Patents

Literature

109results about How to "Avoid magnetization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

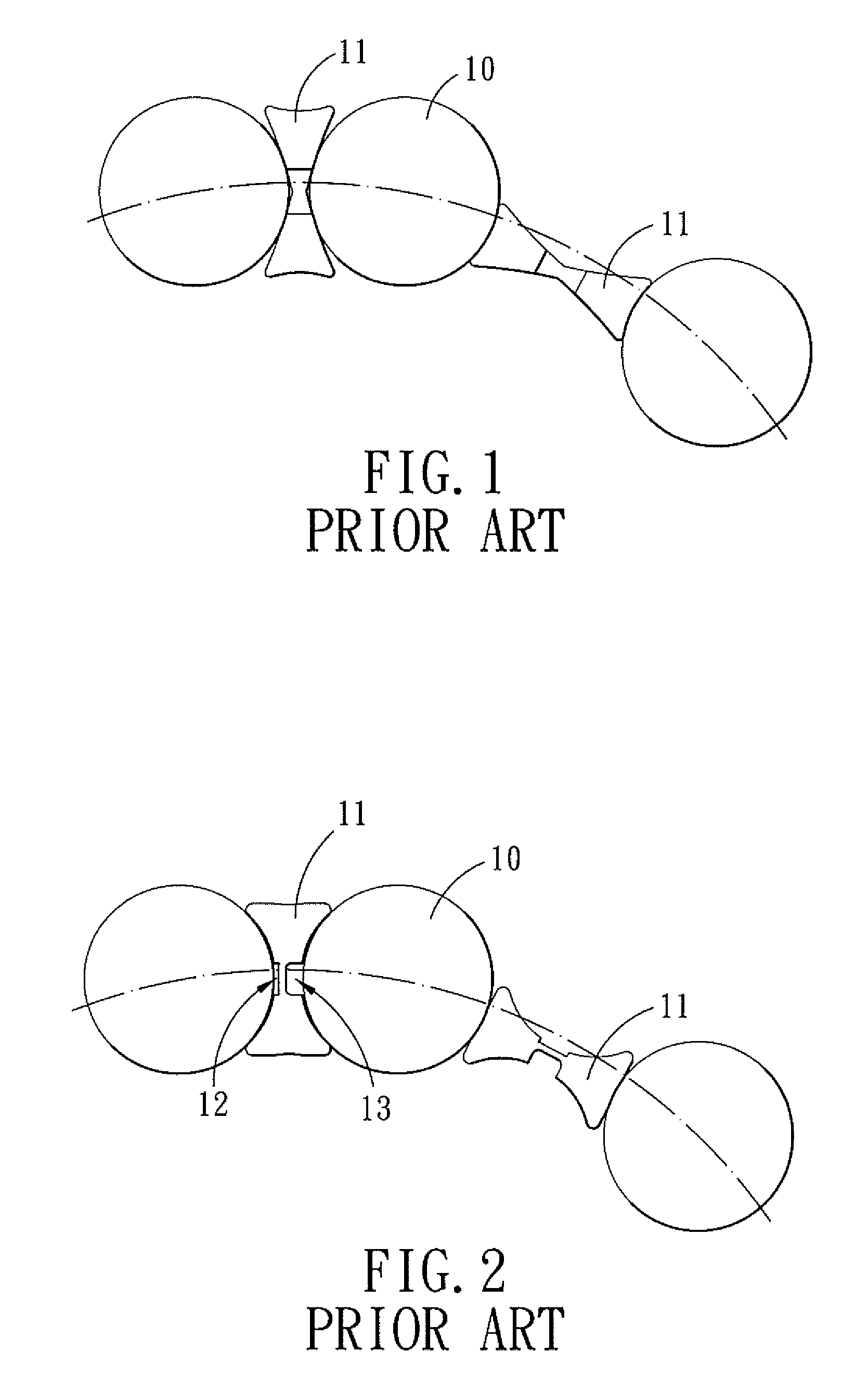

Portable terminal

InactiveUS7028410B2Higher precision without eliminating the adverse influenceEliminating adverse influence of magnetic noiseDevices with GPS signal receiverDevices with sensorForce linesTerminal equipment

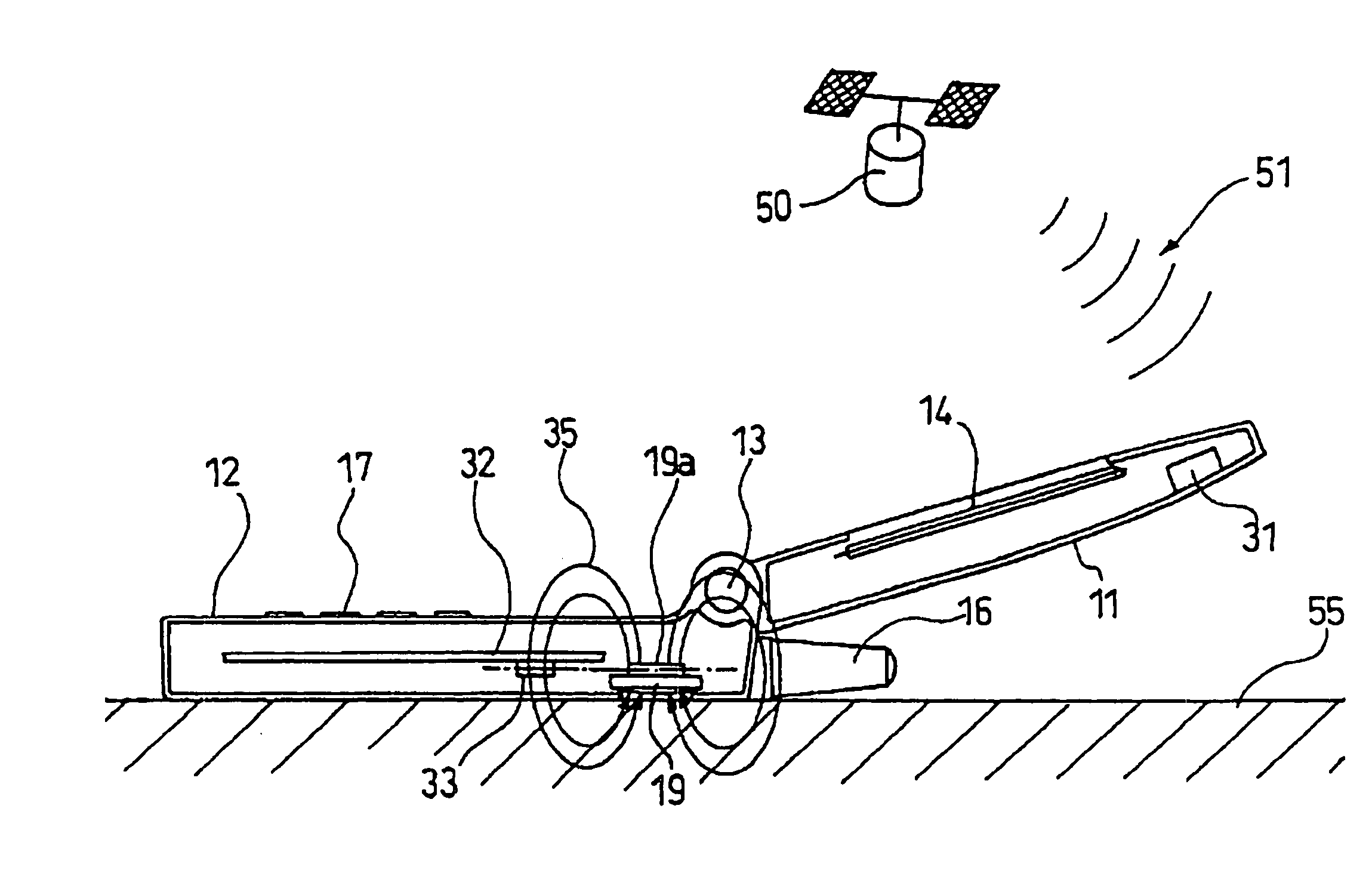

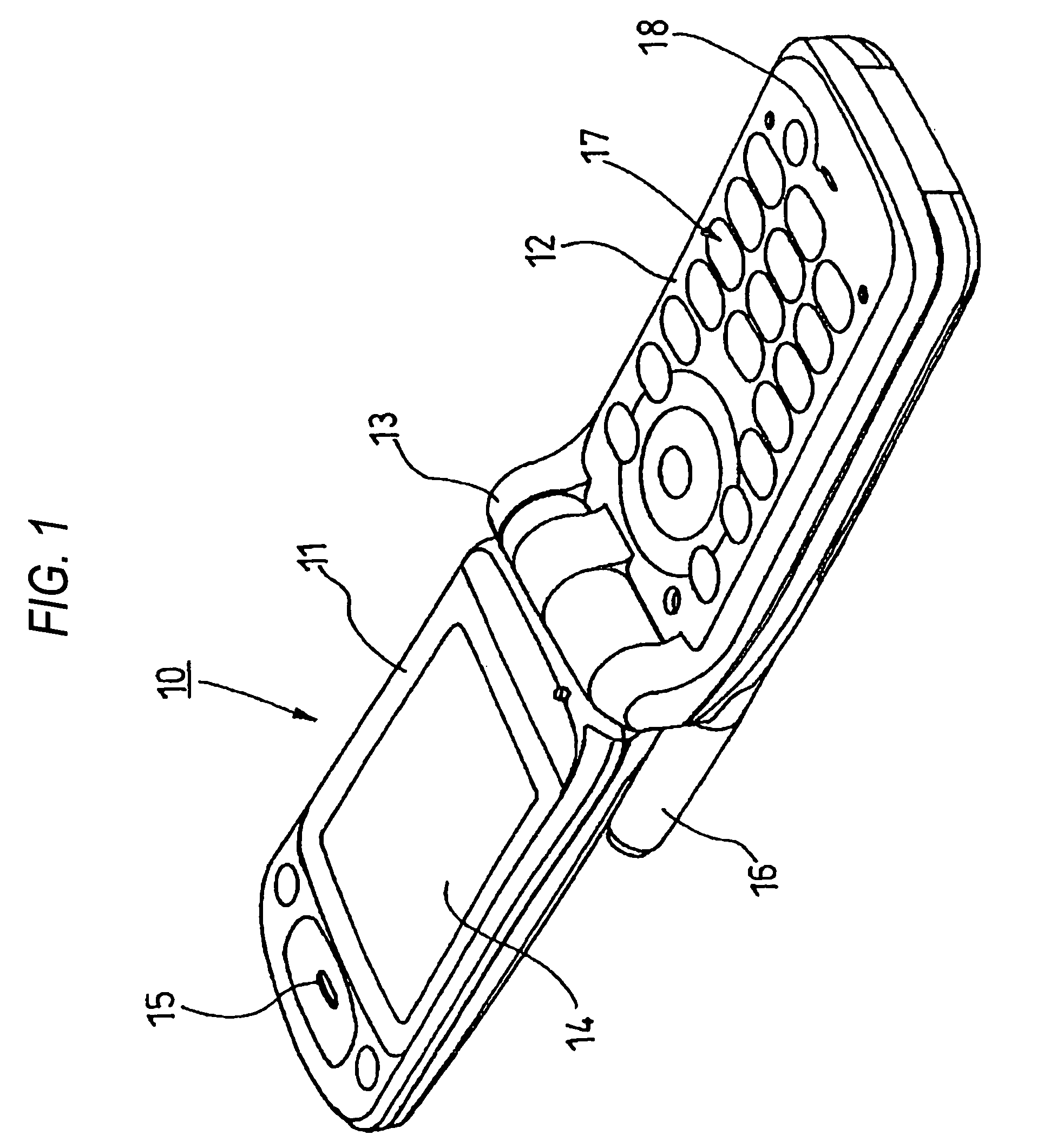

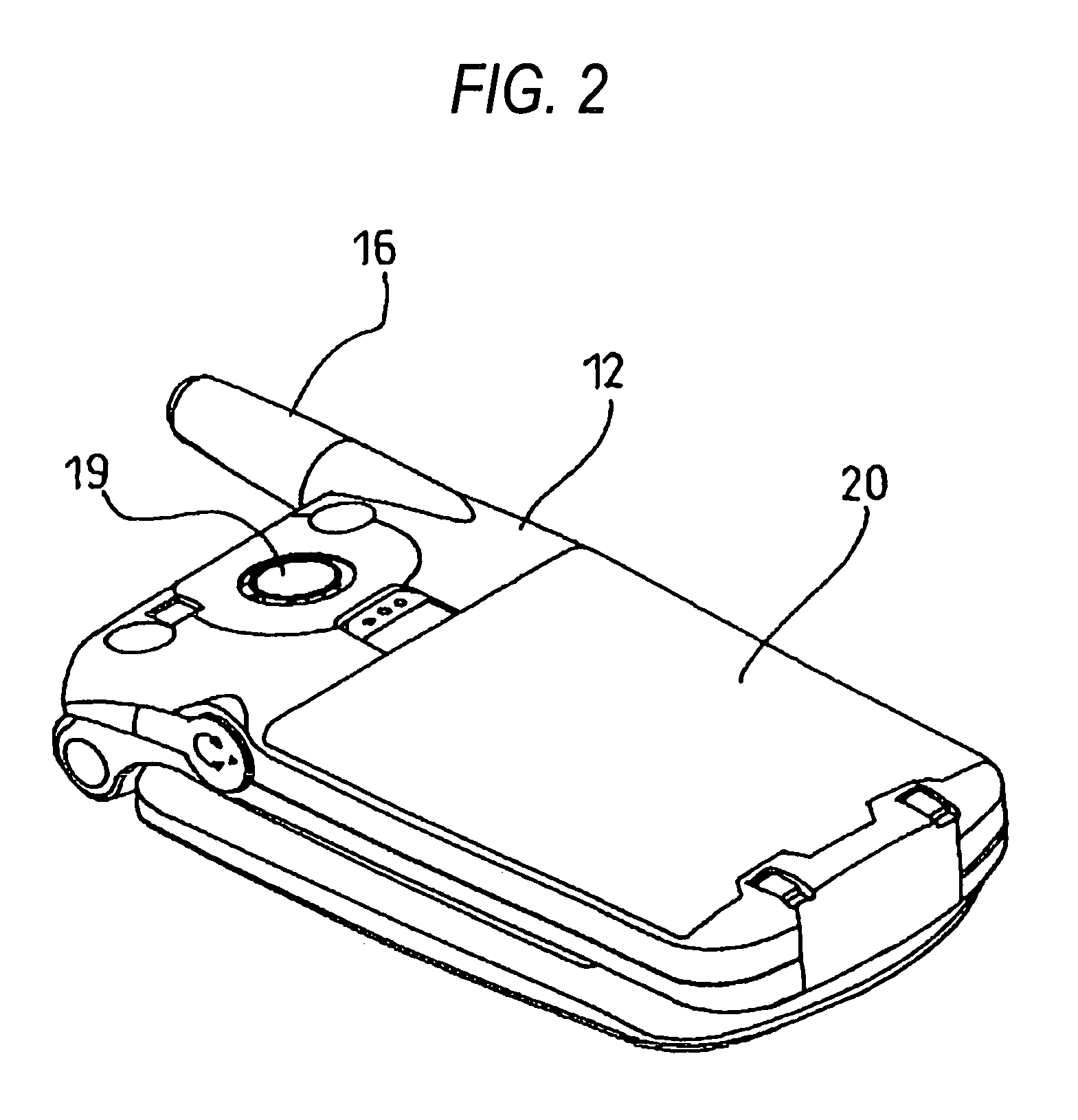

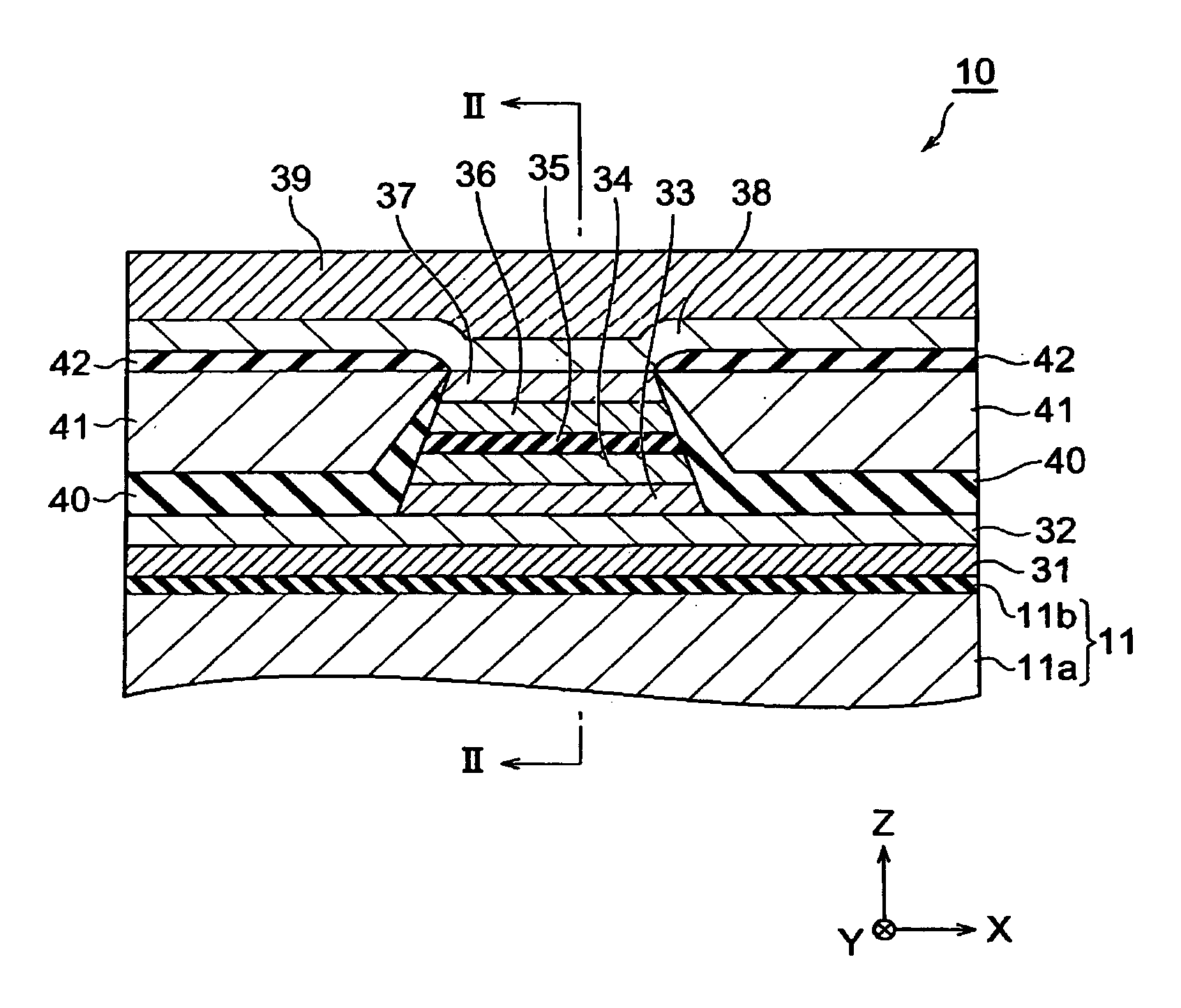

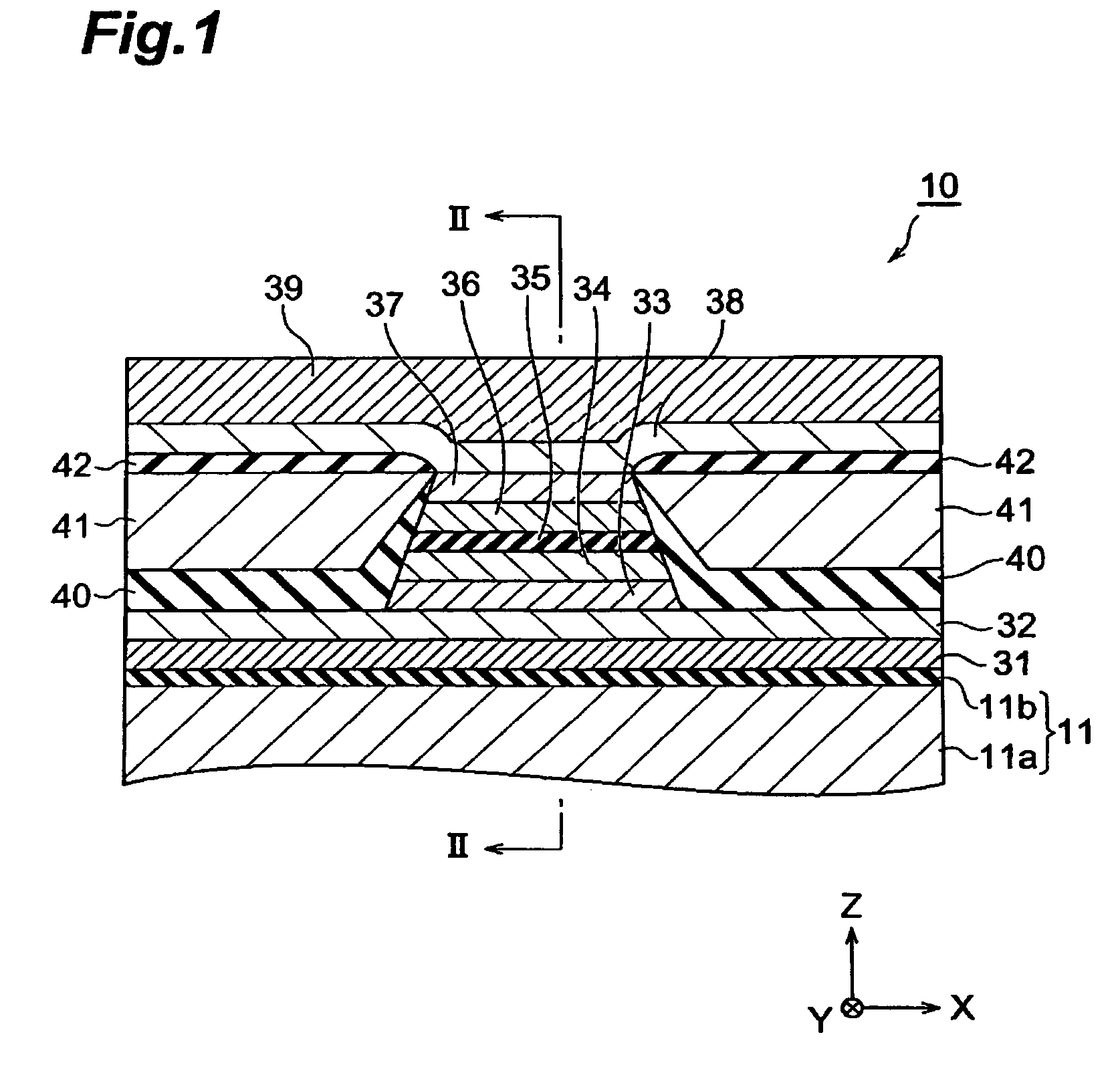

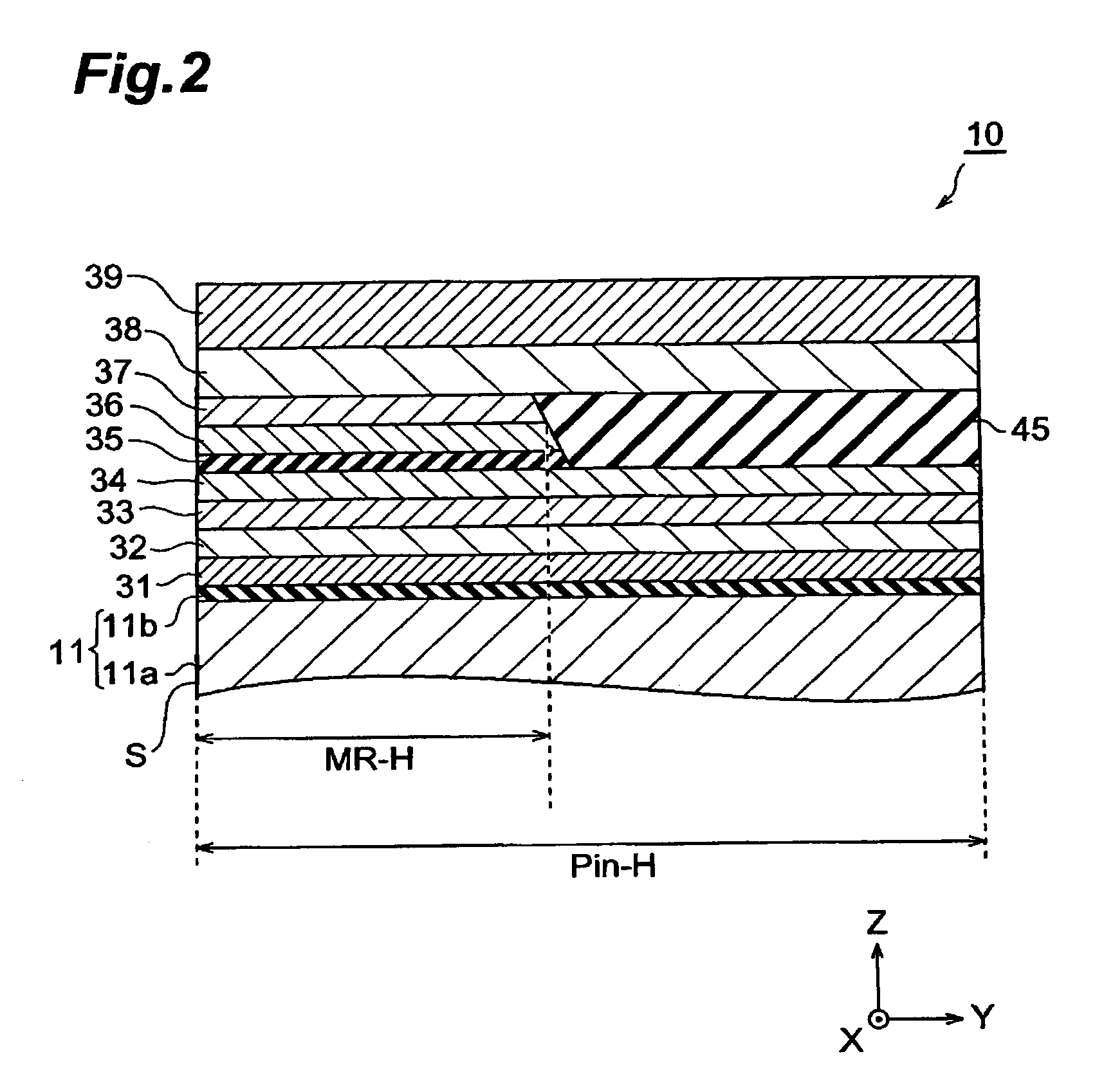

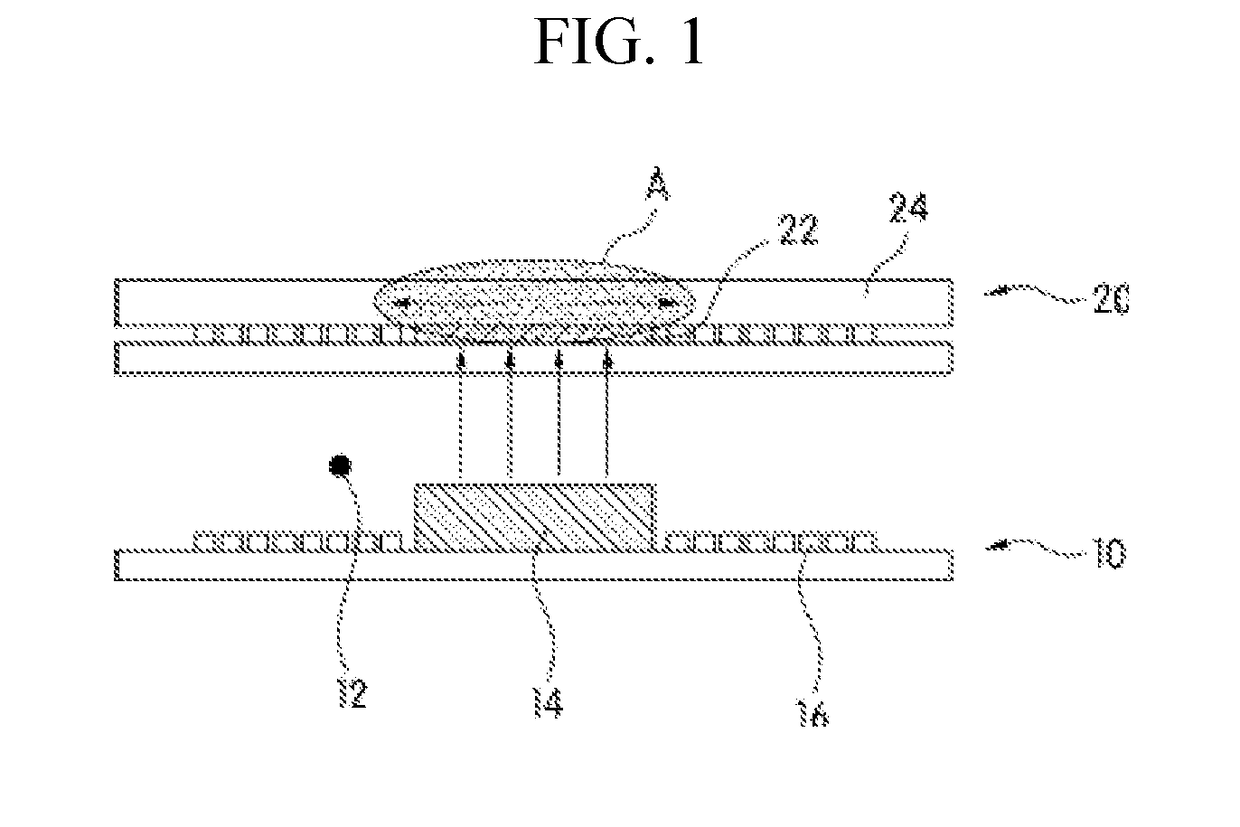

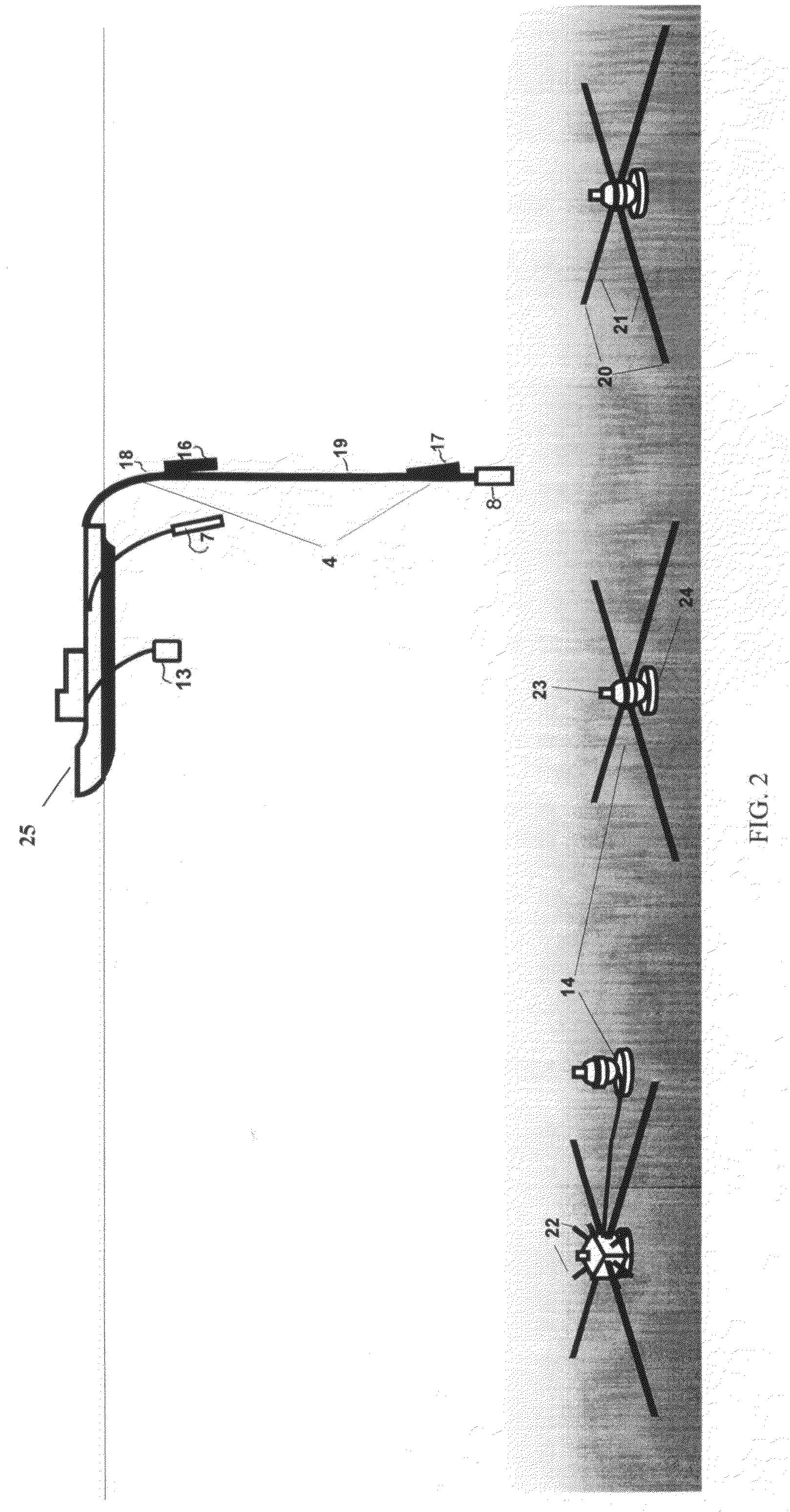

The present invention aims to achieve that geomagnetism can be sensed in high precision while eliminating an adverse influence by magnetic noise with respect to a geomagnetic sensor provided in a housing, and correct azimuth information can be acquired.A portable terminal apparatus according to the present invention is arranged by that both a first housing (11) and a second housing (12) are coupled to each other by way of a hinge portion (13) under pivotable condition, a geomagnetic sensor (33) is provided on a circuit board (32) in the second housing (12), and also, a speaker (19) is provided on the side of a rear surface thereof. Both this geomagnetic sensor (33) and a speaker (19) corresponding to a component for generating magnetic noise which gives an adverse influence with respect to the geomagnetic sensor (33) are provided in the vicinity of each other within the same second housing (12), and both the members are arranged on the same plane. In this structure, since a magnetic force line (35) which is caused by magnetic noise generated from a magnet (19a) of the speaker (19) is intersected with respect to the geomagnetic sensor (33) at a right angle, and thus, a horizontal direction component thereof is not produced, the geomagnetic sensor (33) can correctly sense the geomagnetism without being adversely influenced by the magnetic noise.

Owner:PANASONIC CORP

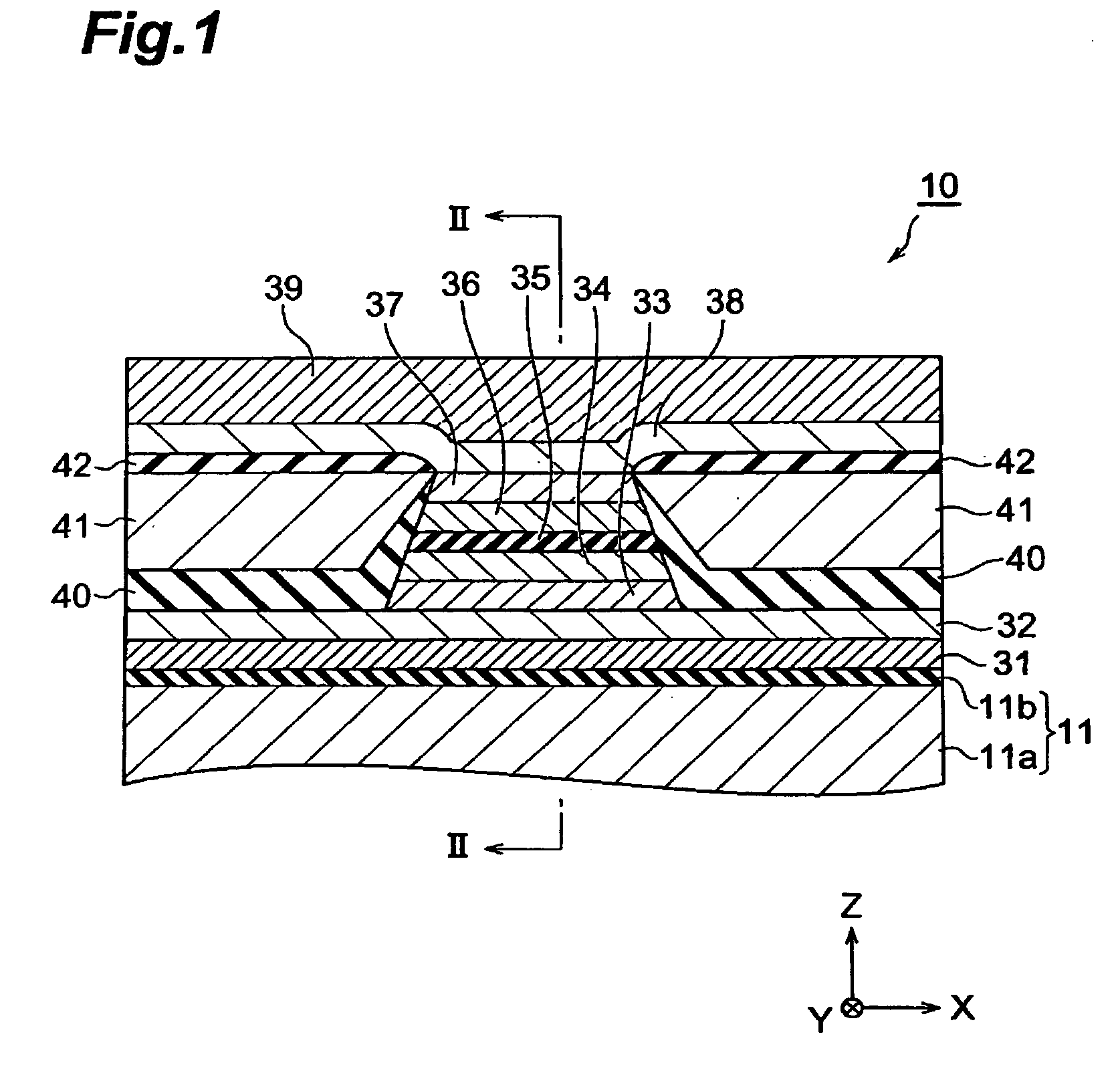

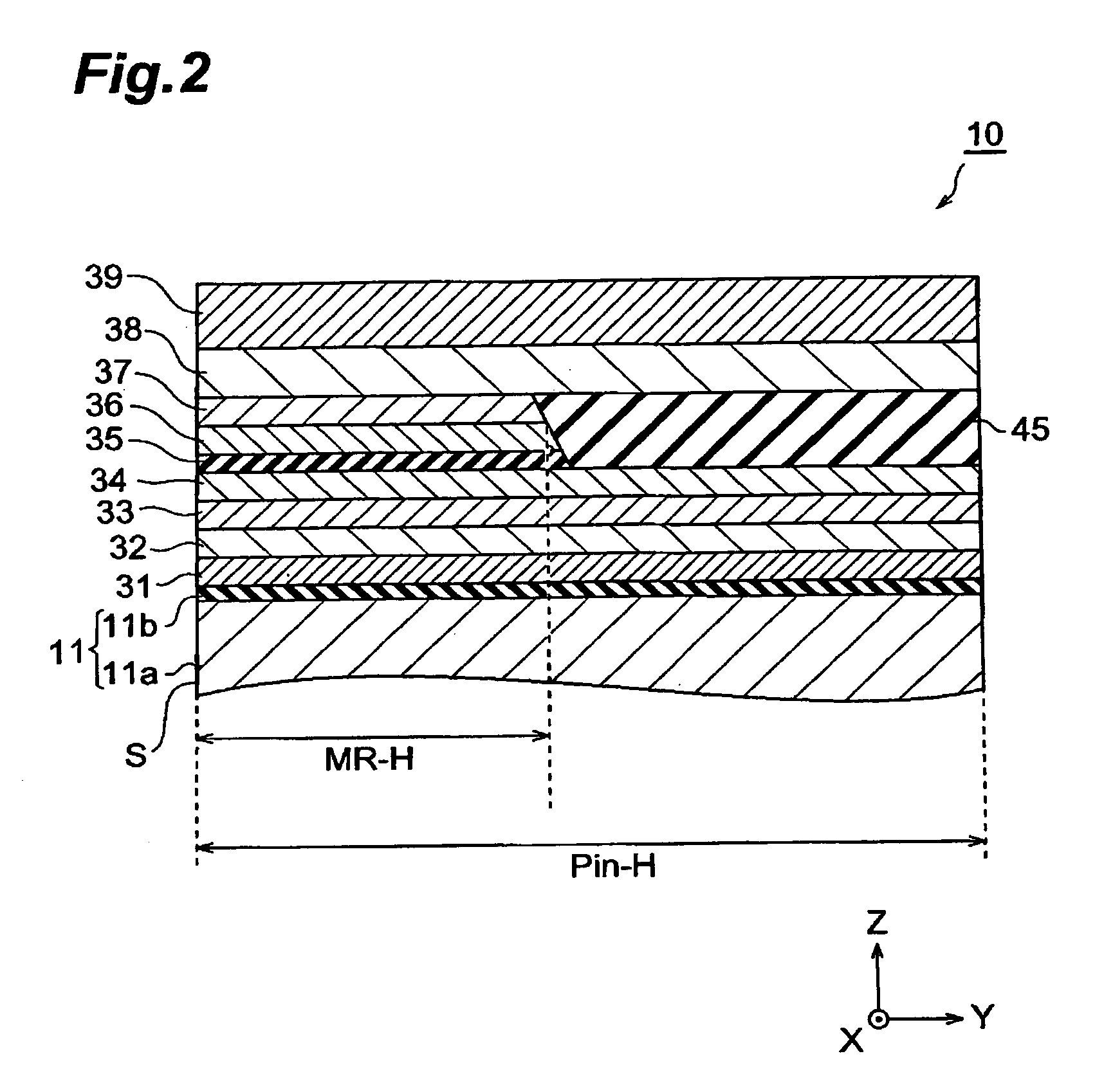

Thin-film magnetic head

ActiveUS20040061986A1Avoid layeringInclination in the direction of magnetization can be suppressed more effectivelyNanomagnetismDisposition/mounting of recording headsMagnetizationDepth direction

Owner:TDK CORPARATION

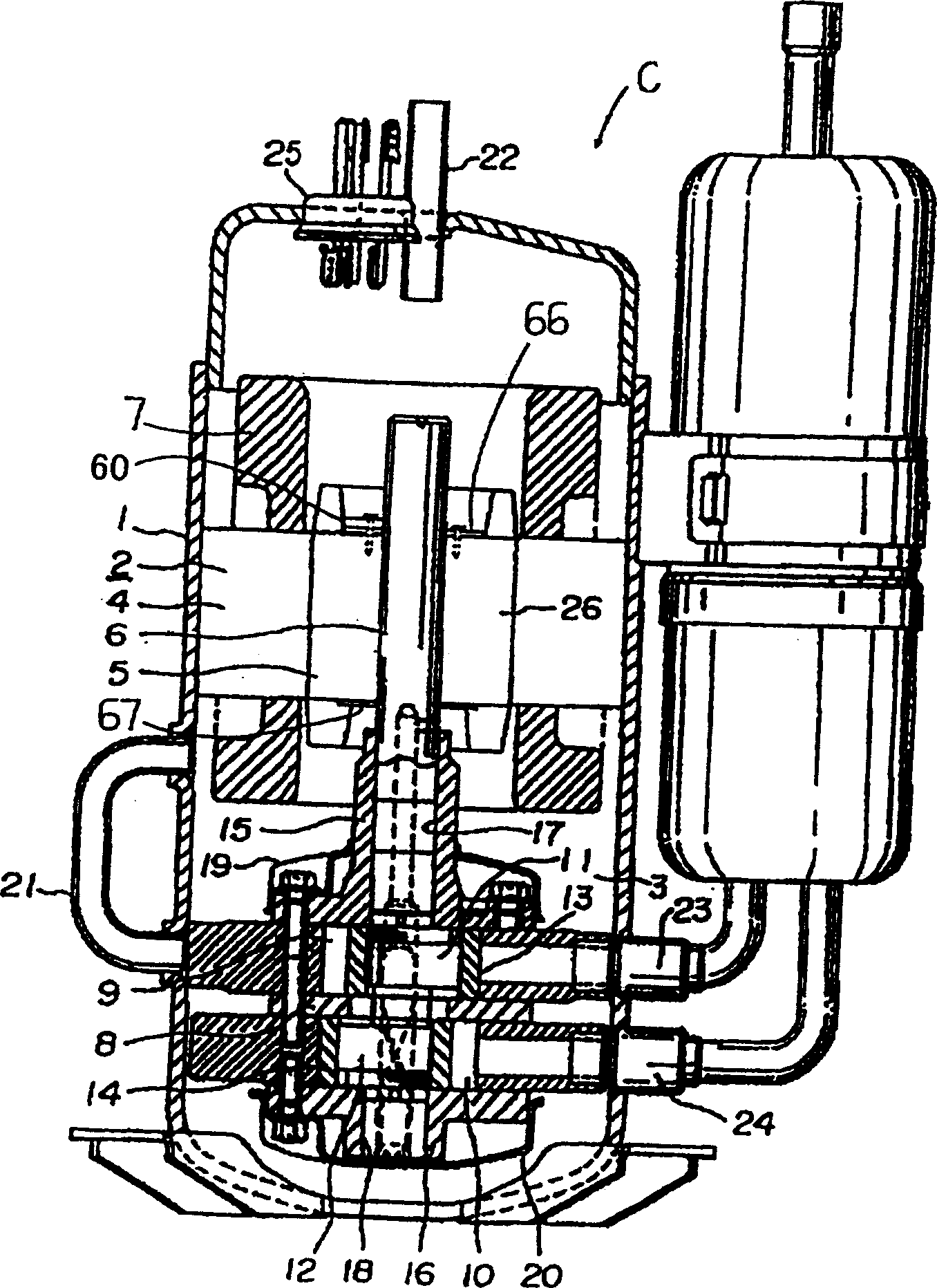

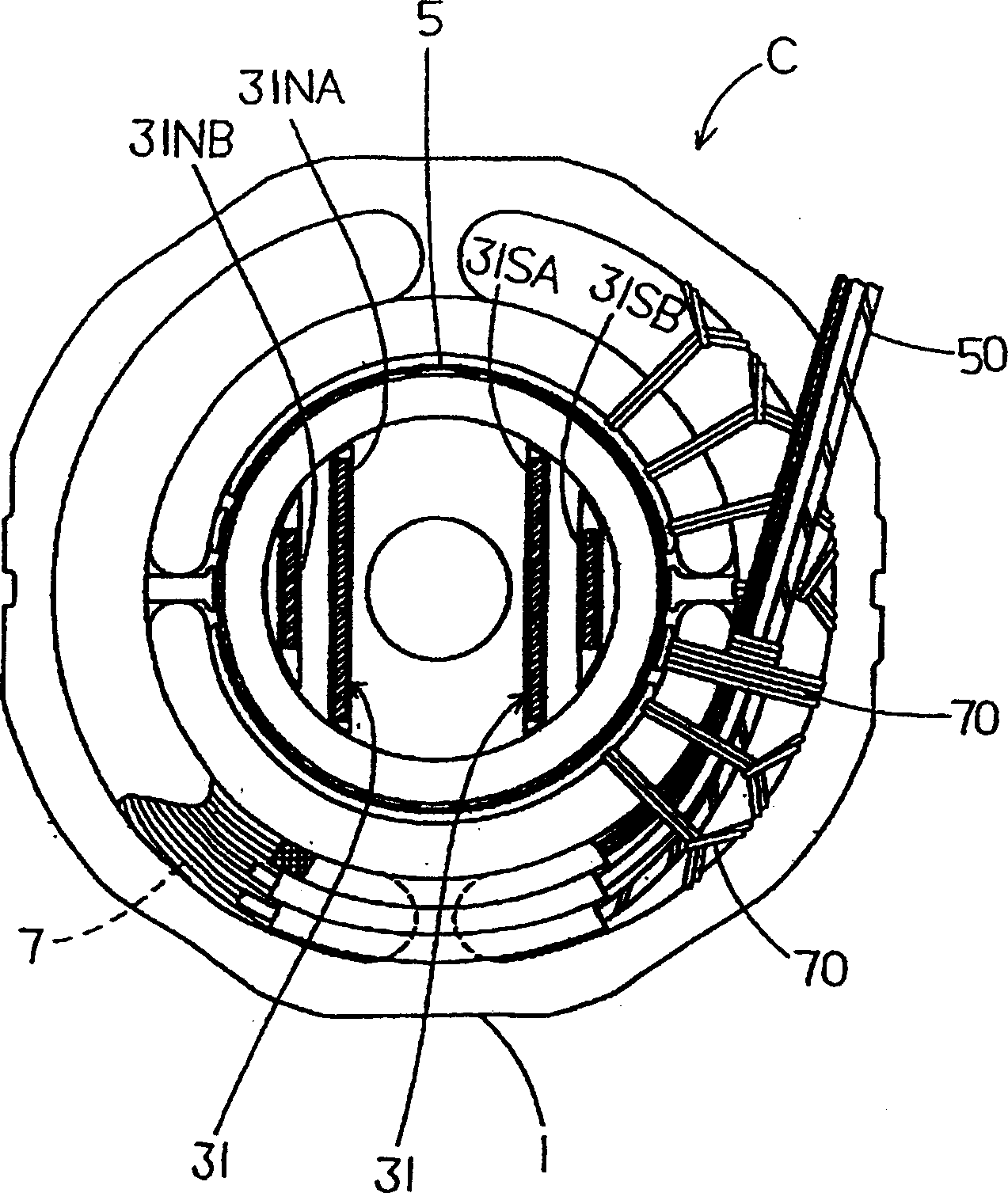

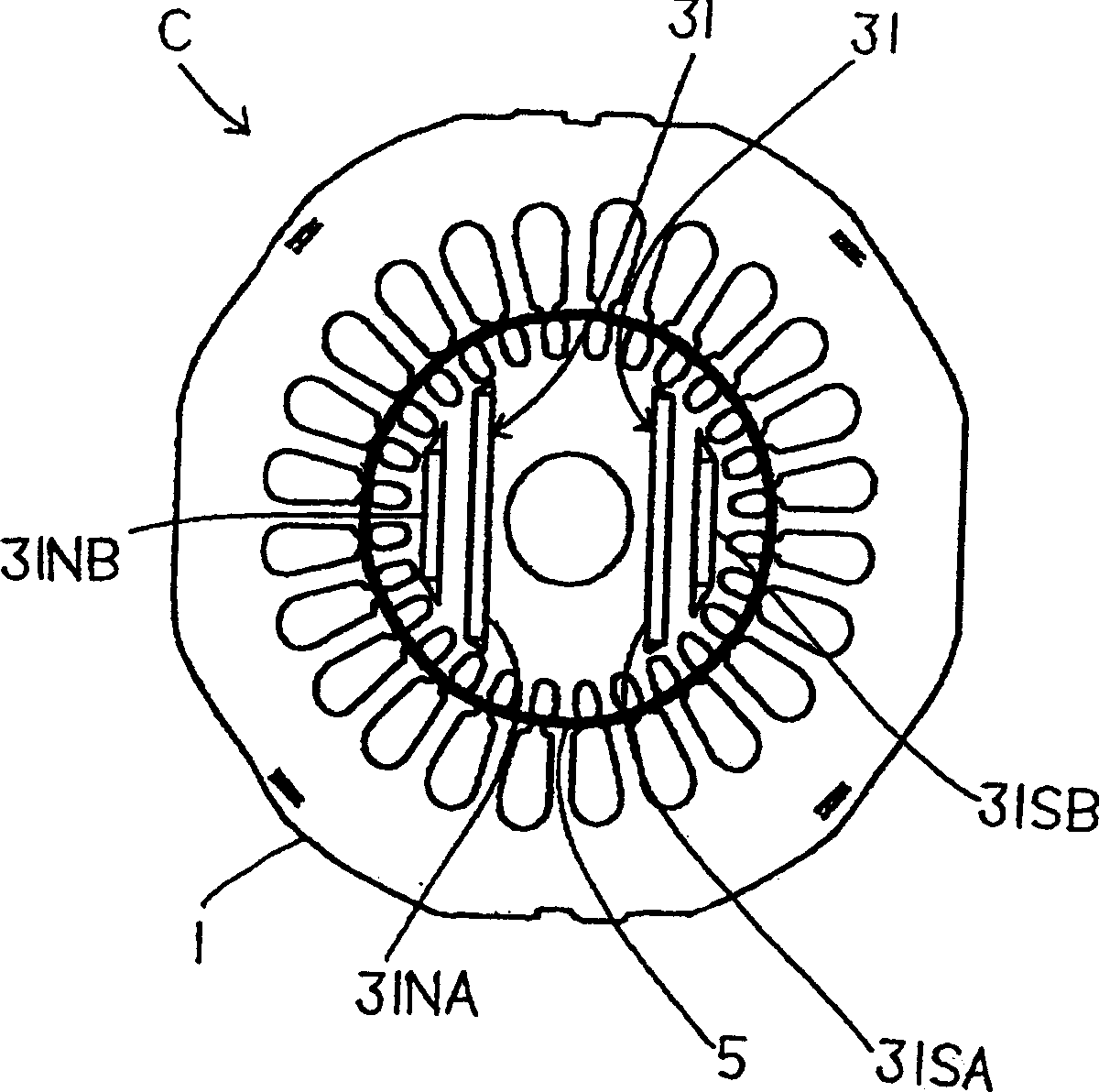

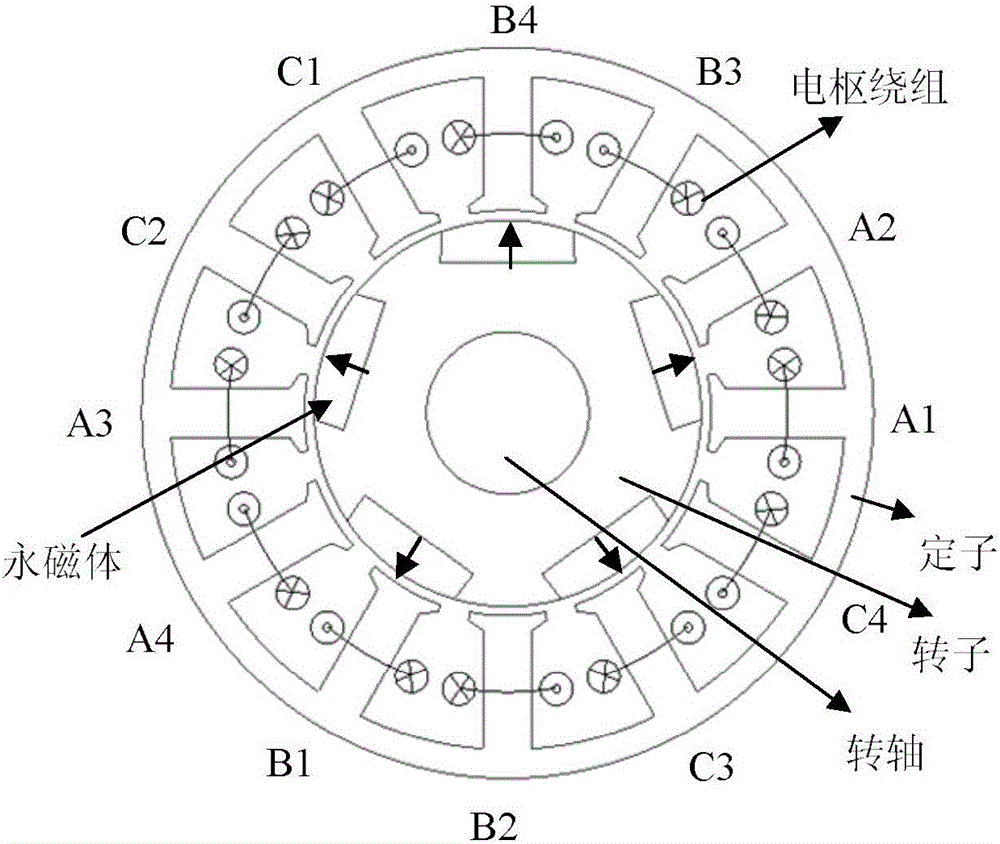

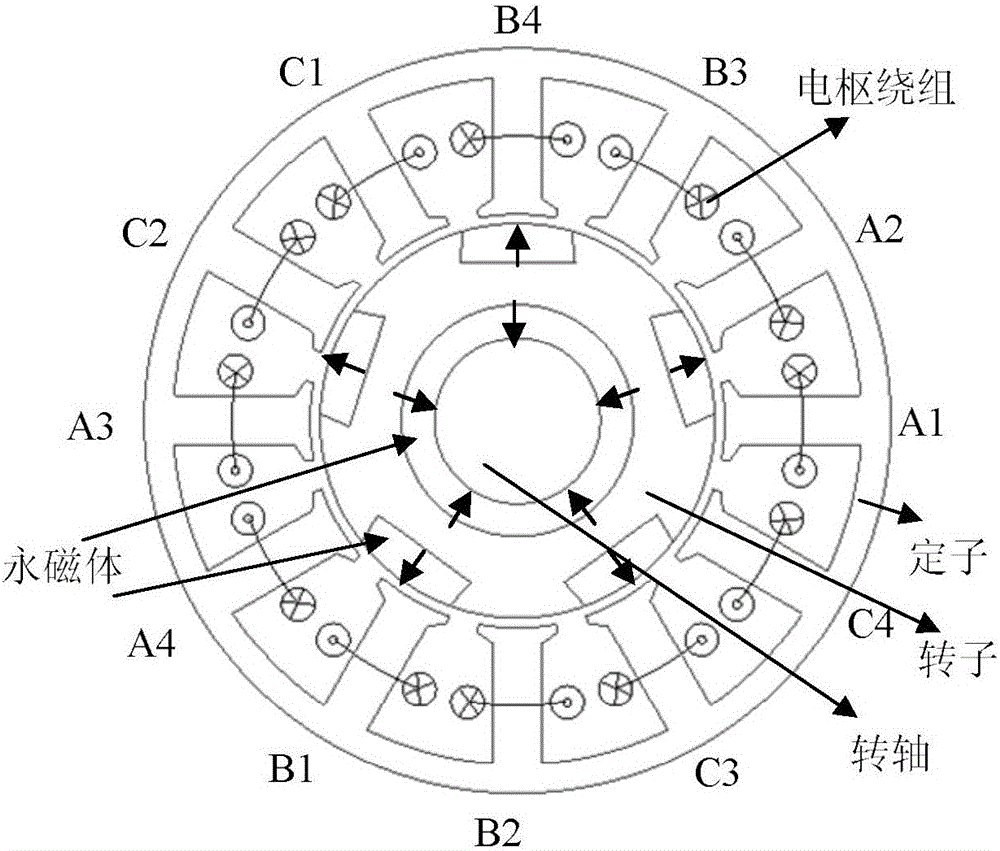

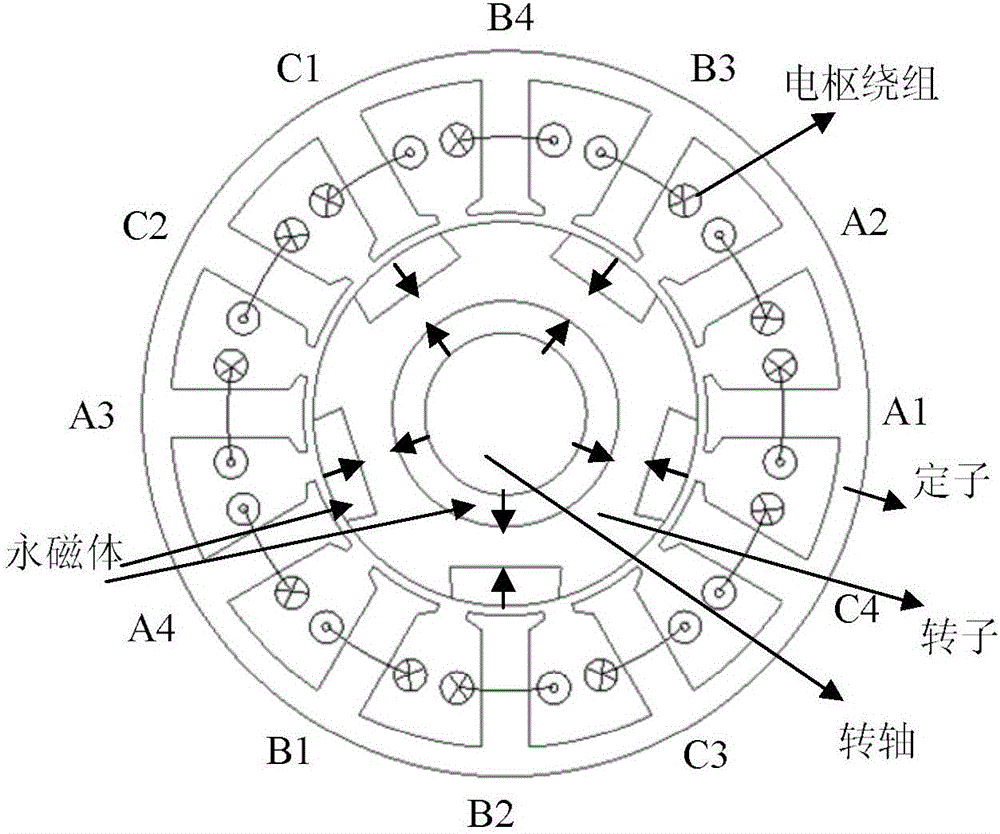

Synchronous induction motor

InactiveCN1447491AAvoid damageAvoid magnetizationMagnetic circuit rotating partsMagnetic/electric field screeningElectrical conductorInduction motor

A synchronous induction motor 2 comprises a stator 4 which has a stator winding 7, and the rotor 5 which is fixed to the rotary shaft 6, and rotates inside the stator 4. A secondary conductor disposed in the peripheral part of a rotor yoke part which constitutes the rotor 5, and permanent magnets, embedded in the rotor yoke part, are provided. The permanent magnets are disposed on both sides interposing the rotary shaft 6. The permanent magnets which pull in magnetic field constituted by the permanent magnets are disposed on both sides of a line which passes through the permanent magnets and the rotary shaft 6. Providing a synchronous induction motor, which largely prevents magnetization of a rotary shaft to which a rotor of the synchronous induction moor comprising two poles is fixed.

Owner:SANYO ELECTRIC CO LTD

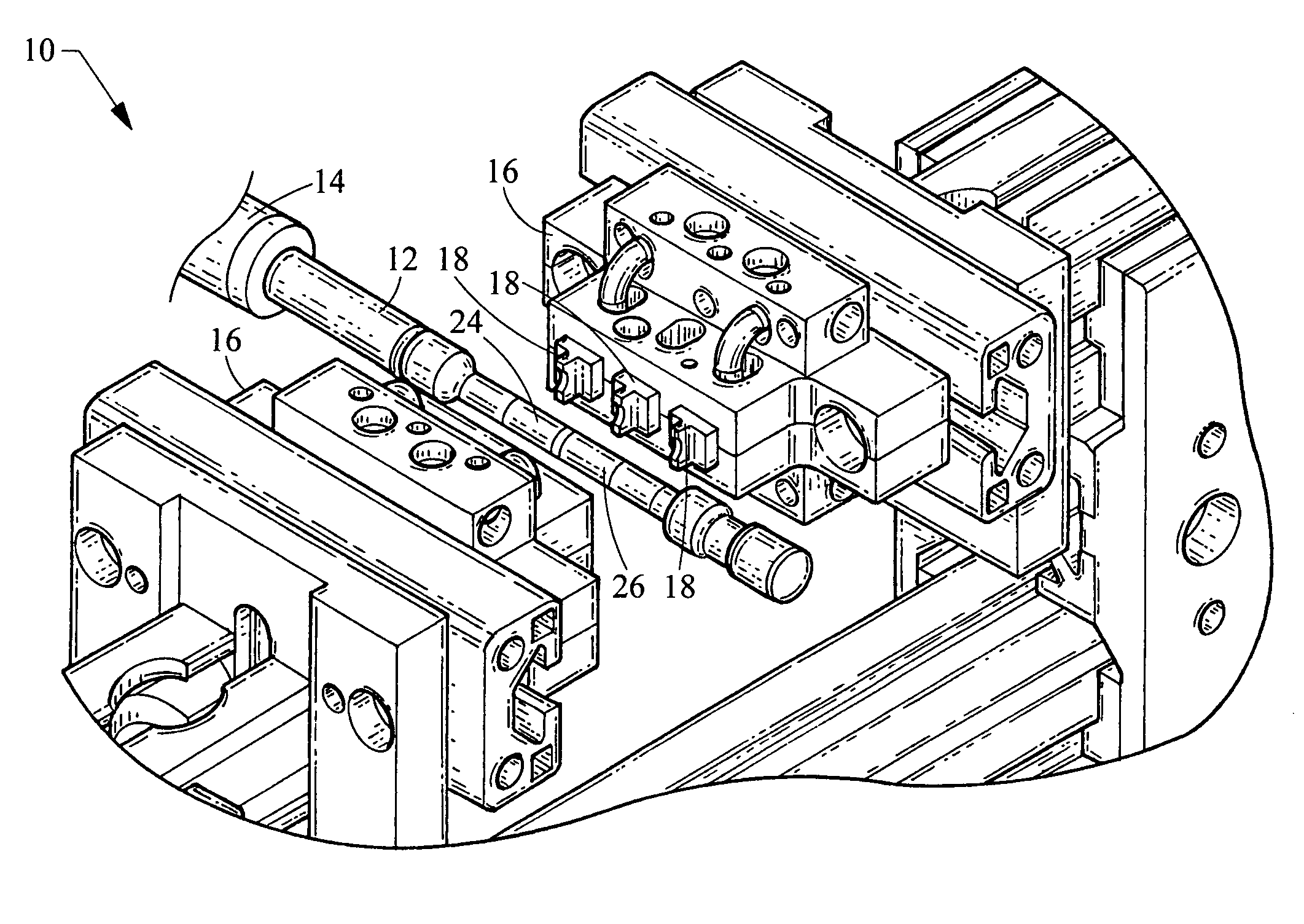

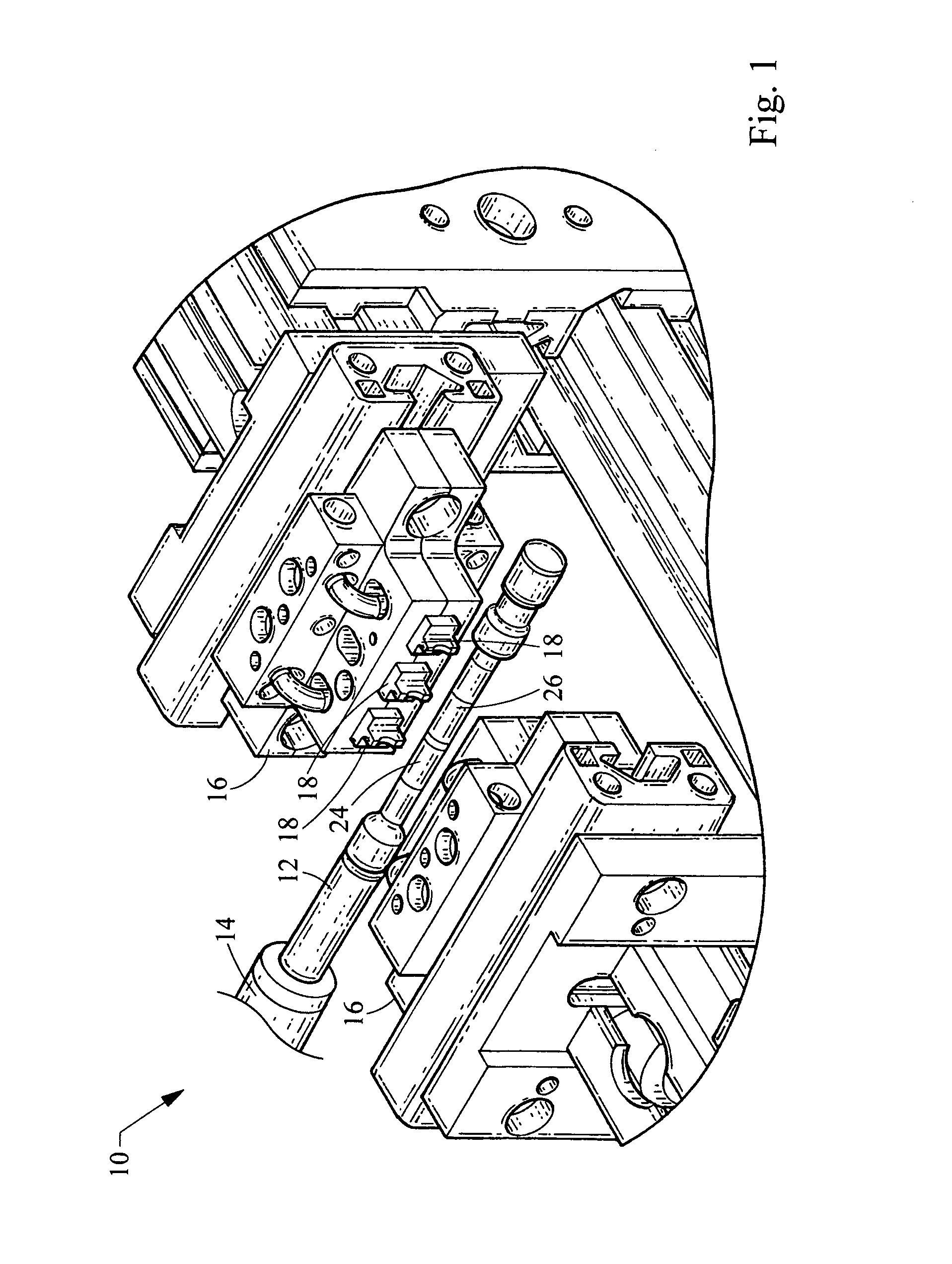

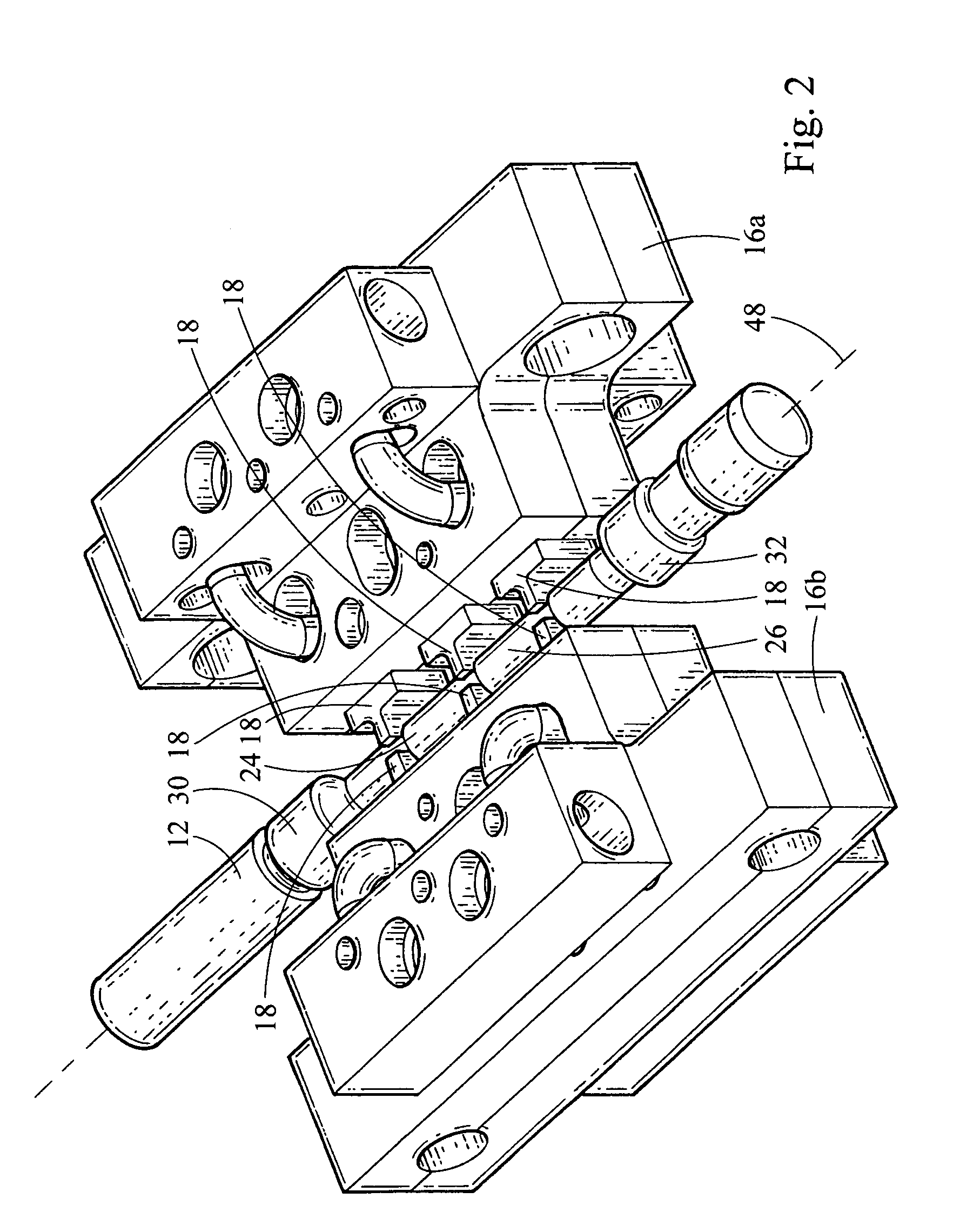

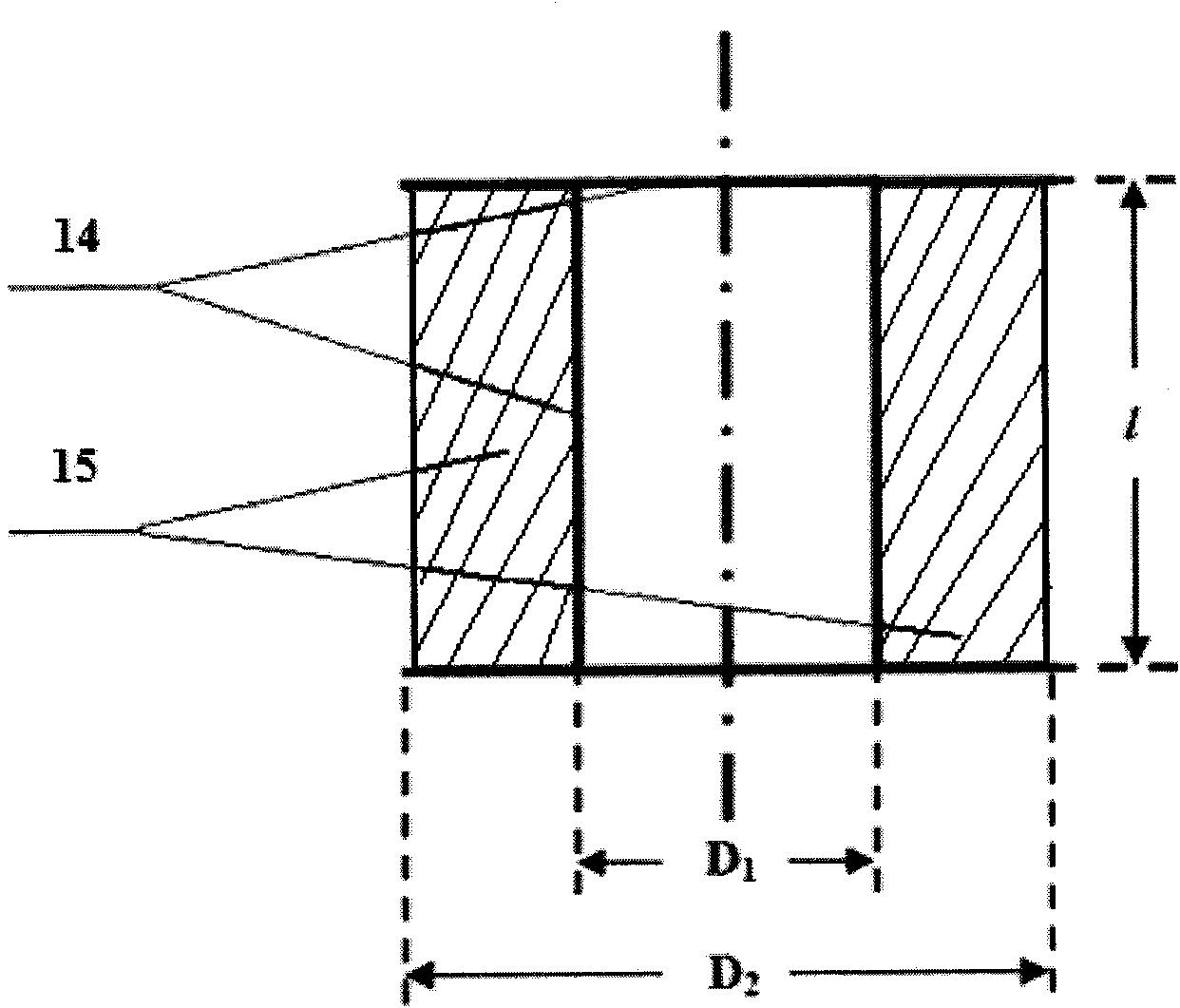

Process for circumferential magnetization of magnetoelastic shafts

InactiveUS6975196B1Avoid magnetizationElectromagnets without armaturesWork measurementMagnetizationEngineering

An apparatus for magnetizing selected portions of a shaft in a substantially circumferential direction includes a fixture mounted onto the apparatus adapted to receive a shaft to be magnetized, at least one magnetization head, the magnetization head being mounted moveably on the apparatus such that the magnetization head can be moved radially relative to the fixture, a plurality of brushes mounted onto the magnetization head, each brush having a distal end defining an internal diameter sized to circumferentially contact the shaft, the brushes being spring-loaded such that when the magnetization head is moved toward the fixture, each brush engages the shaft with proper pre-load force, and a buss bar, wherein the brushes are electrically connected to the buss bar for even distribution of electrical current to the brushes.

Owner:TEDRIVE HLDG

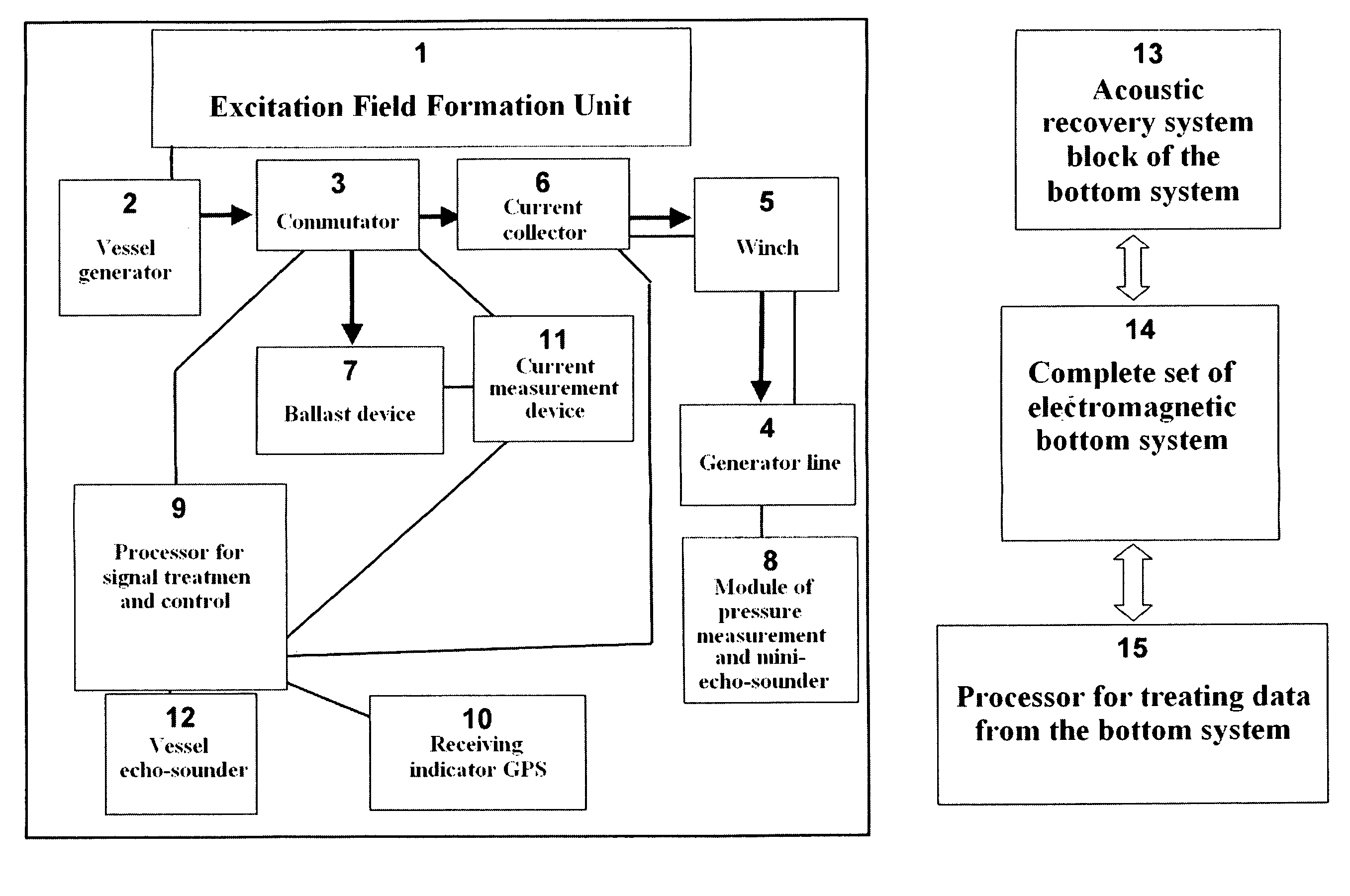

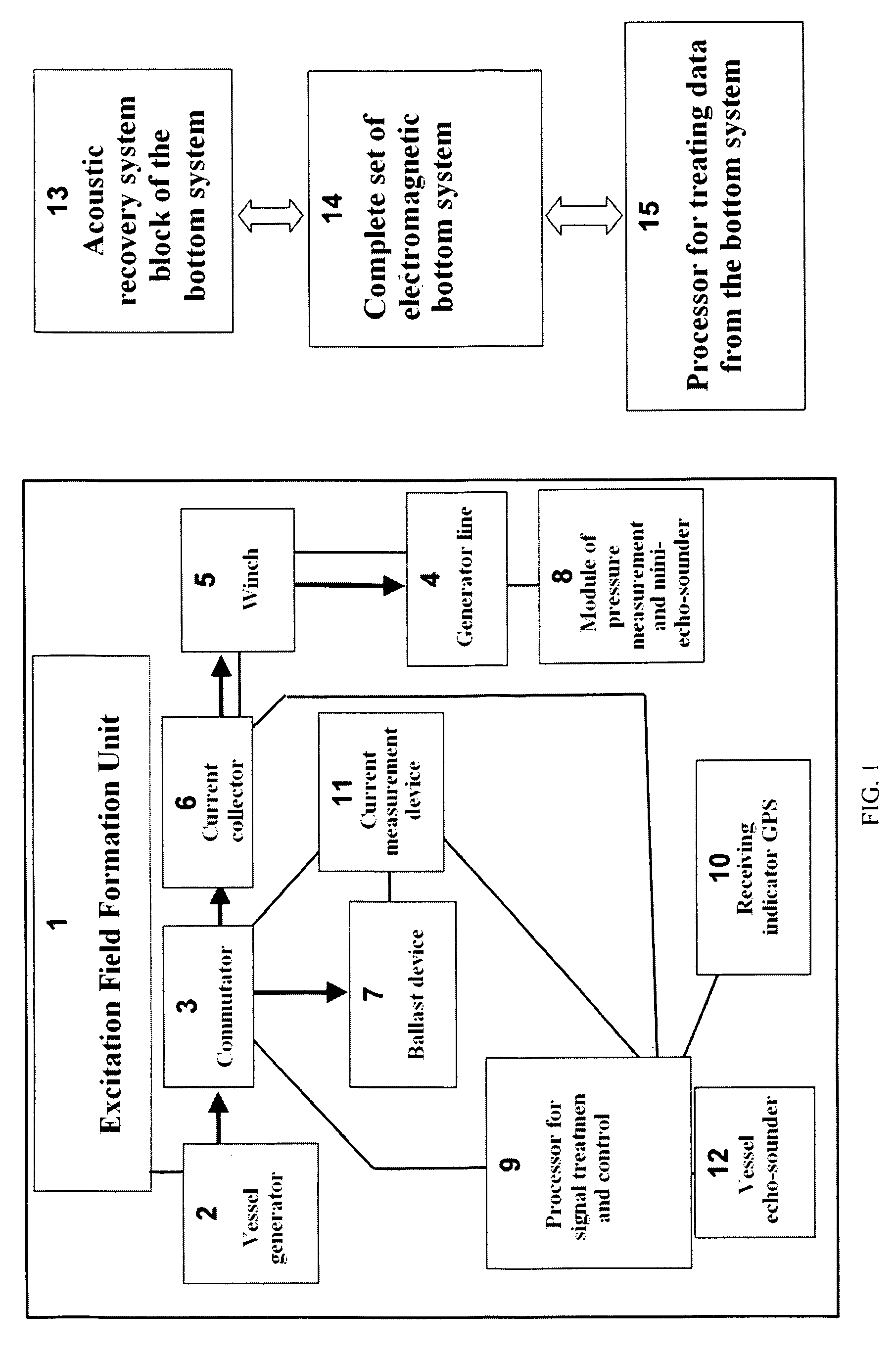

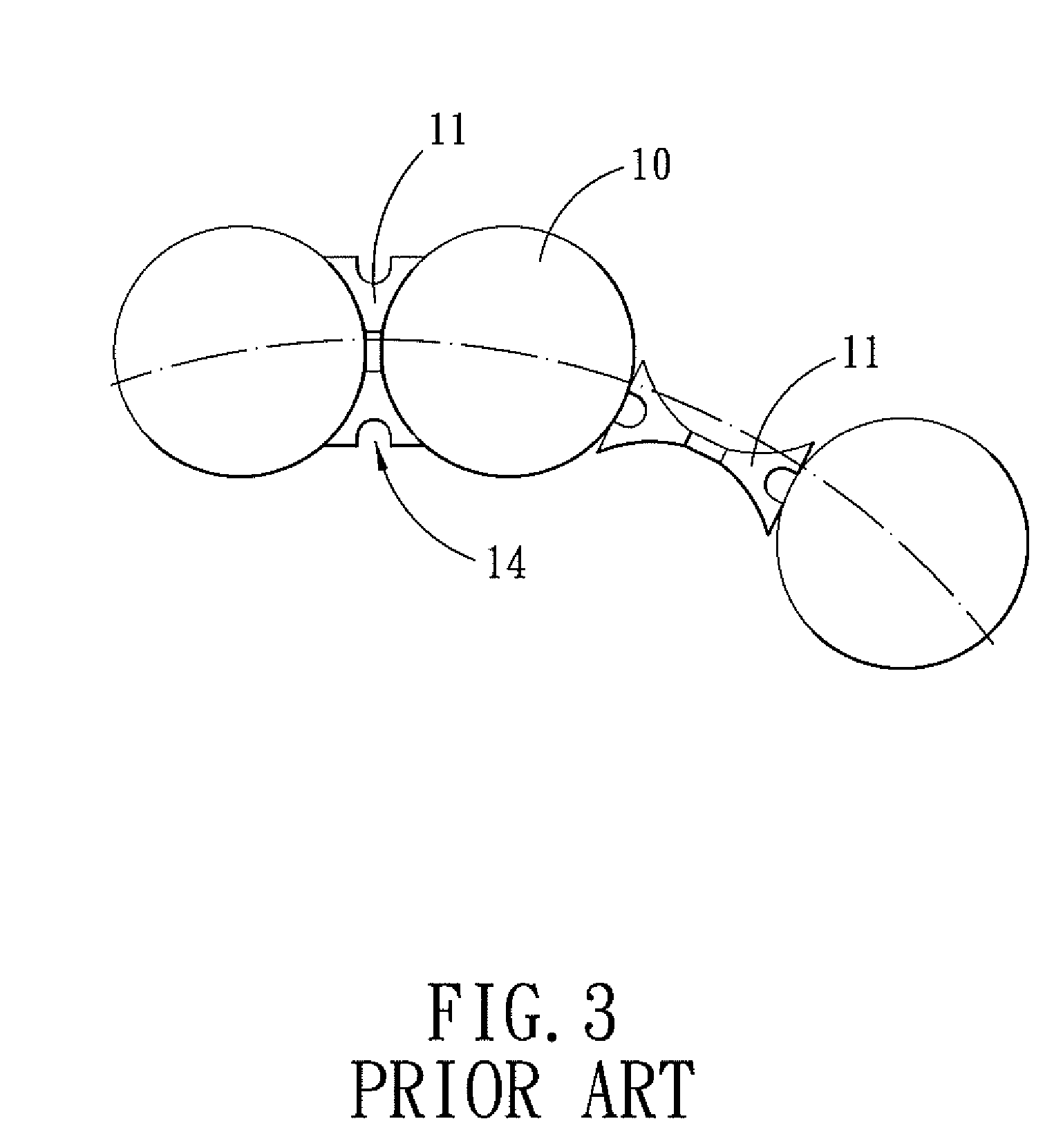

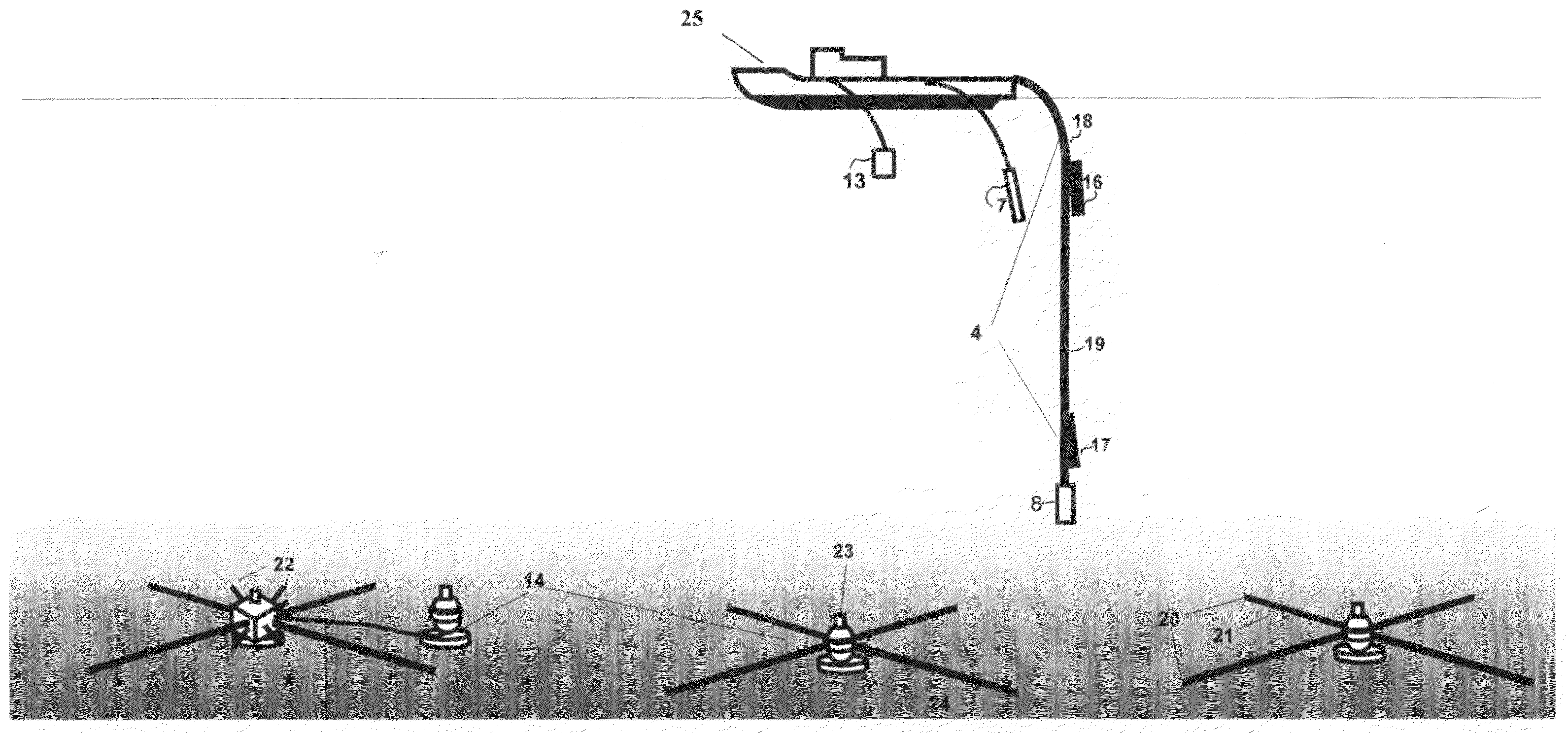

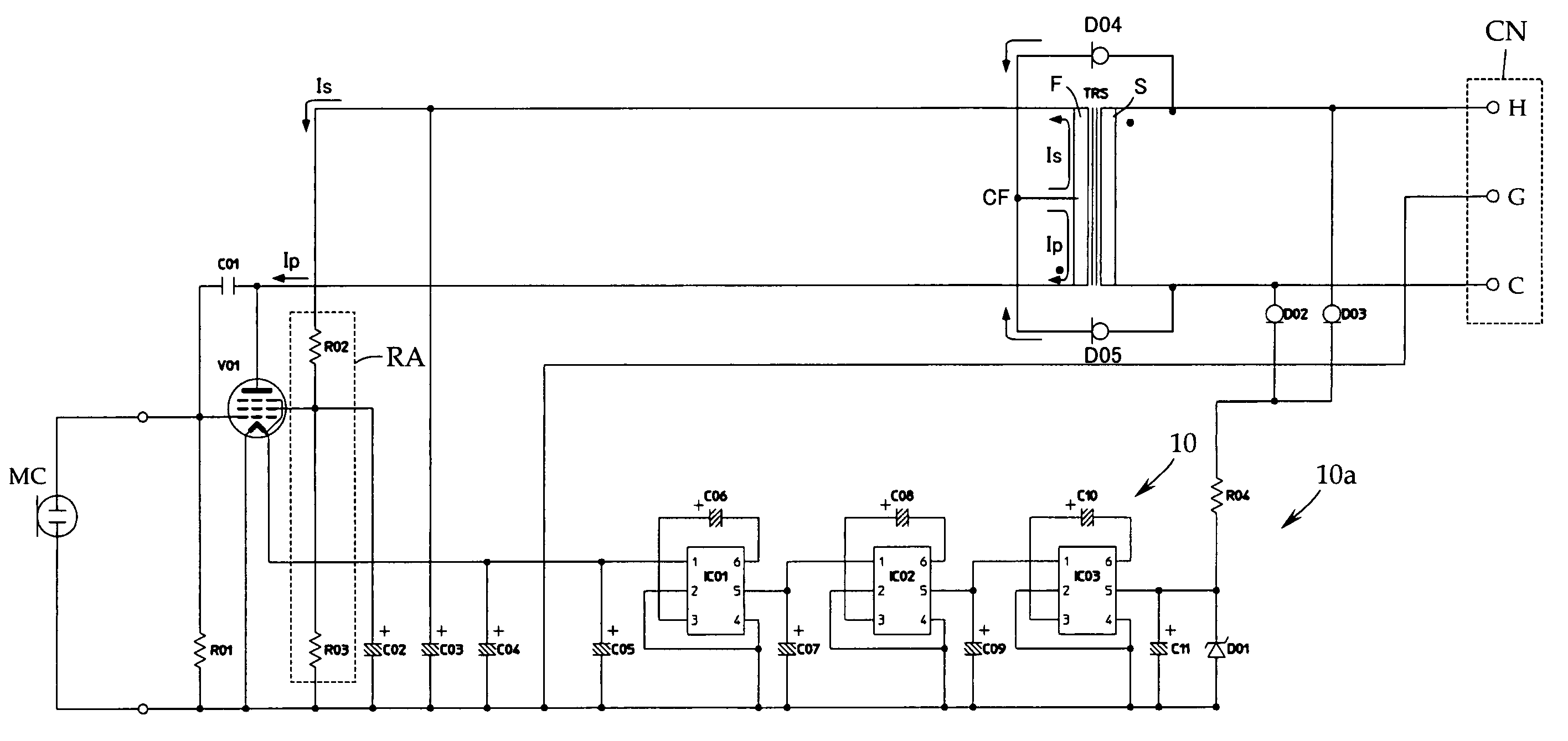

Method of sea electrical survey of oil and gas deposits and apparatus complex for its realization 'VeSoTEM'

InactiveUS7529627B2Improve accuracyAvoid magnetizationElectric/magnetic detection for well-loggingDigital variable/waveform displayElectromagnetic fieldSecondary field

A method for electrical survey of hydrocarbons deposits under seabed depths up to 1500 m and equipment therefor are provided. The equipment includes a vessel, a generator, an excitation field block, connected with a vertical dipole with coax electrodes, a data registration / processing block, bottom systems with. The lower dipole electrode is situated at maximally 100 m from the seabed, the upper electrode at maximally 200 m from the surface. The operation of the generator and bottom systems is synchronized the dipole is submersed into the sea, and fed with alternating-sign rectangular current pulses, whose on-off time ratio and duration are programmably determined. The bottom systems register reflected signals and electromagnetic field components, when the dipole's current is on and off. Analysis of the signals accounts modifications of primary and secondary fields, transient field changes for determination of the environment resistivity and strata polarization characteristics thereby improving the hydrocarbons deposits prognosis.

Owner:ZAKRYTOE AKTSIONERNOE OBSHCHESTVO EMMET

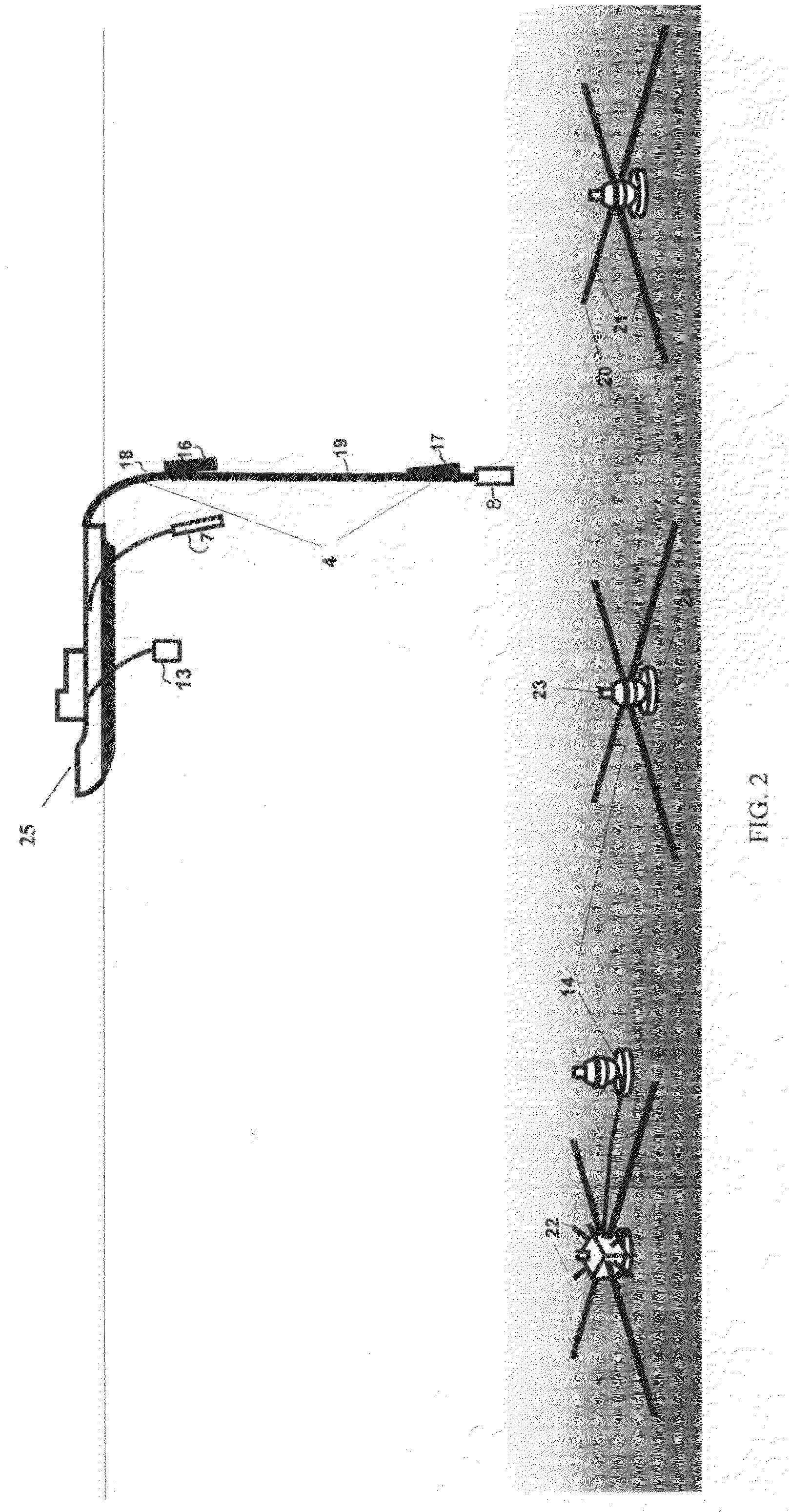

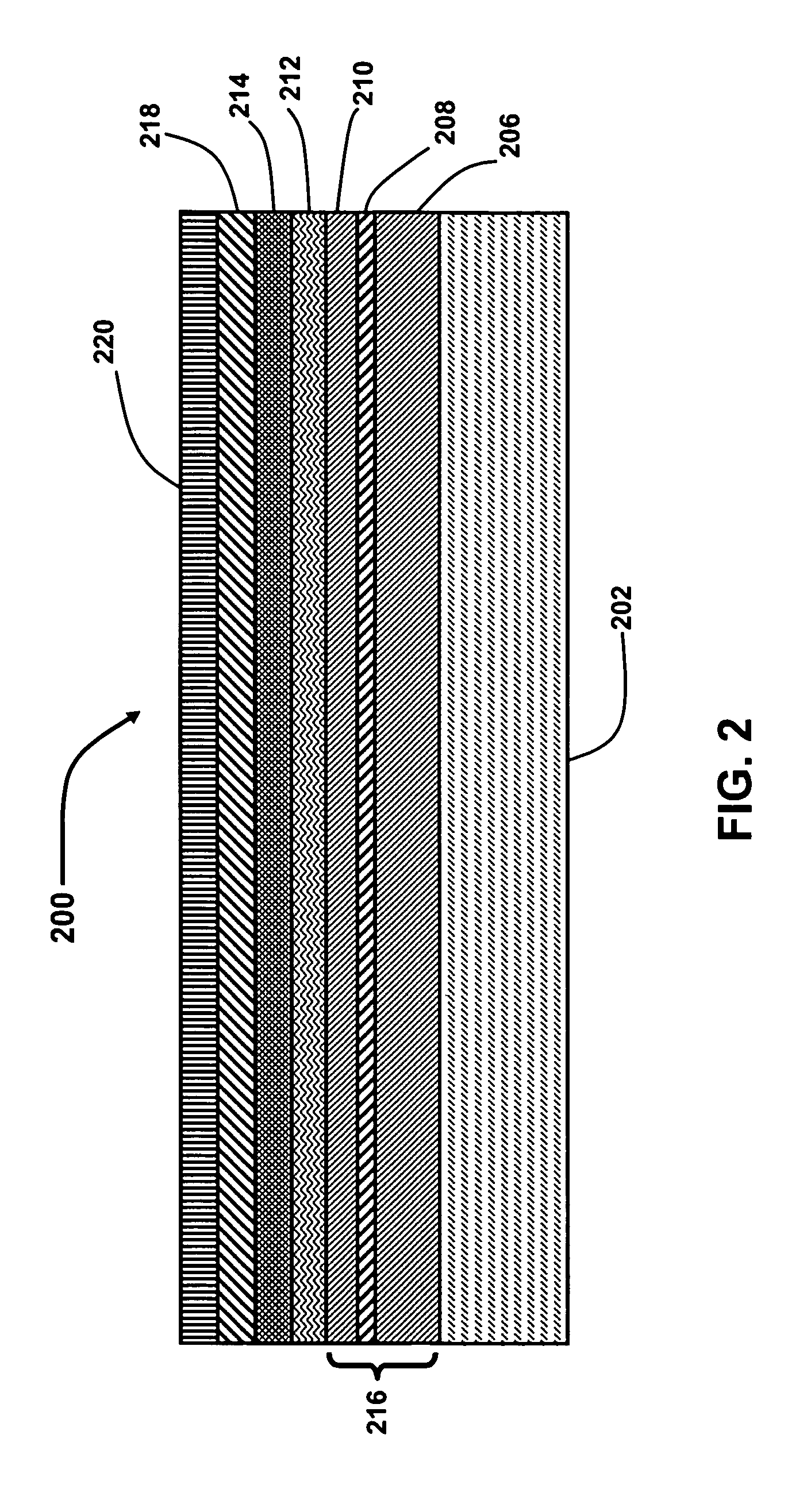

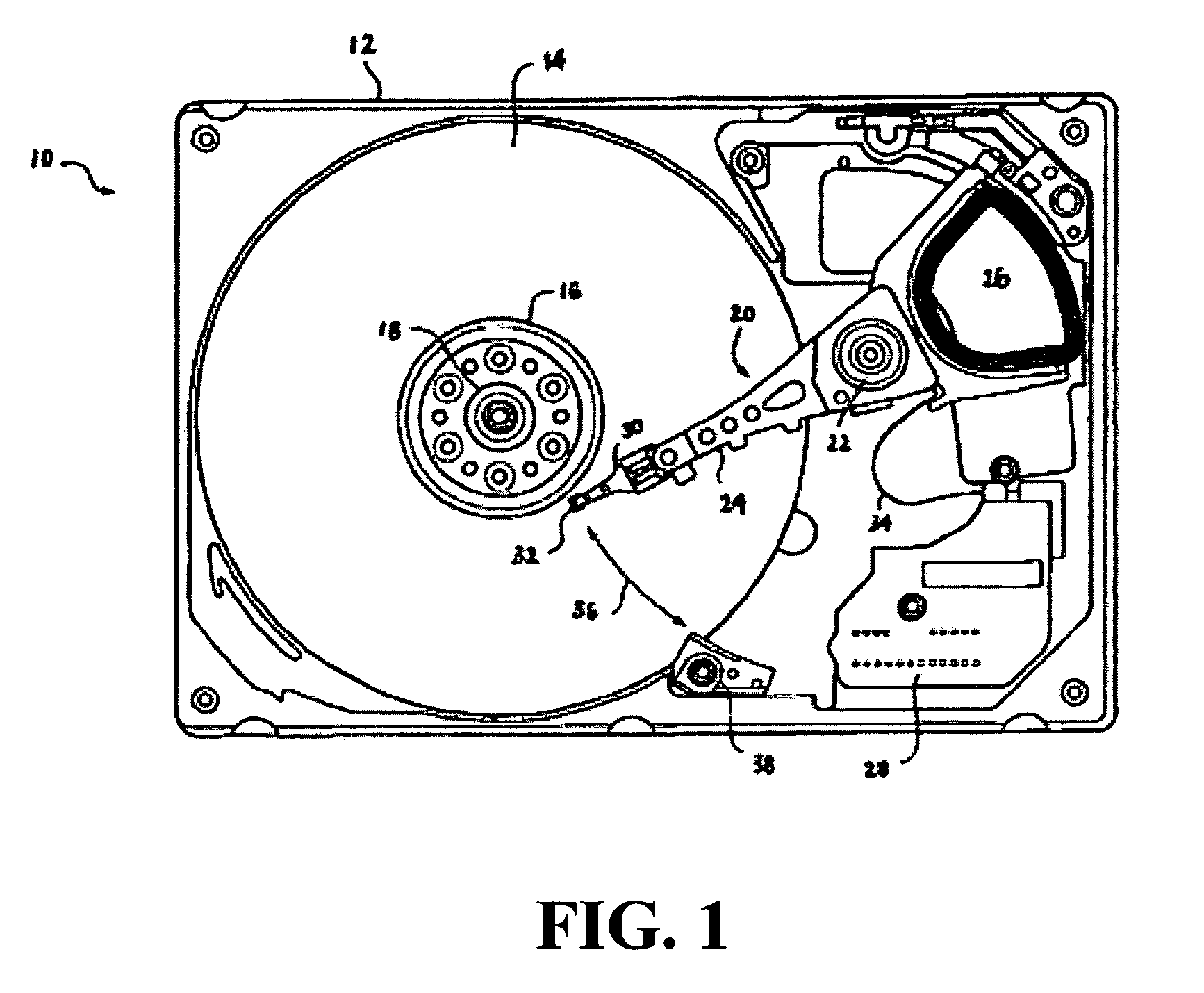

Media for high density perpendicular magnetic recording

ActiveUS8110298B1Thermal stability of becomes lowHigh magnetizationRecord information storageMagnetic recordingNuclear magnetic resonanceOxide

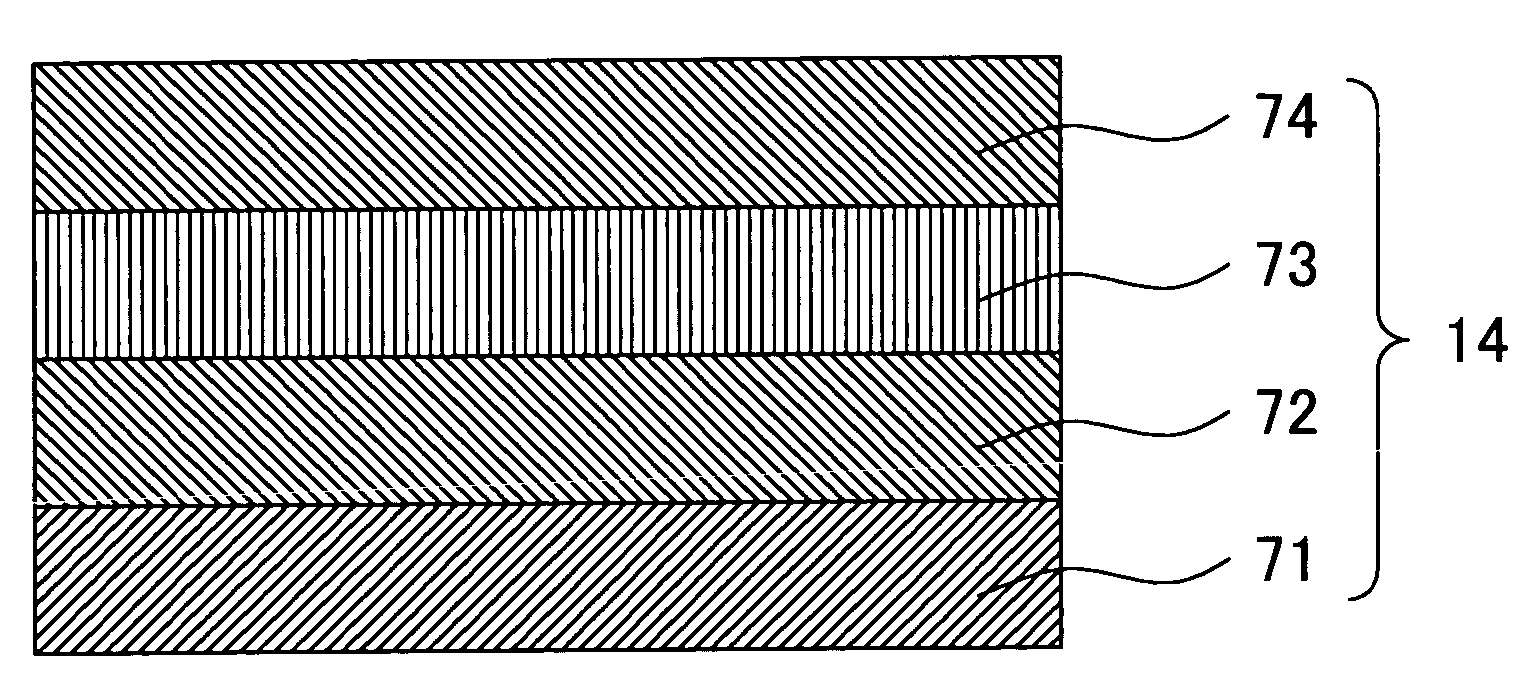

Perpendicular magnetic recording media having a magnetic capping layer that is exchange coupled to an underlying perpendicular magnetic recording layer. The magnetic coupling layer is a granular layer having a high saturation magnetization (Ms). The perpendicular magnetic recording layer can include magnetic grains separated by an oxide grain boundary phase.

Owner:SEAGATE TECH LLC

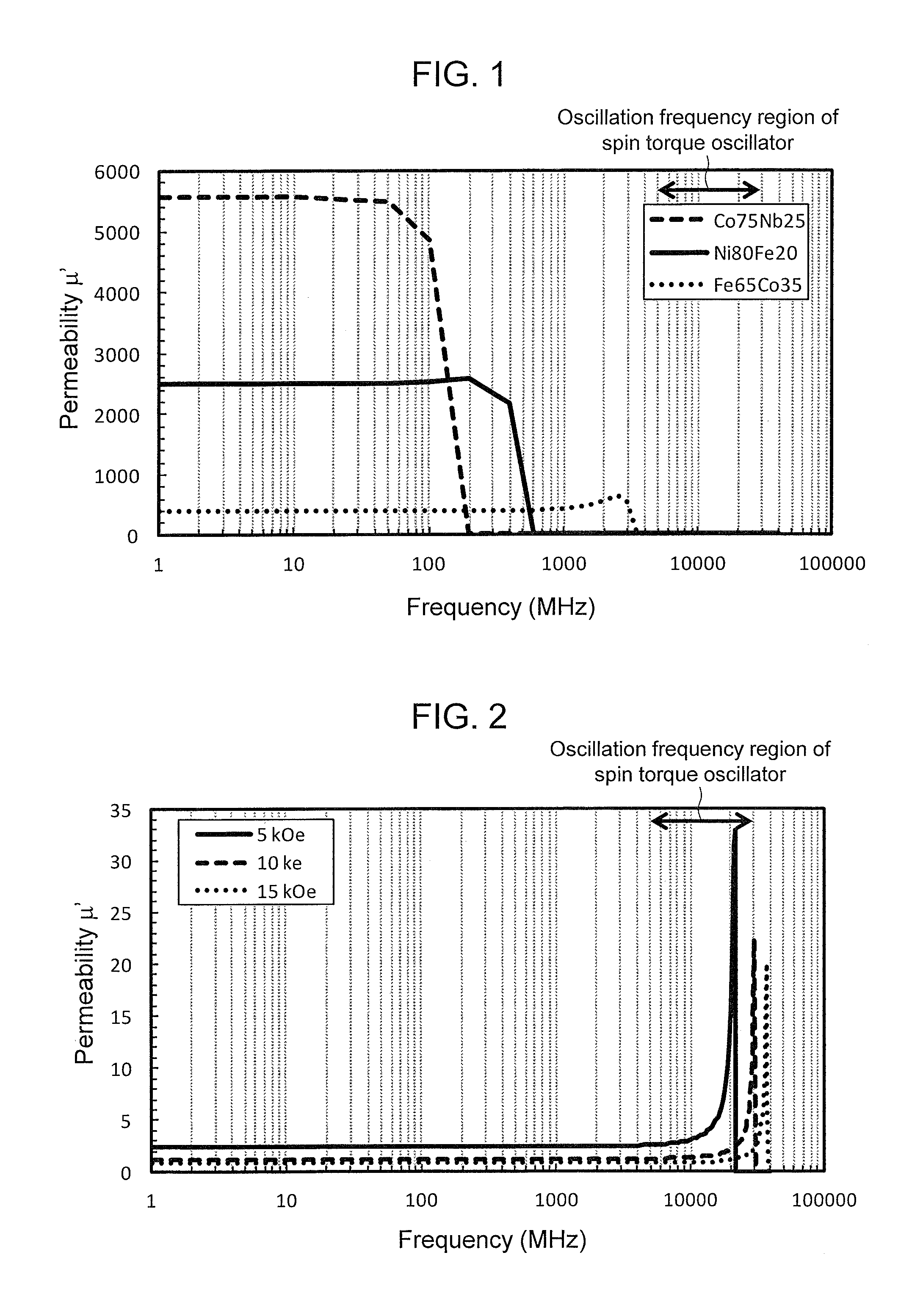

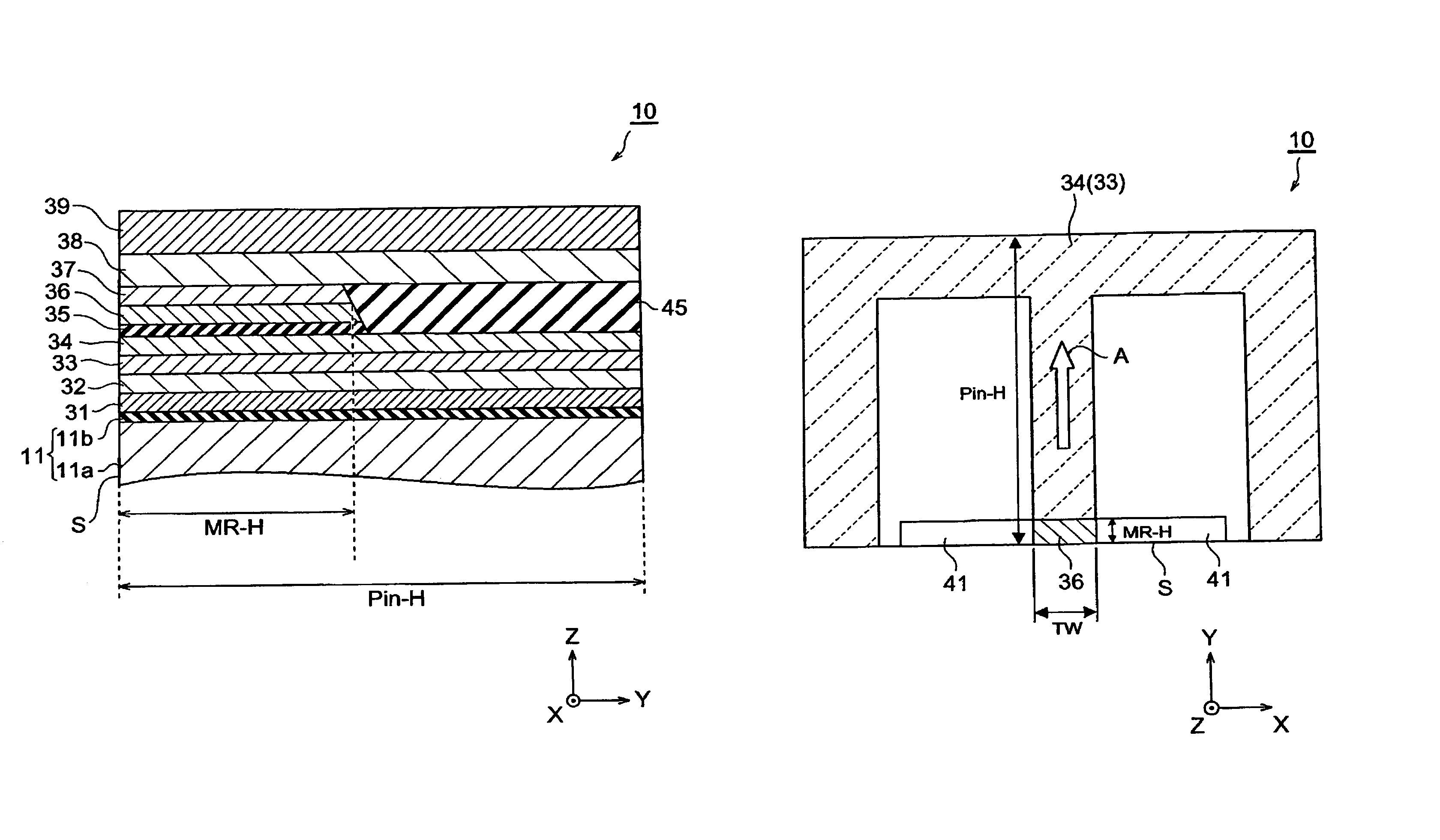

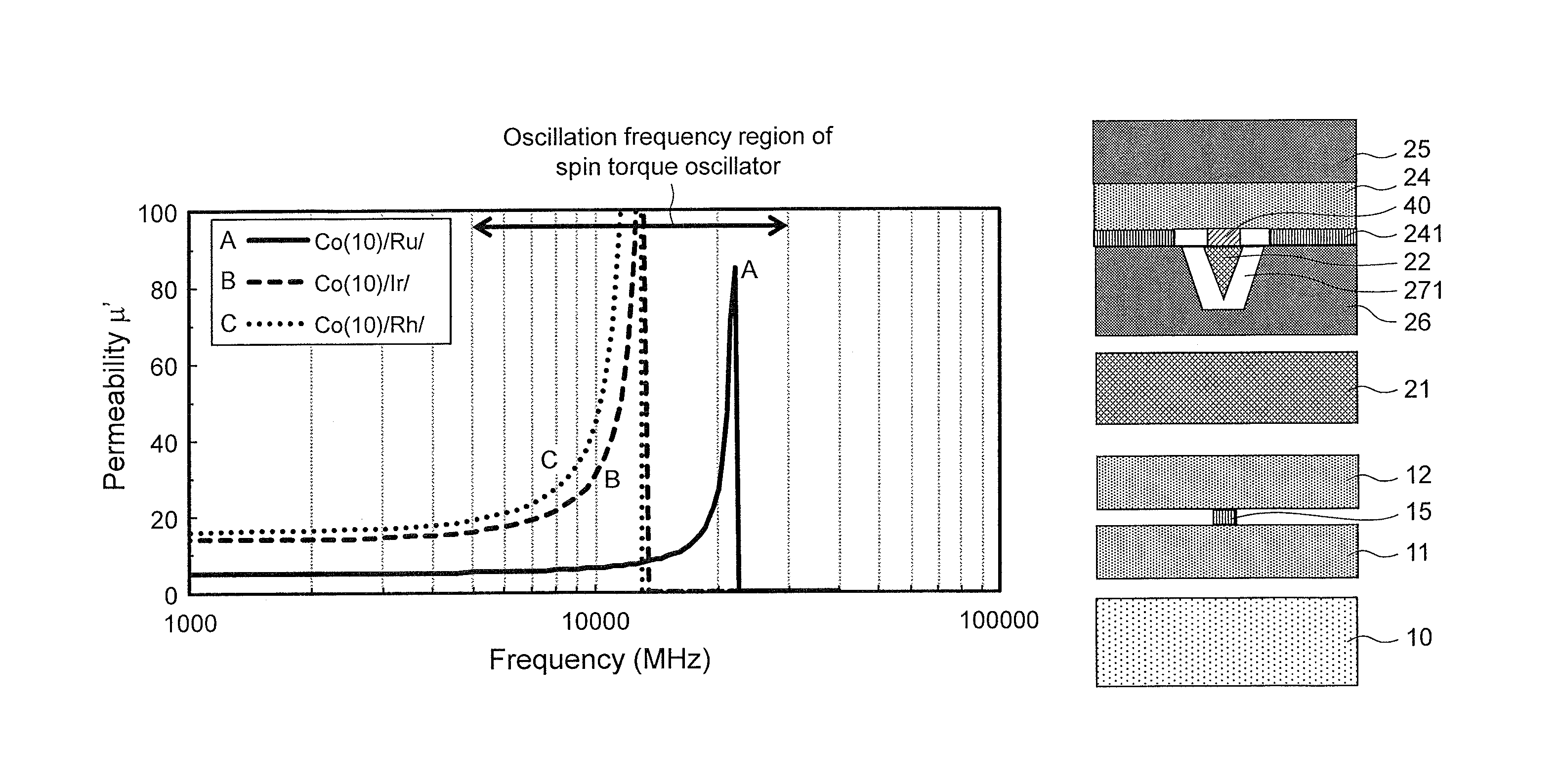

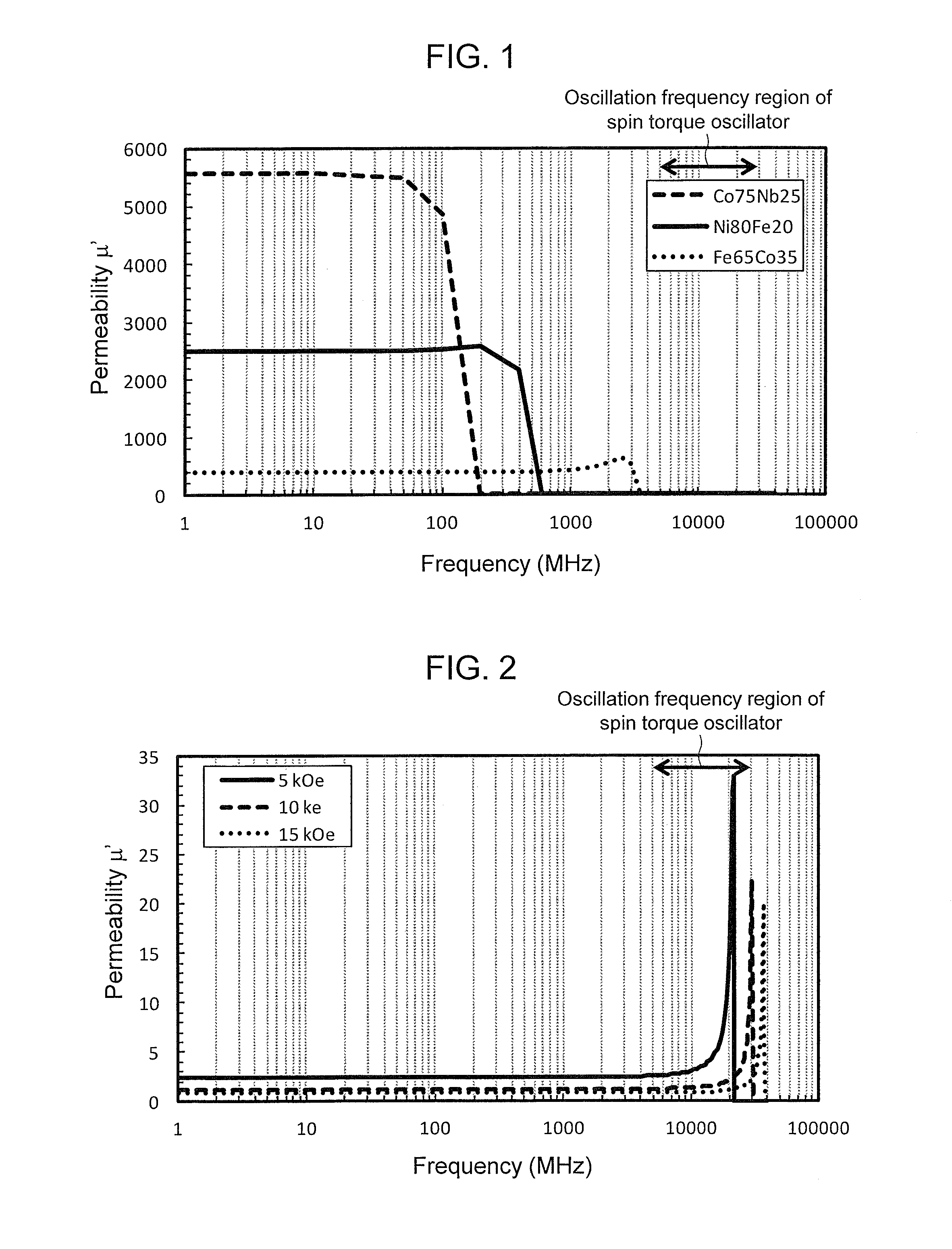

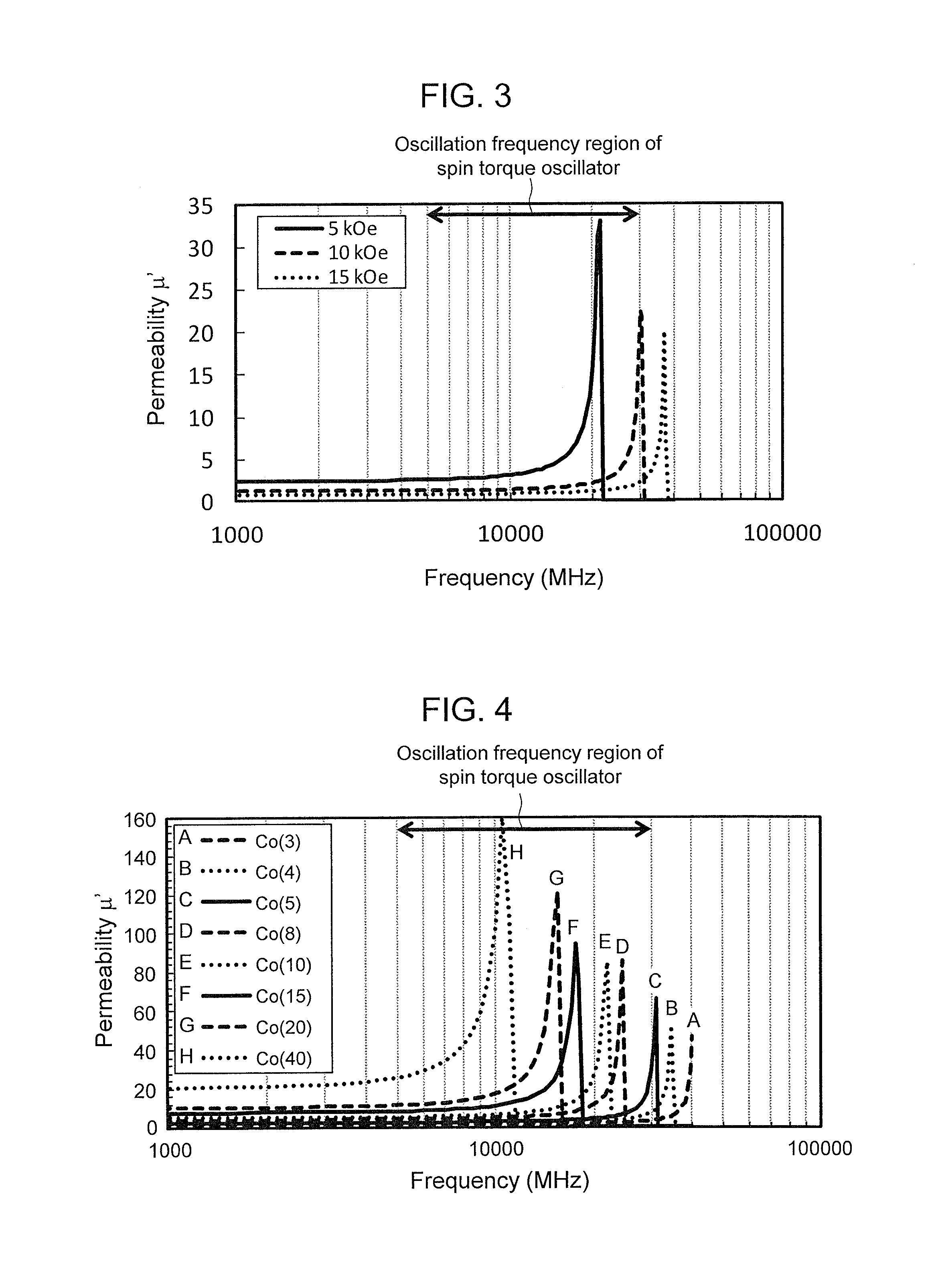

Microwave assisted magnetic recording head and magnetic data storage apparatus

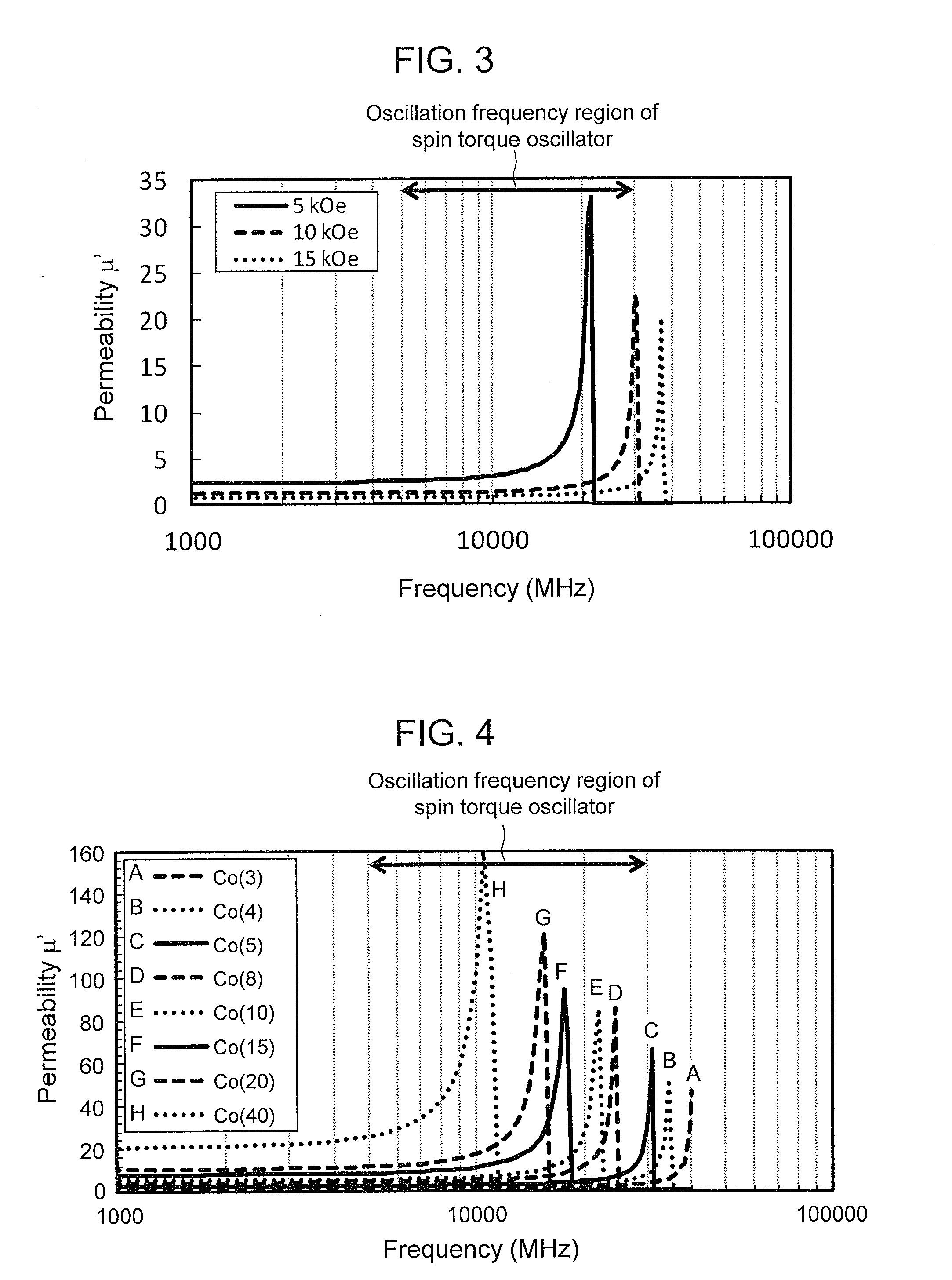

InactiveUS20130329316A1Inhibited DiffusionReduce resistanceRecord information storageAlignment for track following on disksSpin torque oscillatorsMicrowave assisted

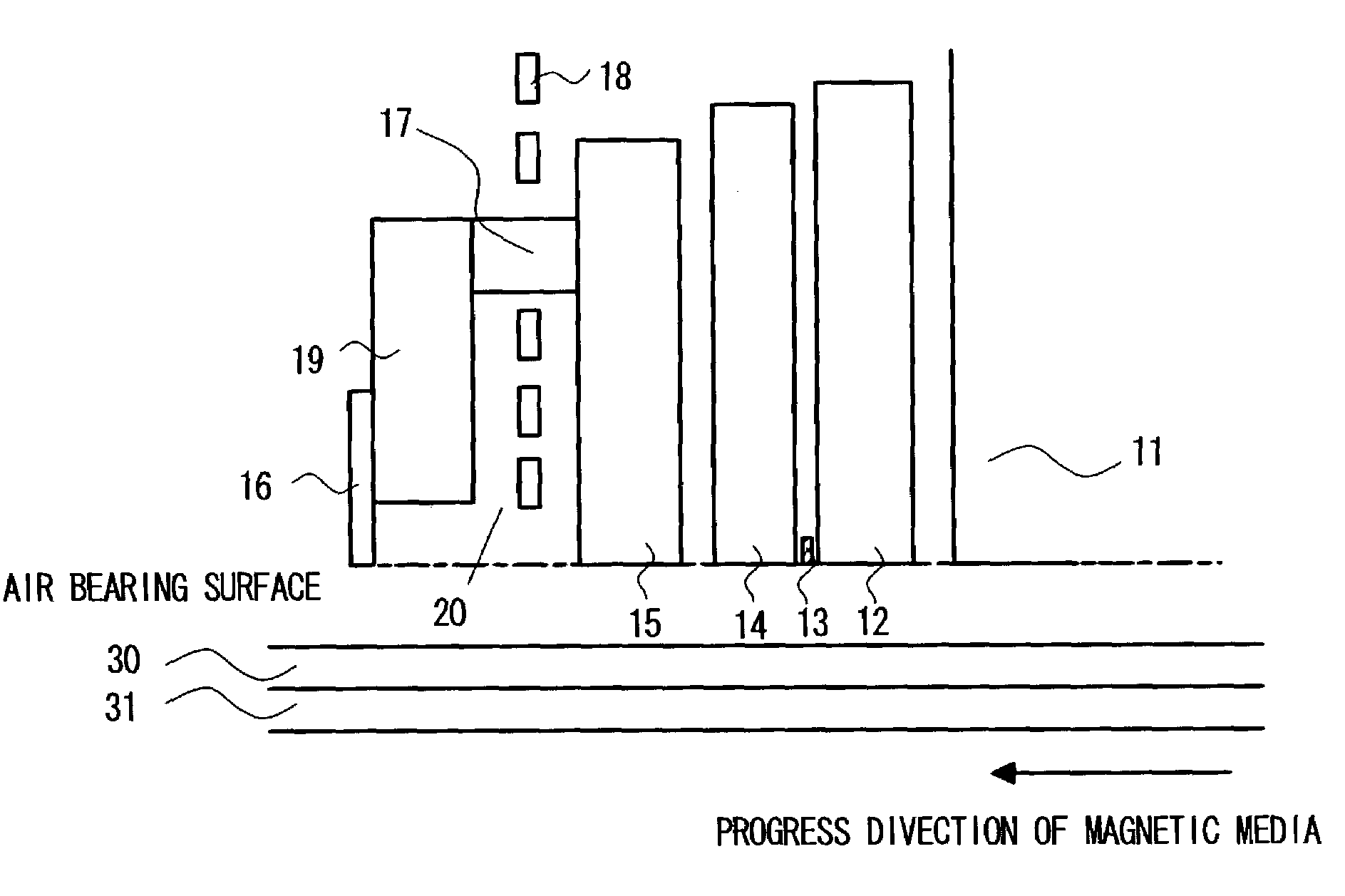

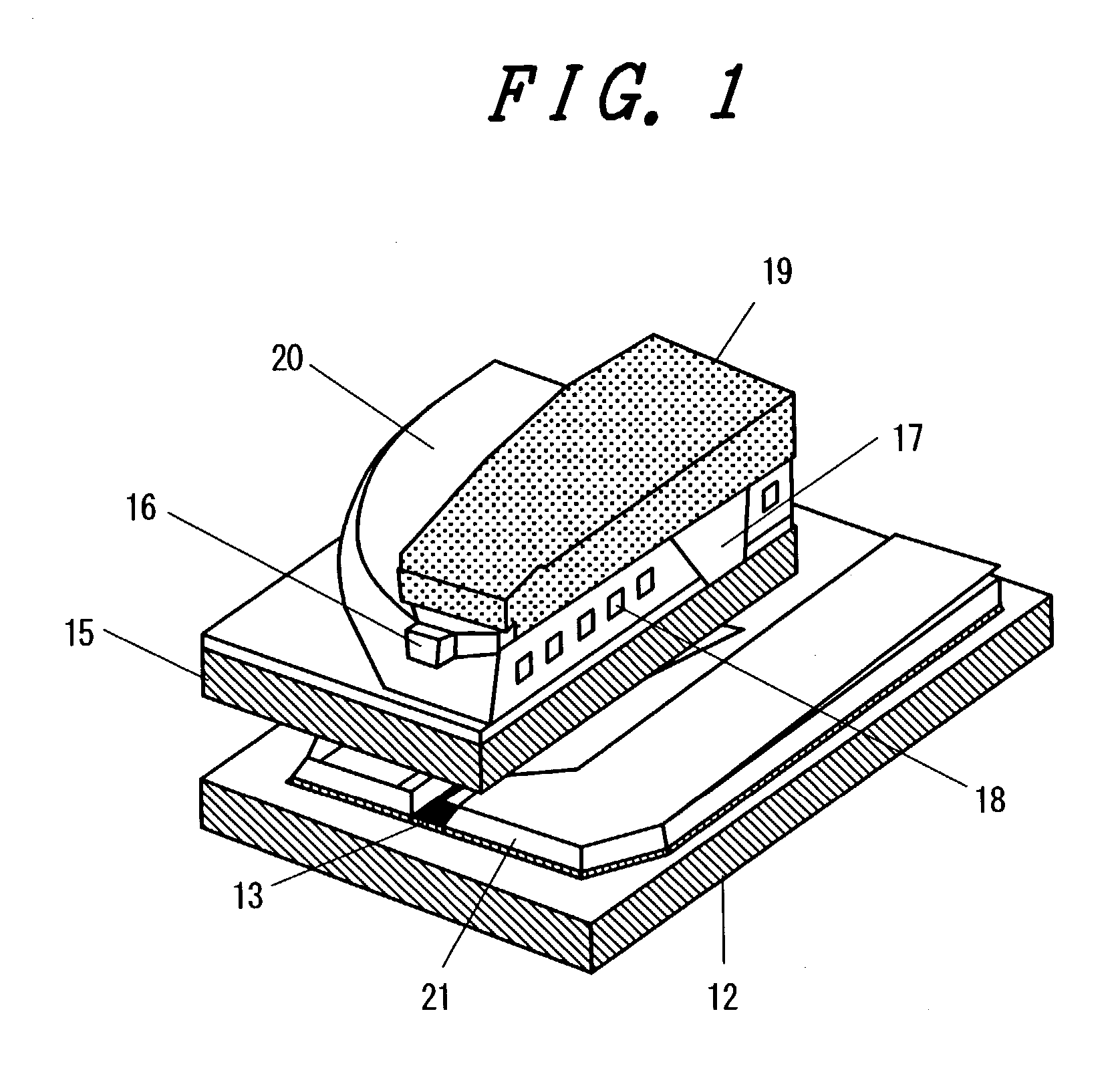

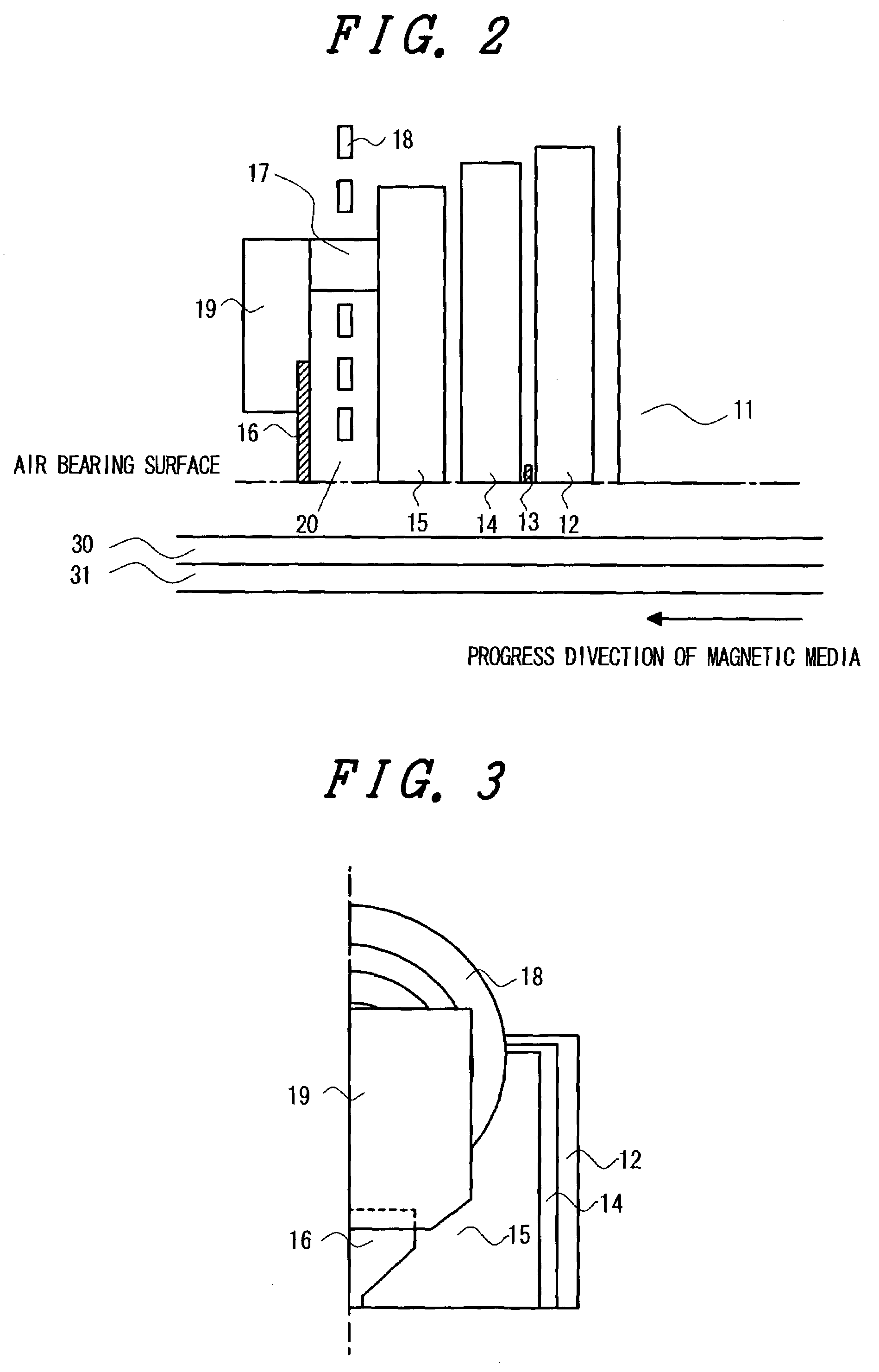

To suppress a spread of not only a recording magnetic field generated from a main pole but also a high-frequency magnetic field generated from a spin torque oscillator in a microwave assisted magnetic recording head. The main pole and the spin torque oscillator are surrounded by a trailing shield layer and are also surrounded by a side / leading shield layer with an insulator sidegap layer interposed therebetween, and a high-frequency magnetic field shield layer, which absorbs a high-frequency magnetic field generated from the spin torque oscillator, is arranged in at least part of the shield layers.

Owner:HITACHI LTD

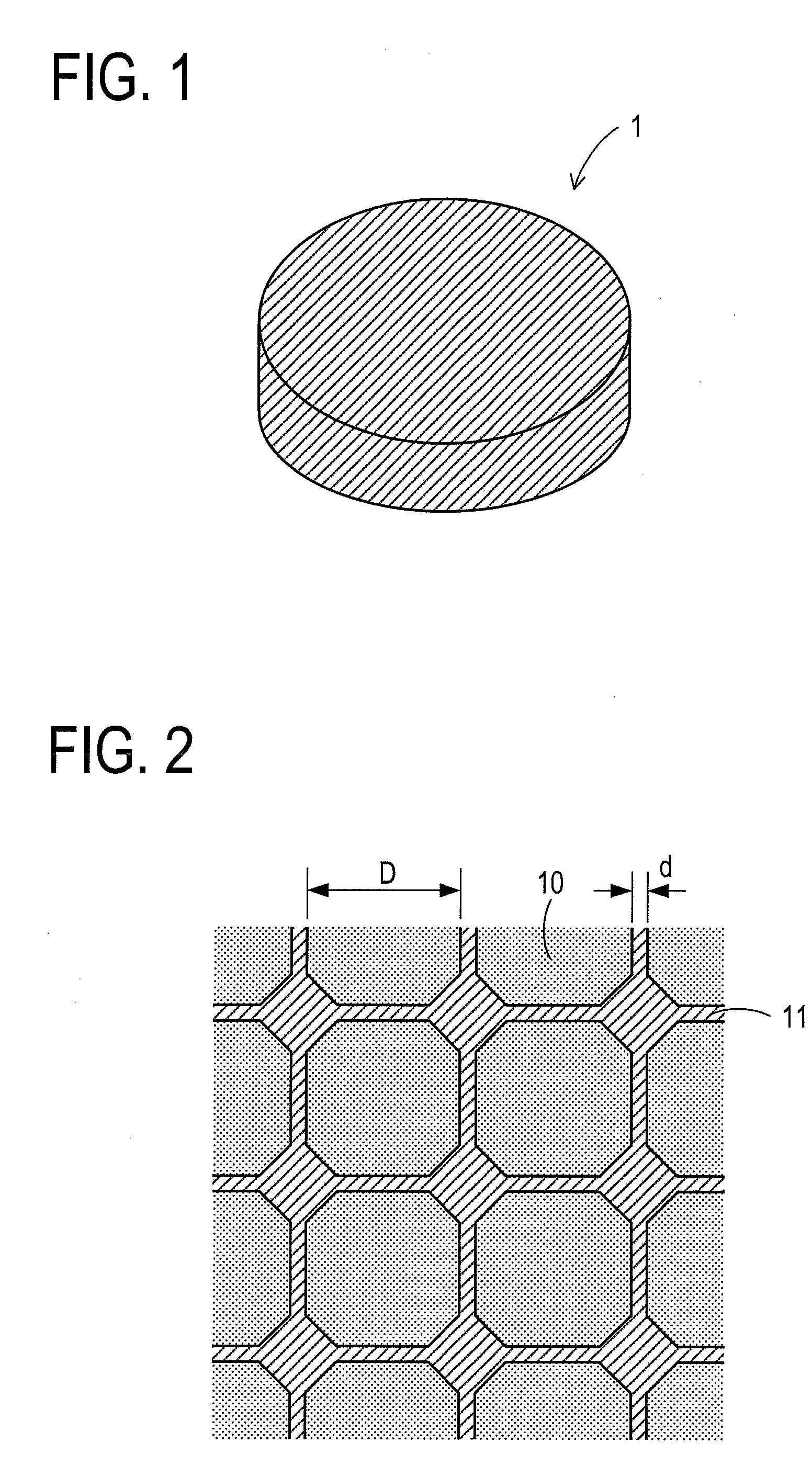

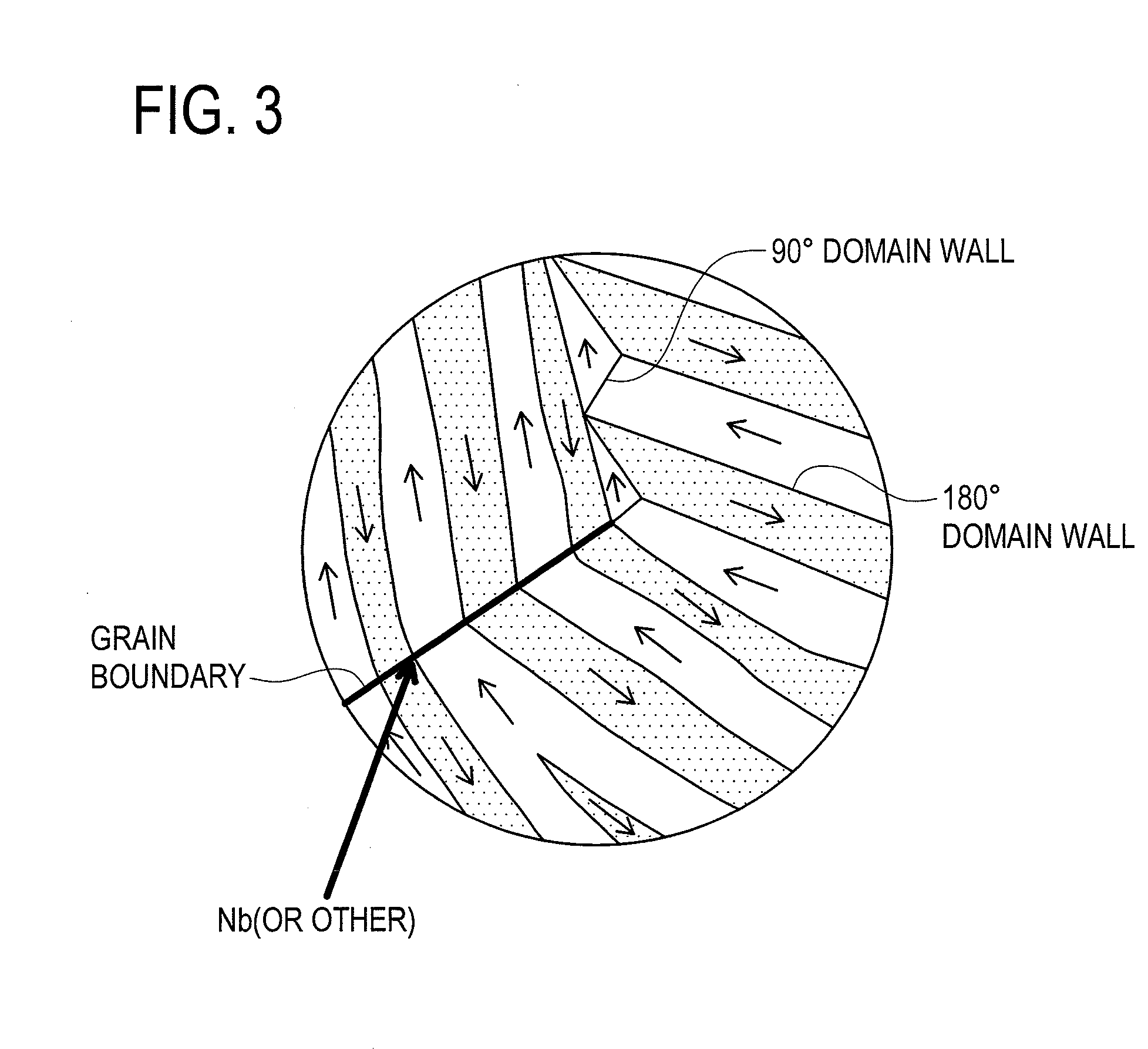

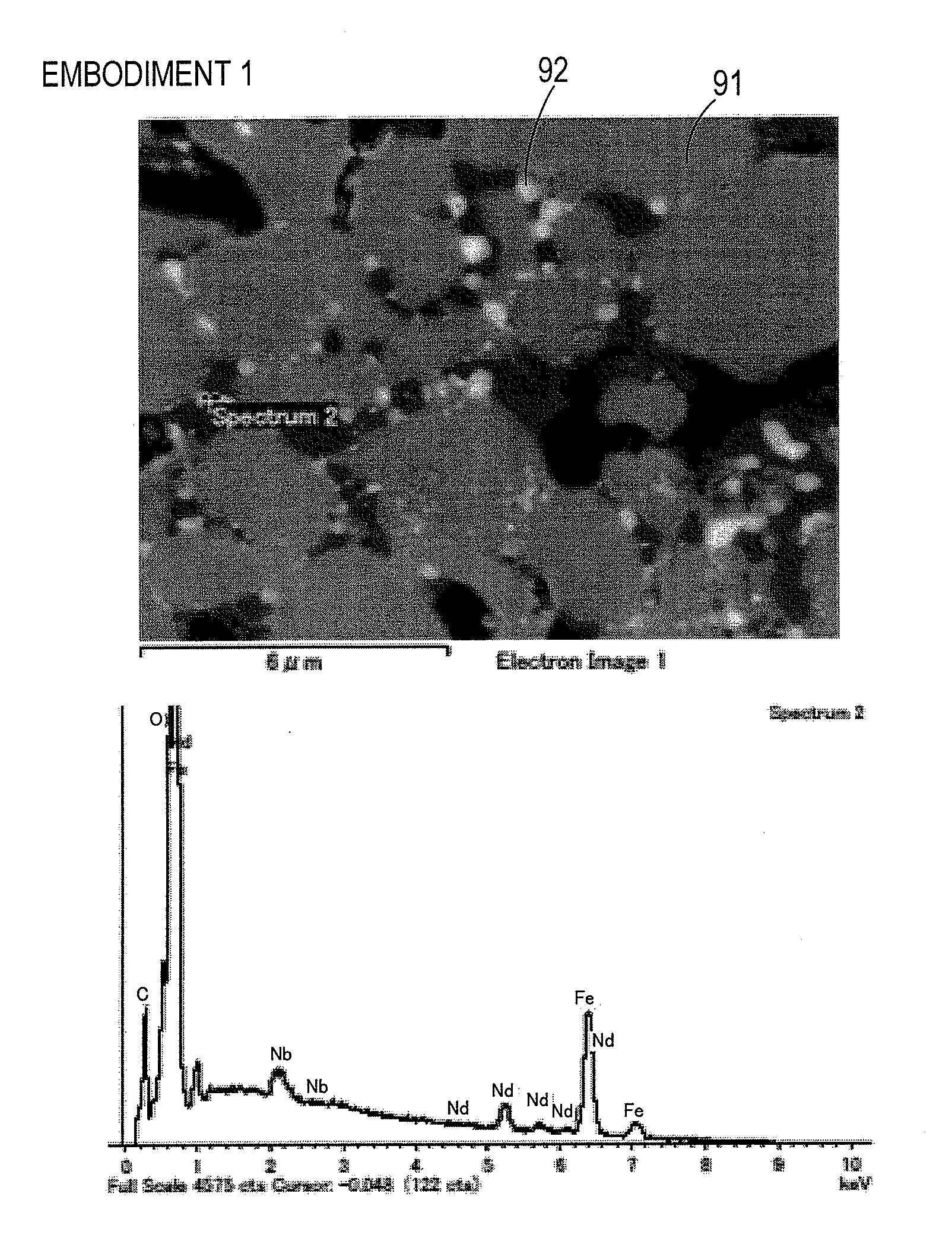

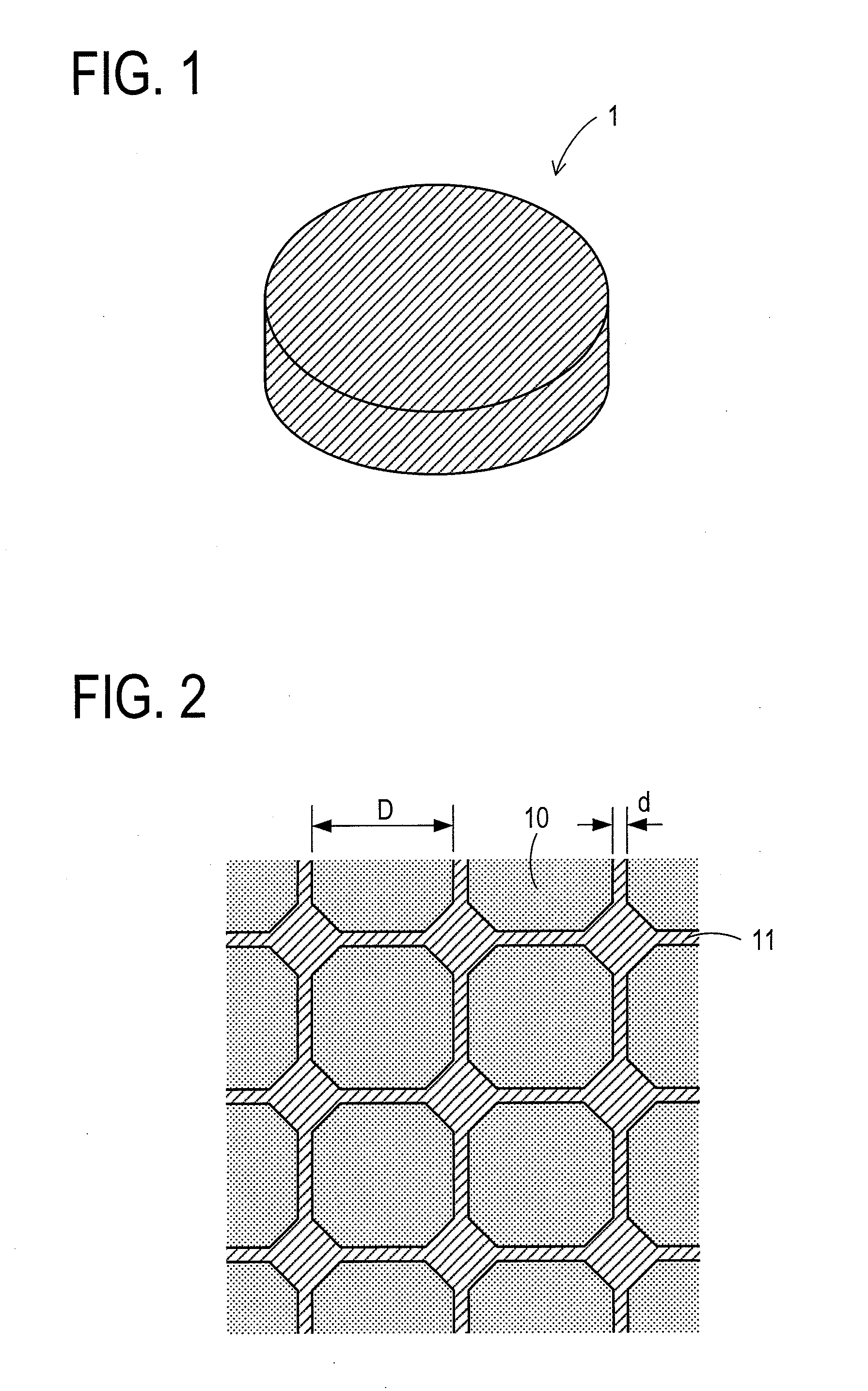

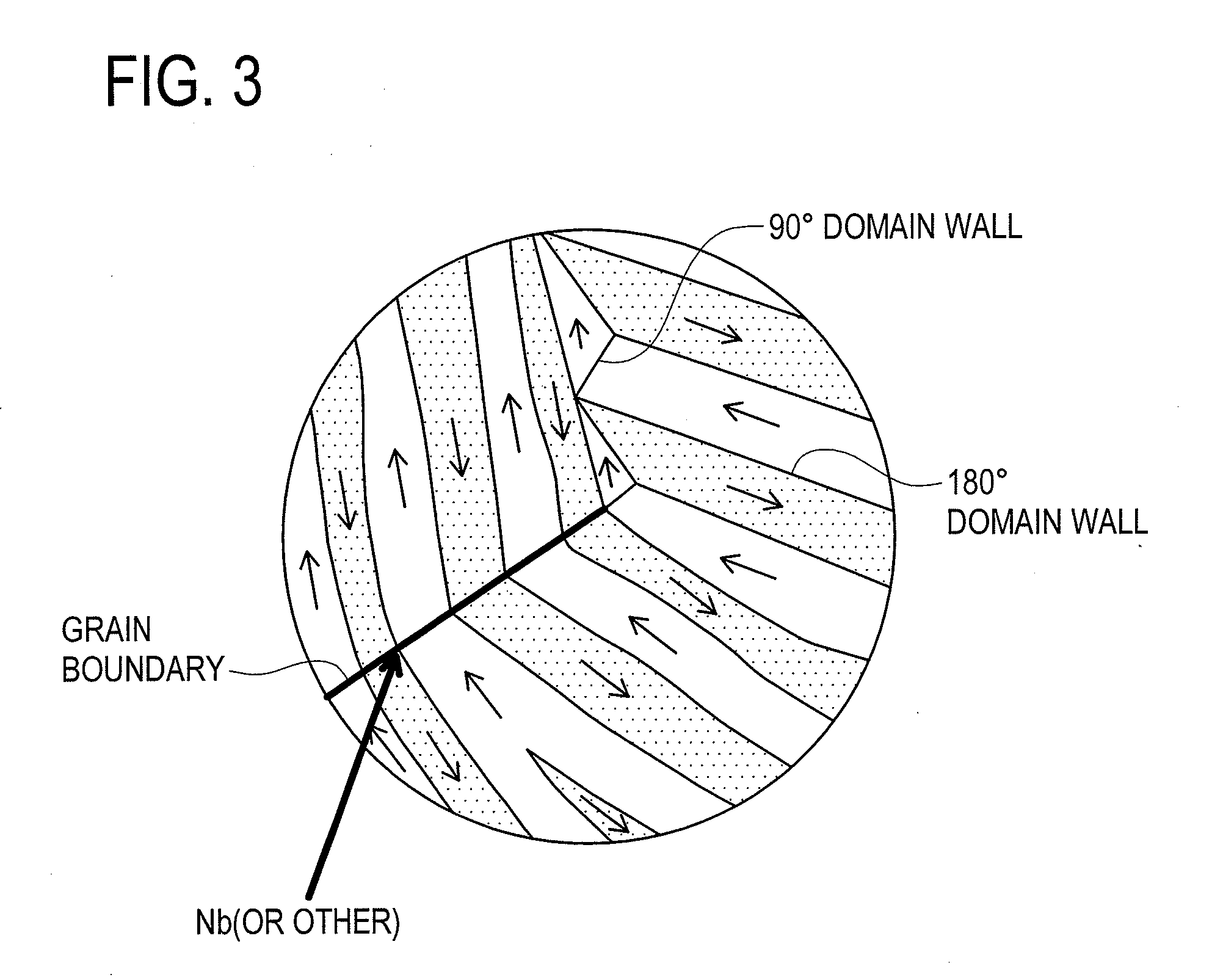

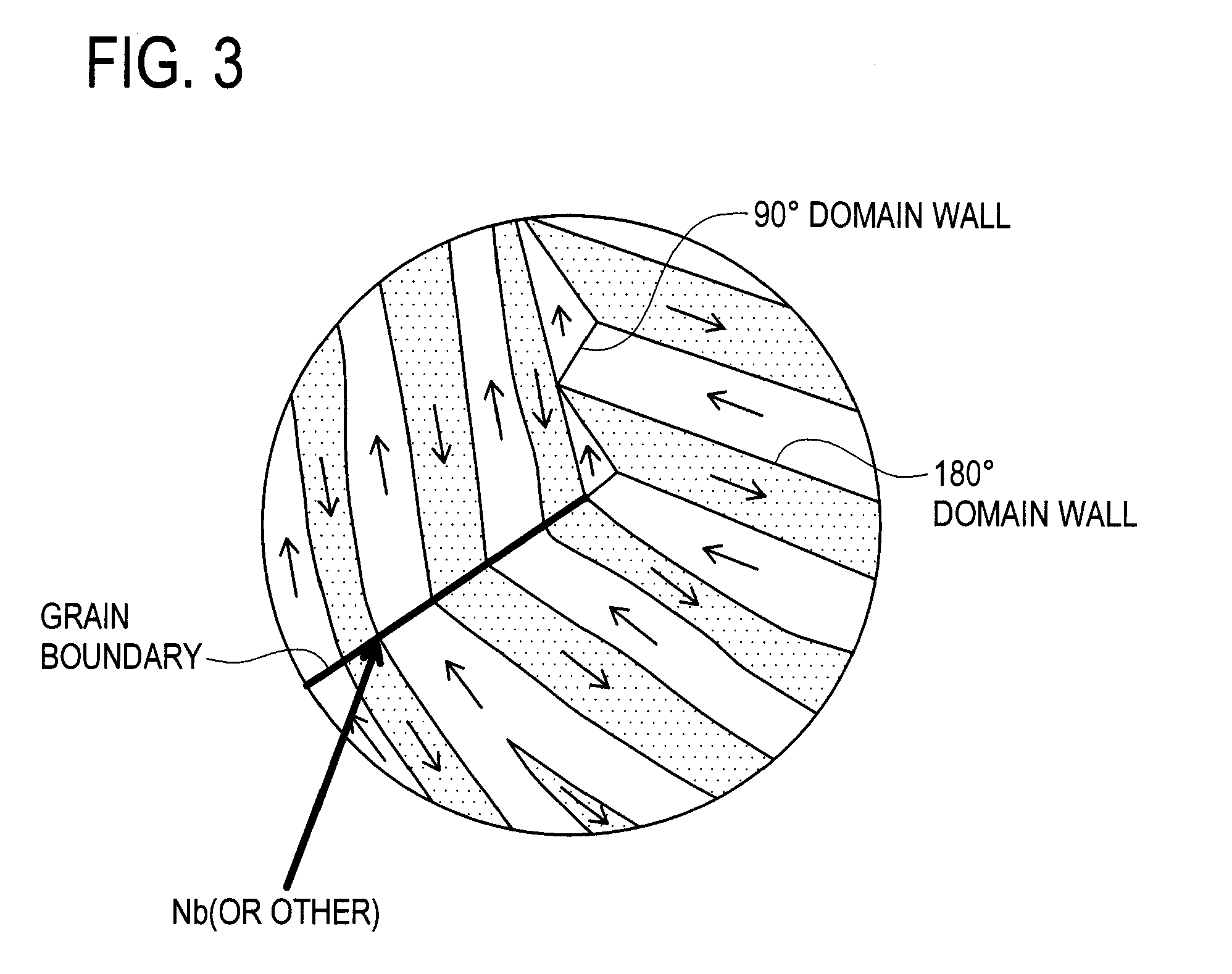

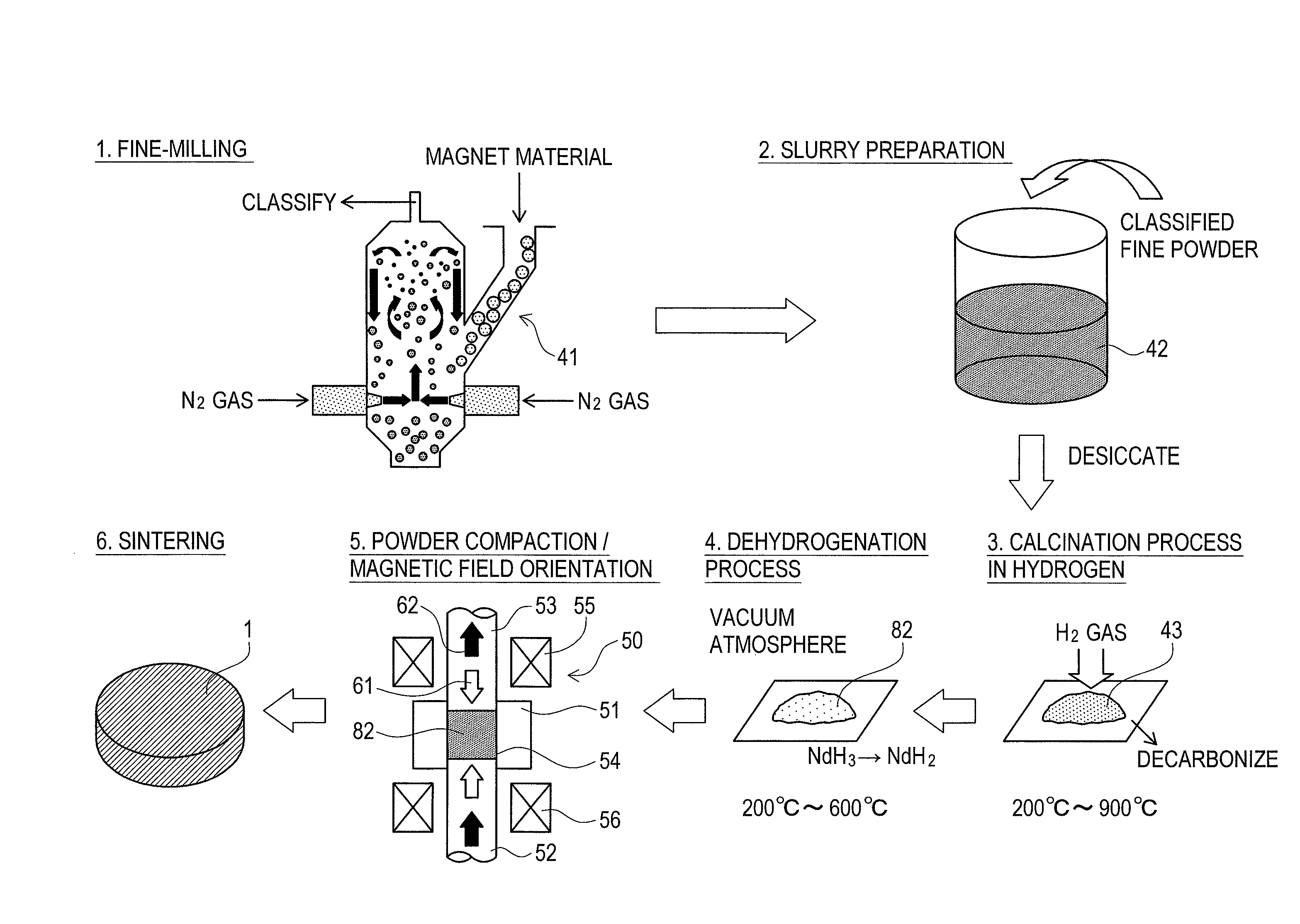

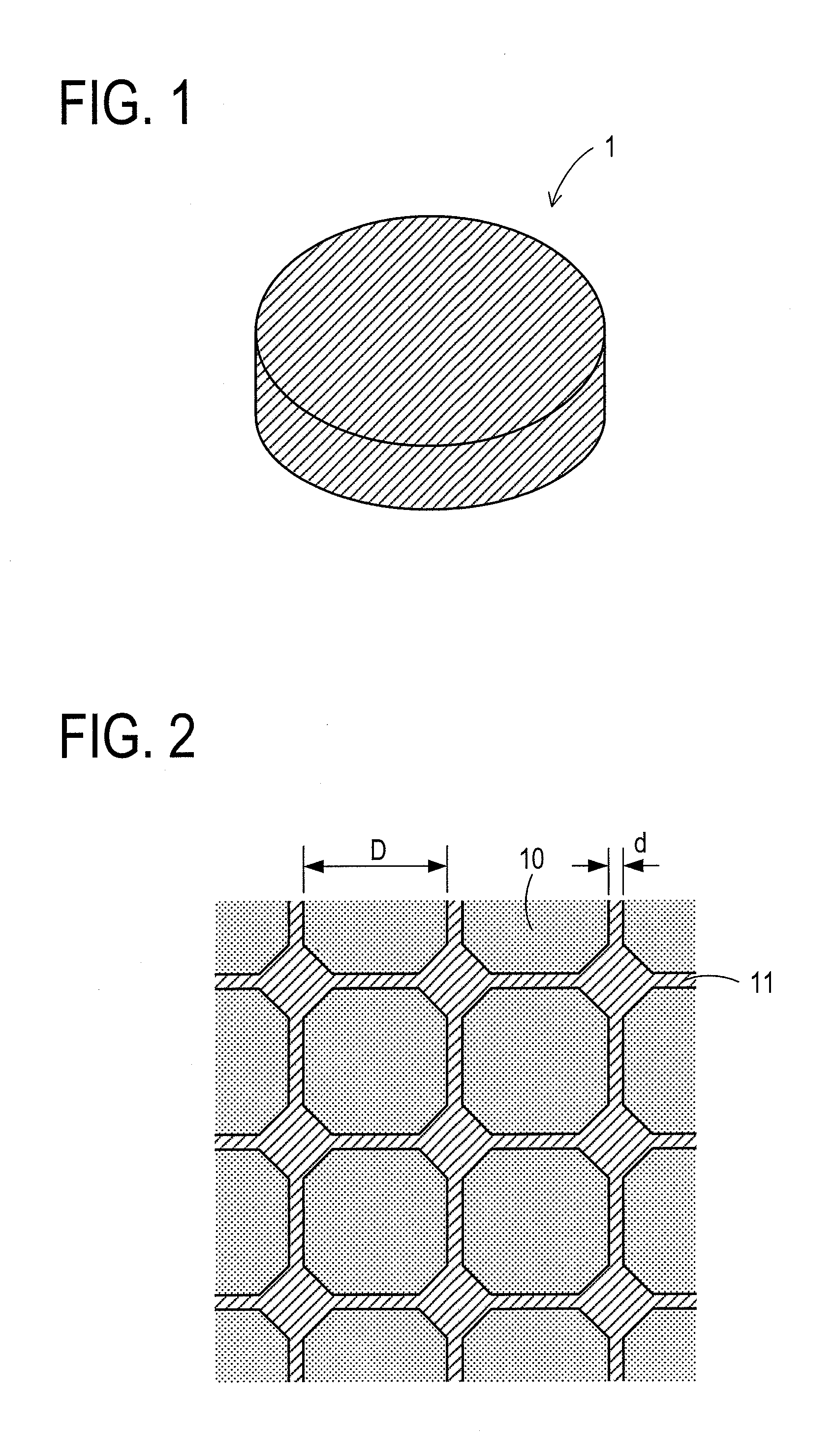

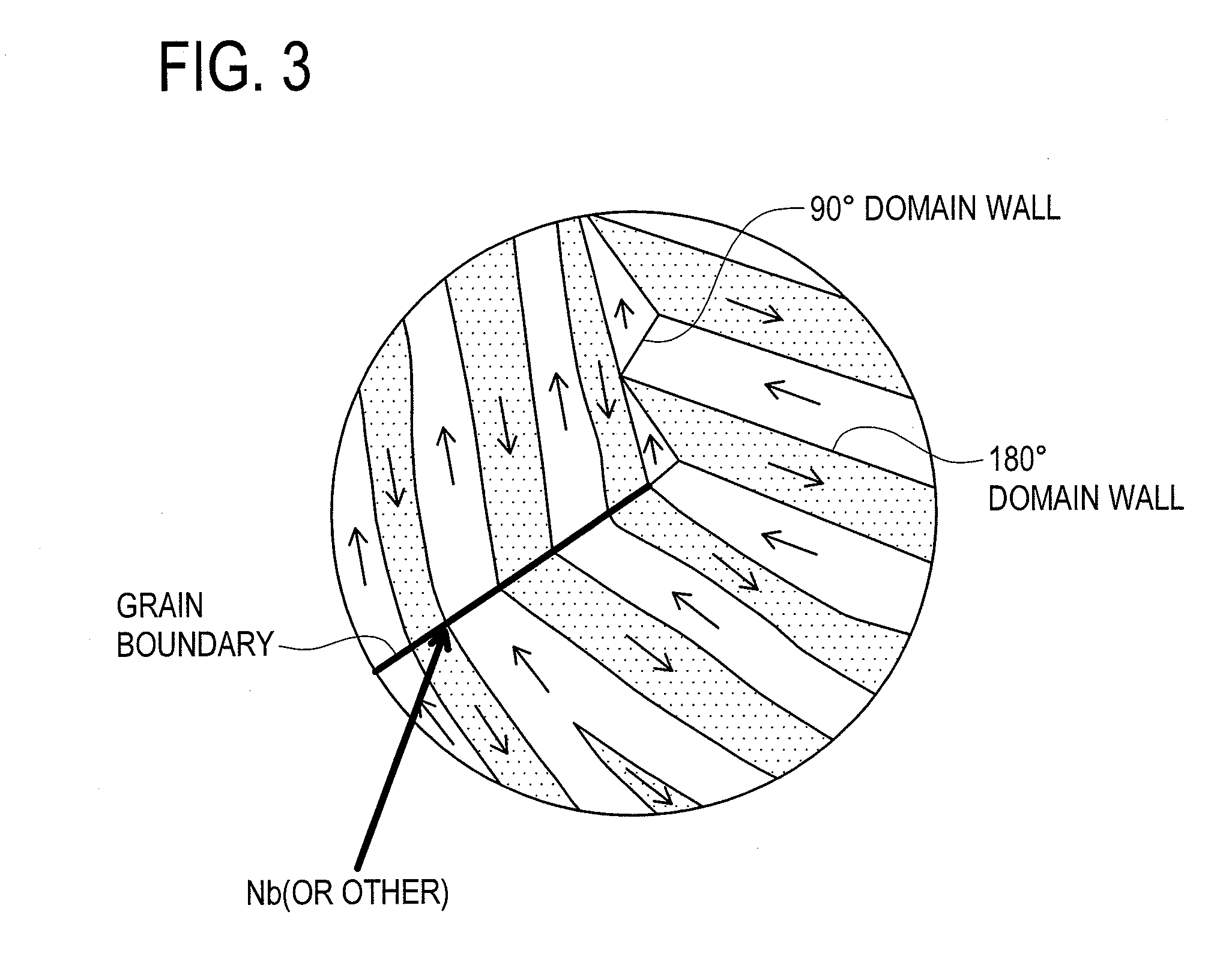

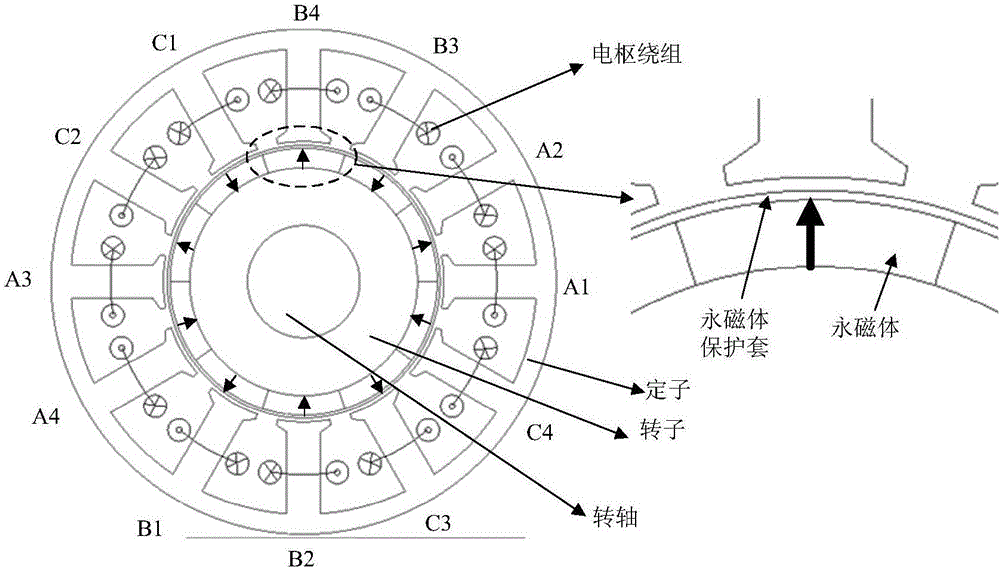

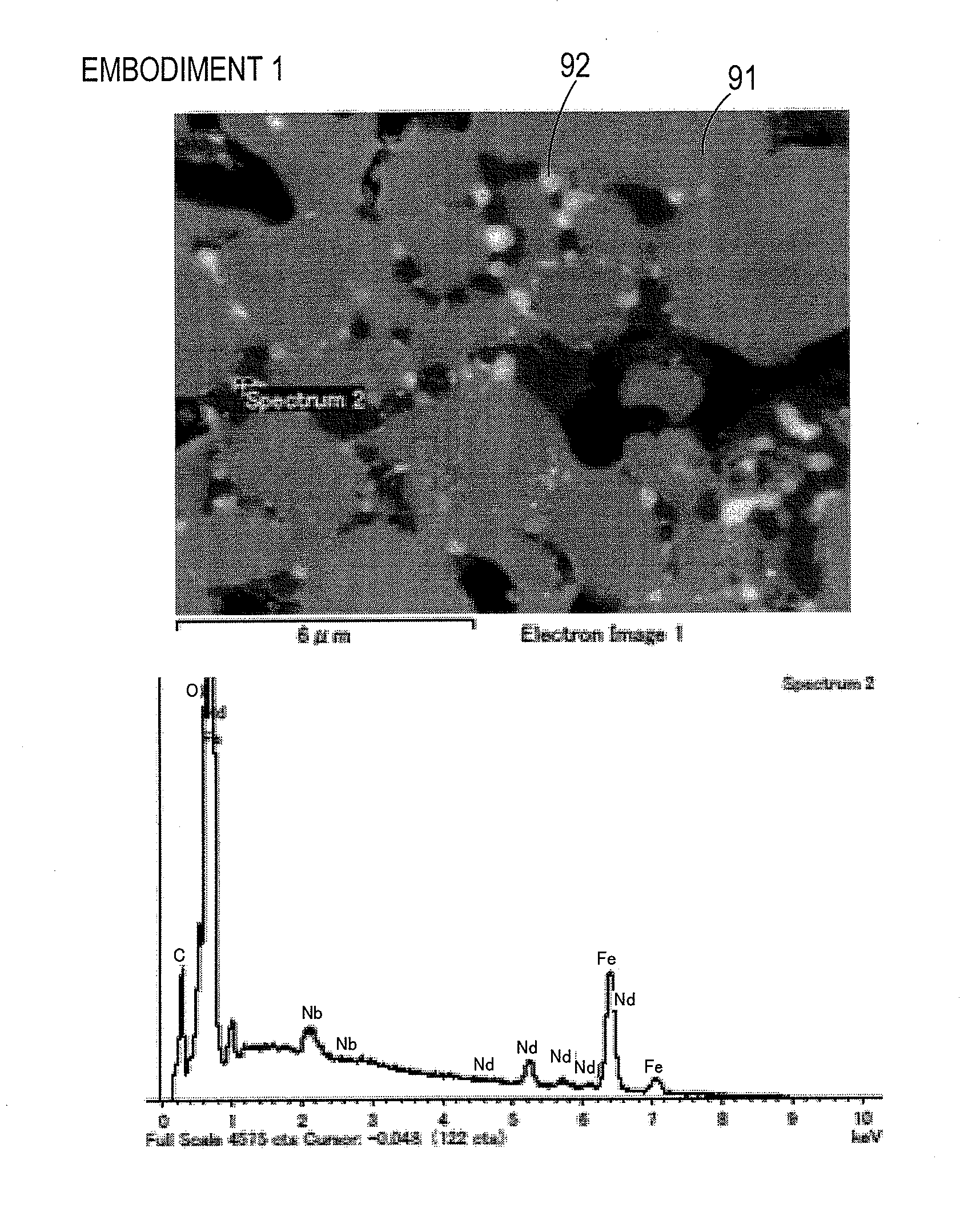

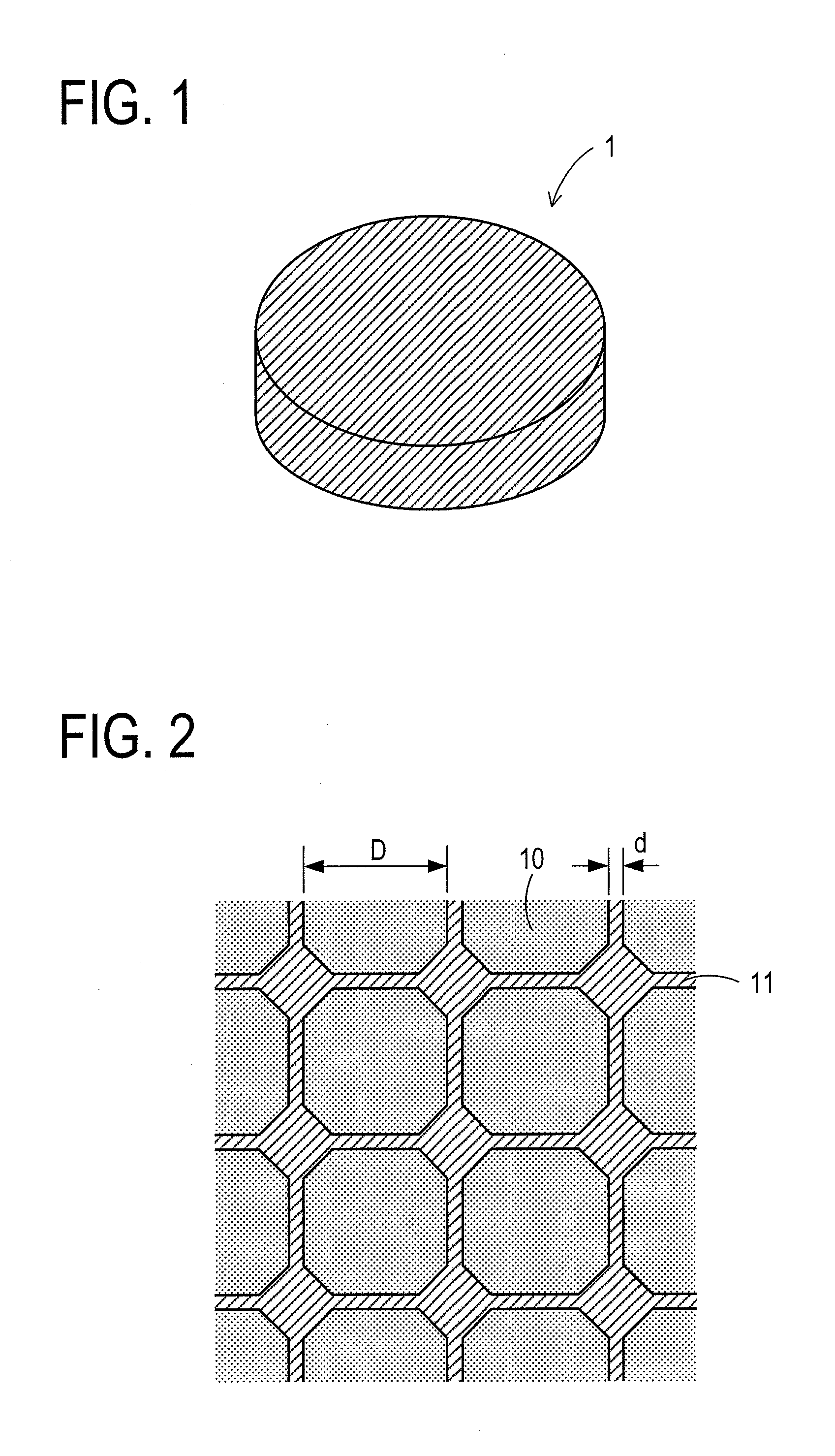

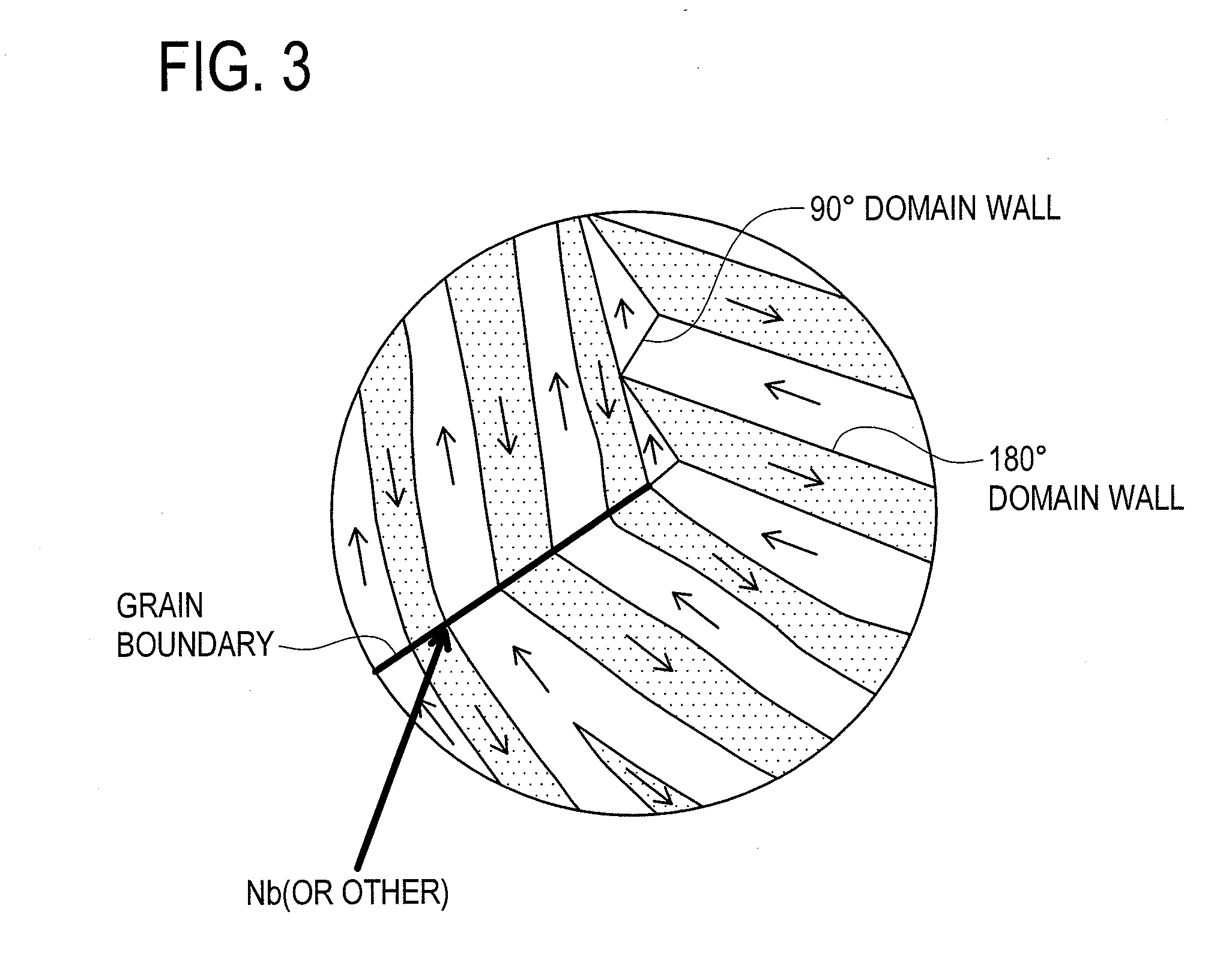

Permanent magnet and manufacturing method thereof

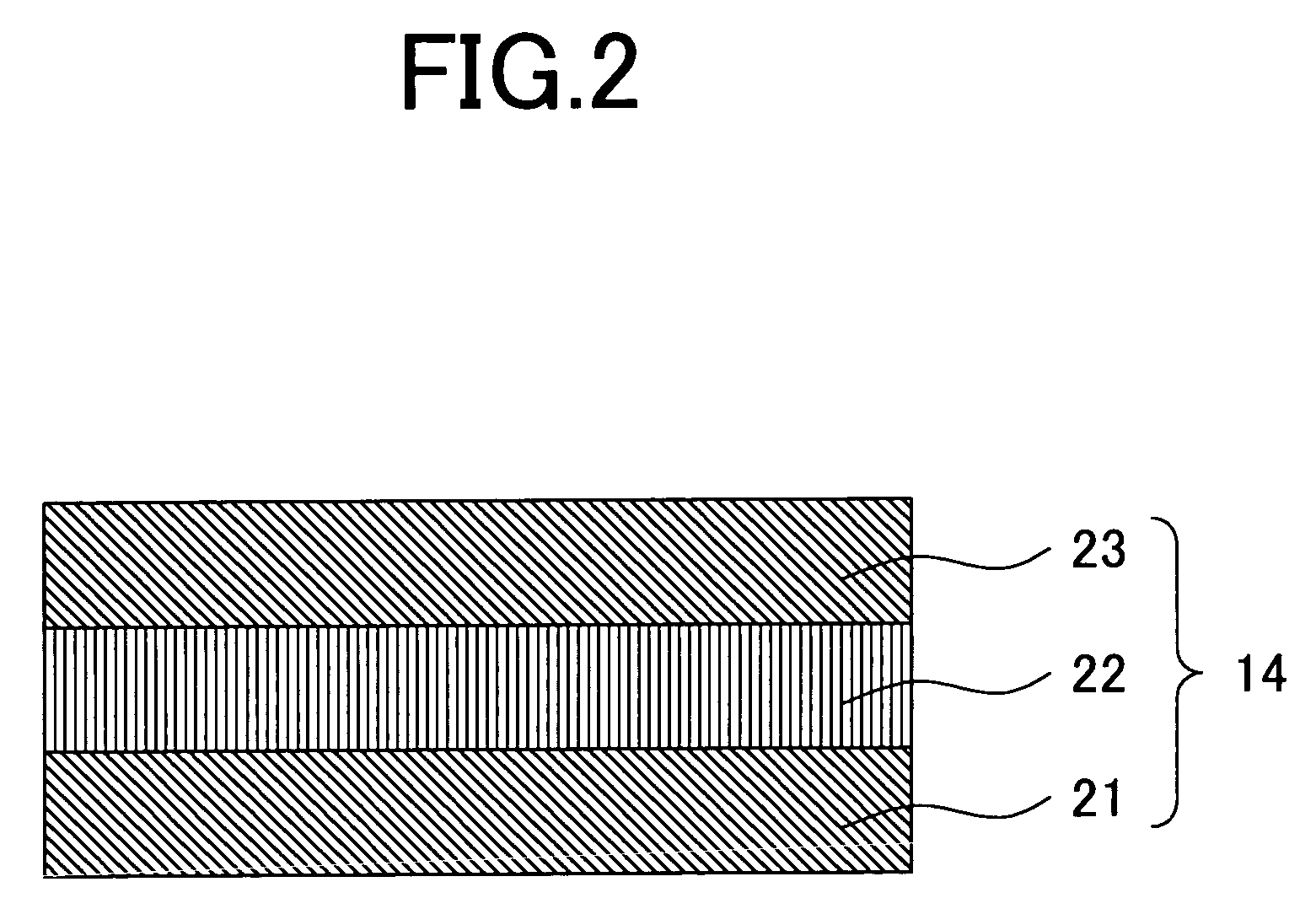

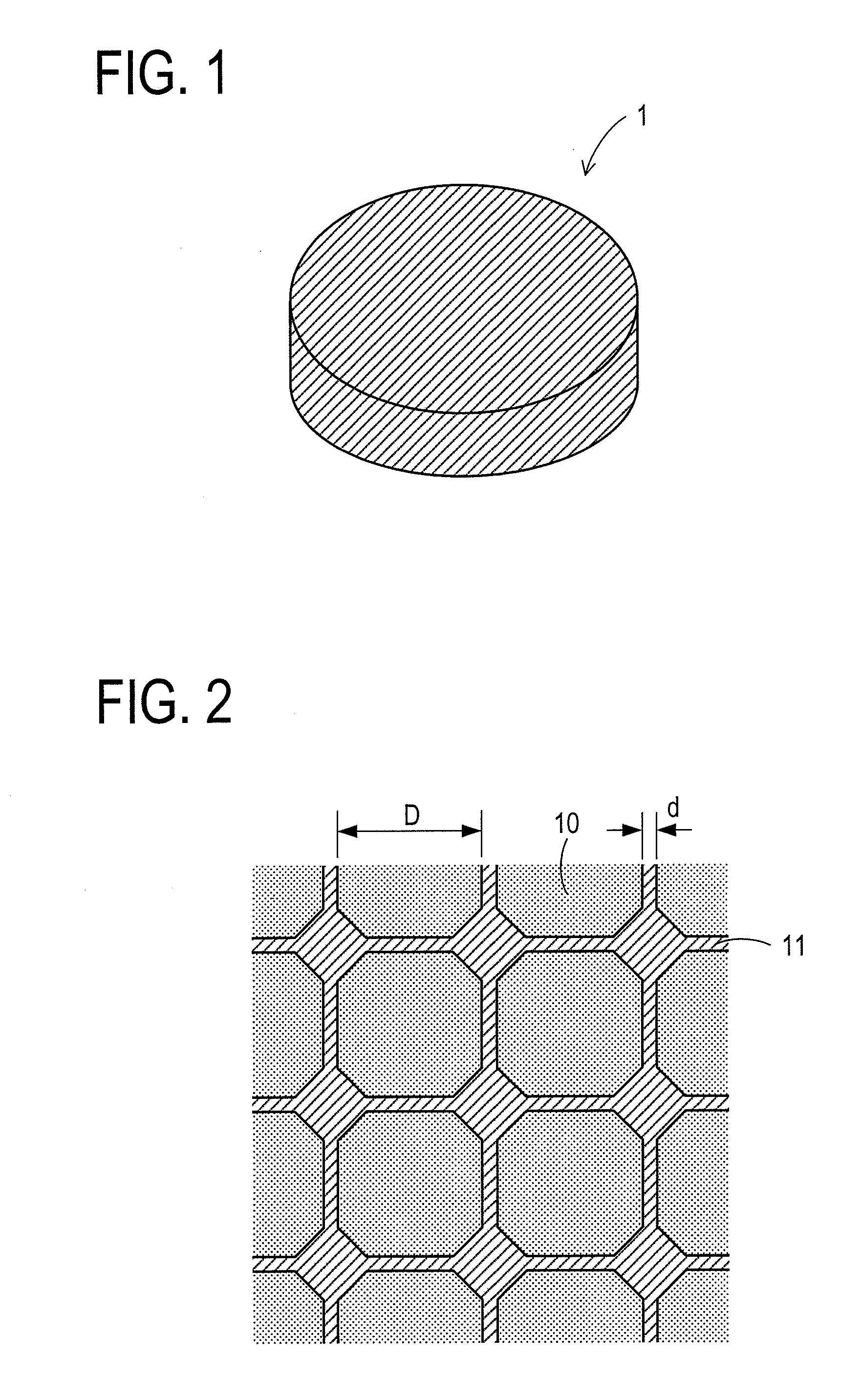

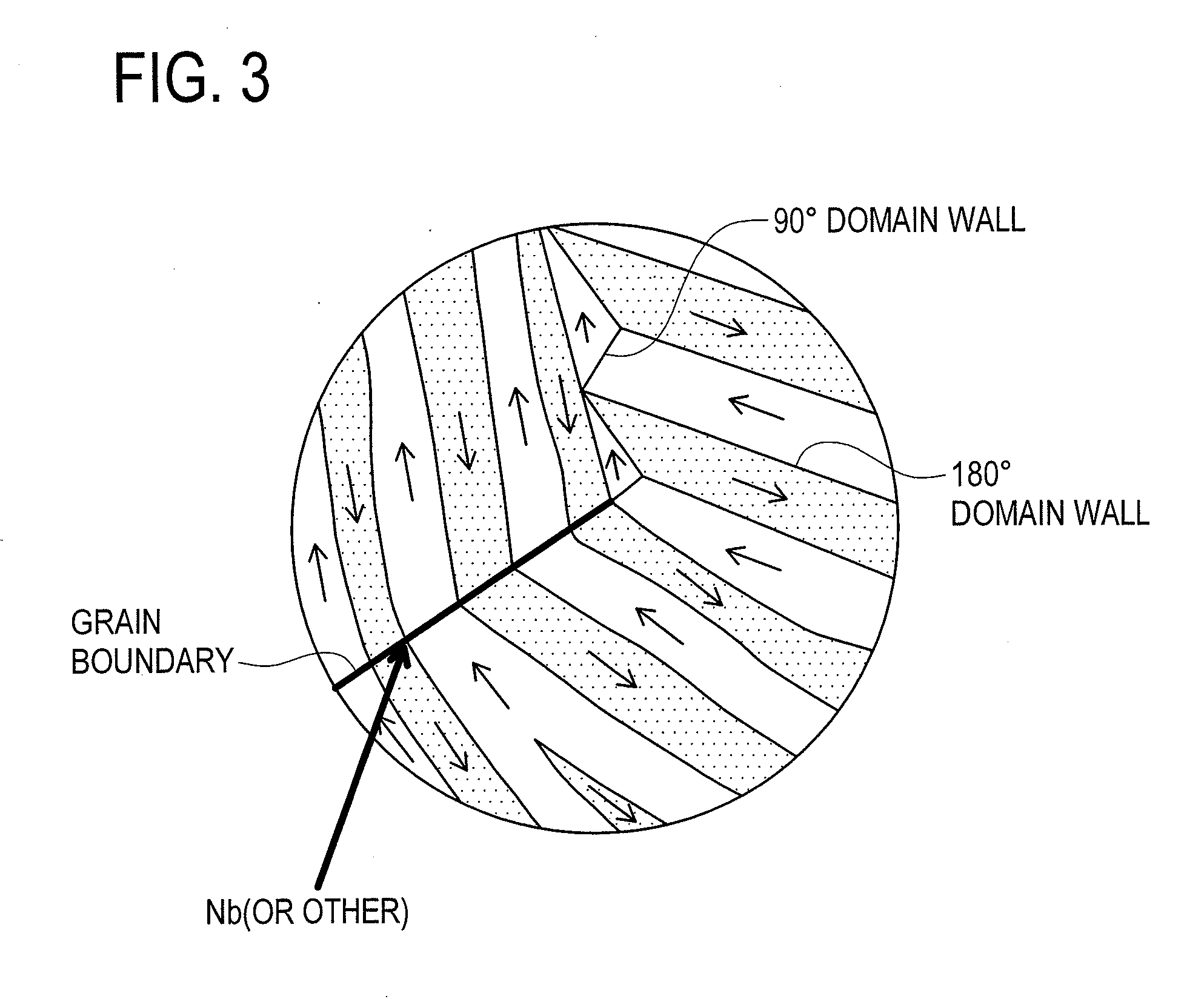

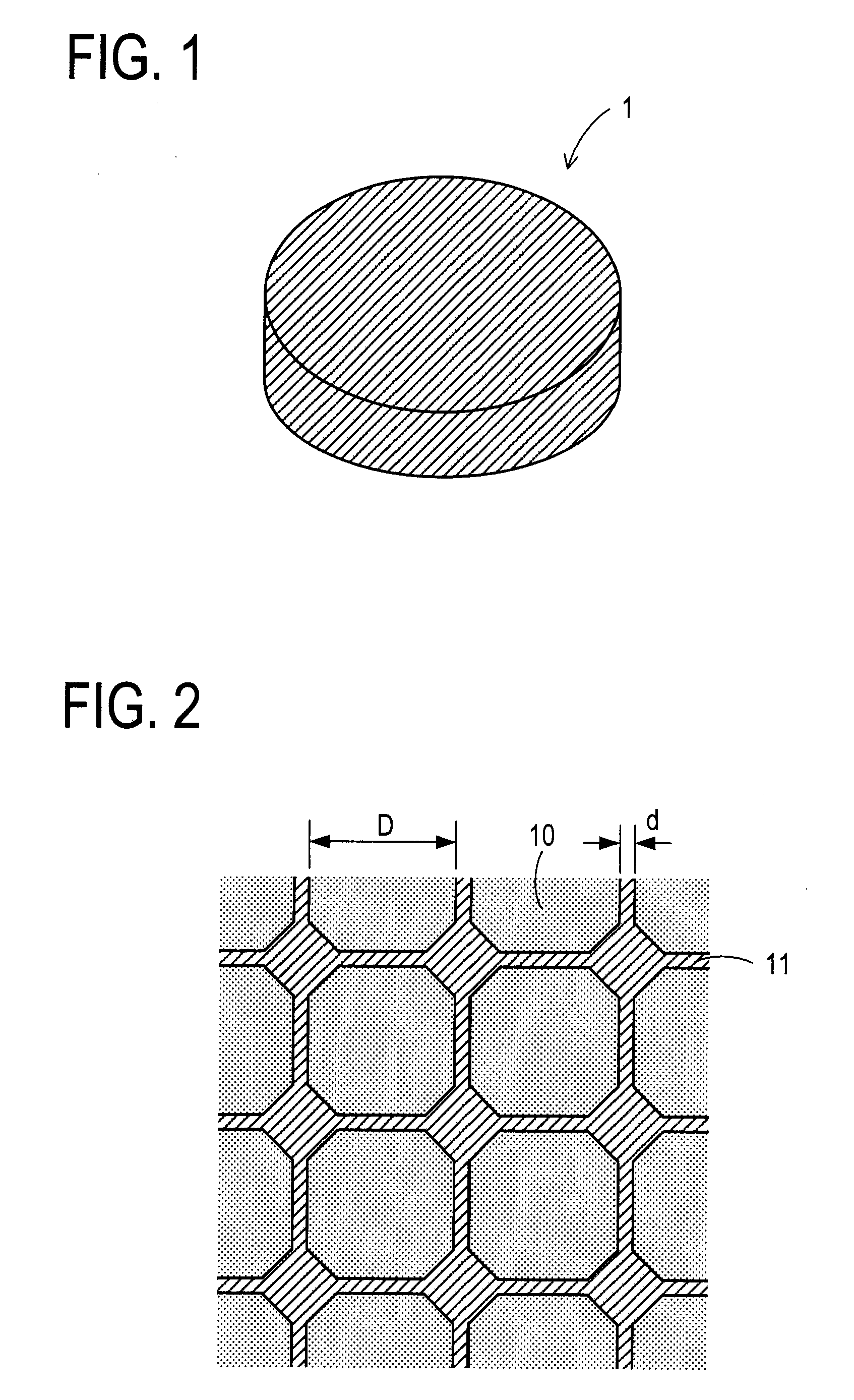

InactiveUS20120182109A1Residual magnetic flux density decreaseImprove magnetic propertiesTransportation and packagingMetal-working apparatusNeodymium magnetStructural formula

There are provided a permanent magnet and a manufacturing method thereof capable of inhibiting grain growth of magnet grains having single domain particle size during sintering so as to improve magnetic properties. To fine powder of milled neodymium magnet is added an organometallic compound solution containing an organometallic compound expressed with a structural formula of M-(OR)x (M represents V, Mo, Zr, Ta, Ti, W or Nb, R represents a substituent group consisting of a straight-chain or branched-chain hydrocarbon, x represents an arbitrary integer) so as to uniformly adhere the organometallic compound to particle surfaces of the neodymium magnet powder. Thereafter, the desiccated magnet powder is calcined by utilizing plasma heating and the powdery calcined body is sintered so as to form a permanent magnet 1.

Owner:NITTO DENKO CORP

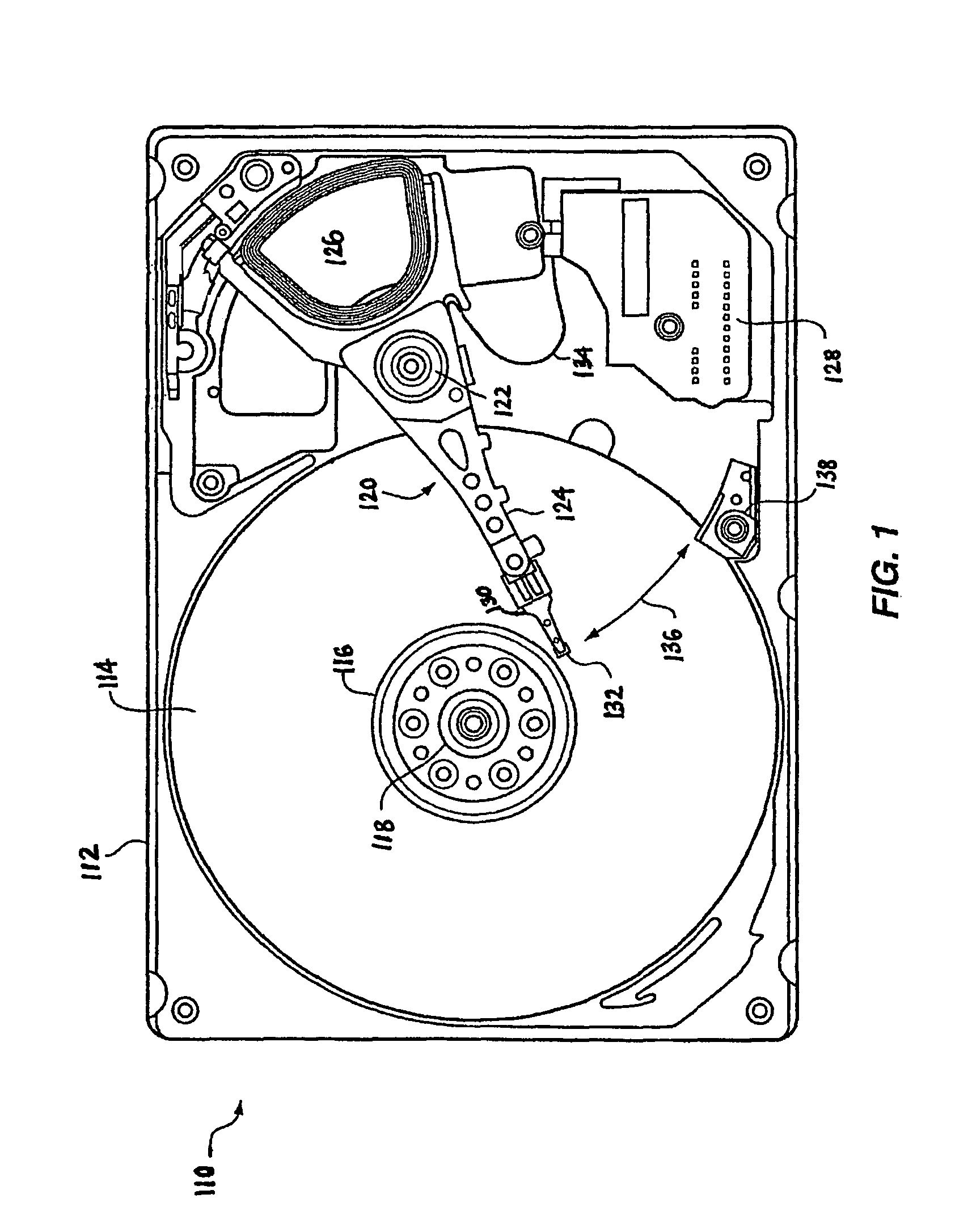

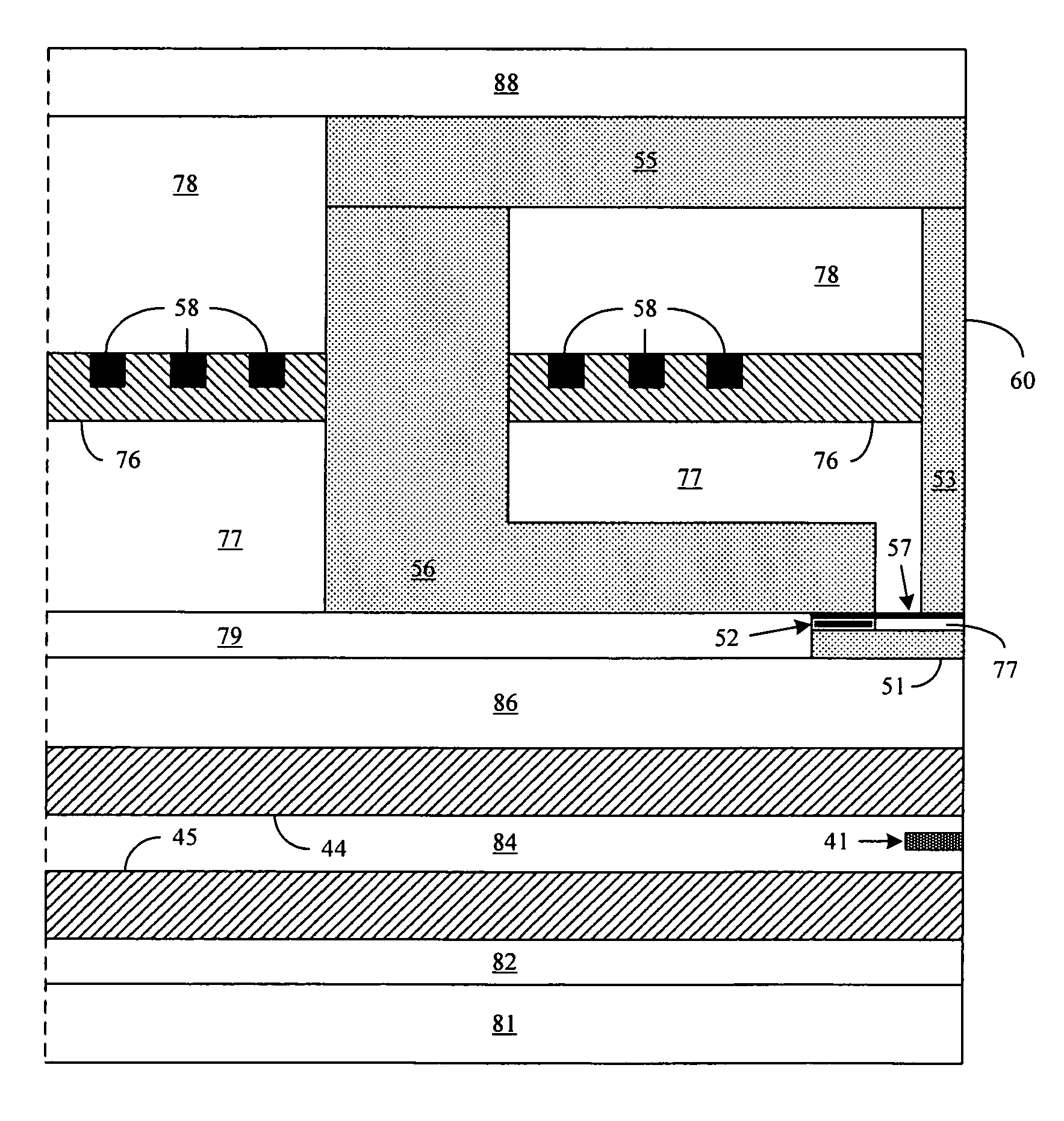

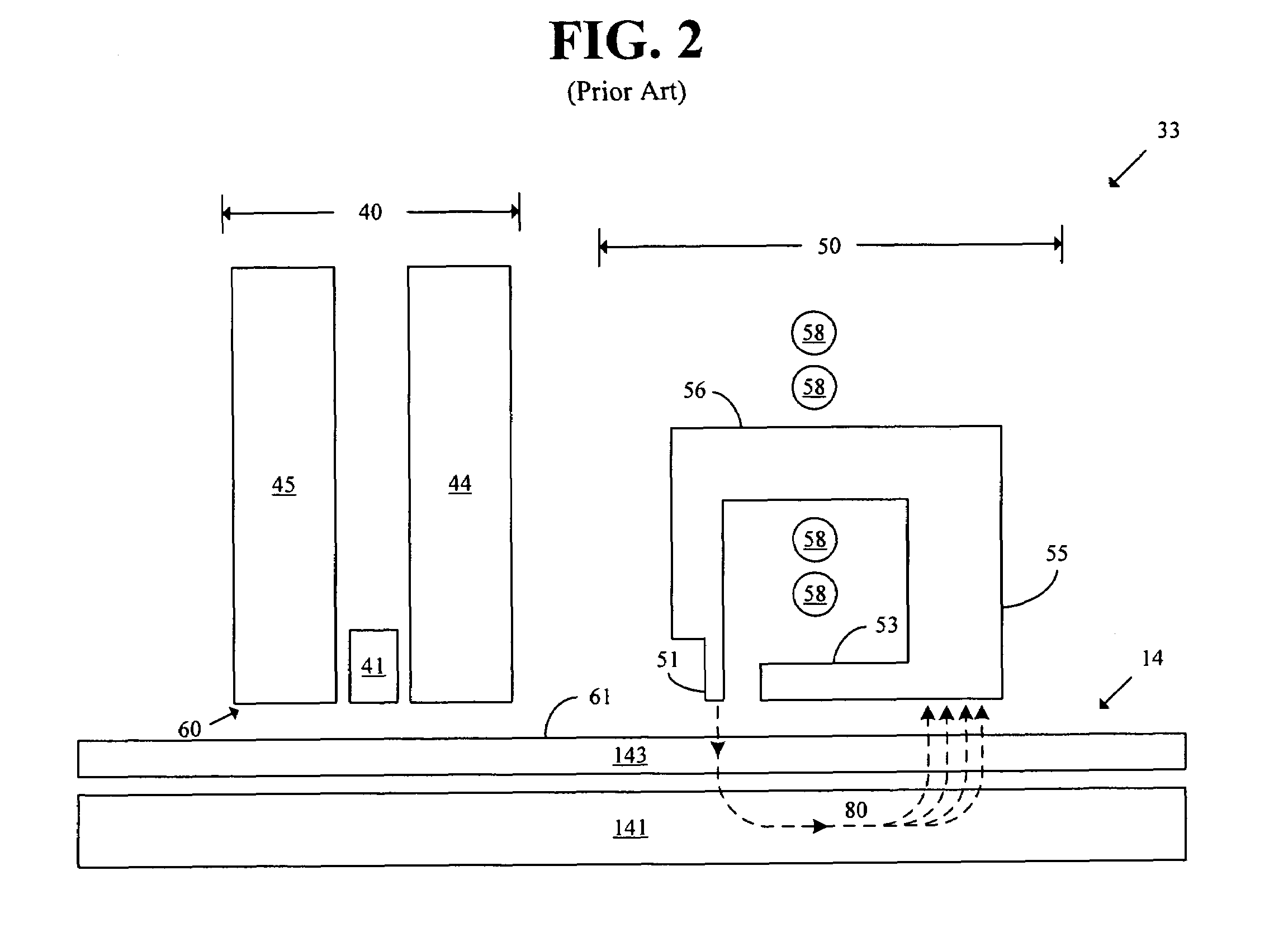

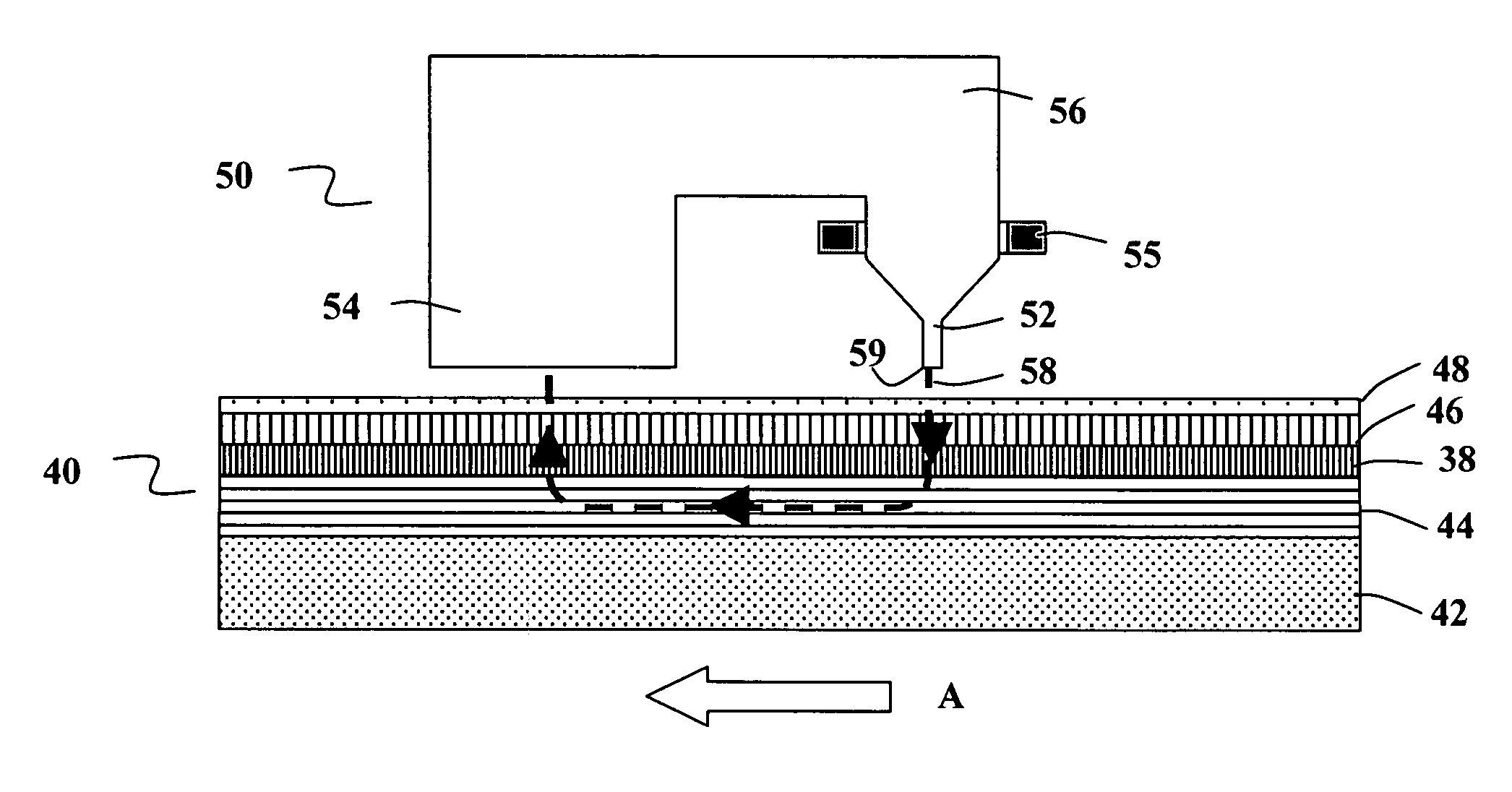

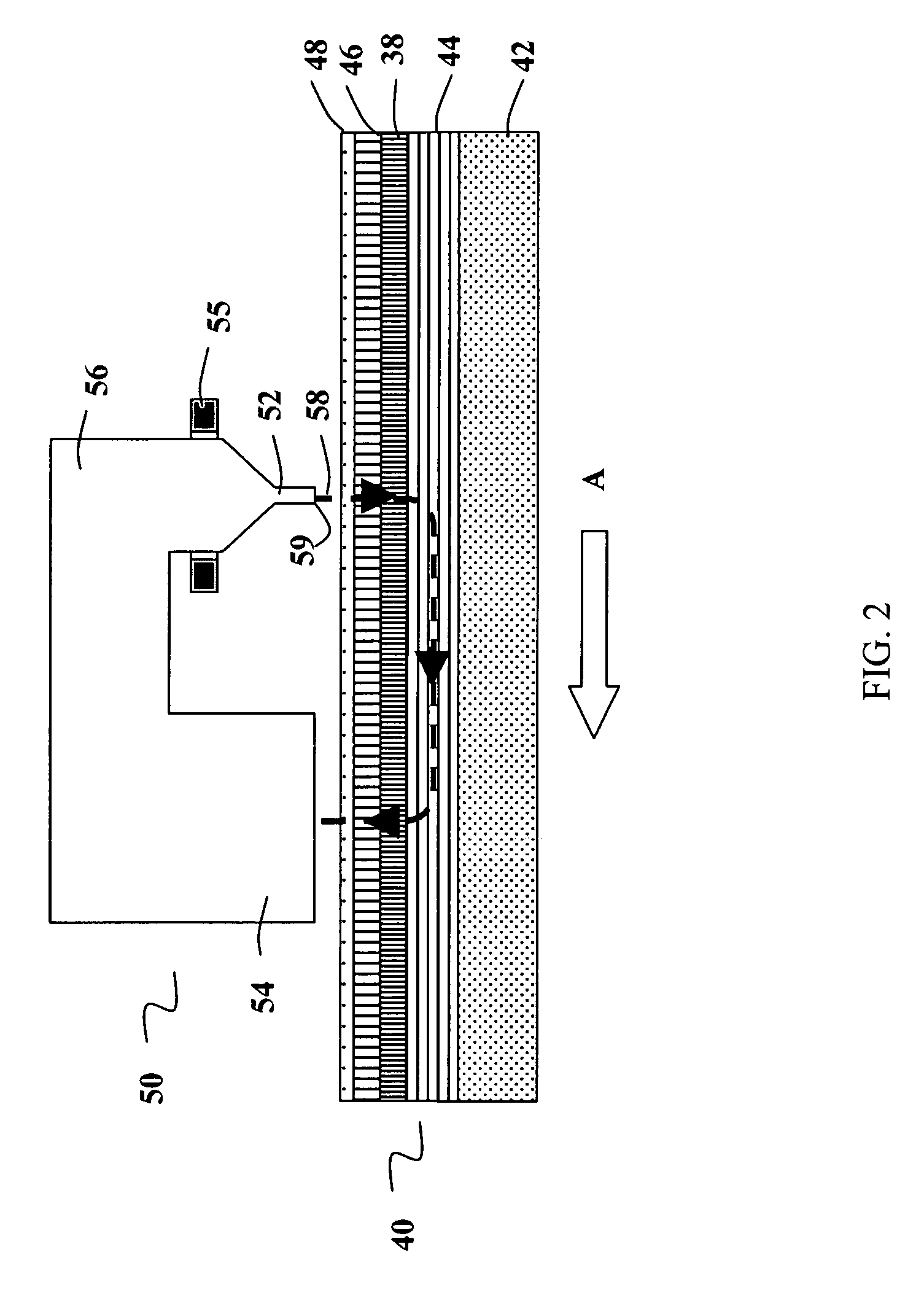

Magnetic heads disk drives and methods with floating pole tip or shunted pole tip for reduced pole tip erasure

InactiveUS7688544B1Minimize impactAvoid magnetizationManufacture head surfaceRecord information storageResidual magnetic fieldMagnetic poles

A write head includes a write return yoke, a write yoke connected to the write return yoke, conductive coils surrounding the write yoke, a write pole tip, and a non-magnetic spacer connecting the write pole tip to the write yoke. The non-magnetic spacer allows for reducing a magnetization of the write pole tip due to a remnant magnetic field in the write yoke. In another embodiment, the write head comprises a write shield, a write return yoke, a write yoke, conductive coils, a write pole tip, and a saturable yoke shunt connecting the write pole tip and the write shield. The saturable yoke shunt directs a limited amount of magnetic flux from the write pole tip to the write shield, such that when there is a remnant magnetic field in the write pole tip, the magnetic flux is directed to the write shield rather than to a disk.

Owner:SEAGATE TECH LLC

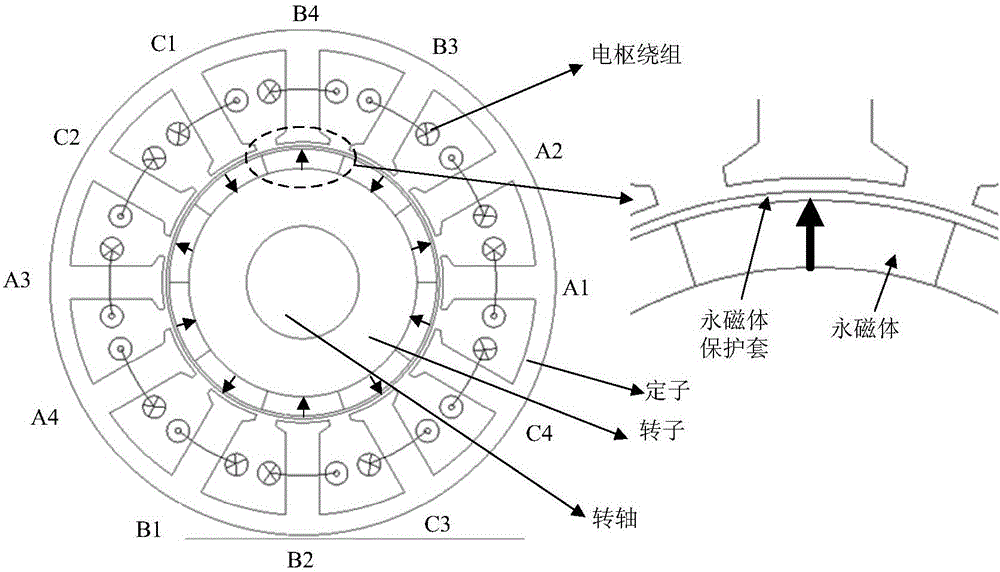

Segmented rotor consequent pole permanent magnet motor

InactiveCN106505760AReduce usageImprove fastnessMagnetic circuit rotating partsSurface mountingMagnetization

The invention discloses a segmented rotor consequent pole permanent magnet motor. The segmented rotor consequent pole permanent magnet motor comprises two segments of rotors, wherein the two segments of rotors are connected in an axial direction of the rotors, a surface of each segment of rotor is provided with multiple convex poles, grooves among the adjacent convex poles are embedded with permanent magnets, a convex pole and permanent magnet alternating arrangement structure is formed on surfaces of the rotors, the shape of the permanent magnets is in matching with the shape of the grooves, each surface of the permanent magnets and each surface of the grooves realize tight contact, upper surfaces of the permanent magnets and upper surfaces of the convex poles are arc-shaped surfaces, radian of the upper surfaces of the permanent magnets and radian of the upper surfaces of the convex poles are identical, all the upper surfaces of the convex poles and all the upper surfaces of the permanent magnets form an integral cylindrical surface, the permanent magnets on the two segments of rotors circumferentially offset for a half electric period angle, magnetizing directions of the permanent magnets on one segment of rotor are identical, and magnetizing directions of the permanent magnets on different segments of rotors are opposite. The segmented rotor consequent pole permanent magnet motor is advantaged in that disadvantages of a traditional surface-mounted permanent magnet motor are solved, permanent magnet materials and protection sleeves are saved, and magnetization of an end portion of a rotation shaft can be avoided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

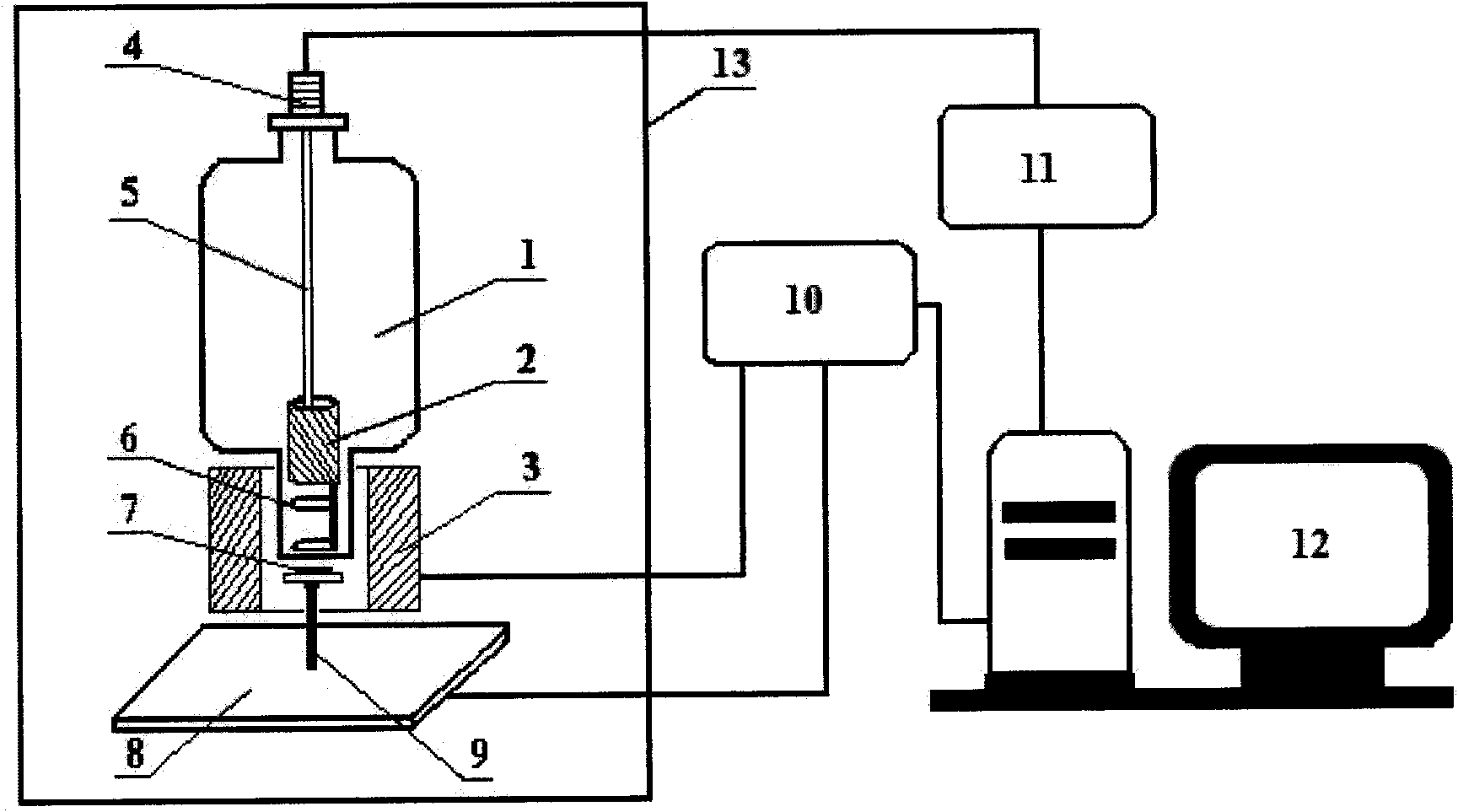

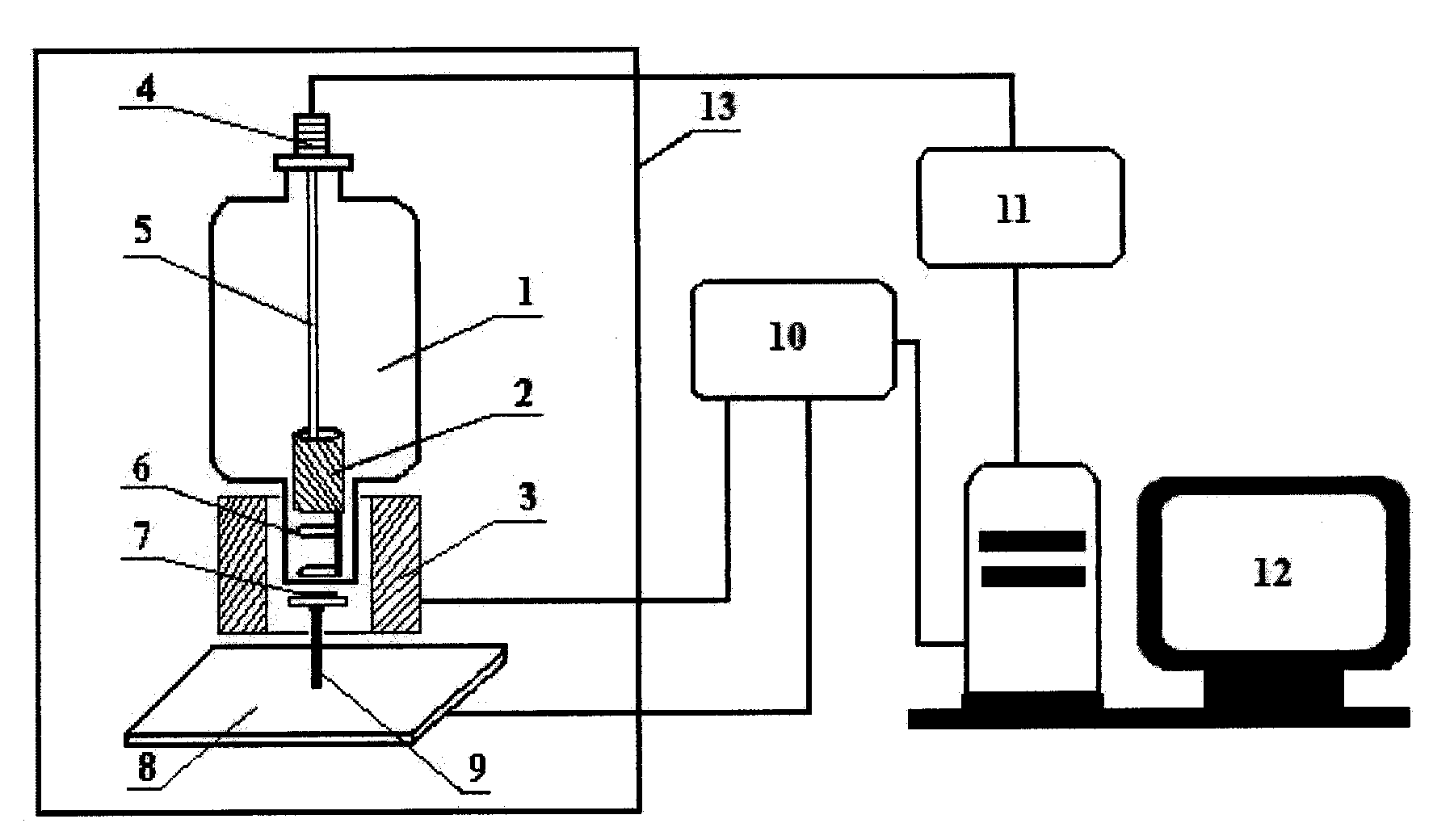

Biological endogenous magnetic particle detection device

InactiveCN101865981ARealize shielding functionPrevent remagnetizationMagnetic property measurementsDc currentControl signal

The invention discloses a biological endogenous magnetic particle detection device. A gradient receiving coil (6) is connected with an input coil of a low-temperature DC superconducting quantum interference device (2); the low-temperature DC superconducting quantum interference device (2) is connected with a preamplifier (4); and the low-temperature DC superconducting quantum interference device (2), the gradient receiving coil (6) and a low-temperature data wire (5) are packaged in a low-temperature non-magnetic Dewar (1). When DC passes through a magnetization and demagnetization unit (3), a static magnetic field is generated to magnetize a biological sample; and when AC passes through the magnetization and demagnetization unit (3), an AC magnetic field is generated to demagnetize the biological sample. A mobile platform and a magnetization and demagnetization unit controller (10) complete control signal acquisition and feedback control of the magnetization and demagnetization unit (3) and the mobile platform (8). The low-temperature non-magnetic Dewar (1), the magnetization and demagnetization unit (3), the magnetic nanoparticle-containing biological sample (7), the mobile platform (8) and a non-magnetic sample holder (9) are arranged in a magnetically shielded room (13).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

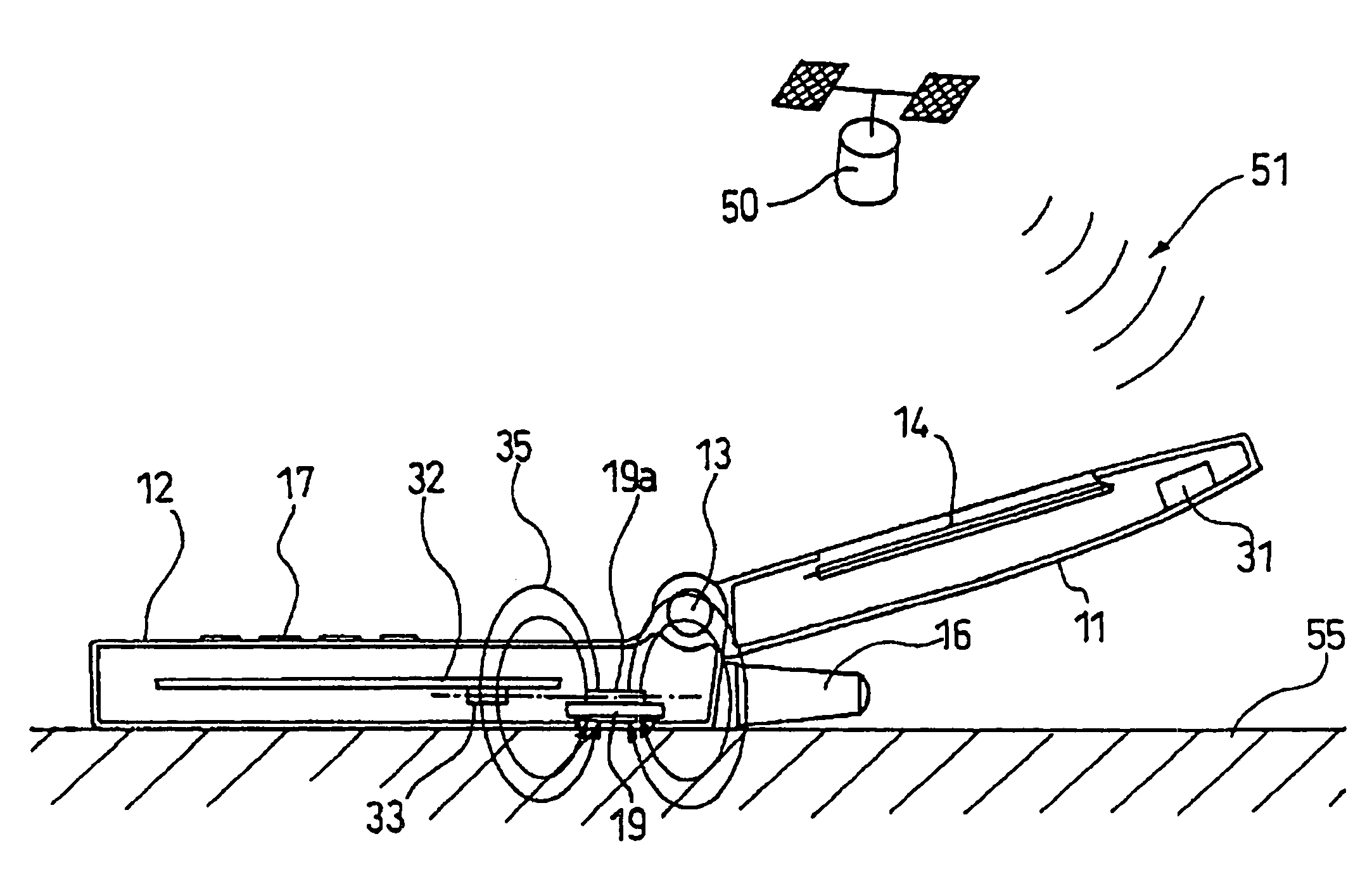

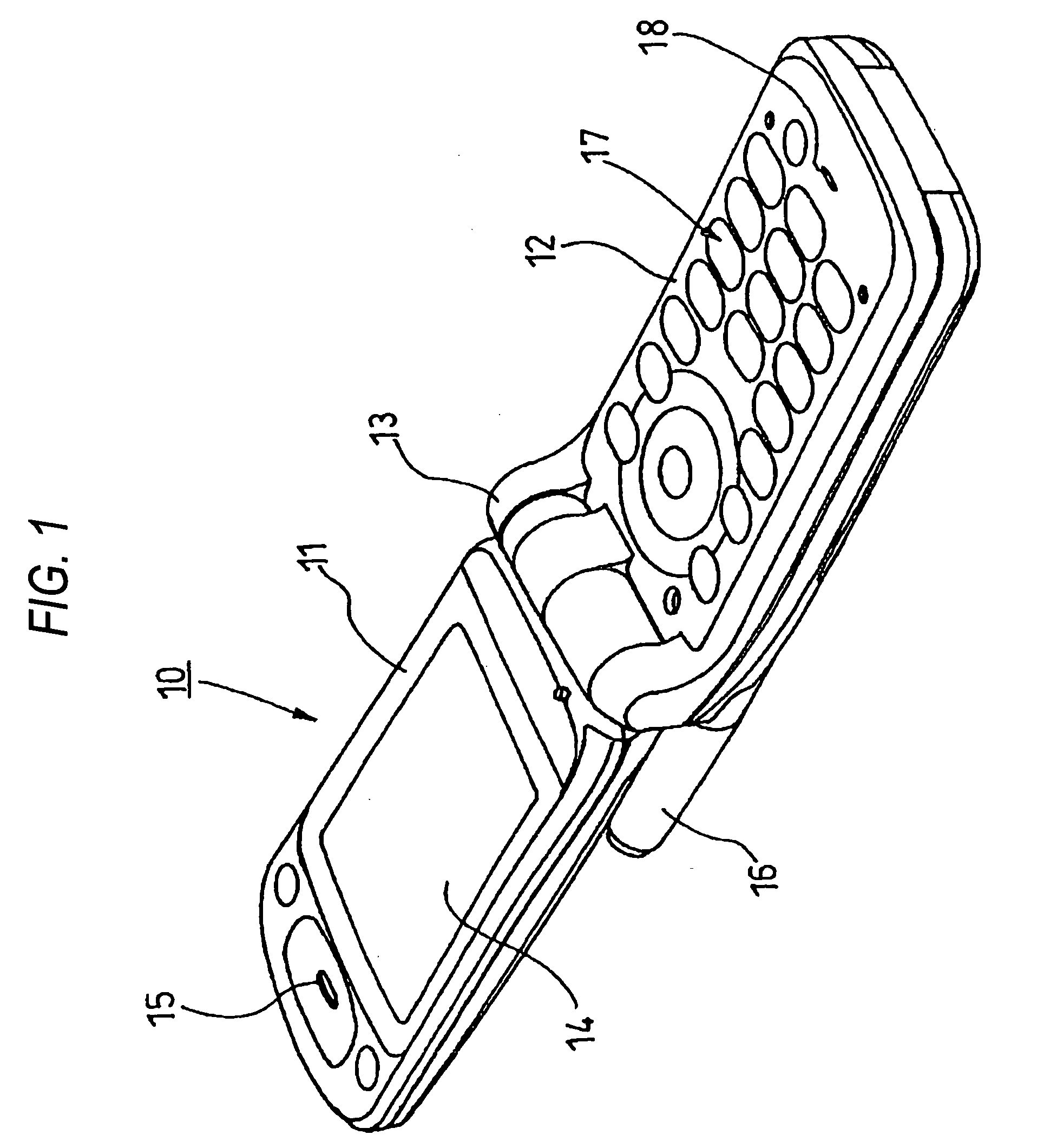

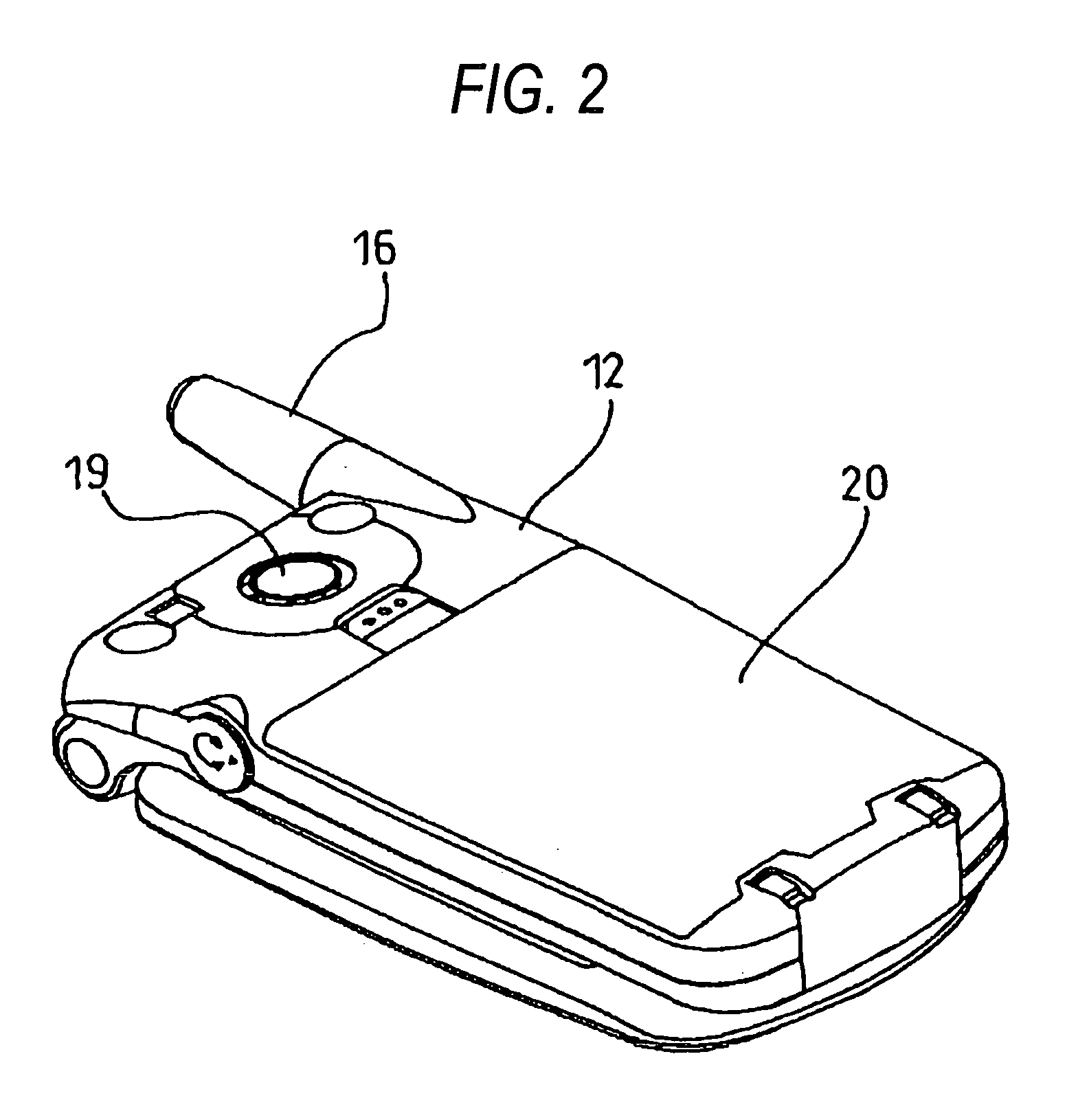

Portable terminal

InactiveUS20050143148A1Superior visibly-recognizable characteristicEasy to operateDevices with GPS signal receiverDevices with sensorForce linesTerminal equipment

the present invention aims to achieve that geomagnetism can be sensed in high precision while eliminating an adverse influence by magnetic noise with respect to a geomagnetic sensor provided in a housing, and correct azimuth information can be acquired. A portable terminal apparatus according to the present invention is arranged by that both a first housing (11) and a second housing (12) are coupled to each other by way of a hinge portion (13) under pivotable condition, a geomagnetic sensor (33) is provided on a circuit board (32) in the second housing (12), and also, a speaker (19) is provided on the side of a rear surface thereof. Both this geomagnetic sensor (33) and a speaker (19) corresponding to a component for generating magnetic noise which gives an adverse influence with respect to the geomagnetic sensor (33) are provided in the vicinity of each other within the same second housing (12), and both the members are arranged on the same plane. In this structure, since a magnetic force line (35) which is caused by magnetic noise generated from a magnet (19a) of the speaker (19) is intersected with respect to the geomagnetic sensor (33) at a right angle, and thus, a horizontal direction component thereof is not produced, the geomagnetic sensor (33) can correctly sense the geomagnetism without being adversely influenced by the magnetic noise.

Owner:PANASONIC CORP

Permanent magnet and manufacturing method thereof

InactiveUS20120182107A1Improve magnetic propertiesResidual magnetic flux density decreaseTransportation and packagingMetal-working apparatusNeodymium magnetCelsius Degree

There are provided a permanent magnet and a manufacturing method thereof that enables concentration of V, Mo, Zr, Ta, Ti, W or Nb contained in an organometallic compound in grain boundaries of the permanent magnet. To fine powder of milled neodymium magnet is added an organometallic compound solution containing an organometallic compound expressed with a structural formula of M-(OR)x (M represents V, Mo, Zr, Ta, Ti, W or Nb, R represents a substituent group consisting of a straight-chain or branched-chain hydrocarbon, x represents an arbitrary integer) so as to uniformly adhere the organometallic compound to particle surfaces of the neodymium magnet powder. Thereafter, a compact body obtained by compacting the magnet powder is held for several hours in hydrogen atmosphere at 200 through 900 degrees Celsius so as to perform a calcination process in hydrogen. Thereafter, through sintering, a permanent magnet is manufactured.

Owner:NITTO DENKO CORP

Thin-film magnetic head having the length of the pinned and antiferromagnetic layers greater than the width dimension thereof and/or the length of the free layer

ActiveUS7190559B2Avoid layeringInclination in the direction of magnetization can be suppressed more effectivelyNanomagnetismDisposition/mounting of recording headsMagnetizationDepth direction

Owner:TDK CORPARATION

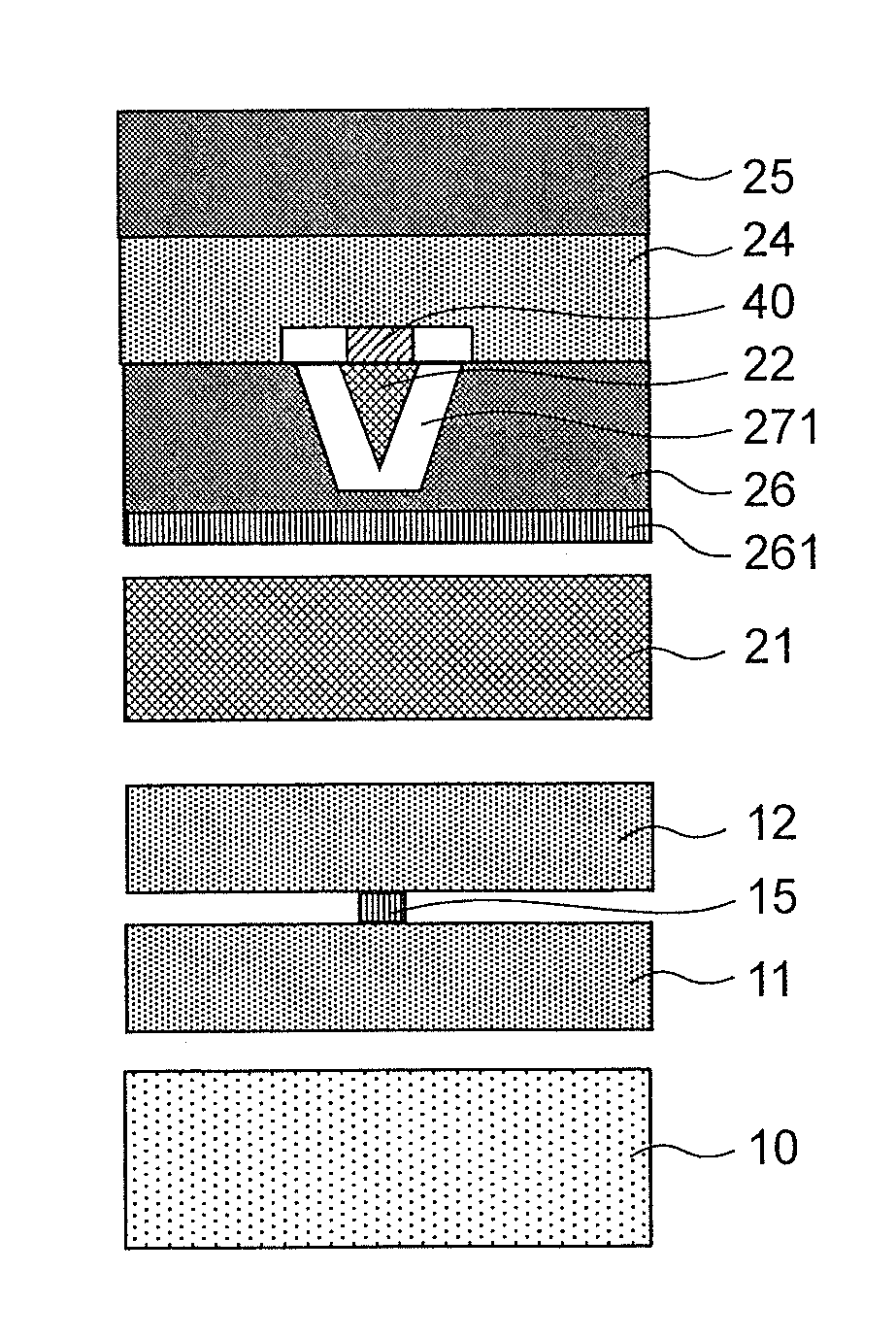

Perpendicular magnetic recording medium and magnetic recording/reproducing apparatus

InactiveUS7217467B2Avoid relative motionAvoid noiseBase layers for recording layersRecord information storageControl layerA domain

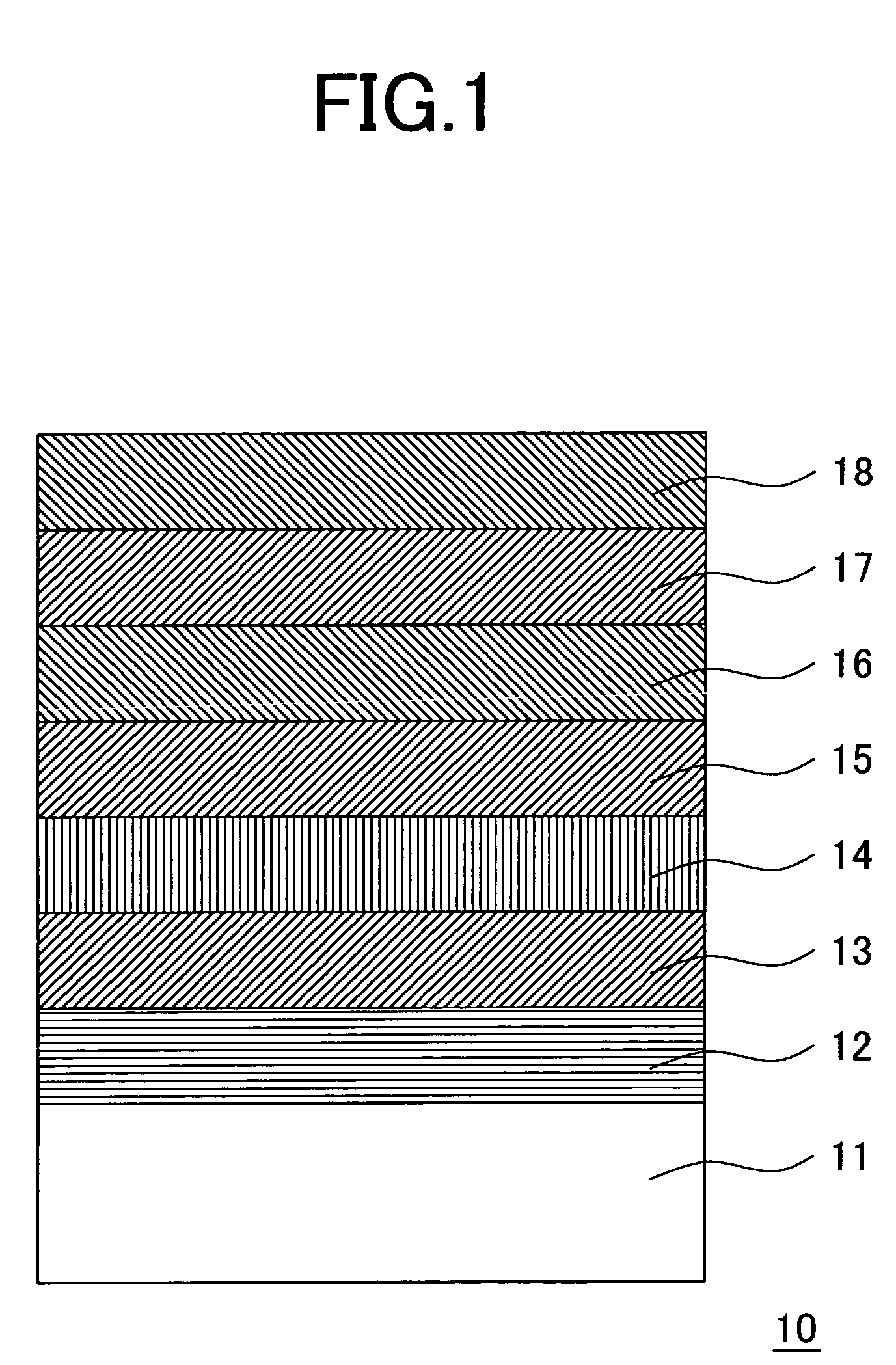

A magnetic recording / reproducing apparatus is disclosed with high storage capability. The apparatus also prevents fluctuation of readback output and decay of magnetization or erasure of recorded magnetization in the recording layer. A soft magnetic underlayer and a perpendicular recording layer are formed in specific order on the substrate of a magnetic disk. The soft magnetic underlayer has a triple-layered structure in which a domain control layer, including an anti-ferromagnetic layer, is sandwiched between two first and second soft magnetic layers. The thickness of the first and second soft magnetic layers (d1, d2) is between 25 nm and 150 nm and a ratio of d1 / d2 is within a range of 0.3 to 1.5. Accordingly, magnetic domains in the soft magnetic underlayer of a perpendicular magnetic recording medium can be controlled and magnetic domain wall motion can be inhibited.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

Permanent magnet and manufacturing method thereof

InactiveUS20120187327A1Improve magnetismResidual magnetic flux density decreaseMagnetic paintsTransportation and packagingNeodymium magnetHydrogen atmosphere

There are provided a permanent magnet and a manufacturing method thereof capable of decreasing an activity level of a calcined body activated by a calcination process. To fine powder of milled neodymium magnet is added an organometallic compound solution containing an organometallic compound expressed with a structural formula of M-(OR)x (M represents V, Mo, Zr, Ta, Ti, W or Nb, R represents a substituent group consisting of a straight-chain or branched-chain hydrocarbon, x represents an arbitrary integer) so as to uniformly adhere the organometallic compound to particle surfaces of the neodymium magnet powder. Thereafter, desiccated magnet powder is held for several hours in hydrogen atmosphere at 200 through 900 degrees Celsius. Thereafter, the powdery calcined body calcined through the calcination process in hydrogen is held for several hours in vacuum atmosphere at 200 through 600 degrees Celsius for a dehydrogenation process.

Owner:NITTO DENKO CORP

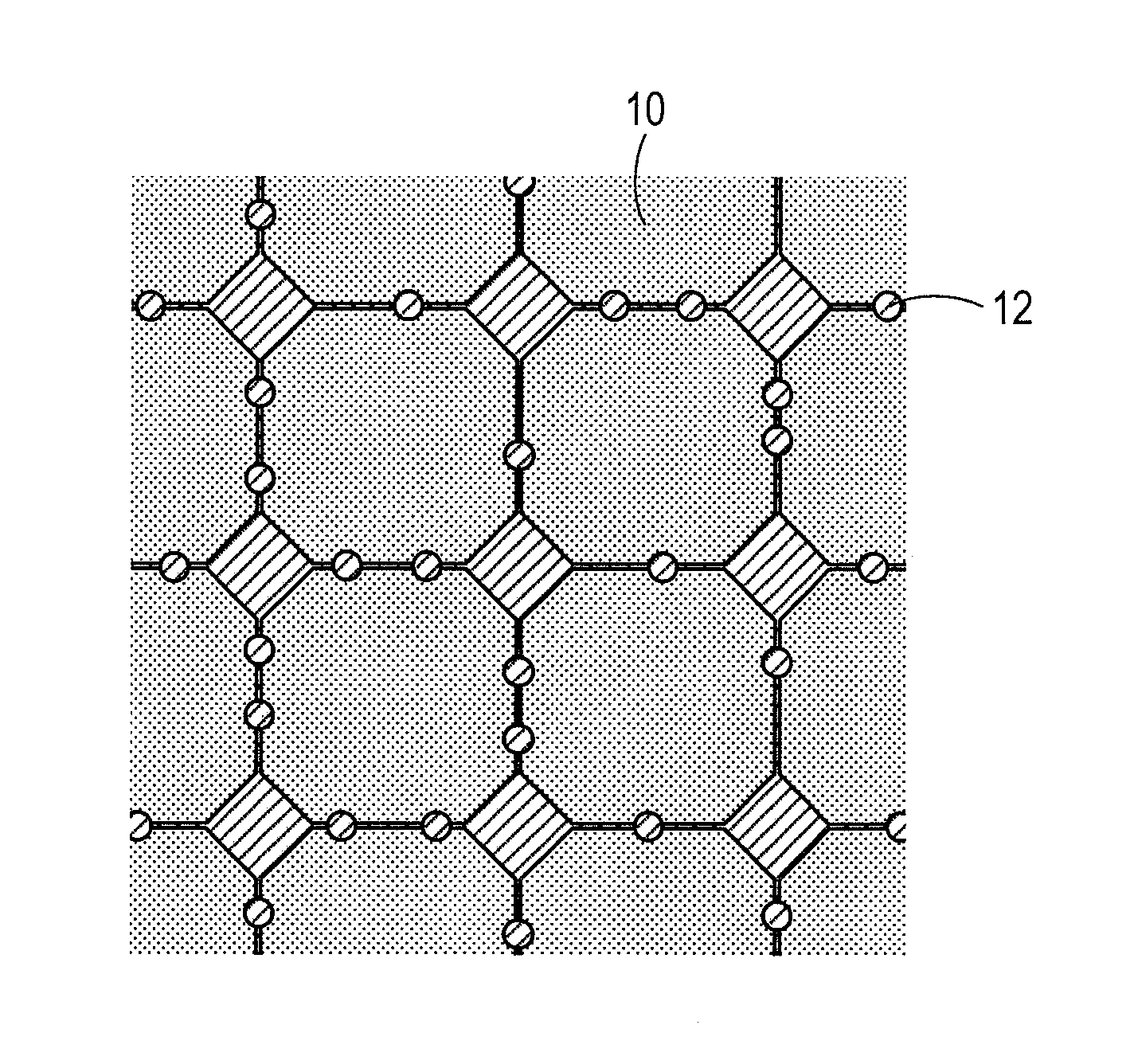

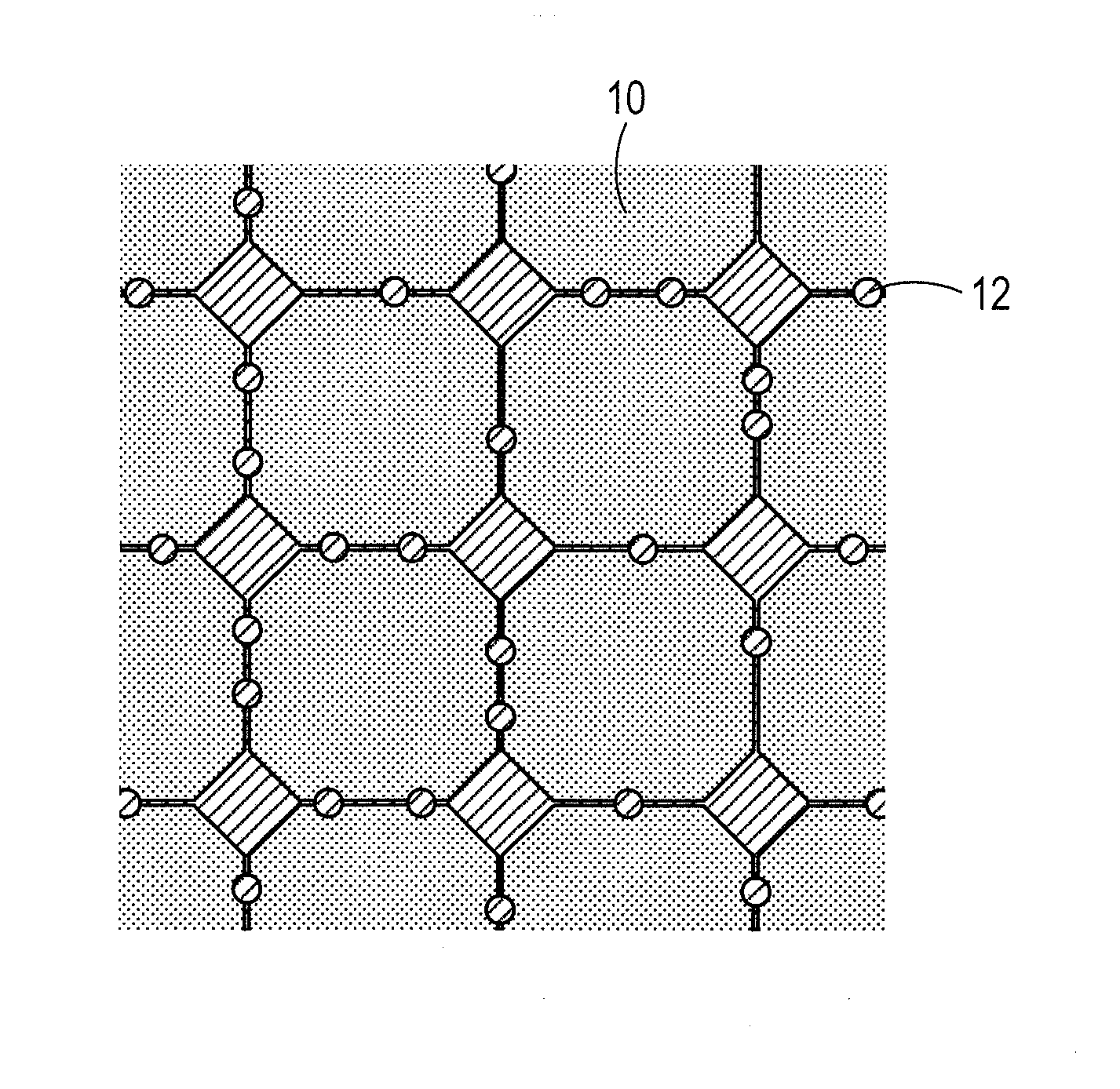

Shielding unit for wireless power transmission module and wireless power transmission module including same

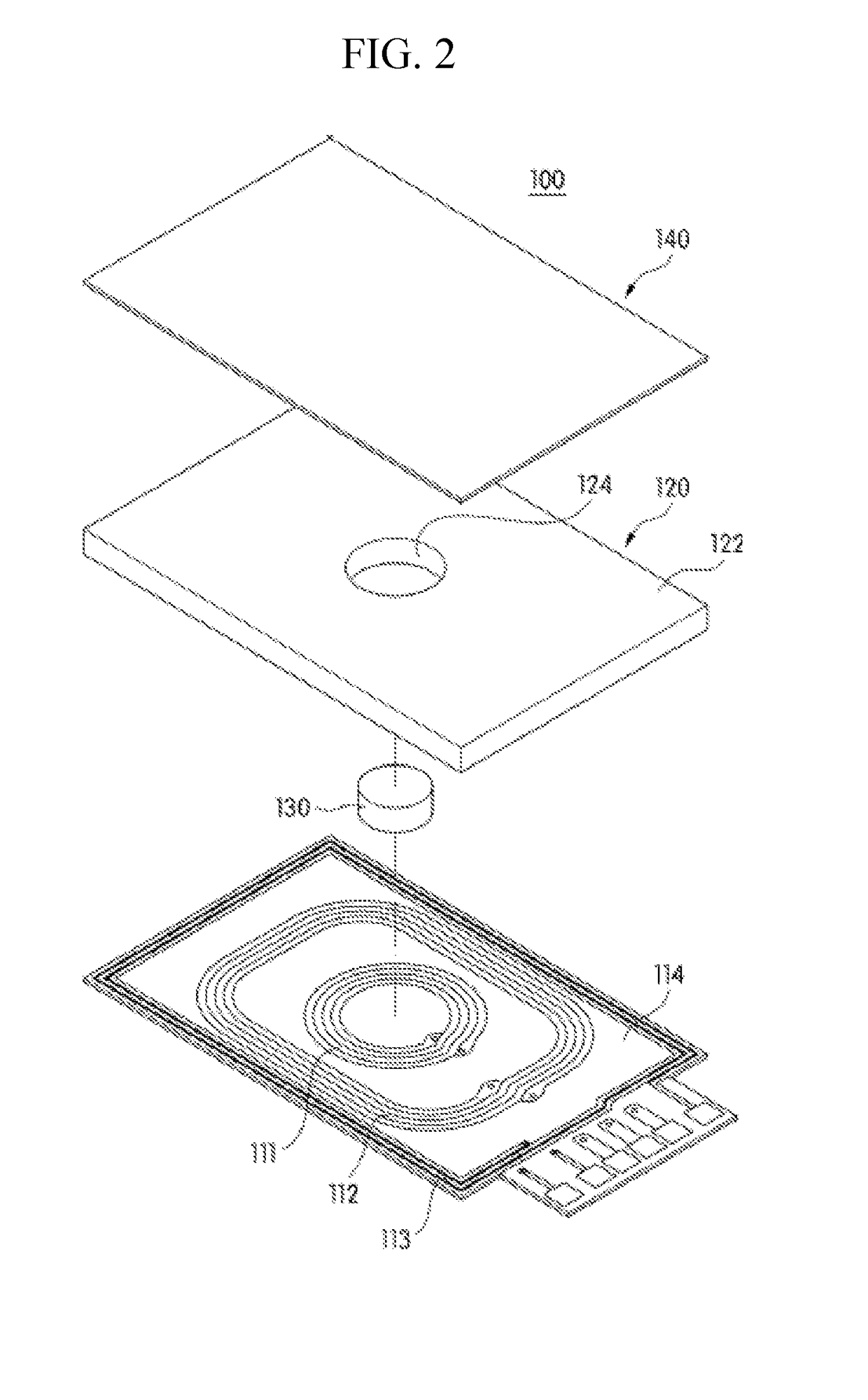

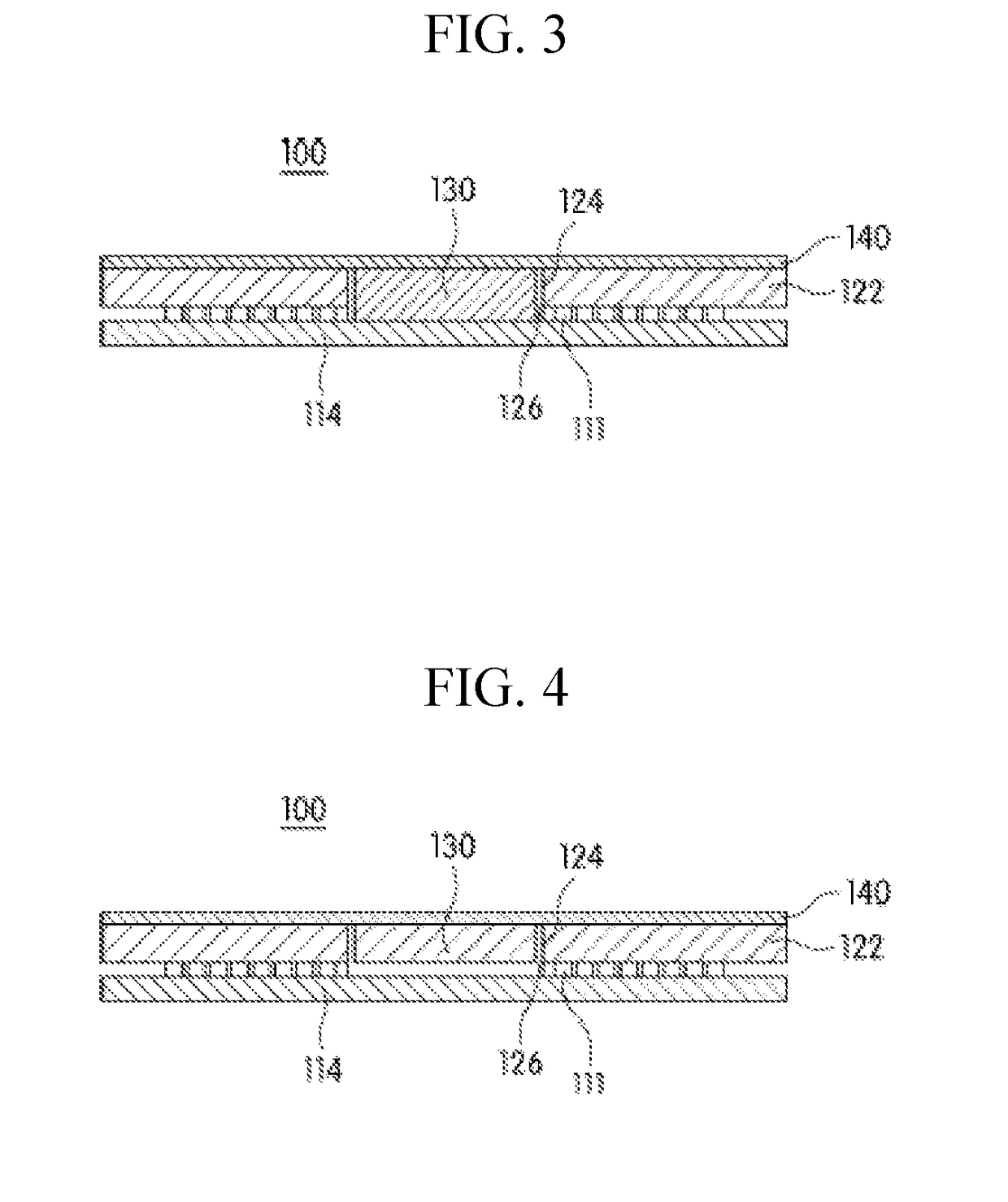

ActiveUS20190044391A1Reduce the amount requiredAvoid magnetizationNear-field transmissionTransformersFrequency bandElectric power transmission

A shielding unit for a wireless power transfer module and the wireless power transfer module including the same are provided. The shielding unit for the wireless power transfer module according to an embodiment of the present invention comprises a magnetic field shielding sheet for shielding a magnetic field generated in a predetermined frequency band and condensing the same in a desired direction, and a magnetic body receiving portion which is formed through the magnetic field shielding sheet such that a magnetic body for including magnetic force lines generated from a permanent magnet can be inserted therein, wherein the magnetic body receiving portion is arranged to have a relatively larger size than the magnetic body.

Owner:AMOSENSE

Permanent magnet and manufacturing method thereof

InactiveUS20120187328A1Reduce carbon contentLow coercivityMagnetic paintsInorganic material magnetismCelsius DegreeHydrogen atmosphere

There are provided a permanent magnet and a manufacturing method thereof enabling carbon content contained in magnet particles to be reduced in advance before sintering even when wet milling is employed. Coarsely-milled magnet powder is further milled by a bead mill in a solvent together with an organometallic compound expressed with a structural formula of M-(OR)X (M represents V, Mo, Zr, Ta Ti W or Nb, R represents a substituent group consisting of a straight-chain or branched-chain hydrocarbon, X represents an arbitrary integer) so as to uniformly adhere the organometallic compound to particle surfaces of the magnet powder. Thereafter, a compact body of compacted magnet powder is held for several hours in hydrogen atmosphere at 200 through 900 degrees Celsius to perform hydrogen calcination process. Thereafter, through sintering process, a permanent magnet 1 is formed.

Owner:NITTO DENKO CORP

Composite magnetic recording structure having a metamagnetic layer with field induced transition to ferromagnetic state

ActiveUS7465502B2Softening of coercivityHigh thermostability ratioDifferent record carrier formsRecord information storageWrite bitMagnetization

A magnetic recording medium having a composite magnetic recording structure comprising the combination of a hard magnetic layer and a metamagnetic layer that possesses a field induced metamagnetic transition characteristic at ambient operating temperature. Under an applied external magnetic field, the metamagnetic layer transitions from an antiferromagnetic state to a ferromagnetic state, and the magnetic field induces magnetization of the metamagnetic layer. The hard magnetic recording layer is magnetically exchange coupled to the magnetized metamagnetic layer. This results in the softening of the coercivity of the overall magnetic recording structure and reduction of the required switching field during data recording. Upon removal of the applied magnetic field, the metamagnetic layer experiences transition back to an antiferromagnetic state and the coercivity of the hard magnetic layer is restored. This restoration allows the written bit to be stored at a high thermostability ratio and thus, preventing magnetization thermal decay of the data bit.

Owner:SEAGATE TECH LLC

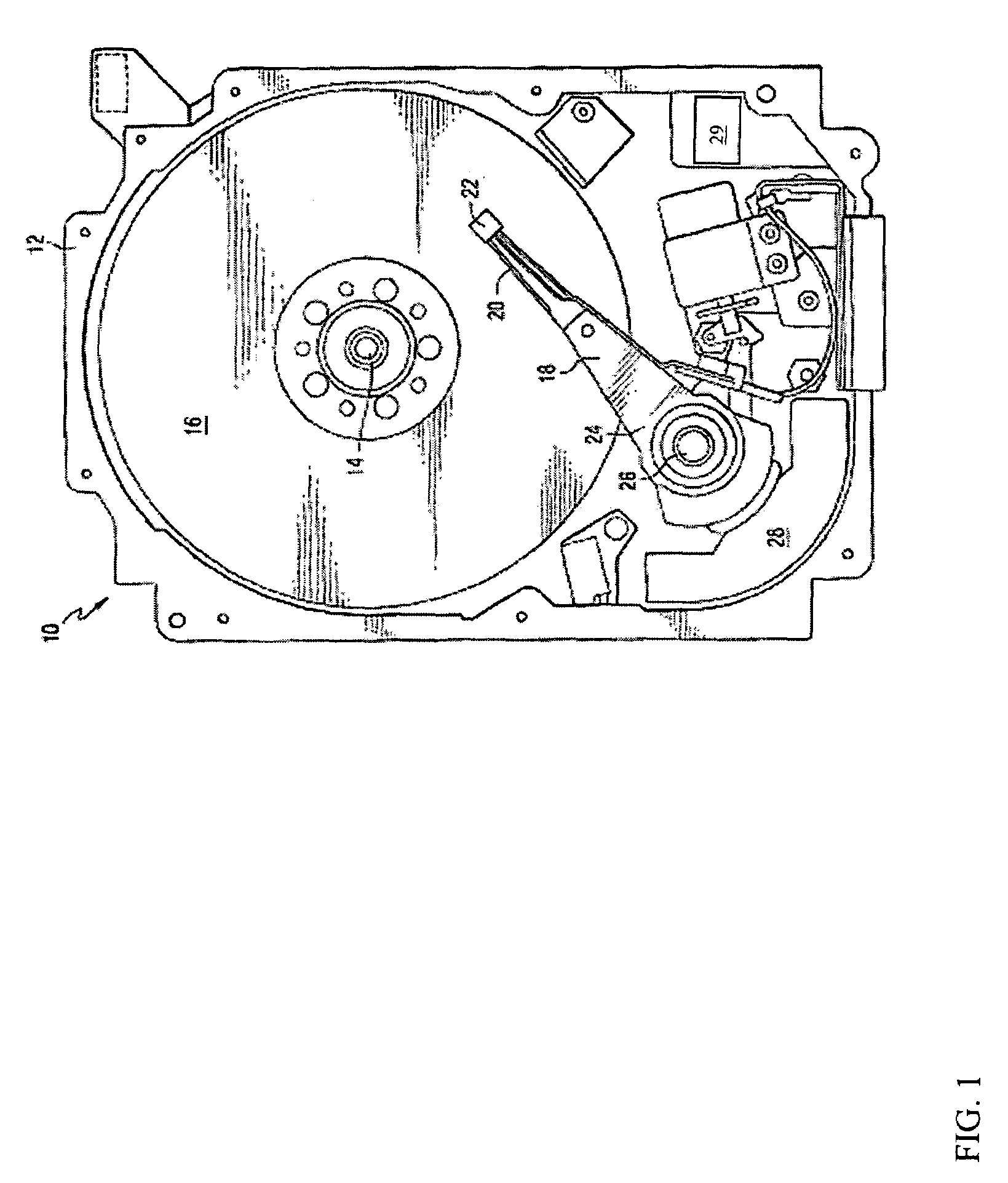

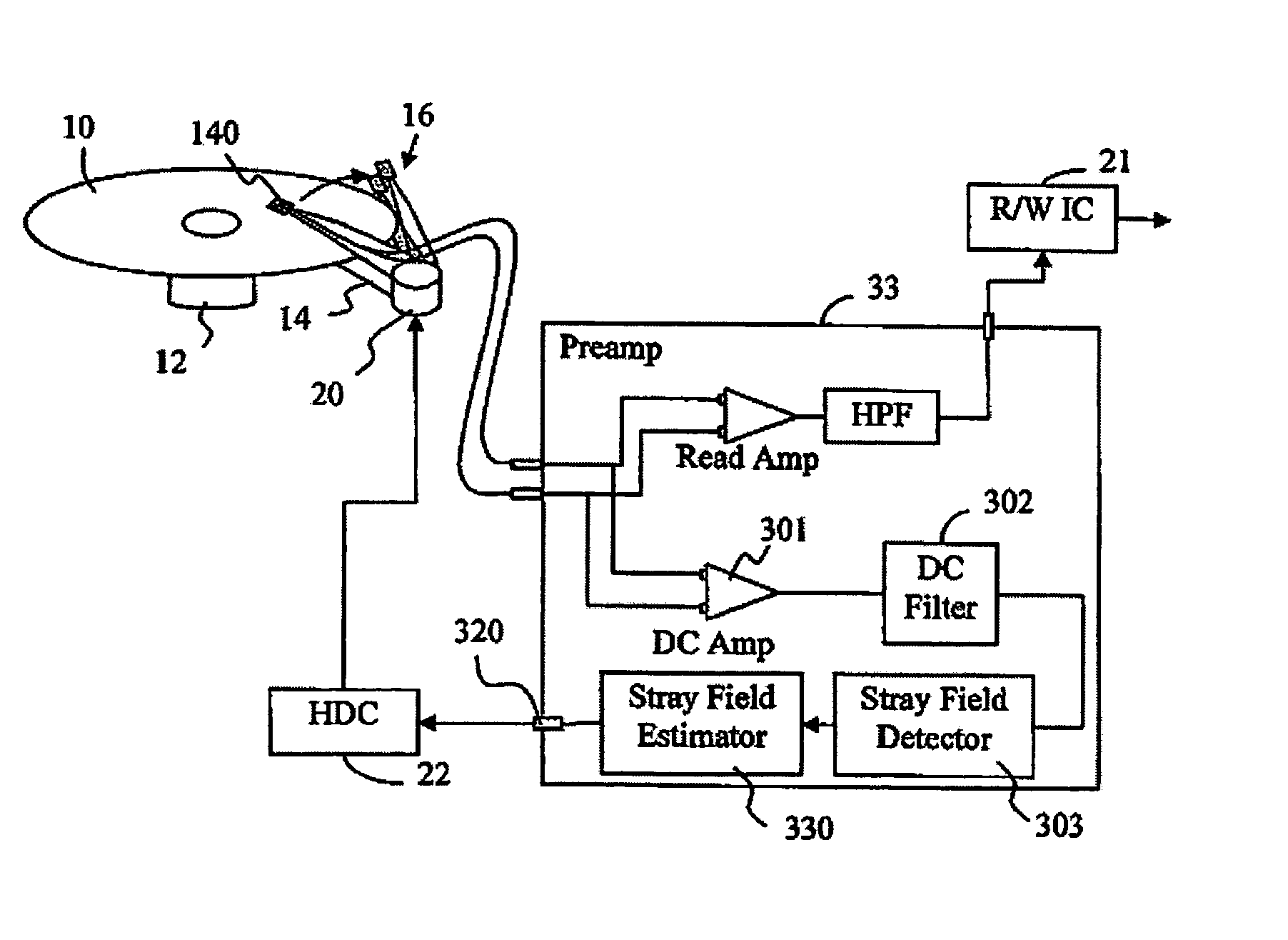

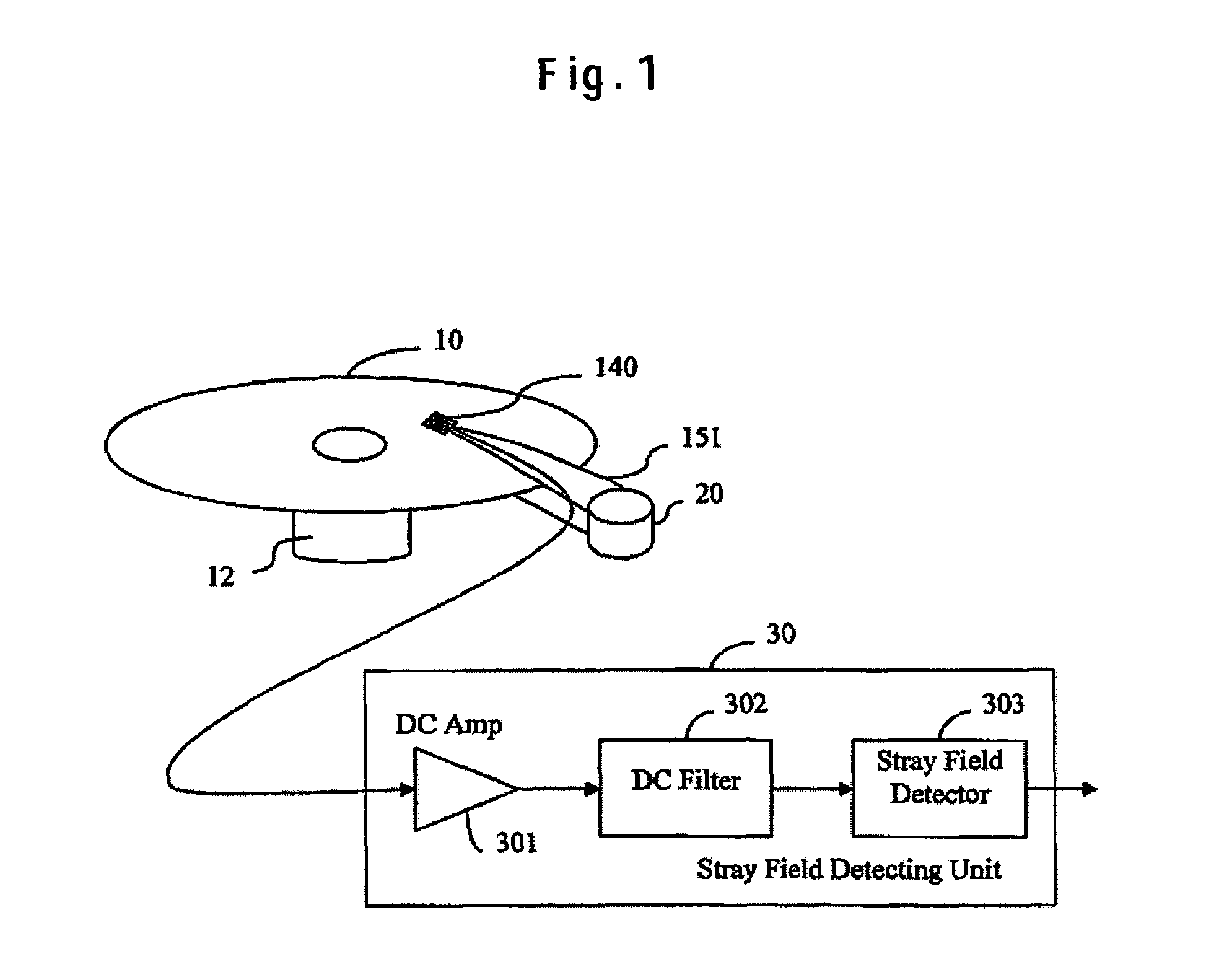

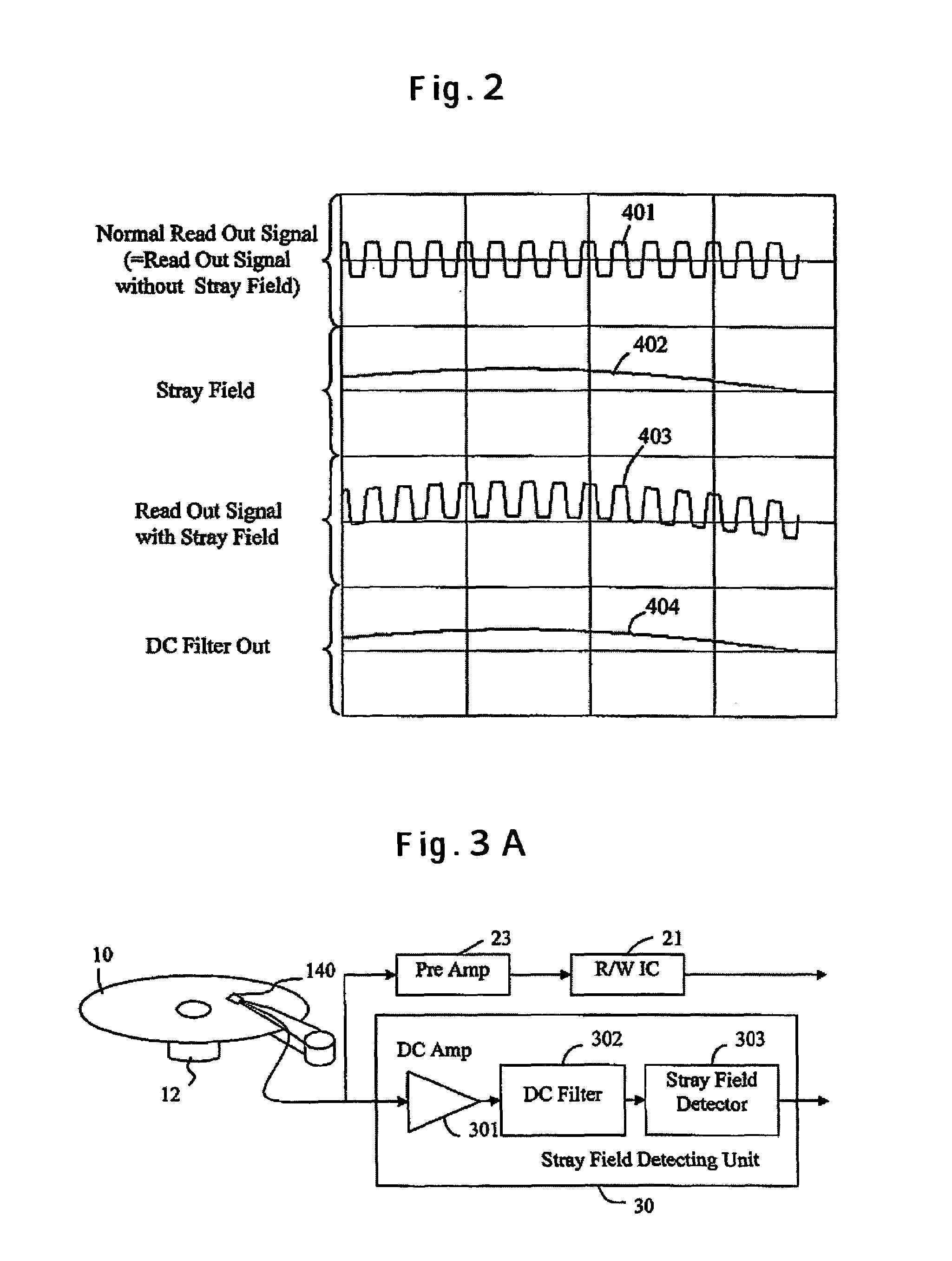

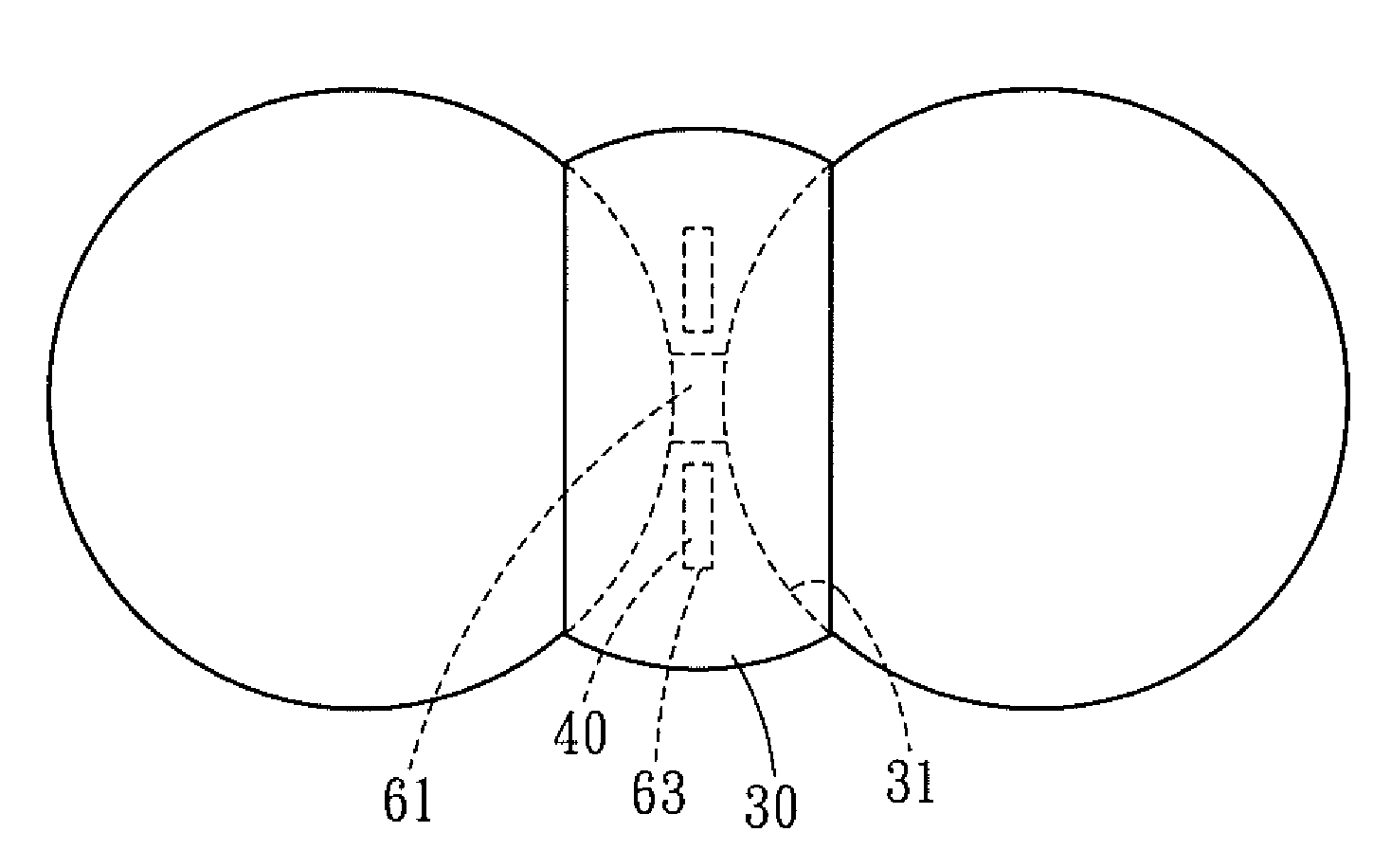

Stray field detector, magnetic disk drive, and method of head escaping

InactiveUS7289284B2Prevents demagnetization and degaussingAvoid demagnetizationDisc-shaped record carriersDriving/moving recording headsMagnetizationDegaussing

Embodiments of the invention prevent demagnetization or degaussing of recorded magnetizations, even if a stray field is applied. In one embodiment, an output of a read head including a magneto-resistive effect element is inputted to a stray field detector through a DC amplifier and a DC filter. The stray field detector monitors dc components of the output from the read head, and escapes a head from above a magnetic recording medium.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Magnetic spacer

ActiveUS7458722B2Prevent tippingAvoid magnetizationLinear bearingsBall bearingsEngineeringCentrifugal force

A spacer contains a magnetic filler and is disposed between the magnetic conductive balls. The magnetic filler produces an indirect magnetic attractive force on the balls, therefore, when the interval between the two neighboring balls is overlarge, the spacer will not tip over under the effect of gravity or centrifugal force, but will be adsorbed on the balls by the magnetic filler.

Owner:HIWIN TECH

Method Of Sea Electrical Survey Of Oil And Gas Deposits And Apparatus Complex For Its Realization 'VesoTem'

InactiveUS20080189042A1Increase hydrocarbon prognosis accuracyImprove accuracyElectric/magnetic detection for well-loggingDigital variable/waveform displayOcean bottomElectromagnetic field

A method for electrical survey of hydrocarbons deposits under seabed depths up to 1500 m and equipment therefor are provided. The equipment includes a vessel, a generator, an excitation field block, connected with a vertical dipole with coax electrodes, a data registration / processing block, bottom systems with. The lower dipole electrode is situated at maximally 100 m from the seabed, the upper electrode at maximally 200 m from the surface. The operation of the generator and bottom systems is synchronized the dipole is submersed into the sea, and fed with alternating-sign rectangular current pulses, whose on-off time ratio and duration are programmably determined. The bottom systems register reflected signals and electromagnetic field components, when the dipole's current is on and off. Analysis of the signals accounts modifications of primary and secondary fields, transient field changes for determination of the environment resistivity and strata polarization characteristics thereby improving the hydrocarbons deposits prognosis.

Owner:ZAKRYTOE AKTSIONERNOE OBSHCHESTVO EMMET

Magnetic head and magnetic storage apparatus

InactiveUS7054106B2Prevents “erasure after recordingNarrow widthConstruction of head windingsNanomagnetismMagnetic storageMagnetic poles

Disclosed herein is a magnetic head for perpendicular recording in which the main magnetic pole has reduced remanent magnetization and is less liable to cause erasure after recording. These characteristic properties were realized by constructing the magnetic head such that the recording magnetic pole and the yoke are separate from each other and the main magnetic pole is formed from a material with a high saturation magnetic flux density and the yoke is formed from a material having a negative magnetostriction constant.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

Non-magnetism high-voltage sheet type multilayer ceramic capacitor and its producing method

InactiveCN1921038ASufficient process scopeMeet the needs of normal productionFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorManganese

The invention relates to a non-magnetic high-voltage I-type multilayer ceramic capacitor and relative preparation. Wherein, said capacitor is formed by inner electrode, medium layer, and end electrode, which are made from non-magnetic medium ceramic, non-magnetic inner slurry, and non-magnetic end slurry, without manganese, chromic, nickel and other magnetic metals; the number of medium layer is dual, while the thickness of each layer is 2-15mil; and in the processes as mixing slurry, compressing, adhering and sintering end electrode, it all uses non-magnetic tools. The invention has high Q value, to work under strong magnetic field.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

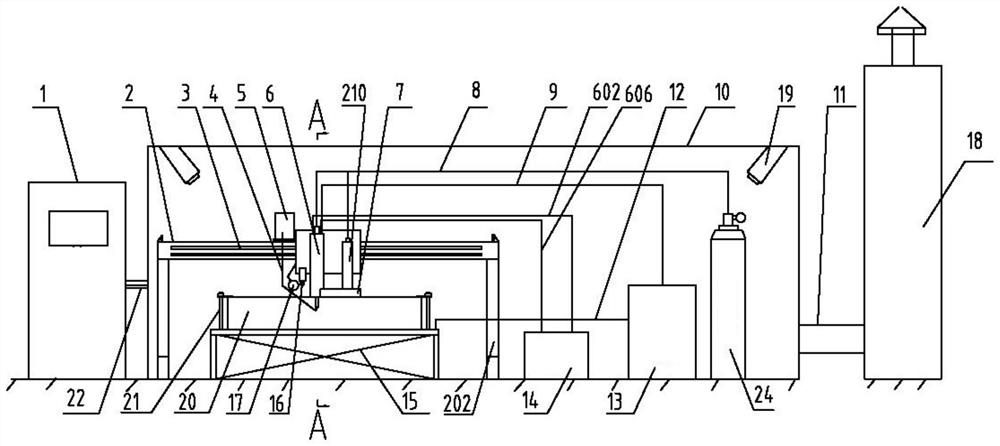

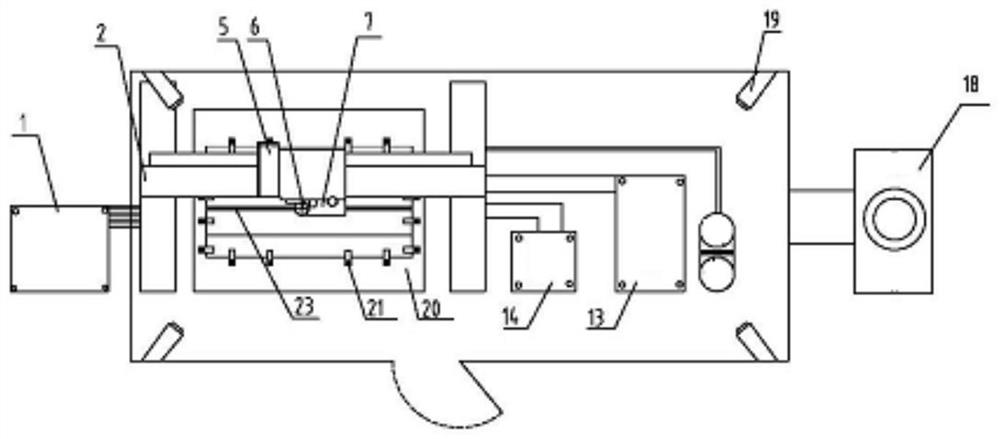

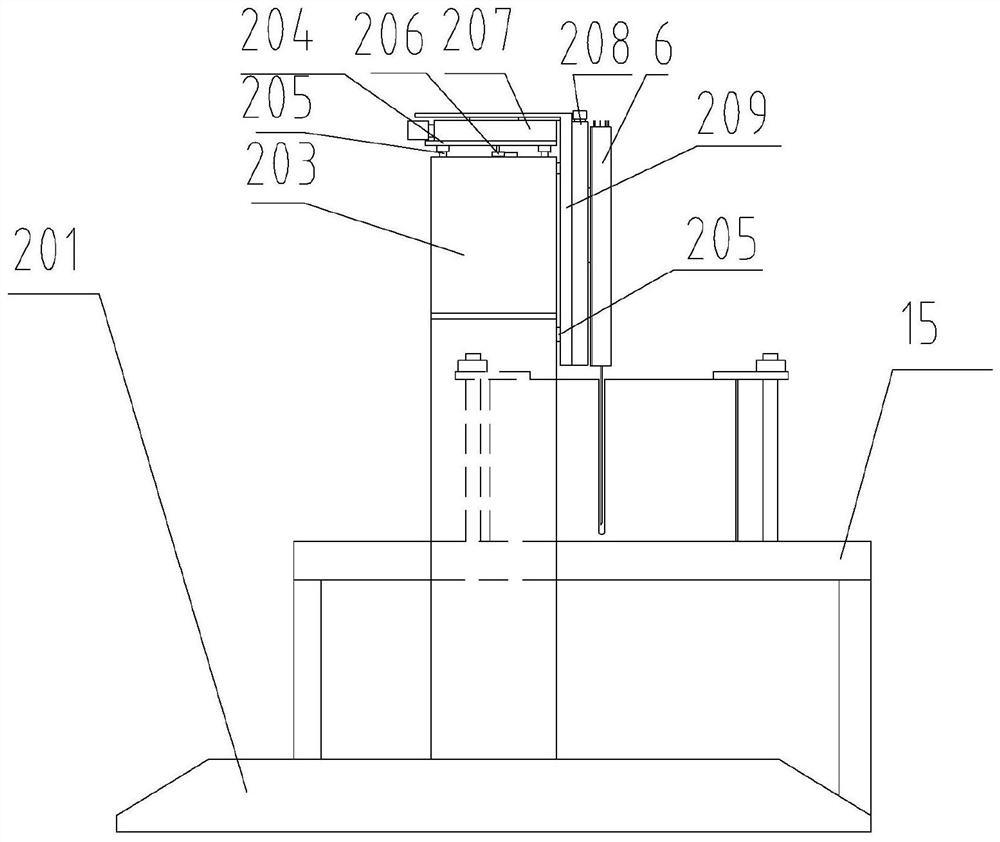

Narrow gap tungsten electrode argon arc welding technology method for thick plate

ActiveCN111618402APlay a binding rolePlay a buffer roleWelding accessoriesLaser rangingAC - Alternating current

The invention relates to a narrow gap tungsten electrode argon arc welding technology method for a thick plate, belongs to the technical field of narrow gap welding, utilizes narrow gap tungsten electrode argon arc welding equipment, and adopts a non-axisymmetric tungsten electrode rotation way to carry out the automatic welding of an ultra-thick plate (0-300 mm) and a narrow gap (4-10 mm). The narrow gap tungsten electrode argon arc welding technology method comprises the following steps of: (1) arranging a groove, and carrying out groove processing; (2) clamping the narrow gap tungsten electrode argon arc welding equipment; (3) installing the tungsten electrode, and carrying out equipment programing; (4) positioning: moving the tip of the welding gun tungsten electrode to the bottom of the center of a welding line, enabling a gas hood to be covered above the welding line, and then, through laser distance measurement, carrying out second positioning; (5) carrying out welding line backing weld: in a welding process, carrying out arc pressure and laser tracking to guarantee that the tungsten electrode is centered, utilizing an alternating current pulse hot filament TIG (Tungsten Inert Gas Welding) technology, and regulating welding current and pulse frequency to accurately control the heat input of the welding line; (6) carrying out layered filling weld; and (7) carrying out cosmetic weld. Compared with common tungsten electrode argon arc welding, the narrow gap tungsten electrode argon arc welding technology method disclosed by the invention greatly increases weldable platethickness and improves production efficiency and production quality.

Owner:SHANDONG UNIV +1

Permanent magnet and manufacturing method thereof

InactiveUS8500921B2Improve magnetic propertiesLow densityTransportation and packagingMetal-working apparatusNeodymium magnetHydrogen atmosphere

Owner:NITTO DENKO CORP

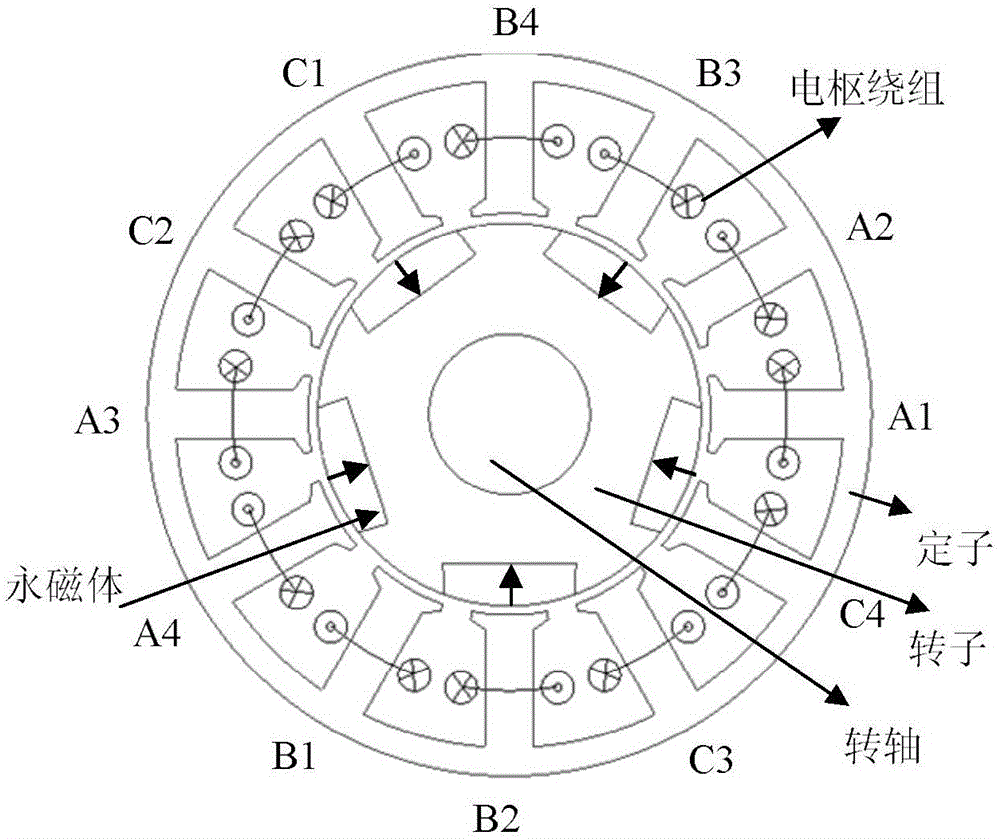

Magnetic field enhanced consequent-pole permanent magnet motor

ActiveCN106787310AReduce in quantityReduce manufacturing costMagnetic circuit rotating partsElectricitySurface mounting

The invention discloses a magnetic field enhanced consequent-pole permanent magnet motor, comprising n rotor sections, wherein the n rotor sections are connected in sequence in the axial direction of a rotor, an annular permanent magnet magnetized axially is arranged between two adjacent rotor sections, and the magnetized directions of the adjacent annular permanent magnets are opposite; the n rotor sections are of the same structure, a plurality of salient poles are uniformly arranged on the surface of each rotor section, a permanent magnet is embedded into a groove between the adjacent salient poles, and an alternate arrangement structure of the salient poles and the permanent magnets is formed on the surface of the rotor; the magnetized directions of the permanent magnets on the surface of the same rotor section are same, and the magnetized directions of the permanent magnets on the surfaces of the adjacent rotor sections are opposite; a hollow cylindrical permanent magnet is arranged between the inner side of each rotor section and a rotating shaft, and the magnetized directions of the permanent magnets on the inner sides of the two adjacent rotor sections are opposite. The magnetic field enhanced consequent-pole permanent magnet motor overcomes the defects of a traditional surface-mounted permanent magnet motor, reduces the cost of a permanent magnet material, and enhances the output torque.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Permanent magnet and manufacturing method thereof

InactiveUS20120182108A1Improve magnetic propertiesResidual magnetic flux density decreaseTransportation and packagingMetal-working apparatusNeodymium magnetCelsius Degree

There are provided a permanent magnet and a manufacturing method thereof capable of densely sintering the entirety of the magnet without making a gap between a main phase and a grain boundary phase in the sintered magnet. To fine powder of milled neodymium magnet is added an organometallic compound solution containing an organometallic compound expressed with a structural formula of M-(OR)x (M represents V, Mo, Zr, Ta, Ti, W or Nb, R represents a substituent group consisting of a straight-chain or branched-chain hydrocarbon, x represents an arbitrary integer) so as to uniformly adhere the organometallic compound to particle surfaces of the neodymium magnet powder. Thereafter, desiccated magnet powder is held for several hours in hydrogen atmosphere at 200 through 900 degrees Celsius. Thereafter, the powdery calcined body calcined through the calcination process in hydrogen is held for several hours in vacuum atmosphere at 200 through 600 degrees Celsius for a dehydrogenation process.

Owner:NITTO DENKO CORP

Microwave assisted magnetic recording head and magnetic data storage apparatus

InactiveUS8937789B2Inhibited DiffusionReduce resistanceManufacture head surfaceHeads using thin filmsSpin torque oscillatorsMicrowave assisted

To suppress a spread of not only a recording magnetic field generated from a main pole but also a high-frequency magnetic field generated from a spin torque oscillator in a microwave assisted magnetic recording head. The main pole and the spin torque oscillator are surrounded by a trailing shield layer and are also surrounded by a side / leading shield layer with an insulator sidegap layer interposed therebetween, and a high-frequency magnetic field shield layer, which absorbs a high-frequency magnetic field generated from the spin torque oscillator, is arranged in at least part of the shield layers.

Owner:HITACHI LTD

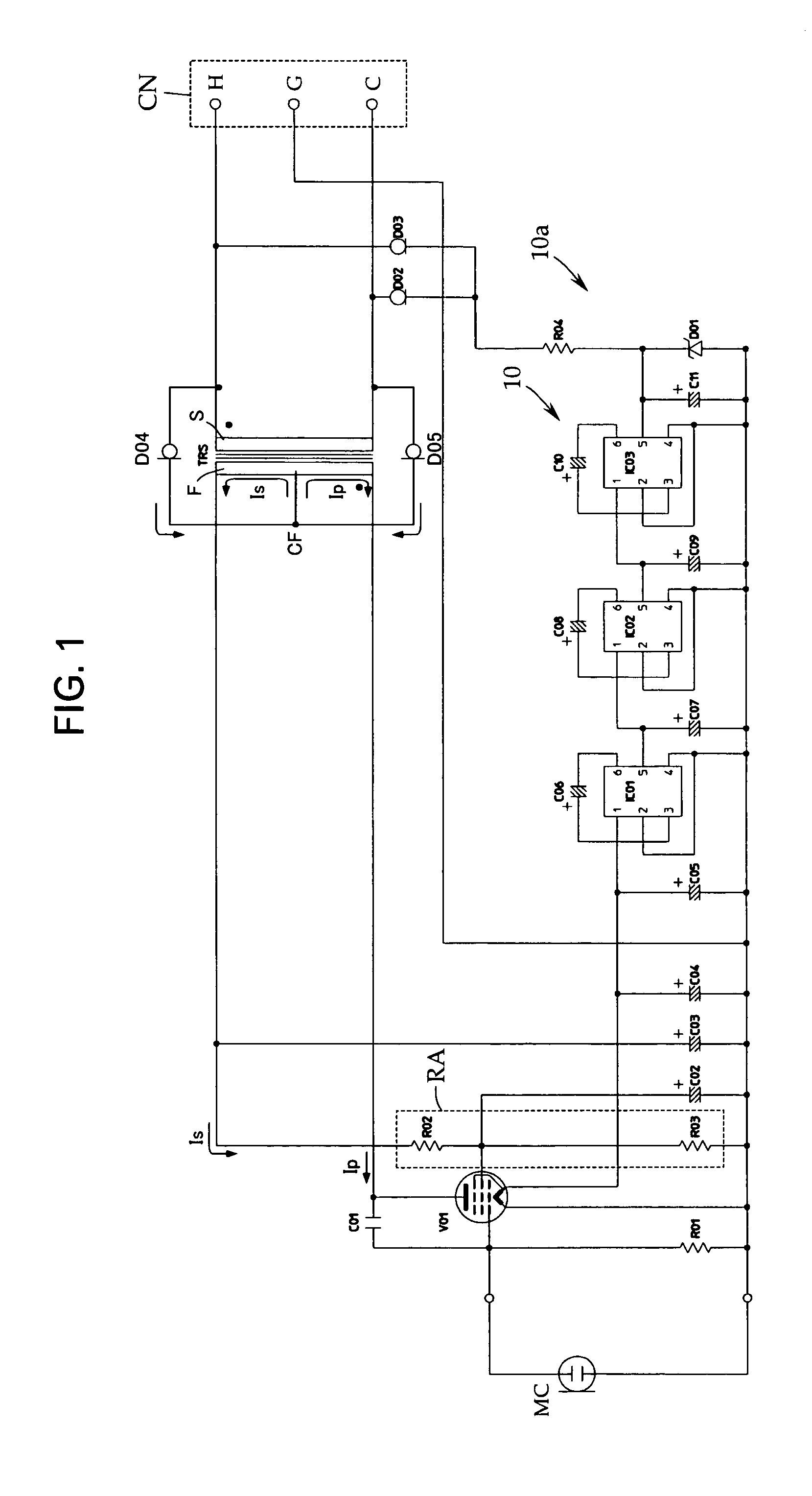

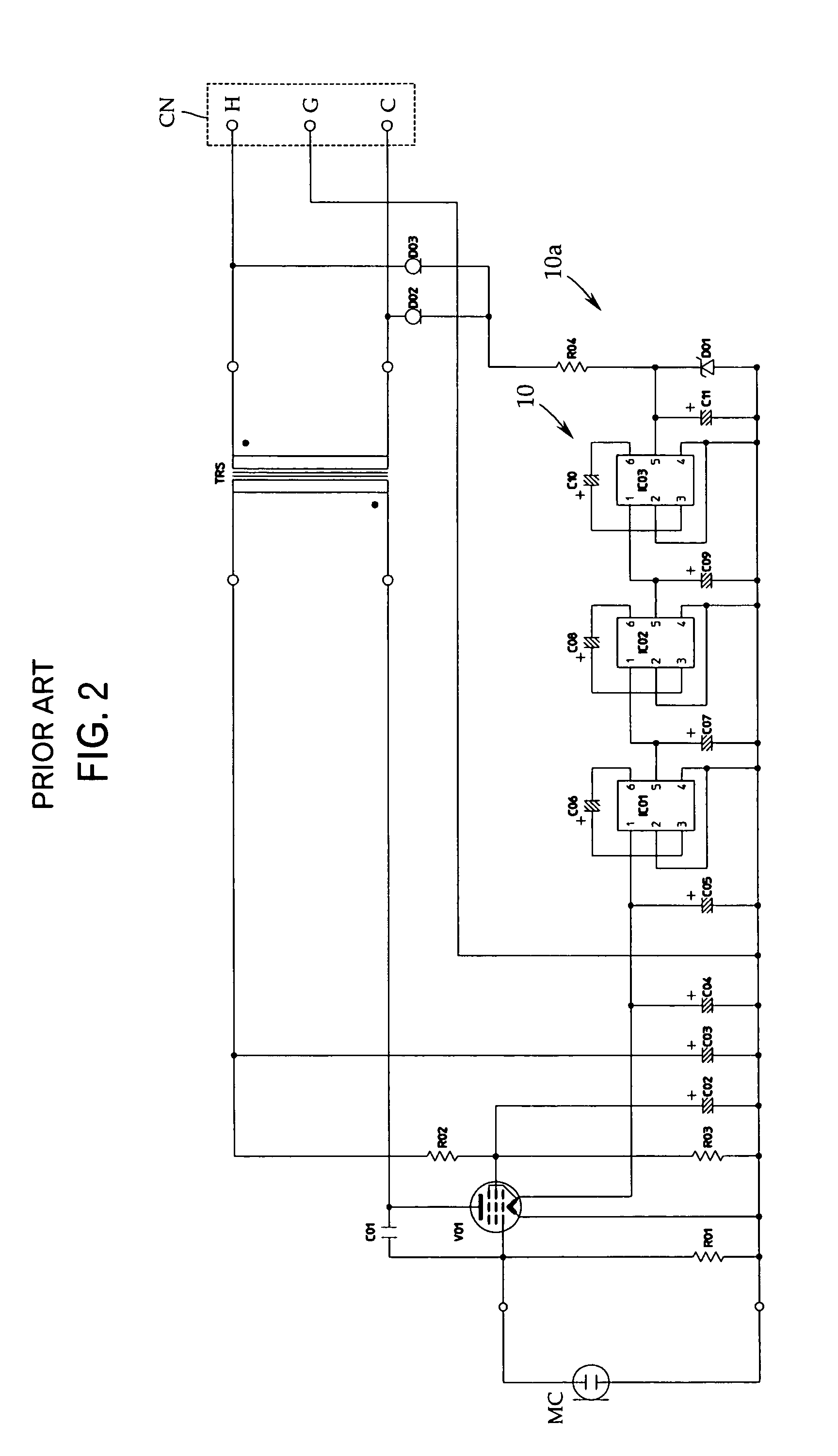

Condenser microphone

InactiveUS7542578B2Avoid magnetizationMicrophone structural associationElectrostatic transducer microphonesOutput transformerCapacitance

Owner:AUDIO-TECHNICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com