A variable stroke free piston engine

A piston engine and engine technology, applied in the direction of free piston engine, internal combustion piston engine, combustion engine, etc., can solve the problems of increased engine weight and cost, low controllability, high difficulty in design and production, and achieve good fuel economy and Power, variable compression ratio, and high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

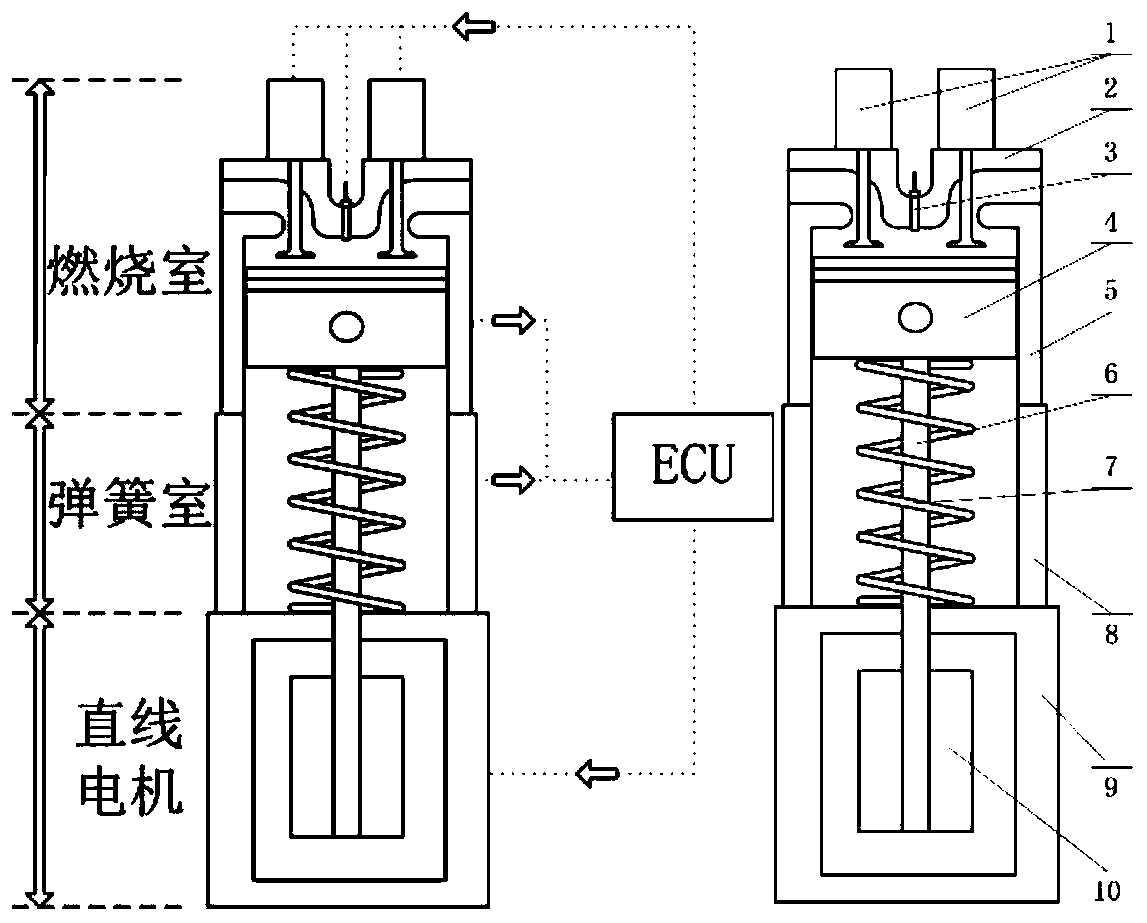

[0029] to combine figure 1 , a variable-stroke free-piston engine of the present invention includes four parts: a combustion chamber part, a spring chamber part, a permanent magnet linear motor part and an electronic control unit part.

[0030] in:

[0031] The combustion chamber part includes a variable valve mechanism 1, an engine cylinder head 2, an engine block 5, a piston 4 and a spark plug 3, wherein the variable valve mechanism 1 changes the valve lift, valve opening time, The valve opening duration realizes the fully flexible control of engine air distribution; the upper and lower dead centers of the piston 4 are variable, and the compression ratio is variable;

[0032] The spring chamber part includes a spring 7 and a bracket 8, wherein the spring 7 is fixed between the engine piston 4 and the linear motor. When the piston 4 goes down, the spring 7 is compressed to limit the displacement of the piston 4 and store energy. When the piston 4 goes up, the spring 7 provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com