Efficient multifunctional tool for finish machining of piston

A multi-functional, piston technology, applied in the direction of pistons, manufacturing tools, metal processing equipment, etc., to achieve efficient multi-functional, eliminate shear stress, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

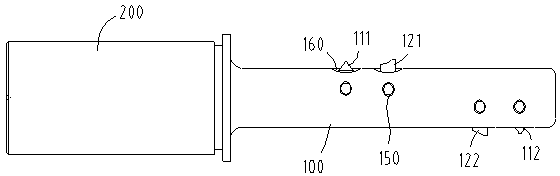

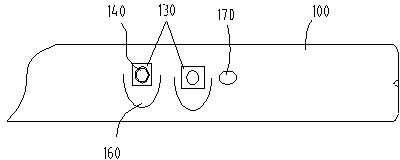

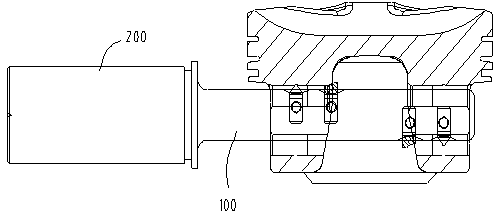

[0022] Such as figure 1 and 3 As shown, the high-efficiency multifunctional tool for piston finishing of the present invention includes a cutter bar 100 and a tool handle 200 connected in sequence, wherein the tool handle is connected with a rotating device to drive the tool bar to rotate synchronously to complete the work. The first snap ring groove cutter 111, the first inner chamfering cutter 121, the second inner chamfering cutter 122 and the second snap ring groove cutter 112 are arranged in sequence along the axial cylindrical side on the said cutter bar 100, wherein the first snap ring groove cutter The ring groove cutter and the first inner chamfering cutter are located on the same side, and the second inner chamfering cutter and the second snap ring groove cutter are located on the same side. Size design. The first snap ring groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com