Opposed piston engine

An opposed-piston, engine technology, applied in engine components, machines/engines, engine cooling, etc., to solve problems such as difficulty in providing effective sealing of cylinders and pistons, inability to maintain tight tolerances, and inability to prevent piston crown expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

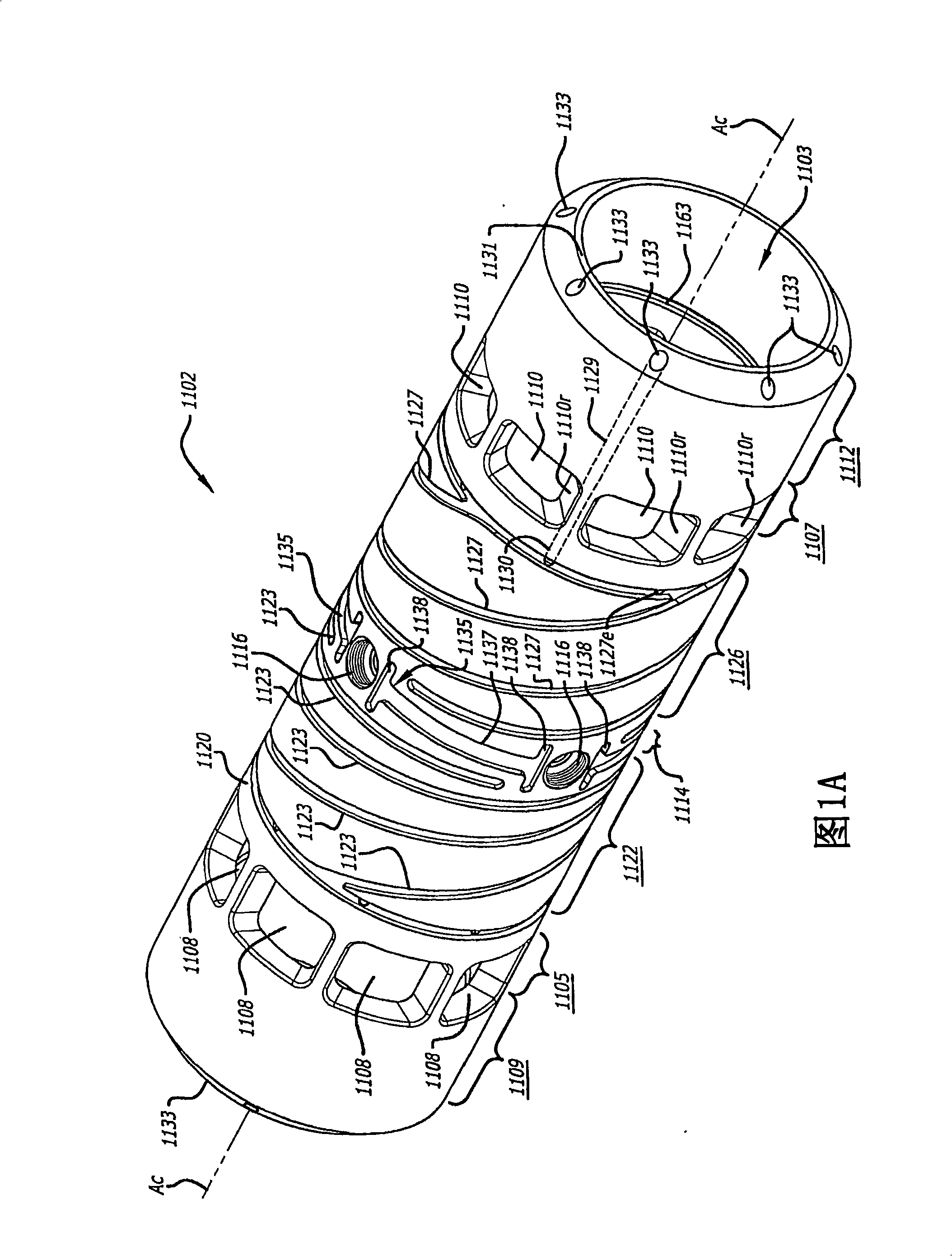

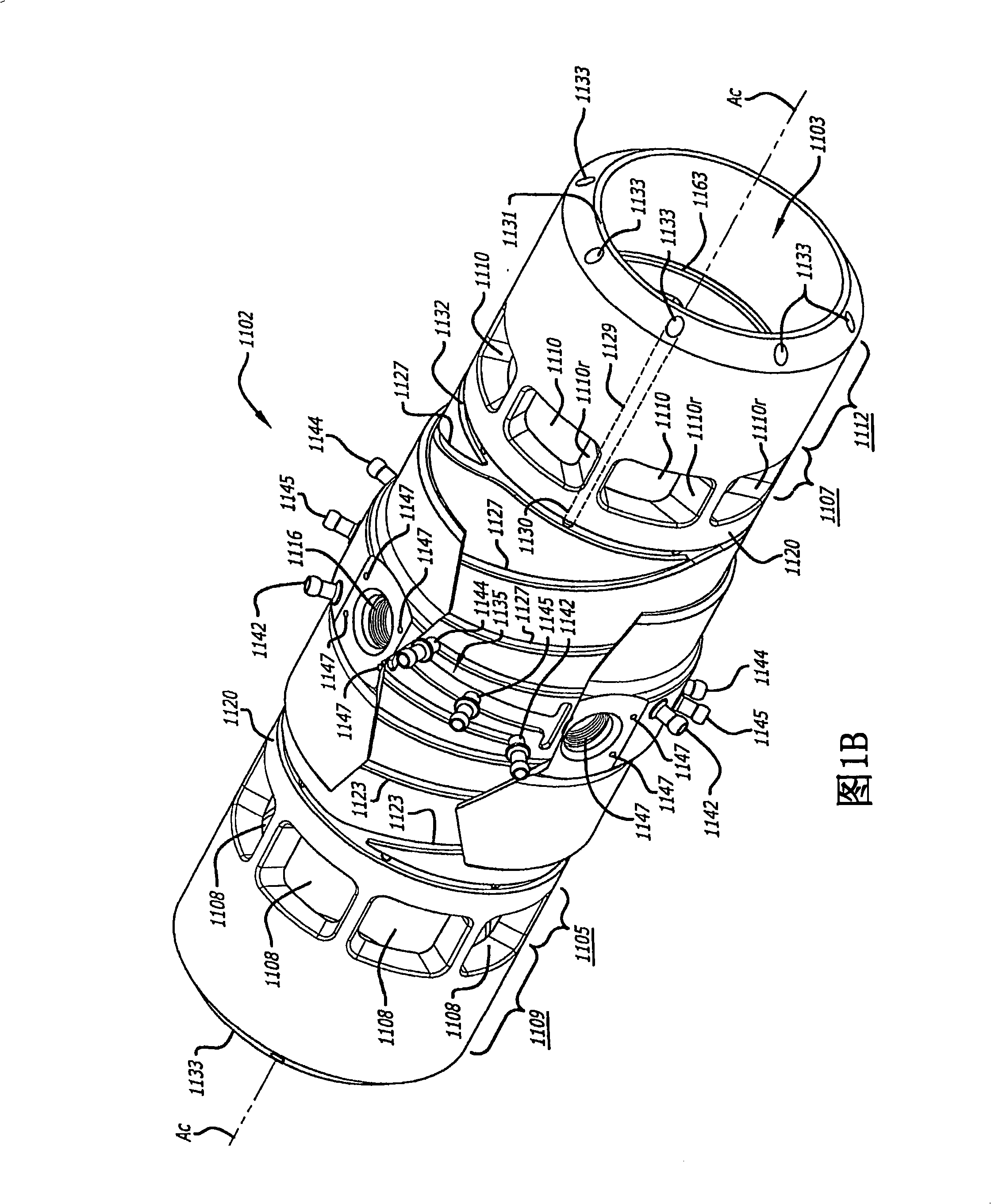

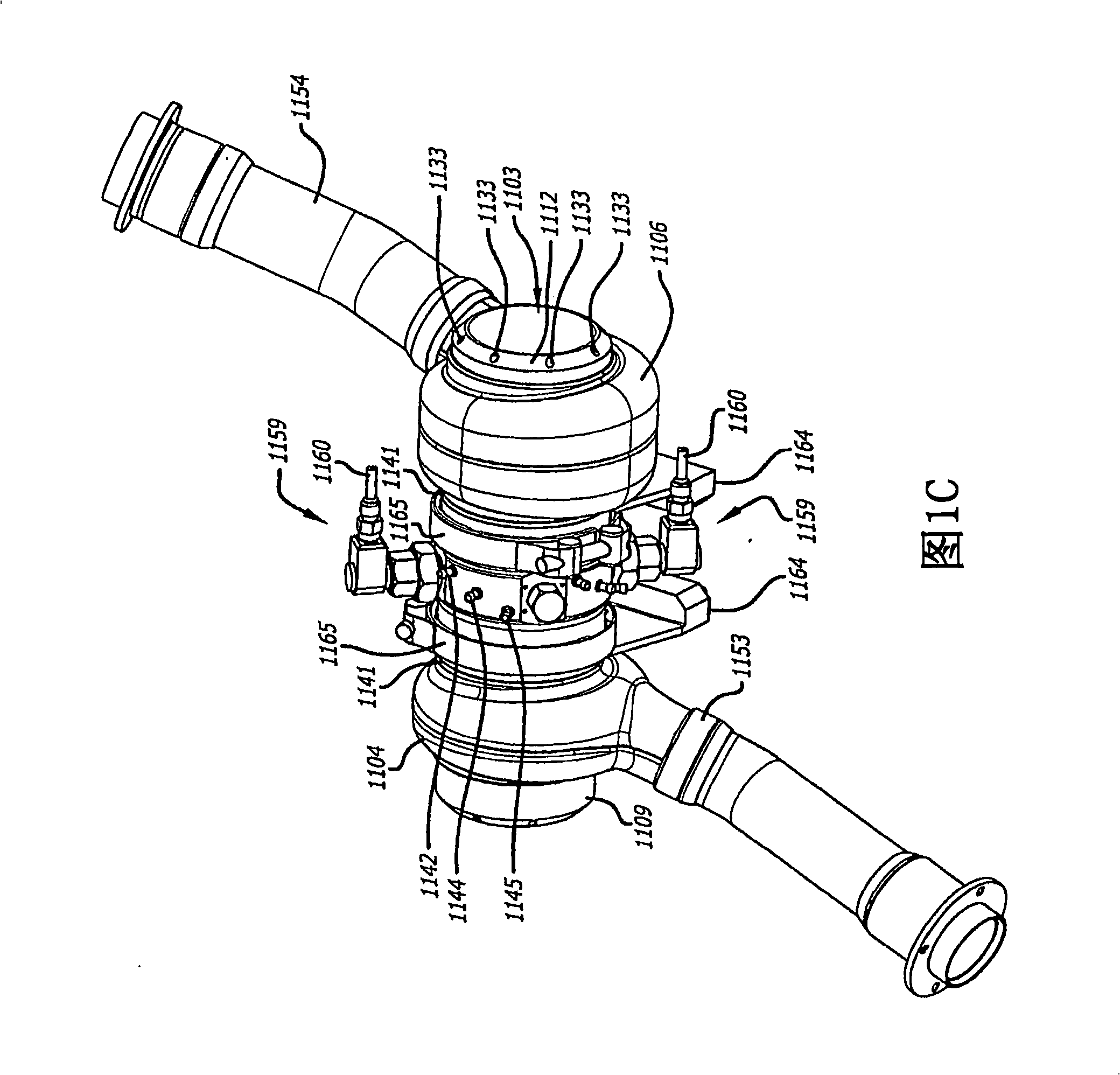

[0021] 1A-1D illustrate a cylinder 1100 that may be used in an opposed-piston internal combustion engine. The cylinder 1100 has four parts: a cylinder liner 1102 formed as an open cylindrical tube with a cylindrical bore 1103 , an exhaust manifold 1104 , an intake manifold 1106 and a cylinder sleeve 1140 . Cylinder 1100 is preferably made of aluminum such as high temperature aluminum alloy and may be cast as a single piece or assembled by securing manifolds 1104 and 1106 to cylinder sleeve 1140 and subsequently securing the subassembly to the outer surface of cylinder liner 1102 form. Longitudinal axis A of cylinder liner 1102 c Also the longitudinal axis of cylinder 1100 .

[0022]As best shown in FIG. 1A , the cylinder liner 1102 has an exhaust port 1105 consisting of a series of circumferentially spaced openings 1108 proximate an exhaust end 1109 of the cylinder liner 1102 . The cylinder liner 1102 also has an intake port 1107 consisting of a series of circumferentially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com