Patents

Literature

74results about How to "Avoid defects such as cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

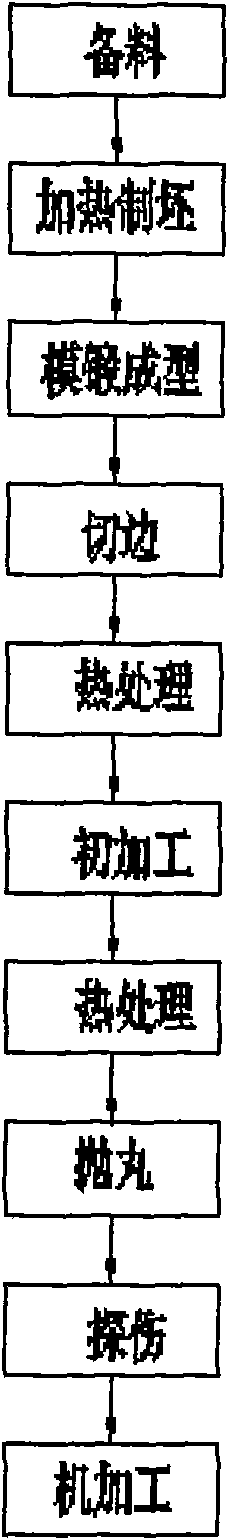

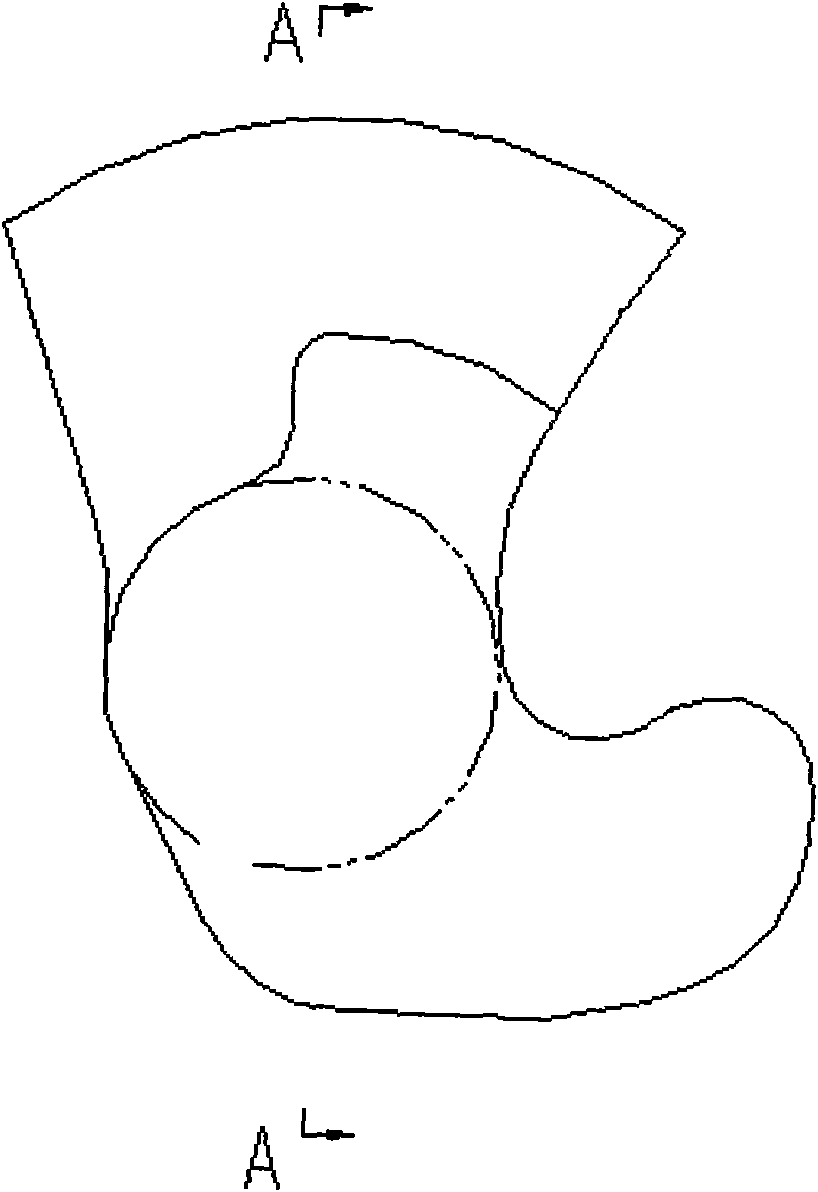

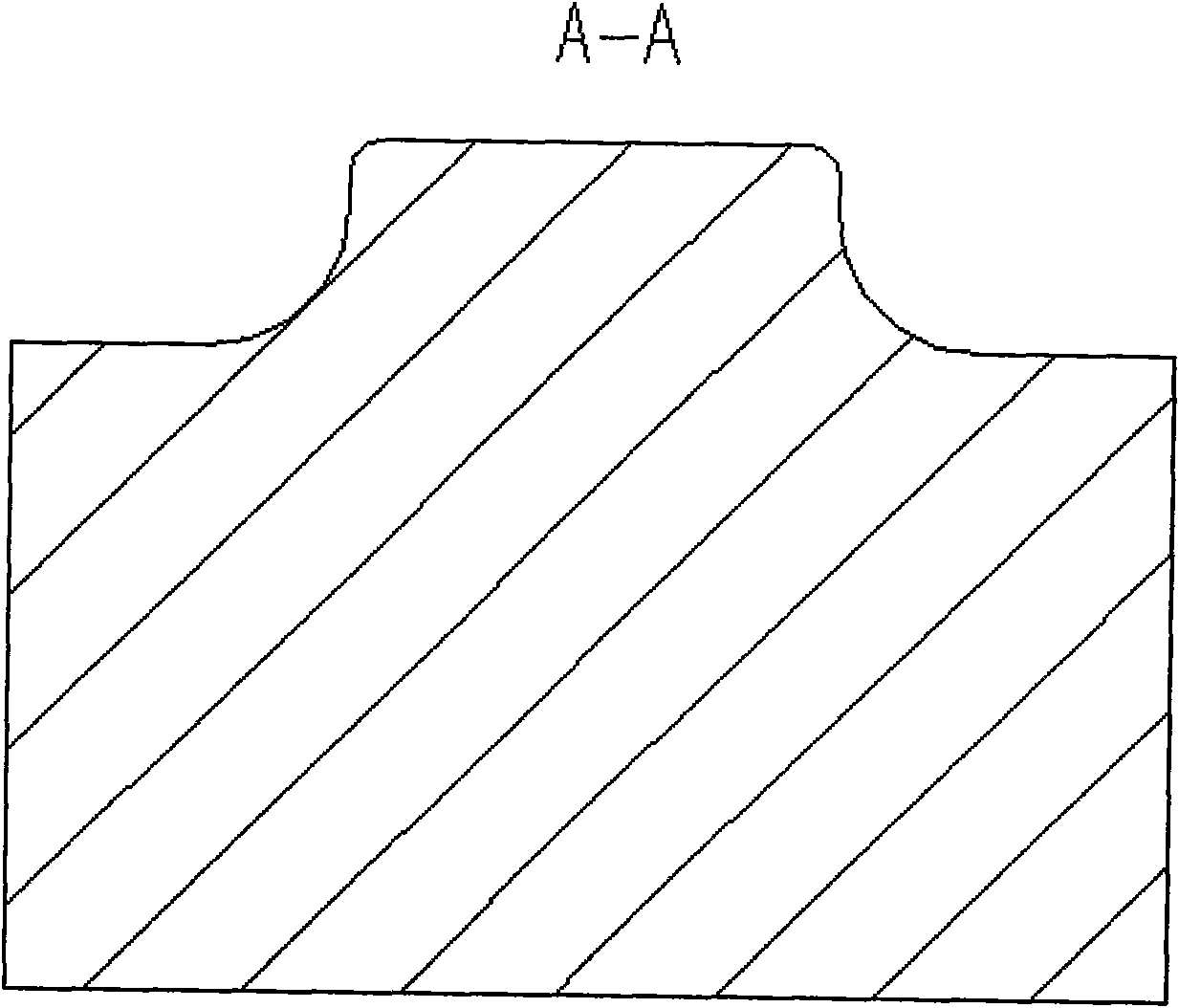

Forging method of coupler knuckle for railway vehicle

InactiveCN101559555AGood mechanical propertiesAvoid air holesOther manufacturing equipments/toolsMaterials preparationToughness

The invention discloses a forging method of a coupler knuckle for railway vehicles. The coupler knuckle for railway vehicles is formed by forging, and coupler knuckle products for railway vehicles with qualified performance and size are forged by the working procedures of material preparation, heating and blank forming, die forging and forming, trimming, heat treatment, preliminary processing, heat treatment, shot blasting, fault detecting and machining. The forging method of the coupler knuckle for railway vehicles, in which the coupler knuckle for railway vehicles has compact texture, high toughness and good fatigue performance, solves the defects of air pore, shrinkage porosity, inclusion, crack, short service life and the like of the coupler knuckle of the existing cast steel vehicle coupler.

Owner:CHONGQING CHANGZHENG HEAVY IND

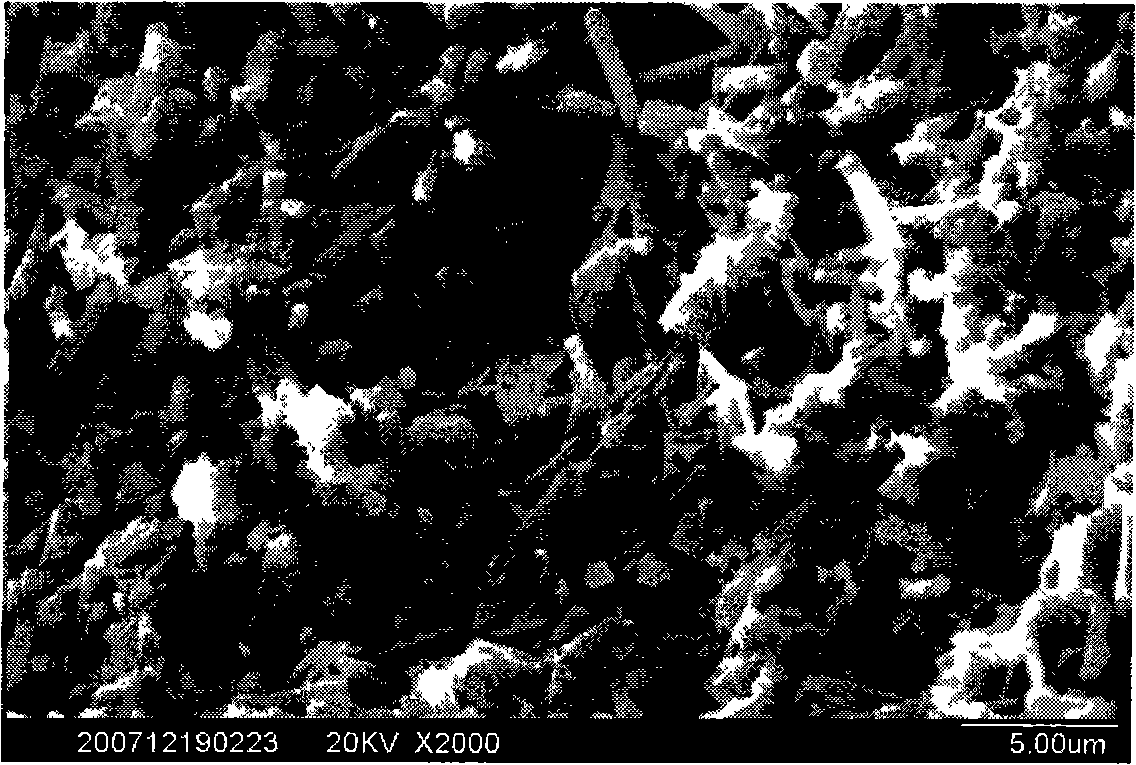

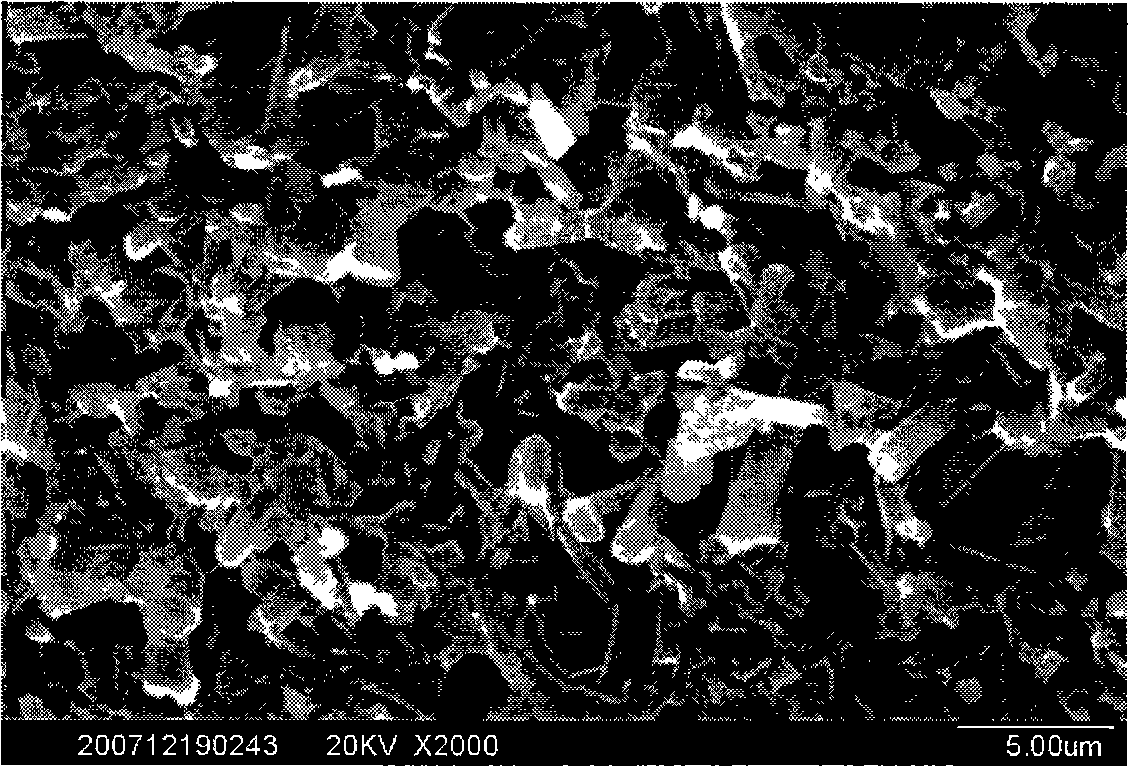

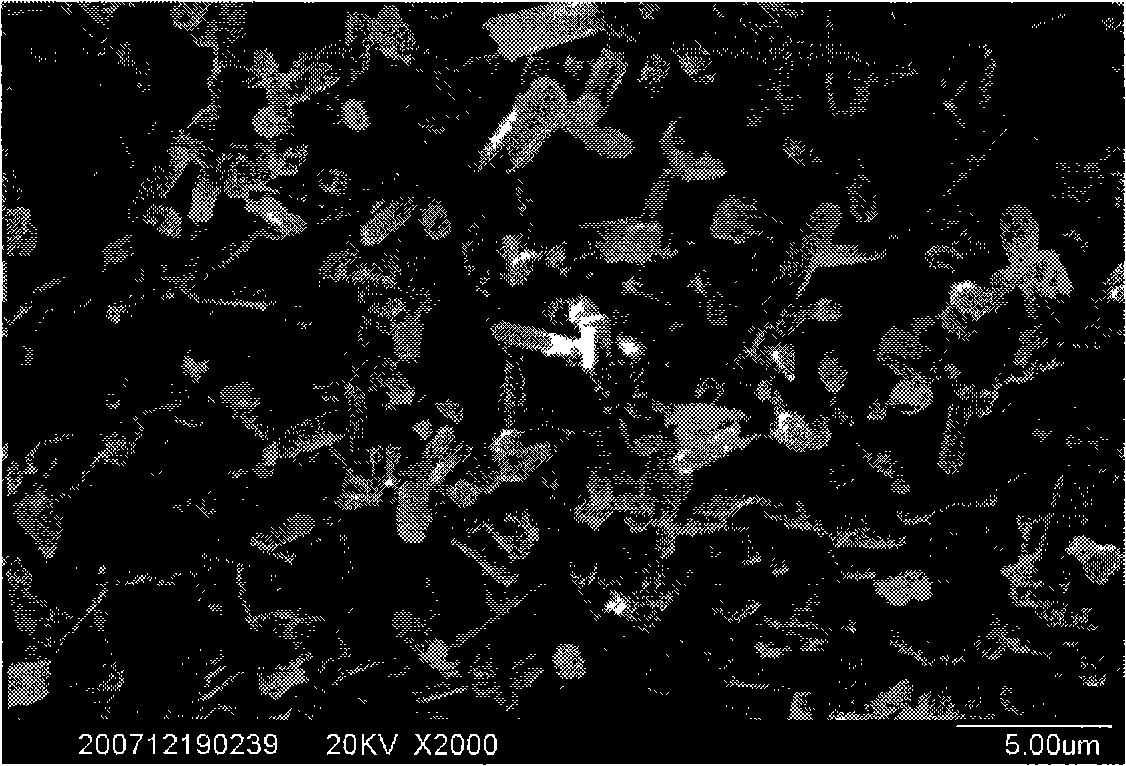

Petroleum case pipe with high strength and toughness and producing method thereof

InactiveCN101285151AImprove toughnessGrain refinementDrilling rodsTemperature control deviceAlloyUltra fine

The invention discloses a petroleum casing pipe with high obdurability and a method for making the same. The invention aims to provide a petroleum casing pipe with high obdurability which can meet the mining conditions of deep wells or ultra-deep wells in the oil field and a method for making the same. The compositions in percentage by weight of the petroleum casing pipe are: 0.22 to 0.35 percent of C, 0.17 to 0.30 percent of Si, 0.45 to 0.60 percent of Mn, 0.80 to 1.10 percent of Cr, 0.70 to 1.10 percent of Mo, 0.015 to 0.040 percent of Al , less than 0.20 percent of Ni, less than 0.20 percent of Cu, 0.070 to 0.100 percent of V, less than 0.050 percent of Nb, less than 0.0015 percent of Ca, less than 0.010 percent of P, less than 0.003 percent of S, the balance being Fe. The petroleum casing pipe of the invention adopts a quenched and tempered steel of Cr-Ni-Mo-V alloy system. An ultra-fine lath is obtained after the steel is heat-treated. A certain amount of austenitic toughness phases are distributed dispersedly on a martensite matrix, which improves the obdurability of the steel so as to adapt to bear the outside squeezing load and the axial load brought by the deep wells or the ultra-deep wells.

Owner:TIANJIN UNIV OF COMMERCE

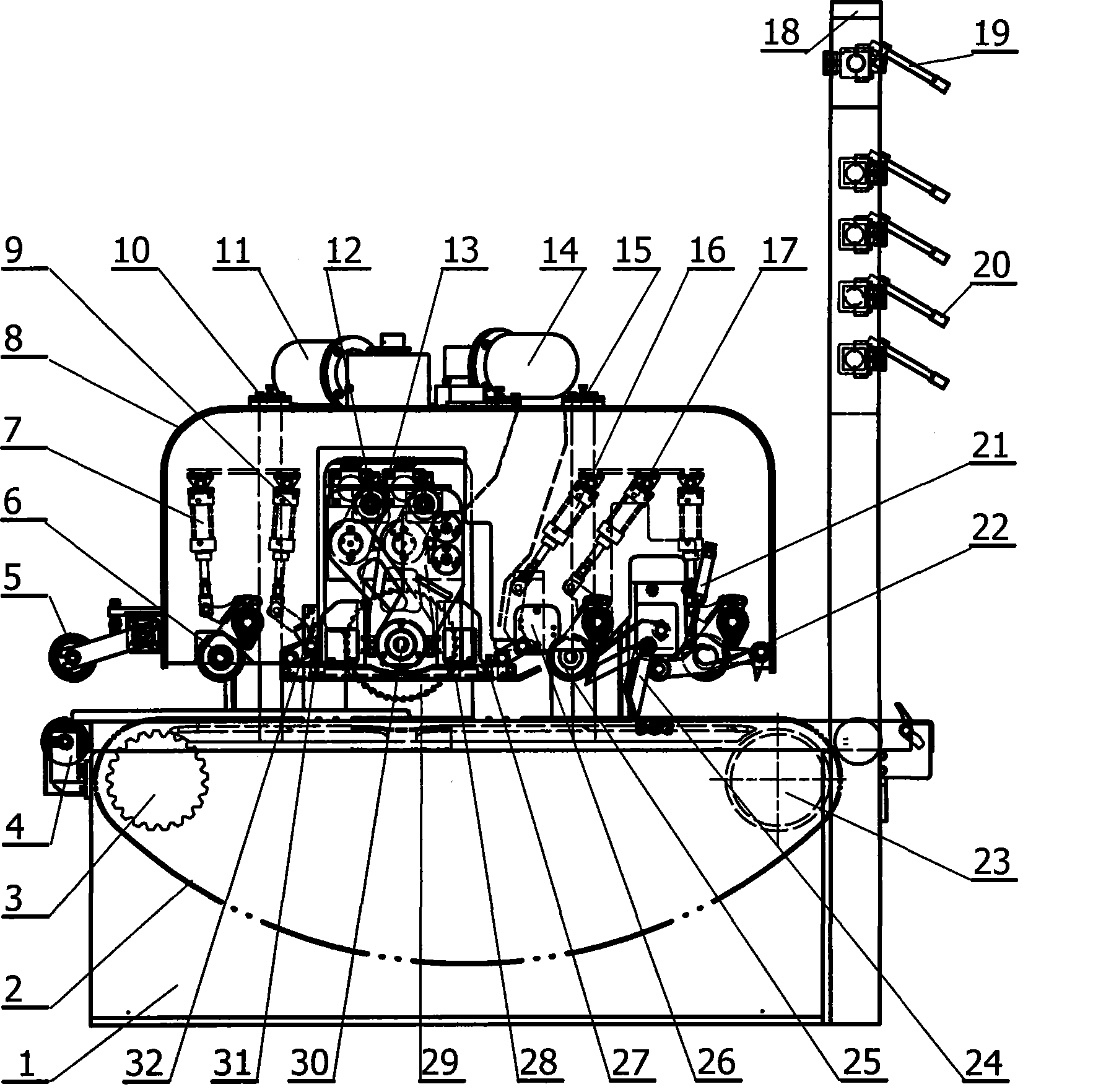

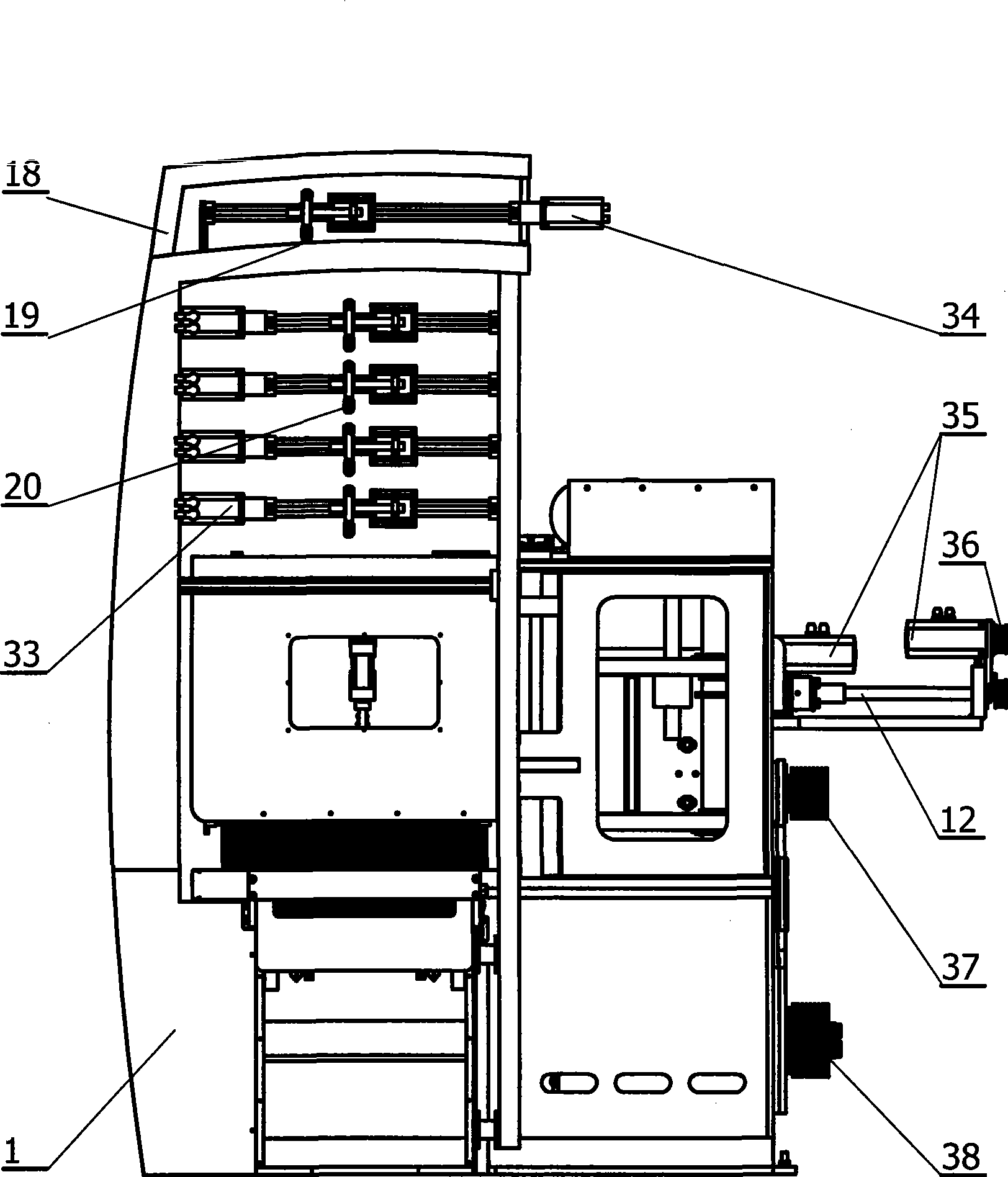

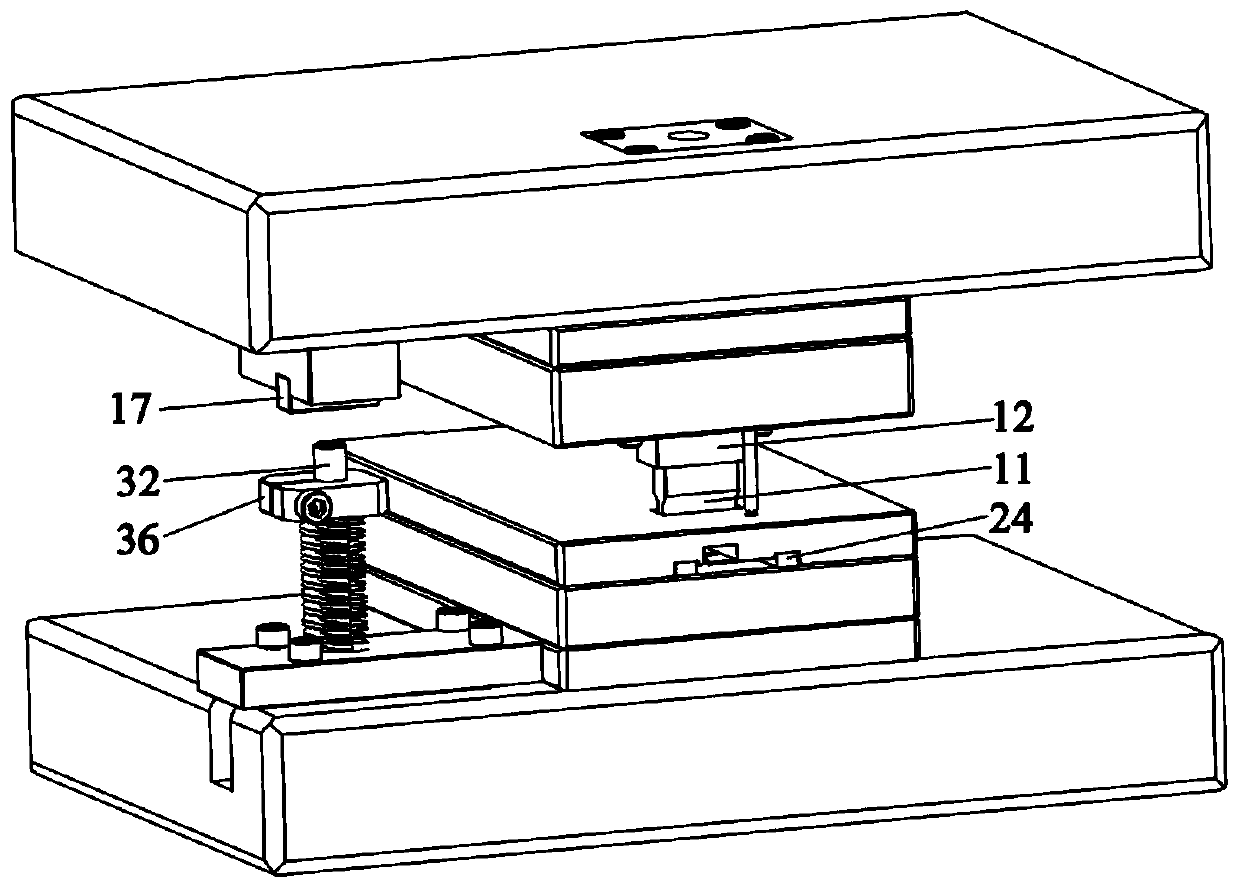

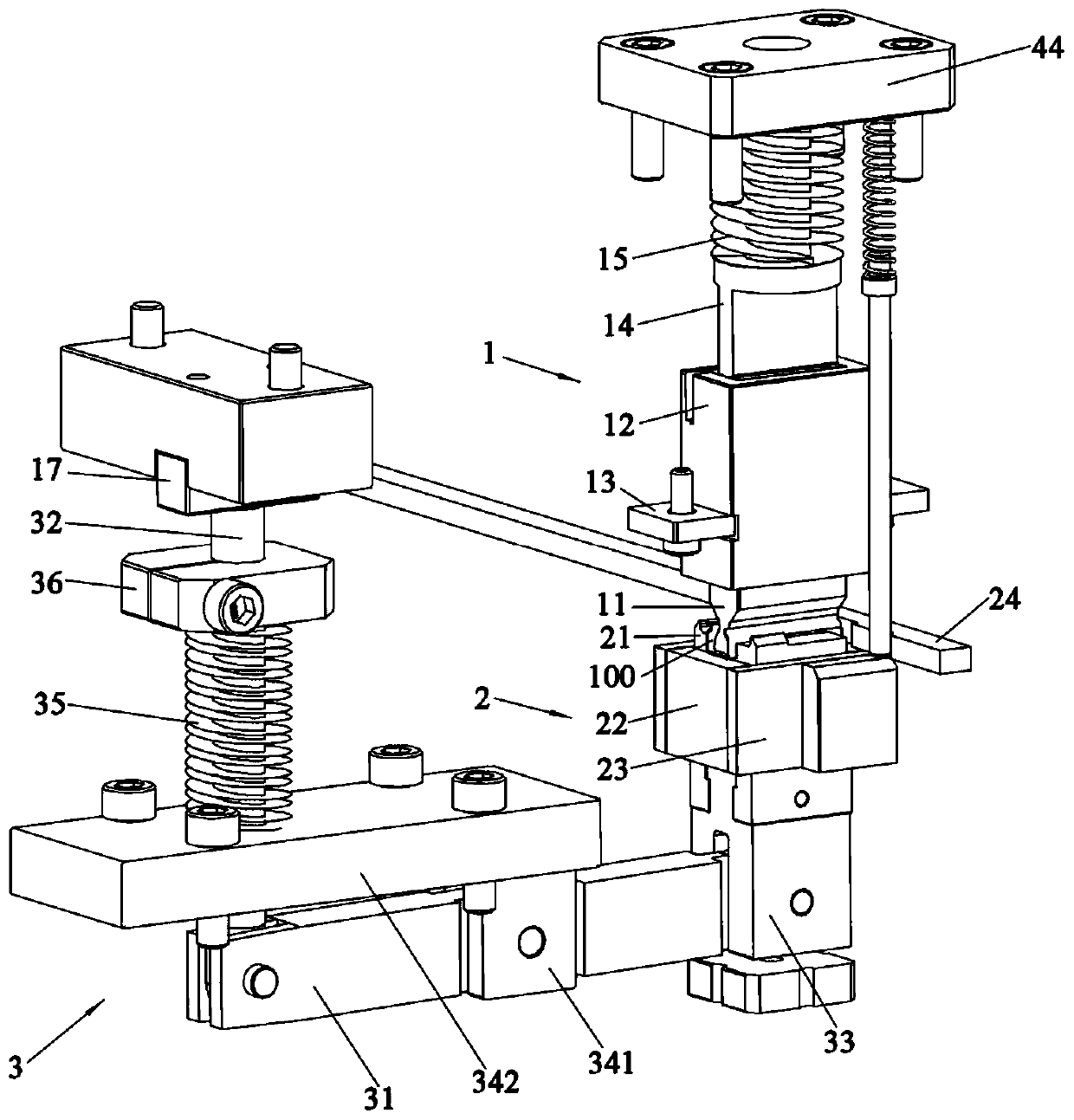

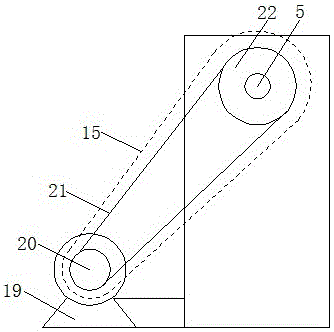

Method for preferably cutting timber in longitudinal direction and circular saw machine for preferably cutting timber in longitudinal direction

The present invention discloses a method for longitudinally optimizing cutting timber. The method comprises the following steps: inputting a cutting data list into a computer device beforehand, selecting a width reference border of sawtimber to be cut for confirming the maximum width of sawtimber to be cut, transmitting the information to the computer device for selecting an optimal cutting plan through analyzation and calculation, axially moving the circular saw blade of saw cutting machine to a cut line position corresponding with the sawtimber to be cut according to instruction of computer device for longitudinally cutting the sawtimber to be cut to finished sawtimber and waste edge material. The timber cutting optimizing circular sawing machine for realizing the method of the invention comprises a circular sawing machine base, a feeding chain plate, a sawblade main shaft, a front compression roller and a back compression roller, wherein the front compression roller and the back compression roller are positioned at the front side and the back side. The marking-off equipment stand which is fixedly installed at the front end of engine base is installed with follower marking-off equipment. A moving circular saw blade is installed on the main shaft of sawblade. The main shaft assembly and the upper frame are respectively supported on the front lifting upright post and the back lifting upright post with a liftable mode. The method of the invention can greatly increase the material yielding rate and production efficiency and has the advantages of high automatization degree and wide application sphere.

Owner:JIANGSU JIANGJIA MACHINERY

Silicon nitride porous ceramic composition and preparation method thereof

The invention discloses a porous silicon nitride ceramics composing prescription and a method for the products thereof, containing the following components by weight: 50-70 per centsilicon nitride powder, 5-30 per cent bentonite, 0-10 per cent sintering additives and 20-30 per cent water. The sintering additives, contain at least one of Y2O3, Al2O3 and MgO and the method includes: weighing the components except water before placing into a ball mill for dry mixing-grinding to make a mixed powder which is then put into a wheel roller for wheel grinding and kneading to obtain a pug; putting the pug into an extruder for extrusion forming to obtain a shaped body; then drying the shaped body before putting into an atmosphere oven where the shaped body is heated to a temperature of 1700-1850 DEG C in the nitrogen at a heating rate of 10 DEG C / min and then insulation sintered for 1 to 3 hours at a nitrogen pressure of 1-6 atmospheric pressure to obtain a sintered body . The porous silicon nitride ceramics of the invention can be widely used as matrix of filters for gas separation at high temperature and in corrosive atmosphere and as heat-resistant or enhanced materials for power generation gas turbines, engines and space shuttles.

Owner:XI AN JIAOTONG UNIV

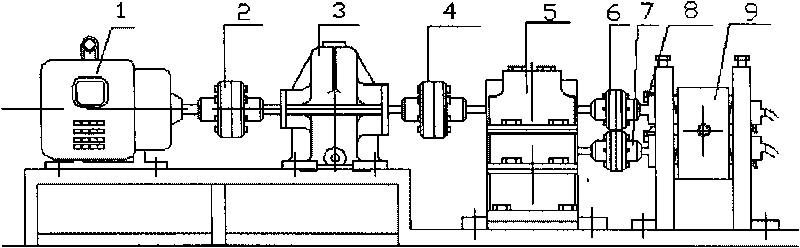

Multi-purpose double-roll continuous rheological forming device for liquid metal

InactiveCN101690941AIncrease productivitySolve low production efficiencyMetal rolling arrangementsLiquid stateCoupling

The invention discloses a multi-purpose double-roller continuous rheological forming device for liquid metal, which is mainly used for double-roller continuous rheological forming of plates, strips, pipes, profiles, wires, composite materials and wrapping materials. The device consists of a motor, a half coupling, a decelerator, a gear box, a main machine, a cooling water tank and a coiling machine, wherein the main machine consists of a stander, an upper working roller, a lower working roller, a feeding shoe, an extrusion shoe, a die in a cavity of the extrusion shoe, and rotating speed sensors at shaft heads of the upper working roller and the lower working roller of the main machine. An annular groove of the upper working roller is mutually matched with an annular lug boss of the lower working roller. The feeding shoe is arranged at the feeding end of the main machine, and the feeding shoe and the annular groove of the upper working roller form a feeding cavity. A metal material enters into a roller gap between the two working rollers through the feeding cavity. When producing pipes, profiles, wires and wrapping materials, the extrusion shoe is arranged at the discharging end of the main machine, and an extrusion forming die can be arranged in the cavity of the extrusion shoe. The device can realize quick continuous rheological forming of the liquid metal, and can also be used for direct forming of a semi-solid metal material.

Owner:NORTHEASTERN UNIV

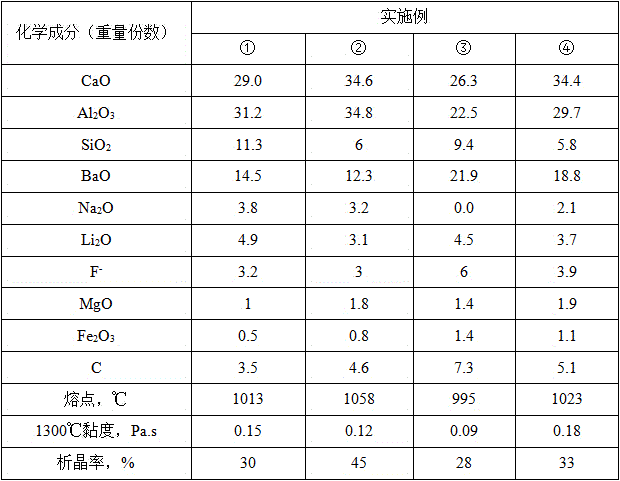

Crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of crystallizer covering slag

The invention provides a crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of the crystallizer covering slag. The covering slag is prepared from the following components in parts by weight: 20-38 parts of CaO, 20-35 parts of Al2O3, 5-18 parts of SiO2, 10-22 parts of BaO, 2-7 parts of Li2O, 5-12 parts of F<->, 1-4 parts of MgO, 2-8 parts of C and Fe2O3 which is less than or equal to 2 parts. According to the preparation method disclosed by the invention, wollastonite, limestone, quartz sand, fluorite, bauxite, barium carbonate, magnesia, soda, lithium carbonate and carbonaceous materials are used as raw materials, and the covering slag is prepared through the following steps of: calculating of consumption, melting, smashing, fine grinding, drying and granulation. The covering slag disclosed by the invention has the characteristics of being low in reactivity and good in property stability, the lubrication and the thermal transmission of casting blanks can be effectively coordinated and controlled, the smooth performing of the continuous casting process of the high-manganese high-aluminum steel can be guaranteed, high-manganese high-aluminum steel continuous casting blanks with excellent surface quality are cast, and multi-heat continuous casting can be realized.

Owner:CHONGQING UNIV

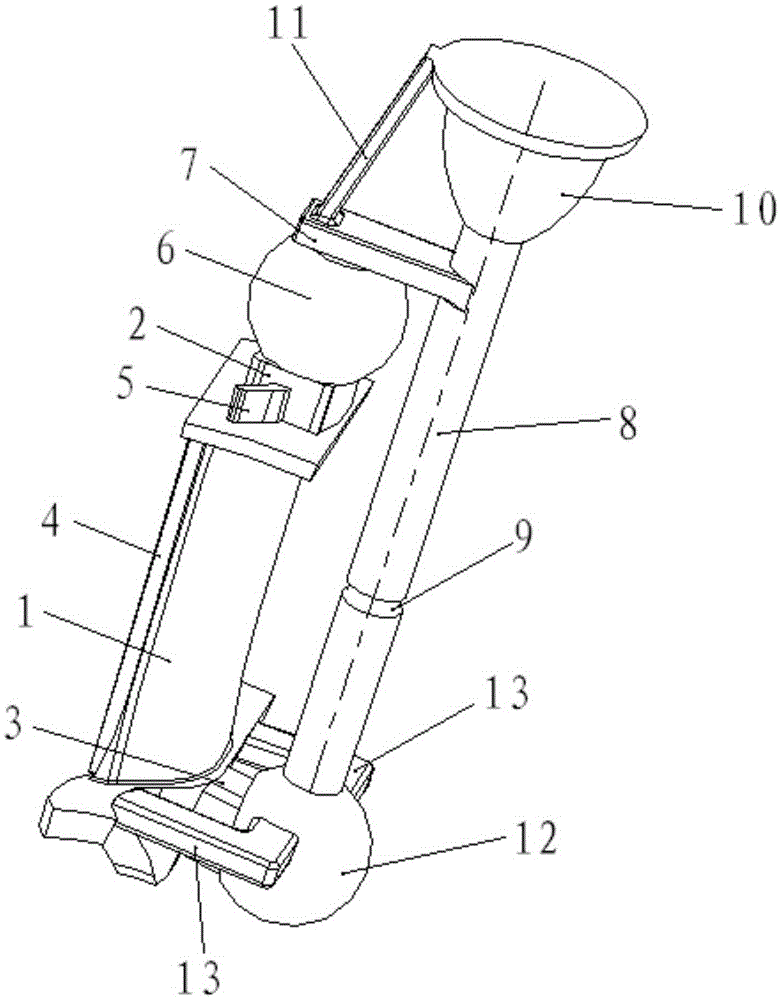

Wax mold of large-size hollow shrouded blade casting pouring system and manufacturing method of wax mold

The invention provides a wax mold of a large-size hollow shrouded blade casting pouring system and a manufacturing method of the wax mold. The wax mold comprises a casting wax mold and a runner wax mold; a core is arranged in the casting wax mold; a shroud inner gate is formed in the top of the casting wax mold, while a tenon inner gate is formed in the bottom of the casting wax mold; the runner wax mold comprises a first spherical riser of which the bottom is bonded to the top of the shroud inner gate and the top is connected to one end of a first horizontal runner; the other end of the first horizontal runner is connected to a straight runner; the top of the straight runner is bonded to a gate cup, while the bottom of the straight runner is connected to a second spherical riser; the second spherical riser is bonded to the tenon inner gate; the second spherical riser is connected to one end of a second horizontal runner, and the other end of the second horizontal runner is connected to the casting wax mold. According to the wax mold of the large-size hollow shrouded blade casting pouring system, the spherical risers and the corresponding runners are designed reasonably, such that smooth filling and effective feeding to a casting can be realized and the stress can be reduced; hence, the wax mold is applicable to produce large-size, hollow shrouded and complex-structure blades; the pouring difficulty can be reduced, such defects as core breakage, looseness and cracks of the casting can be avoided, and the product qualification rate can be increased.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

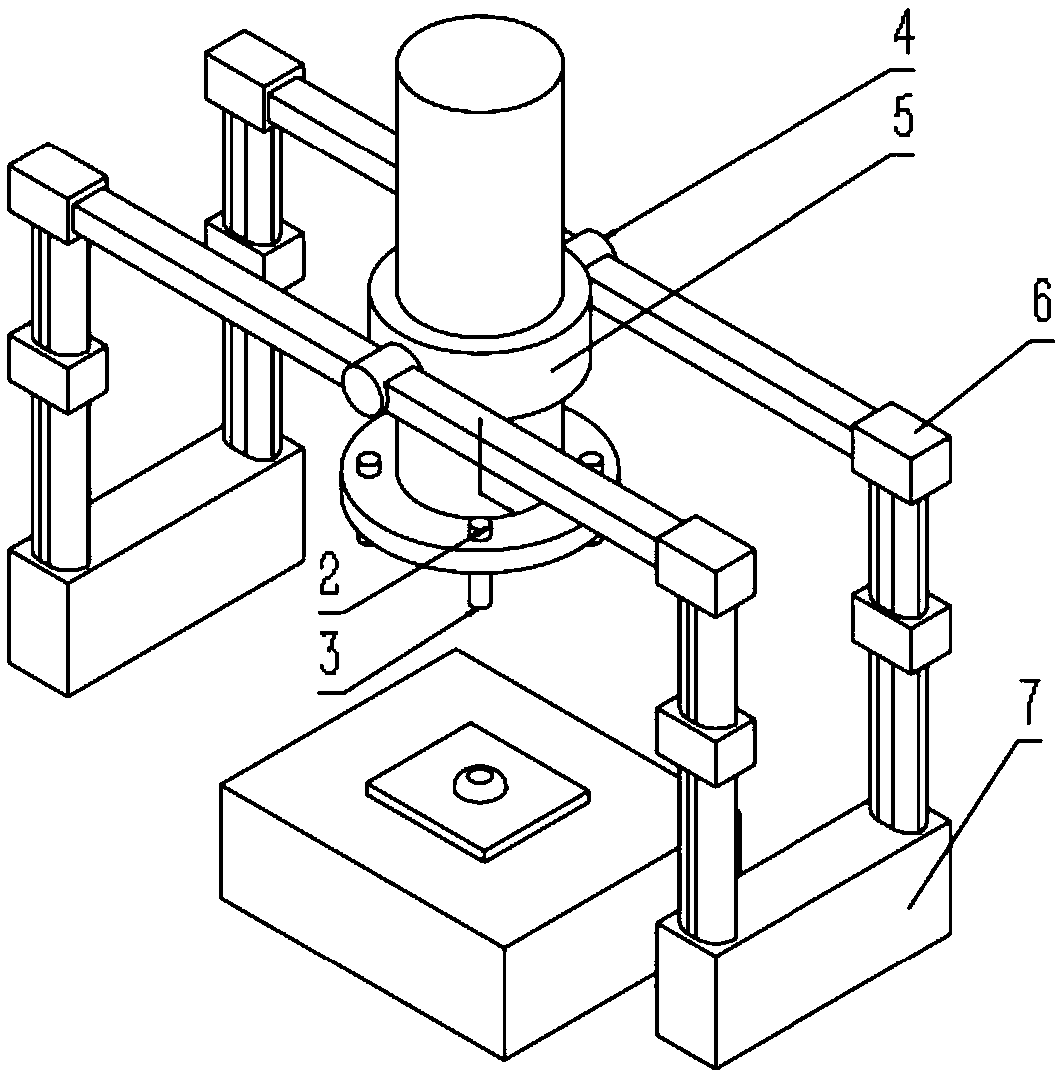

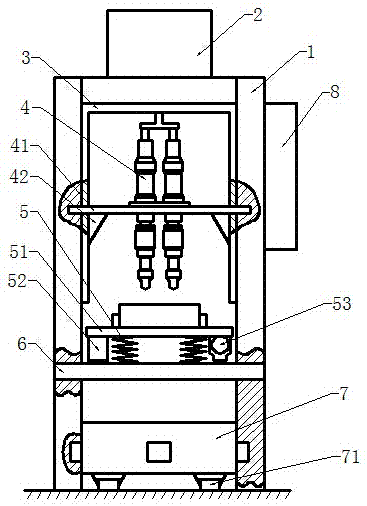

Additive manufacturing device capable of conducting magnetic field control and parent metal transport

ActiveCN108620585ARealize online controlEasy to useAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankLaser transmitter

The invention discloses an additive manufacturing device capable of conducting magnetic field control and parent metal transport. A magnetic field is applied in the metal laser solid forming quick solidification process, a thermoelectric current can be generated at the quickly solidified solid / liquid interface under the action of the magnetic field, the thermoelectric current and the magnetic field interact to generate thermoelectric magnetic force triggering melt flow, shearing is caused after the force effect is conducted on the end of dendritic crystal, thus, the dendritic crystal is broken, a lot of new crystal nucleuses are formed, and the nucleation rate is increased; and metal melt flow is inhibited by the magnetic field, and the segregation effect in the solidification process is relieved. According to the additive manufacturing device, different laser metal additive manufacturing parent metal transport devices are combined, and parent metal transport and structure control under the conditions of powder paving, powder feeding and wire feeding and other various printing conditions are achieved. The magnetic field control device is fixed to a laser transmitter to serve as a parent metal transport device, the effect that a laser molten pool is located at the center of the magnetic field all the time is ensured, control over the magnetic field is facilitated, and the influence of the magnetic field on the laser solid forming quick solidification process is further explored.

Owner:SHANGHAI UNIV

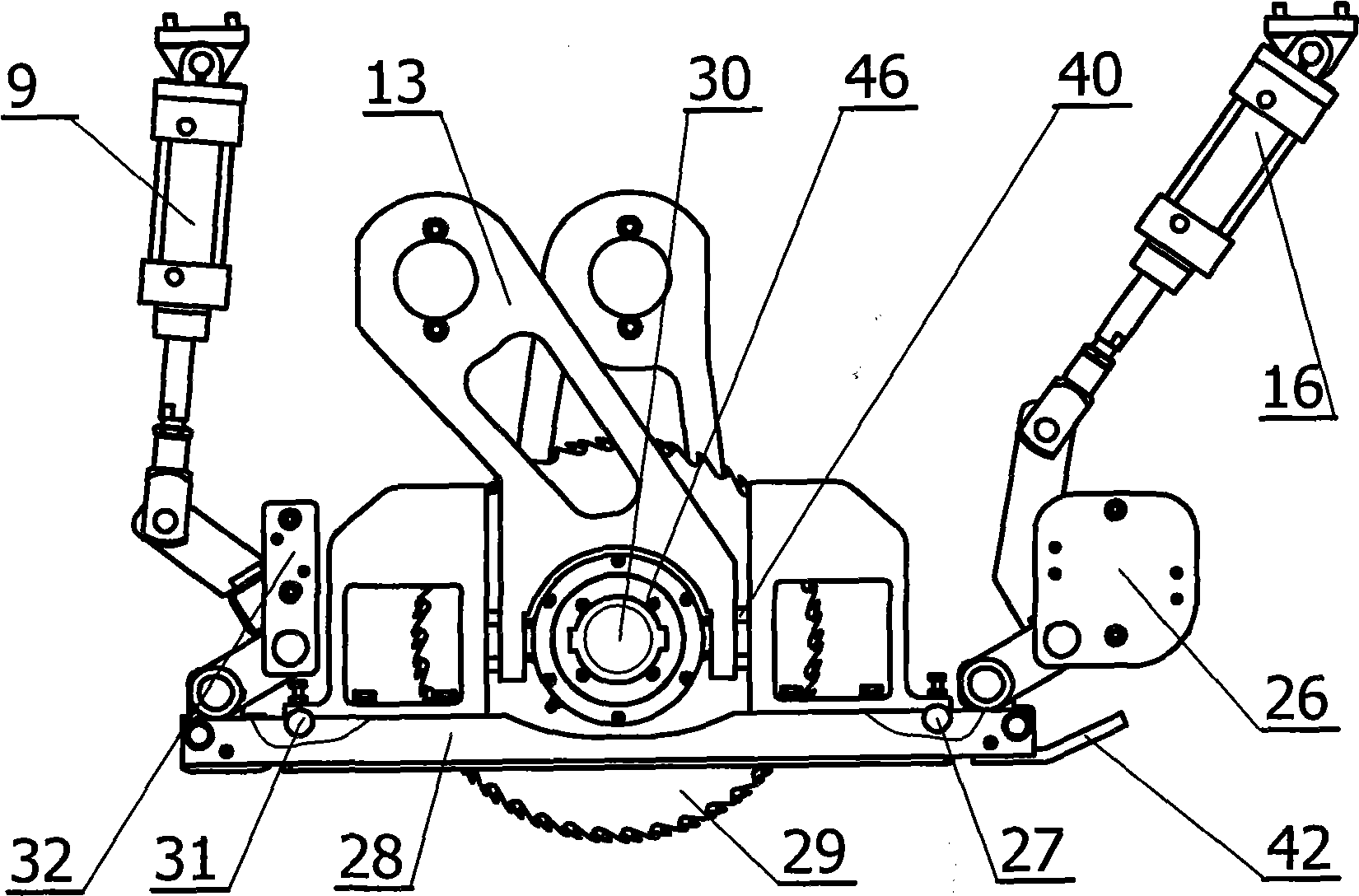

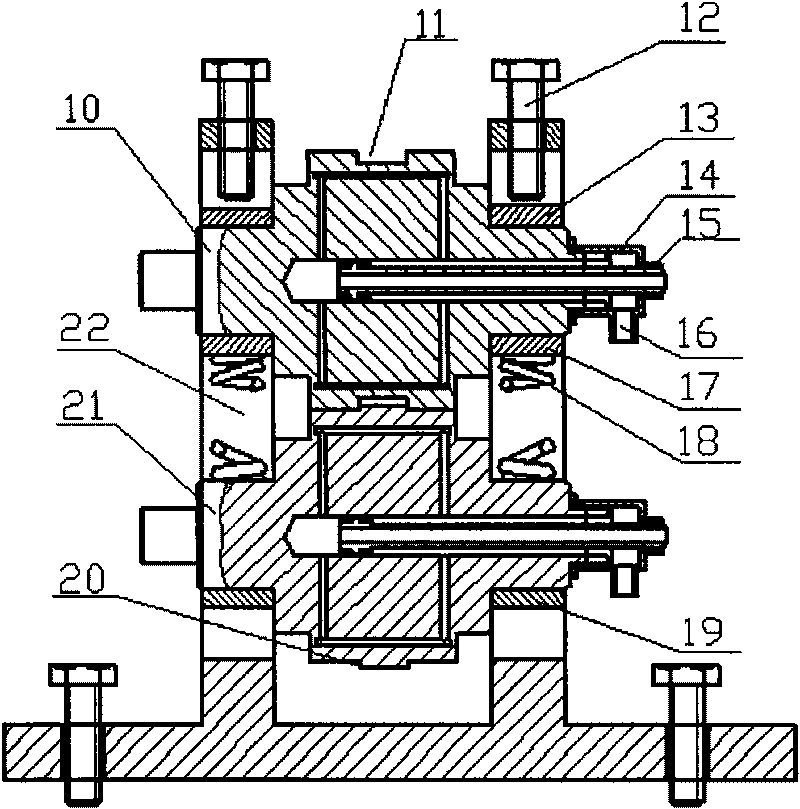

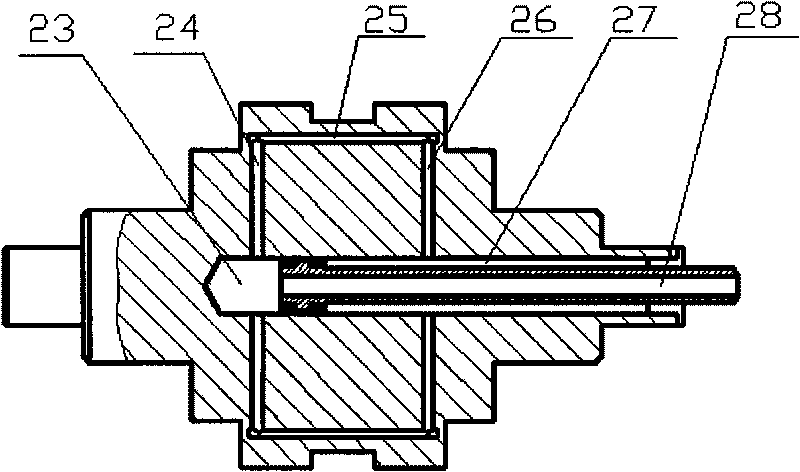

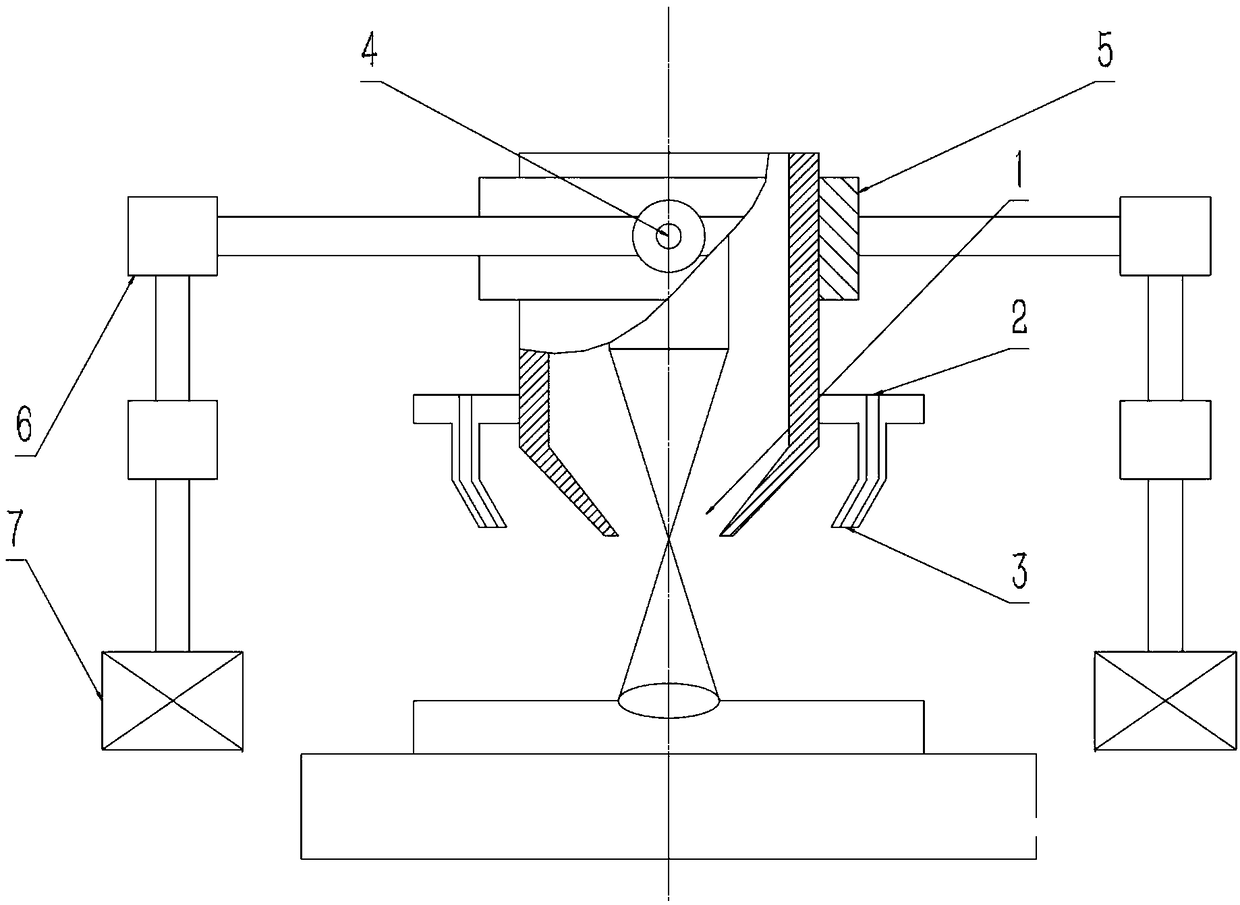

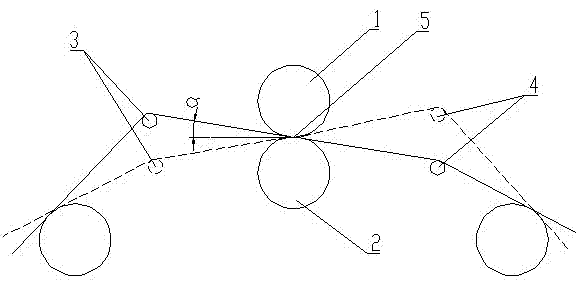

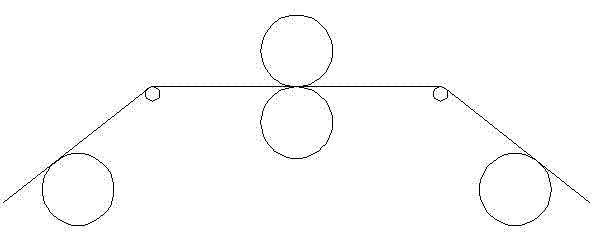

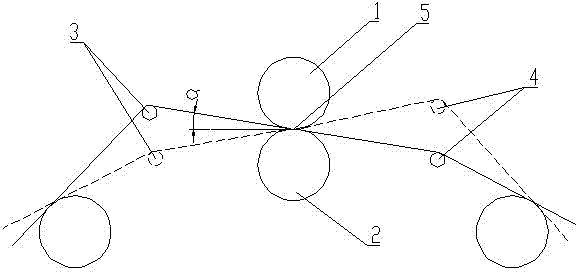

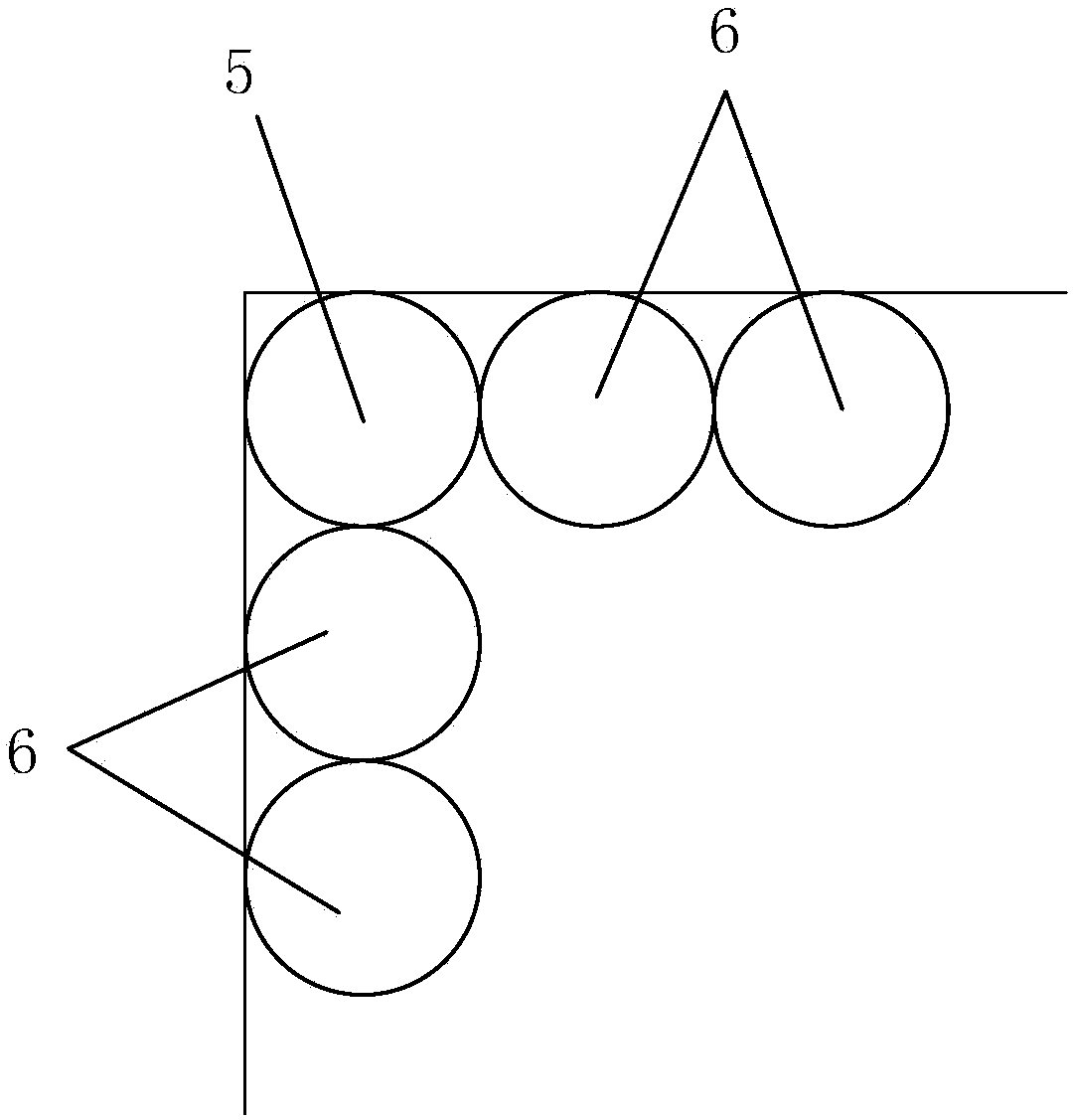

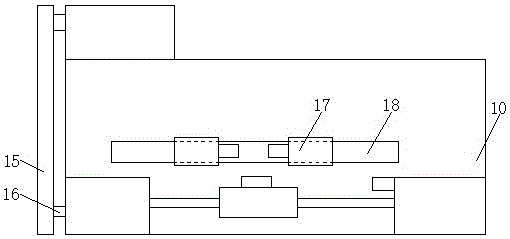

Magnesium alloy plate rolling device

InactiveCN102357527AGood molding effectAvoid defects such as cracksMetal rolling arrangementsMagnesium alloyGrain orientation

The invention discloses a magnesium alloy plate rolling device, which comprises a roller pair consisting of an upper roller and a lower roller, and a front tension roller and a rear tension roller distributed at two sides of the roller pair; through the front tension roller, the tension part of a plate higher than or lower than a roller gap between the upper roller and the lower roller forms a structure that the plate is obliquely nipped into the roller gap; and because the plate blank is obliquely nipped into the roller gap, the rolling time of the upper and lower rollers is different, the grain orientation of the rolled magnesium alloy plate is oblique, the forming performance of the plate is improved, and the defects of cracks produced at the bent position during forming and the like are avoided.

Owner:CHONGQING UNIV

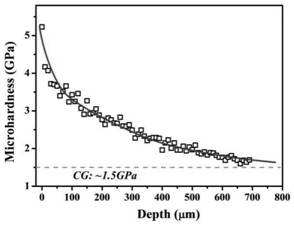

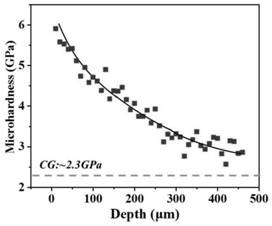

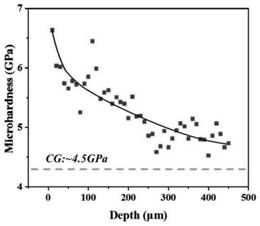

High-temperature alloy with gradient nanostructure surface layer and preparation method of high-temperature alloy

The invention discloses a high-temperature alloy with a gradient nanostructure surface layer and a preparation method of the high-temperature alloy, and belongs to the technical field of metal material surface nanocrystallization. The high-temperature alloy is treated through surface mechanical grinding technology, a spherical head is pressed into the surface of a material by a certain depth for grinding, gradient plastic deformation is generated on the surface layer of the material, a gradient organization structure for transition from nano-crystalline grains to micron-crystalline grains is formed on the surface of the high-temperature alloy, and a large hardness gradient is generated from outside to inside, so that the problems of coarse surface grains, uneven microstructure, insufficient mechanical properties and the like of the high-temperature alloy are solved. The high-temperature alloy with the gradient nanostructure surface layer and the preparation method of the high-temperature alloy have the characteristics of being simple in treatment, low in energy consumption, and suitable for industrial application.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for processing square groove or special-shaped groove in printed circuit board with corner radius being less than 0.30 mm

InactiveCN108650791AQuality assuranceNo additional punching process requiredPrinted circuit manufacturePunchingMilling cutter

The invention discloses a method for processing a square groove or special-shaped groove in a printed circuit board with the corner radius being less than 0.30 mm. The method comprises the following steps: firstly drilling a first pre-drilled hole with a drill bit in a corner, wherein the first pre-drilled hole is tangent on the both sides of the corner; then drilling one or a plurality of secondpre-drilled holes in the both sides of the first pre-drilled hole, the first pre-drilled hole is tangent to the second pre-drilled holes, and the second pre-drilled holes is tangent to the edge of thecorner; secondly, drilling a plurality of pre-drilled holes between the first pre-drilled hole and the second pre-drilled holes to form a pre-drilled groove, and finally, changing to a milling method, and milling the contour of the square groove or special-shaped groove and other areas in the contour by a milling cutter. The method not only does not need to increase a punching process, reduces the production cost, and can avoid the occurrence of defects such as non-straight edge, layering, ink falling off, cracks and the like, and the quality of the printed circuit board is ensured.

Owner:DALIAN CHONGDA CIRCUIT

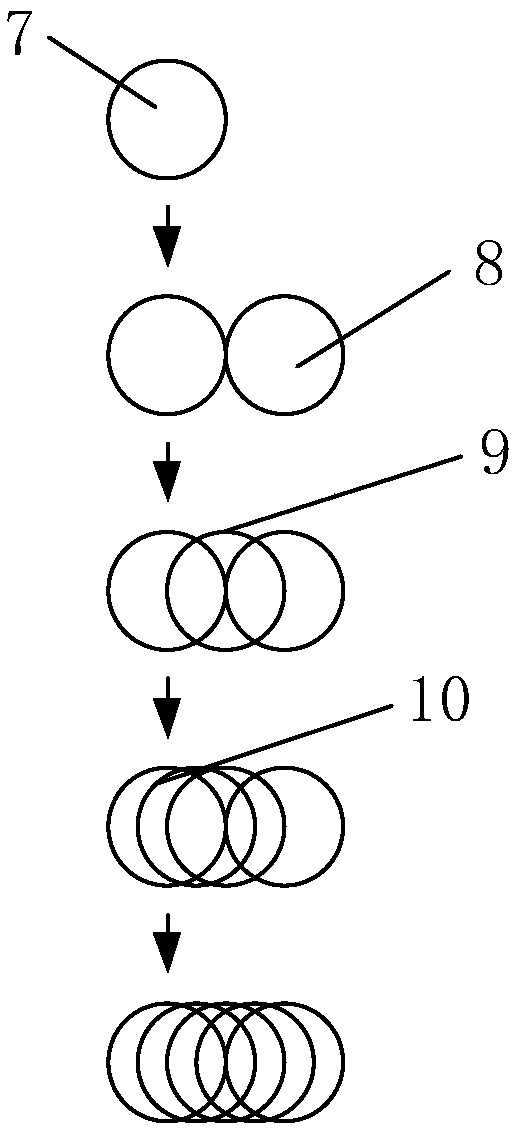

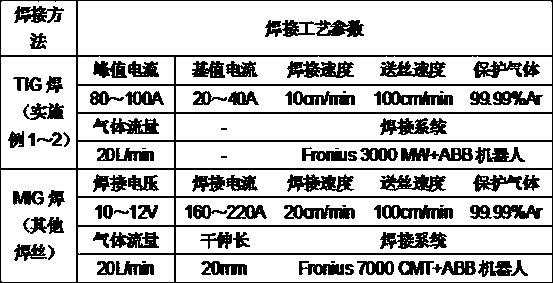

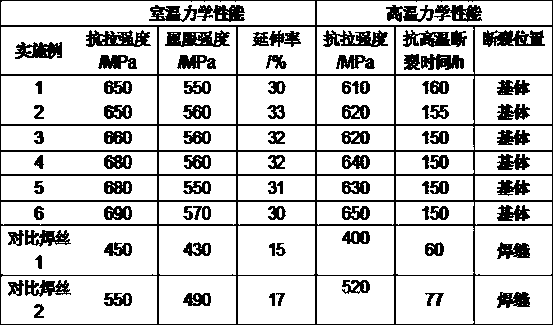

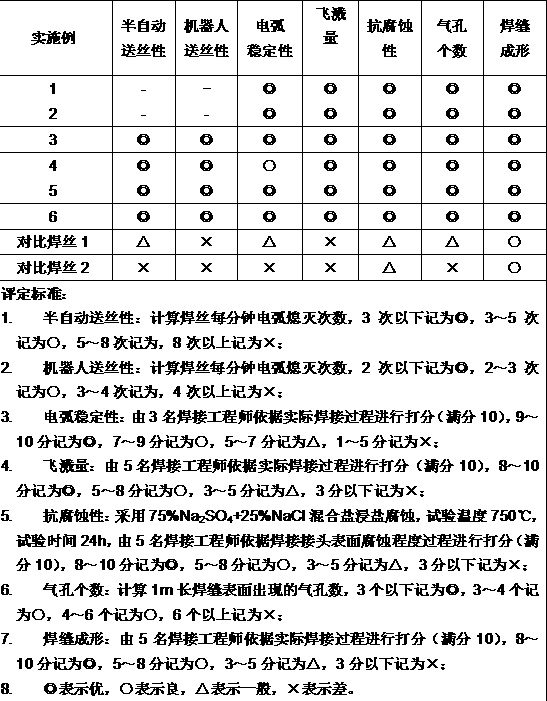

NiCrNb-Re high-temperature-resistance and corrosion-resistance welding wire for ethylene cracking furnace cast pipes and preparation method thereof

InactiveCN109894770AAvoid oxidation burnAvoid welding requirements for high temperature and corrosion resistanceWelding/cutting media/materialsSoldering mediaAcid washingAlloy

The invention discloses a NiCrNb-Re high-temperature-resistance and corrosion-resistance welding wire for ethylene cracking furnace cast pipes and a preparation method thereof, and belongs to the field of welding materials. The welding wire comprises the following components in percentage by weight: 45-50% of Ni, 35-40% of Cr, 1.00-1.50% of Nb, 0.01-0.10% of Re, 0.30-0.55% of C, 0.50-2.00% of Si,1.00-2.00% of Mn, 0.01-0.10% of Al, 0.05-0.20% of Ti, 0.01-0.10% of Zr, and the balance of Fe and inevitable impurities. The preparation method comprises the steps of alloy smelting-electroslag remelting-blooming by hot forging-hot-rolled annealing-mechanical stripping-diameter reduction by drawing-straightening and cutting or precise layer winding. The preparation method is environmentally friendly, free of acid washing pollution, stable in welding arc, free of splashing, beautiful in welding line molding, excellent in welding process and mechanical performance and dense in welding line structure, and can totally meet high-temperature-resistance and corrosion-resistance welding requirements of the ethylene cracking furnace cast pipes.

Owner:DANYANG XINHANG SPECIAL ALLOY

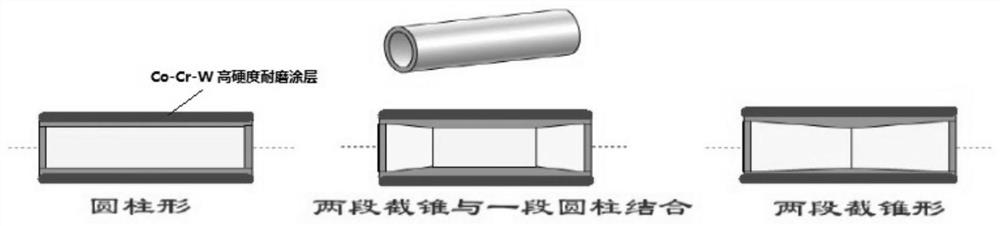

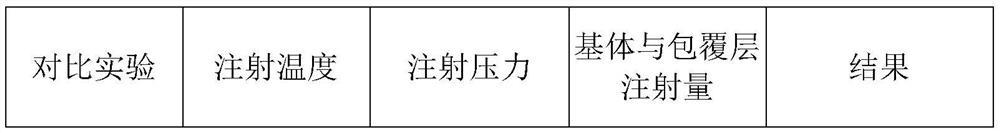

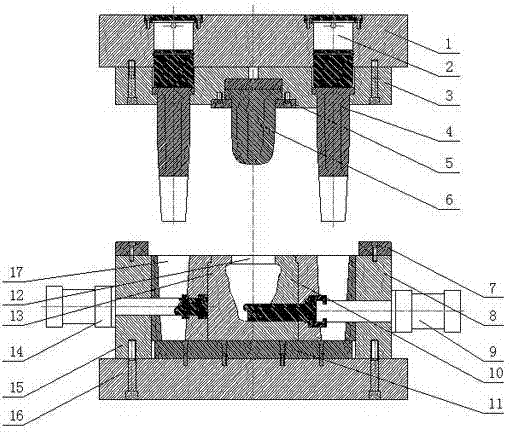

High-hardness wear-resistant piston pin and preparation method thereof

The invention discloses a high-hardness wear-resistant piston pin and a preparation method thereof. The preparation method comprises the following steps of firstly, respectively mixing matrix material powder and Co-Cr-W alloy powder with a binder, and performing granulation to obtain a matrix material feed and a high-hardness wear-resistant coating material feed; then, sequentially injecting the matrix material feed and the Co-Cr-W alloy coating material feed into a mold cavity by using an injection molding technology to obtain a product green body; removing the binder in the green body through catalytic debinding and thermal debinding processes; and finally, performing co-sintering densification to obtain the Co-Cr-W series high-hardness wear-resistant piston pin. The process is simple, the bonding performance of a coating layer and a matrix is good, and the piston pin has the characteristics of high hardness and wear resistance.

Owner:湖南英捷高科技有限责任公司

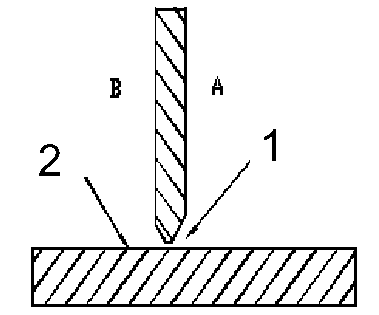

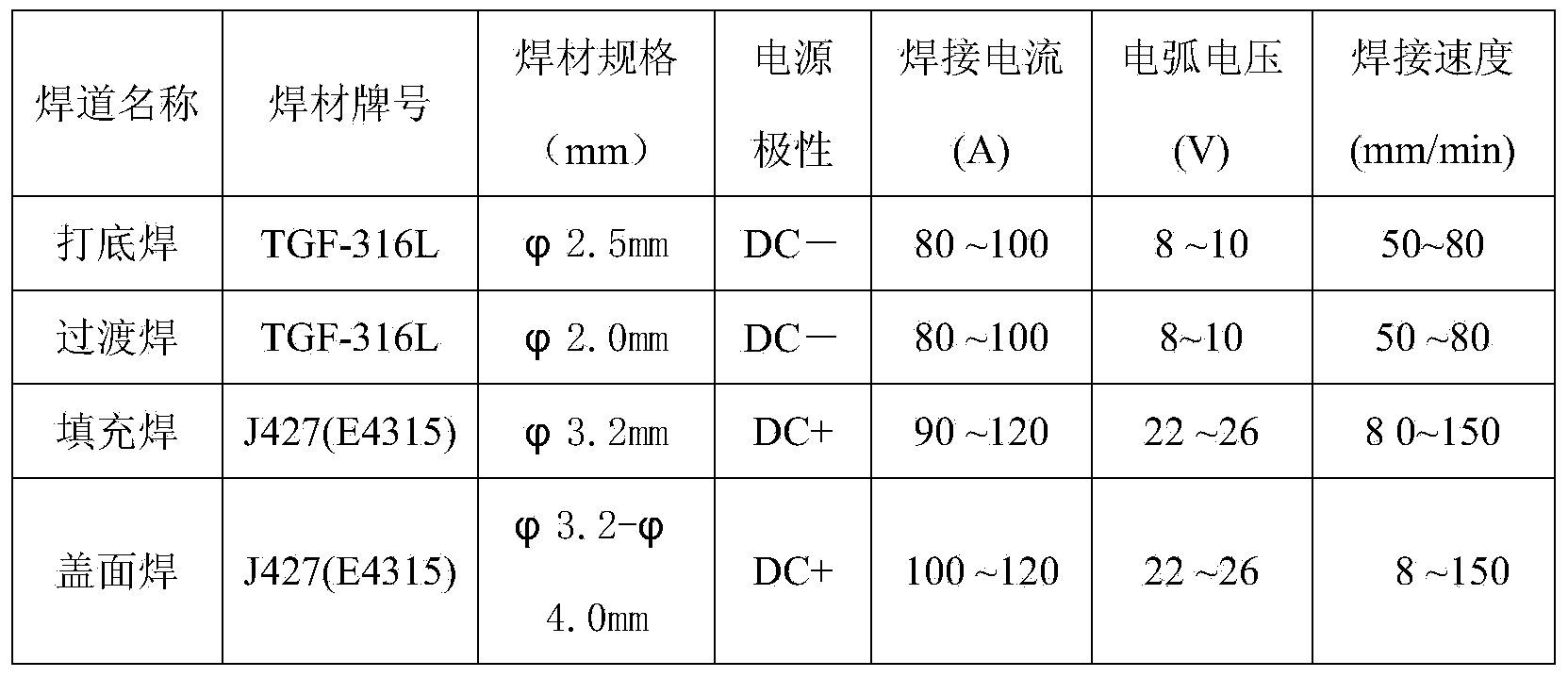

T-type joint single-side-welding double-side-forming groove machining technology method

ActiveCN103252563AAvoid unfused, sharp cornersAvoid defects such as cracksArc welding apparatusStructural engineeringWeld seam

The invention discloses a T-type joint single-side-welding double-side-forming groove machining technology method. The T-type joint single-side-welding double-side-forming groove machining technology method comprises the following steps: machine machining allowance is reserved on a base plate in the thickness direction in advance; an upright plate installing and welding position line is determined on the base plate; a boss is machined on the base plate corresponding to the installing and welding position line in advance, the width of the truncated edge of the boss after the truncated edge is machined is L, and circular corners R1 are chamfered at two sides of the boss; a groove in the side face of an upright plate is machined to be a slope with an inclined angle a, the bottom of the groove is machined to be a circular arc face R2, and the width of the root portion of the groove is L; the machining height of the truncated edge of the upright plate is L; the upright plate and the base plate are assembled, so that a half-U-type groove is formed; single side welding is conducted on the half-U-type groove in an argon tungsten-arc welding mode. The T-type joint single-side-welding double-side-forming groove machining technology method can effectively overcome the shortages such as incomplete fusion which occurs in the root portion of a welding seam and extrusion and cracks of pointed corners and fusion forming quality at two sides of base metal on the root portion of the welding seam is good.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

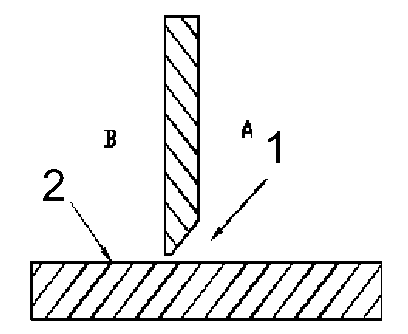

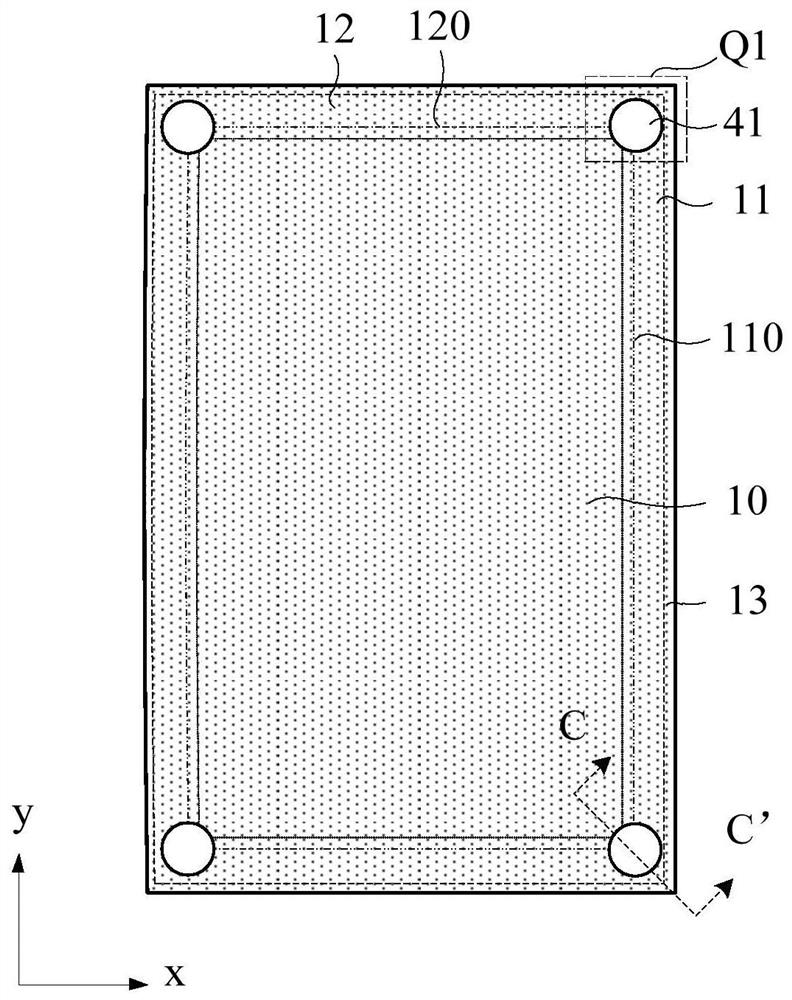

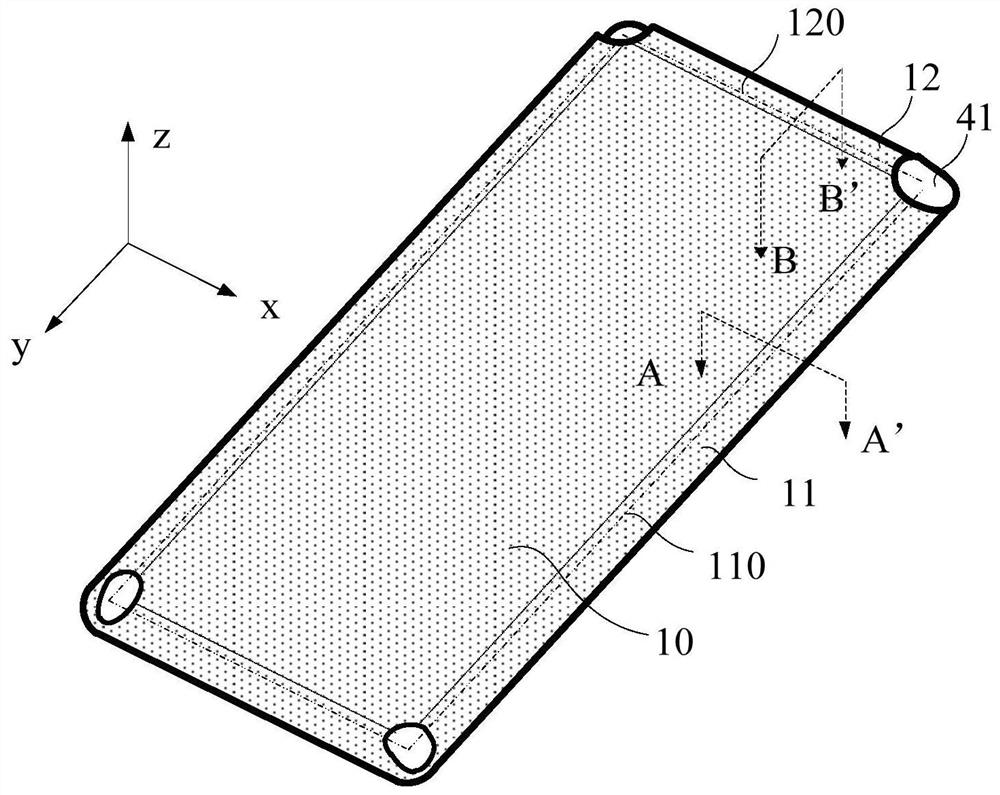

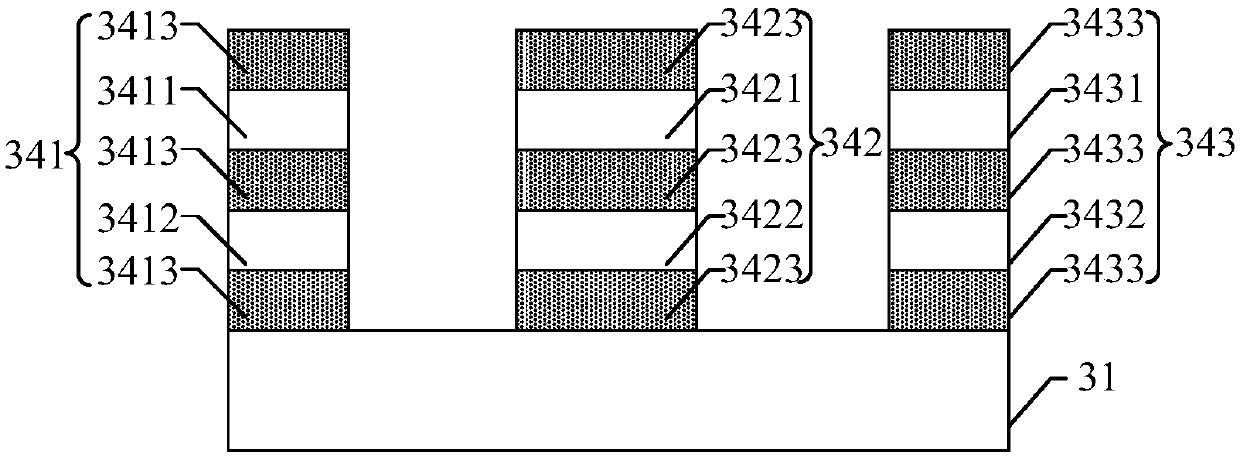

Display panel and display device

ActiveCN111785738AIncrease the screen ratioImprove viewing experienceStatic indicating devicesSolid-state devicesStructural engineeringMechanical engineering

The embodiment of the invention provides a display panel and a display device, relates to the technical field of display, and is used for improving the screen-to-body ratio of the display panel and ensuring the reliability of the display panel. The display panel includes: a main display area; a first bending area connected with the main display area and arranged in the first direction; a first bending area which can be bent in the direction deviating from the light emitting surface of the display panel through the first bending shaft; a second bending area which is connected with the main display area and arranged in the second direction intersecting with the first direction, and can be bent in the direction deviating from the light emitting surface of the display panel through the secondbending shaft; and a first hollow area in which the intersection point of the extension lines of the first hollow area, the first bending shaft and the second bending shaft is located.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

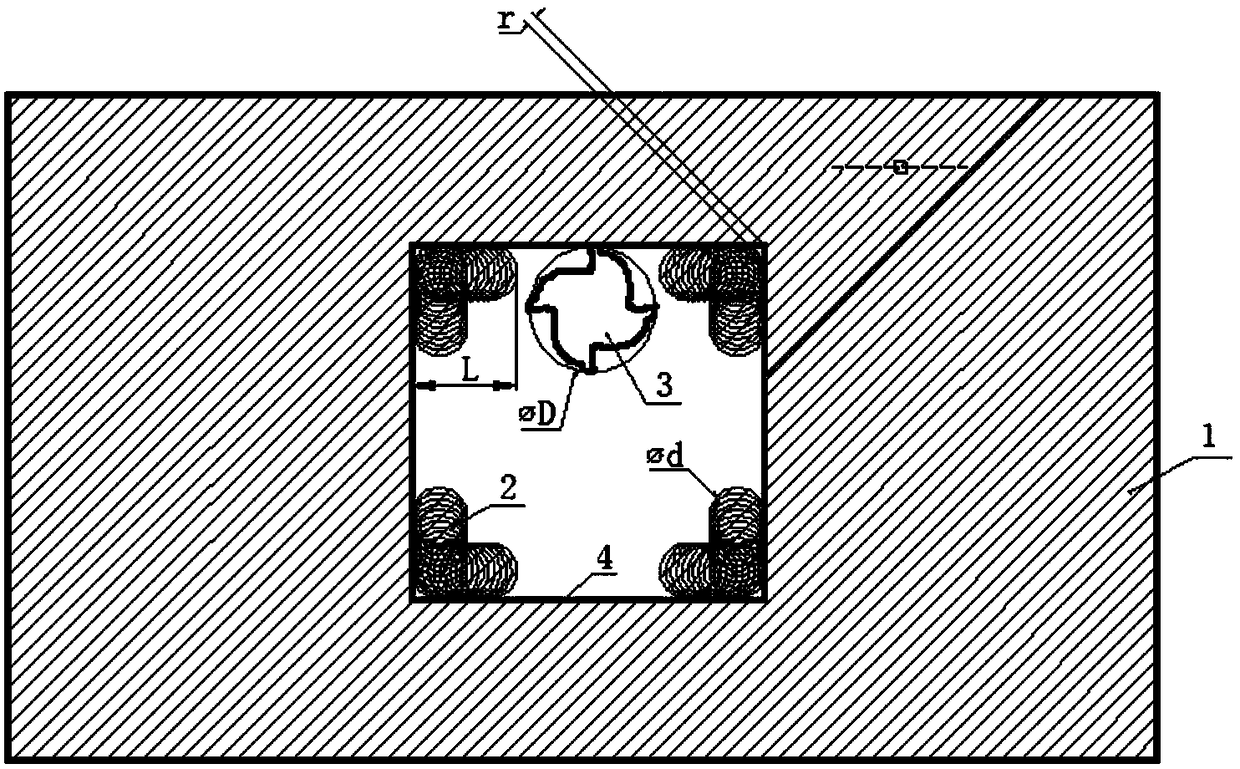

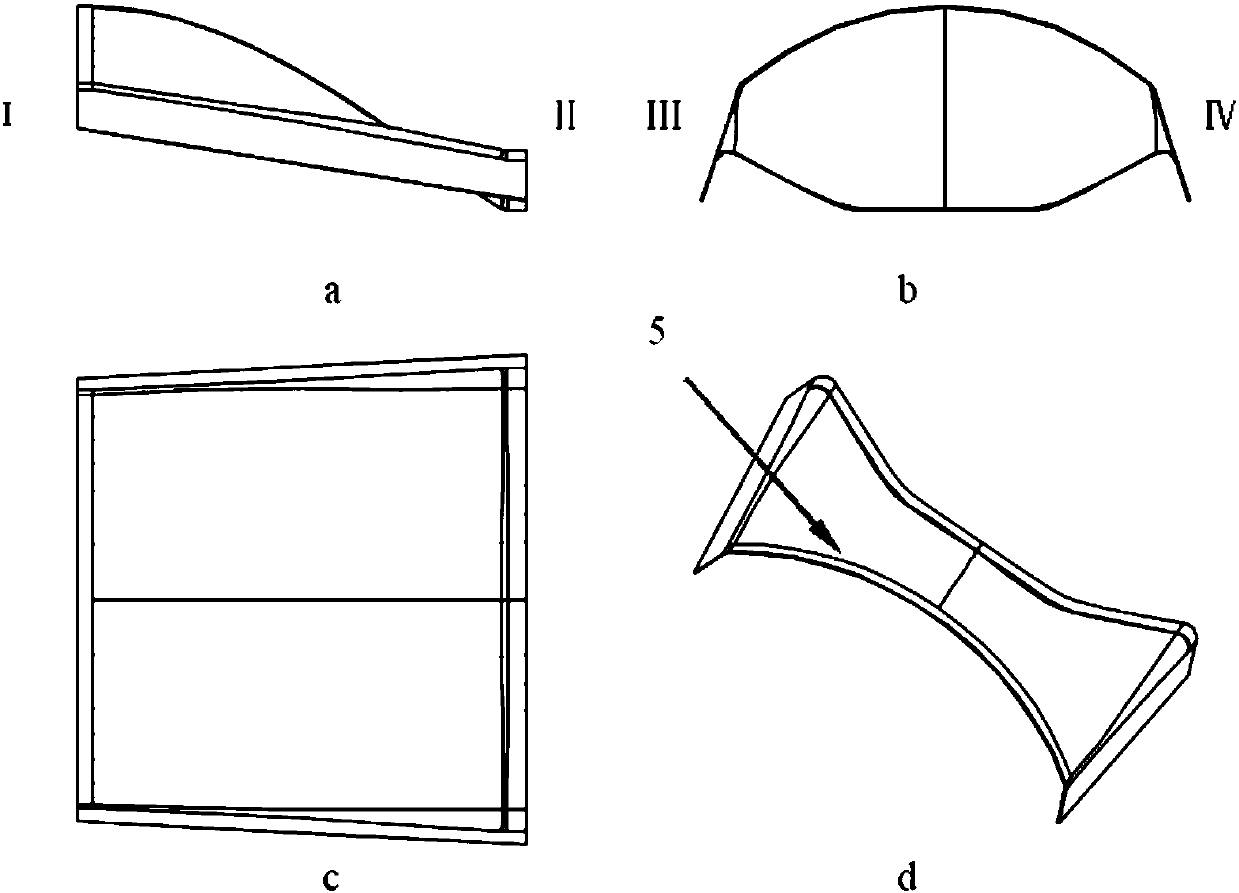

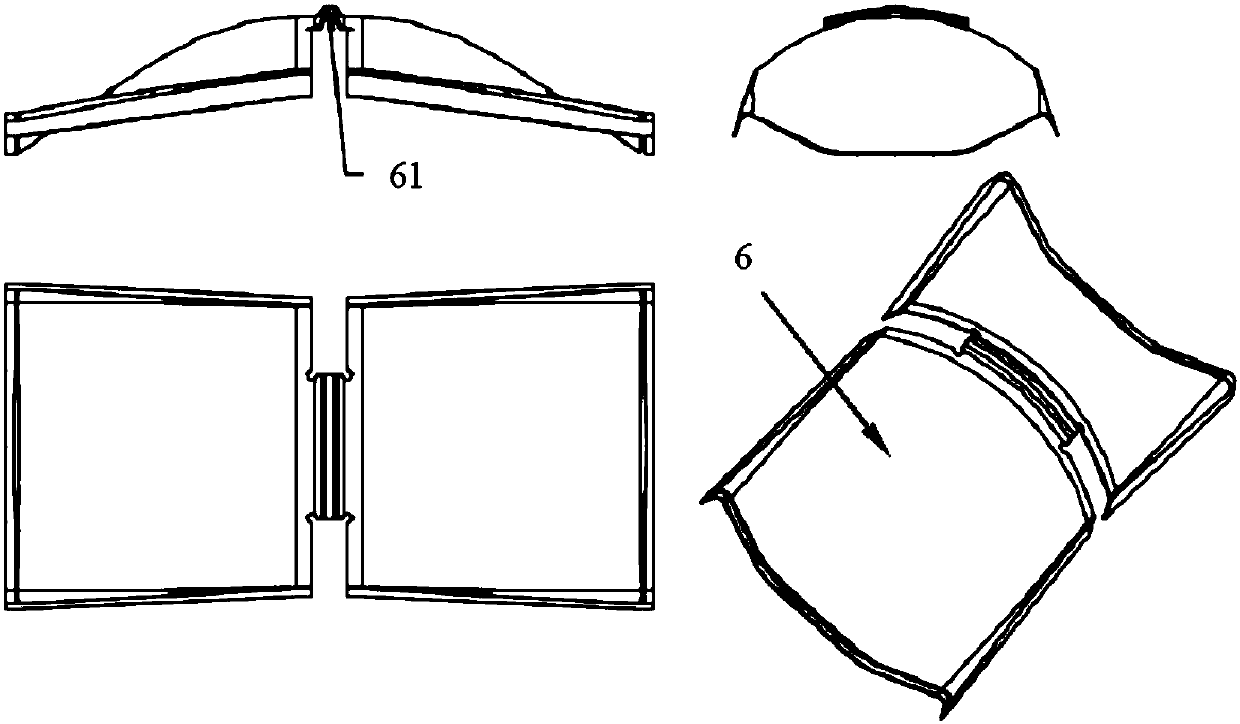

Lightweight hot forming die of special-shaped curved aluminum alloy thin-wall part and design method thereof

The invention relates to a lightweight hot forming die of a special-shaped curved aluminum alloy thin-wall part and a design method thereof. The die comprises a male die (1), a female die (2), positioning plates (3) and lifting lugs (4), wherein the bottom surface of the male die (1) is a forming molded surface which protrudes outwards, and the amplification coefficient of the forming molded surface on the basis of the molded surface of a workblank is determined according to the hot forming temperature requirement; a forming groove is formed in the top surface of the female die (2), and the amplification coefficient of the profile of the forming groove on the basis of the molded surface of the workblank is determined according to the hot forming temperature requirement; the positioning plates (3) are located in the middle of the both sides of the female die (2); and the lifting lugs (4) are respectively distributed on the side surfaces of the male die (1) and the female die (2). According to the lightweight hot forming die, precise hot forming of the special-shaped curved aluminum alloy thin-wall part can be effectively guaranteed, and the special-shaped curved aluminum alloy thin-wall part formed by the die has the advantages of stable quality, high dimensional accuracy, profile accuracy and surface quality, short forming cycle and high production efficiency.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

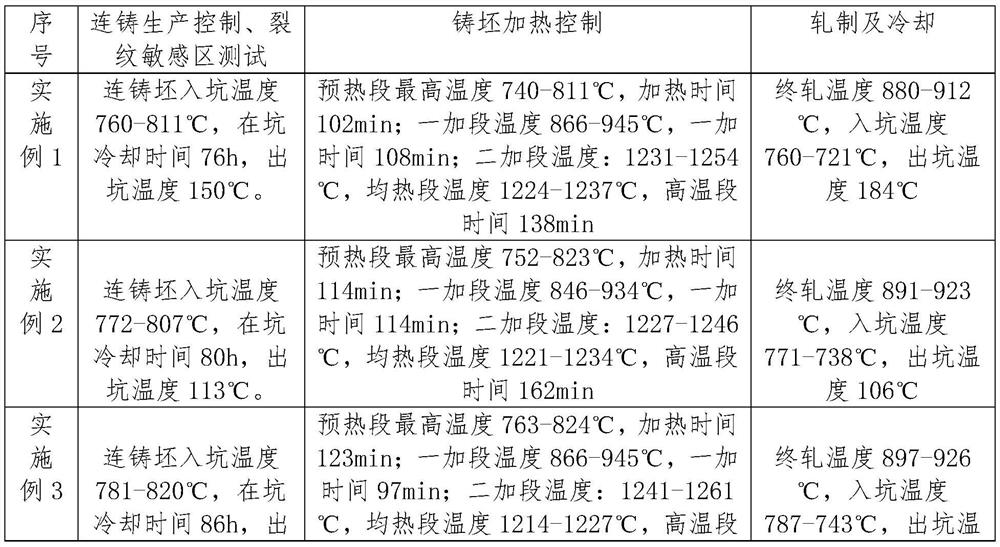

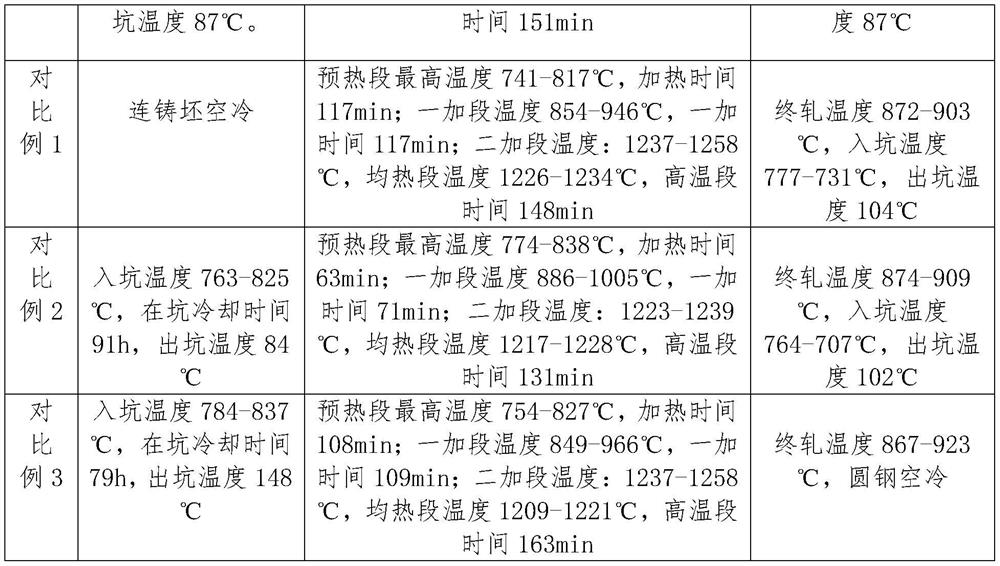

Surface quality control method for vanadium-containing high-nitrogen round steel

ActiveCN113293277AAvoid defects such as cracksAccurate crack sensitive temperature rangeMaterial strength using tensile/compressive forcesFurnace typesQuality controlSlow cooling

The invention discloses a surface quality control method for vanadium-containing high-nitrogen round steel, and belongs to the field of ferrous metallurgy processing. The control method comprises the following steps of testing a crack sensitive temperature interval before heating a continuous casting billet, designing a preheating system of the continuous casting billet according to a measurement result, controlling the highest temperature T3 of a preheating section to be greater than or equal to T2+150 DEG C, controlling the heating rate of the preheating section to be less than or equal to 9 DEG C / min, then matching with a pit-entering slow cooling process of the continuous casting billet and rolled round steel, and finally, the round steel with the surface magnetic flux leakage initial inspection qualified rate reaching 85% or above is obtained.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

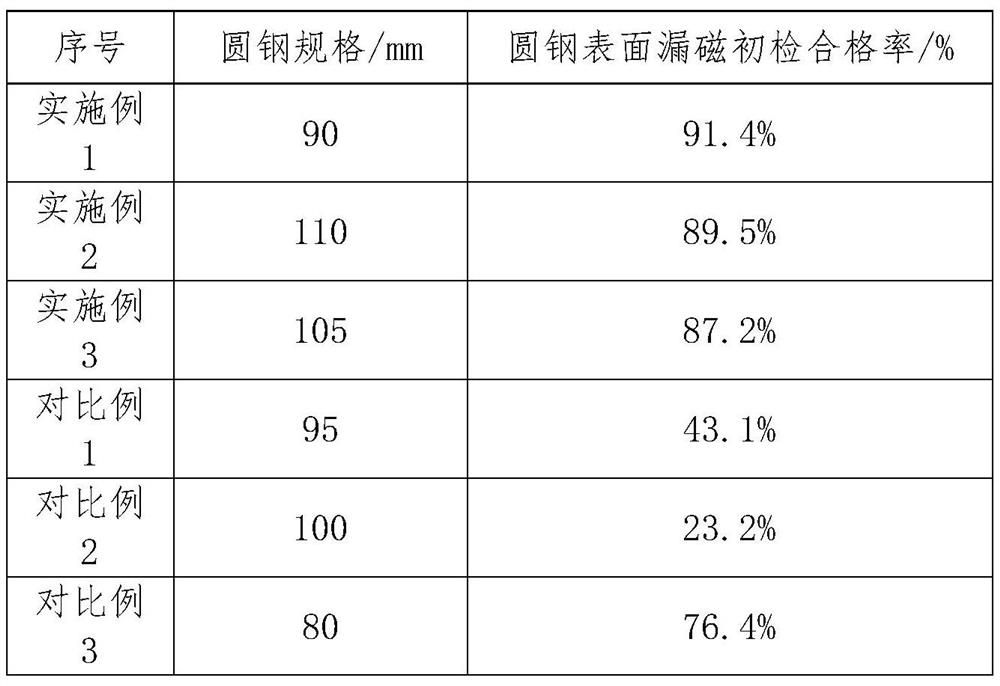

Bending pressing convex die

PendingCN110090894AReduce development costsSimplify the process stepsShaping toolsMechanical engineering

The invention relates to the technical field of dies, and discloses a bending pressing convex die. The bending pressing convex die comprises an upper die assembly, a lower die assembly and a lever assembly, the upper die assembly comprises a bending convex die, and a pressing convex groove is formed in the bending convex die; the lower die assembly comprises two first die cores and a second die core, the two first die cores are symmetrically arranged on the two sides of the second die core respectively, the first die cores and the second die core can be spliced to form the bending convex die,and a pressing convex protrusion matched with the pressing convex groove is arranged on the second die core; and the lever assembly comprises a lever, one end of the lever is capable of being connected with the upper die assembly, and the other end of the lever is connected with the two first die cores. According to the bending pressing convex die, on the one hand, the bending and pressing convexprocedures can be completed by using one set of dies and one-time molding process, the procedure step is simplified, and the cost is reduced; and on the other hand, the two first die cores are drivento move upwards simultaneously through the lever assembly, and a metal plate can be bent simultaneously from the two sides, so that the deformation of the metal plate is more uniform.

Owner:昆山市兴凯胜智能科技有限公司

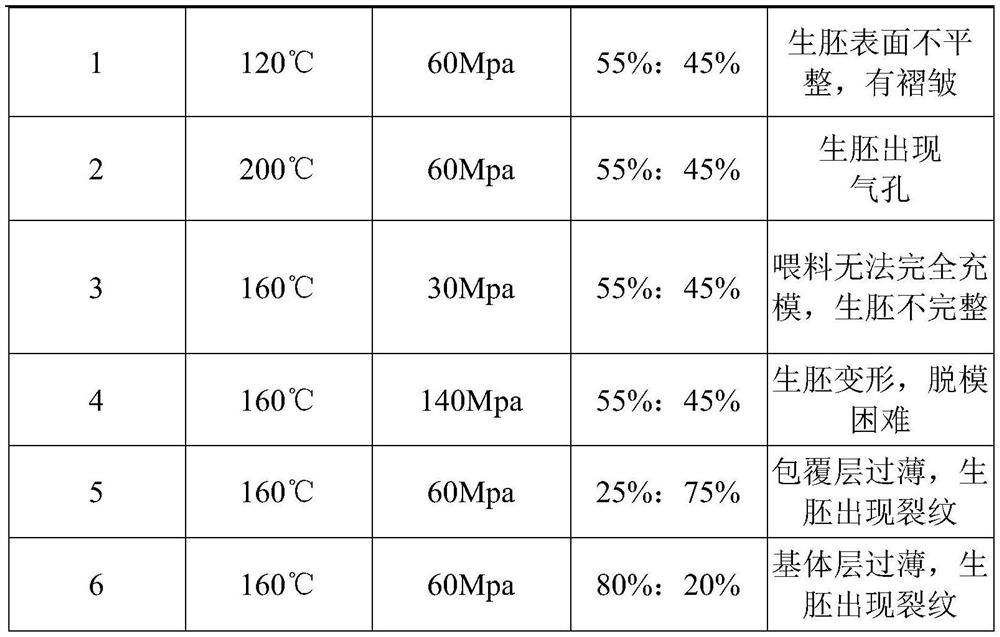

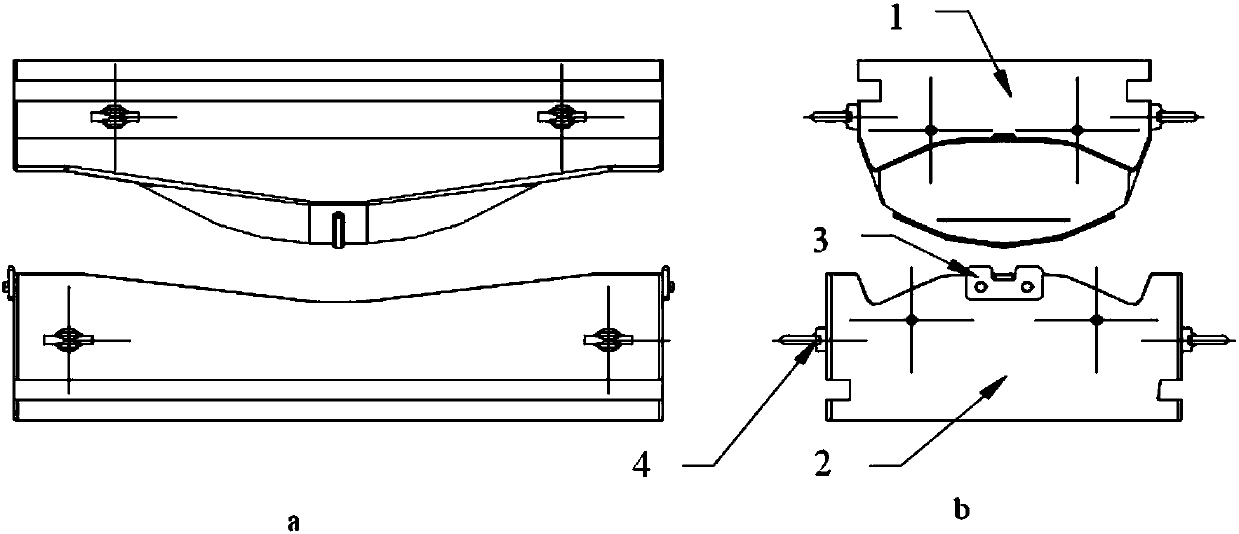

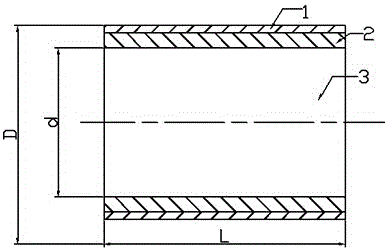

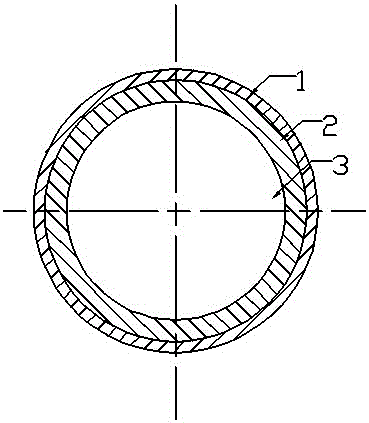

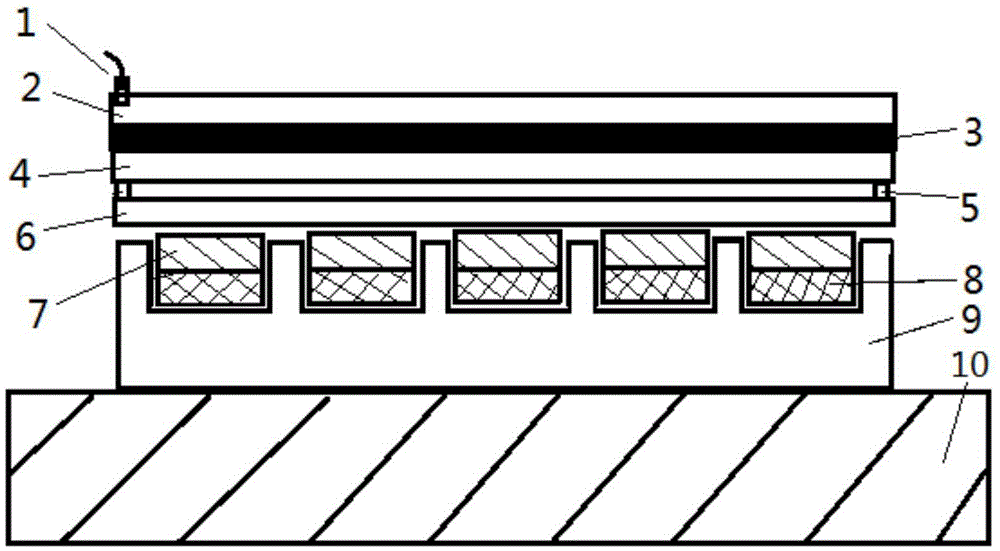

Ladderlike bainite-martensite duplex-phase steel abrasion-resistant roller sleeve and preparation method thereof

ActiveCN105803319AClear competitive advantageSimple heat treatment processFurnace typesGrain treatmentsPressure castingMetallic materials

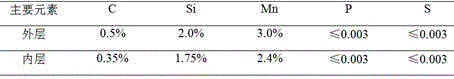

The invention discloses a ladderlike bainite-martensite duplex-phase steel abrasion-resistant roller sleeve and a preparation method thereof, and belongs to the technical field of metal material casting. According to the method, silicomanganese series casting alloy steel with different compositions is prepared through centrifugal pressure casting in a layered mode, an outer layer (1) is a high-hardness abrasion-resistant layer, an inner layer (2) is a ductile matrix layer, and ladderlike bainite-martensite duplex-phase structures are obtained through the inner layer and the outer layer after salt bath isothermal quenching heat treatment, so that different properties are obtained. According to the method, the material composition proportion of the inner layer and the outer layer is optimized, a reasonable centrifugal compound casting process is adopted, and the inner layer and the outer layer are made to obtain the ladderlike bainite-martensite duplex-phase structures with different contents through the simple isothermal quenching heat treatment mode. According to the roller sleeve, the hardness of the outer layer is 57-62 HRC, the impact toughness of the outer layer is 10-13 J / cm<2>, the hardness of the inner layer is 50-55 HRC, the impact toughness of the inner layer is 19-21 J / cm<2>, and the high-quality abrasion-resistant roller sleeve with the high abrasion resistance, good toughness and the low cost is obtained.

Owner:KUNMING UNIV OF SCI & TECH

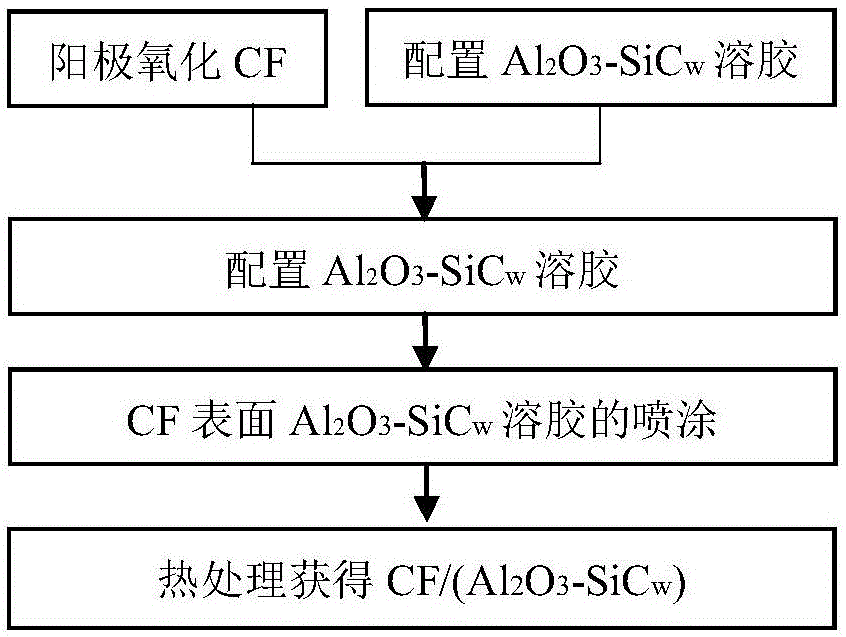

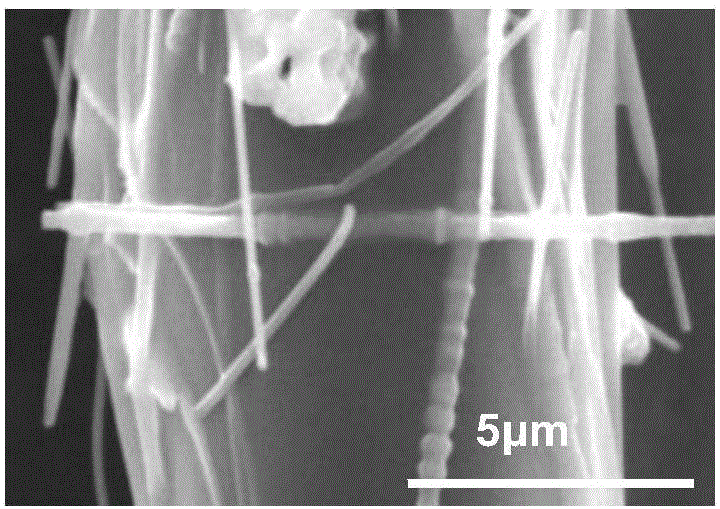

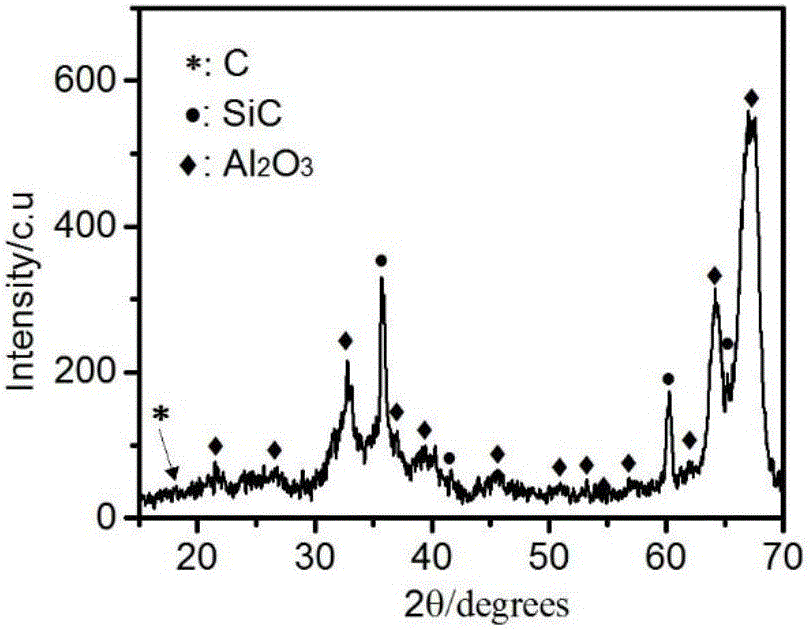

Method for spraying aluminum oxide-silicon carbide whisker anti-oxidation coating on surface of carbon fiber

ActiveCN107523825AGood lookingAccurate ingredientsLiquid/gas/vapor removalTextile treatment by spraying/projectingFiberCarbon fibers

The invention discloses a method for spraying an aluminum oxide-silicon carbide whisker anti-oxidation coating on the surface of a carbon fiber (CF). The method comprises the three steps of CF pretreatment and preparation of Al2O3-SiCw sol, spraying of the Al2O3-SiCw sol on the surface of the CF and heat treatment of the Al2O3-SiCw coating on the surface of the CF. The Al2O3-SiCw (aluminum oxide-silicon carbide whisker) anti-oxidation coating is prepared on the surface of the CF through a sol spraying method, the anti-oxidation performance of the CF under the aerobic atmosphere is improved, and the certain research foundation is laid for preparing a CF / HA composite with the good mechanical performance.

Owner:SHAANXI UNIV OF SCI & TECH

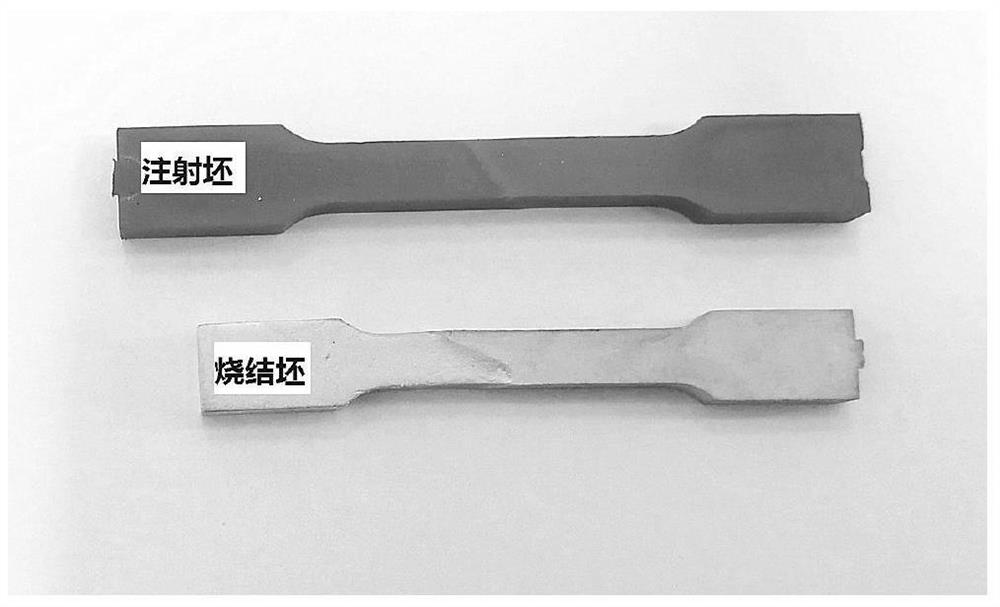

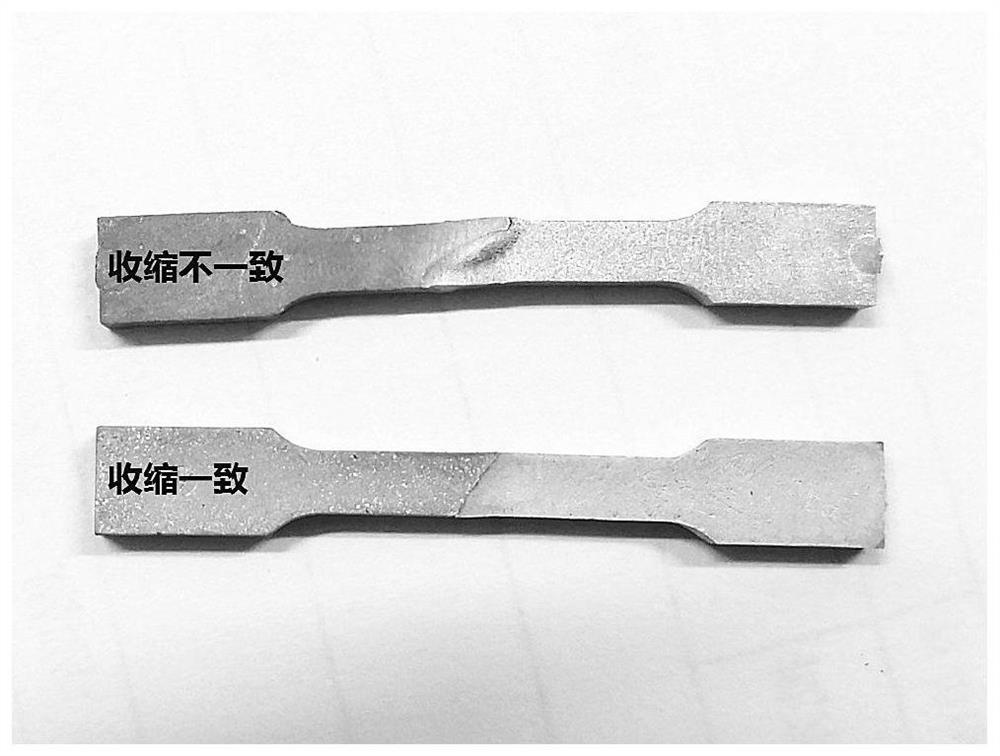

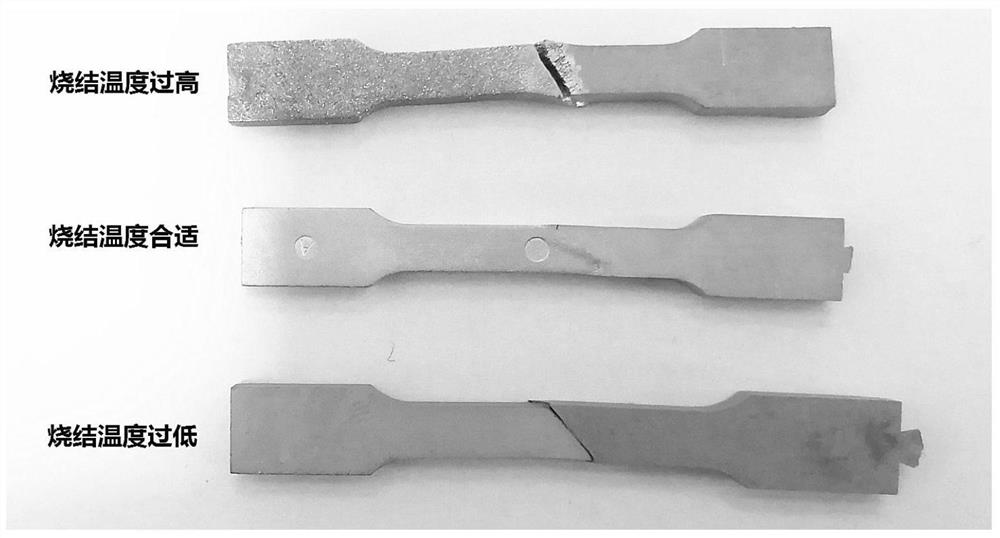

Powder metallurgy preparation method for step-by-step formed cemented carbide hard alloy/steel double-layer structure composite material

The invention relates to a powder metallurgy preparation method of a step-by-step formed cemented carbide hard alloy / steel double-layer structure composite material, belongs to the technical field of composite material preparation. The method includes the steps that firstly, a steel powder material and carbide hard alloy powder are mixed and granulated with a binder to obtain a steel powder material feed and a carbide hard alloy material feed, and then the steel powder material feed and the carbide hard alloy material feed are sequentially injected into a mold cavity step by step through an injection molding technology to obtain a product green body; and part of the binder in the green body is removed through catalytic degreasing, and finally the carbide hard alloy / steel double-layer structure composite material is obtained through co-sintering densification. The powder metallurgy preparation method of the step-by-step formed cemented carbide hard alloy / steel double-layer structure composite material is simple and controllable, an obtained product is excellent in performance, and large-scale industrial application is facilitated.

Owner:湖南英捷高科技有限责任公司

One-step forging die of porcelain insulator cap

InactiveCN103611869AEmission reductionReduce manufacturing costForging/hammering/pressing machinesEngineeringPorcelain insulator

The invention relates to a one-step forging die of a porcelain insulator cap. The one-step forging die mainly comprises an upper die and a lower die. The upper die mainly comprises a lock insert, a lock insert cylinder, a forming die, an upper moving platform and an upper base. The upper moving platform is disposed at the lower end of the upper base. The lock insert and the forming die are disposed at the bottom of the upper moving platform. The lower die mainly comprises a lock cylinder, a lock cylinder holder, a lower moving platform, a washer and a lower base. The lock cylinder holder sleeves outside the lower moving platform. The washer is disposed between the lower moving platform and the lower base. The middle of the lower moving platform is provided with a forming cavity corresponding to the forming die. The one-step forging die has the advantages that the die is available for one-step forging molding, production cost is reduced, work efficiency is improved, emission of three wastes is reduced, the defects such as shrinkage, sand holes and cracks caused during forging can be casting, and products can be more reliable.

Owner:RUGAO DASHENG LINE EQUIP

Preparation method for heat-resistant component containing embedded runner, of fusion reactor blanket

ActiveCN105478991AReduce production processReduce difficultyNon-electric welding apparatusShock waveEngineering

The invention discloses a preparation method for a heat-resistant component containing an embedded runner, of a fusion reactor blanket. The structural material of the component is reduced activation martensitic / ferritic steel, the embedded runner is formed by virtue of a scheme of explosive welding for a bottom plate and a cover plate of a milling groove, and through filling a runner groove with a low-melting-point metal and a carbon steel plate, runner deformation due to an explosive shock wave is reduced and a good welding effect is ensured, and later heating removal at a low temperature is facilitated; and meanwhile, a layer of nano-oxide-reinforced reduced activation martensitic / ferritic steel is formed at the outer side of the component through explosive cladding to increase the maximum service temperature of the component, and buffer layers are added between explosives and the nano-oxide-reinforced reduced activation martensitic / ferritic steel to prevent the plates from cracks. The method is capable of realizing combination for the bottom plate and the cover plate of the milling groove, and the nano-oxide-reinforced reduced activation martensitic / ferritic steel in one process, and capable of effectively increasing the preparation efficiency of the large heat-resistant component of the blanket, and ensuring the stability of the microstructure of the material during the preparation process for the component.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Compound pipeline weld joint repair method for media rich in hydrogen

The invention discloses a compound pipeline weld joint repair method for media rich in hydrogen. The method comprises the following steps of (1) pressure reduction replacement, (2) groove preparation, (3) groove processing and (4) groove welding. The method has the advantages that not only are impurities on the surface of a base material removed according to pre-welding requirements, but also trace gas and solid and liquid impurities inside interlay gaps are cleared by taking measures, hydrogen and organic impurities are prevented from being decomposed, escaping out and being blended into weld metal in welding, and therefore the defects of air holes, cracks and the like in a weld joint are avoided.

Owner:INNER MONGOLIA YITAI CTO

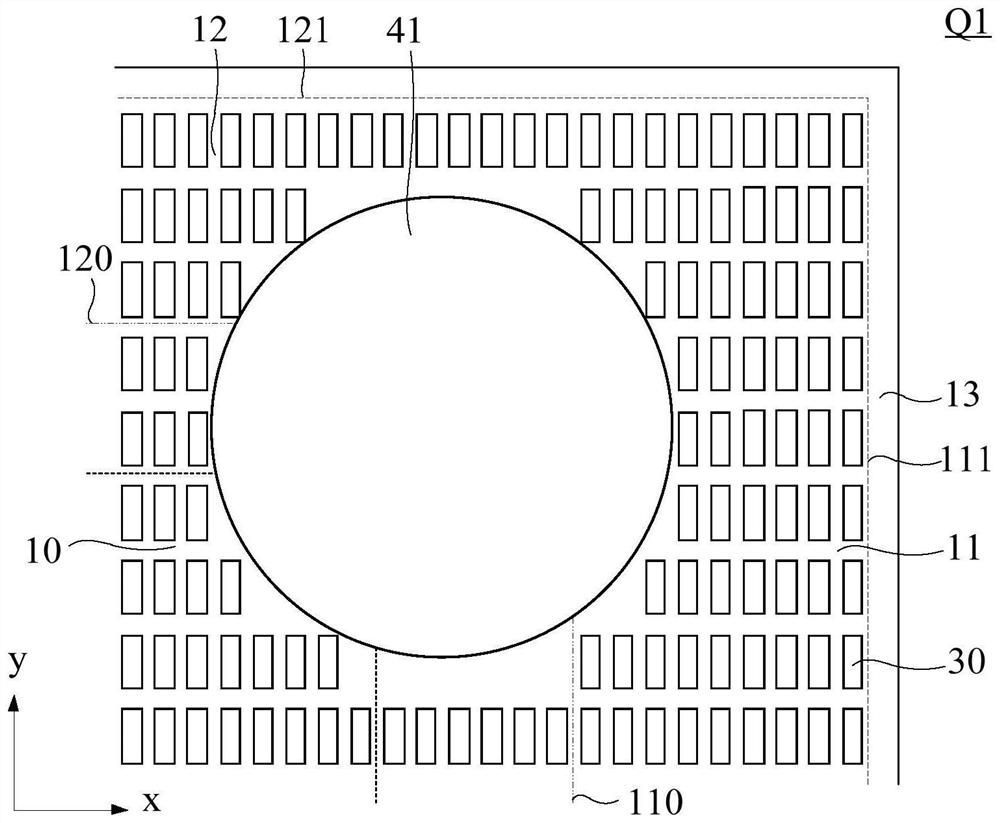

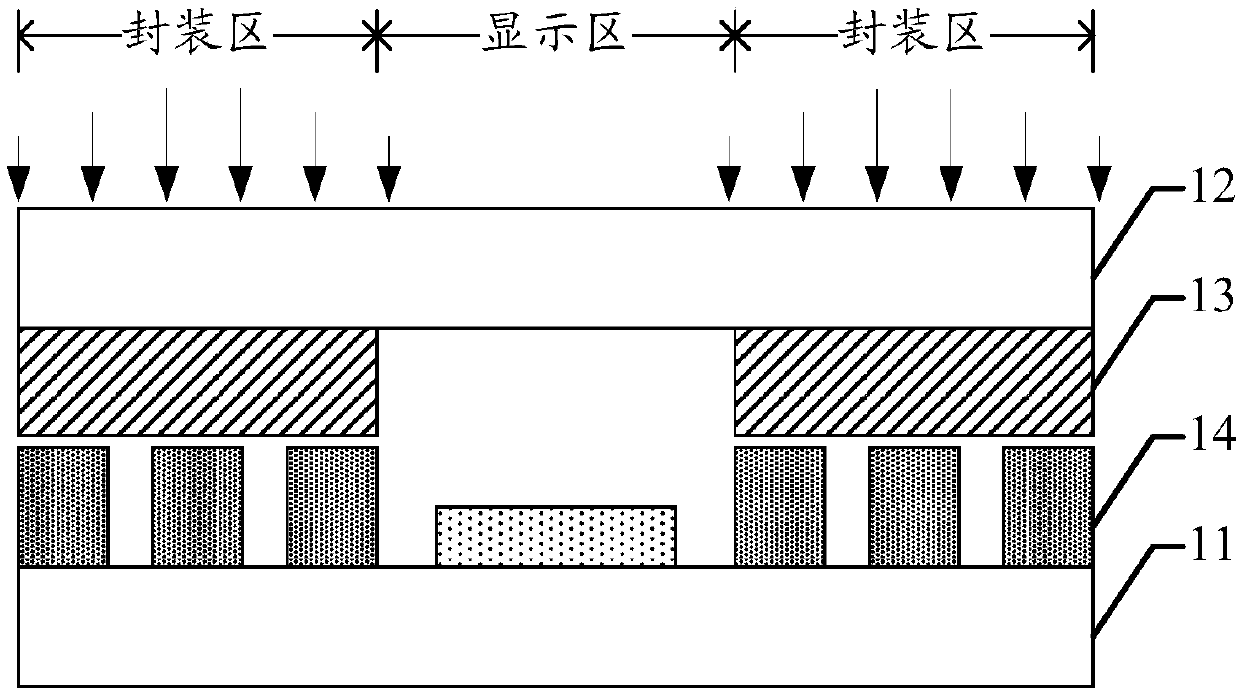

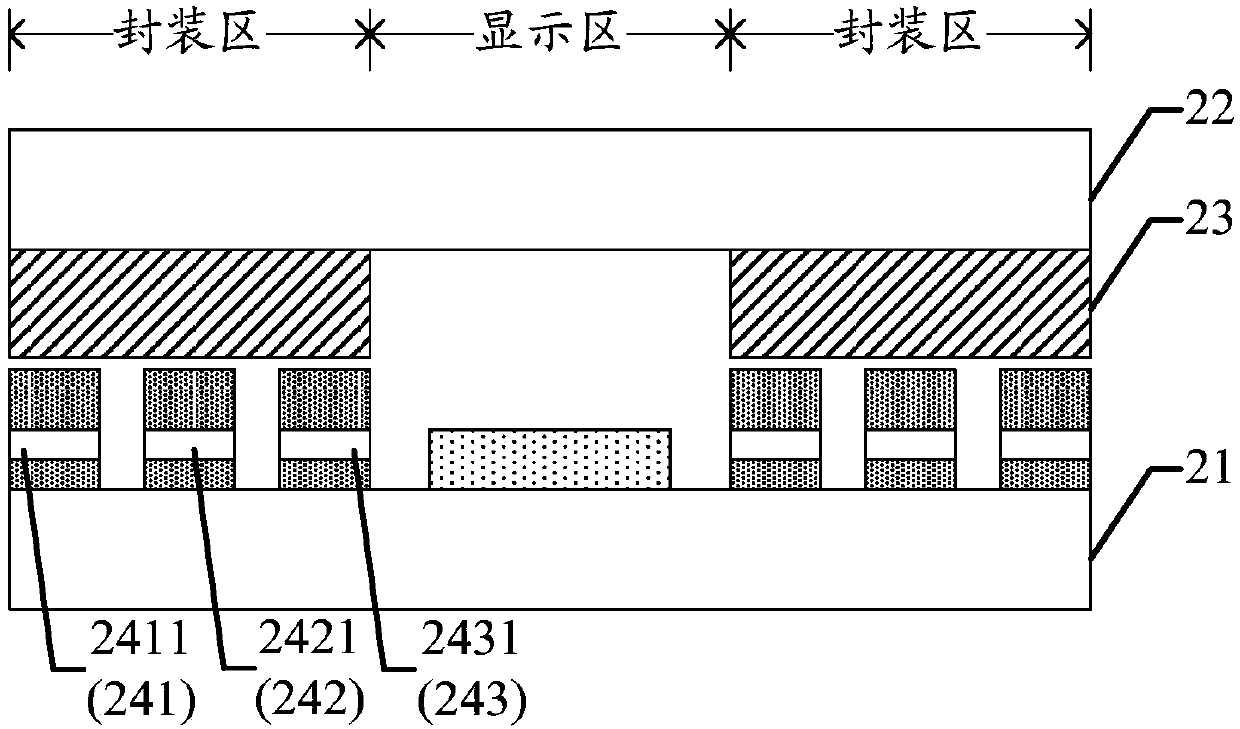

Display panel, display device and manufacturing method

ActiveCN107565051AImprove manufacturing yieldReduce uneven stress distributionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The embodiment of the invention discloses a display panel, a display device and a manufacturing method. The display panel comprises a display area, packaging areas surrounding the display area, a substrate and a cover board arranged oppositely to the substrate, wherein a packaging layer is arranged on the surface, toward the substrate, of the cover board in each packaging area; the packaging layers are used for being bonded to the substrate and the cover board after being irradiated by laser light; a plurality of reflecting blocks are formed on the surface, toward the cover board, of the substrate in each packaging area; and the reflectivity of various reflecting blocks is reduced along with an increase of the intensity of the laser light at the positions of various reflecting blocks. According to the display panel, the melting rates of the packaging layers under different intensity of the laser light can tend to be consistent, thereby reducing the defects, such as cracks, caused by astress difference, of the packaging areas. Meanwhile, improvement of the packaging bonding strength between the substrate and the cover board is facilitated, thereby improving the manufacturing yieldof the display panel.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

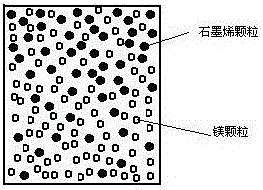

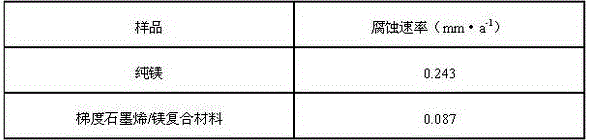

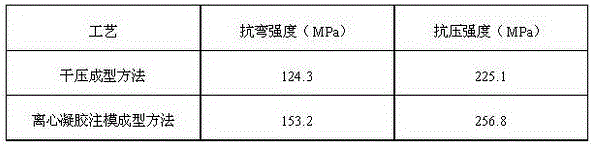

Preparation method of gradient graphene/magnesium composite material

InactiveCN106086561AAvoid layeringAvoid defects such as cracksTissue regenerationProsthesisCross-linkBenzoyl peroxide

The invention discloses a preparation method of a gradient graphene / magnesium composite material. Firstly, an organic monomer-hydroxyethyl methylacrylate, a cross linking agent-trimethylolpropane triacrylate, a dispersing agent-oleic acid, magnesium powder and graphene powder are dispersed in butanol to prepare a graphene / magnesium complex-phase pulp; an initiator-benzoyl peroxide and a catalyst N, N dimethylaniline are added in the ball-milled pulp; the prepared graphene / magnesium pulp is injected in a centrifuge for centrifugation, so that graphene and magnesium particles in the pulp form continuous gradient distribution; a mold is put in a vacuum oven for quick gel solidification after centrifugation; and a gel-cured sample is put in a pipe furnace for argon atmospheric sintering to obtain a gradient graphene / magnesium biomedical composite material after demolding and vacuum drying. The corrosion resistance and the mechanical performance of a magnesium basal body are improved.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Molding sand clearing device for pneumatic cylinder cover inner cavity

The invention discloses a molding sand clearing device for a pneumatic cylinder cover inner cavity in the field of cylinder cover machining and manufacturing. The molding sand clearing device comprises a rack, a support mechanism, an air pump and a silencing mechanism. The air pump is located at the top end of the rack. The support mechanism comprises a support plate and an installation plate. The support plate is located on the lower portion of the rack. The installation plate is located above a vibrating plate. A high pressure blower gun which is connected with the air pump is installed on the installation plate. A vibrating spring is arranged on the support plate. The vibrating plate is arranged at the upper end of the vibrating spring and provided with a vibrating motor and a limiting block. The vibrating plate and the support plate are both provided with sand dropping holes. The silencing mechanism is fixed to the side wall of the rack. A sand collecting box is arranged below the support plate. According to the scheme, molding sand remained in a cylinder cover is cleared up more thoroughly, and the sand dropping ratio is higher. The cylinder cove is buffered through the vibrating spring, so that the defects such as deformation or cracks caused by repeated blows of compressed air to the cylinder cover are effectively avoided, and the defective percentage caused by inner machining is lowered. Noise generated inside is absorbed and weakened through a sponge silencing layer, so that noise pollution is reduced.

Owner:CHONGQING HONGQI CYLINDER HEAD MFG

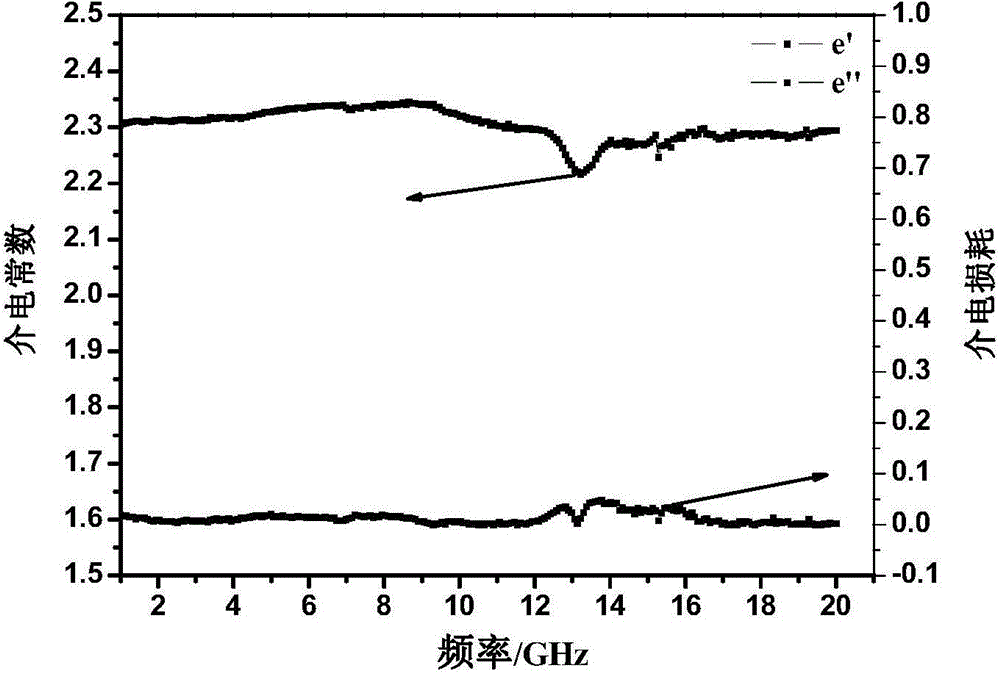

Preparation method of cross-linked polystyrene with high light transmittance

InactiveCN104672390AImprove qualityImprove densification performanceHigh energy electron irradiationCross-link

The invention discloses a preparation method of cross-linked polystyrene with high light transmittance, and belongs to the field of cross-linking polymerization of polymers. The method comprises steps as follows: 1), a polystyrene solution is prepared and uniformly mixed with divinyl benzene in a certain proportion; 2), the mixed solution is subjected to freezing layer by layer and high-energy electron irradiation layer by layer; 3), later forming of a cross-linked polystyrene material is completed through a temperature control process. The method has the main characteristics as follows: a product is pure and transparent and doesn't have defects of bubbles, impurities and the like; 2) the cross-linking polymerization process is performed at an ultralow temperature, and the product qualification ratio is high; 3), the product has excellent light transmittance, stable dielectric property, higher processing mechanical property and the like.

Owner:WUHAN UNIV OF TECH

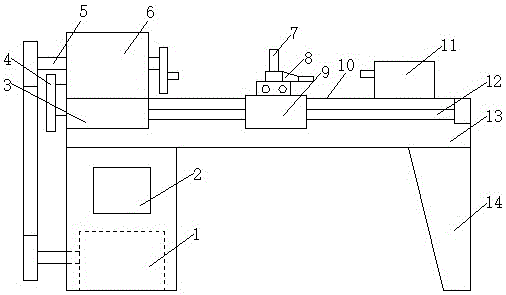

Lathe used for machining red copper workpiece

InactiveCN105945306APrevent slippingAchieve the purpose of processingAutomatic/semiautomatic turning machinesAuxillary equipmentCopperTailstock

The invention discloses a lathe used for machining red copper workpieces. The lathe comprises a motor, a control box, a spindle box and a main lathe body; a post is fixedly mounted on the bottom of the main lathe body; a motor base is fixedly connected with the main lathe body; two pairs of lathe tools are disposed on a tool base; a tailstock is fixedly mounted on the main lathe body; a guide rail is disposed between the spindle box and the tailstock, and is fixedly mounted on the main lathe body; a mounting base is mounted on the guide rail, and is positioned into a same perpendicular line with the tailstock; and a fixed fixture is fixedly mounted on the bottom of a lathe fixture which is movably connected with the guide rail by the fixed fixture. In the lathe used for machining red copper workpieces provided in the invention, the lathe tool is a turnable lathe tool, and the blades are free of high-temperature welding, and the blade defects caused by welding, such as hardness drop and cracks, can be avoided, therefore, the durability of the lathe tool is increased; since the durability of the lathe tool is increased, the service time is prolonged, the tool changing time is shortened, and the production efficiency is increased.

Owner:无锡德斯凯动力科技有限公司

Dried fruit with yoghourt flavor and preparation method of dried fruit

InactiveCN106387275AIncrease economic value addedIncrease appetiteConfectionerySweetmeatsPullulanVegetable oil

The invention relates to the technical field of food processing, in particular to dried fruit with avyoghourt flavor and a preparation method of the dried fruit. The product is mainly prepared from dried fruit covered with powder and a yoghourt pulp layer in sequence, wherein the powder is prepared from the following raw materials: white granulated sugar, skim milk powder, whey powder and maltodextrin; yoghourt pulp is prepared from raw materials as follows: white granulated sugar, skim milk powder, vegetable oil, soybean phospholipid, vanillin, citric acid, yoghourt essence, Span-65, beta-cyclodextrin, hydroxypropyl modified starch, pullulan and collagen. The yoghourt layer on the surface of the dried fruit with the yoghourt flavor is bright in color and luster, smooth and crack-free and tastes fine and smooth; due to the combination of the yoghourt layer and the dried fruit on the inner layer, the dried fruit tastes refreshing, is rich in nutrient, has outstanding moisture-proof performance and heat-resistant stability and can maintain good taste and flavor for a long time.

Owner:ZHENGZHOU RONGLIDA BIOLOGICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com