Patents

Literature

474results about How to "Avoid inclusions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

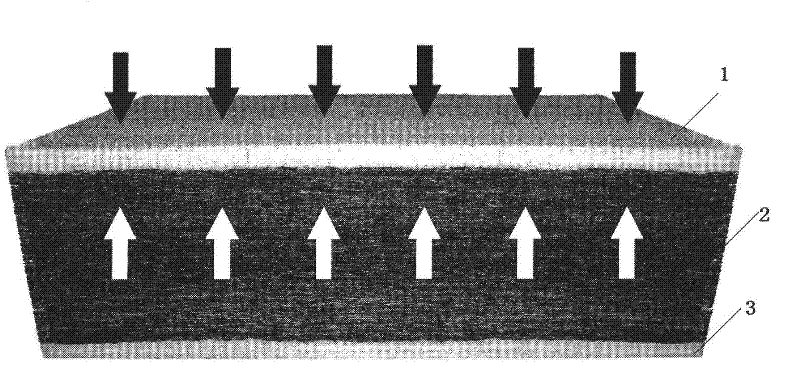

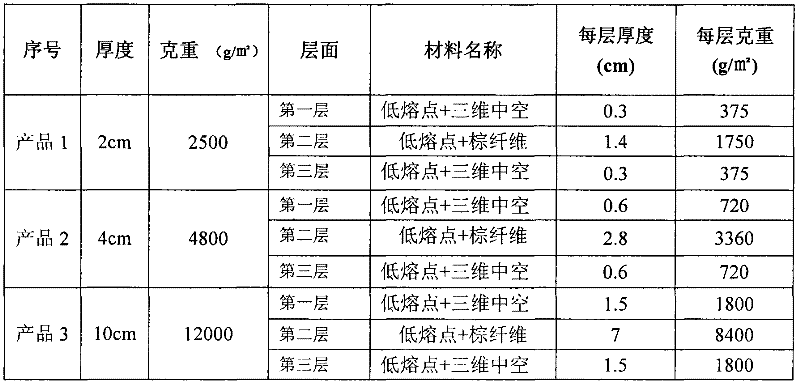

Polyester fiber coconut fiber plate and preparation method thereof

The invention discloses a polyester fiber coconut fiber plate and a preparation method thereof. The polyester fiber coconut fiber plate is characterized by including three layers, wherein the upper and lower layers are made from same materials which are low melting point double-component sheath core fiber and three-dimensionally coiled round hollow fiber, the middle layer is made from low melting point double-component sheath core fiber and coconut fiber, and the three layers are molded integrally through a process. The coconut fiber plate is formed by heat-melting hot-air penetration, melting, bonding and cooling technologies. The polyester fiber coconut fiber plate is environmental-friendly, formaldehyde-free, odorless, temperature-difference-resistant, deformation-free, elastic, strong in tension, impact-resistant, uniform in thickness, and good in sound insulation effect; three layers are molded integrally through the process, the upper and lower layers made from polyester fiber cotton have strong tension, the lining is formed by combining the low melting point polyester fiber with the coconut fiber; and under stress, each layer orderly buffers pressure so as to avoid deformation.

Owner:昆山吉美川纤维科技有限公司

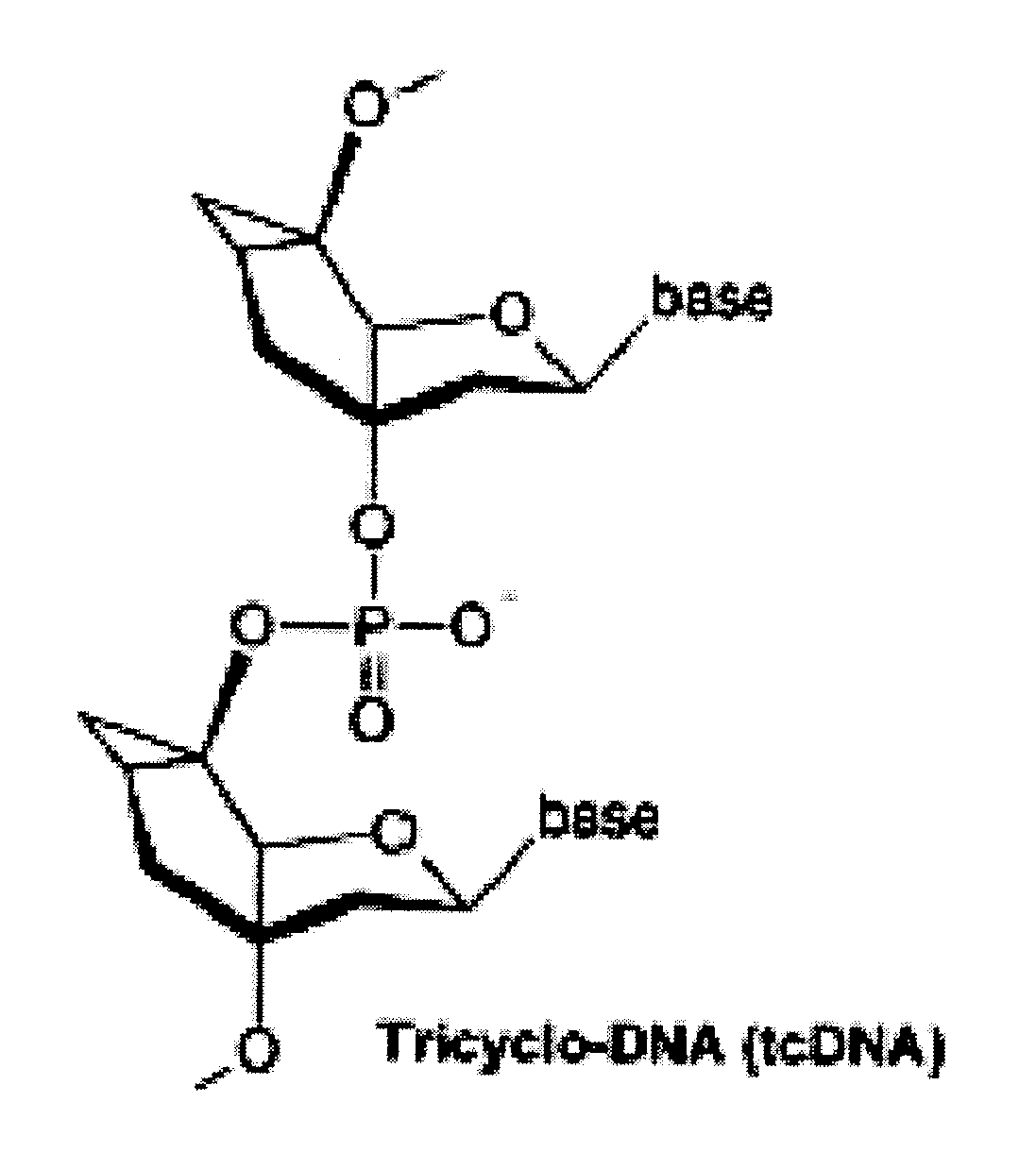

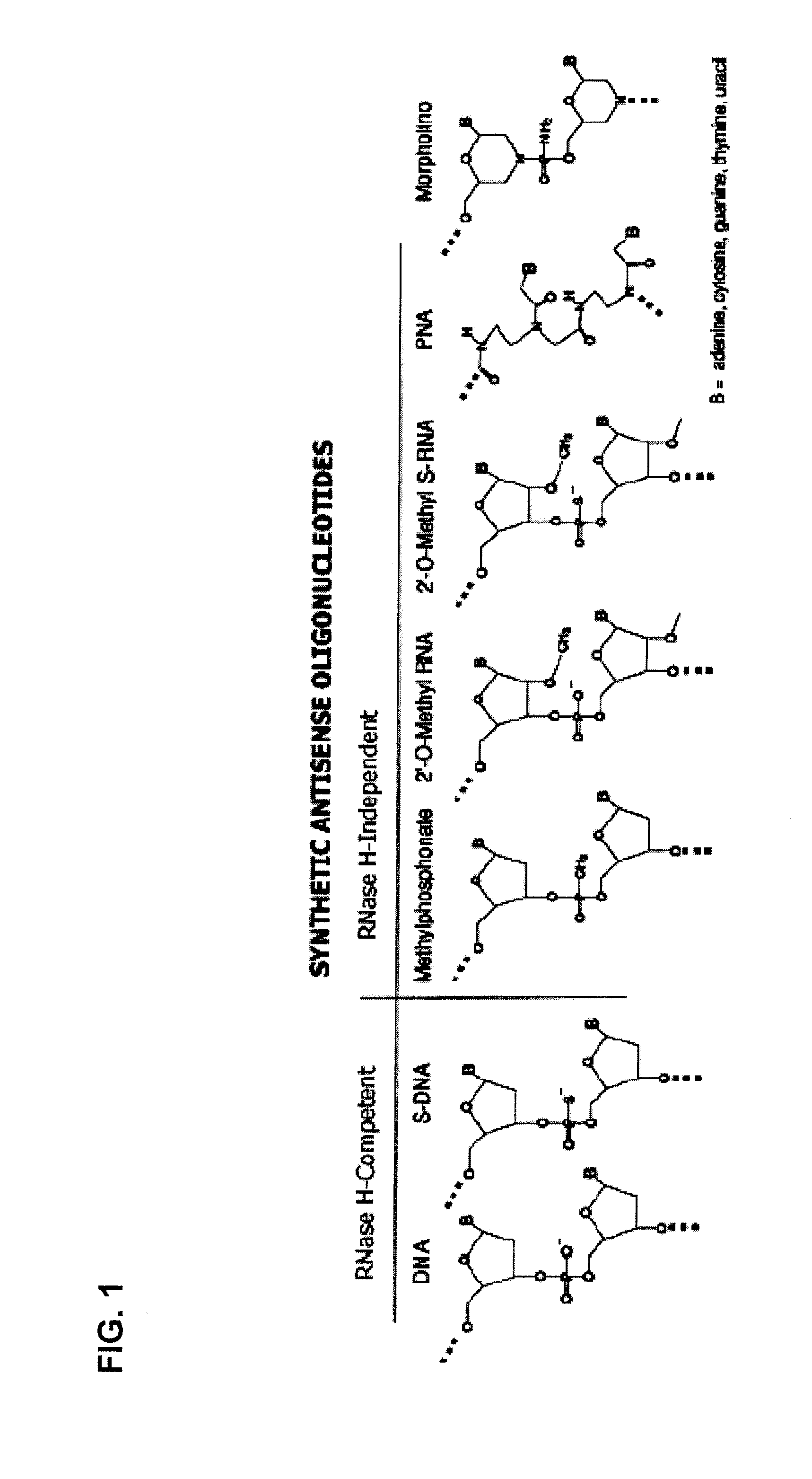

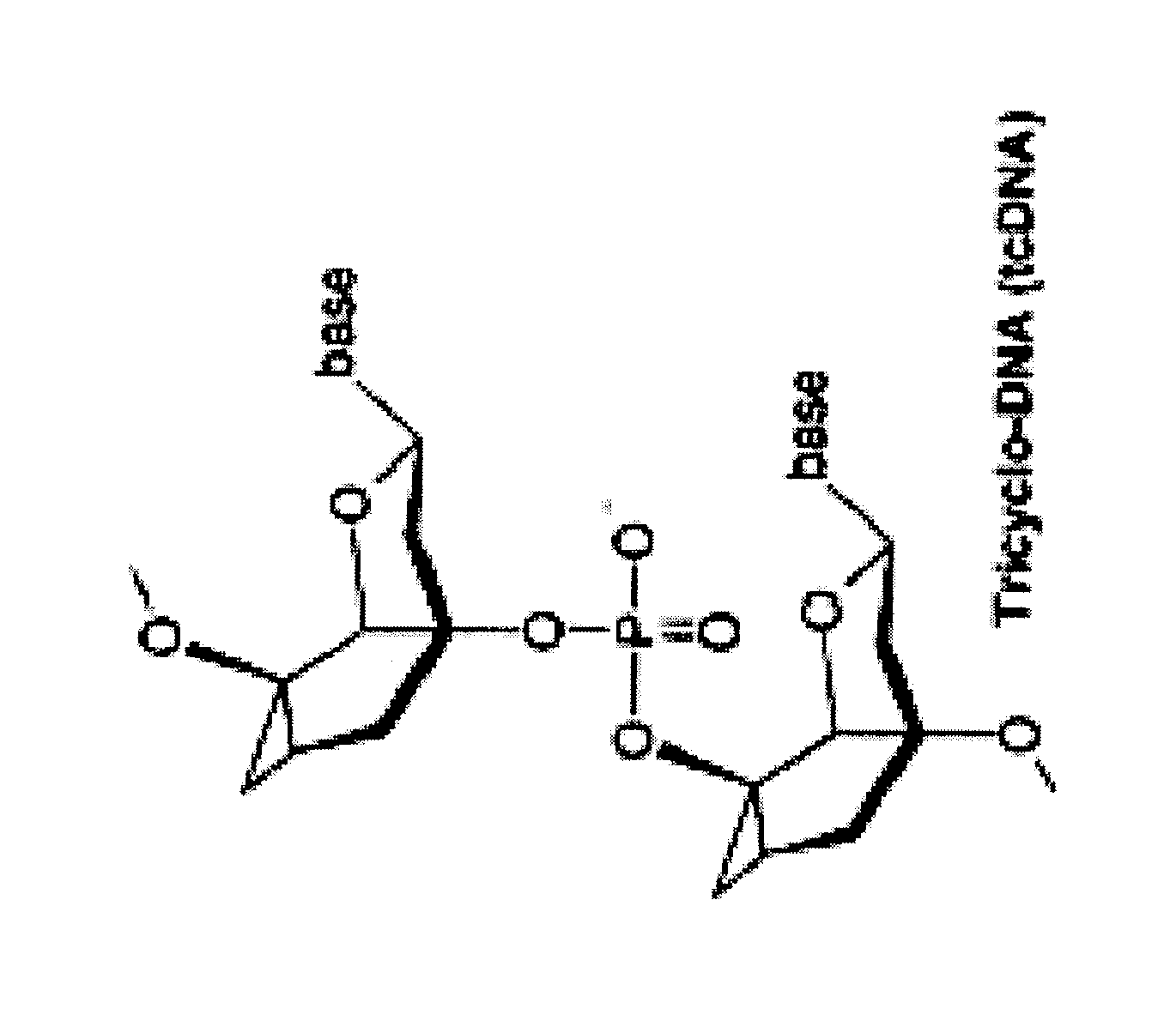

Tricyclo-dna antisense oligonucleotides, compositions, and methods for the treatment of disease

InactiveUS20120149756A1Find utilityFacilitates inclusionOrganic active ingredientsSplicing alterationDiseasePre mrna processing

Provided are tricyclo-DNA (tc-DNA) AON and methods employing tc-DNA AON for modifying splicing events that occur during pre-mRNA processing. Tricyclo-DNA (tc-DNA) AON are described that may be used to facilitate exon skipping or to mask intronic silencer sequences and / or terminal stem-loop sequences during pre-mRNA processing and to target RNase-mediated destruction of processed mRNA. Tc-DNA AON described herein may be used in methods for the treatment of Duchenne Muscular Dystrophy by skipping a mutated exon 23 or exon 51 within a dystrophin gene to restore functionality of a dystrophin protein; in methods for the treatment of Spinal Muscular Atrophy by masking an intronic silencing sequence and / or a terminal stem-loop sequence within an SMN2 gene to yield modified functional SMN2 protein, including an amino acid sequence encoded by exon 7, which is capable of at least partially complementing a non-functional SMN1 protein; and in methods for the treatment of Steinert's Myotonic Dystrophy by targeting the destruction of a mutated DM1 mRNA comprising 3′-terminal CUG repeats.

Owner:INST NAT DE LA SANTE & DE LA RECHERCHE MEDICALE (INSERM) +4

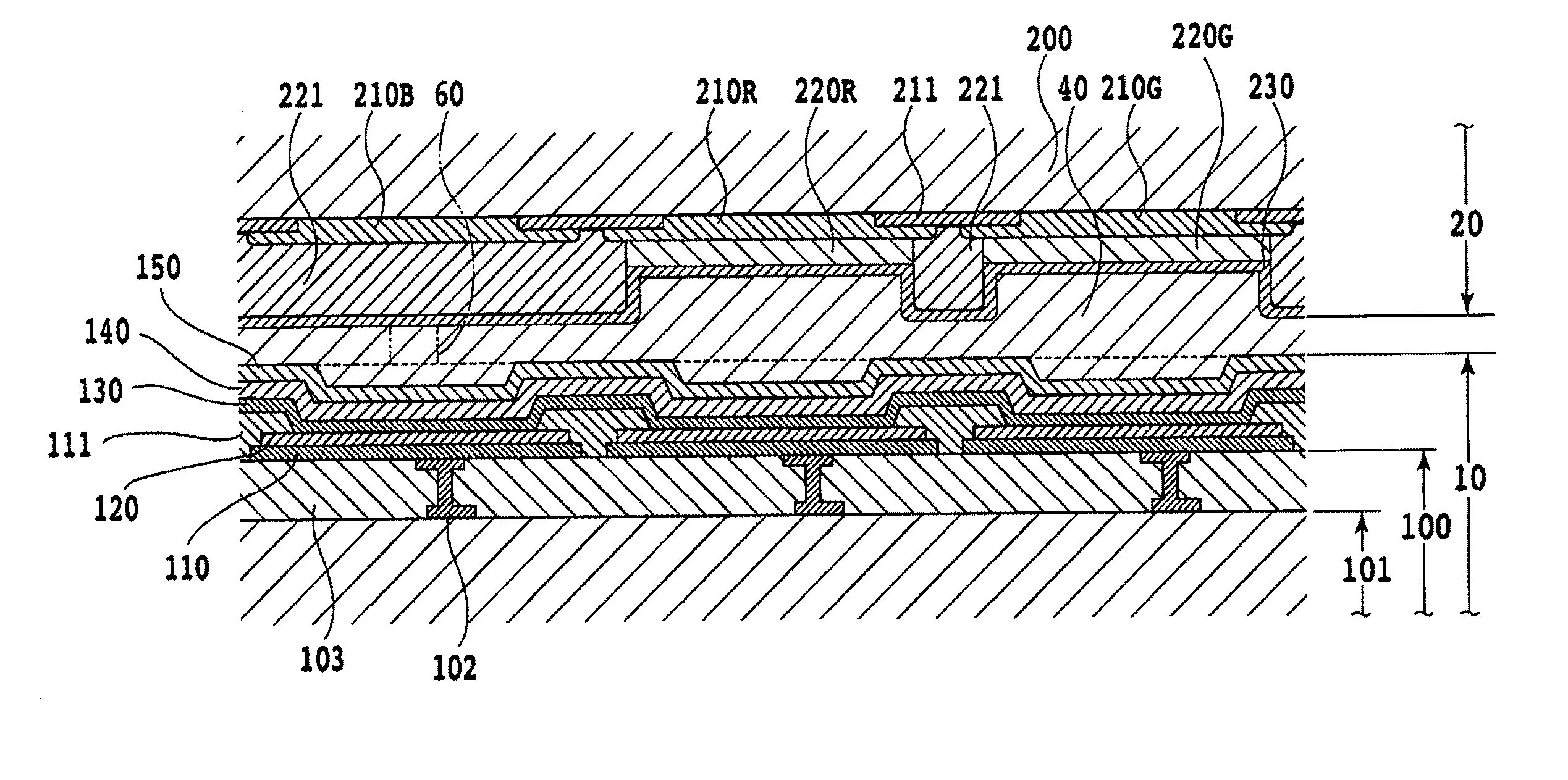

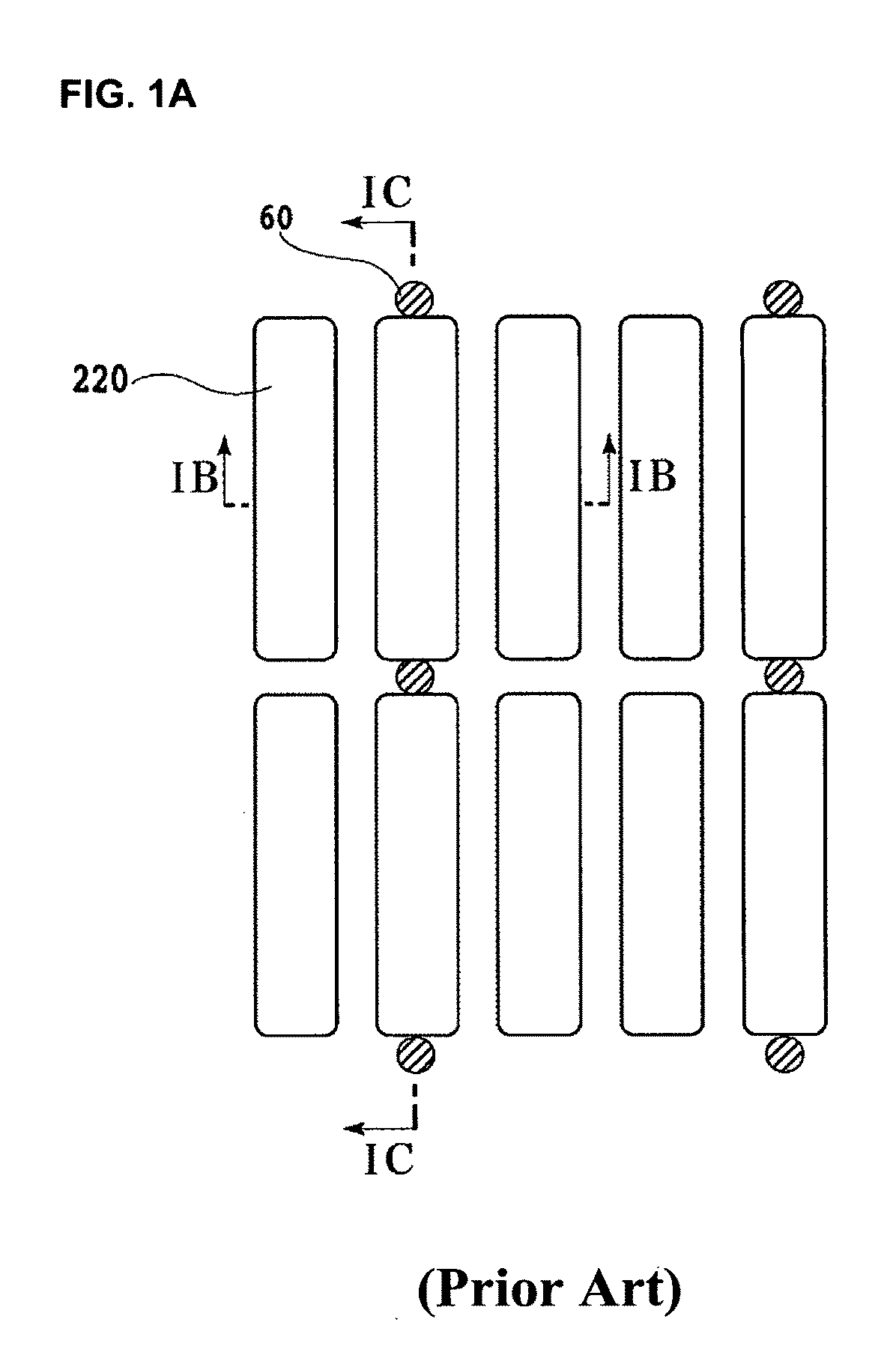

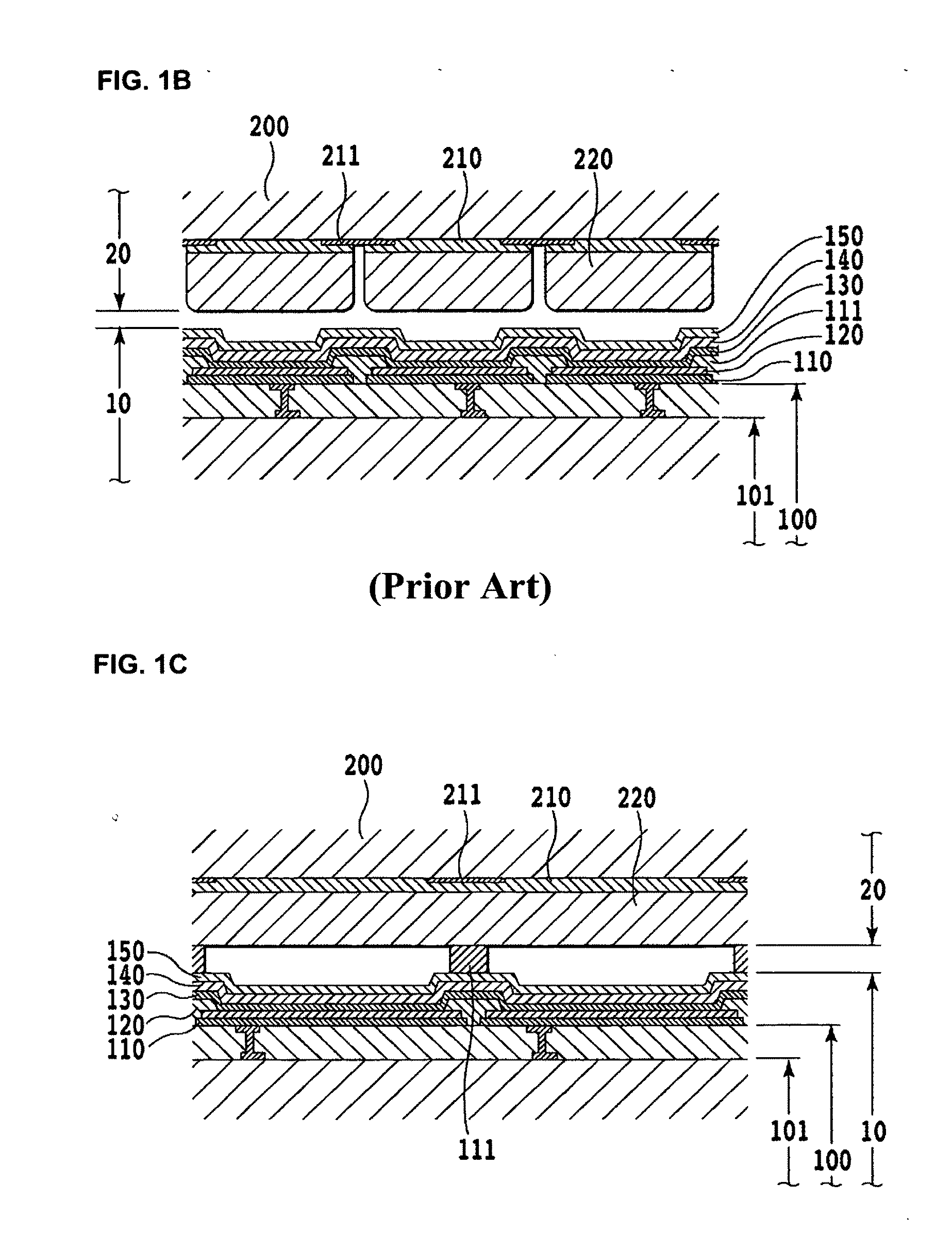

Organic el display and method for manufacturing same

ActiveUS20110084290A1Perfect sealAvoid inclusionsElectroluminescent light sourcesSolid-state devicesFilling materialsFilling defect

An object of this invention is to provide a top-emission type organic EL display in which filling defects of a resin filler material are alleviated during bonding of an organic EL emission panel and a color conversion filter panel with the resin filler material, as well as to provide a method for manufacturing such an organic EL display. An organic EL display of this invention is characterized in having stripe-shaped barrier walls for inkjet application placed on a color conversion filter panel, and a filler material guide wall placed between the length-direction end portions of the barrier walls for inkjet application and a peripheral seal member.

Owner:SHARP KK

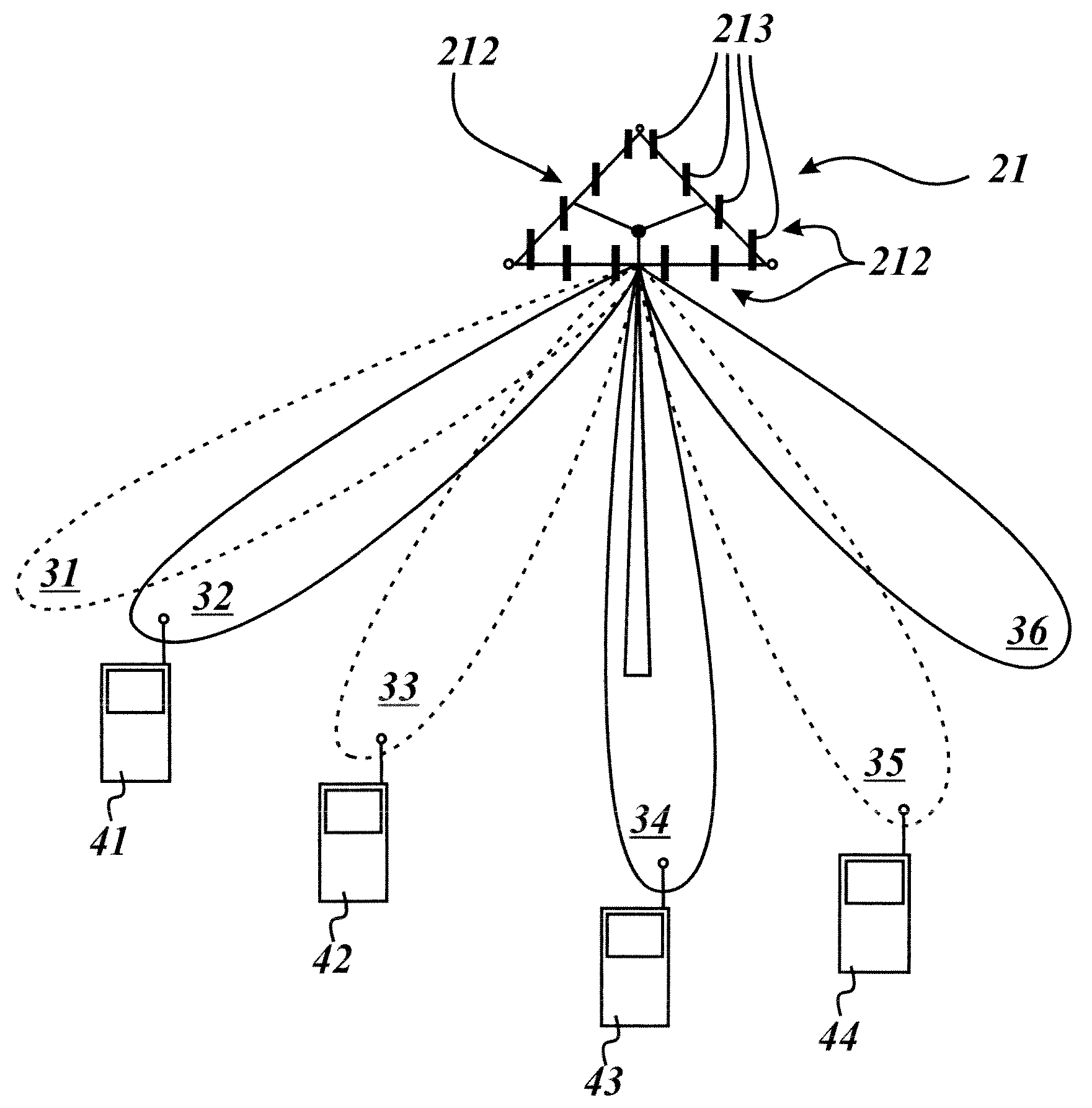

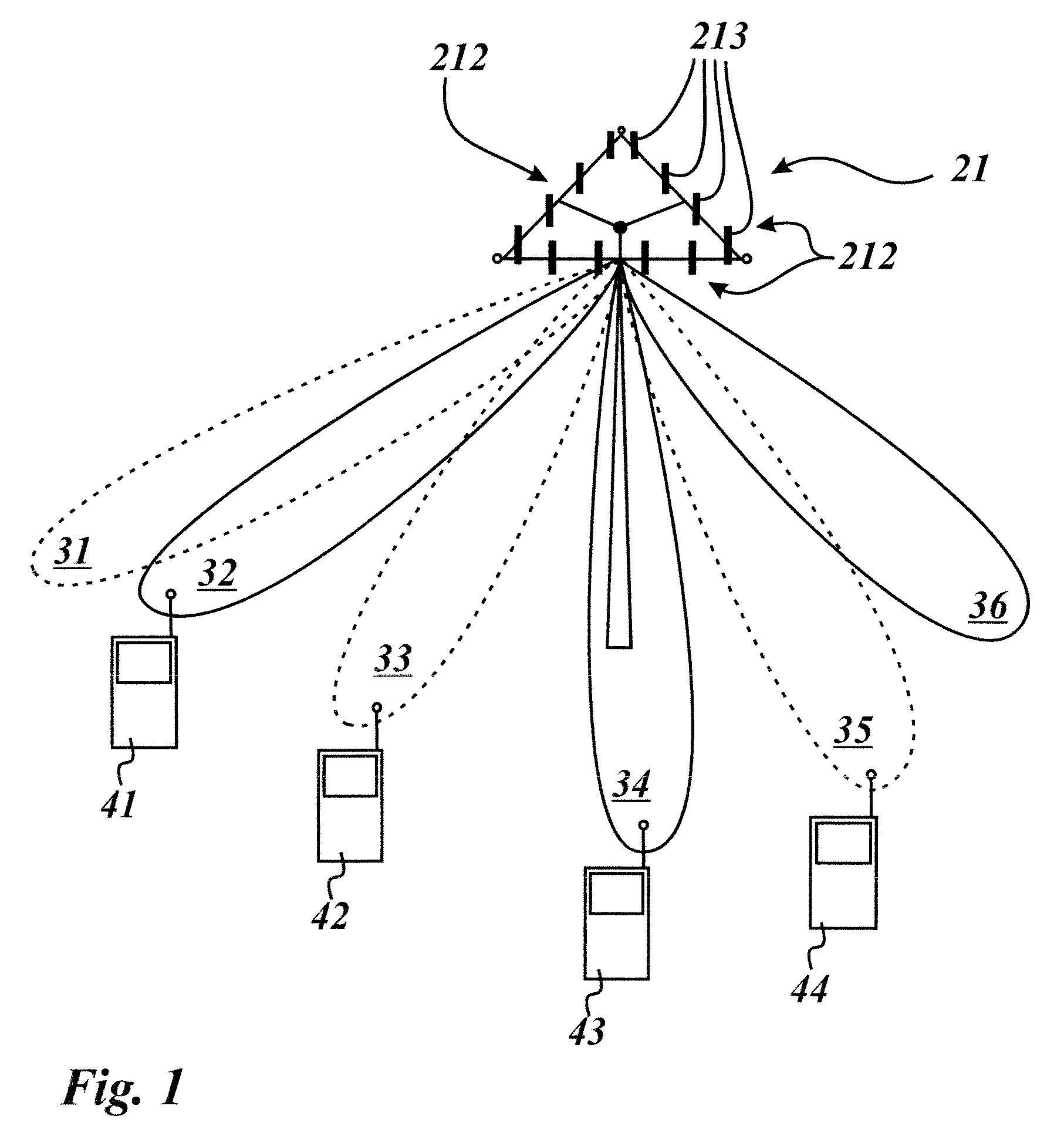

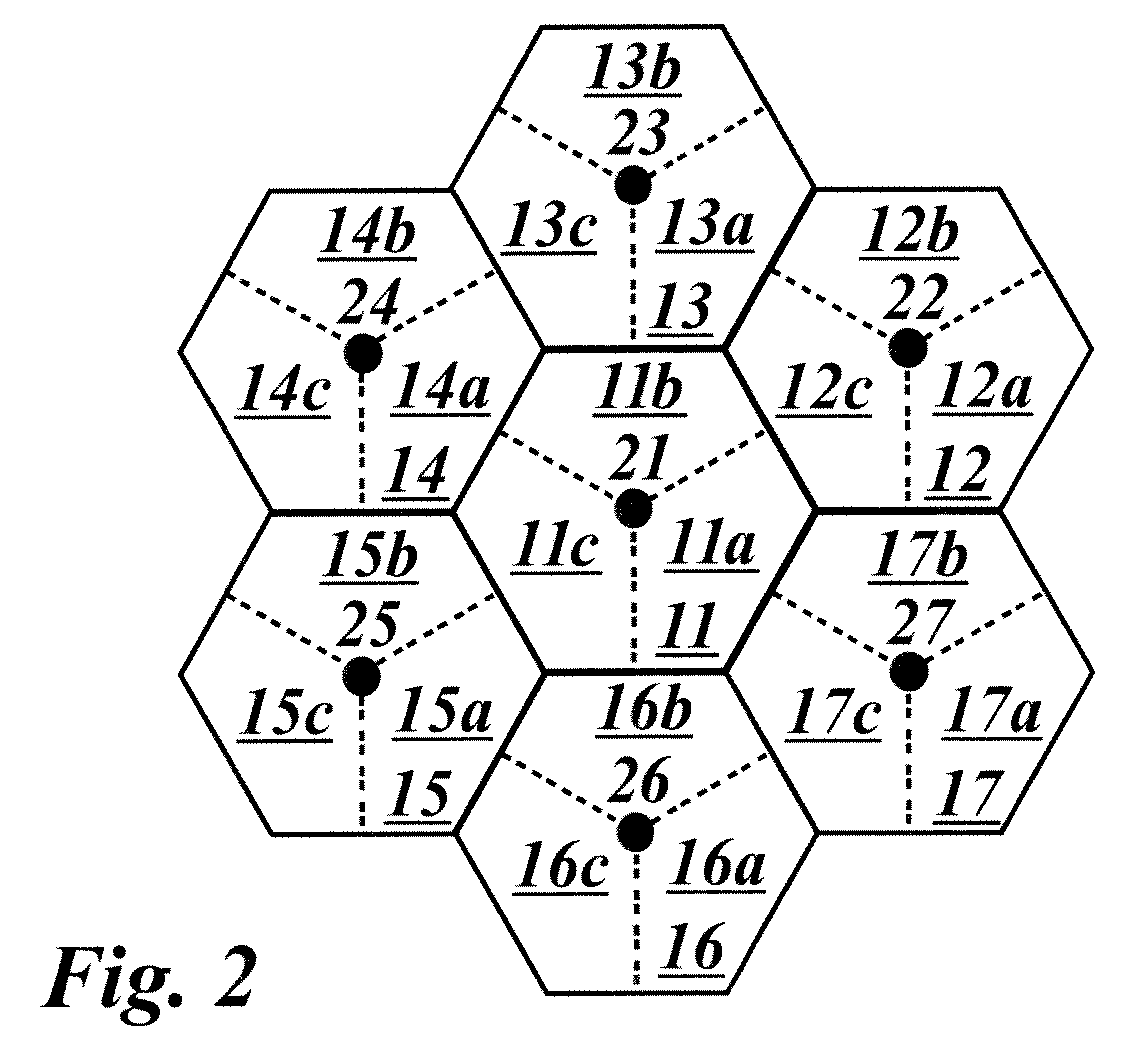

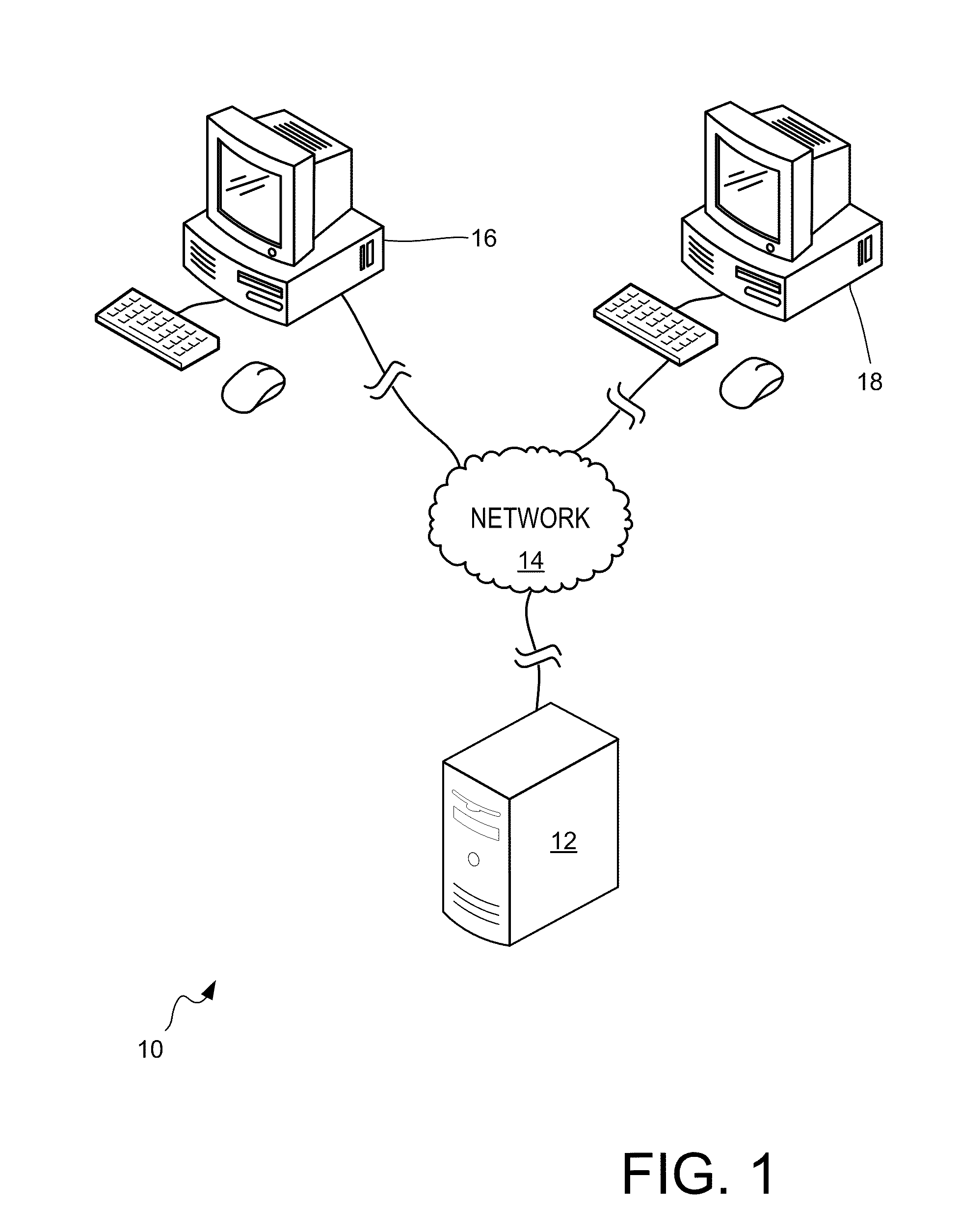

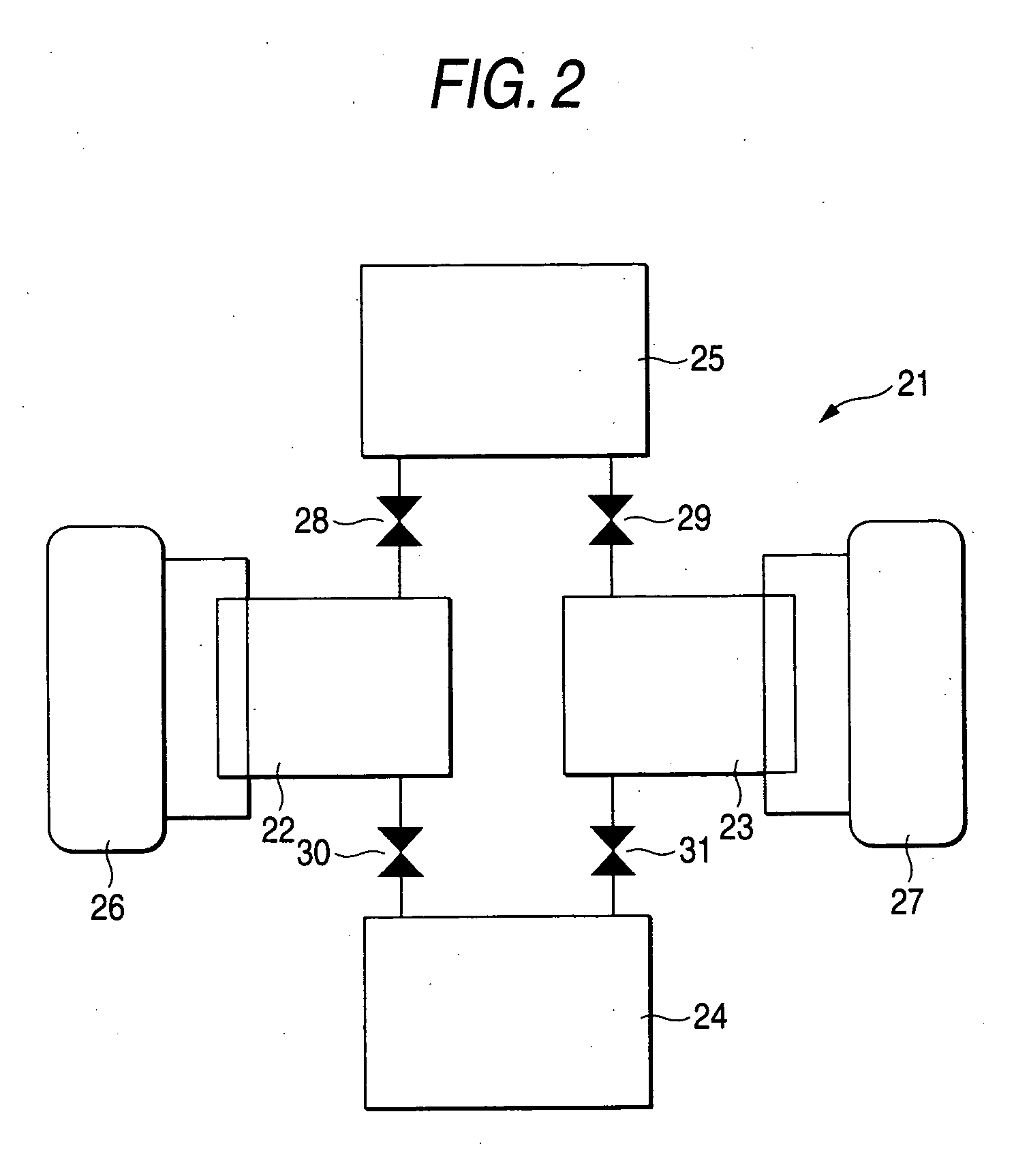

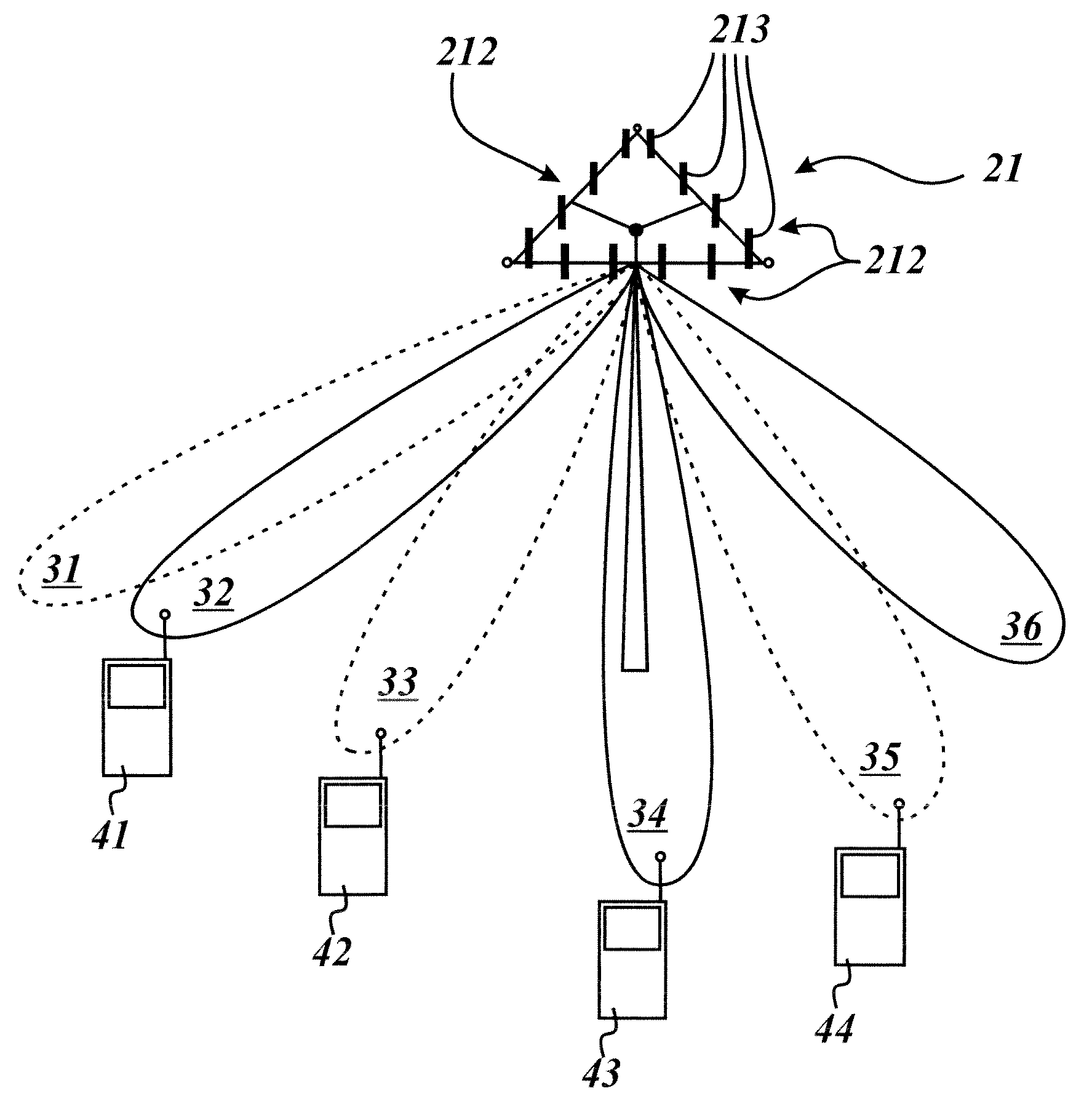

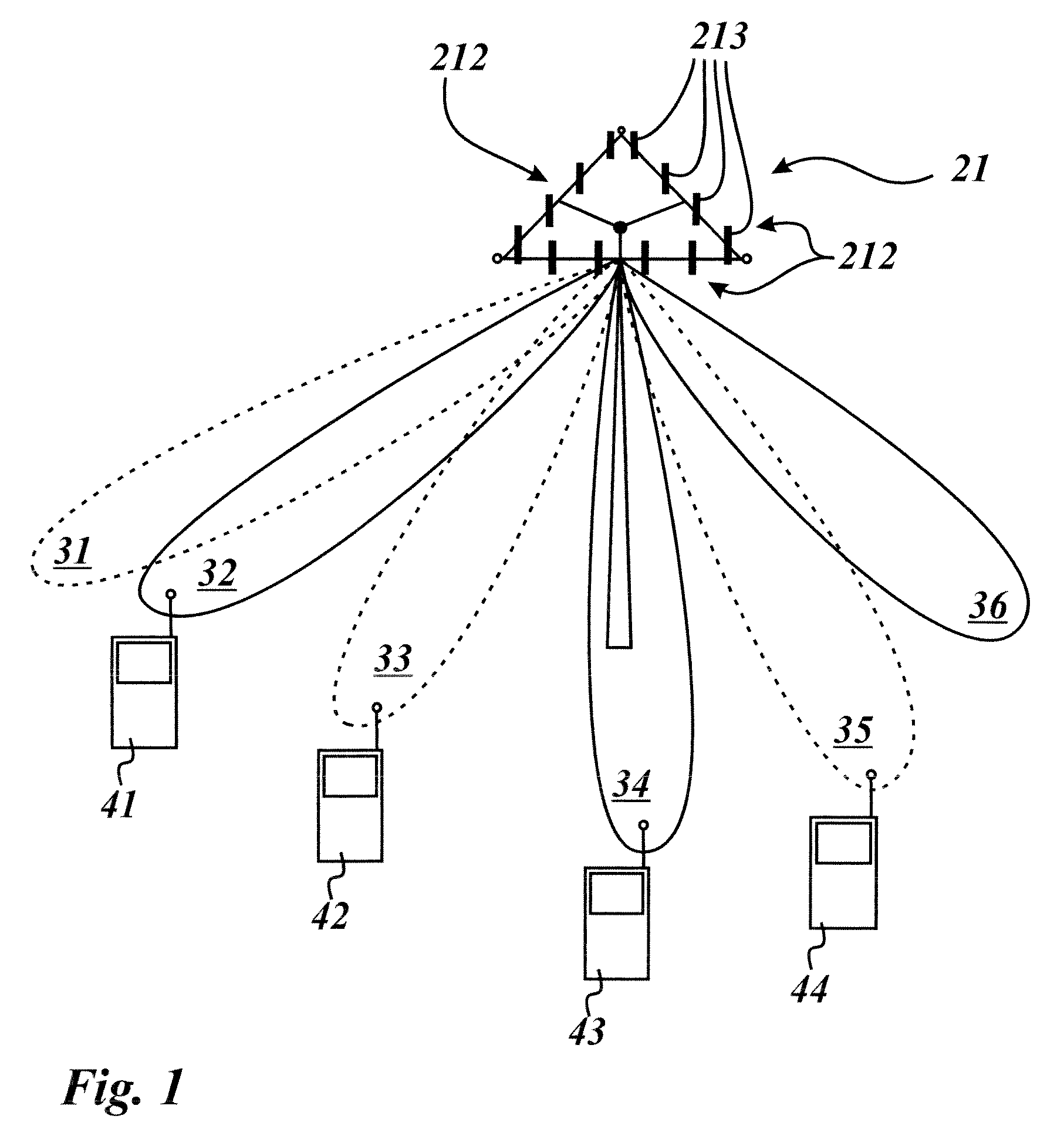

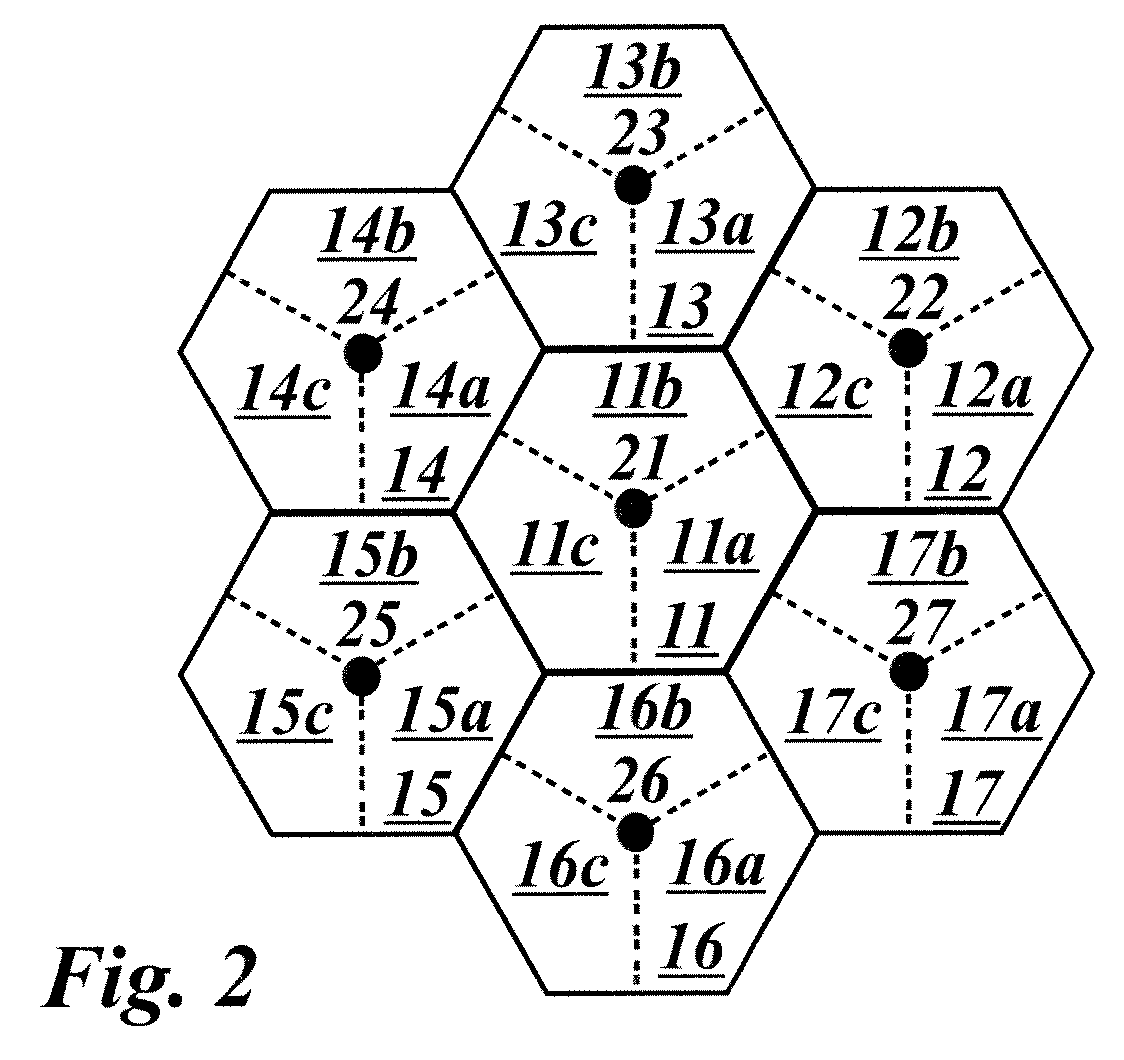

Method of and base station for controlling beam forming in a mobile cellular network

InactiveUS20090296663A1Improved beam formingAvoid negative effectsNetwork topologiesSubstation equipmentPattern sequenceSignal quality

The invention concerns a method and a base station (21) for controlling beam forming in a mobile cellular network: Antenna units (212) of base stations (21) of a cluster of neighbored base stations (21) apply a respective beam pattern sequence on each sector of a cell served by the respective base station (21). The beam pattern sequence is selected from a respective predefined set of beam pattern sequences and each beam pattern sequence defines a sequence of beam subsets used for communication with mobile units (41, 42, 43, 44). One of the base stations (21) of the cluster which acts as trigger base station informs all neighbored base stations of the cluster of neighbored base stations (21, 22, 23, 24, 25, 26, 27) not to change their beam pattern sequences. The trigger base station (21) controls the antenna unit (212) of the trigger base station (21) to change the beam pattern sequence applied on the sectors of the cell and sequently apply two or more different beam pattern sequences of the predefined set of beam pattern sequences on the respective sector. The trigger base station (21) triggers one or more mobile units (41, 42, 43, 44) located in the cluster of neighbored base stations to calculate one or more signal quality parameters for currently applied beam pattern sequences of the trigger base station (21). The trigger base station (21) selects an optimal beam pattern sequence from the set of the predefined beam pattern sequences based on the one or more calculated signal quality parameters and the antenna unit (212) of the trigger base station (21) applies the optimal beam pattern sequence as a new beam pattern sequence on the respective sector.

Owner:WSOU INVESTMENTS LLC

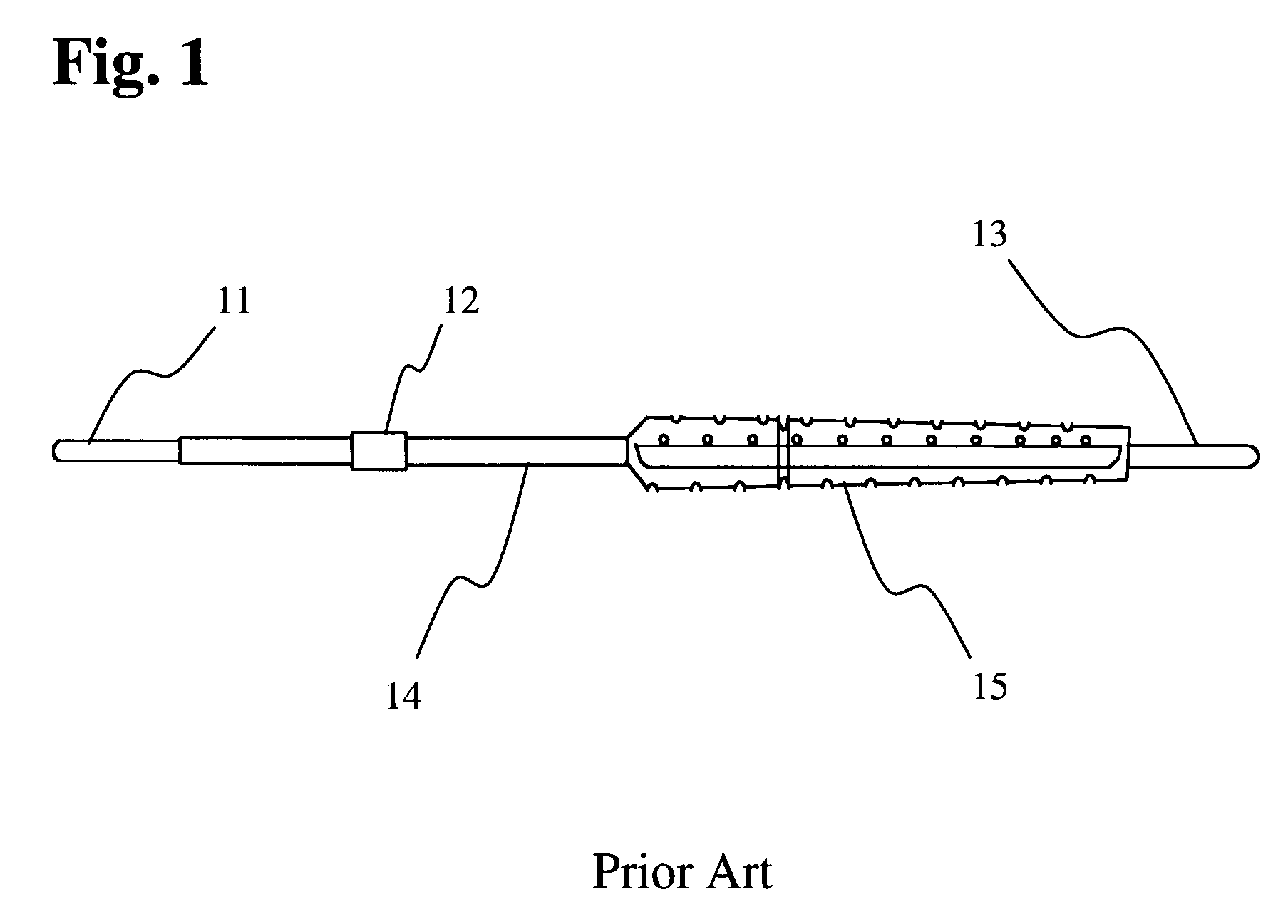

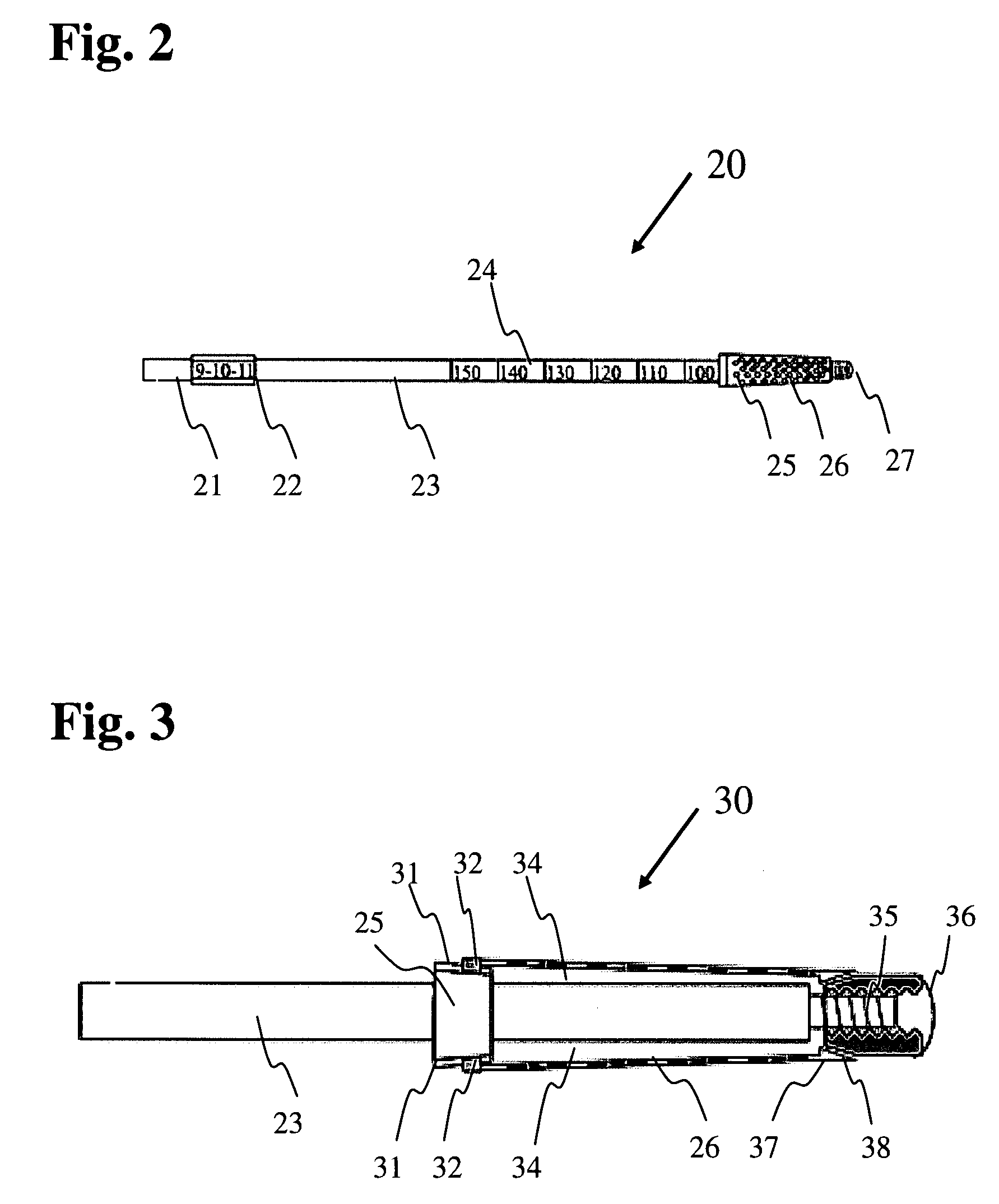

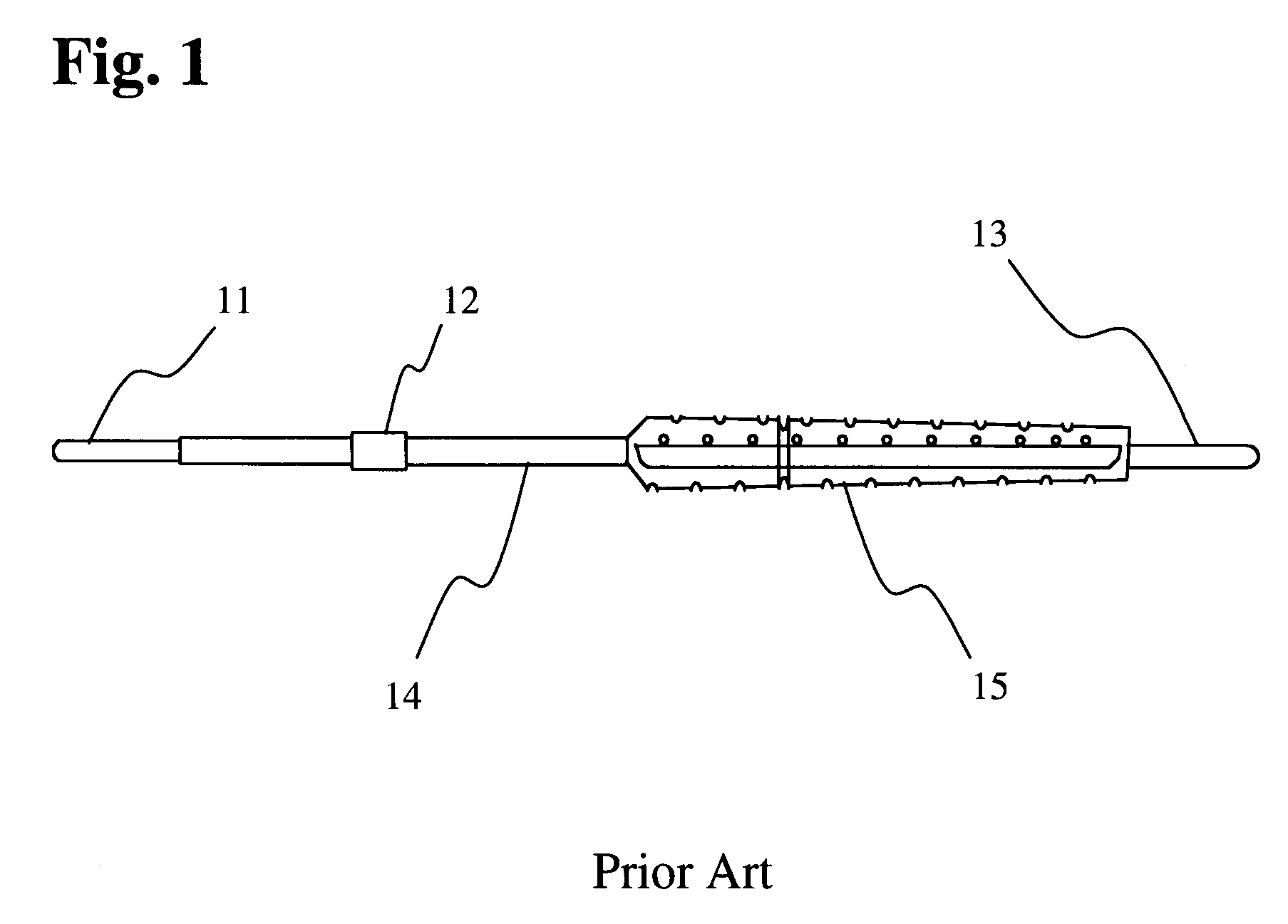

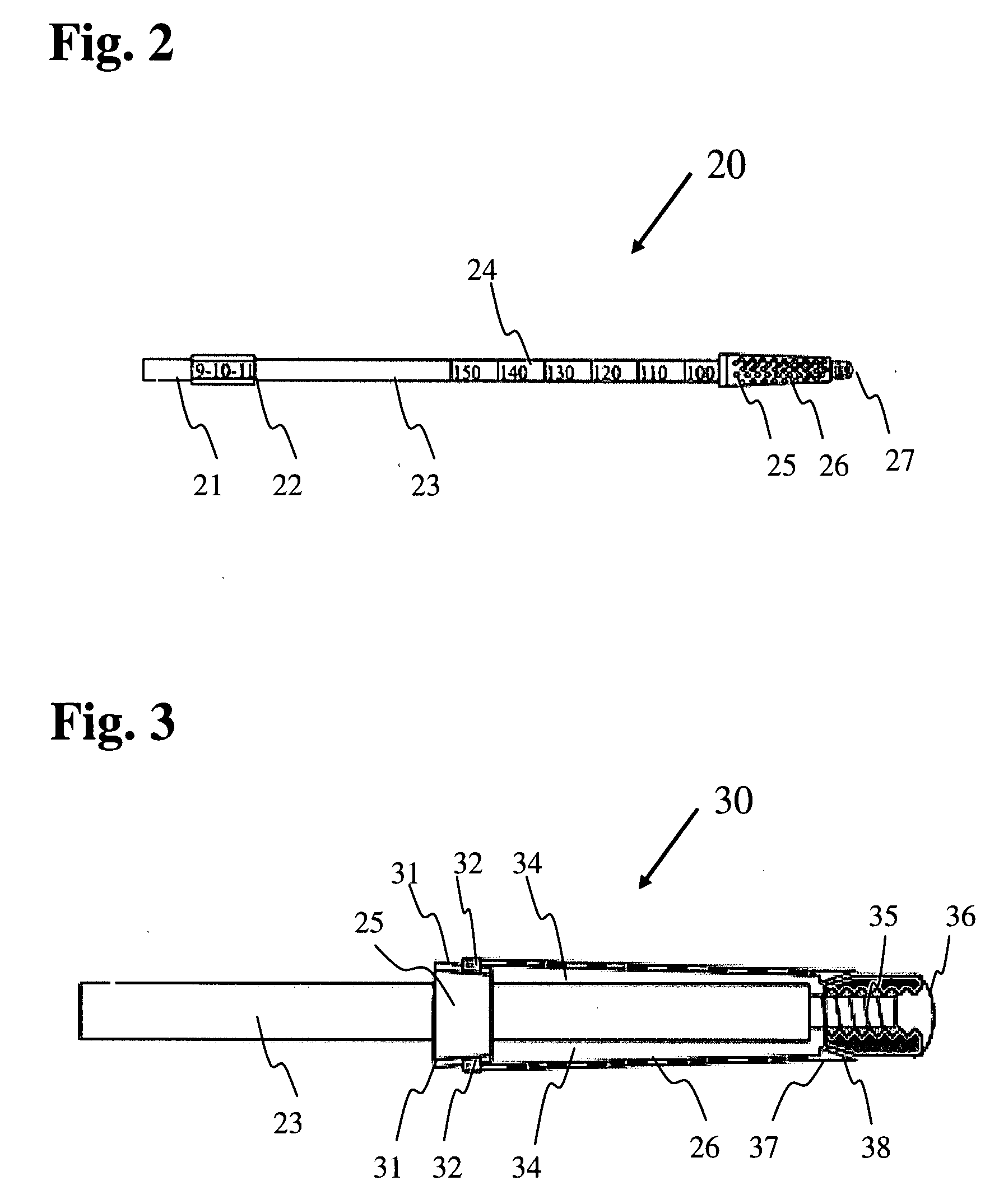

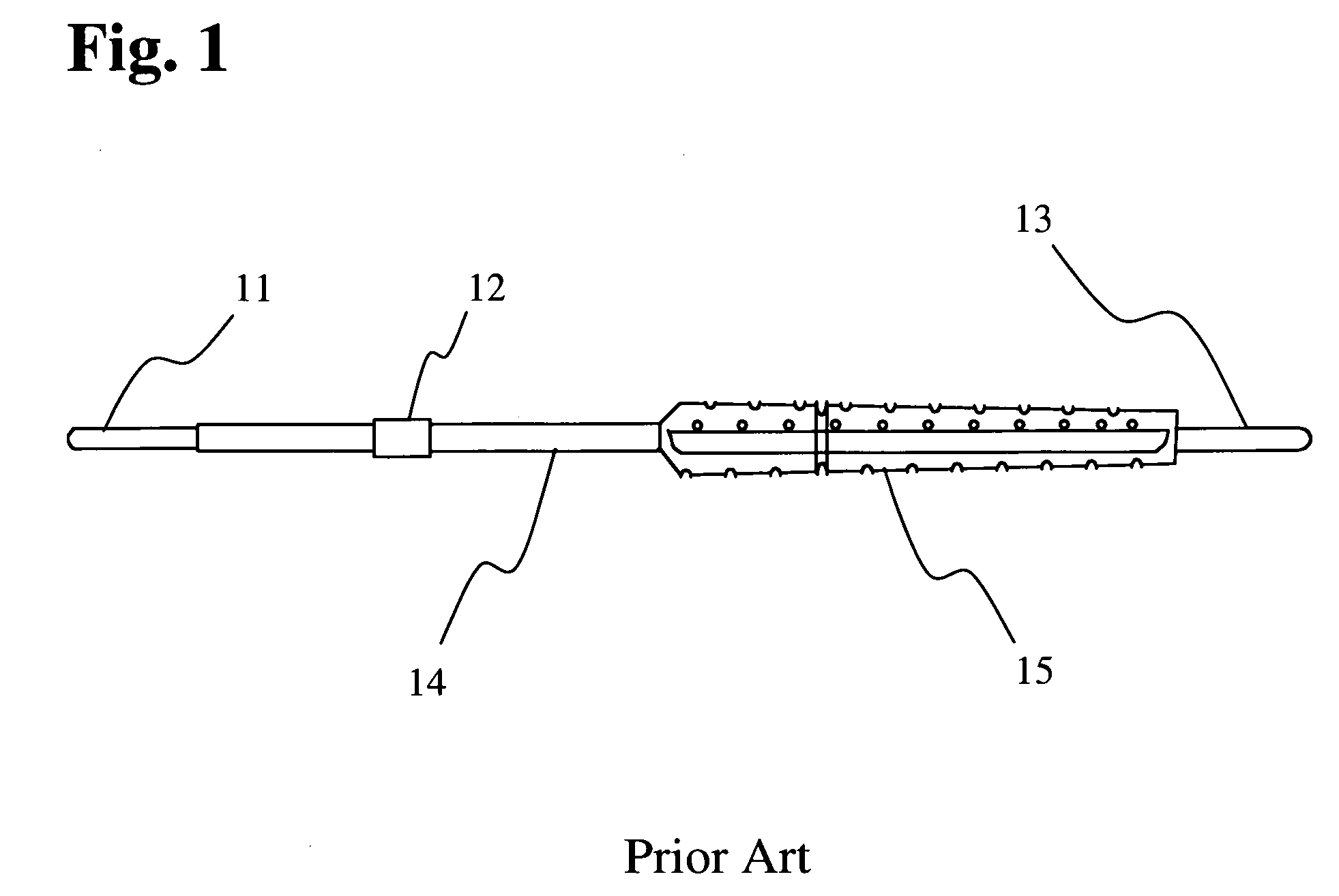

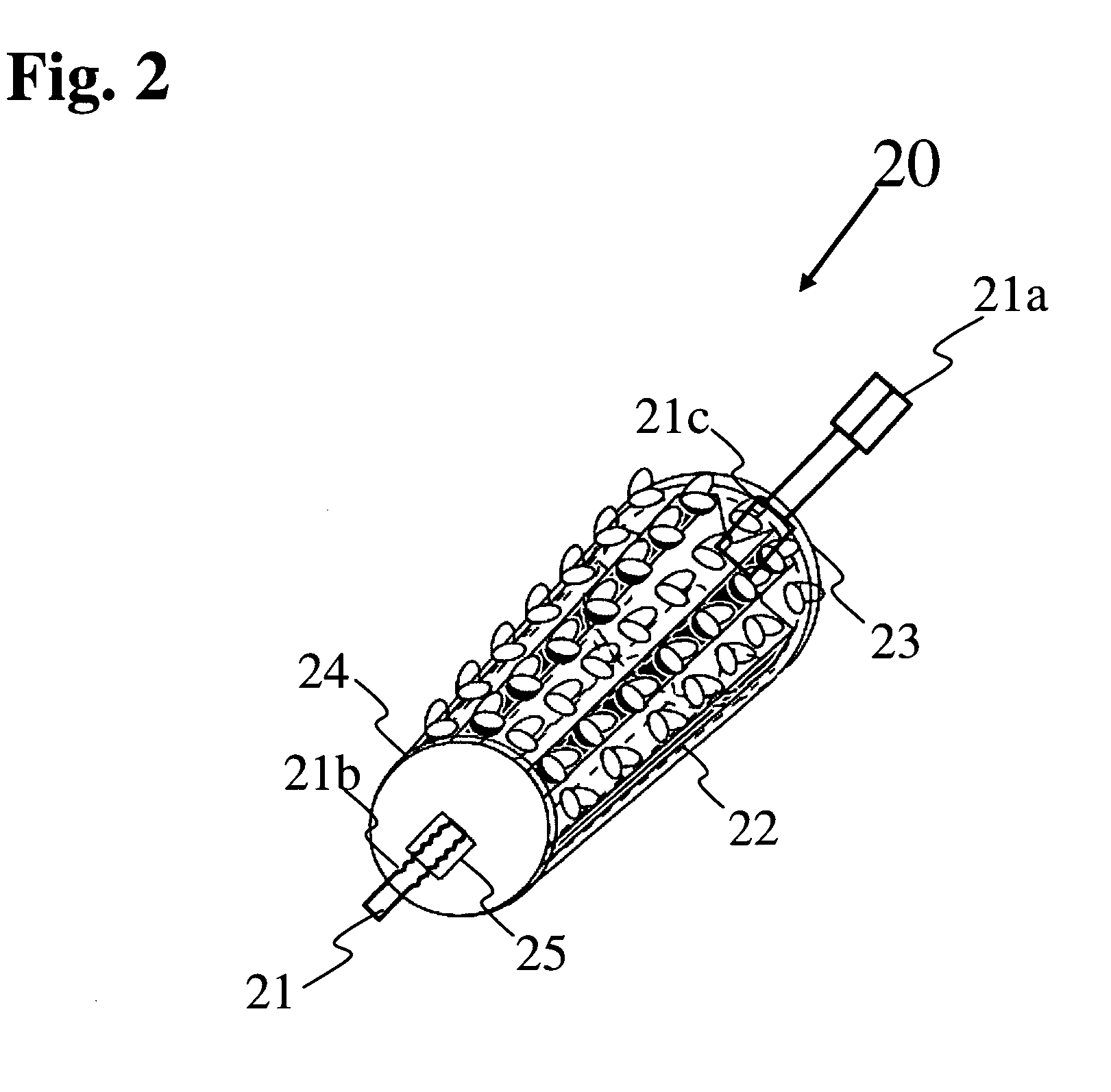

Modular tapered hollow reamer for medical applications

A reamer for medical applications comprising a shaft portion, a disposable tapered hollow reamer sleeve and a modular pilot. The shaft portion has a proximal end for attachment to a drill, a central cone element with one or more slots and a distal threaded end. The reamer sleeve has attached one or more torque transmitting tabs at the larger end and a collet taper at the smaller end and slides over the shaft engaging tabs with the slots. The modular pilot has a threaded central aperture engaging shaft thread and a collet taper mating with the collet taper of the reamer sleeve substantially coinciding their centerlines. The disposable hollow cutter sleeve has a plurality of cutting elements and apertures that discharge bone and bone cement debris into the space between the reamer and the shaft. With this construction, the reamer transmits reliable reaming torque in an efficient manner.

Owner:LRS SCI & TECH LLC

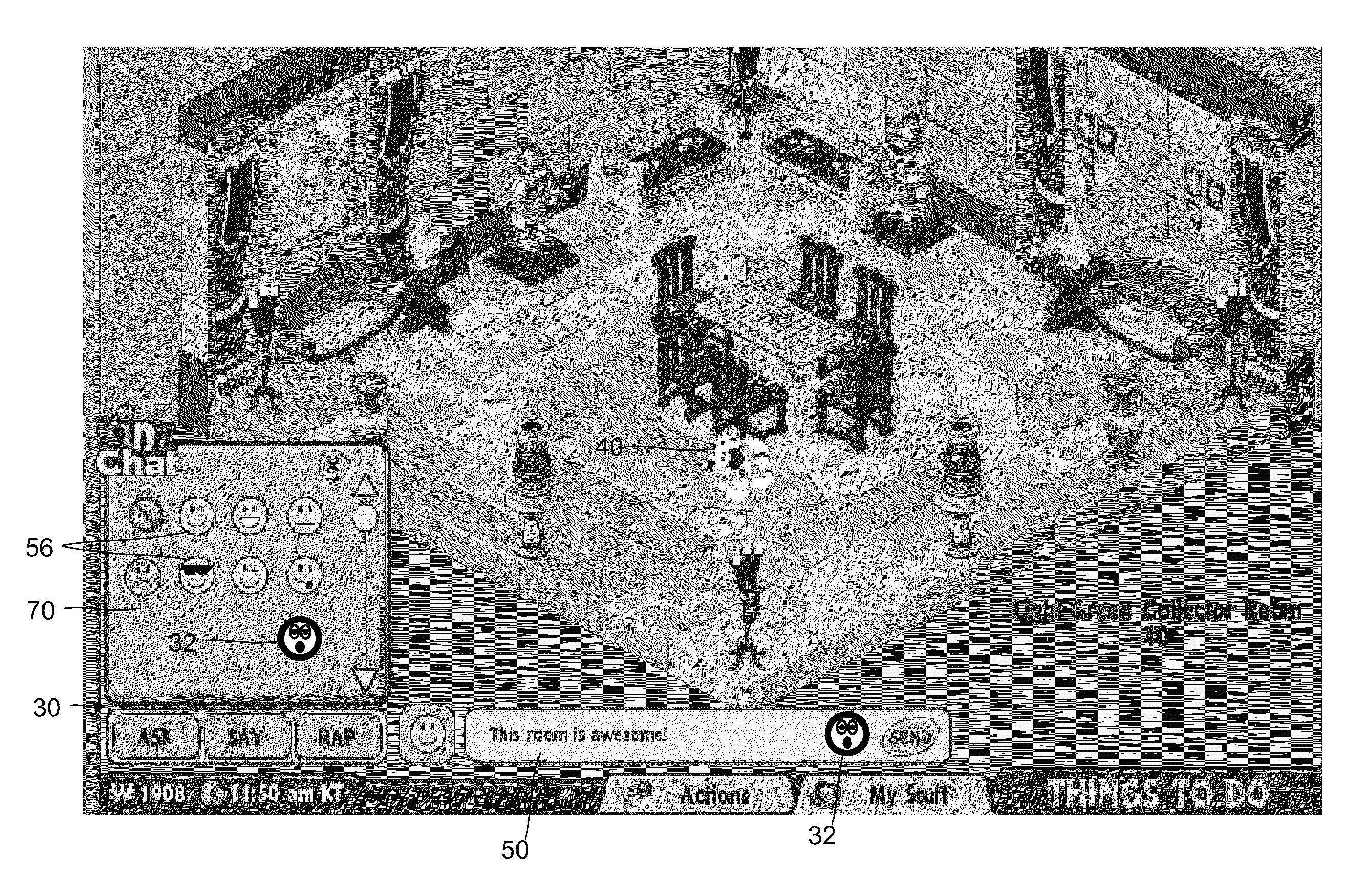

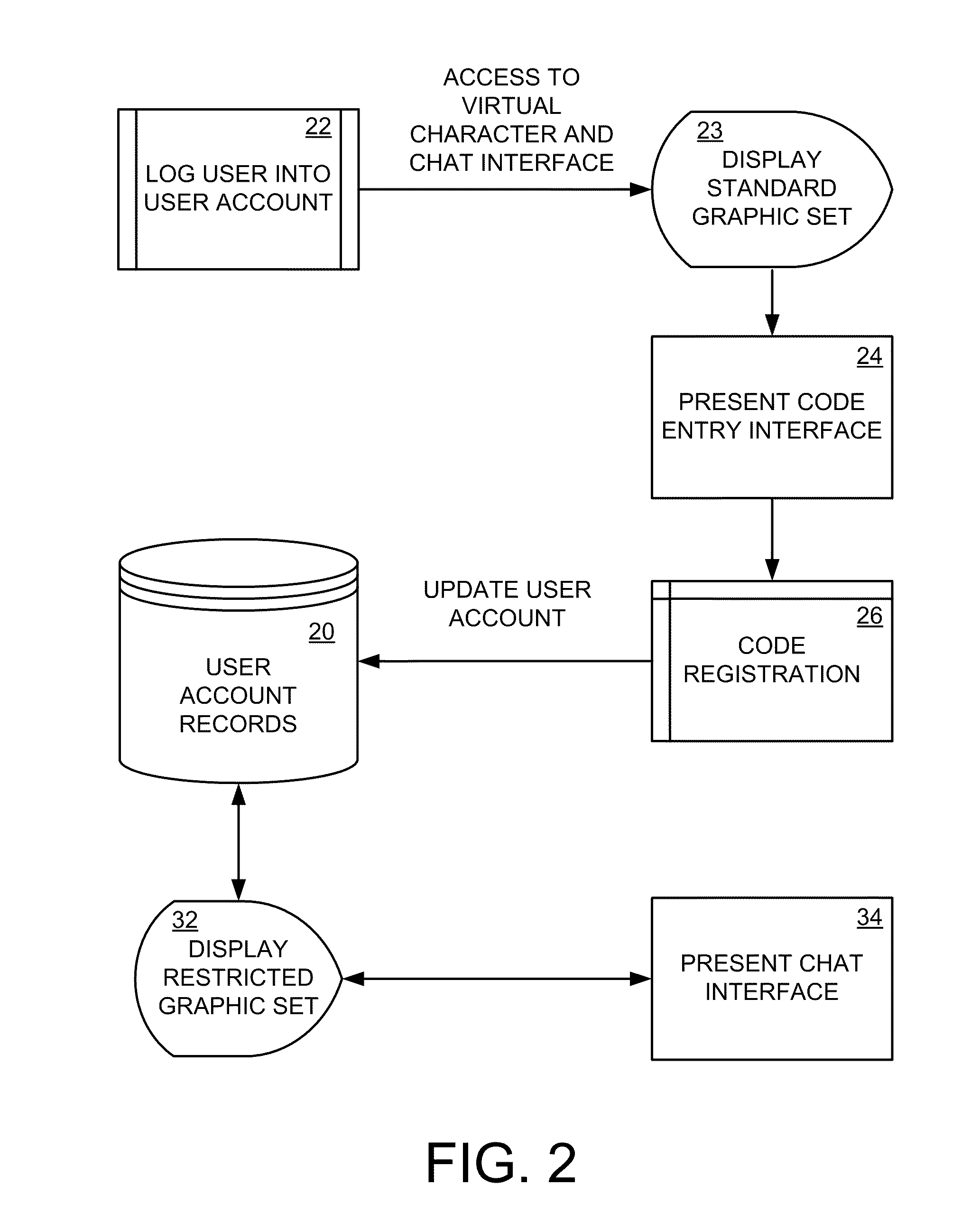

Unlocking emoticons using feature codes

ActiveUS20100293473A1Avoid inclusionsWell formedData switching networksInput/output processes for data processingGraphicsComputer science

Owner:GANZ

Integral easting method of cast steel supporting roller

ActiveCN1597180AImprove rationalityShorten the production cycleFoundry mouldsFoundry coresAir bubbleSystems design

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

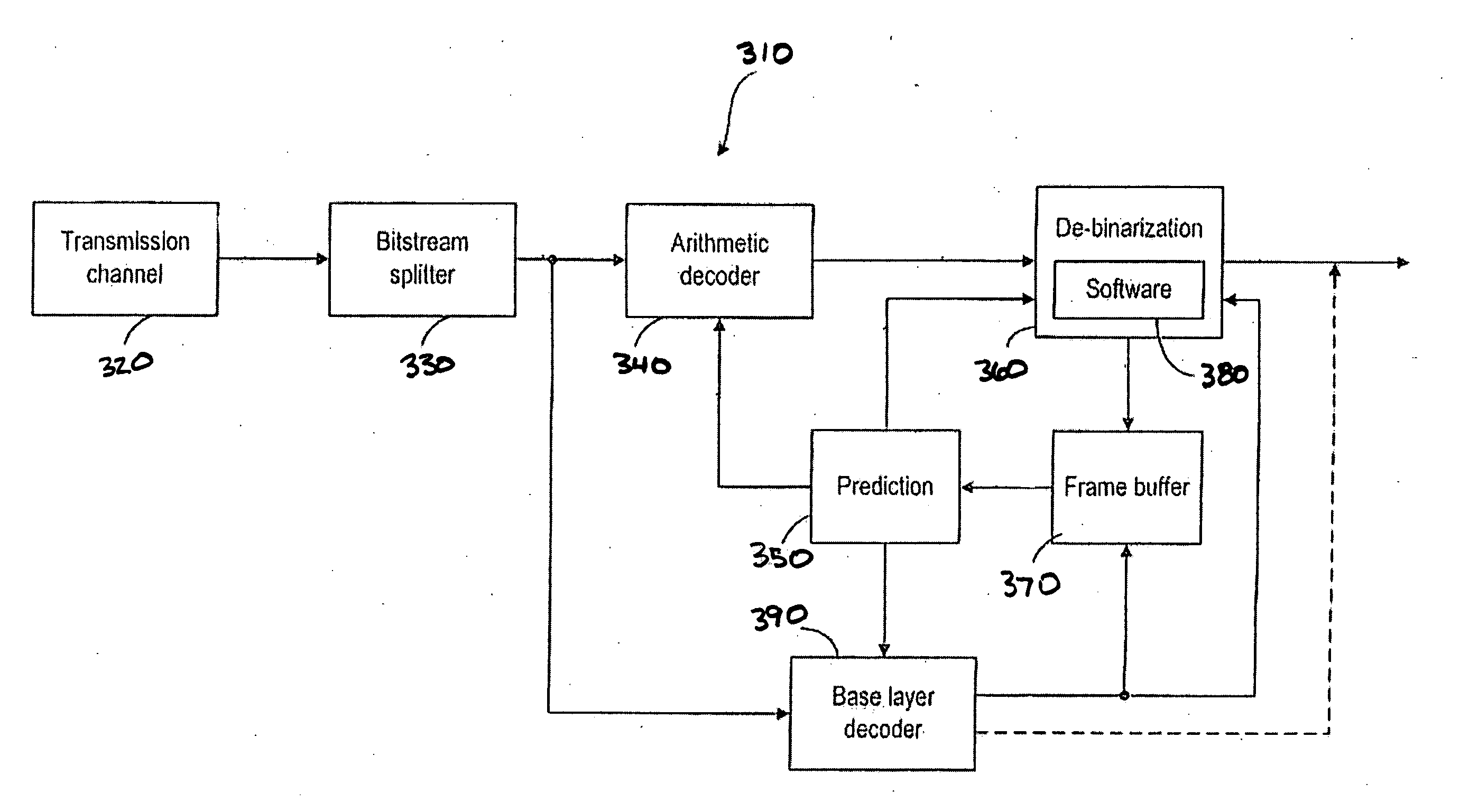

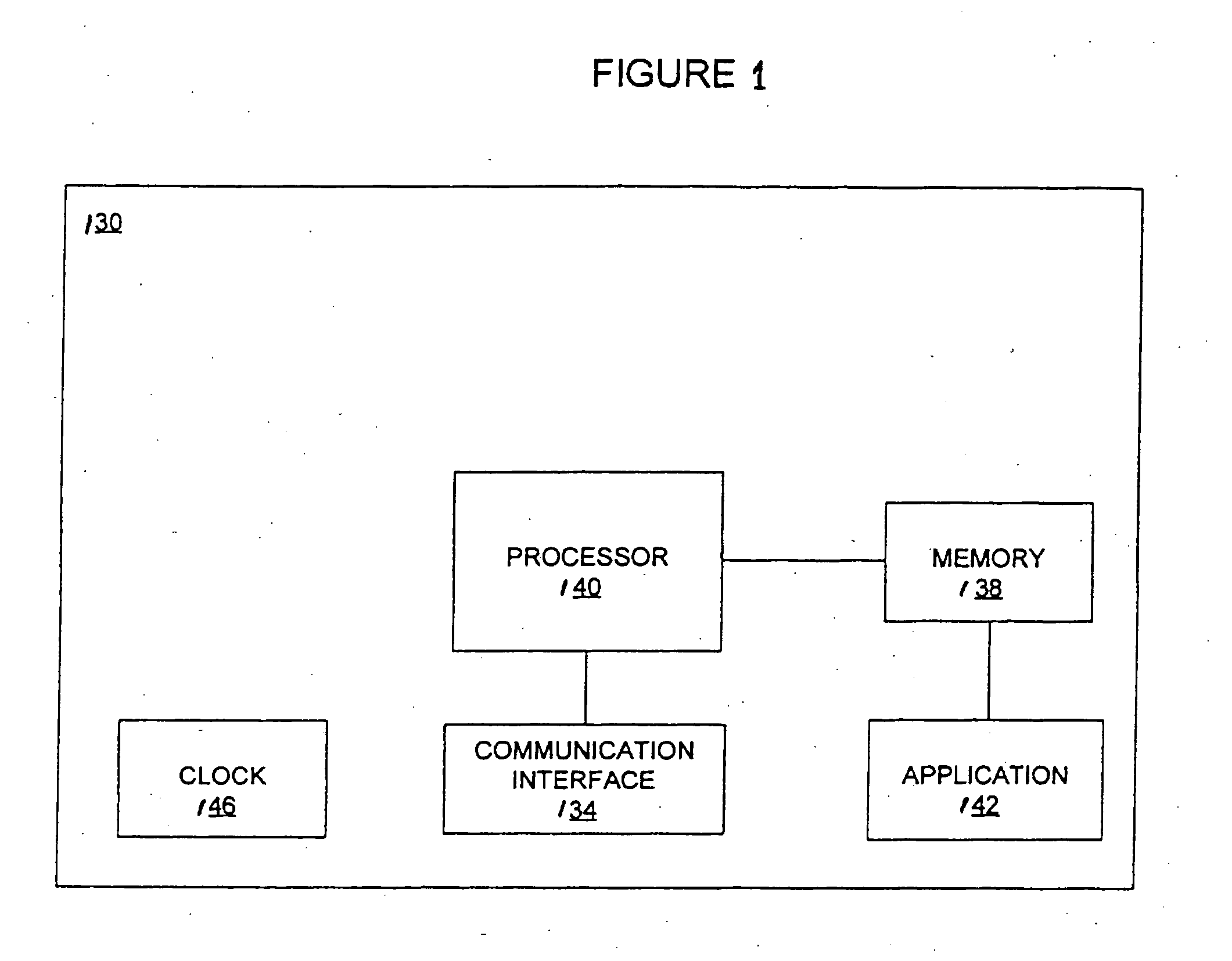

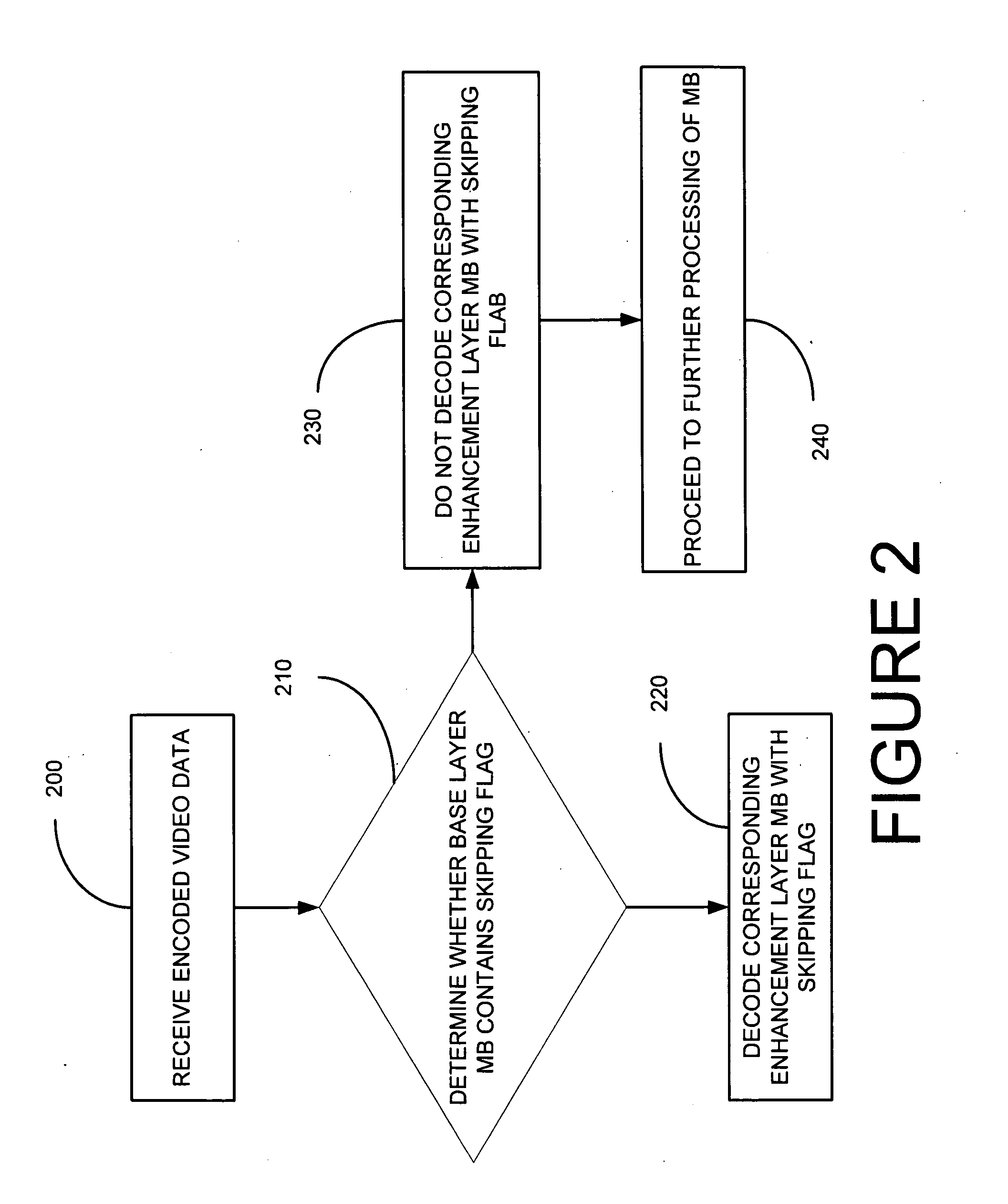

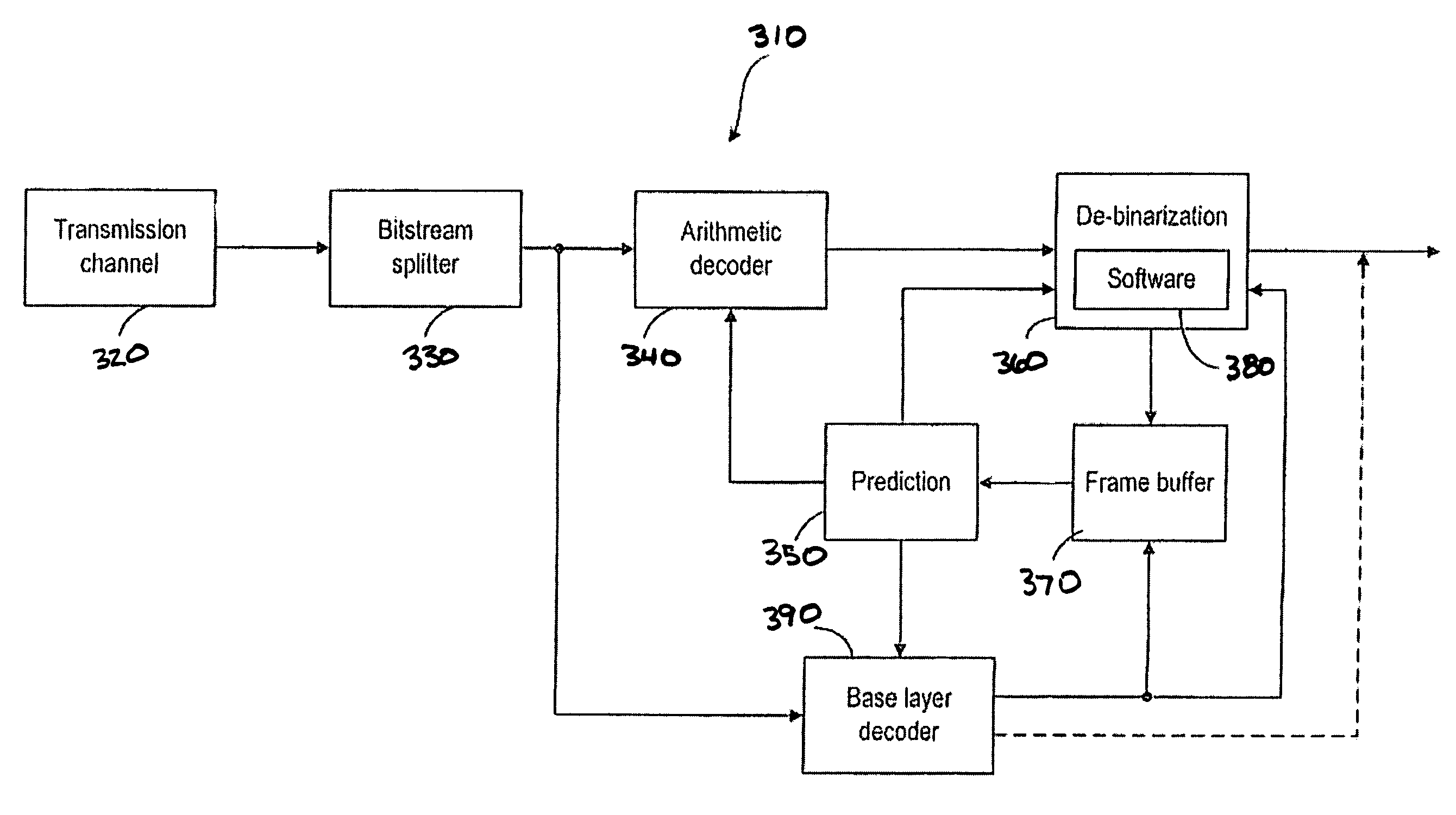

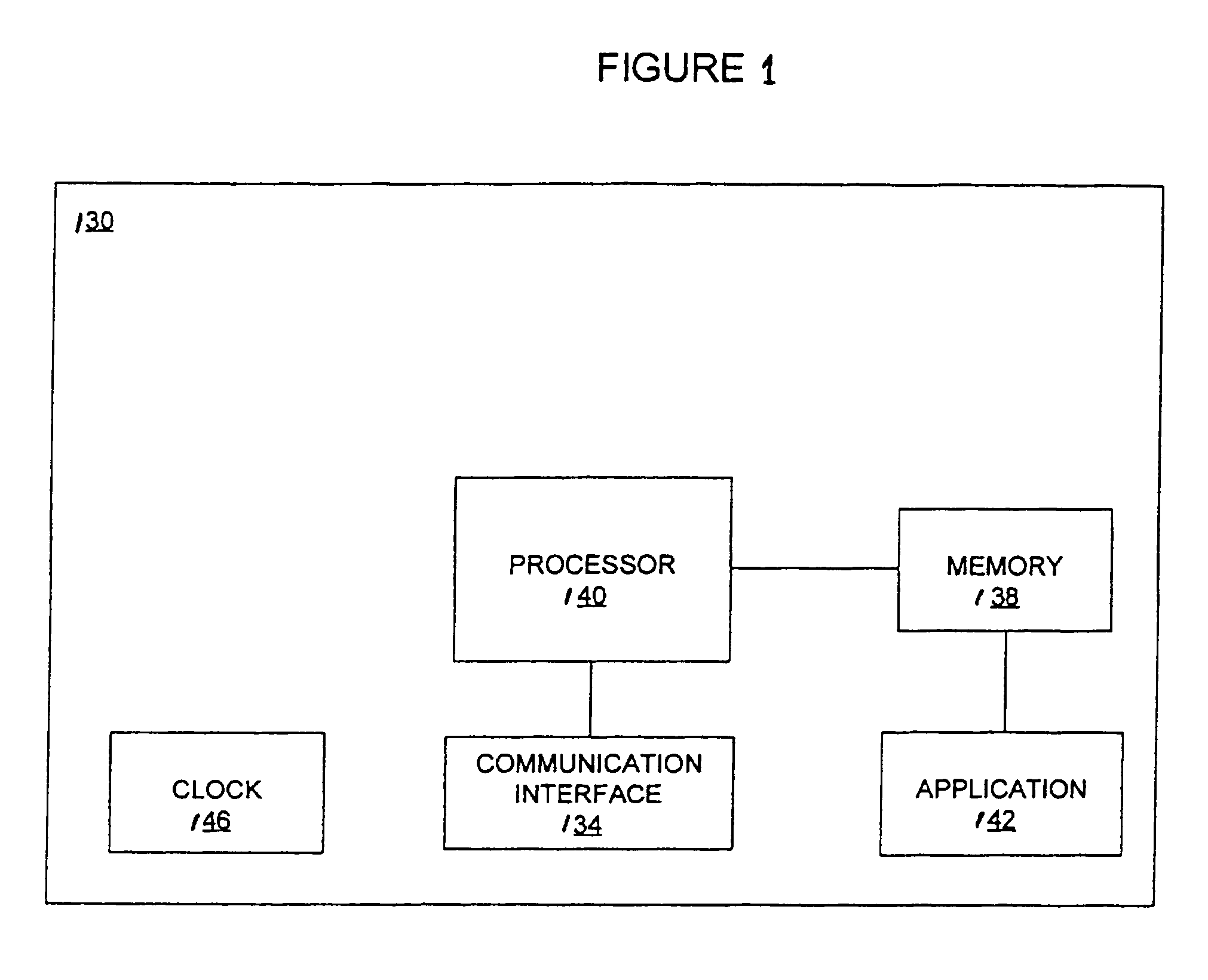

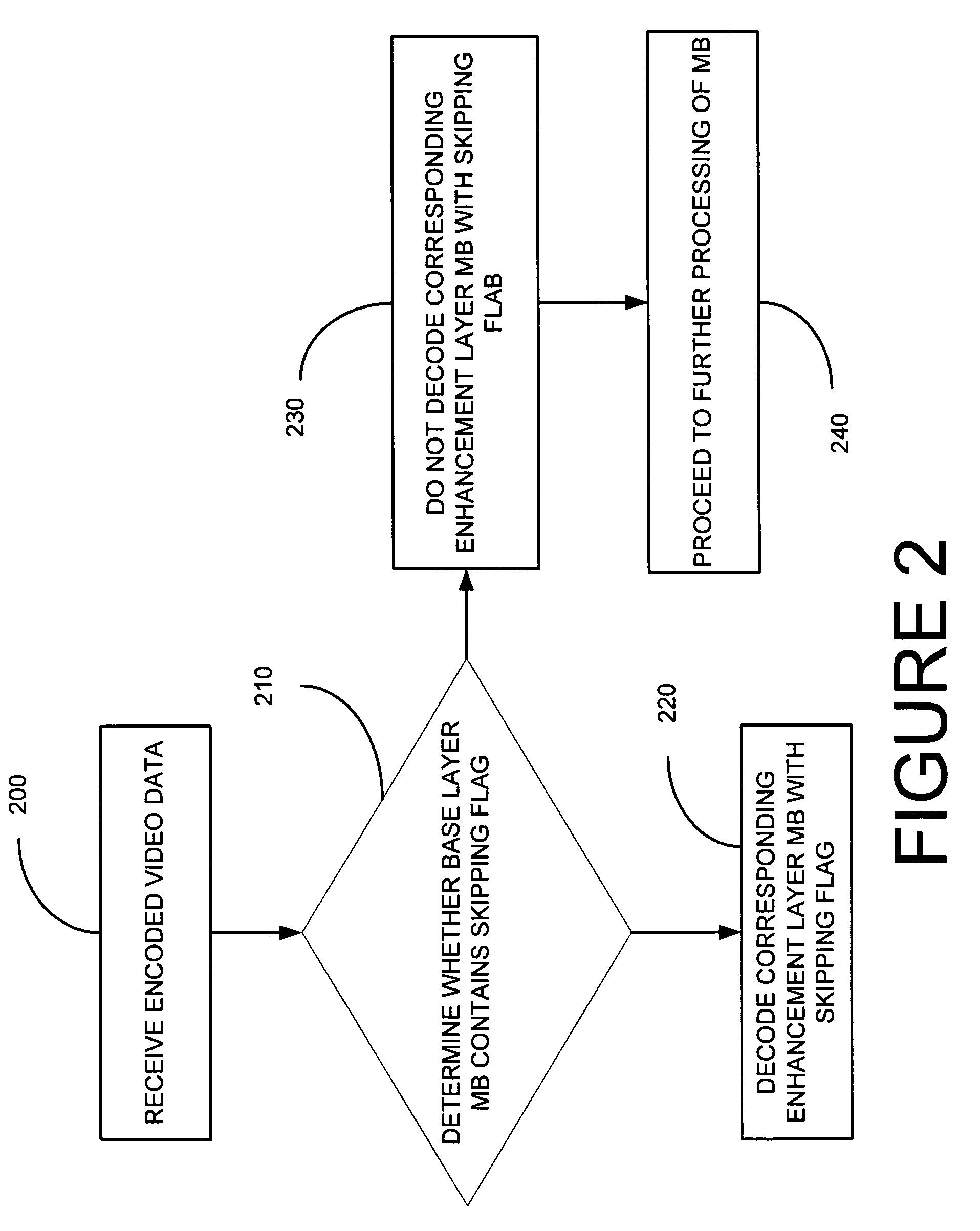

Method and system for entropy decoding for scalable video bit stream

ActiveUS20060013302A1Small sizeImprove visual qualityColor television with pulse code modulationColor television with bandwidth reductionVideo bitstreamCoding block

A method, program product and apparatus for decoding from a scalable bit stream the binarization results of a video sequence by selectively decoding syntax elements and avoiding redundancy in coding. The result is a decrease in the size of the compressed bit stream of an enhancement layer bit stream. One method includes determining whether a skipping flag in the base layer macro block of the video data is set, and decoding a skipping flag from an enhancement layer macro block of the video data, corresponding to the base layer macro block, only if the base layer macro block skipping flag is set. Another method includes determining which of a plurality of blocks in a base layer macro block contain zero coefficients, decoding an abbreviated coded block pattern (CBP) of an enhancement layer macro block, where the CBP includes a number of digits equal to the number of blocks in said base layer macro block containing only zero coefficients, and then generating a complete CBP for the enhancement layer based on the results of said decoding. Yet another method includes decoding a CBP value of a base layer macro block and differentially decoding a CBP value for an enhancement layer macro block relative to the CBP of the base layer macro block. An additional method includes determining the zero-value coefficients in a block of a base layer, decoding a coded block flag for a corresponding block in an enhancement layer, and determining, based on the value of said encoded block flag, whether any of the zero-coefficients become non-zero coefficients in said enhancement block.

Owner:RPX CORP

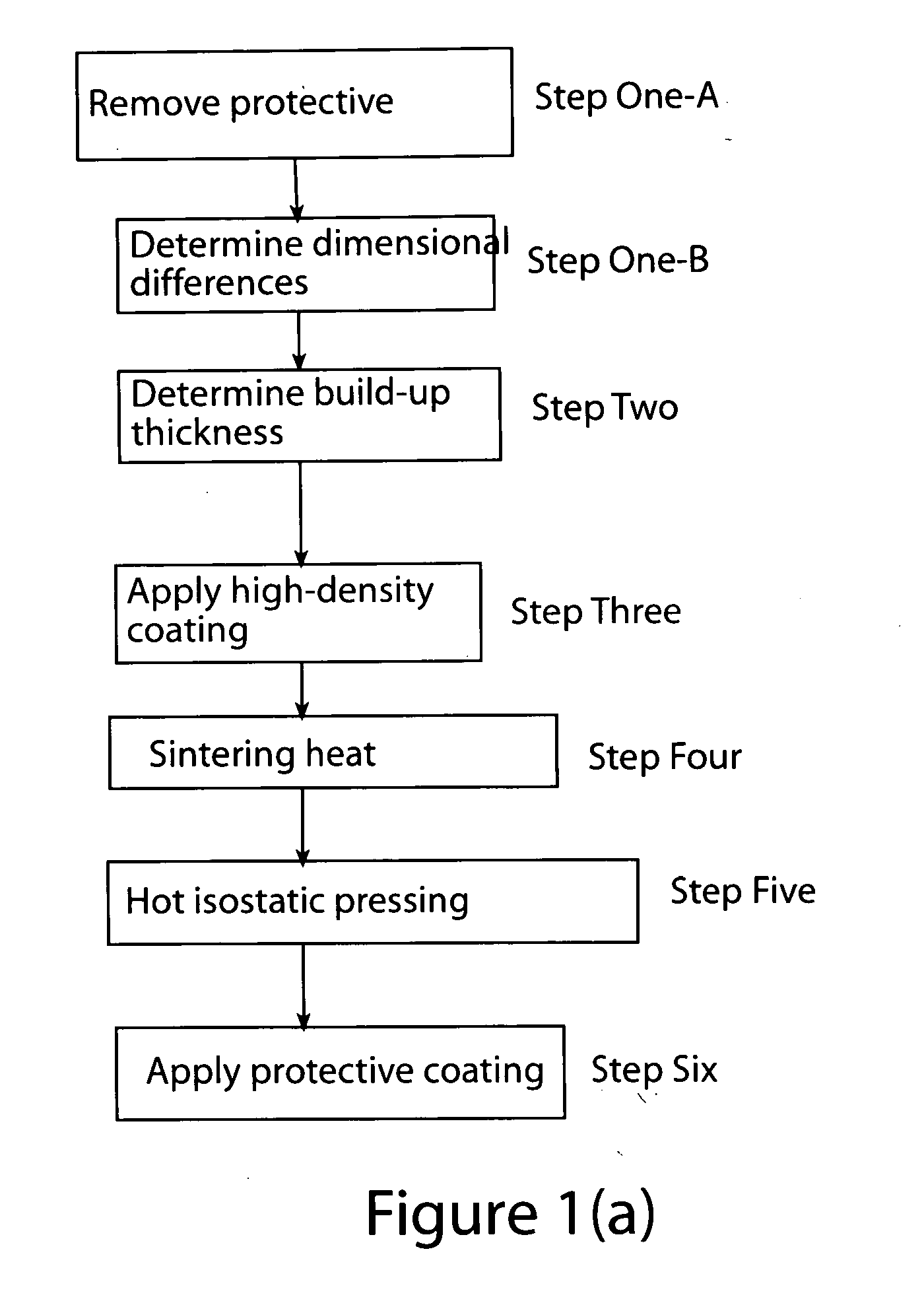

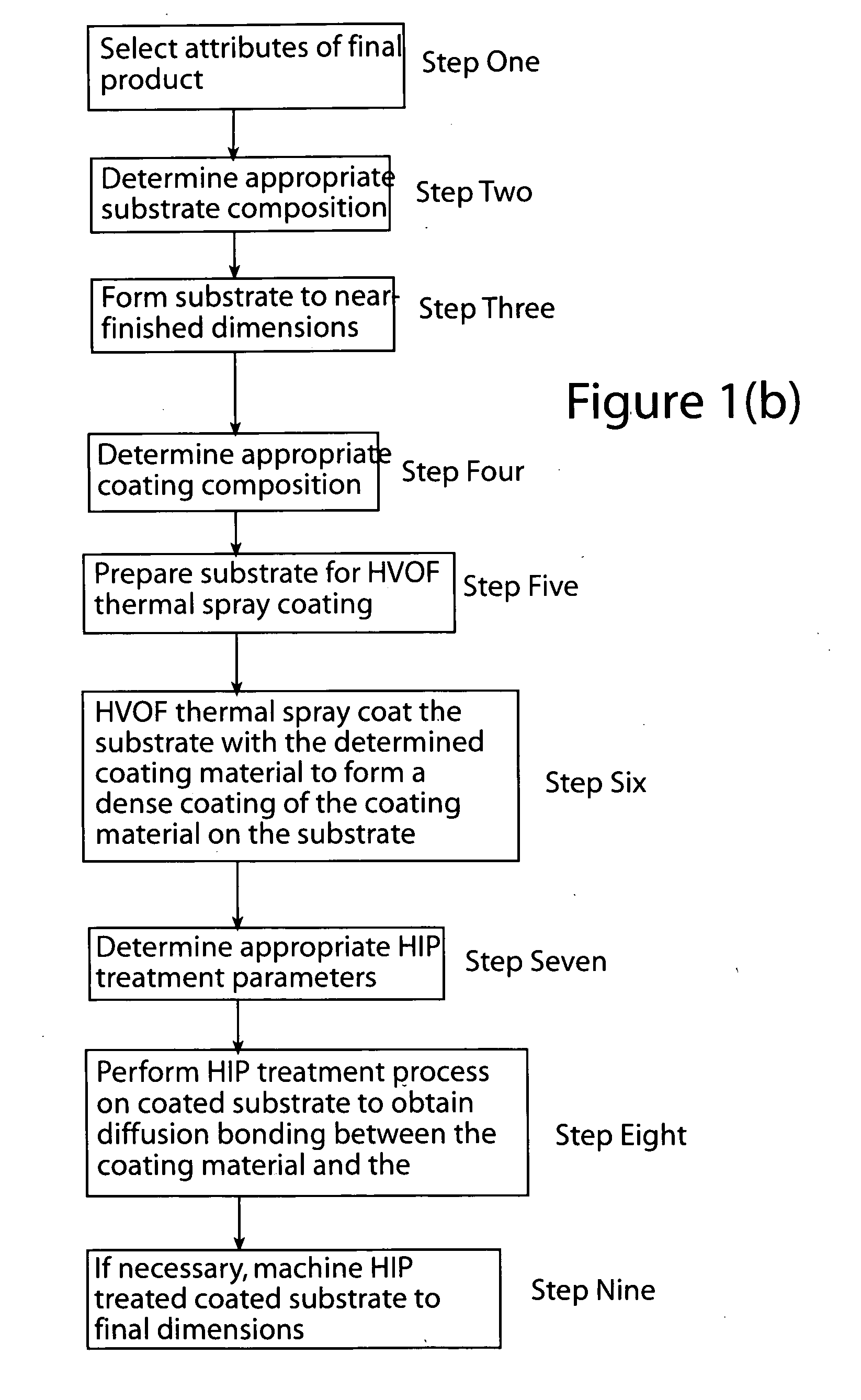

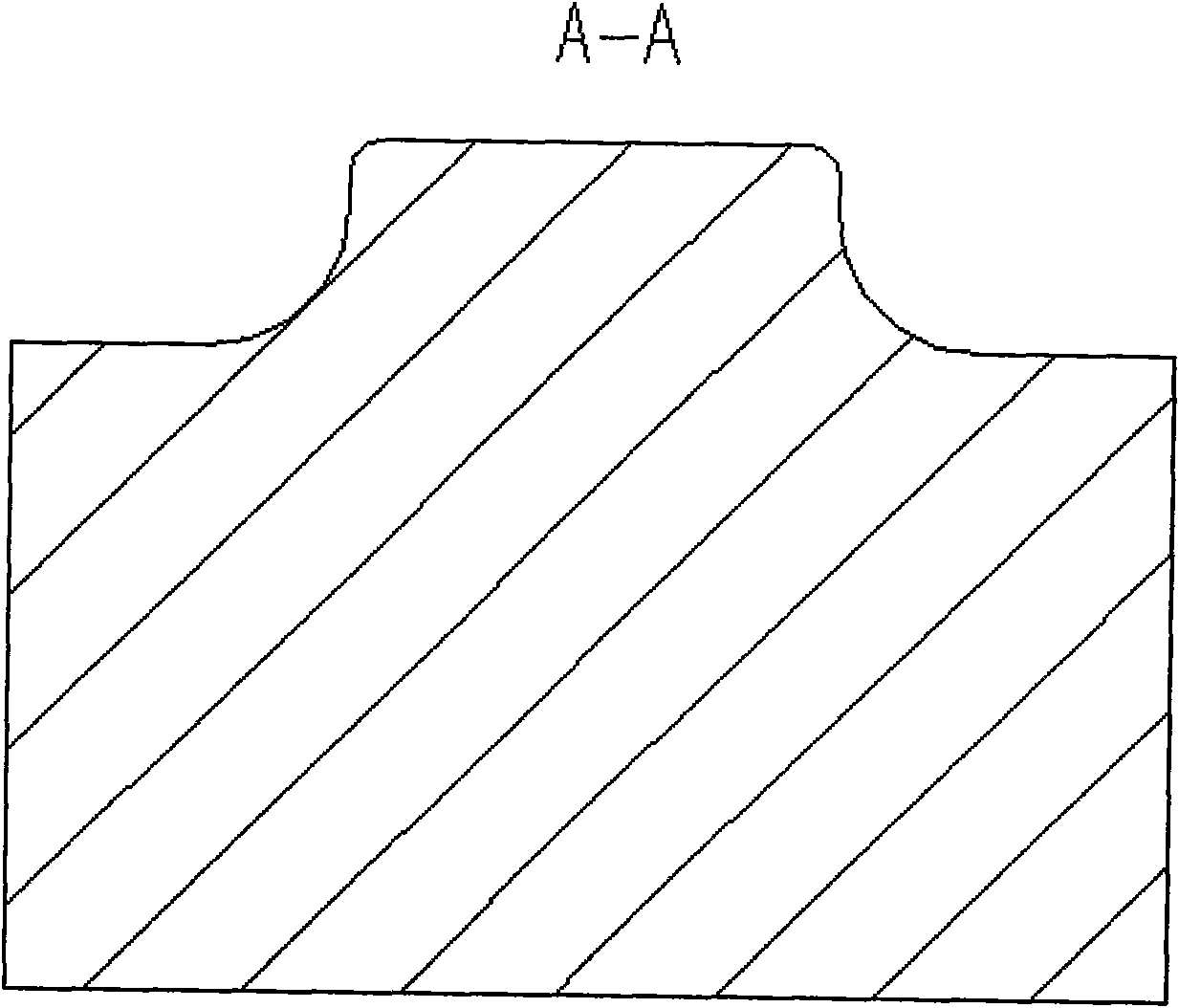

Method for repairing a cold section component of a gas turbine engine

InactiveUS20050241147A1InhibitionAvoid inclusionsMolten spray coatingWind motor controlHigh densityWear resistant

A method for forming a wear-resistant hardfaced contact area on the shroud section of a gas turbine engine blade. A predetermined contact area of a shroud section of a gas turbine engine blade is selectively coated with a high-density hardface coating material. The hardface coating material is capable of forming a diffusion boundary between the hardface coating material and the shroud section. A hot isostatic heat treatment process is performed to form the diffusion boundary between the hardface coating material and the shroud section to form a wear-resistant hardfaced contact area diffusion bonded to the shroud section. Depending on the coating process, and the necessity for doing so, the predetermined contact area can be masked off before the step of selectively coating. A sintering heat treatment can be perfomed before the step of performing the hot isostatic heat treatment to limit the occurrence bubbles on the surface of the hardface coating material after the isostatic heat treatment step. The sintering heat treatment may be performed at a temperature substantially the same as the temperature of the hot isostatic heat treatment. The hardface coating material may comprise an alloy with substantially no oxide forming constituents so as to avoid the formation of oxide inclusions in the coating material.

Owner:RECAST AIRFOLI GRP

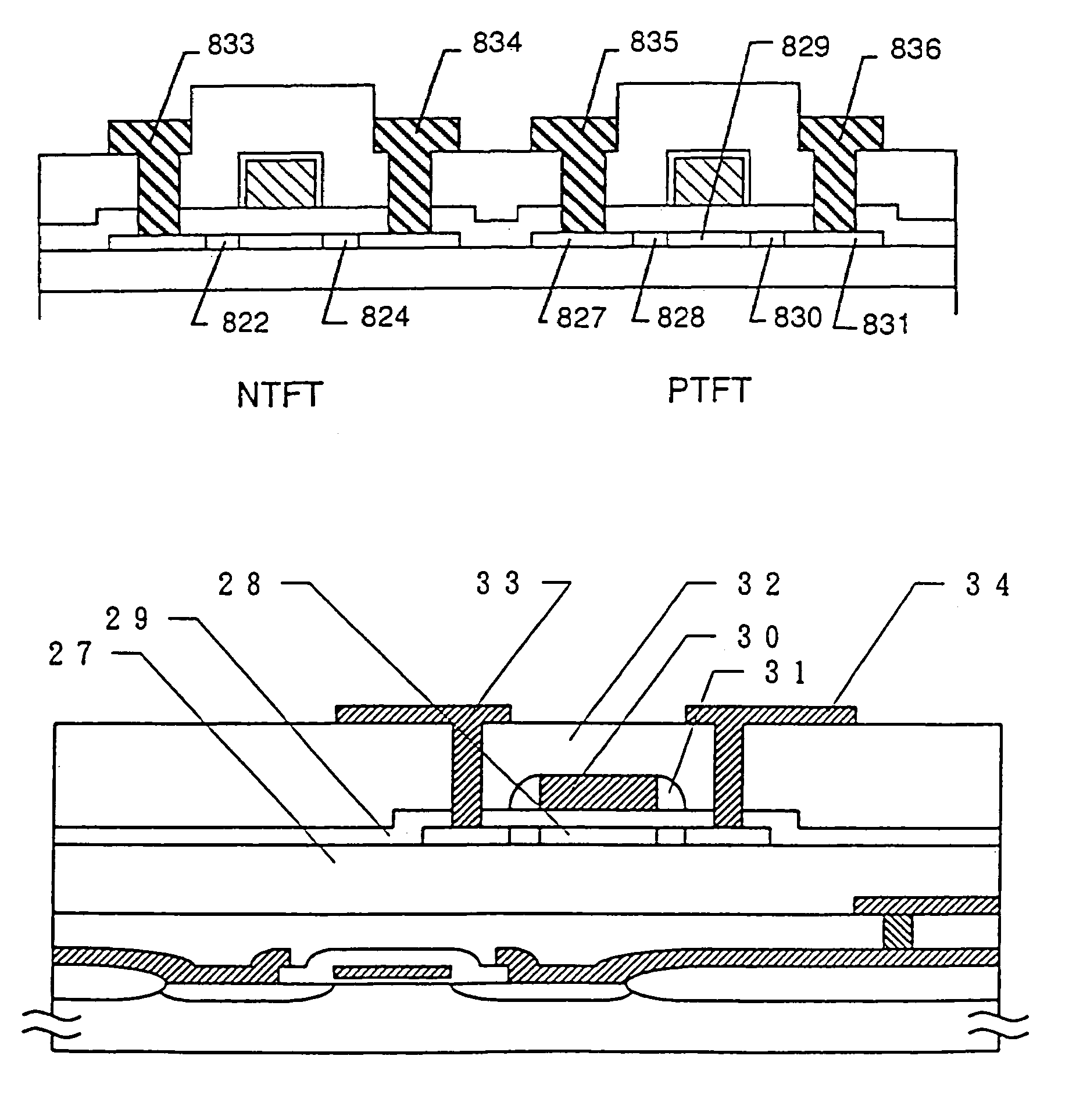

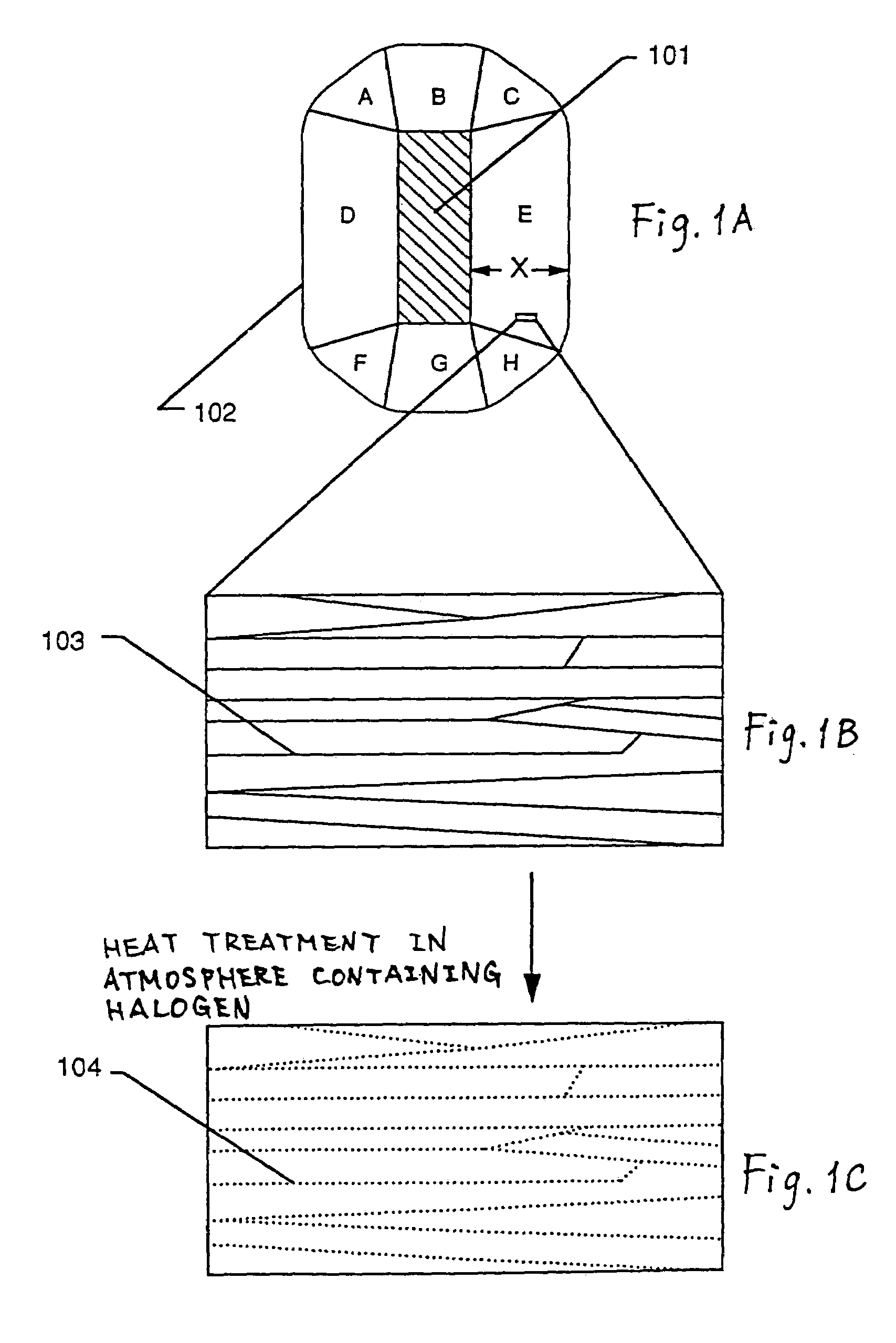

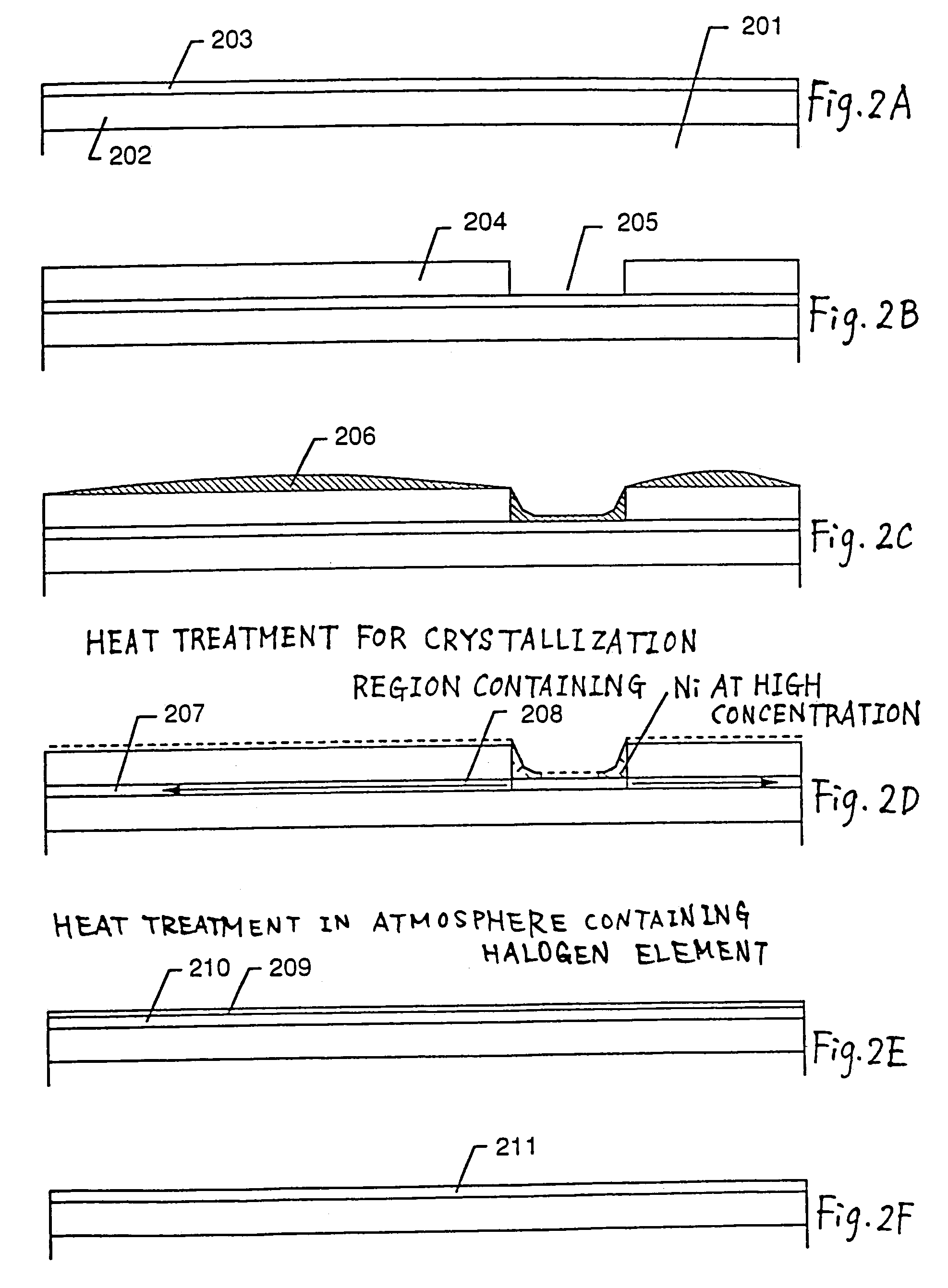

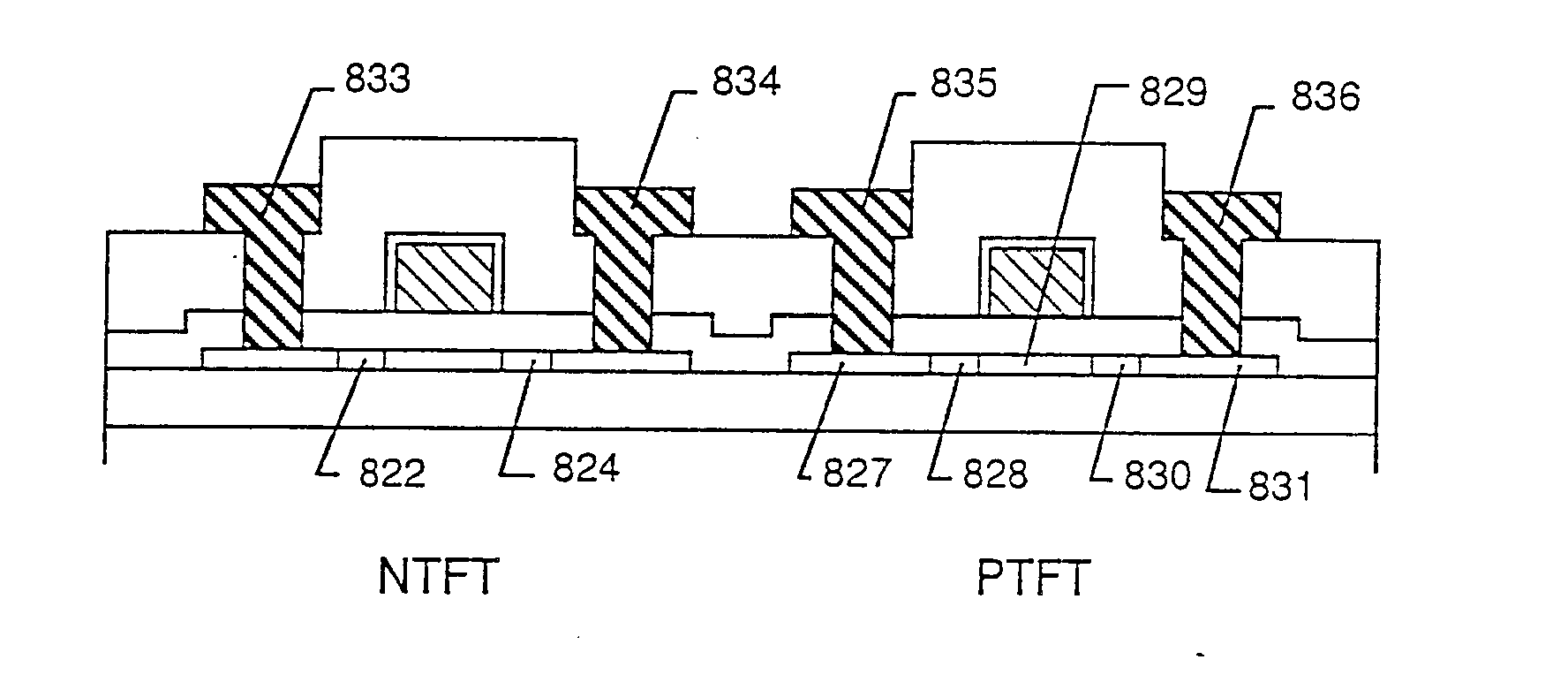

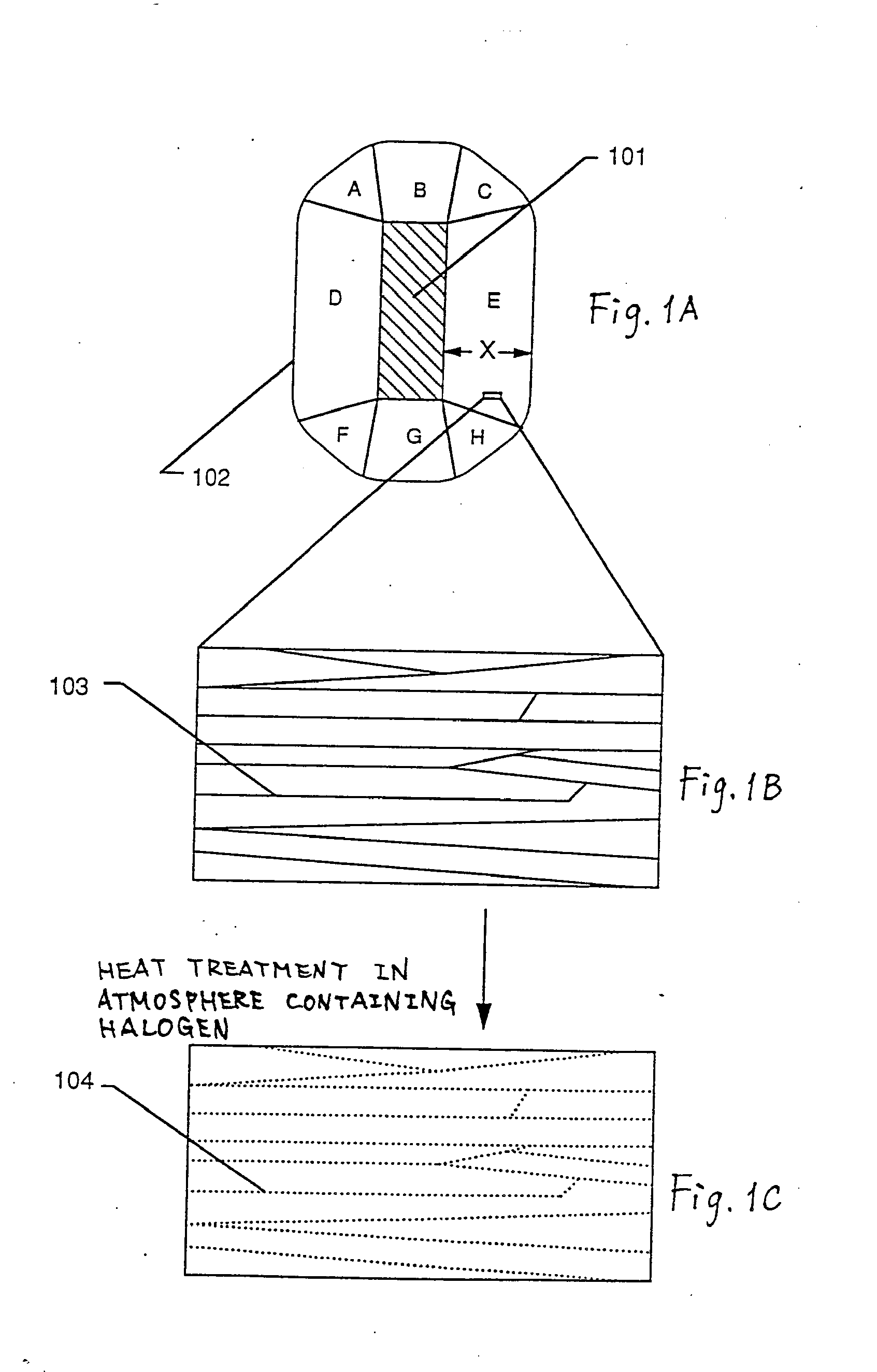

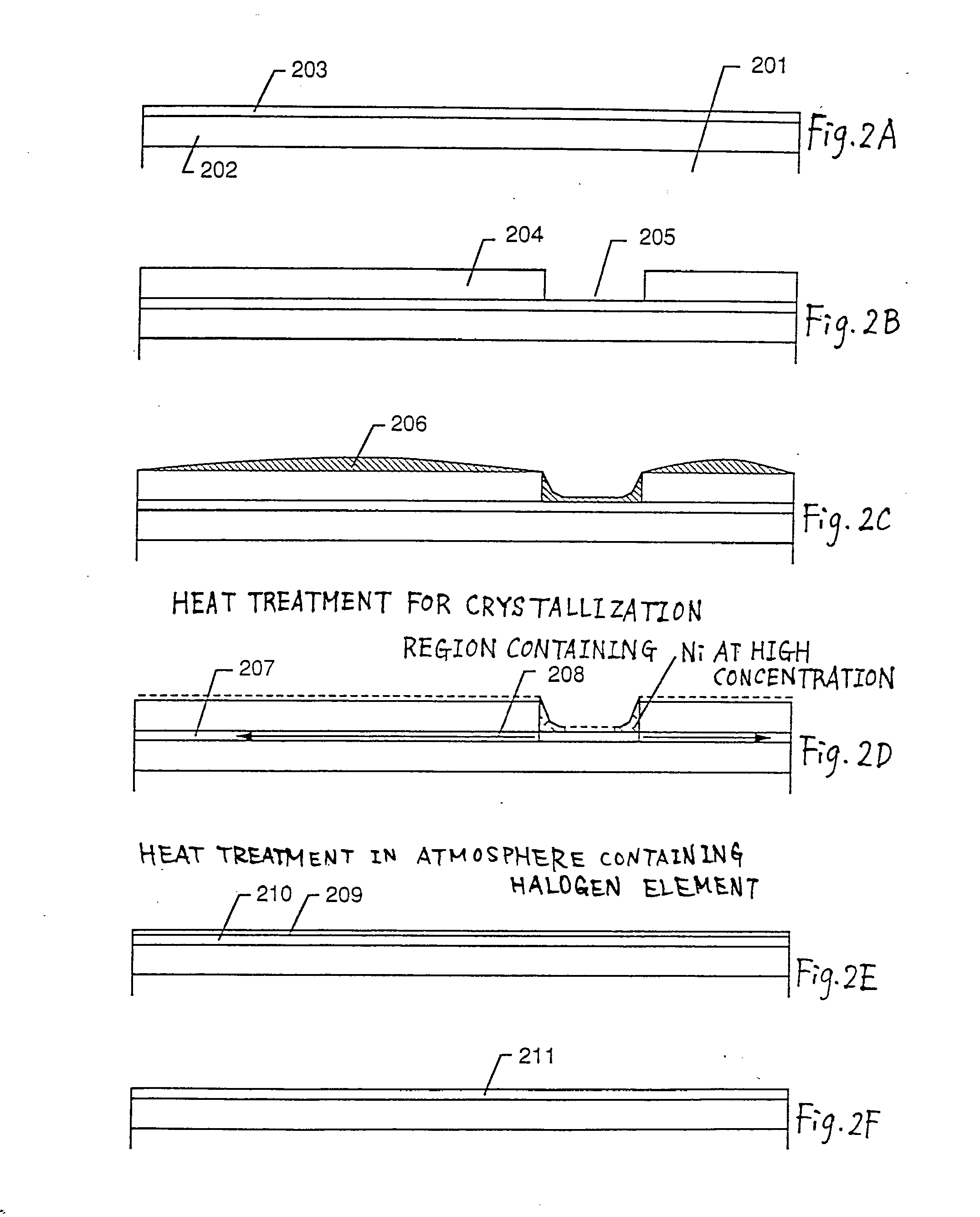

Semiconductor thin film and method of manufacturing the same and semiconductor device and method of manufacturing the same

InactiveUS7172929B2Avoid problemsImprove performanceTransistorSolid-state devicesSingle crystalCrystallinity

A thin film semiconductor transistor structure has a substrate with a dielectric surface, and an active layer made of a semiconductor thin film exhibiting a crystallinity as equivalent to the single-crystalline. To fabricate the transistor, the semiconductor thin film is formed on the substrate, which film includes a mixture of a plurality of crystals which may be columnar crystals and / or capillary crystal substantially parallel to the substrate. The resultant structure is then subject to thermal oxidation in a chosen atmosphere containing halogen, thereby removing away any metallic element as contained in the film. This may enable formation of a mono-domain region in which the individual columnar or capillary crystal is in contact with any adjacent crystals and which is capable of being substantially deemed to be a single-crystalline region without presence or inclusion of any crystal grain boundaries therein. This region is for use in forming the active layer of the transistor.

Owner:SEMICON ENERGY LAB CO LTD

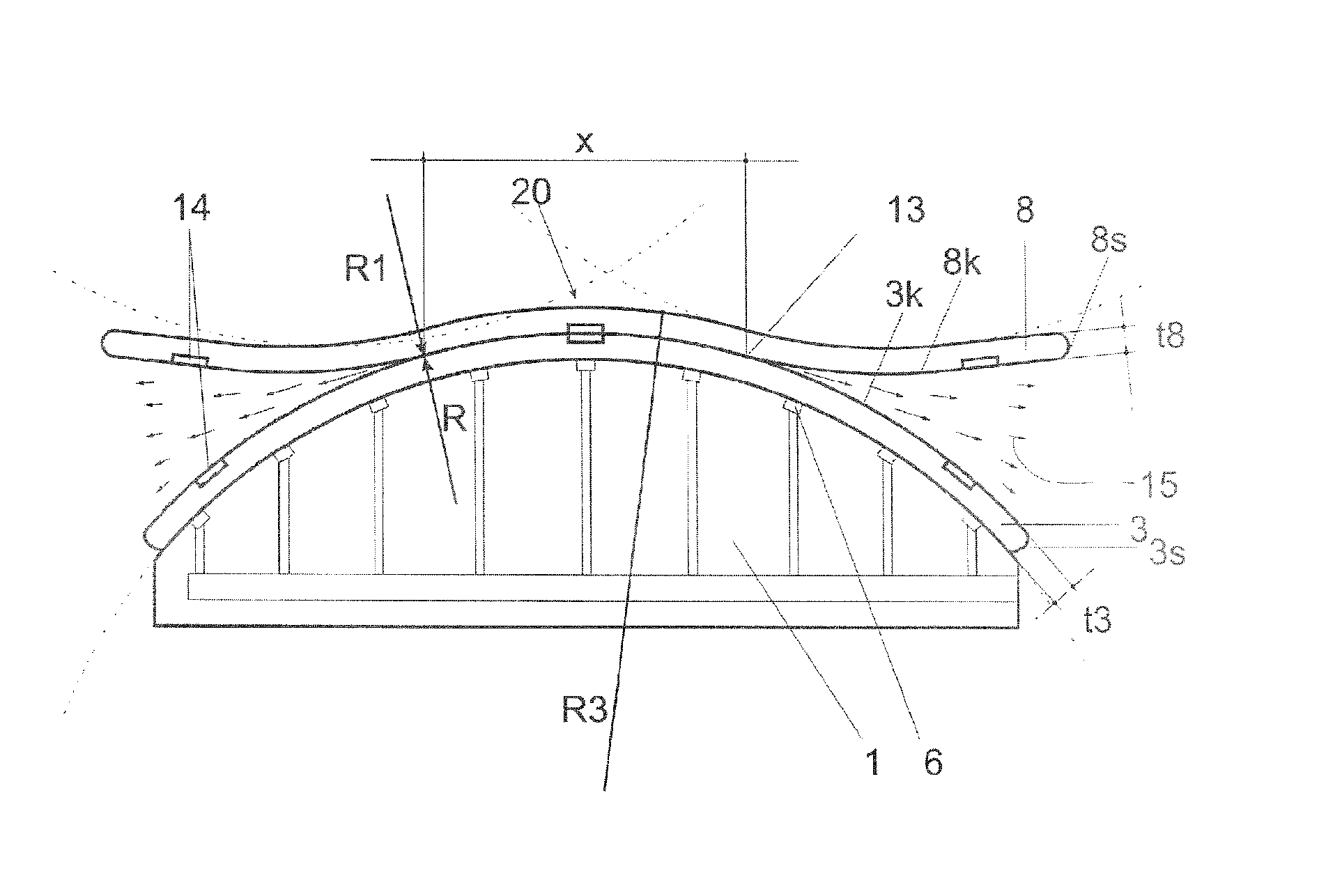

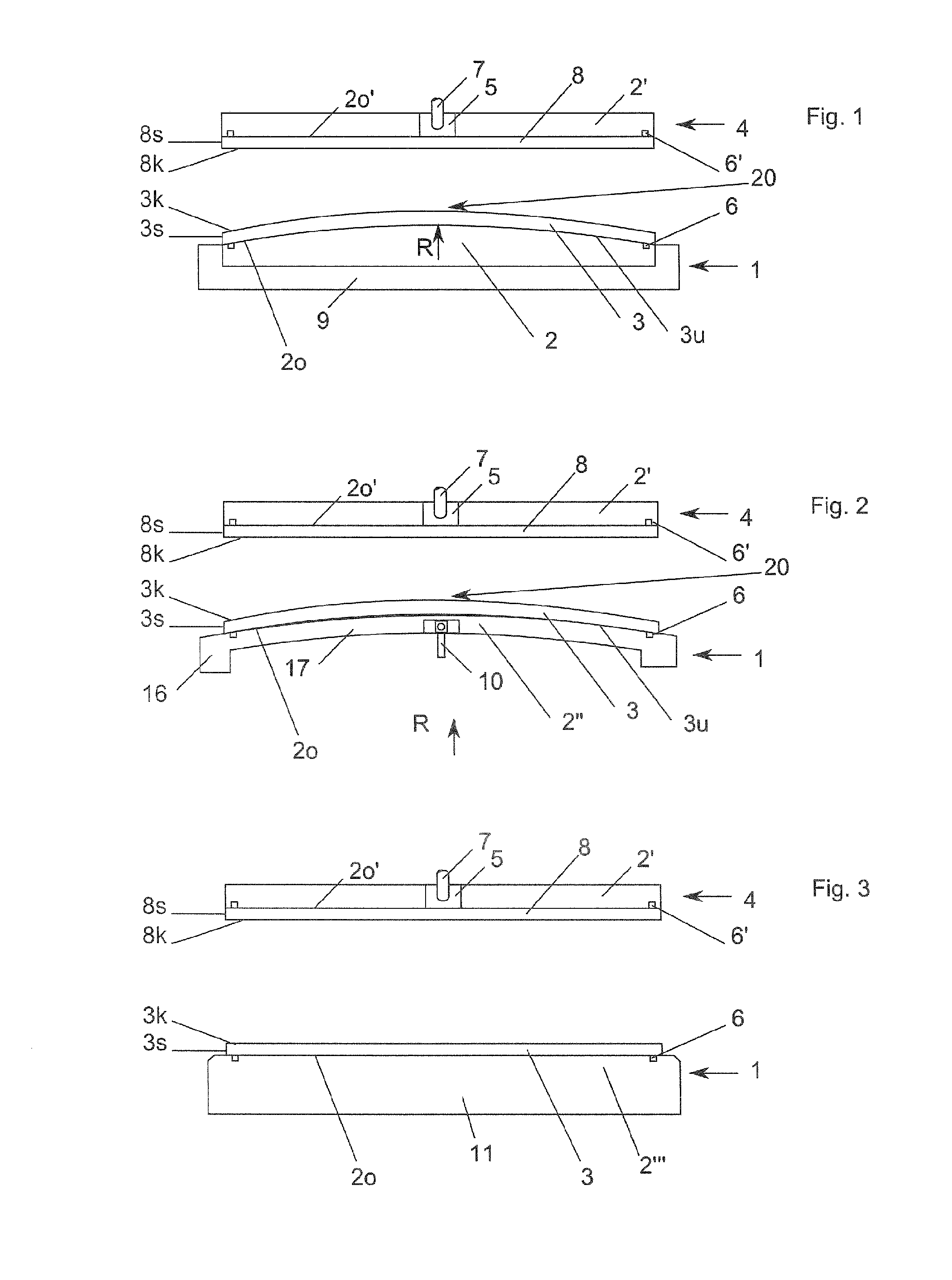

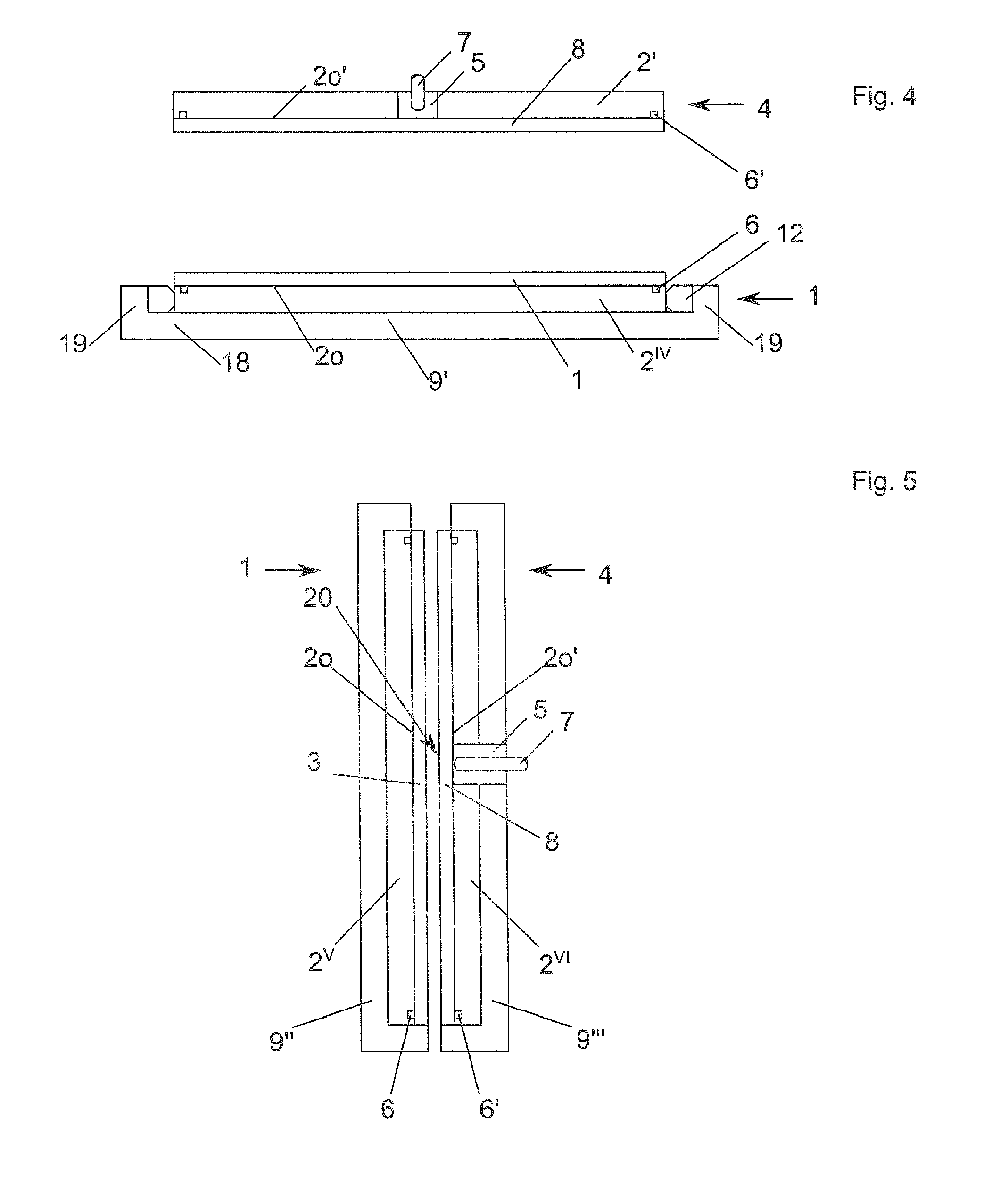

Device and method for bonding substrates

ActiveUS20150210057A1Easy to transformReduce inertiaLamination ancillary operationsSolid-state devicesEngineeringElectrical and Electronics engineering

A method for bonding a contact surface of a first substrate to a contact surface of a second substrate comprising of the steps of: positioning the first substrate on a first receiving surface of a first receiving apparatus and positioning the second substrate on a second receiving surface of a second receiving apparatus; establishing contact of the contact surfaces at a bond initiation site; and bonding the first substrate to the second substrate along a bonding wave which is travelling from the bond initiation site to the side edges of the substrates, wherein the first substrate and / or the second substrate is / are deformed for alignment of the contact surfaces.

Owner:EV GRP E THALLNER GMBH

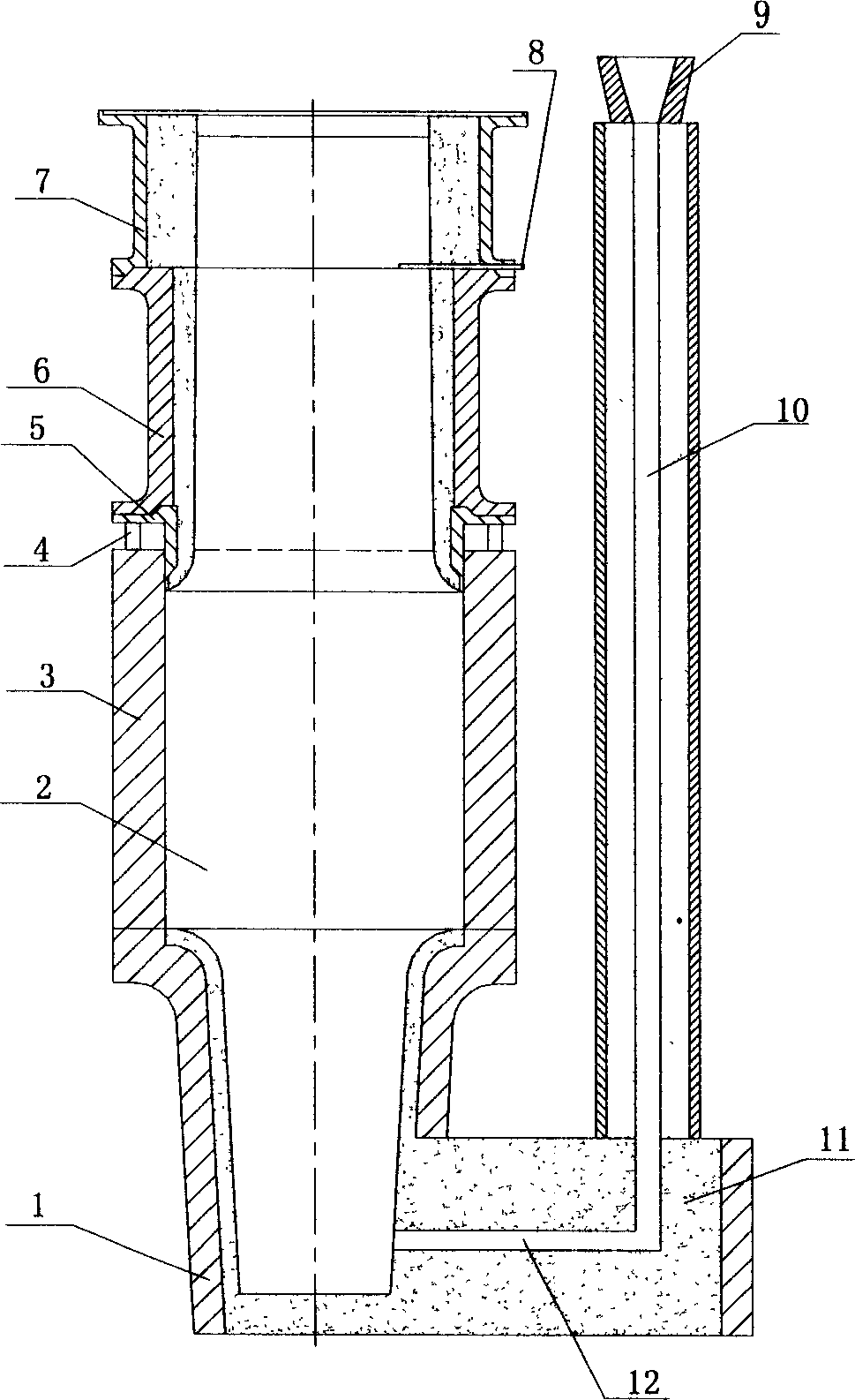

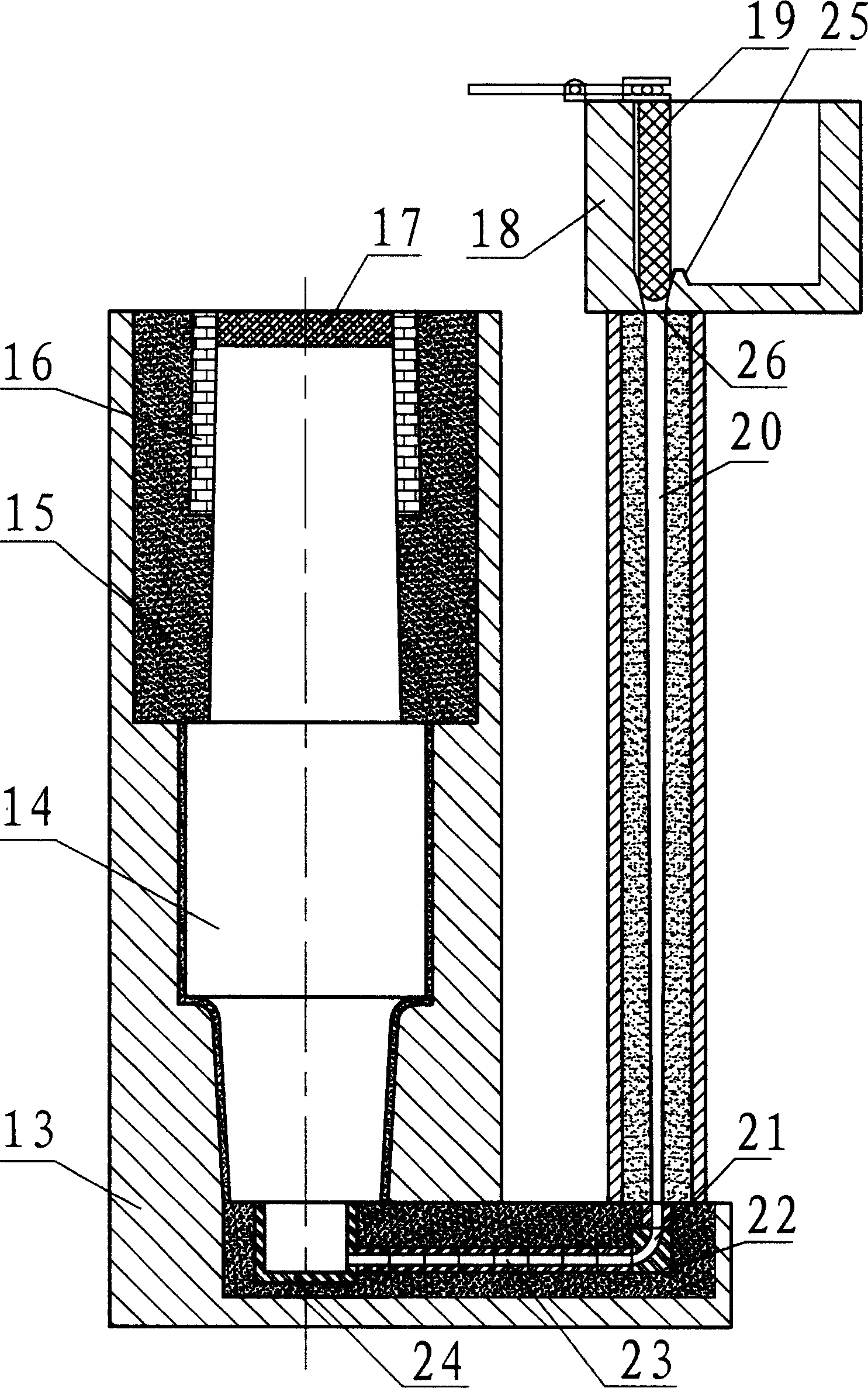

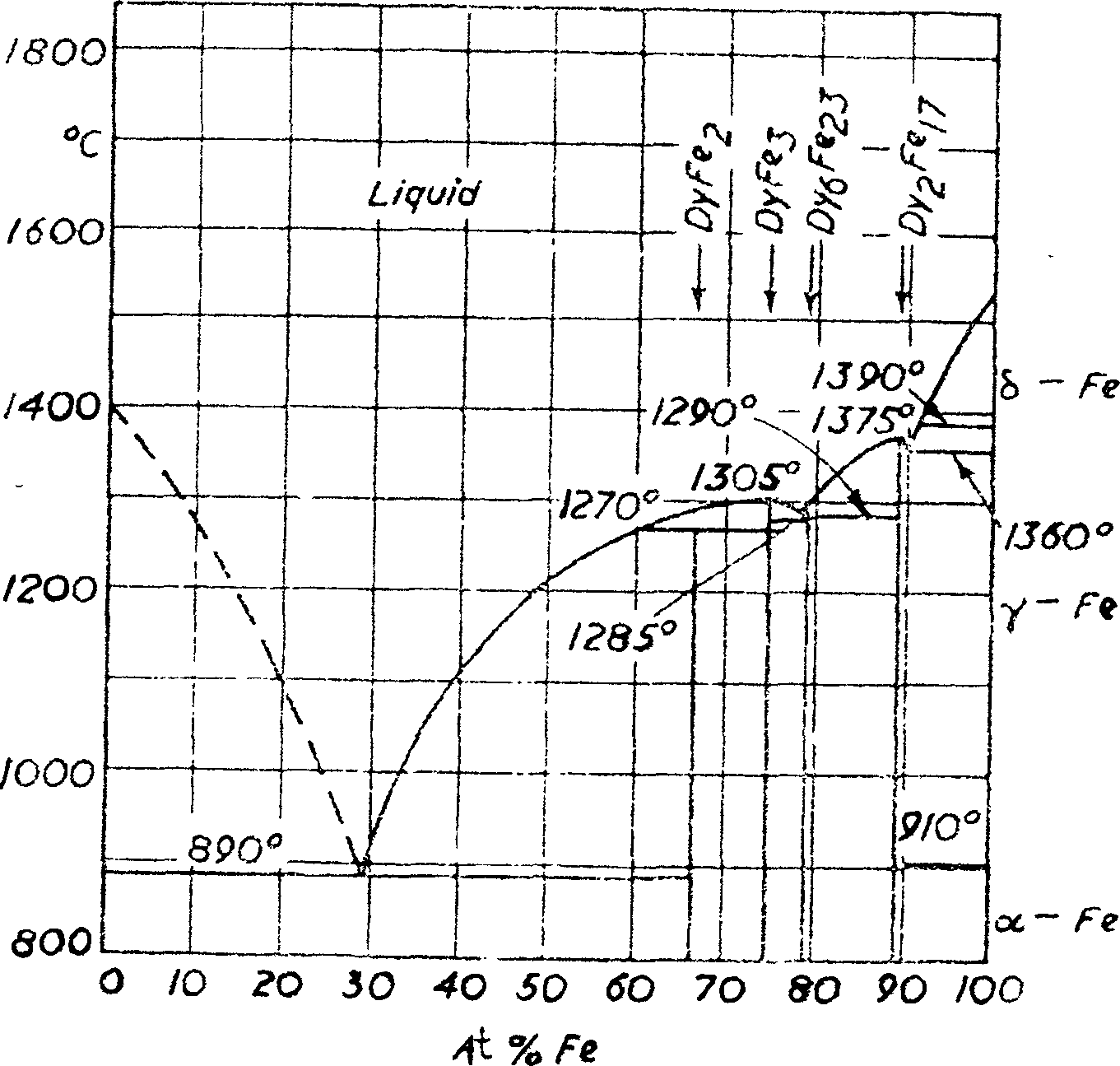

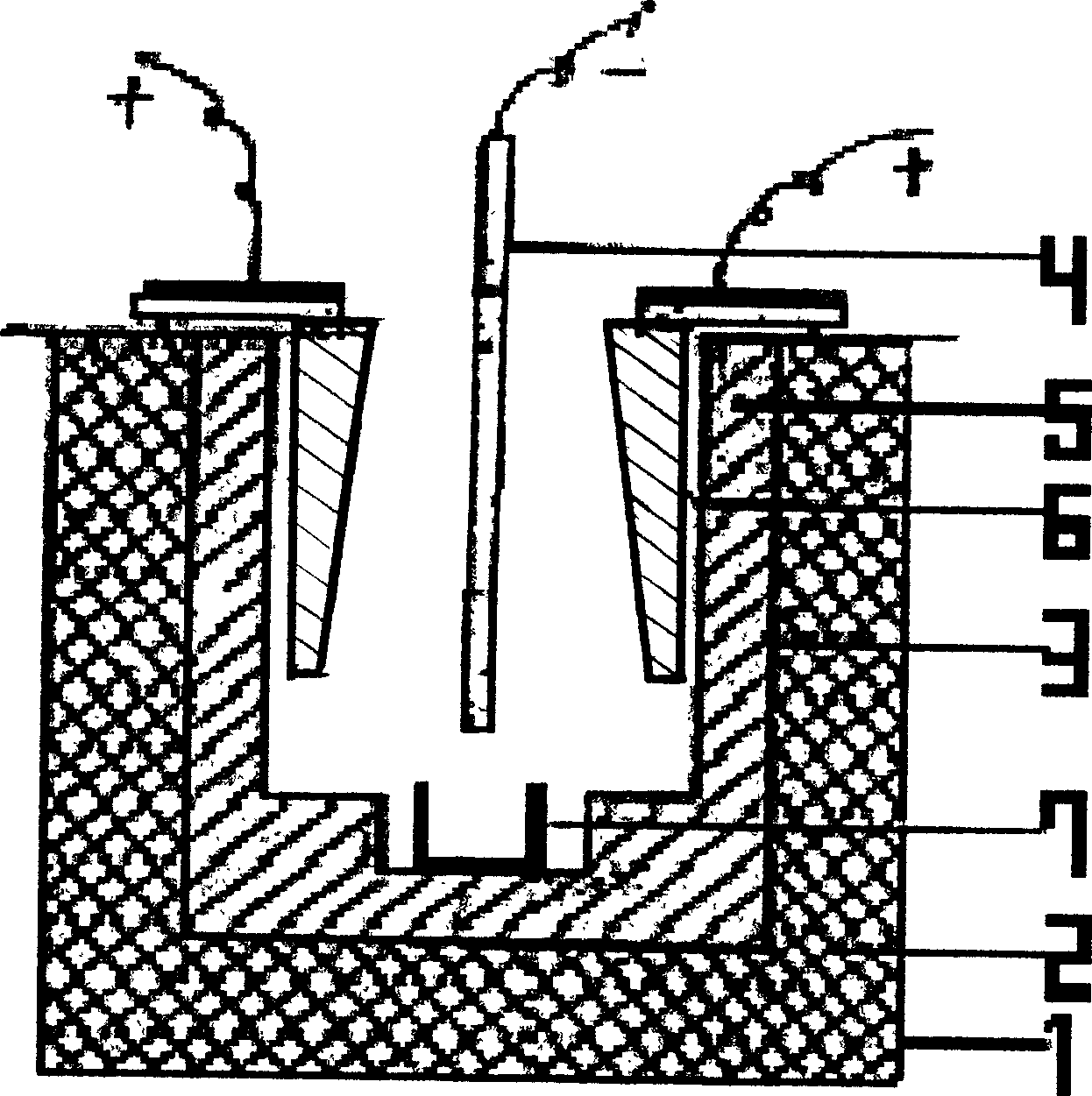

Process and apparatus for producing Dy-Fe alloy by molten salt electrolysis method

The invention relates the dysprosium-iron alloy technology with fused salt electrolysis process and device, belonging to rare-earth products preparing field. The method comprises the following steps: at high temperature, dysprosium oxide melting at fluoride, dysprosium oxide beginning ionizing; at the condition of 95V / M direct current field, separating out Dy3+ on the surface of iron cathode, deacidizing Dy3+ to Dy, and alloying Dy and Fe to form Dy-Fe. O2- is oxygenated to O2 on the surface of graphite cathode, and it reacts with carbite to form CO2. The melting point of dysprosium-iron (20úÑFe) is 1046Deg.C, and the melting point of Dy is 1407Deg.C, so the electrolyzation is carried out at 1050Deg.C. The invention has the advantages of low investment, low cost, simple technology, continuous production and low impurity content.

Owner:包头市稀土应用技术研究所

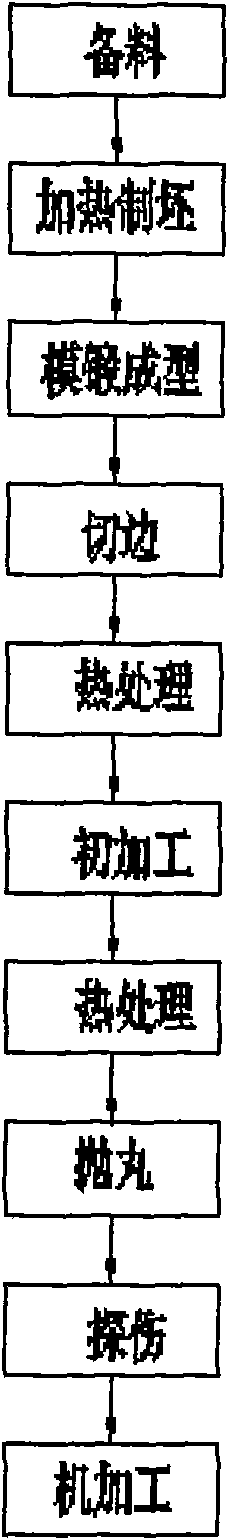

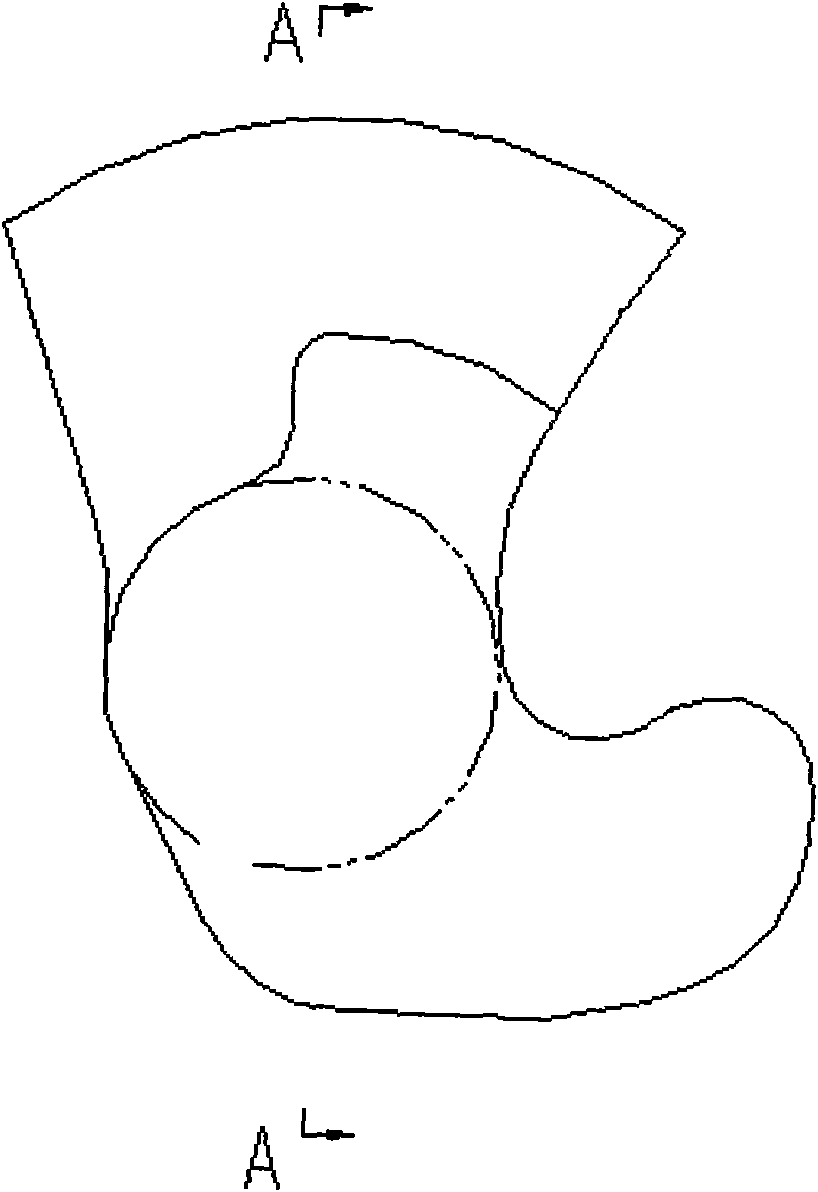

Forging method of coupler knuckle for railway vehicle

InactiveCN101559555AGood mechanical propertiesAvoid air holesOther manufacturing equipments/toolsMaterials preparationToughness

The invention discloses a forging method of a coupler knuckle for railway vehicles. The coupler knuckle for railway vehicles is formed by forging, and coupler knuckle products for railway vehicles with qualified performance and size are forged by the working procedures of material preparation, heating and blank forming, die forging and forming, trimming, heat treatment, preliminary processing, heat treatment, shot blasting, fault detecting and machining. The forging method of the coupler knuckle for railway vehicles, in which the coupler knuckle for railway vehicles has compact texture, high toughness and good fatigue performance, solves the defects of air pore, shrinkage porosity, inclusion, crack, short service life and the like of the coupler knuckle of the existing cast steel vehicle coupler.

Owner:CHONGQING CHANGZHENG HEAVY IND

Semiconductor thin film and method of manufacturing the same and semiconductor device and method of manufacturing the same

InactiveUS20070252206A1Improve reliability and performanceHigh crystallinityTransistorSolid-state devicesOptoelectronicsSingle crystal

A thin film semiconductor transistor structure has a substrate with a dielectric surface, and an active layer made of a semiconductor thin film exhibiting a crystallinity as equivalent to the single-crystalline. To fabricate the transistor, the semiconductor thin film is formed on the substrate, which film includes a mixture of a plurality of crystals which may be columnar crystals and / or capillary crystal substantially parallel to the substrate. The resultant structure is then subject to thermal oxidation in a chosen atmosphere containing halogen, thereby removing away any metallic element as contained in the film. This may enable formation of a mono-domain region in which the individual columnar or capillary crystal is in contact with any adjacent crystals and which is capable of being substantially deemed to be a single-crystalline region without presence or inclusion of any crystal grain boundaries therein. This region is for use in forming the active layer of the transistor.

Owner:SEMICON ENERGY LAB CO LTD

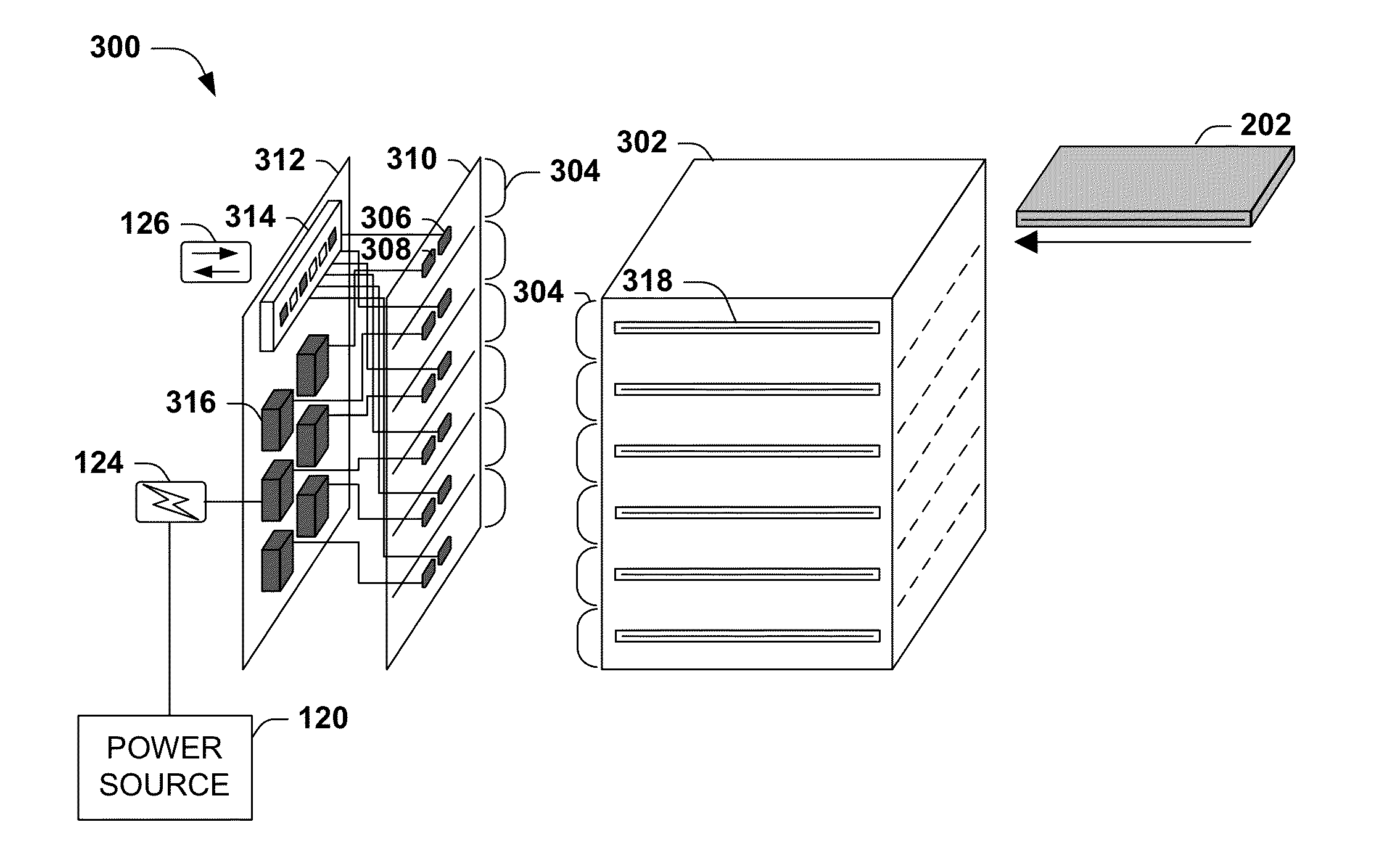

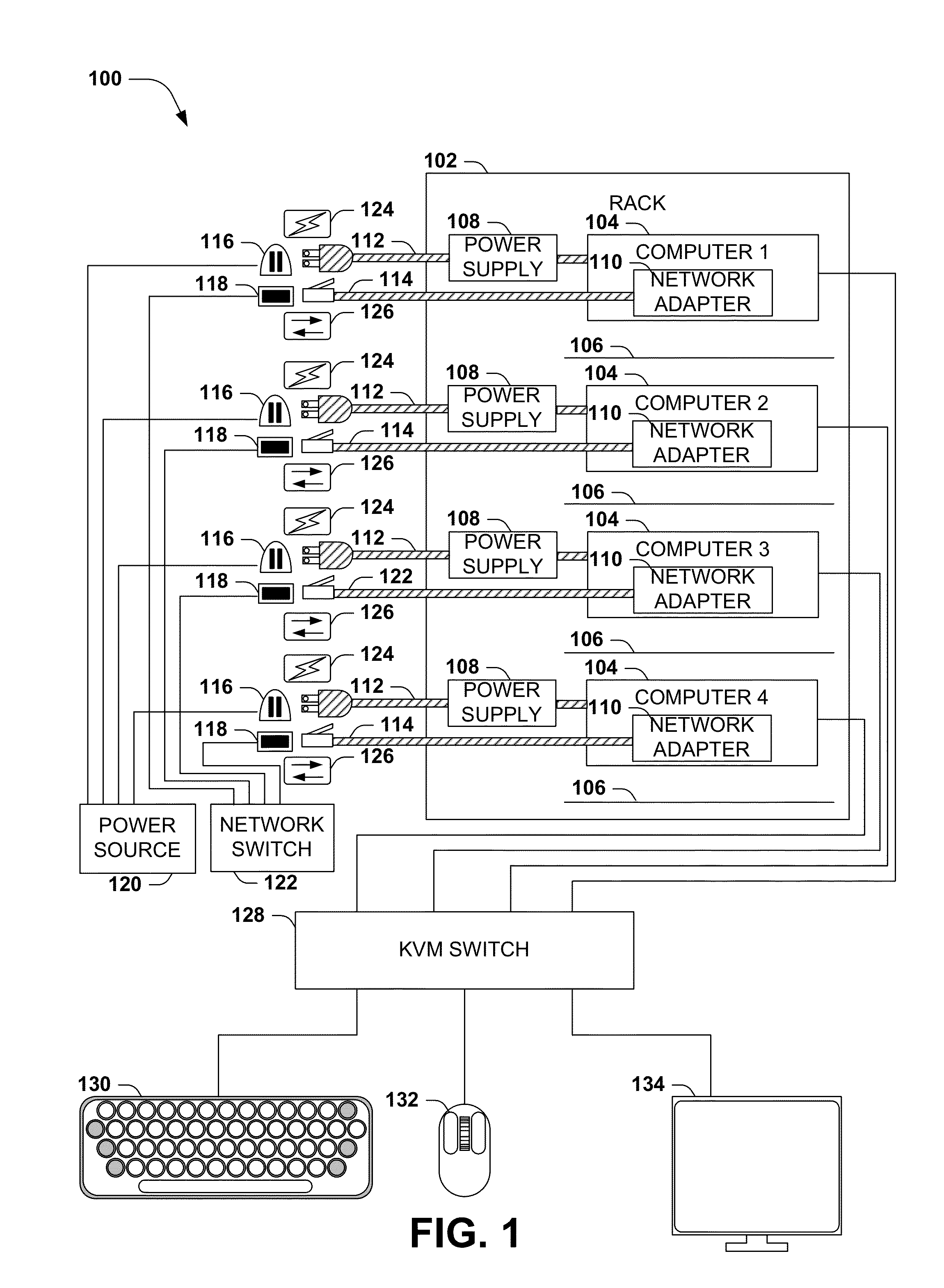

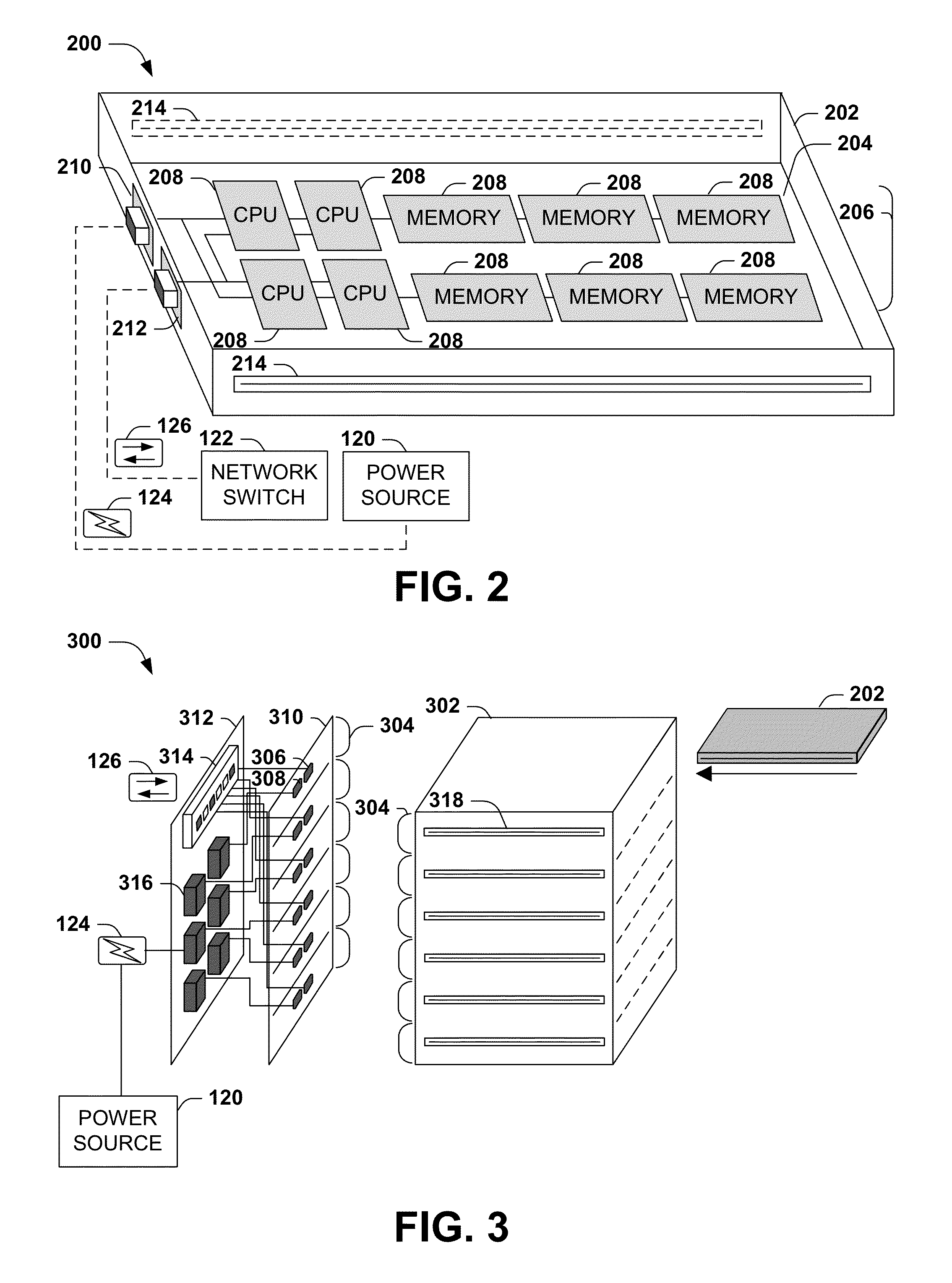

Tray and chassis blade server architecture

InactiveUS20130335907A1Avoid inclusionsServersDigital data processing detailsBlade serverEngineering

In computing scenarios involving an aggregation of multiple computational units into a server or computer set, many architectures may be devised to provide physical storage and logical aggregation of the computational units. Presented herein are variations of one such architecture, comprising a chassis having a set of slots, into which may be inserted a tray storing the computational units of one or more blades. Respective trays and chassis slots comprise a power connector and a network connector that are positioned to connect directly (i.e., without a cable or manual interaction) when a tray is inserted into a slot. The chassis stores a set of power supplies, and may connect each blade with a power supply, optionally providing power routing and failover capabilities. The chassis may also provide a management component that connects to and provides management capabilities of the blades of the trays, power supplies, and climate regulating components.

Owner:MICROSOFT TECH LICENSING LLC

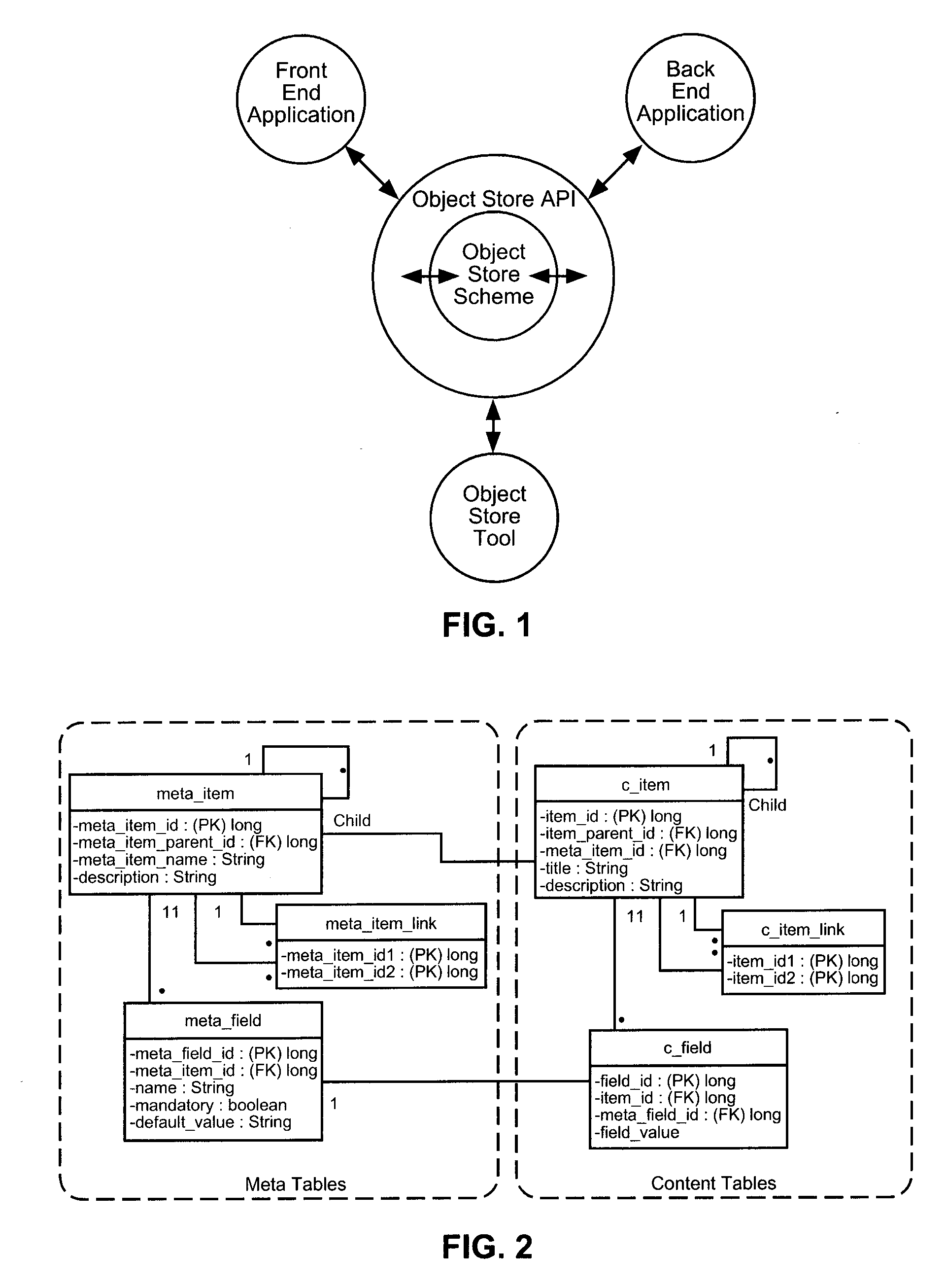

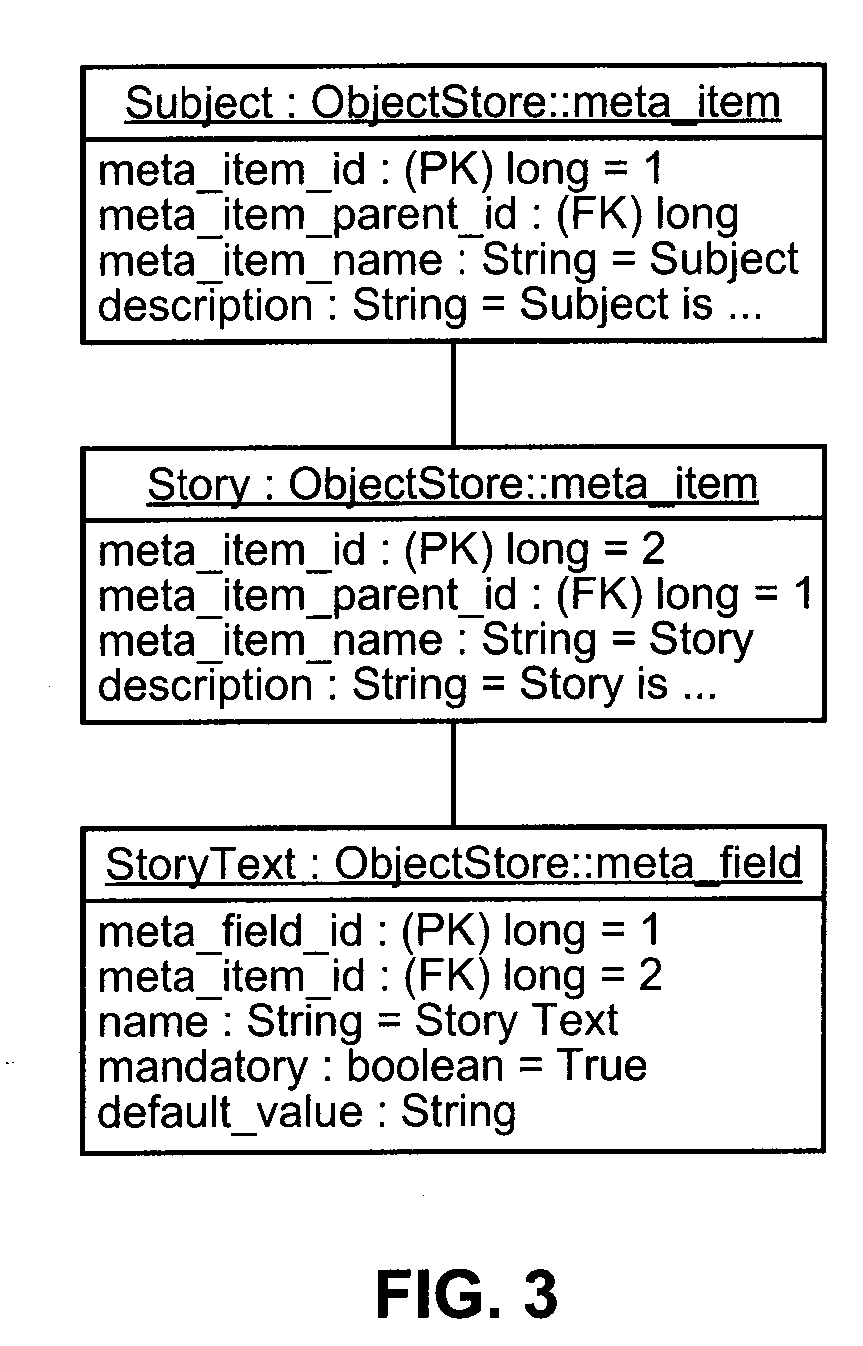

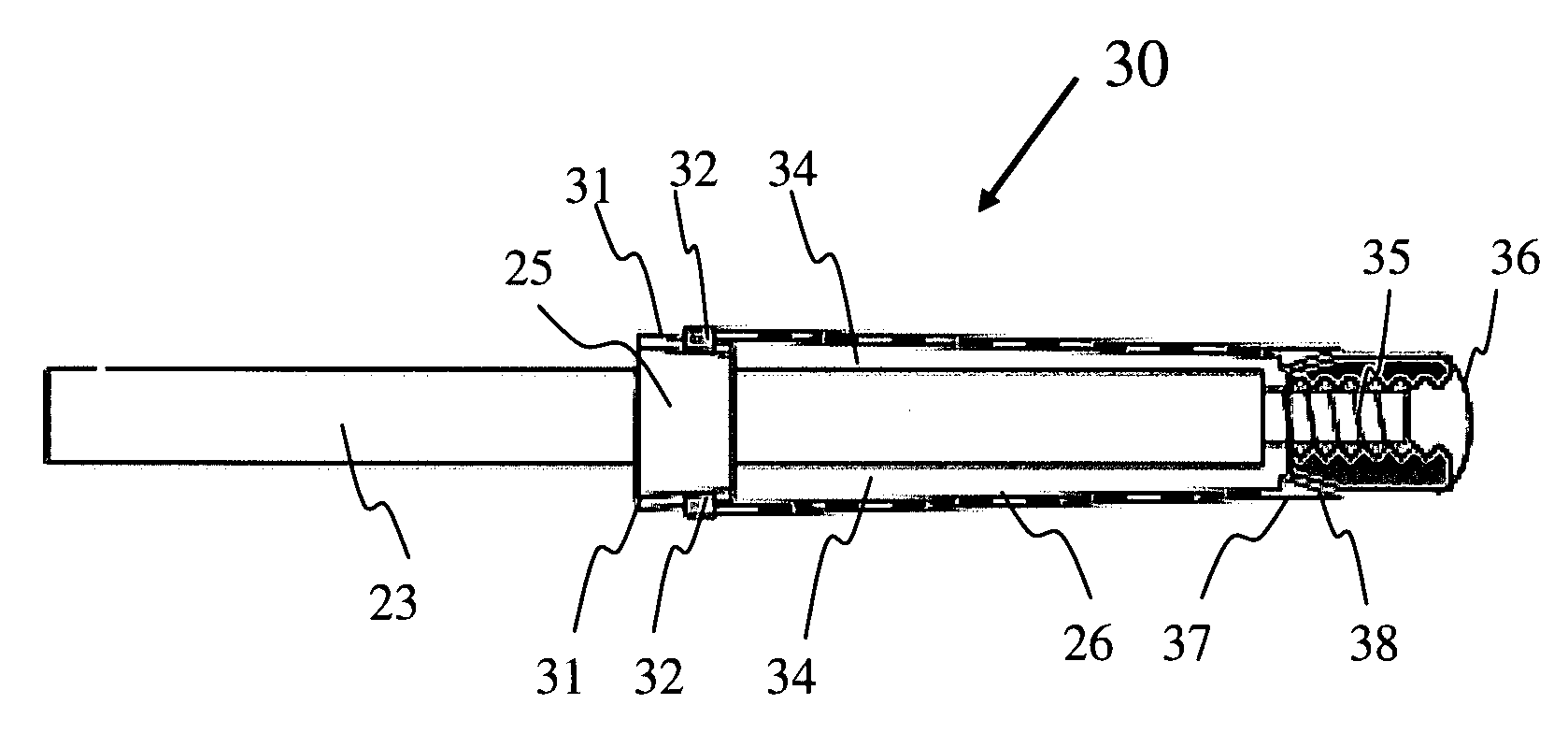

Database system, particularly for multimedia objects

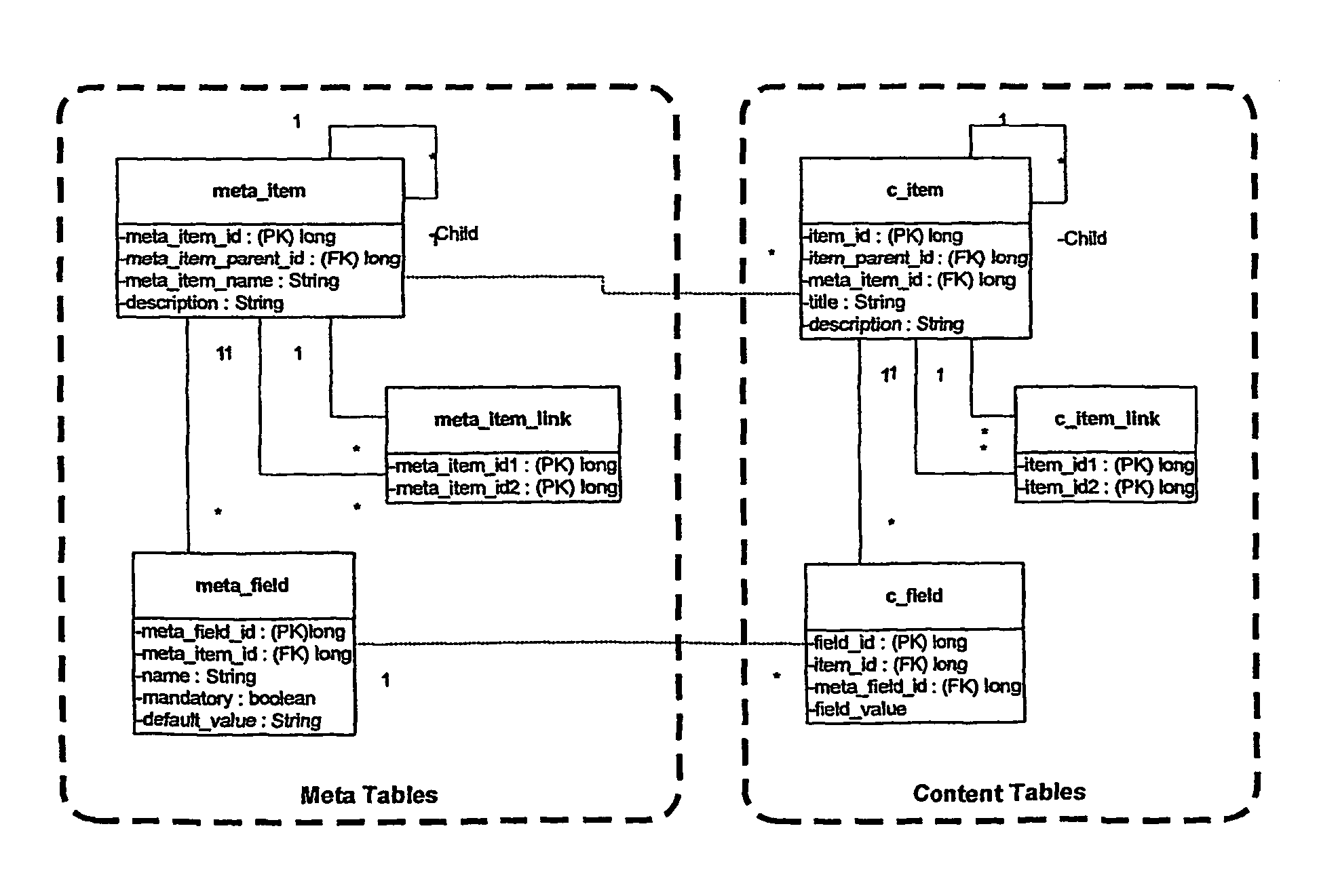

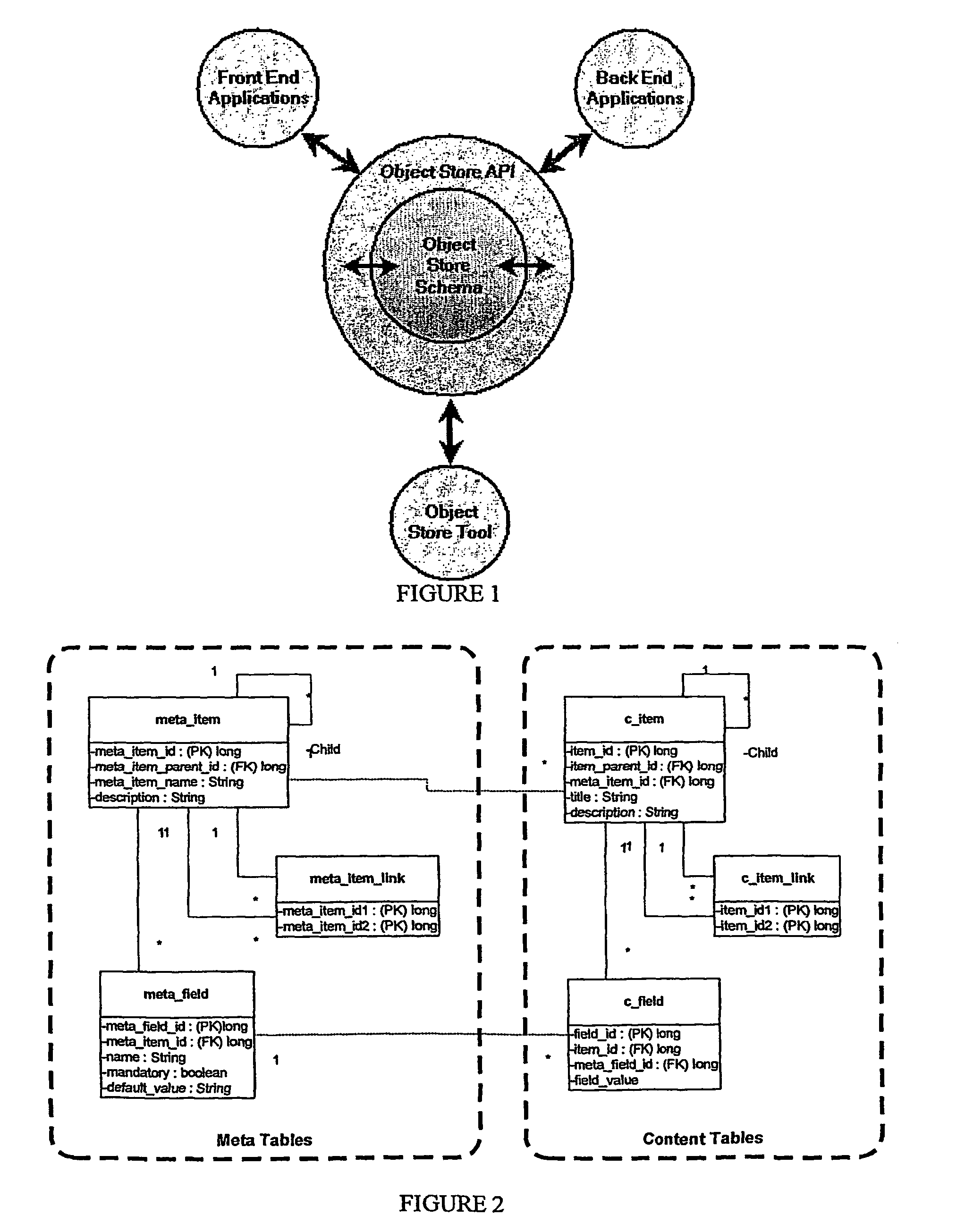

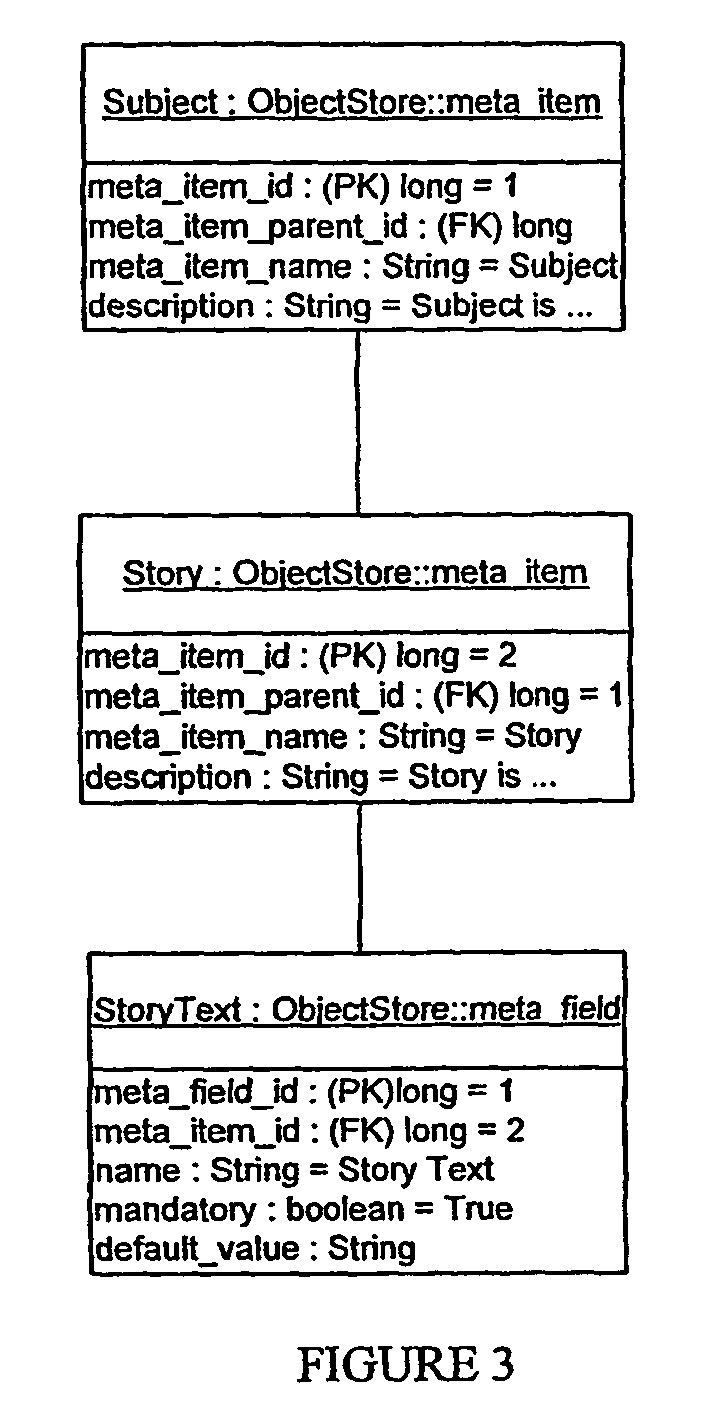

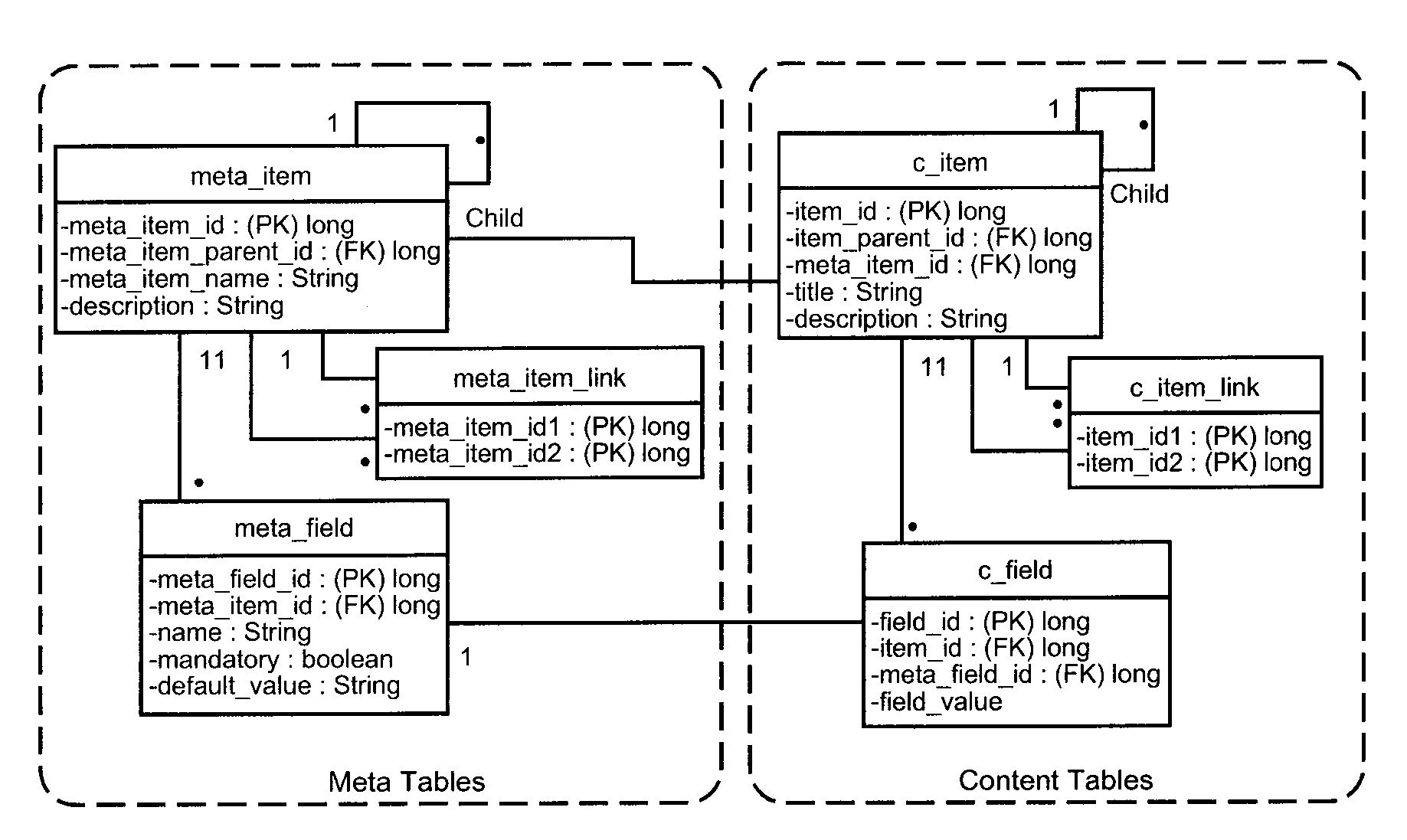

InactiveUS7096226B2Simple and extendible systemReduce decreaseData processing applicationsDigital data processing detailsSystems analysisRecord linkage

A database system stores data relating to media objects and includes a meta table, a supplementary meta table, a content table, a supplementary content table, each supplementary content data record being linked to a supplementary metadata record and to a content data record. An object type link table links together records in the meta table, and a content data link table links together records in the content data table. An information retrieval system analyzes the tables and provides, for a selected instance of an object, information about that object's attributes and relationships with other objects in a hierarchical form.

Owner:KNAPP INVESTMENT

Database system, particularly for multimedia objects

ActiveUS20080021926A1Simple and extendible systemReduce decreaseData processing applicationsDigital data processing detailsSystems analysisRecord linkage

A database system stores data relating to media objects and includes a meta table, a supplementary meta table, a content table, a supplementary content table, each supplementary content data record being linked to a supplementary metadata record and to a content data record. An object type link table links together records in the meta table, and a content data link table links together records in the content data table. An information retrieval system analyzes the tables and provides, for a selected instance of an object, information about that object's attributes and relationships with other objects in a hierarchical form.

Owner:KNAPP INVESTMENT

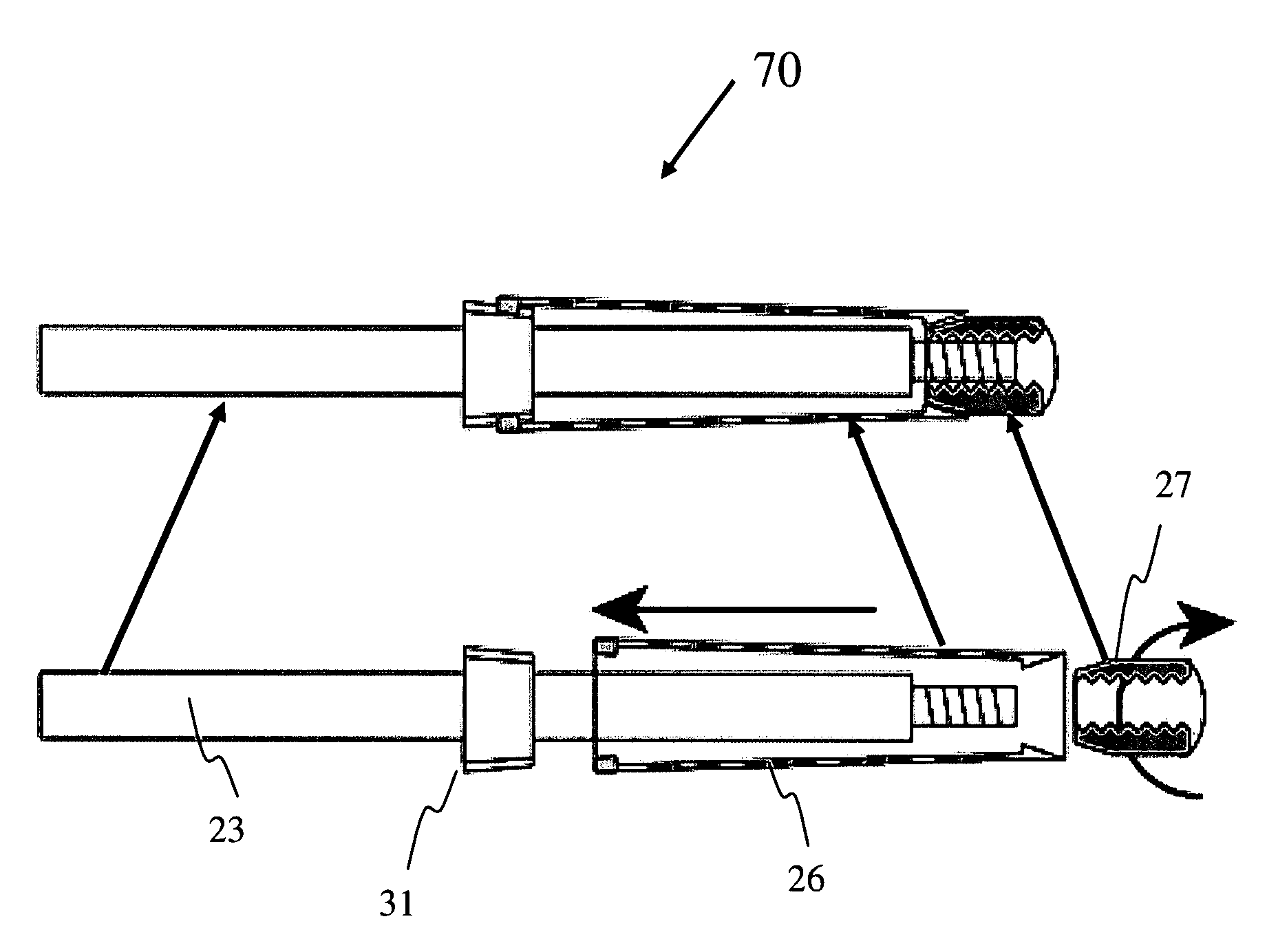

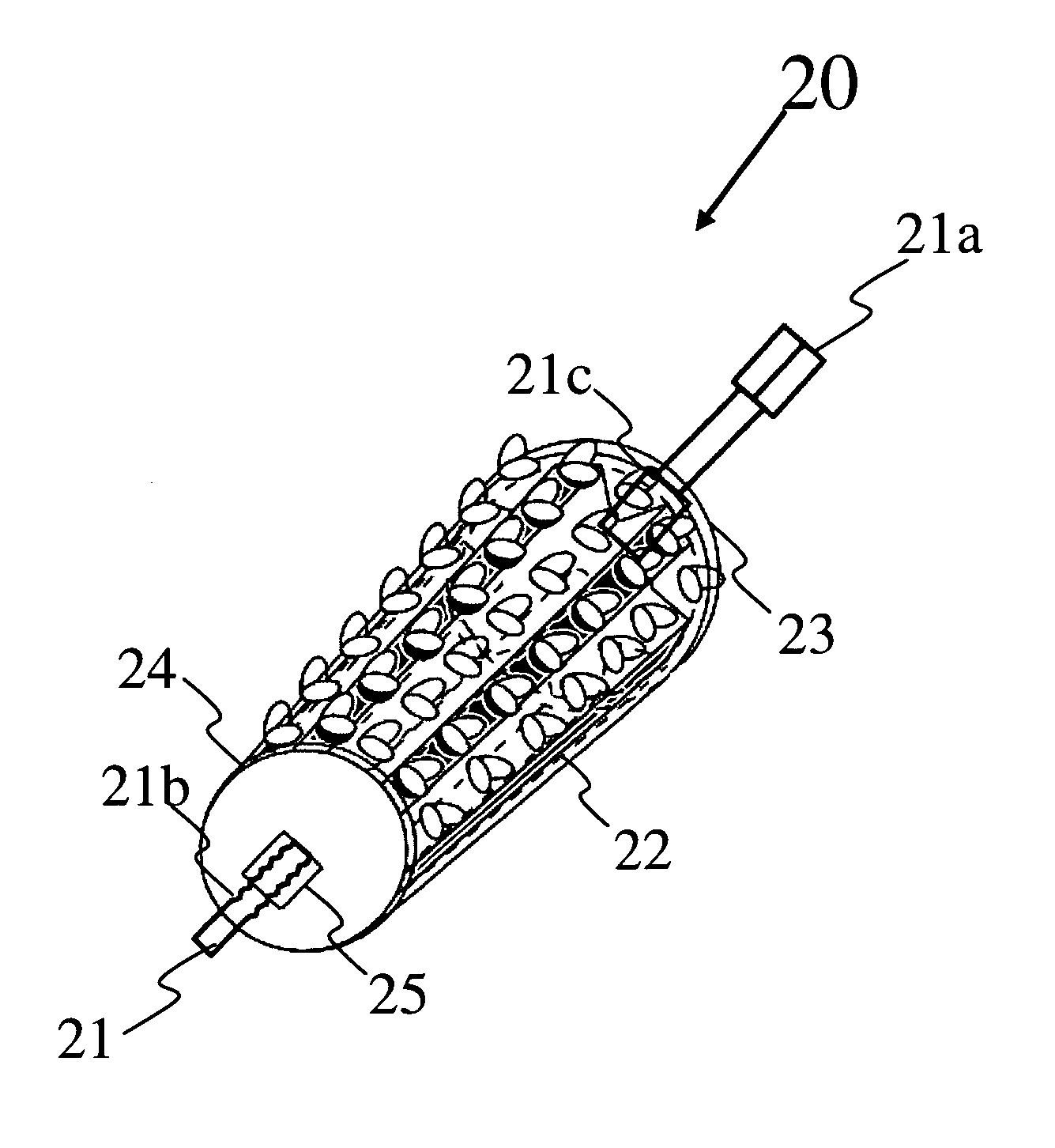

Modular tapered hollow reamer for medical applications

An easy-to-assemble reamer for medical applications includes a shaft portion, a disposable tapered hollow reamer sleeve and a modular pilot. The shaft portion has a proximal end for attachment to a drill, a central cone element with one or more slots and a distal threaded end. The tapered hollow reamer sleeve has integrally attached one or more torque transmitting tabs at the larger end and a collet taper at the smaller end and slides over the shaft distal end engaging tabs with the slots. The modular pilot has a threaded central aperture engaging shaft thread and a collet taper mating with the collet taper of the reamer sleeve substantially coinciding their centerlines. The disposable hollow cutter sleeve has a plurality of cutting elements and apertures that discharge bone and bone cement debris into the space between the reamer and the shaft. With this construction, the reamer transmits reliable, wobble free, reaming torque in a highly efficient manner.

Owner:LRS SCI & TECH LLC

Method and system for entropy decoding for scalable video bit stream

ActiveUS7664176B2Small sizeImprove visual qualityColor television with pulse code modulationColor television with bandwidth reductionComputer hardwareVideo bitstream

A method, program product and apparatus for decoding from a scalable bit stream the binarization results of a video sequence by selectively decoding syntax elements and avoiding redundancy in coding. The result is a decrease in the size of the compressed bit stream of an enhancement layer bit stream. It has been demonstrated that the compression efficiency equals that of a single, non-scalable video stream for some video sequences. These features may be achieved by determining whether a skipping flag in the base layer macro block of the video data is set, and decoding a skipping flag from an enhancement layer macro block of the video data, corresponding to the base layer macro block, only if the base layer macro block skipping flag is set.

Owner:RPX CORP

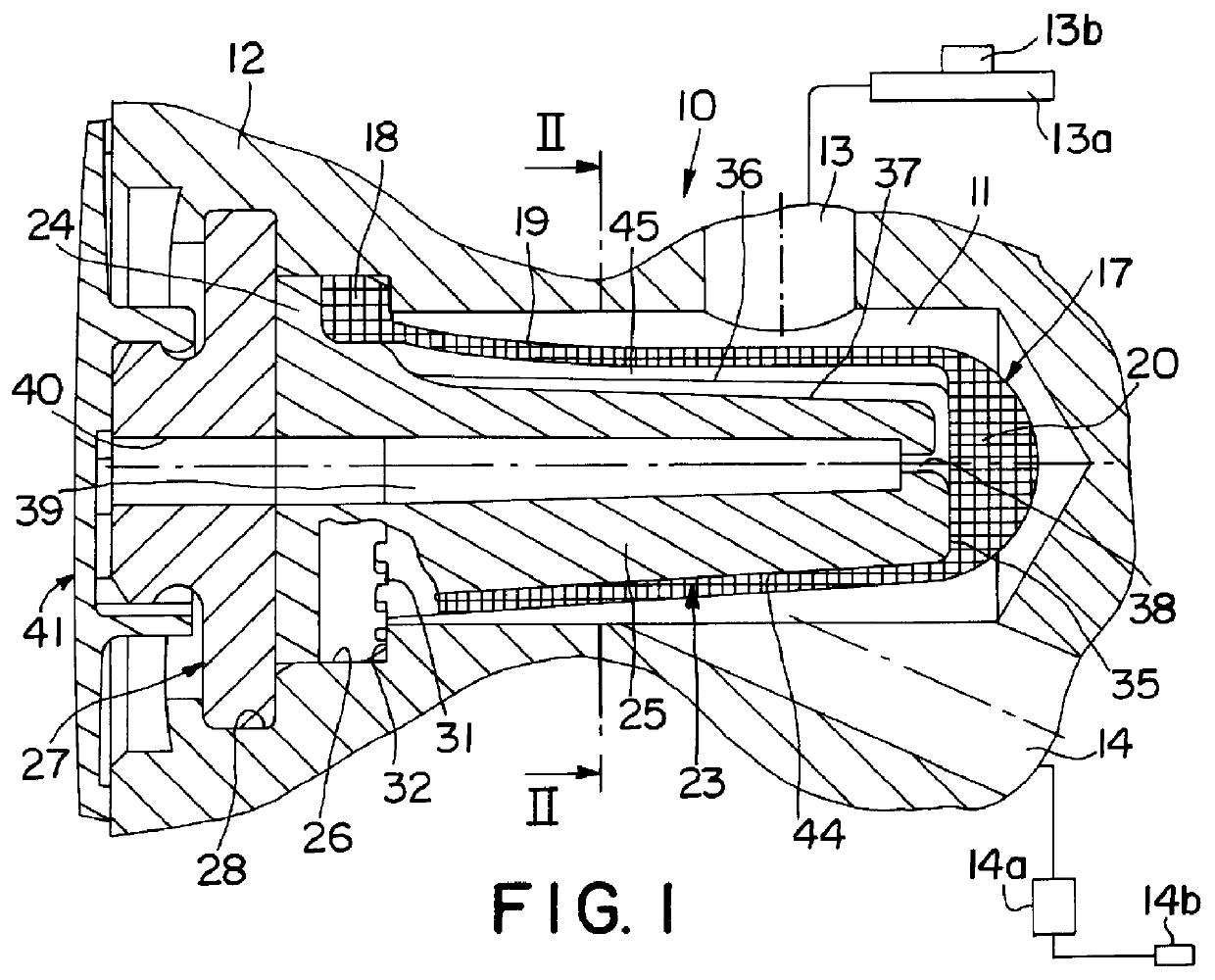

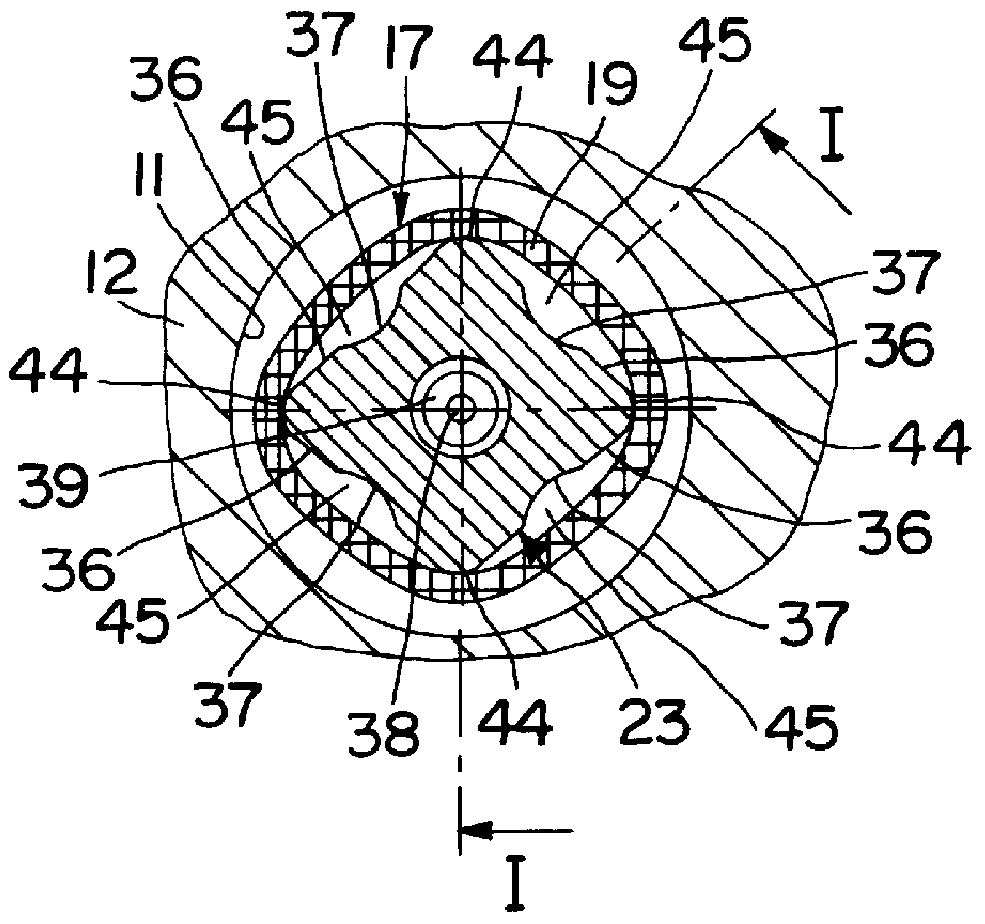

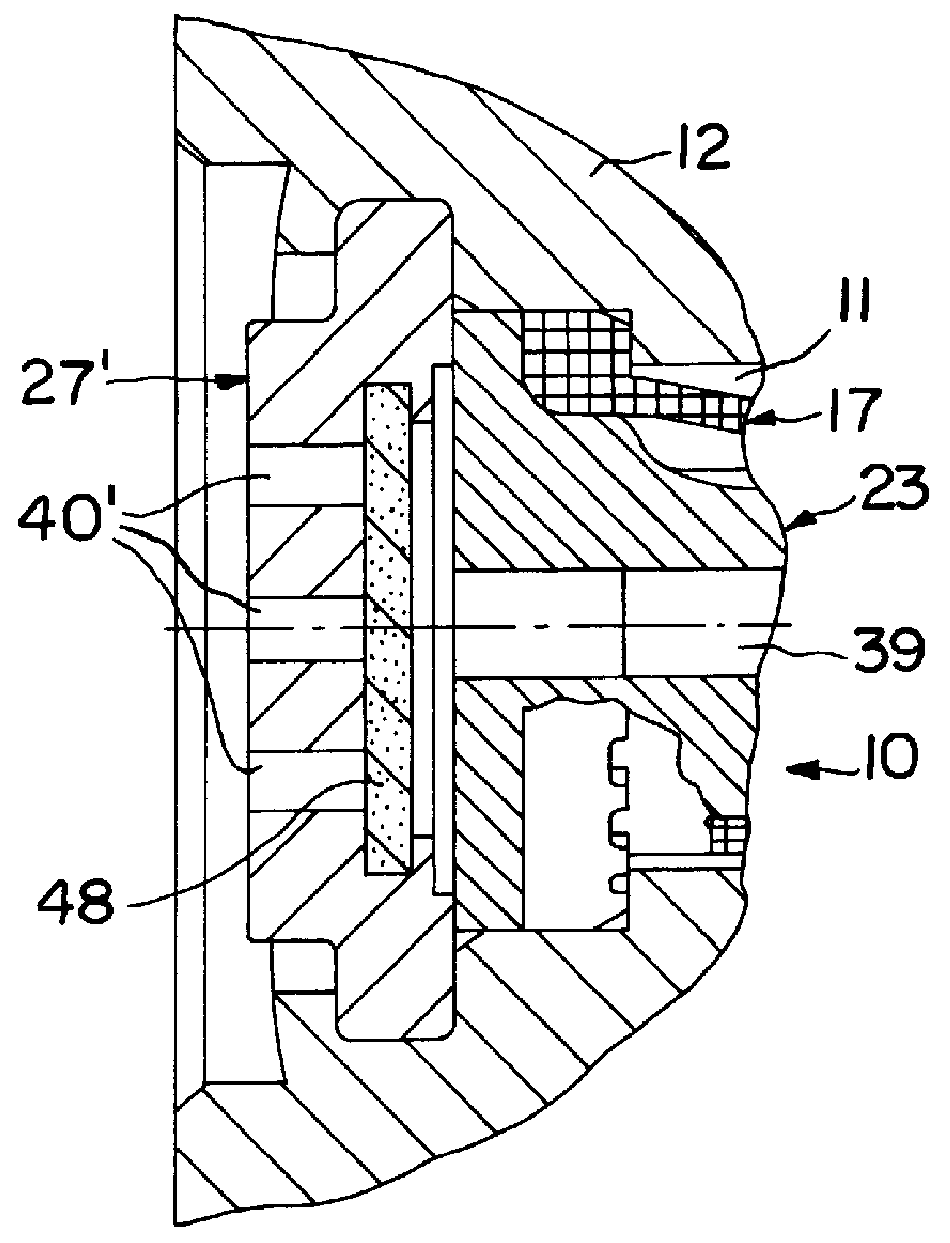

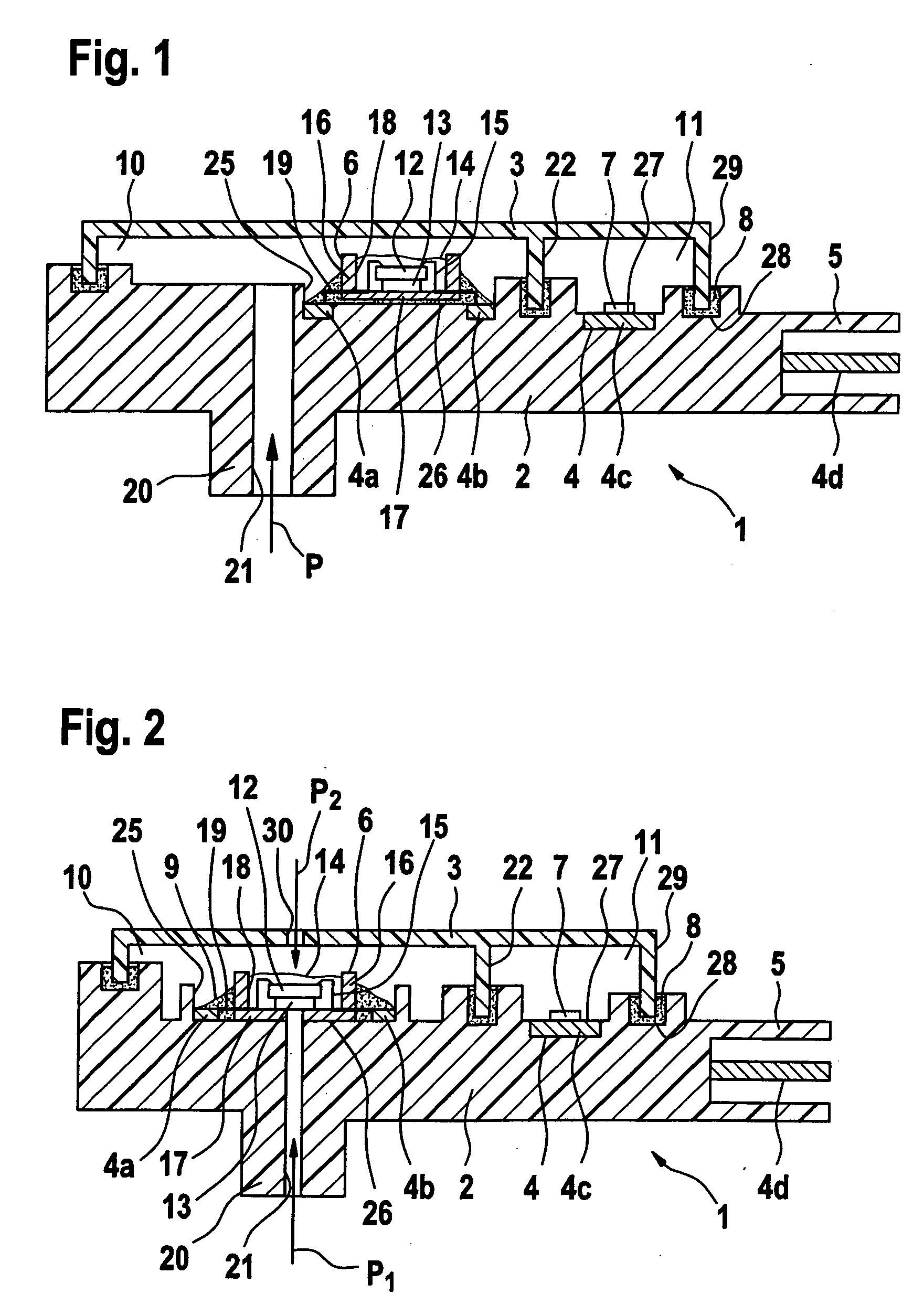

Oscillation damper for damping fluid oscillation in a hydraulic anti-slip control braking system in motor vehicles

InactiveUS6017099ASufficient compression volumeReduce rigidityServomotorsPipe elementsElastomerEngineering

PCT No. PCT / DE96 / 00917 Sec. 371 Date Feb. 23, 1998 Sec. 102(e) Date Feb. 23, 1998 PCT Filed May 25, 1996 PCT Pub. No. WO97 / 02971 PCT Pub. Date Jan. 30, 1997The vibration damper has a sleevelike shaped part comprising an elastomer as a diaphragm. The shaped part is received tightly on the opening end of a bore of a housing and surrounds an extension of a support body disposed in the bore. Provided on a side face of the extension is a groove, which communicates with a chamber in the extension. The shaped part, which on its outside is exposed to the brake fluid, with the inside of its jacket wall defines a hollow chamber, formed toward the extension of the support body and having atmospheric pressure. The vibration damper can be used in a slip-controlled hydraulic brake systems of motor vehicles.

Owner:ROBERT BOSCH GMBH

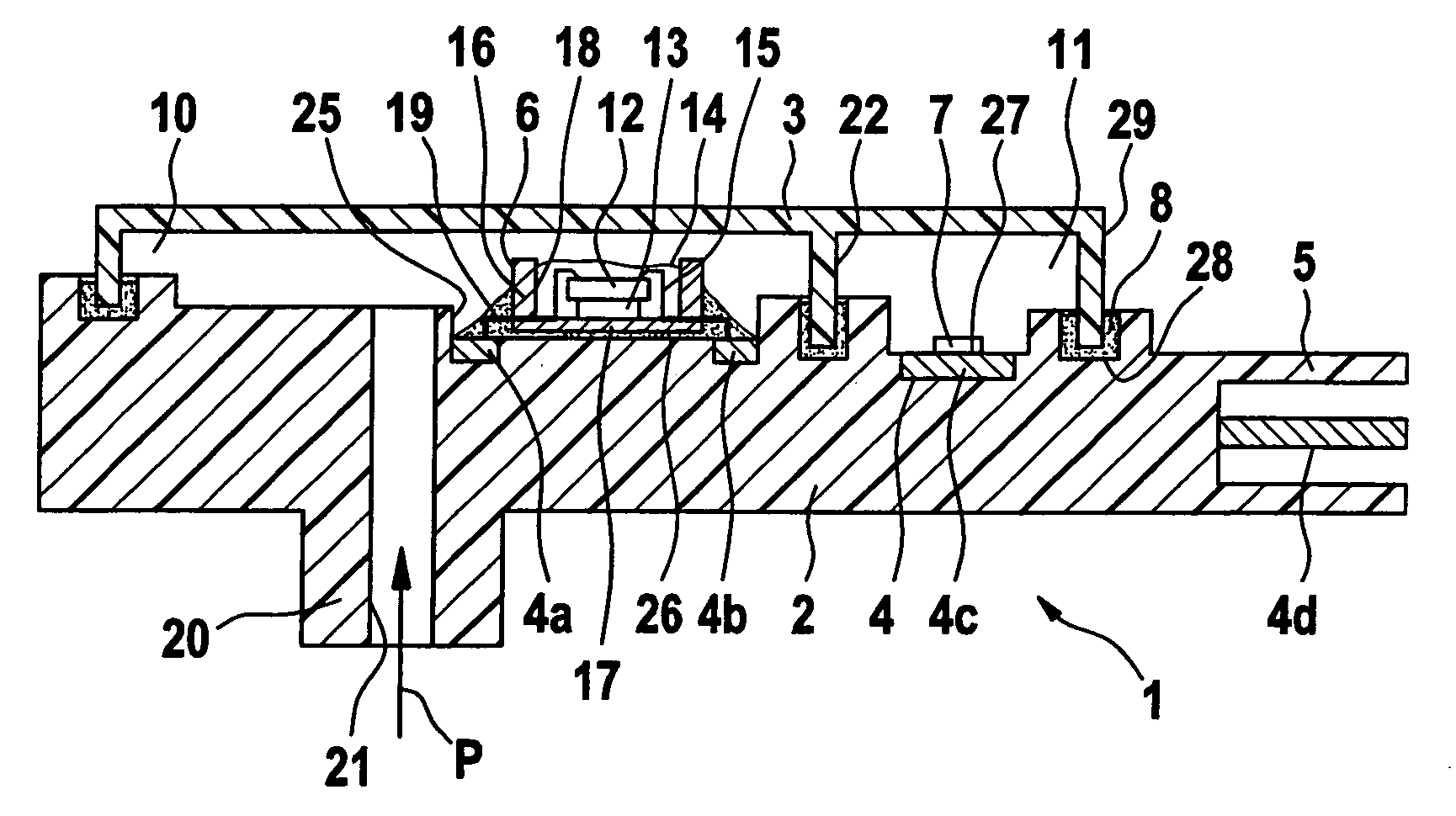

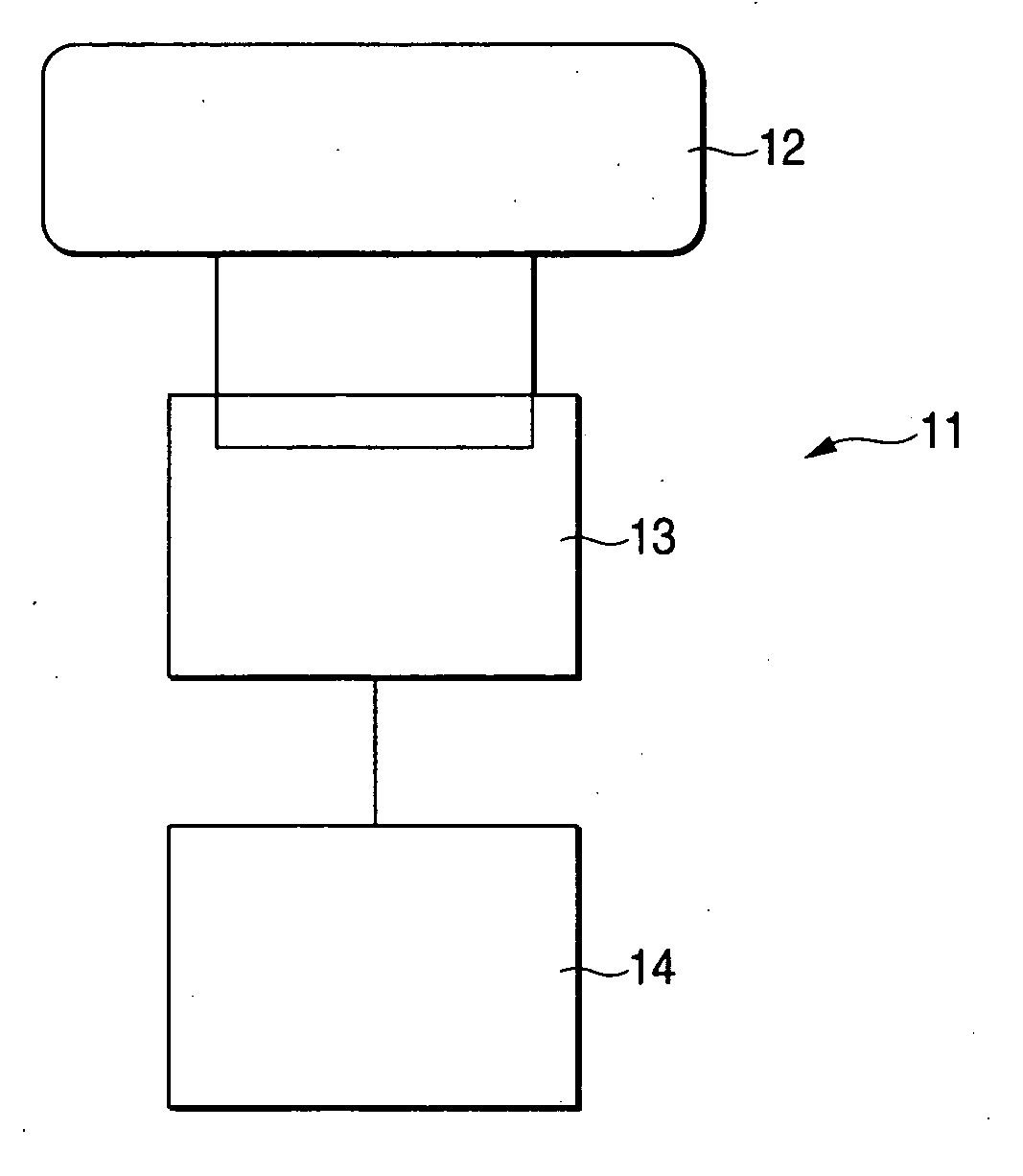

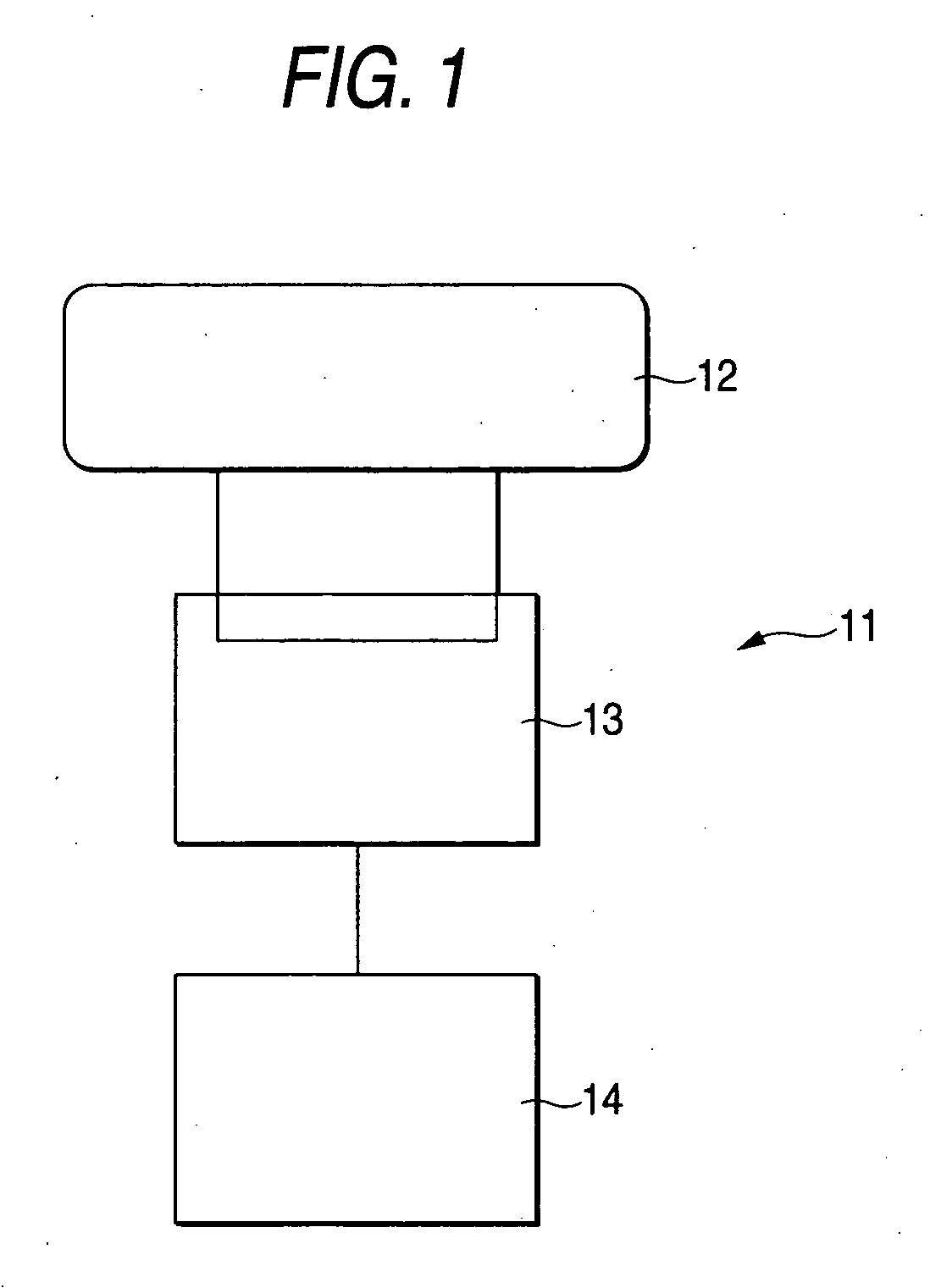

Sensor Module

ActiveUS20080034877A1Simple and compact designEliminate p.cFluid pressure measurement by electric/magnetic elementsFluid pressure measurement by mechanical elementsConductive materialsCapacitor

A pressure sensor module having a sensor housing which includes a housing part in which electrical conductors are partially embedded, the sensor housing being provided with a first cavity, in which a sensor system is situated, and a second cavity which is sealed against the first cavity and in which is provided at least one capacitor, and the first cavity being provided with a receptacle part having a receptacle formed by a peripheral wall, the sensor system being inserted into this receptacle and covered by a protective covering filled into the receptacle. The sensor system is contacted with connecting elements provided on the receptacle part, these connecting elements being directly connected to connecting sections of the electrical conductors; and the at least one capacitor provided in the second cavity is connected to at least one of the electrical conductors via an electrically conductive material.

Owner:ROBERT BOSCH GMBH

Pipe-pipe site butt welding method of continuous pipes

InactiveCN101862884ASlow downDisrupted growthFurnace typesWorkpiece edge portionsRoundingButt welding

The invention relates to a pipe-pipe site butt welding method of continuous pipes. The pipe-pipe site butt welding method comprises the following steps: firstly adopting a cold straightening method to straighten the continuous pipes, then adopting a cold rounding method to carry out rounding, secondly carrying out groove processing with same angles on the butted positions of the pipe ends, then adopting an outer aligning mode to process the two continuous pipes into pipe ends with grooves so as to carry out welding and aligning assembly, and then adopting full-position non-melt electrode argon arc (TIG) automatic welding or manual welding; and finally carrying out electric arc burn-back heat treatment. The pipe-pipe site butt welding method can finish pipe-pipe site butt welding of the continuous pipes in situ, and obtain welding joints with the structure size of being consistent to that of the continuous pipes and comprehensive mechanical property of being near to that of a main body.

Owner:XI'AN PETROLEUM UNIVERSITY

Zeolite, process for producing the same, adsorbent comprising the zeolite, heat utilization system, adsorption heat pump, cold/heat storage system, and air-conditioning apparatus for humidity regulation

InactiveUS20060245994A1Increased durabilityReduce adsorptionMaterial nanotechnologyPhosphatesSorbentNitrogen

Subjects for the invention are to provide a zeolite reduced in performance deterioration in repetitions of use or during long-term use and a process for producing the same and to provide an adsorbent comprising the zeolite and a heat utilization system or the like employing the adsorbent. The invention relates to a zeolite which has a framework density of from 10 T / nm3 to 16 T / nm3 and a carbon content of from 1% by weight to 6% by weight and satisfies the following (1) or (2): (1) the zeolite is an aluminophosphate which has a nitrogen content of from 0.5% by weight to 12% by weight and in which the aluminum may be partly replaced by Me; (2) the zeolite is a silicoaluminophosphate in which the aluminum may be partly replaced by Me and which, when burned to a carbon content lower than 0.3% by weight, retains the framework structure possessed by the silicoaluminophosphate before the burning: (provided that Me in (1) and (2) above is at least one element selected from the elements in Groups 2A, 7A, 8, 1B, and 2B of the periodic table).

Owner:MITSUBISHI PLASTICS INC

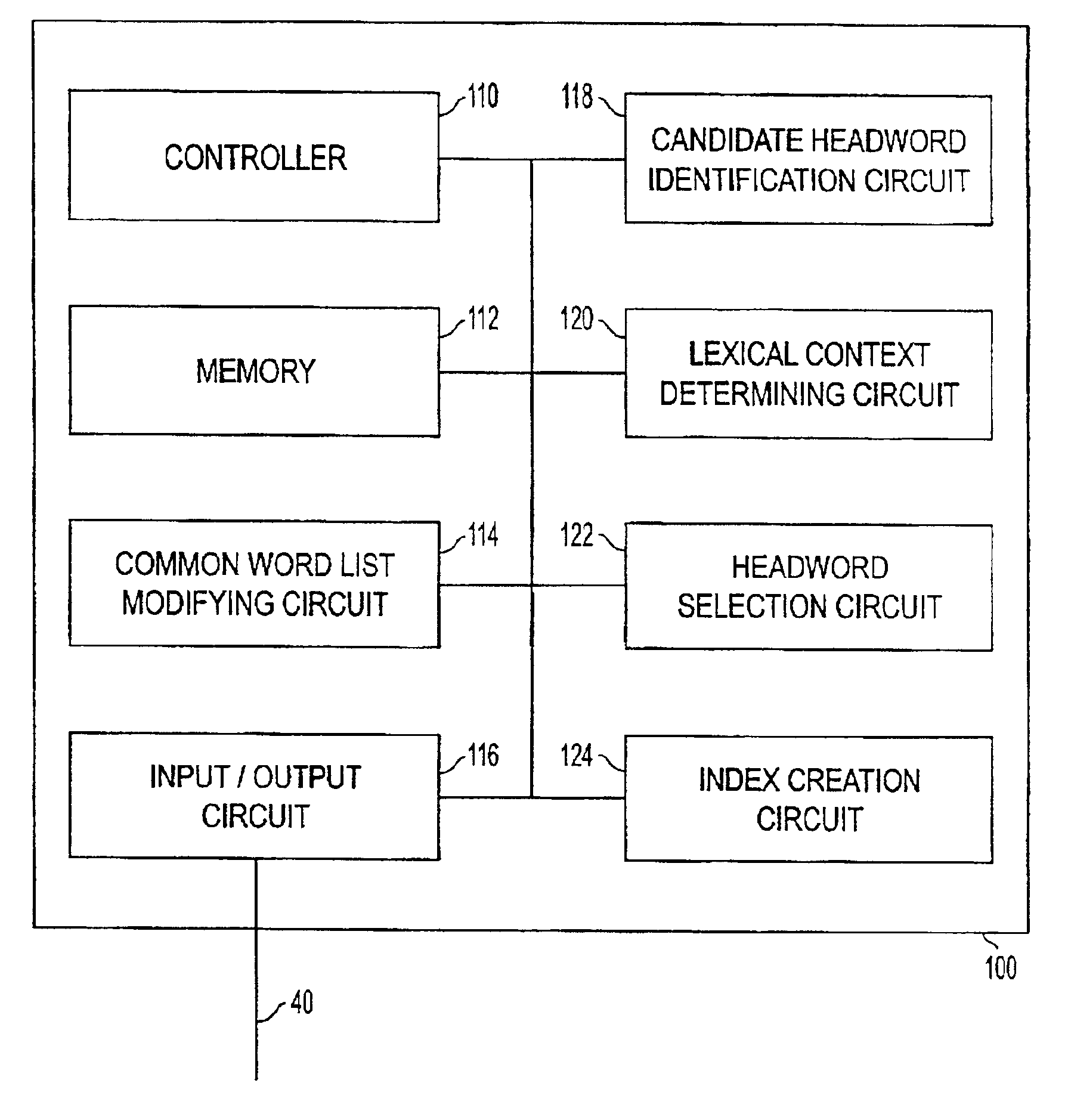

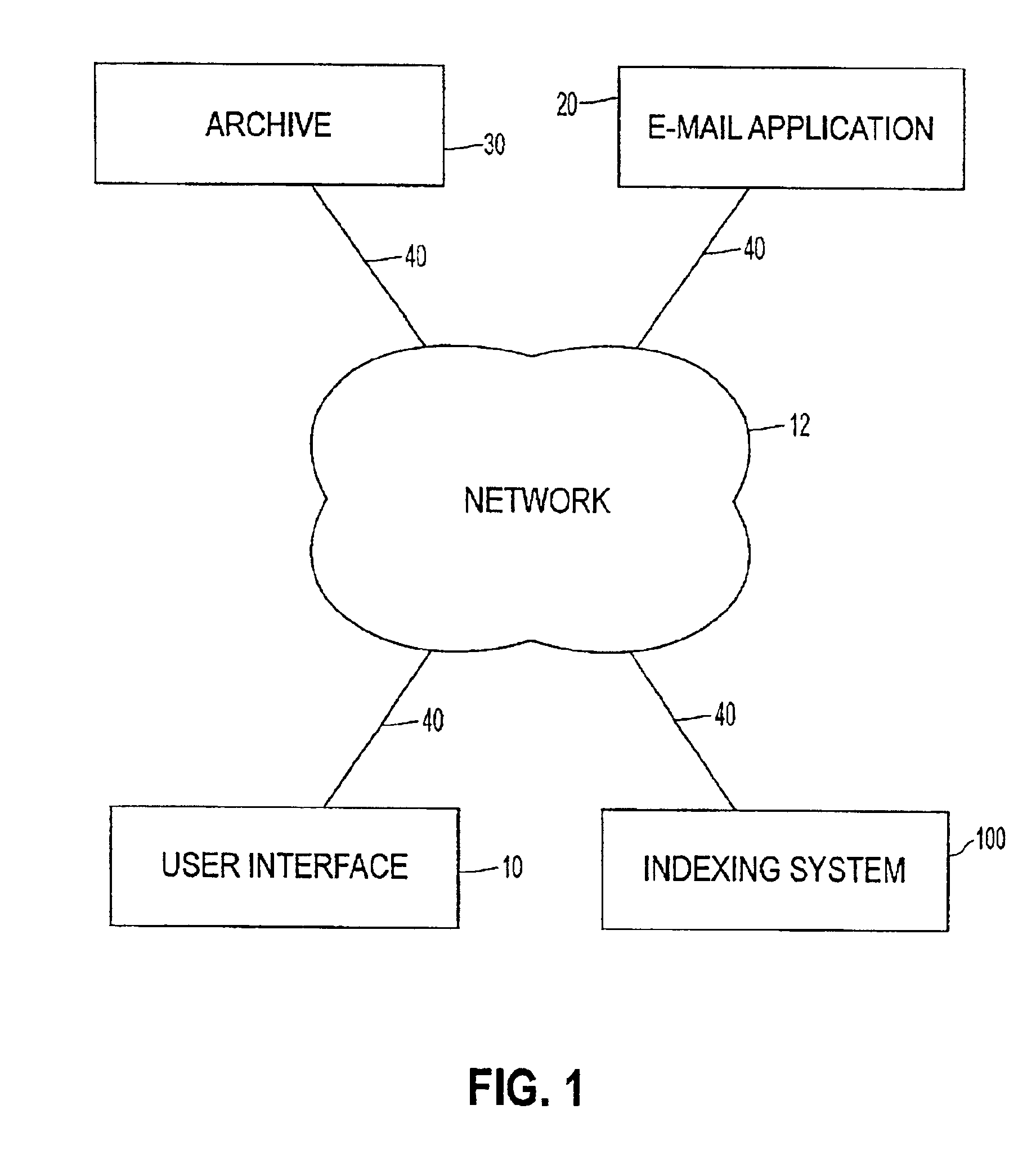

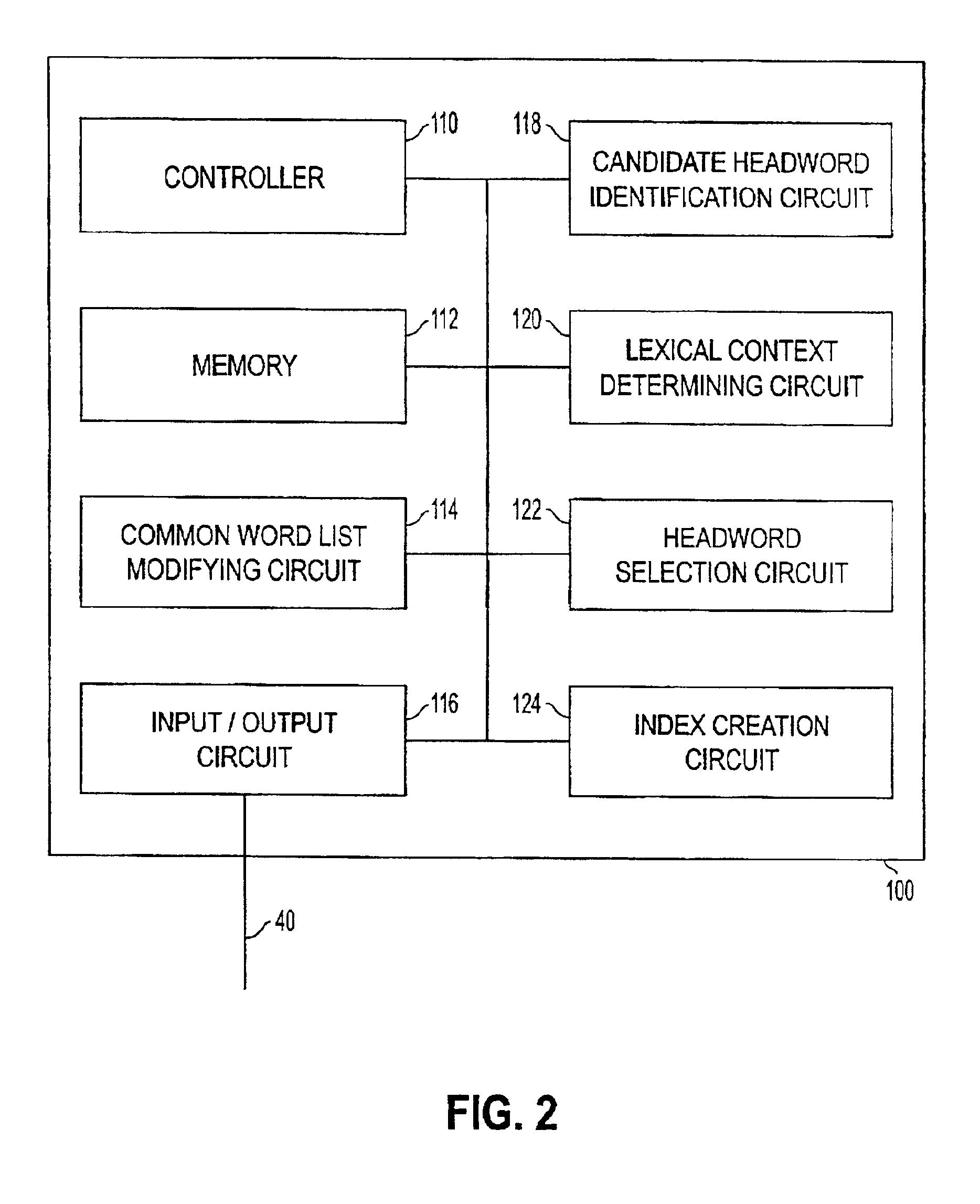

Lightweight subject indexing for e-mail collections

InactiveUS6873985B2Increase the lengthSearch for appropriate contexts for the topic words is significantly simplifiedData processing applicationsDigital data information retrievalSubject matterRanking

A light weight subject indexing system including a candidate headword identification system for identifying candidate words in the subject line of a document which are not listed in a user modified common word list, a lexical context system for creating lexical context for an identified candidate headword, a ranking system for ranking all the candidate headwords identified for the subject lines of a document or message collection, and selecting among the ranked headwords for inclusion in an index based on that ranking, and an index creation system for listing candidate headwords selected by the ranking system.

Owner:XEROX CORP

Low cost modular tapered hollow reamer for medical applications

An easy-to-assemble modular reamer for medical applications includes a shaft portion, a disposable tapered hollow reamer and a modular pilot. The shaft portion has a proximal end for attachment to a drill, two or more torque transmitting tabs and a distal threaded end. The disposable tapered hollow reamer has an integrally attached cutter sleeve with externally protruding cutters, apertures through the sleeve thickness for discharging bone fragments and cement debris and inwardly protruding anchoring projections. A central molded polymeric portion attaches to the anchoring projection and is fixed to the shaft through central holes and slots in the polymeric portion, which engage torque transmitting shaft tabs. Channels in the polymeric portion collect bone fragments and bone debris. A threaded modular pilot coaxially secures the disposable tapered hollow reamer to the threaded distal end of the shaft, permitting rotation of the tapered hollow reamer without wobbliness.

Owner:LRS SCI & TECH LLC

Method of and base station for controlling beam forming in a mobile cellular network

InactiveUS8055303B2Avoid negative effectsMaximize throughputNetwork topologiesSubstation equipmentSignal qualityBeam pattern

The invention concerns a melhod and a base station for controlling beam forming in a mobile cellular network: Antenna units apply a respective beam pattern sequence on each sector of a cell served by the respective base station. A base station acts as trigger base station informing all neighbored base stations of the cluster not to change their beam pattern sequences. The trigger base station changes the beam pattern sequence applied on the sectors of its cell. The trigger base station triggers one or more mobile units to calculate signal quality parameters for currently applied beam pattern sequence. The trigger base station selects an optimal beam pattern sequence from the set based on the calculated signal quality parameters and applies as a new beam pattern sequence on the respective sector.

Owner:WSOU INVESTMENTS LLC

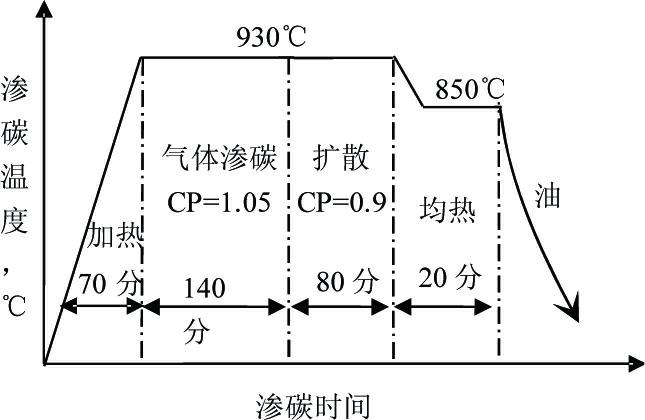

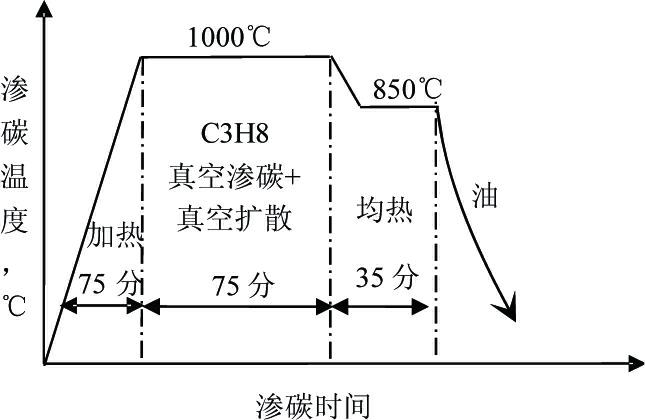

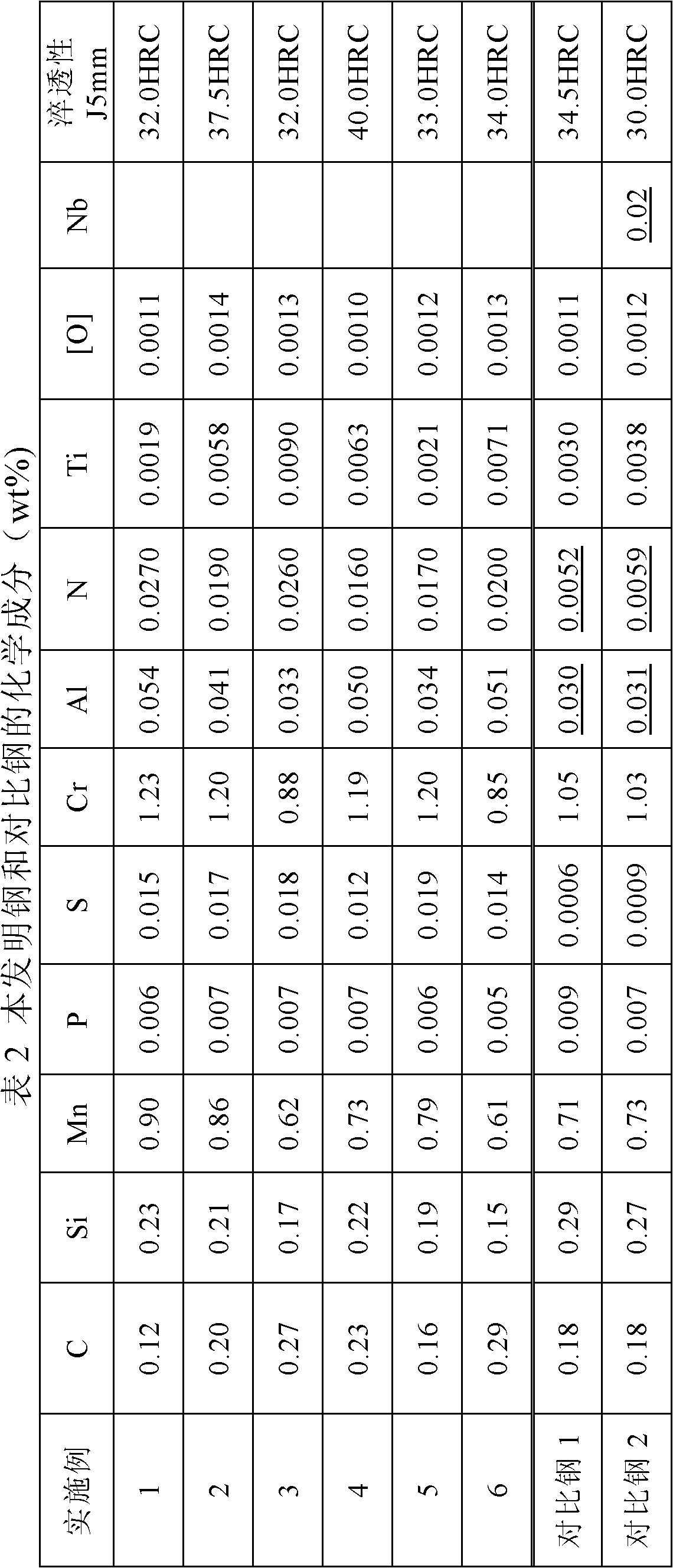

High-temperature vacuum carburized gear steel

The invention discloses high-temperature vacuum carburized gear steel. The high-temperature vacuum carburized gear steel comprises: by weight, 0.10 to 0.30% of C, 0.15 to 0.25% of Si, 0.60 to 0.90% of Mn, less than or equal to 0.025% of P, 0.010 to 0.020% of S, 0.85 to 1.25% of Cr, 0.033 to 0.055% of Al, 0.0160 to 0.0300% of N, 0.001 to 0.009% of Ti, less than or equal to 0.0020% of O and the balance Fe and unavoidable impurities. Through a micro-alloying method, abnormal growth of austenite grains of gear steel in high-temperature vacuum carburizing is controlled and thus steel grain granularity is strictly controlled in a range of 7.0 to 8.0 grade and hardenability (J5mm) is stably controlled in a range of 32 to 42 HRC so that various performance requirements of common gear steel are satisfied. The high-temperature vacuum carburized gear steel contains simple alloy elements, has a low cost, allows stable and reliable process control, can be utilized for high-temperature vacuum carburizing, greatly reduces carburizing time, is environmentally friendly and saves energy.

Owner:宝钢特钢有限公司

Aluminum-containing and sulfur-containing series gear steel smelting process

ActiveCN104611502AControl Si contentInhibit peroxidationProcess efficiency improvementElectric furnaceGranularitySmelting process

The invention discloses an aluminum-containing and sulfur-containing series gear steel smelting process. Liquid iron is required to contain 0.20-0.50% of Si, less than or equal to 0.035% of S, and less than or equal to 0.110% of P, and at a temperature T greater than or equal to 1250 DEG C; lime for an electric furnace and refining is required to contain greater than or equal to 90% of CaO and less than or equal to 1.2% of SiO2, and has the activity degree of greater than or equal to 300 and the granularity of 10-40mm; a low-silicon refining agent is required to contain greater than or equal to 45% and less than or equal to 55% of CaO, less than or equal to 2.0% of SiO2, and greater than or equal to 35% and less than or equal to 40% of Al2O3. The liquid iron hot charge ratio of the electric furnace reaches up to 90%; for LF refining, a first strong and later weak deoxidization manner is adopted; at the middle-late stages, a weak deoxidizer is adopted for furnace slag maintenance to realize further deoxidization. Meanwhile, deoxidization and S removal are performed, and then an S wire is fed to obtain a certain S content; in addition, the S wire is allowed to be fed only in more than 5 minutes after the denaturalization treatment of feeding a calcium-iron wire into VD liquid steel, and therefore, the formation of CaS inclusion in a clogging material at other water gap is prevented; and at last, the castability of the liquid steel is guaranteed while excellent structural properties of the steel product are obtained, and the purity of the liquid steel is improved.

Owner:ZENITH STEEL GROUP CORP +1

Composite deoxidizing agent aluminum-calcium-iron alloy for smelting steel

The invention provides steel-smelting complex deoxidizing agent- calcium-aluminium- ferrum alloy. It is to solve problems of great loss of aluminium during deoxidation process, low effective component content, bad utilization rate and large consumption, easy secondary oxidation and Al2O3 generation. The alloy comprises aluminium 20- 70%, calcium 1- 10% and left is ferrum and inevitable foreign substance. The manganese 1- 20%, silicon 1- 20% and titanium 1- 5% can be added into said alloy to prevent alloy efflorescence and increase steel alloy element. The invention is characterized by high deoxidation efficiency, lowered foreign substance content in steel, smooth steel smelting process, improved steel quality and reduced cost.

Owner:谢应凯

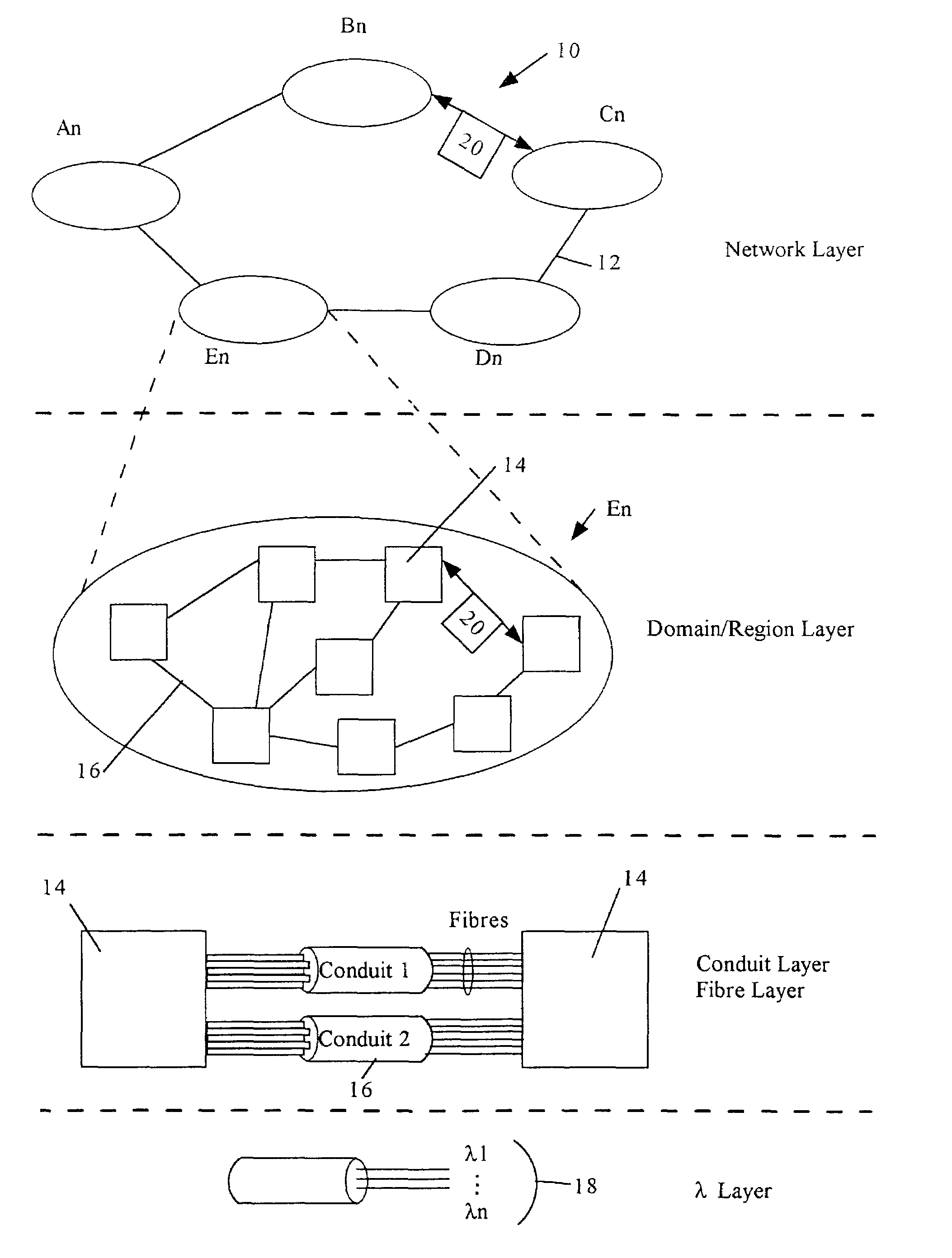

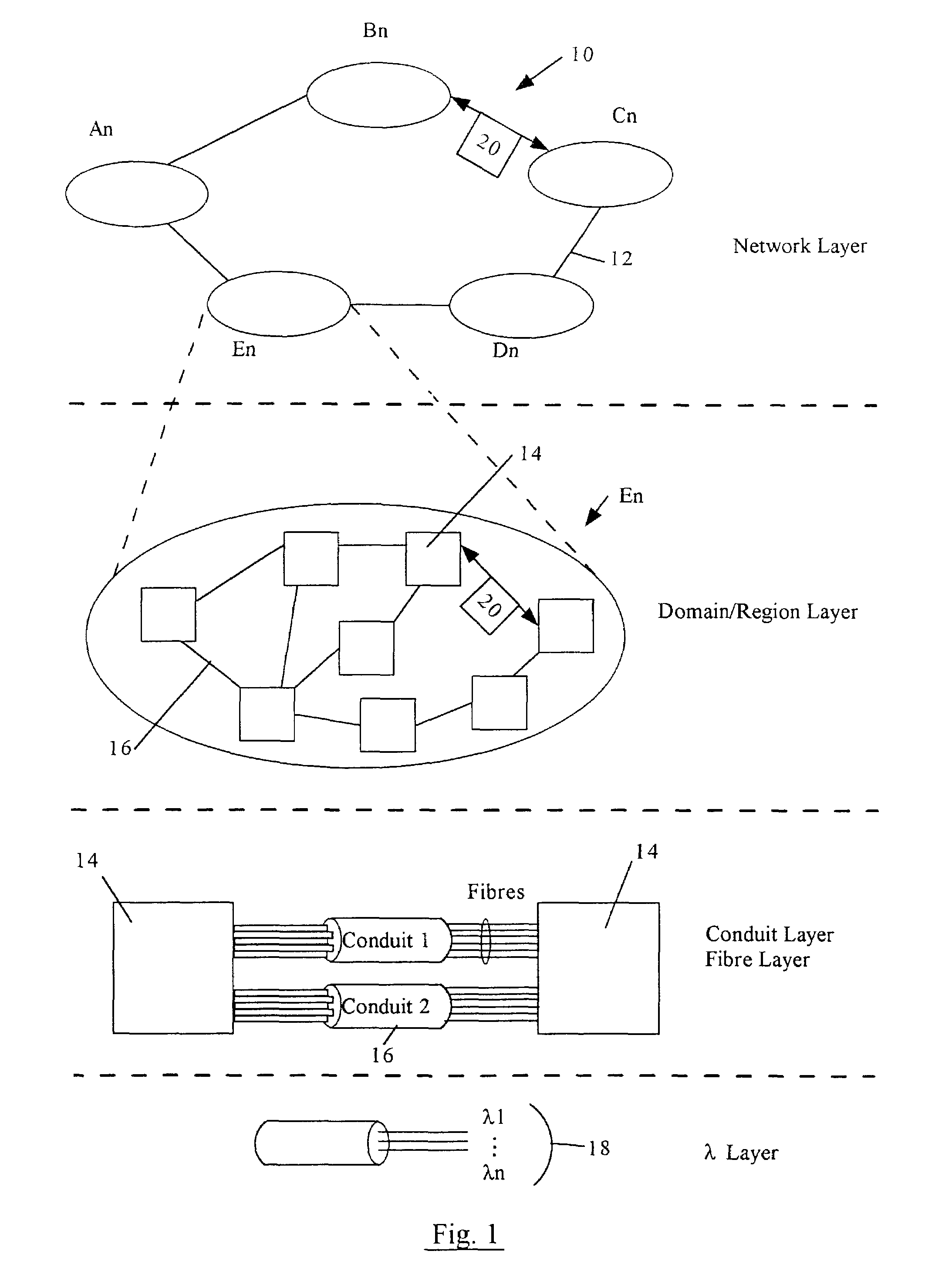

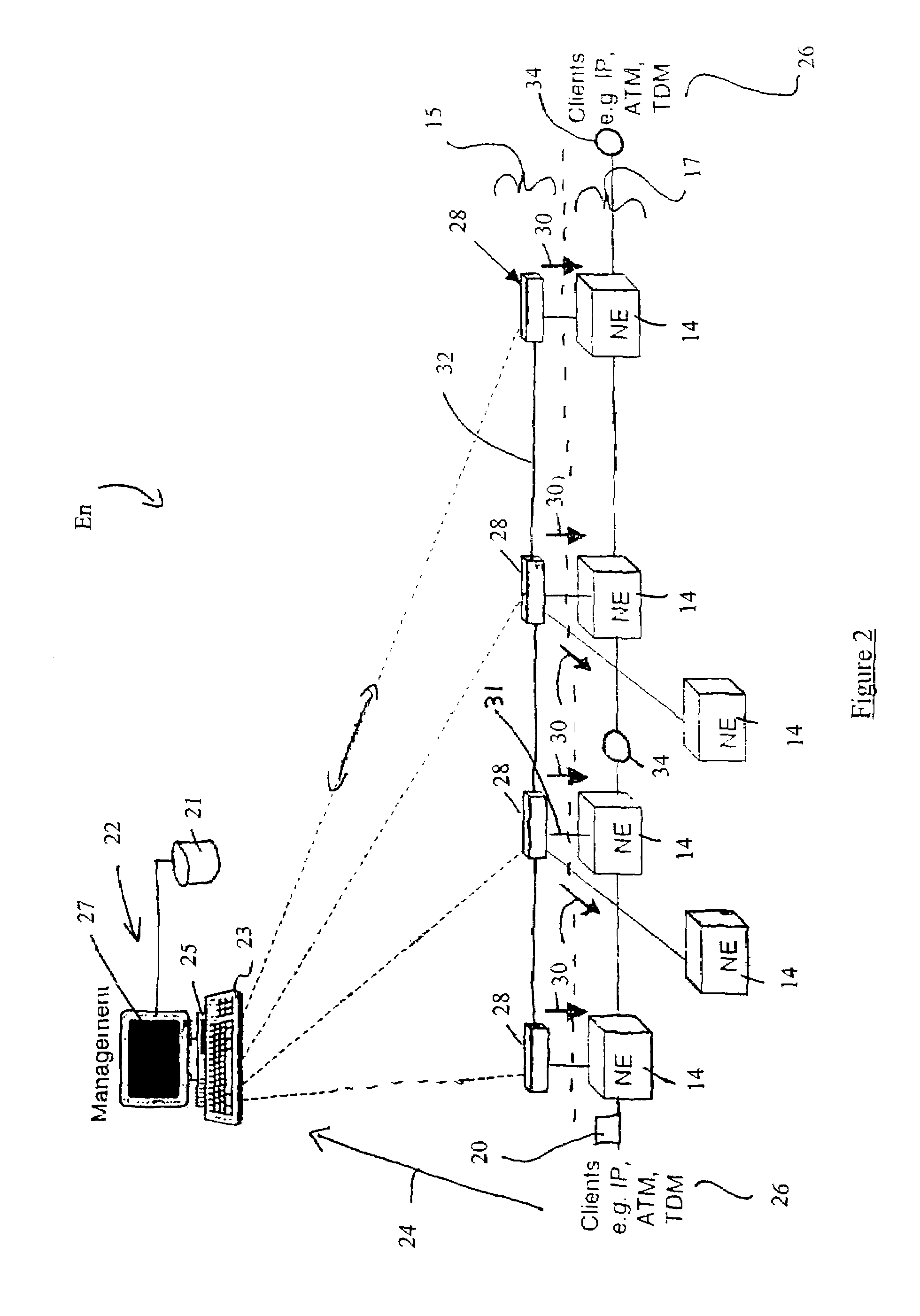

Constraint based routing with non-transitive exceptions

ActiveUS7376086B1Avoid inclusionsError preventionFrequency-division multiplex detailsNetwork elementRouting algorithm

In a multiple element network, a method and network element for providing a constraint based routing system to accommodate non-transitive exceptions. The method and network element receive a connection request for an end to end connection. The network element can select routing information having a pair of adjacent links associated with the multiple elements of the network, where each link of the pair of links has a shared network resource. The shared network resource is compared to a database of exception sets, the exception sets including at least one non-transitive exception predetermined from a plurality of network resources. The network element confirms whether the shared network resource of the selected pair of links is contained within the exception database. A router designs a pathway over the network for the end to end connection using the results of the shared network resource comparison, wherein inclusion in the pathway is inhibited for the shared network resource matching the predetermined exclusion set contained in the database. Accordingly, the list of exception sets is accessible by a constraint based routing algorithm as input to exclude the selected link pair of a pathway for the end to end connection over the network, if the shared network resource of the link pair is contained within the exception sets.

Owner:CIENA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com