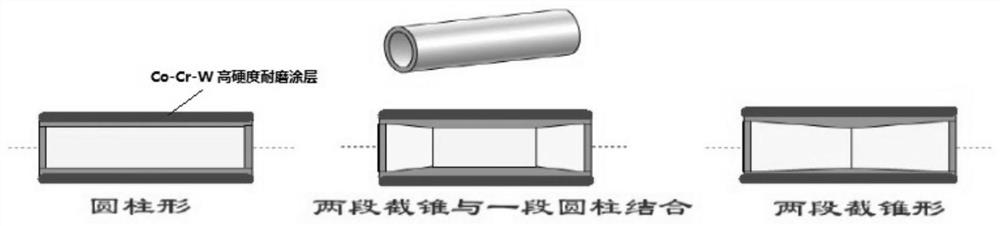

High-hardness wear-resistant piston pin and preparation method thereof

A piston pin, high hardness technology, applied in the direction of piston, cylindrical piston, plunger, etc., can solve the problems of low material utilization rate, large internal stress of the coating, low service life, etc., to improve the bonding performance and high bonding strength. , the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

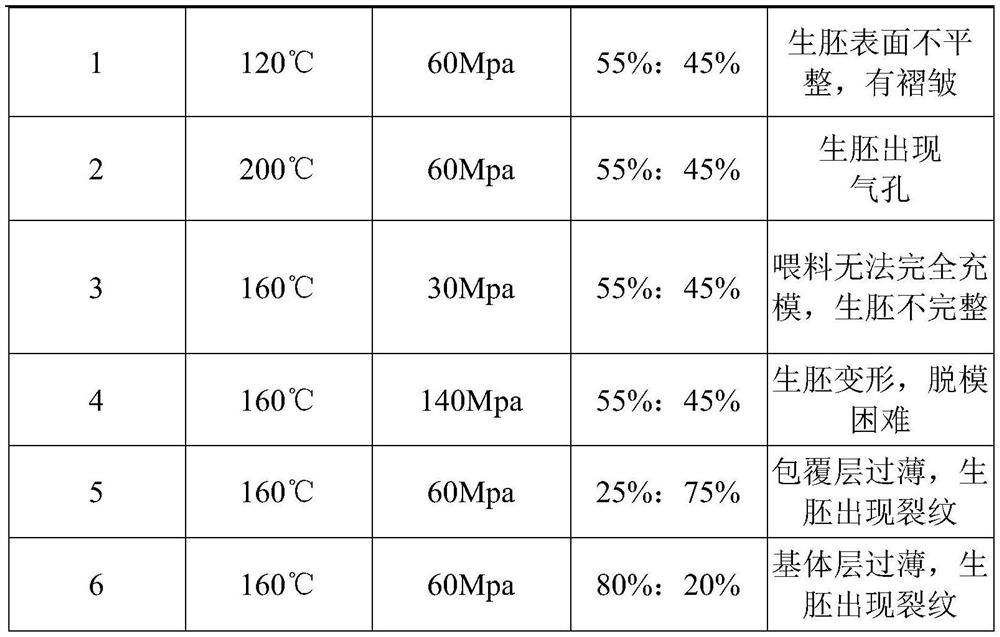

Examples

Embodiment 1

[0054] A high-hardness wear-resistant piston pin and its preparation technology, the process is as follows:

[0055] A. Raw material preparation: the base material is 31CrMoV9 alloy powder prepared by gas atomization, the average particle size is 14.8μm, and the chemical composition is: C: 0.27~0.34wt%, Cr: 2.30~2.70wt%, Mo: 0.15~0.25wt% , V: 0.10 to 0.20 wt%, Fe: balance.

[0056] Co-33Cr-18W-1C-0.5B (wt%) alloy powder prepared by gas atomization is selected as the coating layer material, with an average particle size of 13.6 μm.

[0057] Binders A and B: prepared according to the following mass percentages, polyoxymethylene (POM): 85%; polyethylene (PP): 10%; polyolefin elastomer (POE): 3%; BASF 1098 antioxidant: 1%; Stearic acid (SA): 1%.

[0058] B. Preparation of feed: mix binder A and 31CrMoV9 alloy powder according to the volume ratio of 45%:55%, and granulate to make matrix material feed. The mixing temperature is 155°C, and the speed of the mixer is 90r / min, the m...

Embodiment 2

[0064] A high-hardness wear-resistant piston pin and its preparation technology, the process is as follows:

[0065] A. Raw material preparation: the base material is Inconel718 alloy powder prepared by gas atomization, the average particle size is 16.8 μm, and the chemical composition is: C: ≤0.08wt%, Nb: 4.75-5.5wt%, Mo: 2.8-3.3wt%, Cr: 17-21 wt%, Ni: 50-55 wt%, Ti: 0.65-1.15 wt%, Al: 0.2-0.8 wt%, Fe: balance.

[0066] Co-32Cr-16W-1.2C-0.8B (wt%) alloy powder prepared by gas atomization is selected as the coating layer material, with an average particle size of 15.6 μm.

[0067] Binders A and B: prepared according to the following mass percentages, polyoxymethylene (POM): 84%; polyethylene (PP): 11%; polyolefin elastomer (POE): 3%; BASF 1098 antioxidant: 1%; Stearic acid (SA): 1%.

[0068] B. Preparation of feeding material: mixing and granulating binder A and Inconel718 alloy powder according to the volume ratio of 48%: 52% to make matrix material feeding, the mixing temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com