Lubrication arrangements for maintaining piston pin oil pressure in two-stroke cycle, opposed-piston engines

A technology of opposing pistons and piston pins, which is applied in the direction of engine lubrication, pressure lubricants, engine components, etc., and can solve problems such as increasing the full oil pressure of the engine, overshooting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

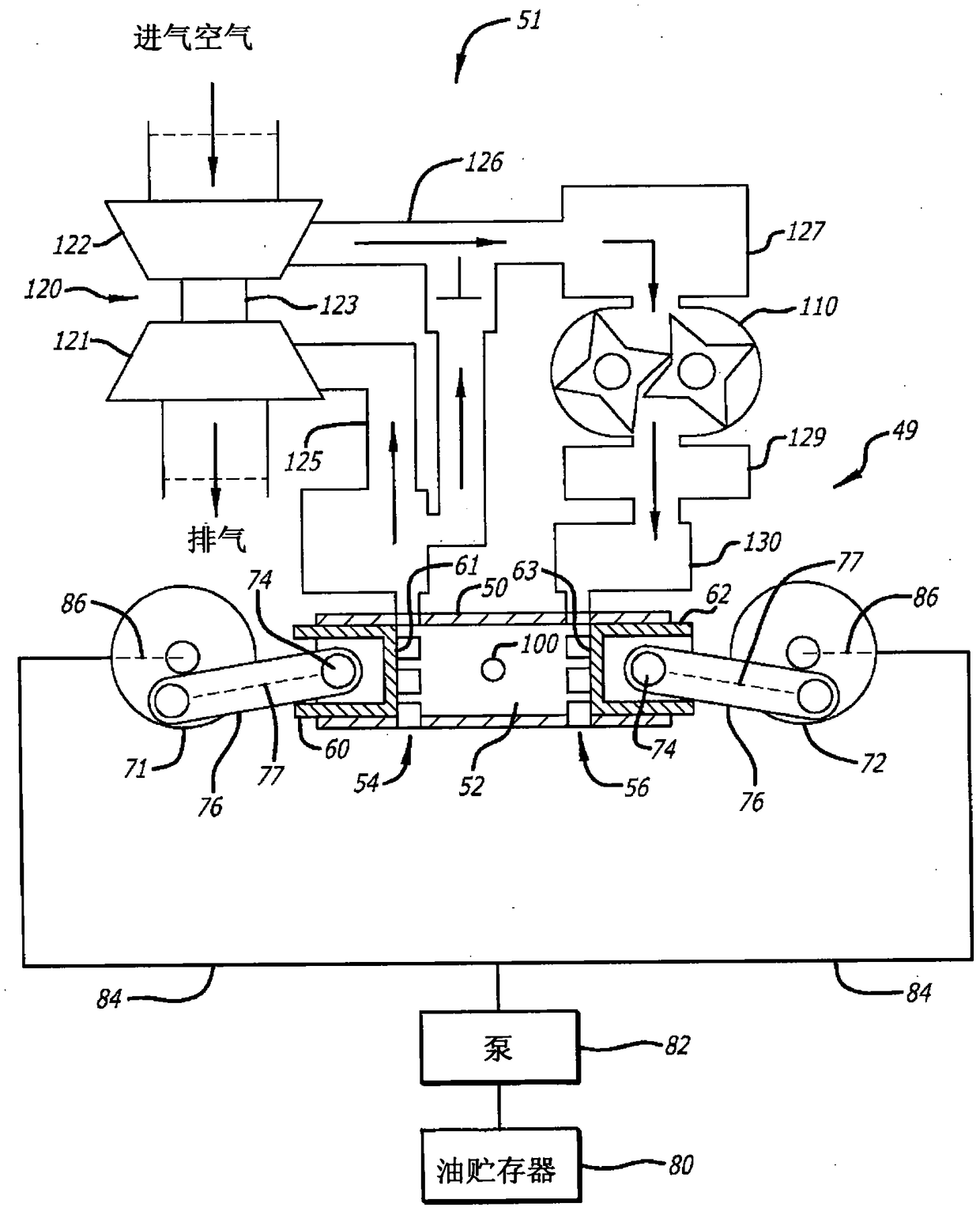

[0017] A two-stroke cycle engine is an internal combustion engine that completes the power cycle with a single full revolution of the crankshaft and two strokes of the piston connected to the crankshaft. One example of a two-stroke cycle engine is an opposed-piston engine, in which a pair of pistons are positioned opposite each other in a bore of a cylinder.

[0018] As seen in FIG. 1 , the opposed-piston engine 49 has at least one ported cylinder 50 . For example, the engine may have one ported cylinder, two ported cylinders, three ported cylinders, or four or more ported cylinders. For illustration purposes, engine 49 is assumed to have multiple ported cylinders. Each cylinder 50 has a bore 52: an exhaust port 54 and an intake port 56 are formed at their respective ends. The exhaust port 54 and the intake port 56 each include one or more circumferential arrays of openings. Exhaust piston 60 and intake piston 62 are slidably disposed in bore 52 with end surfaces 61 and 63 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com