Systems with reciprocating piston engines

A technology of reciprocating piston and engine, applied in the direction of internal combustion piston engine, engine starting, engine components, etc., can solve problems such as trouble, limit the maximum electric power of motor converter, permanent magnet detachment, etc., to prevent adverse effects and reduce long-term demagnetization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

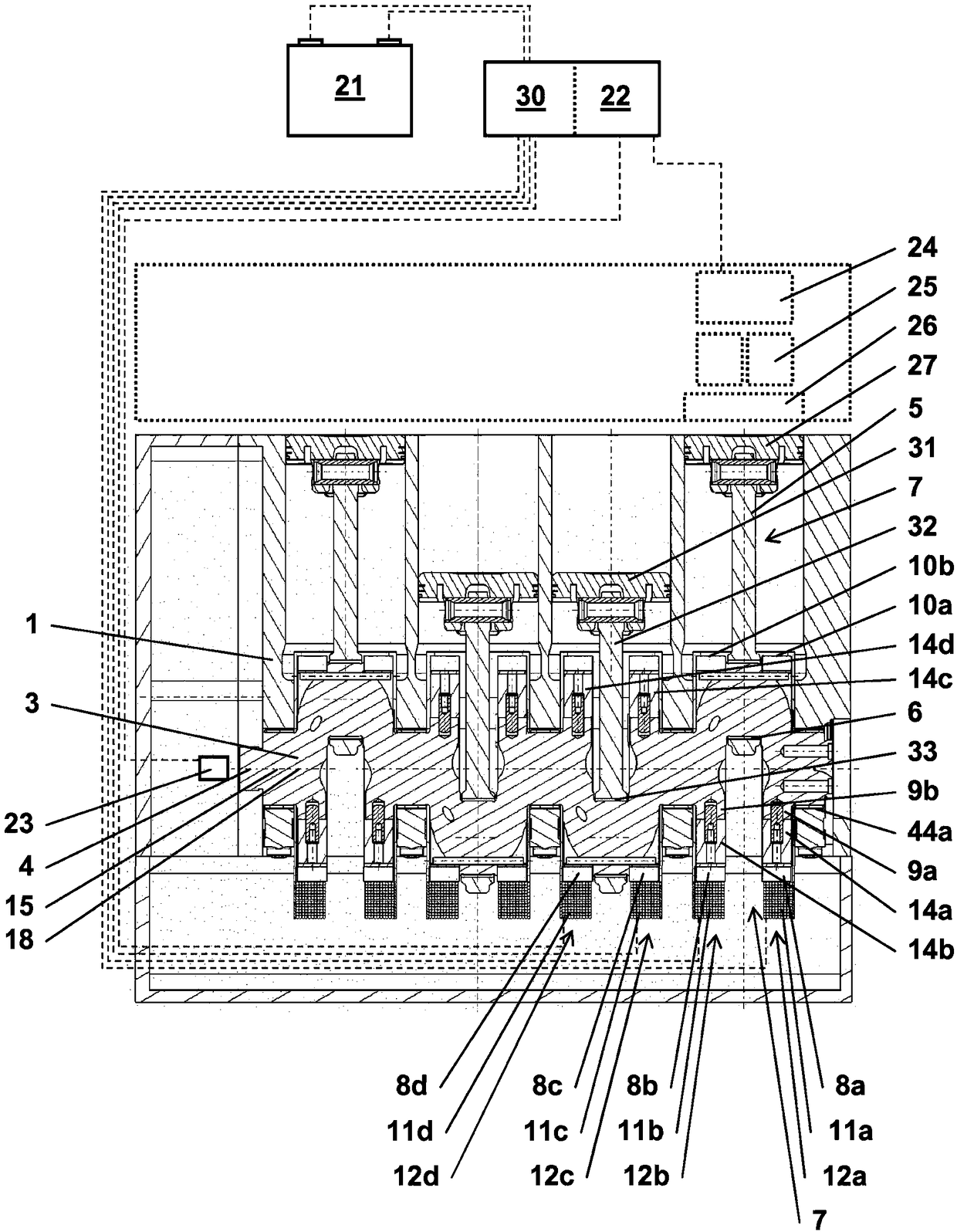

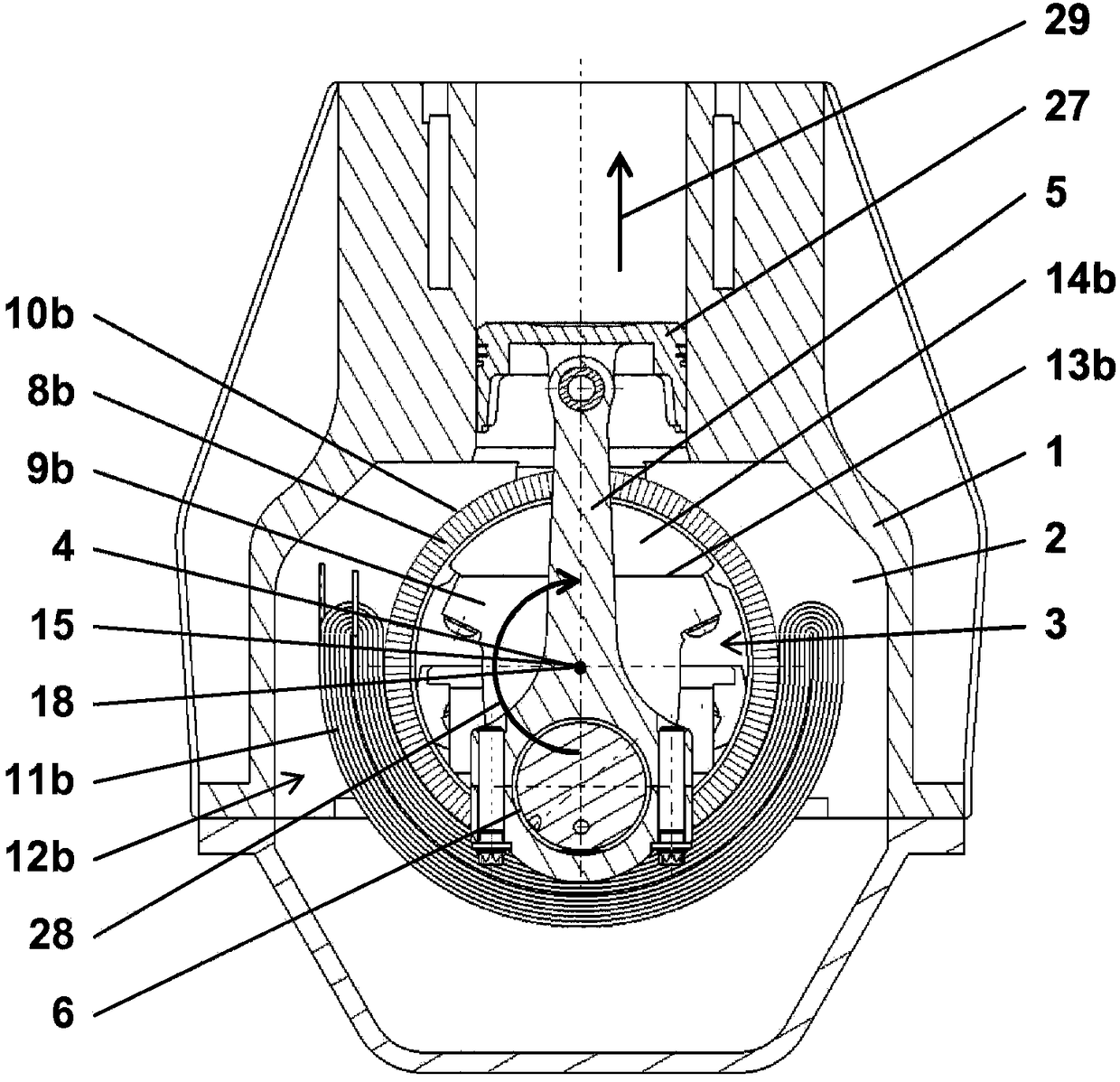

[0102] Since these figures partly show the same exemplary embodiment from different perspectives and in different levels of detail, and these exemplary embodiments only partly differ in certain features, the following description of these figures will partly A repeated explanation of reference signs and features already mentioned above will not be provided, and in part only the differences between the various exemplary embodiments will be discussed.

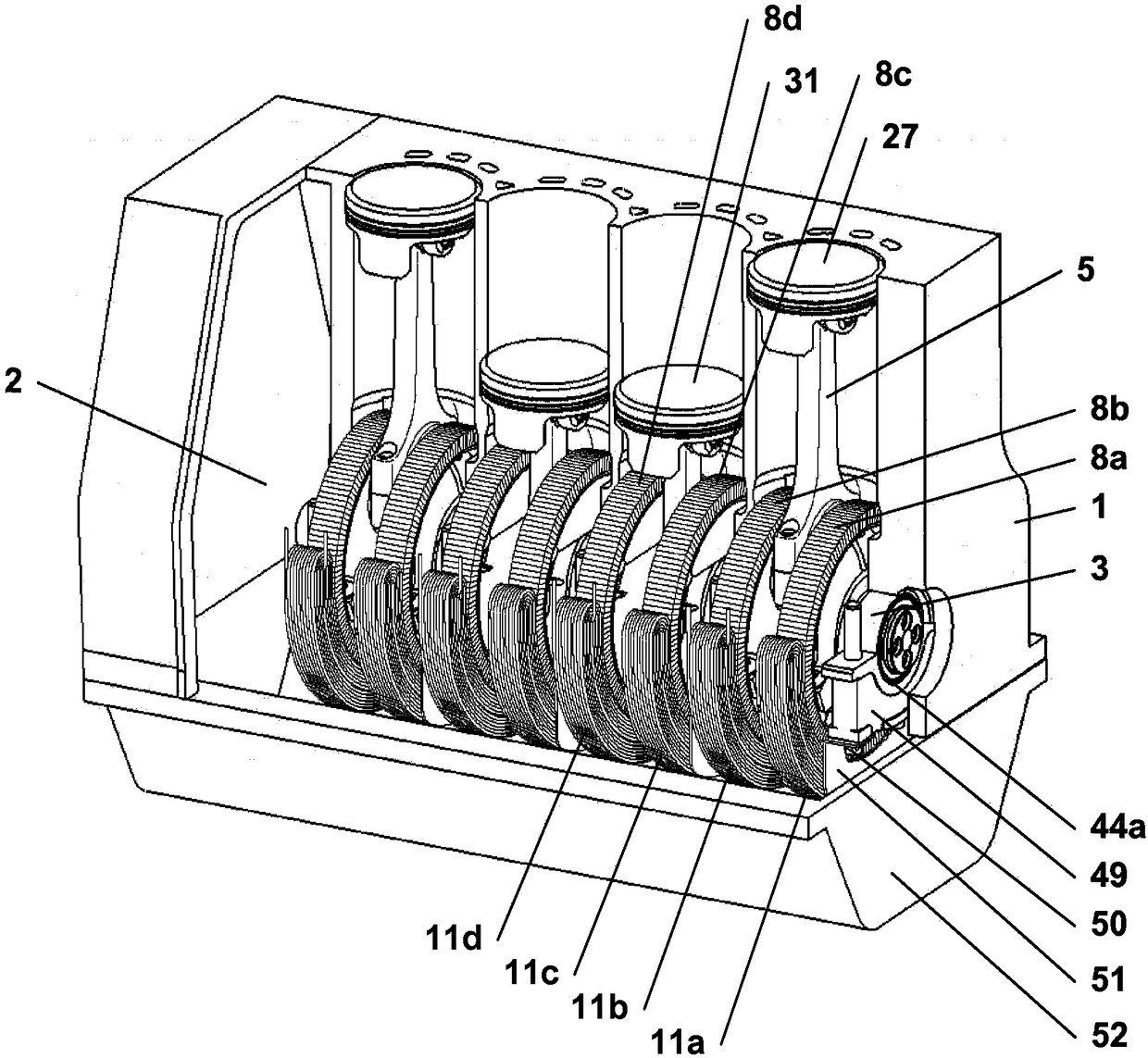

[0103] Figure 1A to Figure 1J The first exemplary embodiment of the reciprocating piston engine according to the invention is shown from different perspectives and with different levels of detail. The figures will be discussed collectively below.

[0104] The reciprocating piston engine of the first exemplary embodiment is a four-cylinder in-line engine operating according to the Otto cycle engine principle, as Figure 1A with Figure 1B shown. This reciprocating piston engine basically consists of a cylinder block 1 , a cran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com