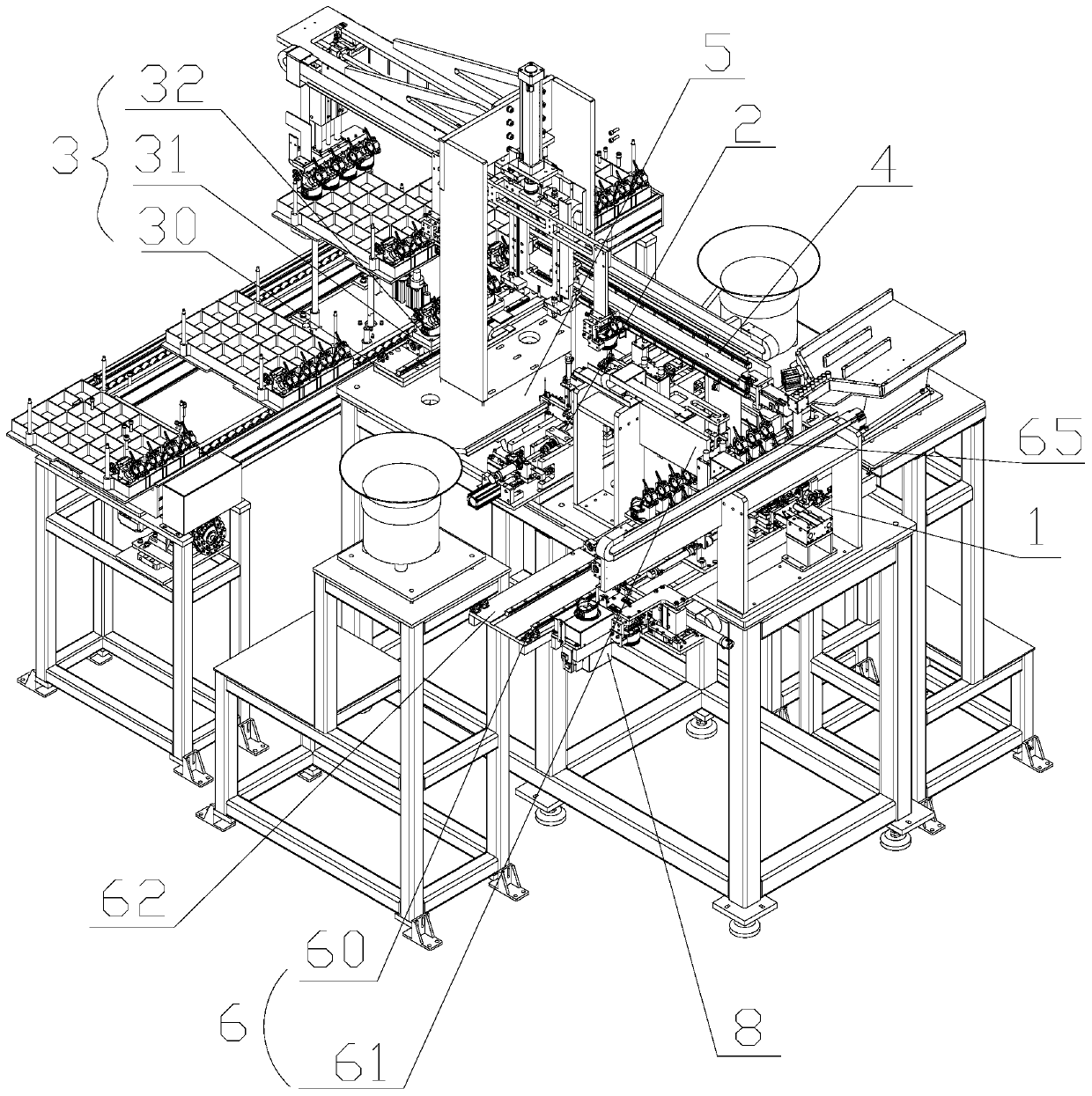

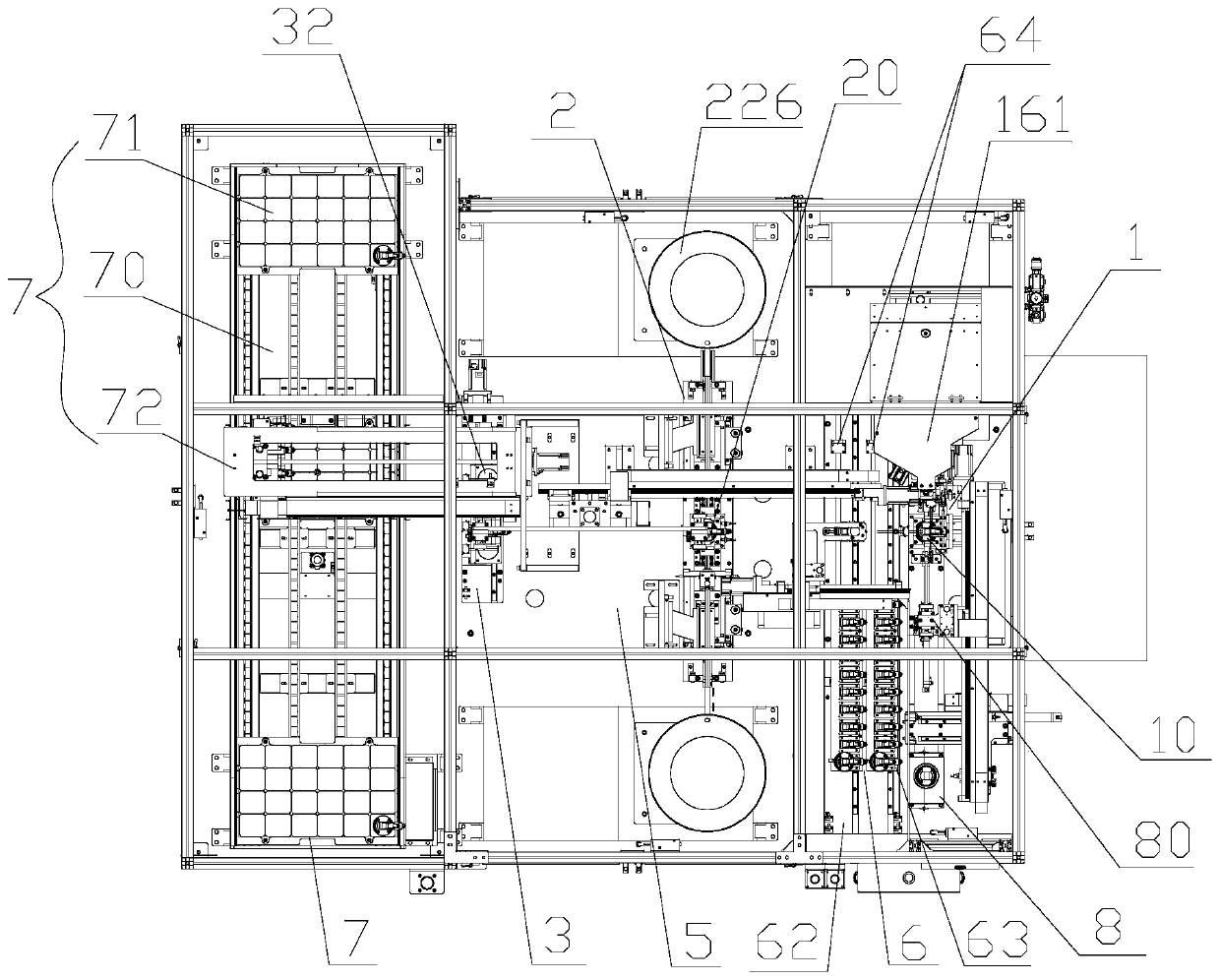

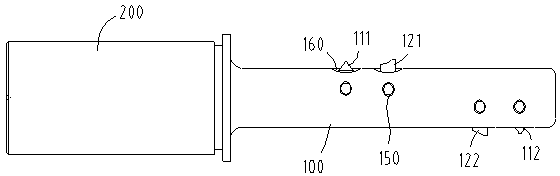

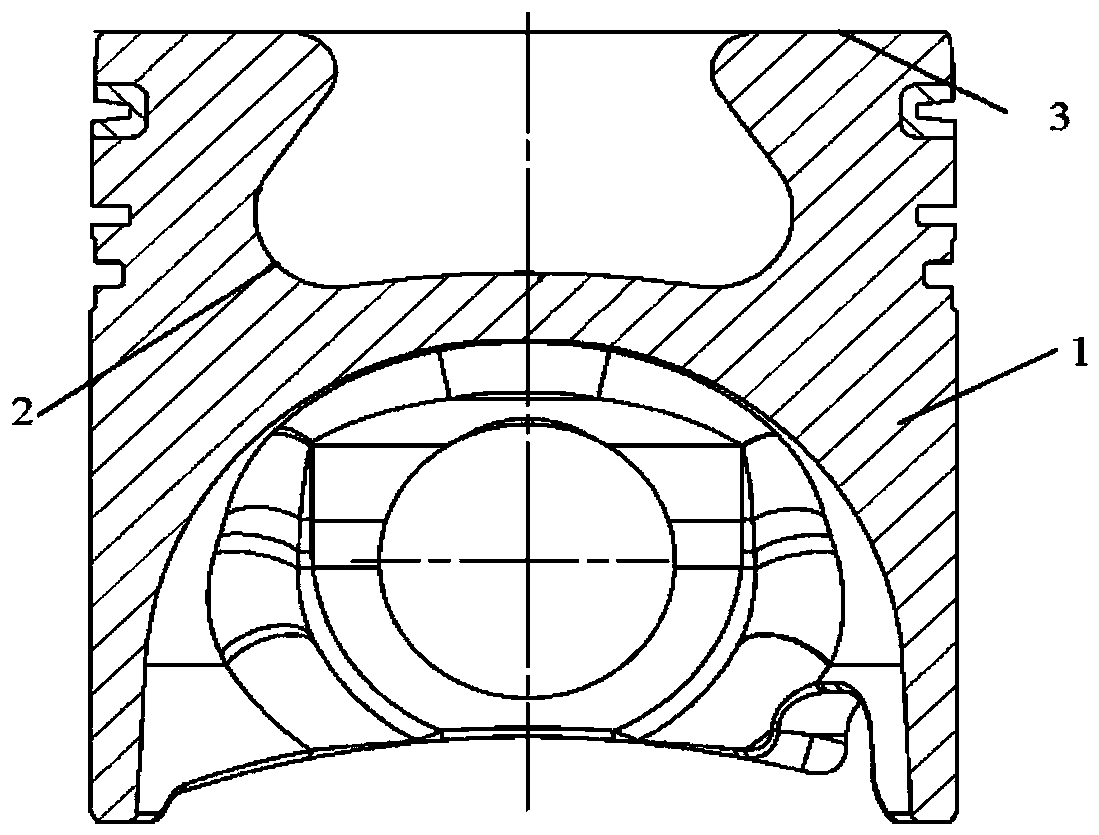

Machine for automatically assembling connecting rod, piston pin and retainer ring

ActiveCN111230472ACompact layoutSmall footprintAssembly machinesMetal working apparatusEngineeringMachine

The invention discloses a machine for automatically assembling a connecting rod, a piston pin and a retainer ring. The machine comprises a workbench, wherein a piston pin press-assembly line, a retainer ring press-assembly line and a finished product temporary storage line are sequentially arranged on the workbench in parallel; a material taking and unloading grab assembly is arranged among the piston pin press-assembly line, the retainer ring press-assembly line and the finished product temporary storage line, and provided with a material taking grab and a material unloading grab; the material taking grab and the material unloading grab are connected with the same movable auxiliary plate; the piston pin press-assembly line is provided with a piston positioning seat A; the retainer ring press-assembly line is provided with a piston positioning seat B; the finished product temporary storage line comprises a base plate C and a storage table movably arranged on the base plate C; and the storage table is provided with at least one piston positioning groove and slides along the length direction of the base plate C so that the piston positioning groove can be collinear with the piston positioning seat A and the piston positioning seat B. According to the scheme, the overall layout structure is compact, the occupied space is greatly reduced, parts are simplified, the mechanism is optimized, the assembly efficiency is improved, meanwhile, the cost is reduced, and the system operation reliability is guaranteed.

Owner:重庆炜海自动化科技有限公司

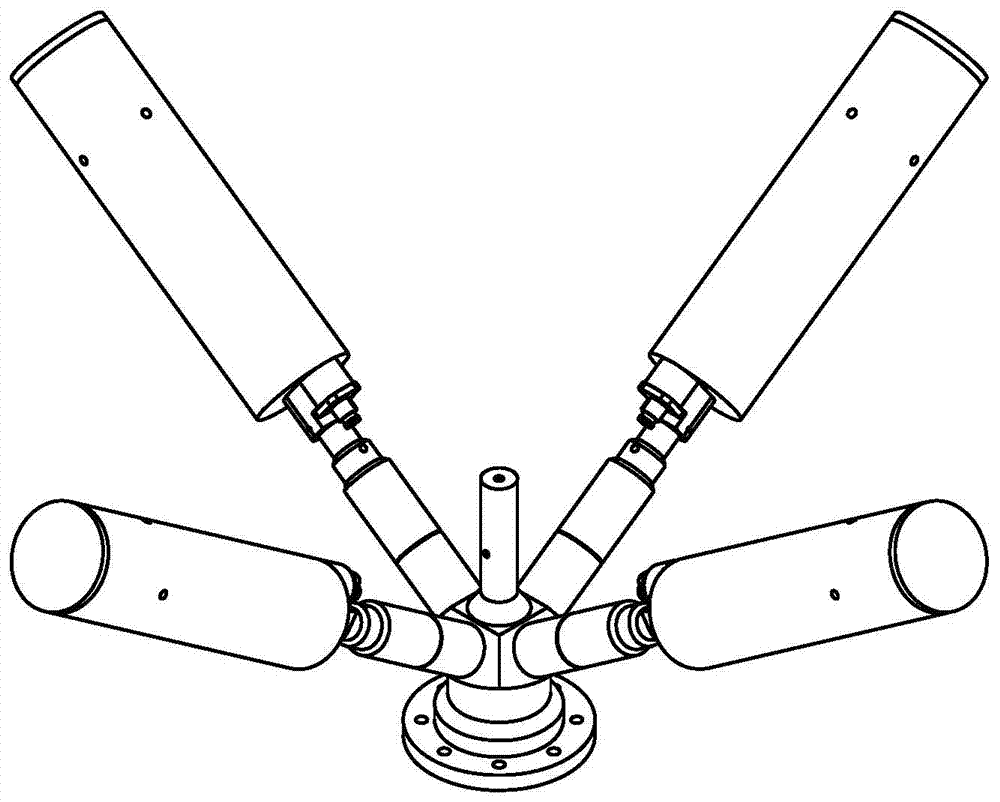

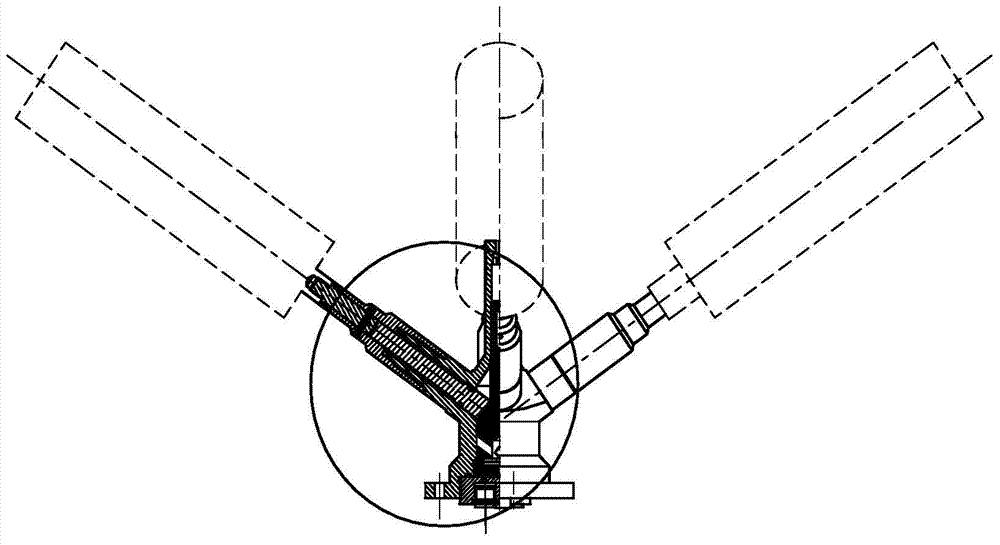

Spatial flying net synchronous launching device

ActiveCN103591844AAchieving Transmit SynchronizationImprove securityLaunching weaponsGudgeon pinSynchronism

The invention discloses a spatial flying net synchronous launching device which comprises an igniter, an exploder, a main piston, a guide pin, a seal ring, four auxiliary piston sleeves, four auxiliary pistons, a shearing pin, a main piston guide sleeve and connecting rods. The four auxiliary pistons are pushed by the main piston, in the initial stage, the main piston pushes the auxiliary pistons to cut off the shearing pin through mechanical contact, the main piston continues to move to allow the seal ring to lose sealing effect, high-pressure fuel gas directly acts on the auxiliary pistons, each auxiliary piston pushes the corresponding connecting rod and the mass block fixedly connected with the connecting rod, so that launching of multiple mass blocks is achieved, launching synchronism of the mass blocks is achieved, launching speed is increased by utilizing the high-pressure fuel gas, and high safety is achieved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

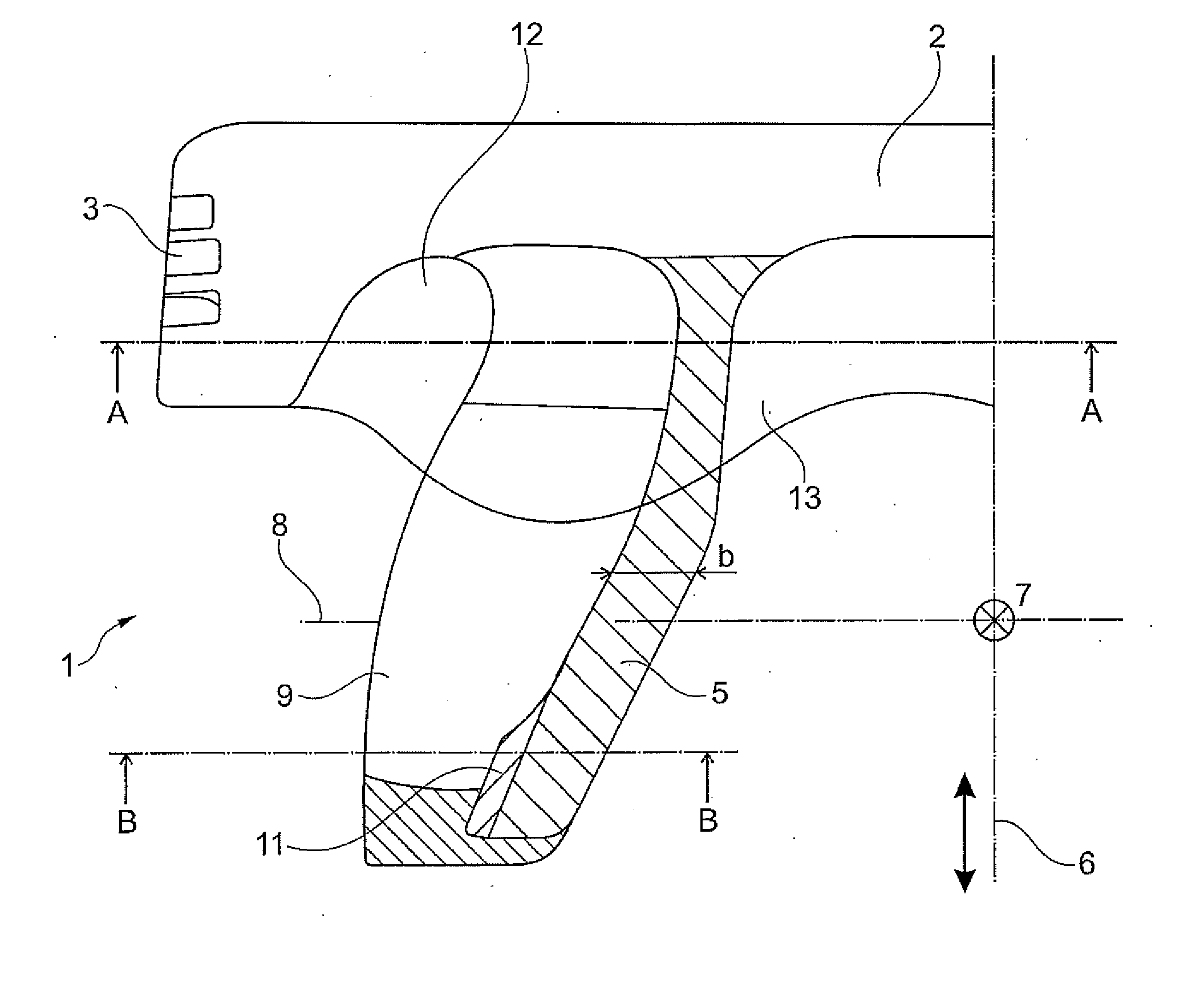

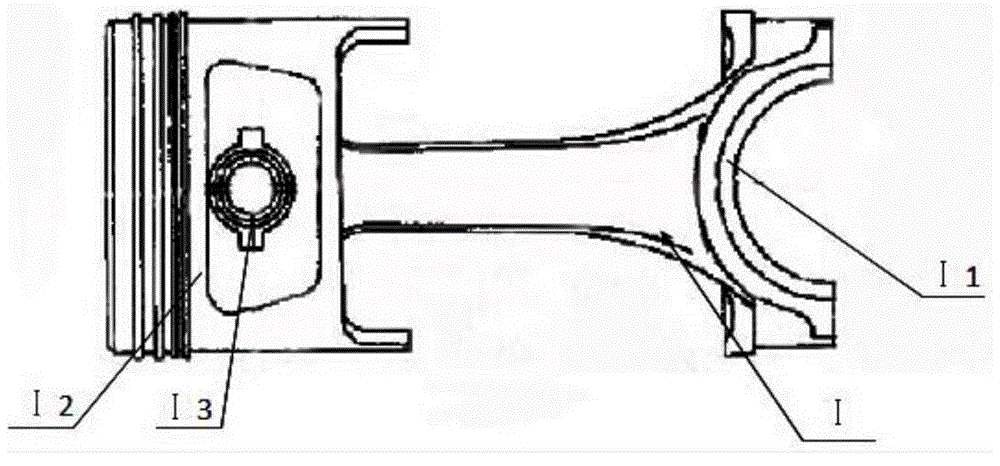

Piston and connecting rod for an internal combustion engine

InactiveUS20150027401A1Increase stiffnessGreat resistance to seizingConnecting rodsSealing arrangements for enginesEngineeringInternal combustion engine

The invention relates to a piston (1) of an internal combustion engine, which piston (1) has a piston head (2) with a ring field (3) and a skirt part which is arranged on the piston head (2), wherein the skirt part has at least two load-bearing skirt-wall sections (4a, 4b), and the load-bearing skirt-wall sections (4a, 4b) are connected to one another via at least two obliquely positioned box walls (5) which are set back with respect to the piston external diameter. In each case one pin boss (9) for receiving a piston pin is arranged in the box wall (5) and one skirt-wall section (4a) forms the pressure side and the other skirt-wall section (4b) forms the counter-pressure side. According to the invention that the inner surface of the pin boss (9), in relation to the piston centre, runs flushly with respect to the surface of the associated box wall (5), and the box wall (5) has a concave profile in the transverse extent with respect to the direction of the pin boss (9). Furthermore, the invention relates to a connecting rod of an internal combustion engine.

Owner:KOLBENSCHMIDT AG

Variable compression ratio piston with limiting ring structure

PendingCN107725210ASmall torqueStrong power outputEngine controllersMachines/enginesPiston ringEngineering

The invention discloses a variable compression ratio piston with a limiting ring structure. The defects that in the prior art, the manufacturing cost is high, the reliability is high, and the structure is complex are overcome. The piston is composed of a piston body, a piston skirt, a piston pin, a connecting rod, a limiting ring, a vane motor, a sealing cover plate and a spiral rotating wheel; the vane motor is placed on a center base of the piston skirt, the vane motor is connected with the spiral rotating wheel through a spline, the internal thread of the piston body is matched with the external thread of the spiral rotating wheel, a pin hole of the piston body is axially parallel to a pin hole of the piston skirt, and the connecting rod is placed in a piston inner cavity, and the piston pin is inserted into the small end of the connecting rod and the pin holes of the piston skirt and the piston body. Hydraulic oil flows through an oil passage formed by the connecting rod, the piston pin and the piston skirt and then enters an oil cavity, pressure in the oil cavity pushes the vane motor to drive the spiral rotating wheel, under the screw thread fit action, the spiral rotating wheel makes the piston body and the piston skirt relatively shift, and then the compression ratio of an engine is changed.

Owner:JILIN UNIV

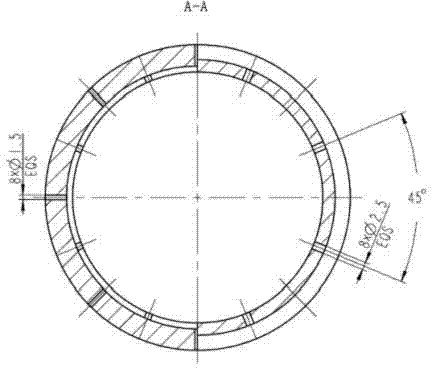

Piston oil-return structure of horizontal opposed piston two-stroke internal combustion machine

InactiveCN103032197AEasy accessOvercome the difficult problem of oil returnPiston ringsMachines/enginesEngineeringCrankcase

The invention discloses a piston oil-return structure of a horizontal opposed piston two-stroke internal combustion machine. The piston oil-return structure comprises two gas rings at the head part of a piston and a piston pin hole (1), a third gas ring (2) and an oil ring (3) which are arranged in sequence from top to bottom; more than two oil return holes (4) are uniformly formed in the circumference of the bottom of an annular channel of the oil ring (3); more than two oil return holes (5) are uniformly formed in the outer circumference of a piston below the third gas ring (2); inner hole openings of the two groups of oil return holes are communicated with a crankshaft box; 8 oil return holes (4) are formed and have the aperture of being 2.5mm respectively; 8 oil return holes (5) are formed and have the aperture of being 1.5mm respectively; and the respective 8 oil return holes of two groups are respectively arranged in a staggered and symmetrical manner. According to the piston oil-return structure, the third gas ring and the oil ring can seal gas and also can sweep off a part of engine oil on the inner wall of a cylinder bushing; and the piston oil-return structure overcomes the defect of difficulty in oil return of a horizontal piston and has the remarkable effect in terms of engine oil consumption of the horizontal opposed two-stroke internal combustion machine.

Owner:NO 70 INST OF CHINA NORTH IND GRP

Efficient multifunctional tool for finish machining of piston

InactiveCN104190971AReduce shear stressImprove coaxialityCutting insertsTurning toolsStructural engineeringMachining

The invention provides an efficient multifunctional tool for finish machining of a piston. The efficient multifunctional tool comprises a shank and a toolbar connected in order. The axial cylindrical side of the toolbar is provided with a pair of snap ring groove blades used for machining snap ring grooves of the piston and a pair of inner chamfer blades used for machining an inner chamfer of the piston. The inner chamfer blades are disposed on the toolbar between the snap ring groove blades. The snap ring groove blades and the inner chamfer blades are both arranged on opposite sides of the toolbar. The efficient multifunctional tool has the advantages tangential force that blade edges bear when snap ring grooves of the piston and the inner chamber of a pinhole are under machining can be eliminated, the toolbar shakes less during machining accordingly, machining stability is improved, coaxiality of the snap ring grooves is improved, product quality stability is guaranteed, snap ring grooves and the inner chamfer of the pinhole are machined at the same time, machining cycle is shortened, and high efficiency and multifunctionality are achieved.

Owner:安庆雅德帝伯活塞有限公司

Engine piston mechanism and machining method thereof as well as corresponding engine and automobile

InactiveCN103147873AReduce wearReduce contact areaMachines/enginesPistonsReciprocating motionControl theory

The invention discloses an engine piston mechanism which comprises a piston head, a piston pin seat fixedly connected to the end surface of the piston head, and a piston skirt part arranged at the periphery of the piston pin seat, wherein the piston skirt part comprises two support parts and a roller column; the two support parts are fixedly connected to the end surface of the piston head and are symmetrically arranged at the two sides of the piston pin seat along the axial direction of the piston pin seat; and the roller column is fixedly connected to the support parts and is contacted with the wall of a cylinder in a rolling way when a piston makes reciprocating motion. The invention also discloses a machining method of the engine piston mechanism, and an engine and an automobile which are respectively provided with the engine piston mechanism. According to the engine piston mechanism, the piston skirt part and the wall of the piston are in rolling friction, so that the frictional loss of the piston skirt part and the wall of the cylinder can be reduced, and the fuel economy is improved. The engine piston mechanism is suitable for various automobile engines, and is further applied to various automobiles.

Owner:GREAT WALL MOTOR CO LTD

Engine Piston and Manufacture

Owner:PARKER DUNCAN +4

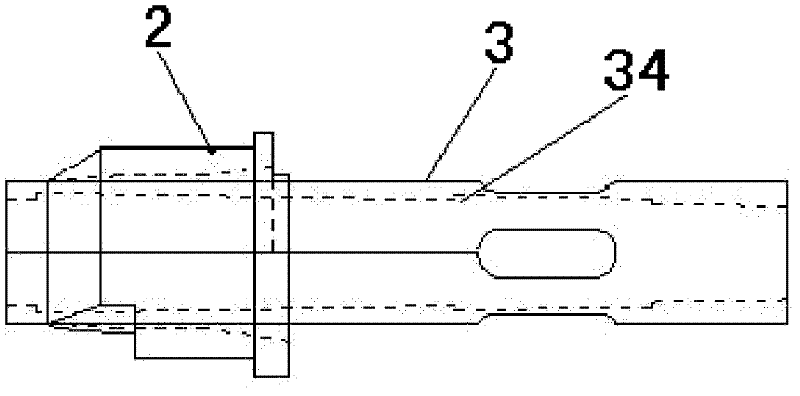

Pressing and disassembling device for engine gudgeon pins

ActiveCN104148923AAvoid contactHigh degree of mechanical automationMetal working apparatusGudgeon pinOil immersion

The invention discloses a pressing and disassembling device for engine gudgeon pins. The device comprises a pin falling tank and a connecting pin oil immersion tank component. The device is characterized by further comprising a support frame component, a pin pressing mechanism and a pin disassembling mechanism. By the device, assembling of piston and connecting rod assemblies can be completed efficiently, and the piston and connecting rod assemblies unqualified in assembling can be disassembled in time; in addition, type stoppers of the piston and connecting rod assemblies are added to the device, assembling and disassembling of the piston and connecting rod assemblies of two different types can be completed, and the device has the advantages of high mechanical automation, high safety and the like; meanwhile, compared with the prior art, the pressing and disassembling device is simple in structure, convenient to operate and high in reliability.

Owner:HEBEI UNIV OF TECH

High temperature-resistant light aluminum alloy piston for internal combustion engines and preparation method thereof

InactiveCN110747498AIncreasing the thicknessGood heat insulationAnodisationMachines/enginesCombustion chamberHeat resistance

The invention discloses a high temperature-resistant light aluminum alloy piston for internal combustion engines and a preparation method thereof. A groove for forming a part of a combustion chamber is formed in the top of the high temperature-resistant light aluminum alloy piston; and the top surface of the high temperature-resistant light aluminum alloy piston and the groove undergo surface treatment by adoption of a high-voltage micro-arc oxidation surface treatment process so as to form ceramic membranes with thicknesses of 70-160 microns. The high temperature-resistant light aluminum alloy piston is capable of solving the negative influences such as large movement inertia, large piston pin hole bearing pressure, related kinematic pair frictional wear deterioration and the like causedby relatively high steel piston density, and solving the problem that the Al2O3 oxide films generated by the anodized illuminant alloy pistons are insufficient in thickness and weak in heat resistance.

Owner:GUANGXI YUCHAI MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com