Machine for automatically assembling connecting rod, piston pin and retainer ring

A technology of piston pins and assembly machines, which is applied in assembly machines, metal processing, metal processing equipment, etc., can solve problems such as difficulty in realizing assembly system integration and miniaturization, difficulty in ensuring product quality consistency, and low assembly efficiency. The effects of reducing occupied space, ensuring reliability, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

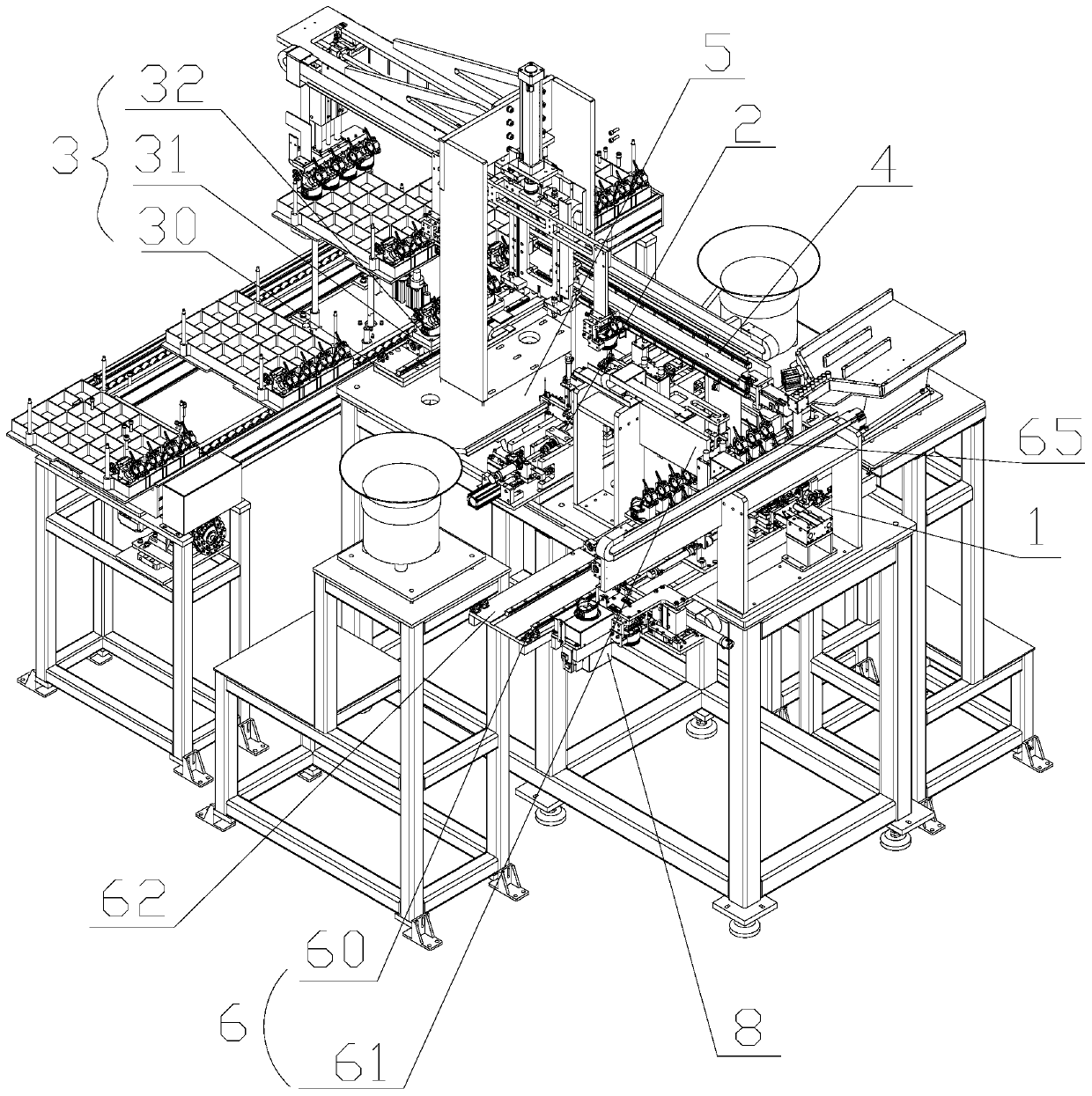

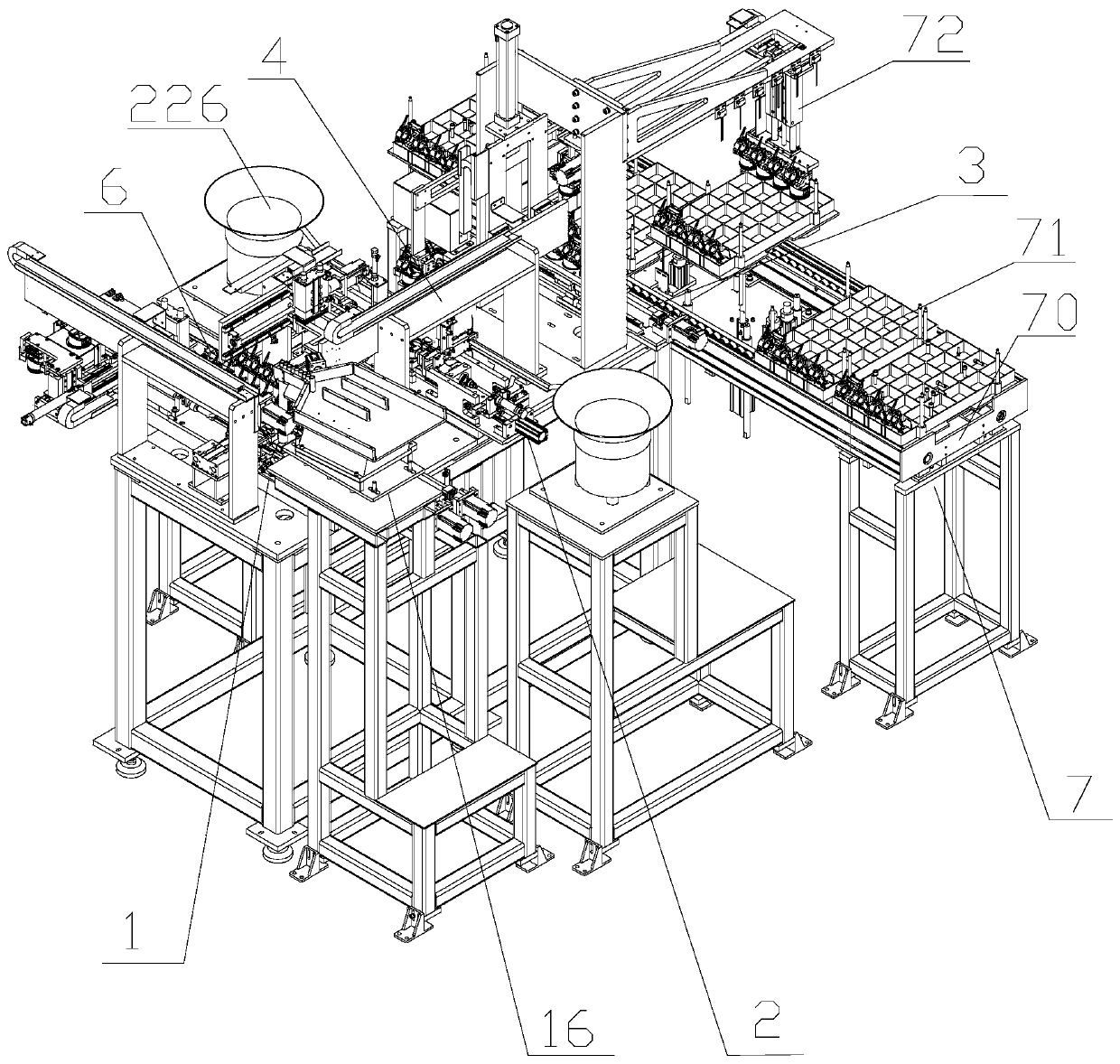

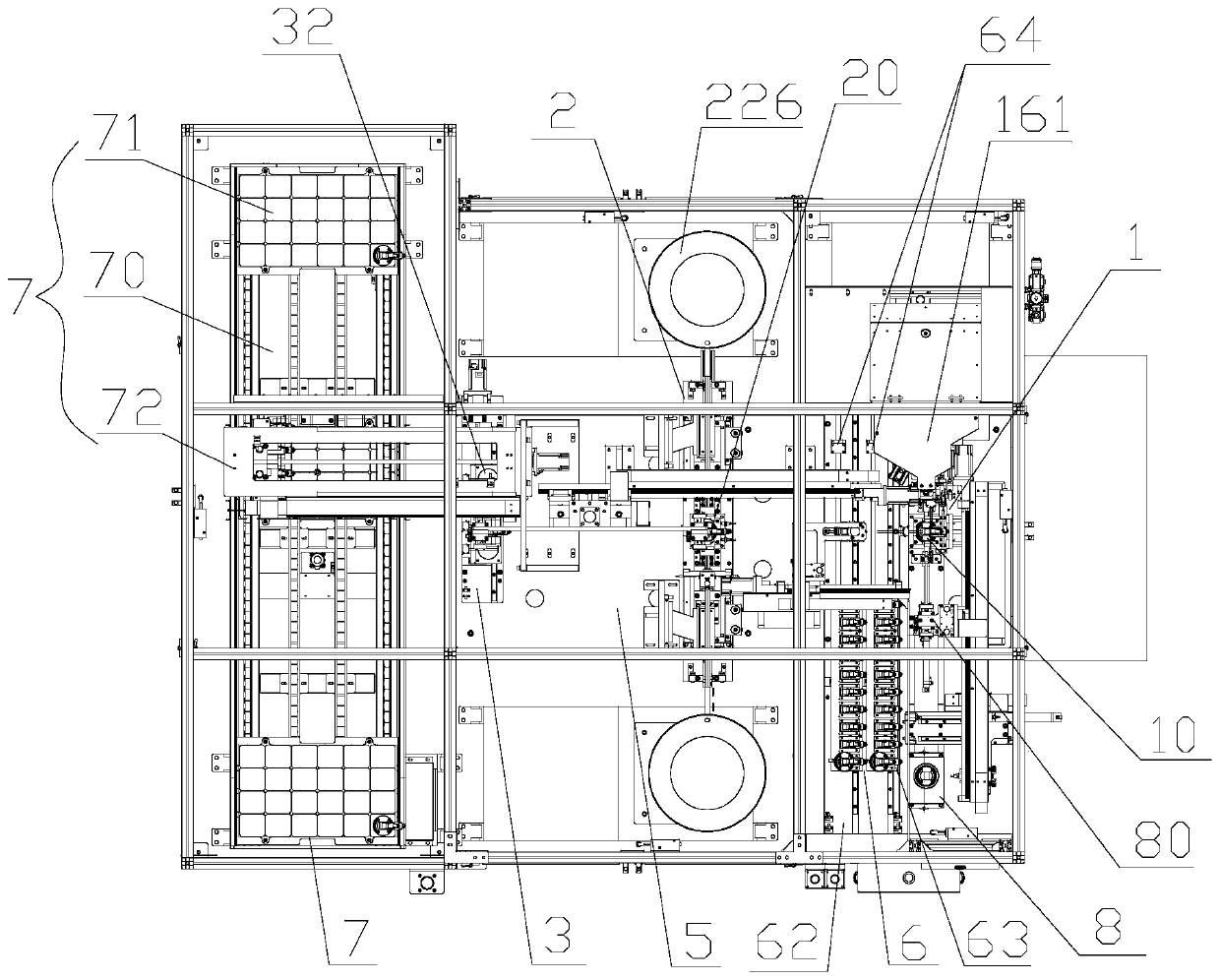

[0049] refer to Figure 1 to Figure 17 , the connecting rod piston pin retaining ring automatic assembly machine of the present invention mainly includes a piston pin pressing line 1, a retaining ring pressing line 2, a finished product temporary storage line 3 and a finished product conveying line 7, as shown in the figure, the piston pin pressing line 1. The retaining ring press-fitting line 2 and the finished product temporary storage line 3 are all installed on the same workbench 5, and the three are arranged in parallel in turn, basically at the same level, and the finished product conveying line 7 is located on the finished product temporary storage line 3 away from the retaining ring On one side of the press-fitting line 2, the piston pin press-fitting line 1 is mainly used to complete the installation of the piston pin and realize the fixed connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com