Forging method of coupler knuckle for railway vehicle

A railway vehicle and coupler knuckle technology, which is applied in the field of forging coupler knuckles for railway vehicles, can solve the problems of inclusions and cracks, short service life, shrinkage and other problems, achieve long service life, reduce the risk of car accidents, and facilitate billet making Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

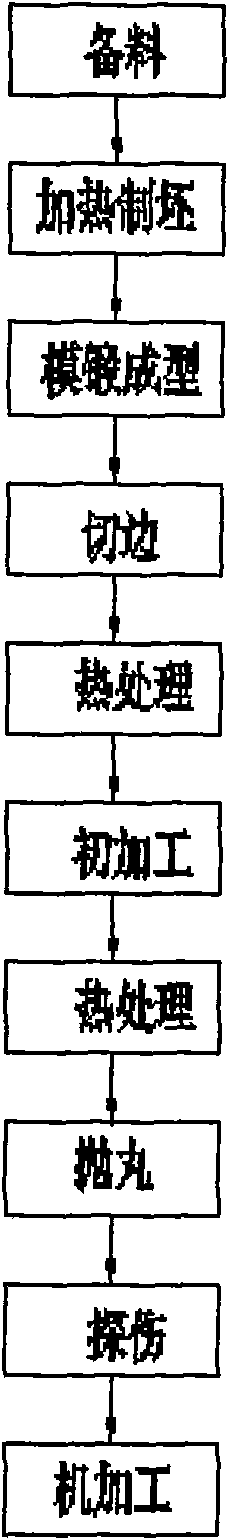

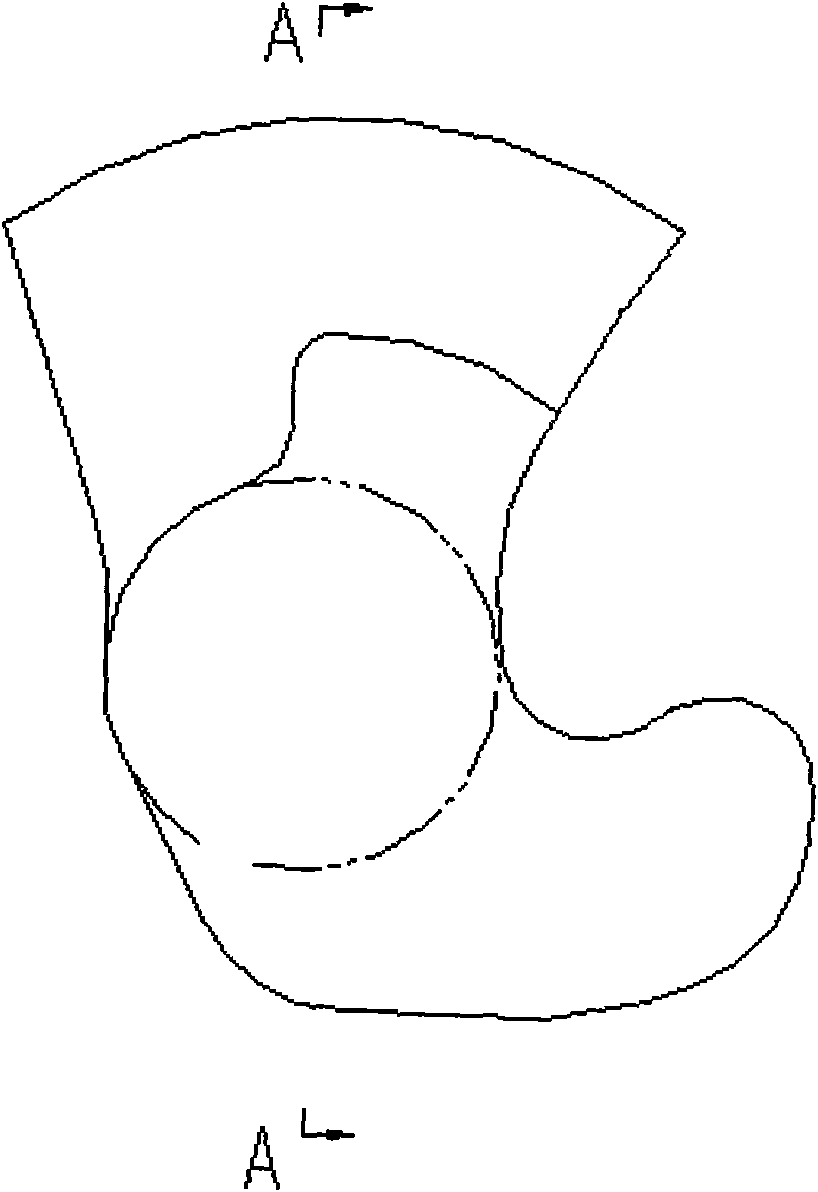

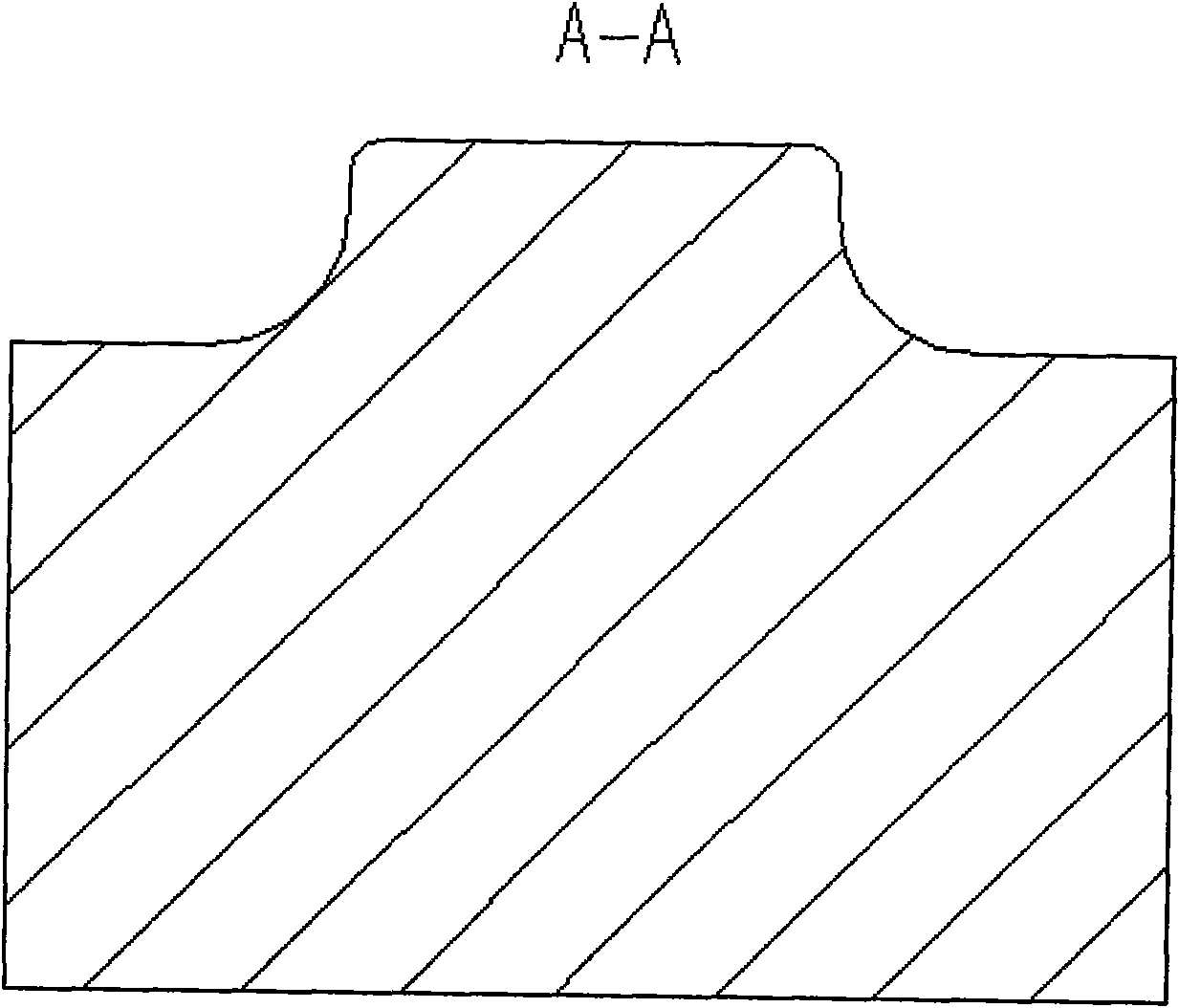

[0034] Such as Figure 1 to Figure 5 As shown, taking the coupler knuckle for No. 16 railway vehicle as an example, the coupler knuckle for this railway vehicle has good forgeability. There is no doubt about the reliability of the forged steel knuckle, but it is impossible to directly forge the product. If forging With machine processing, it is able to produce qualified products. The coupler knuckle for railway vehicles weighs 62kg, so it must be forged on a 16t hammer or other large die forging equipment. The forging steps are:

[0035] (1) Prepare the material to obtain a certain length of blank. The material used is: 35CrMo, the weight of the feed is 72kg, the raw material is Φ160 bar, and the size of the blank is Φ160cm×456cm.

[0036] (2) Heating the billet, after the blank obtained by blanking is heated, free forging is carried out on the free forging anvil of the 16t hammer, so that the blank is subjected to preliminary deformation, and the rough blank of the shape and...

Embodiment 2

[0049] Example 2 of the present invention is the same as Example 1, except that the blanking size in step (1) is Φ160cm×451cm; the heating temperature in step (2) is 1050°C, and the forging temperature range is 850°C; The heating temperature is 1050° C.; the heat treatment of the coupler knuckle body blank for railway vehicles in step (5), that is, the normalizing temperature is 30° C. above Ac3 or Accm; the heat treatment of the coupler knuckle body blank for railway vehicles in step (7) is adjusted Quality treatment, that is, tempering after quenching, the quenching temperature is 830°C, and the tempering temperature is 500°C.

Embodiment 3

[0051] Embodiment 3 of the present invention is the same as Embodiment 1, except that the blanking size in step (1) is Φ160cm×461cm; the heating temperature in step (2) is 1150°C, and the forging temperature range is 1150°C; The heating temperature is 1150° C.; the heat treatment of the coupler knuckle body blank for railway vehicles in step (5), that is, the normalizing temperature is 50° C. above Ac3 or Accm; the heat treatment of the coupler knuckle body blank for railway vehicles in step (7) is adjusted Quality treatment, that is, tempering after quenching, the quenching temperature is 870°C, and the tempering temperature is 650°C.

[0052] The coupler knuckle for No. 16 railway vehicles forged by this method is as follows: Figure 4 and Figure 5 As shown, its various performance indicators can fully meet the requirements of heavy-duty and speed-increasing railway vehicles. Compared with cast steel coupler knuckles, there will be no inherent quality defects in casting pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com