Synchronous induction motor

A technology for induction motors and rotors, applied to electric components, capacitors, electromechanical devices, etc., can solve problems such as rotor wear and achieve the effect of preventing wear and magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

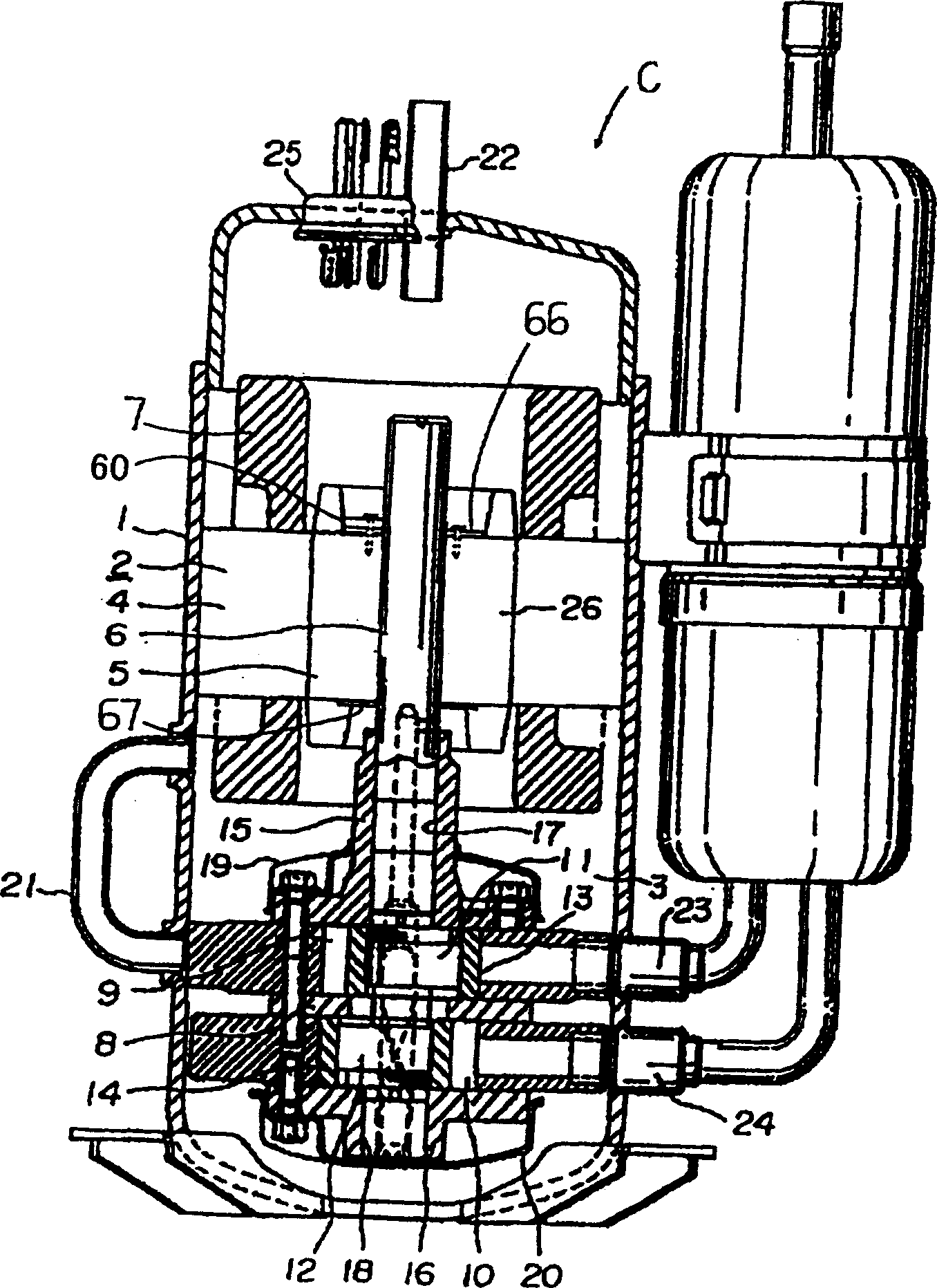

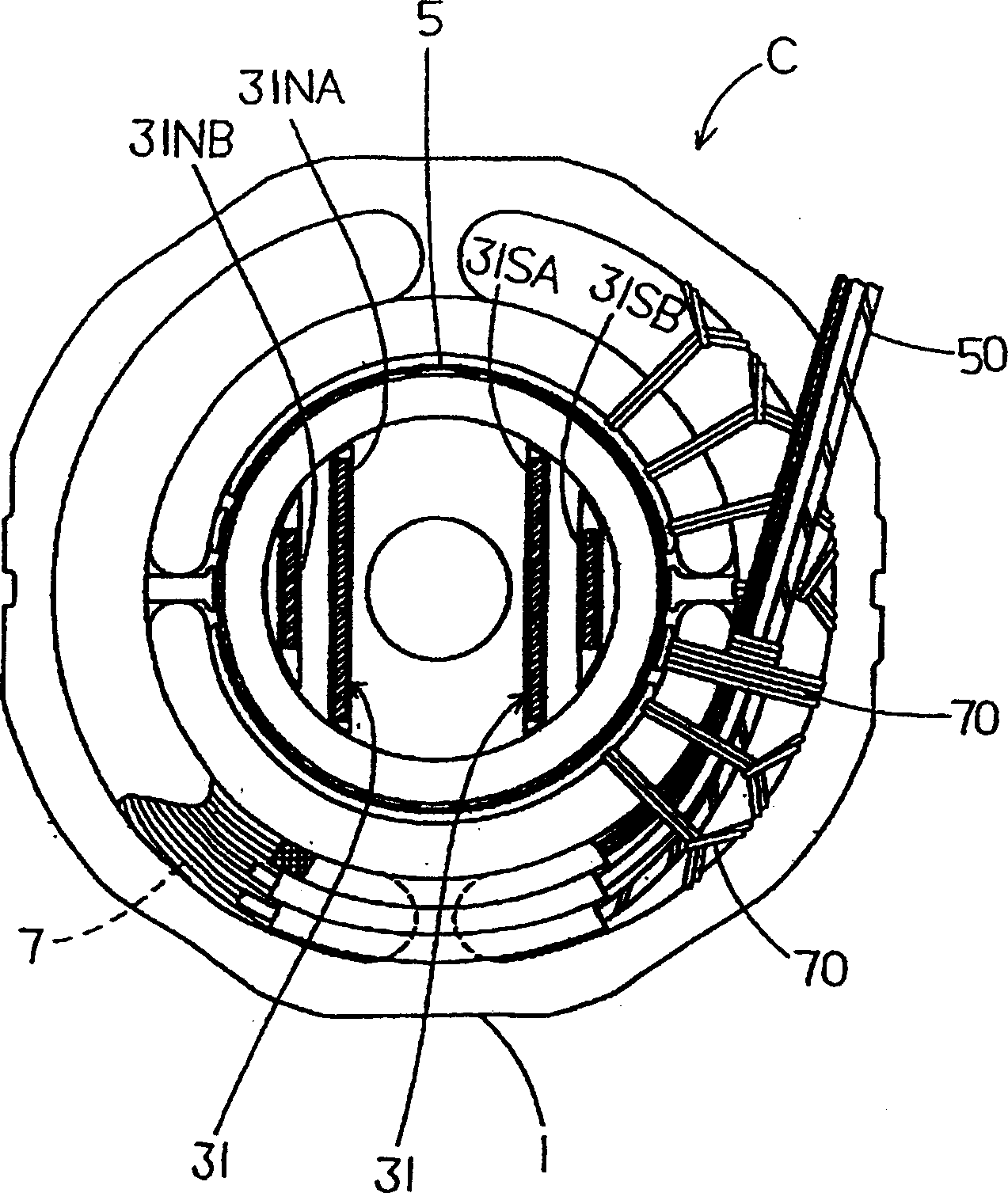

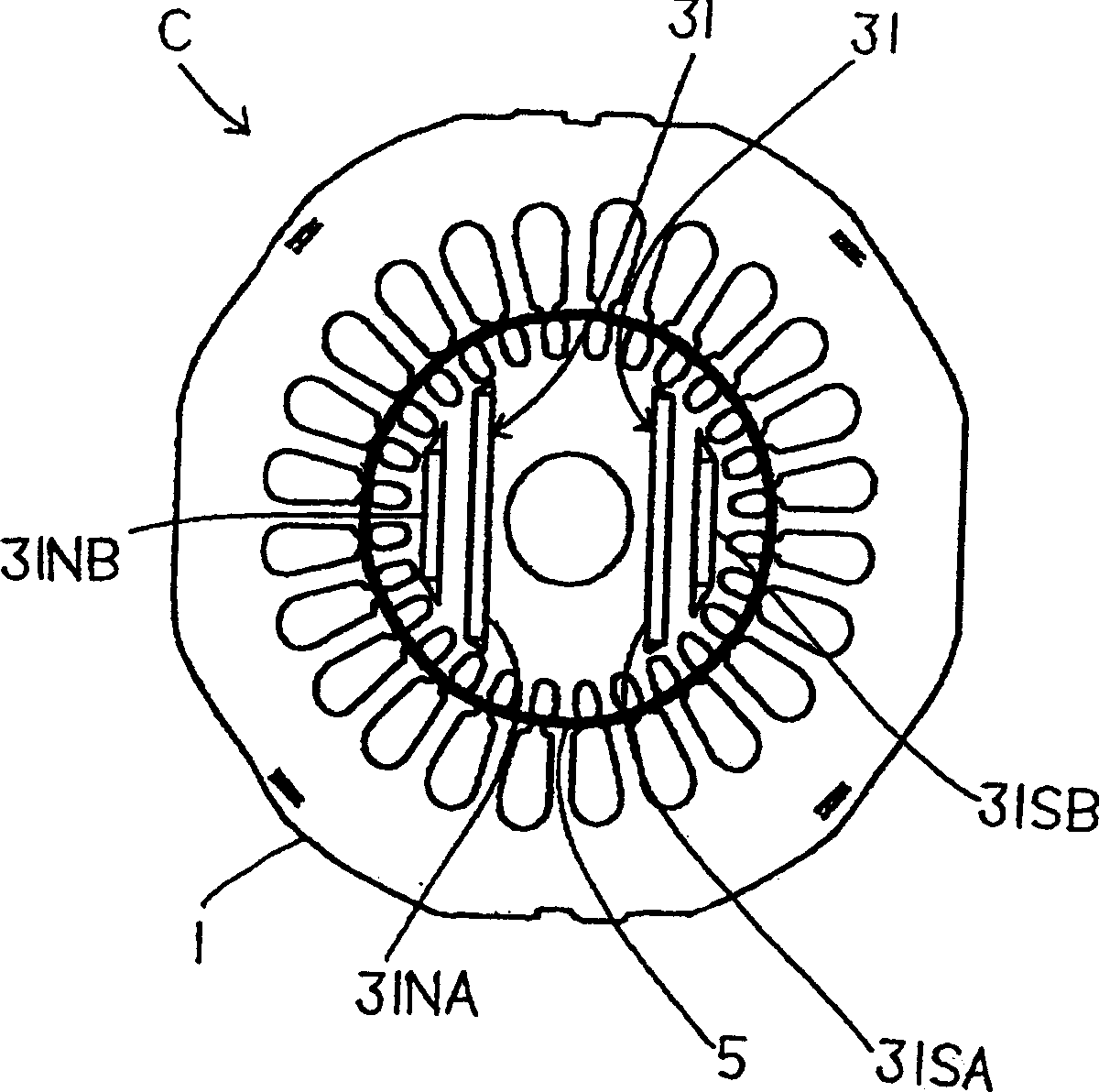

[0059] Next, embodiments of the present invention will be described in detail based on the drawings. figure 1 It is an illustration of a vertical side view of a hermetic electric compressor C to which the synchronous induction motor 2 of the present invention is applied. In the figure, 1 is an airtight container, the synchronous induction motor 2 is accommodated in the upper side inside, and the compressor 3 rotationally driven by the synchronous induction motor 2 is accommodated in the lower side. The airtight container 1 accommodates the synchronous induction motor 2 and the compressor 3 divided into two in advance, and then seals it by high-frequency welding or the like. Also, the hermetic electric compressor C may be, for example, a rotary, reciprocating, or scroll compressor.

[0060] The synchronous induction motor 2 has a single-phase two-pole structure, and is composed of a stator 4 fixed to the inner wall of the airtight container 1 , and a rotor 5 rotatably supporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com