Segmented rotor consequent pole permanent magnet motor

A permanent magnet motor, alternating pole technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of high production cost of surface-mounted permanent magnet motor and larger equivalent air gap between stator and rotor , surface-mounted permanent magnets falling off, etc., to achieve the effect of improving torque output capacity, shortening air gap spacing, and avoiding magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

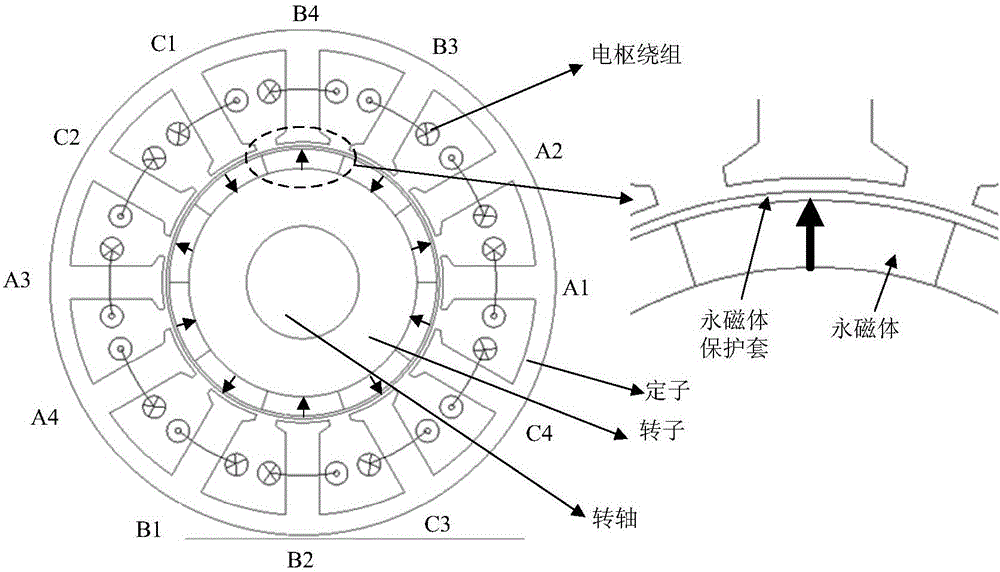

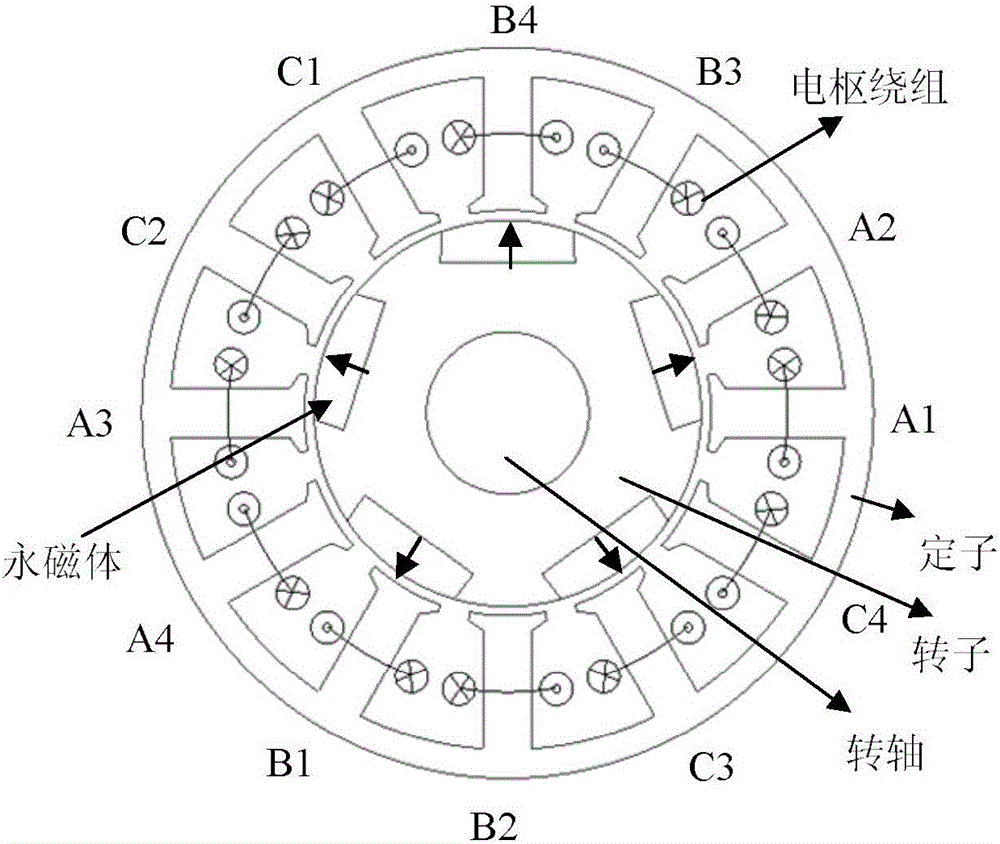

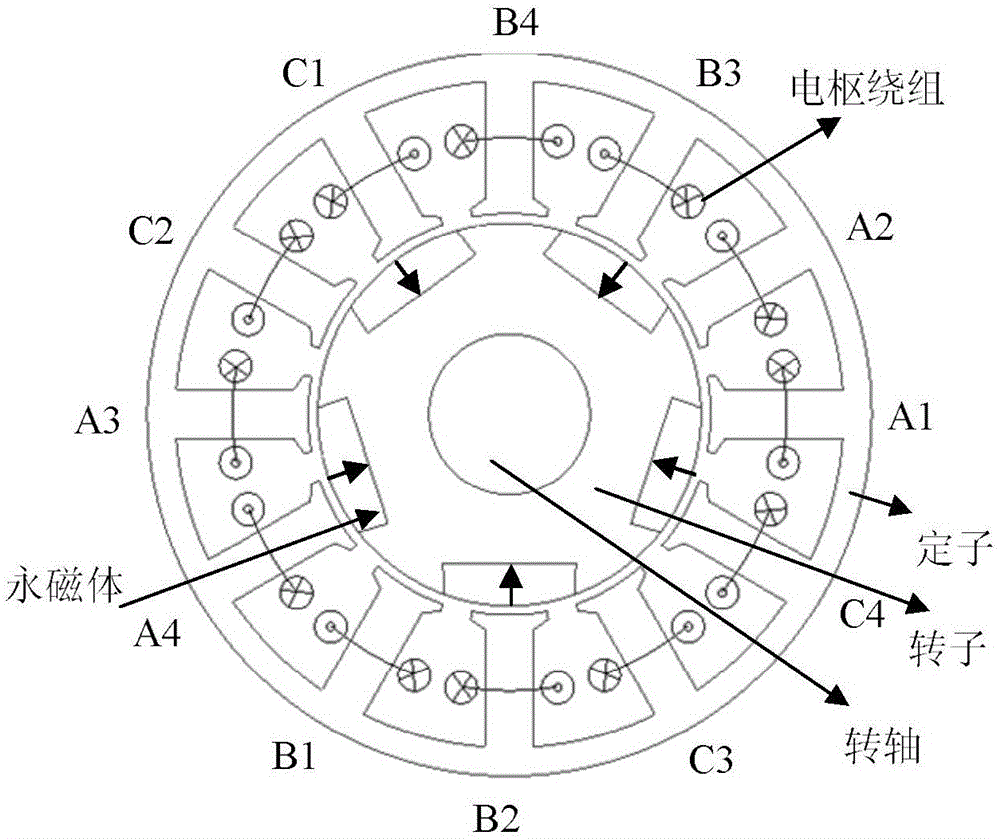

[0019] The present invention takes a three-phase 12 / 10-pole permanent magnet motor as an example, adopts A, B, and C three-phase windings, the A-phase armature winding is composed of A1, A2, A3, and A4 coils in series, and the B-phase and C-phase Armature windings and so on. The motor consists of 12 stator poles.

[0020] The rotor-segmented alternating pole permanent magnet motor includes two-segment rotors, the two-segment rotors are connected along the rotor axis, and the two-segment rotors have the same structure. A plurality of salient poles are uniformly arranged on the surface of each section of the rotor, permanent magnets are inlaid in grooves between adjacent salient poles, and a structure of alternating arrangement of salient poles and permanent magnets is formed on the surface of the rotor, and the shape of the permanent magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com