Patents

Literature

55 results about "Filling defect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Filling defect. An imaging term of art referring to a reduction in filling of a focal, typically rounded hollow viscus (e.g., urinary bladder, gallbladder, colon) by radiocontrast due the presence of a mass that projects into the lumen.

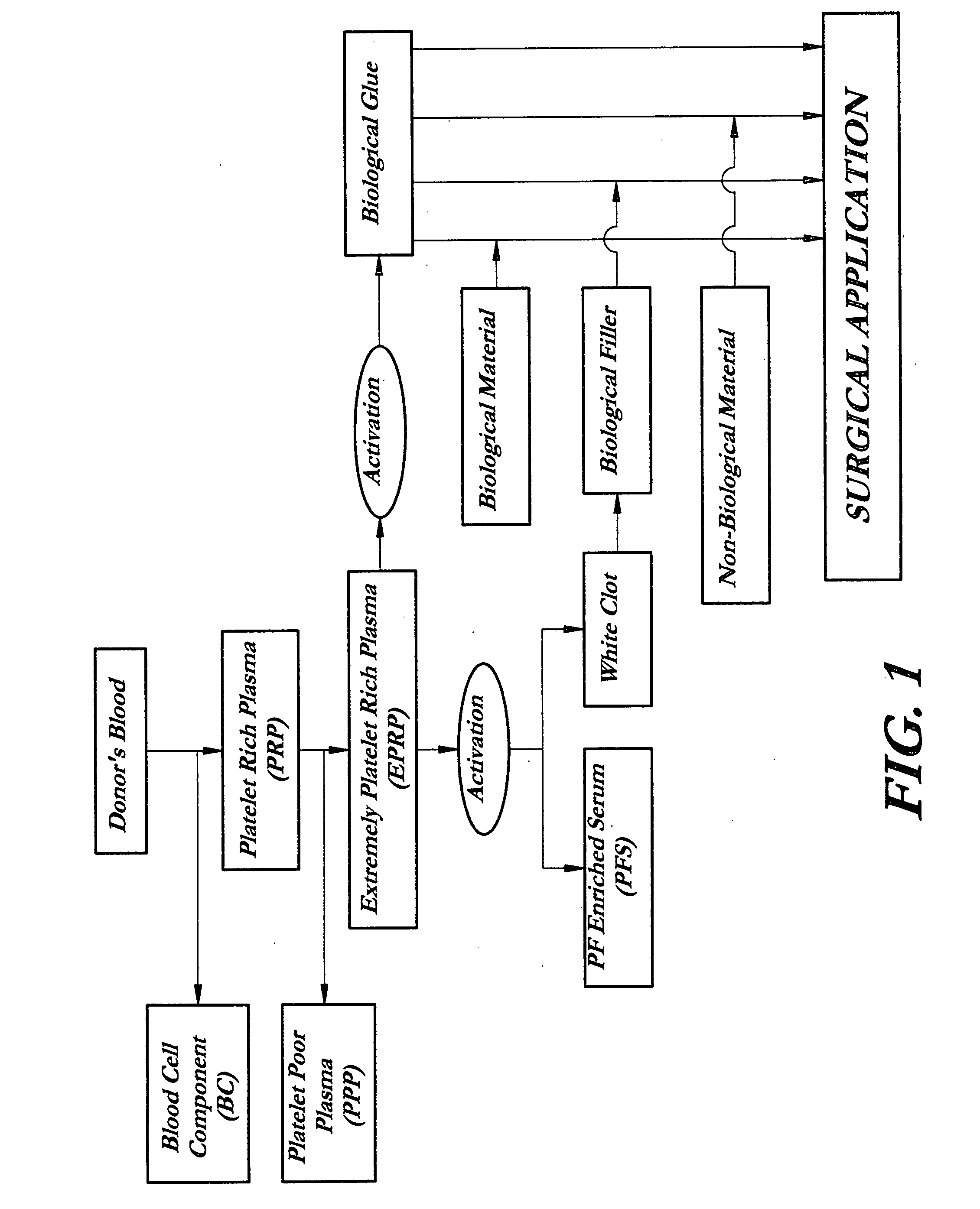

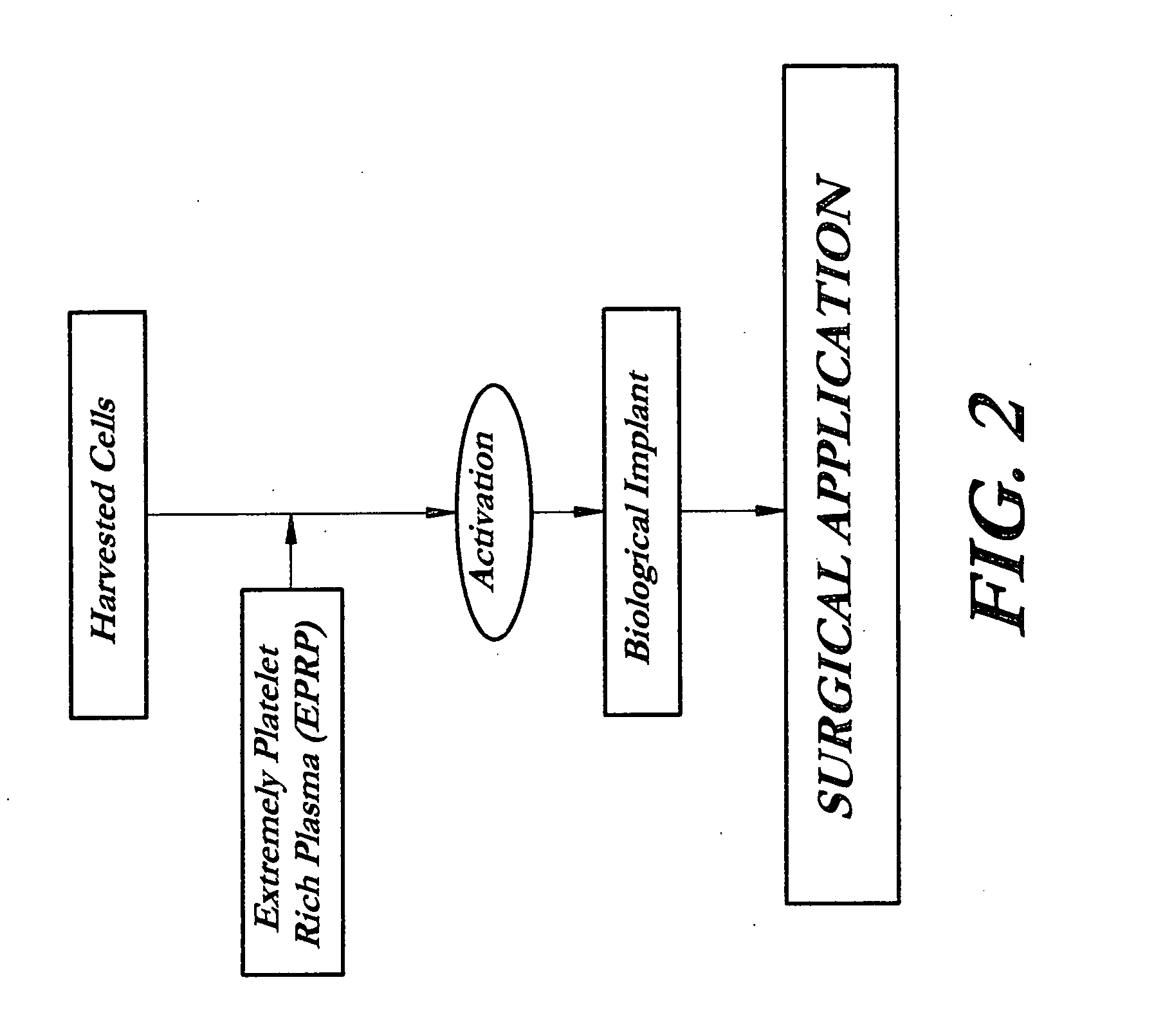

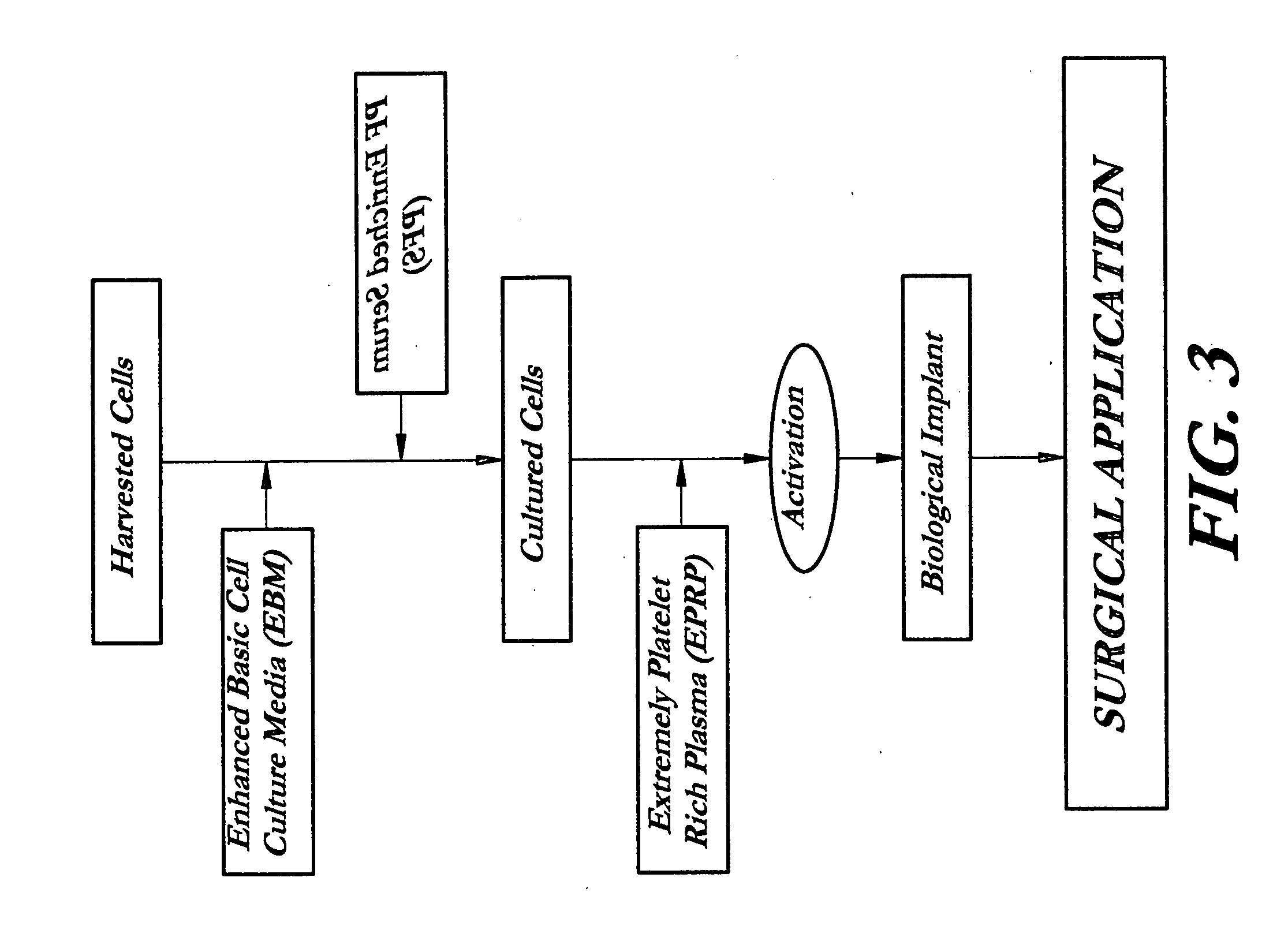

Composition and procedure for tissue creation, regeneration and repair by a cell-bearing biological implant enriched with platelet concentrate and supplements

InactiveUS20070141036A1Fill the voidIncrease the number of cellsBiocideCulture processThrombusIn vivo

A composition and method for enhancing tissue growth, regeneration, and repair includes a Biological Glue formed by extraction of an Extremely Platelet Rich Plasma (EPRP) derived from whole blood, and subsequent activation and clotting. The Biological Glue may be utilized alone to fill defects or may be used as an adhesive agent for other biological and non-biological materials. These materials may include processed thrombus derived from the activation of EPRP. Additionally, the Extremely Platelet Rich Plasma may be impregnated with directly harvested or cultured cells, including stem cells, or other materials, prior to activation, to form a Biological Implant that may be implanted in vivo. A Platelet Factor Enriched Serum (PFS) derived from the activation of the Extremely Platelet Rich Plasma (EPRP) may be added to the cell cultures in preparation of a Biological Implant, in order to provide additional growth factors that speed the development of the cell cultures.

Owner:GORROCHATEGUI BARRUETA ALBERTO

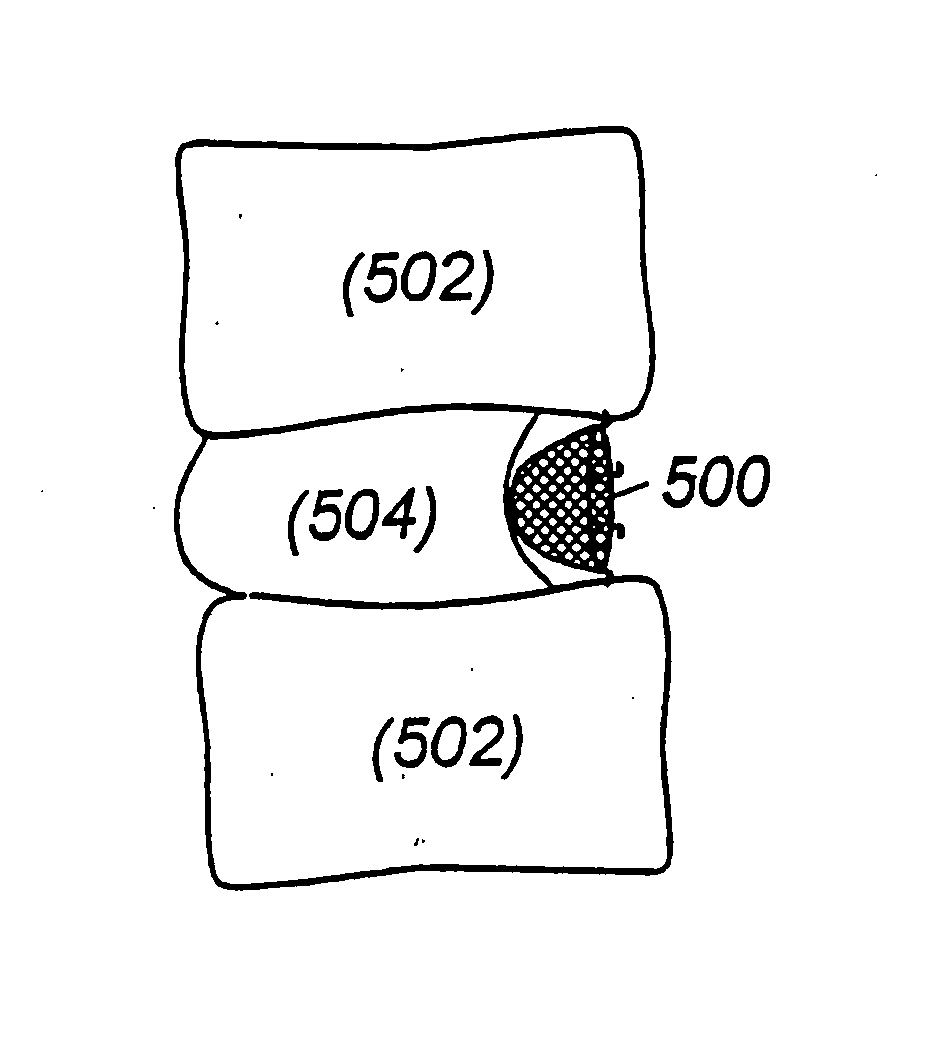

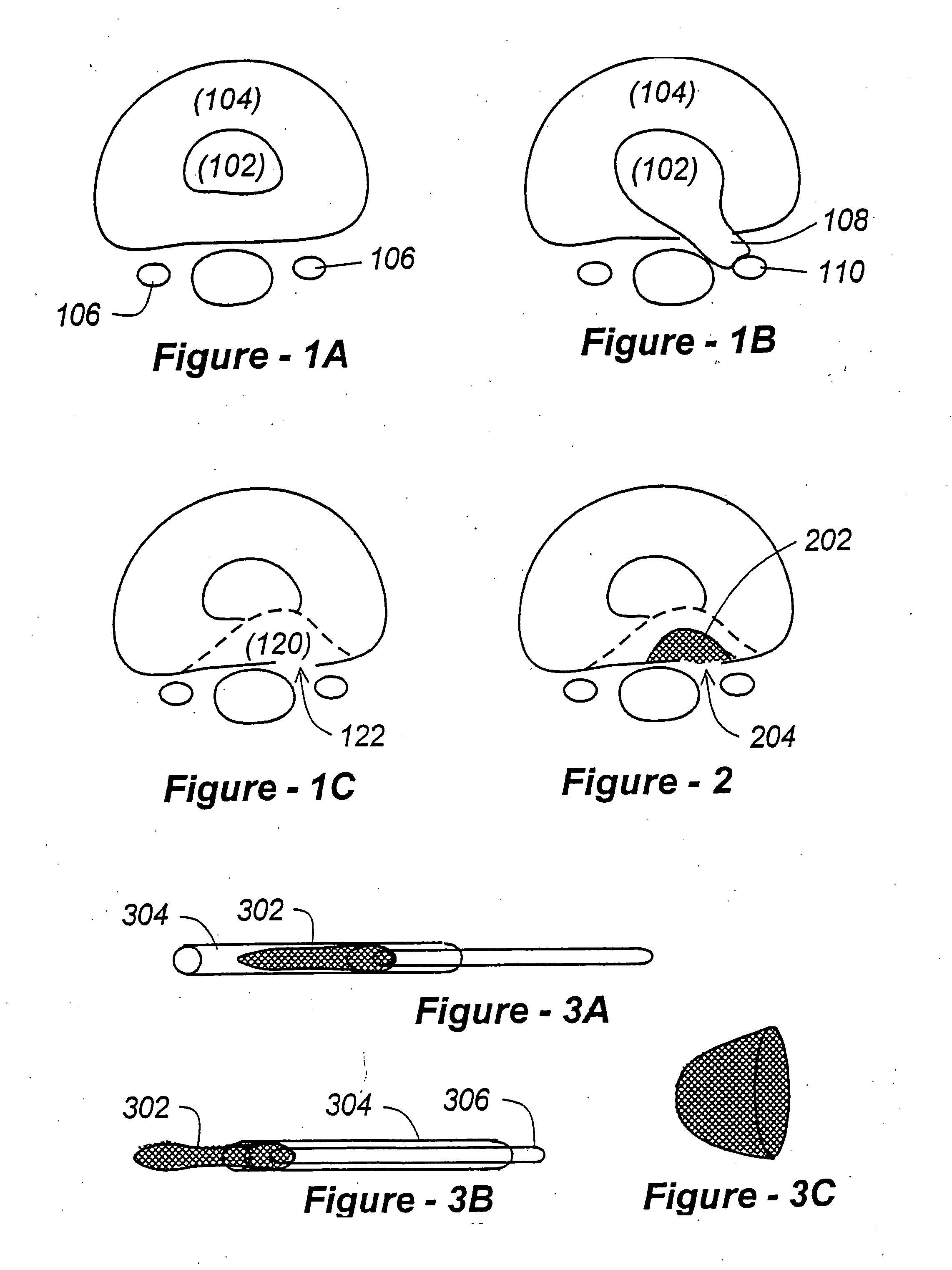

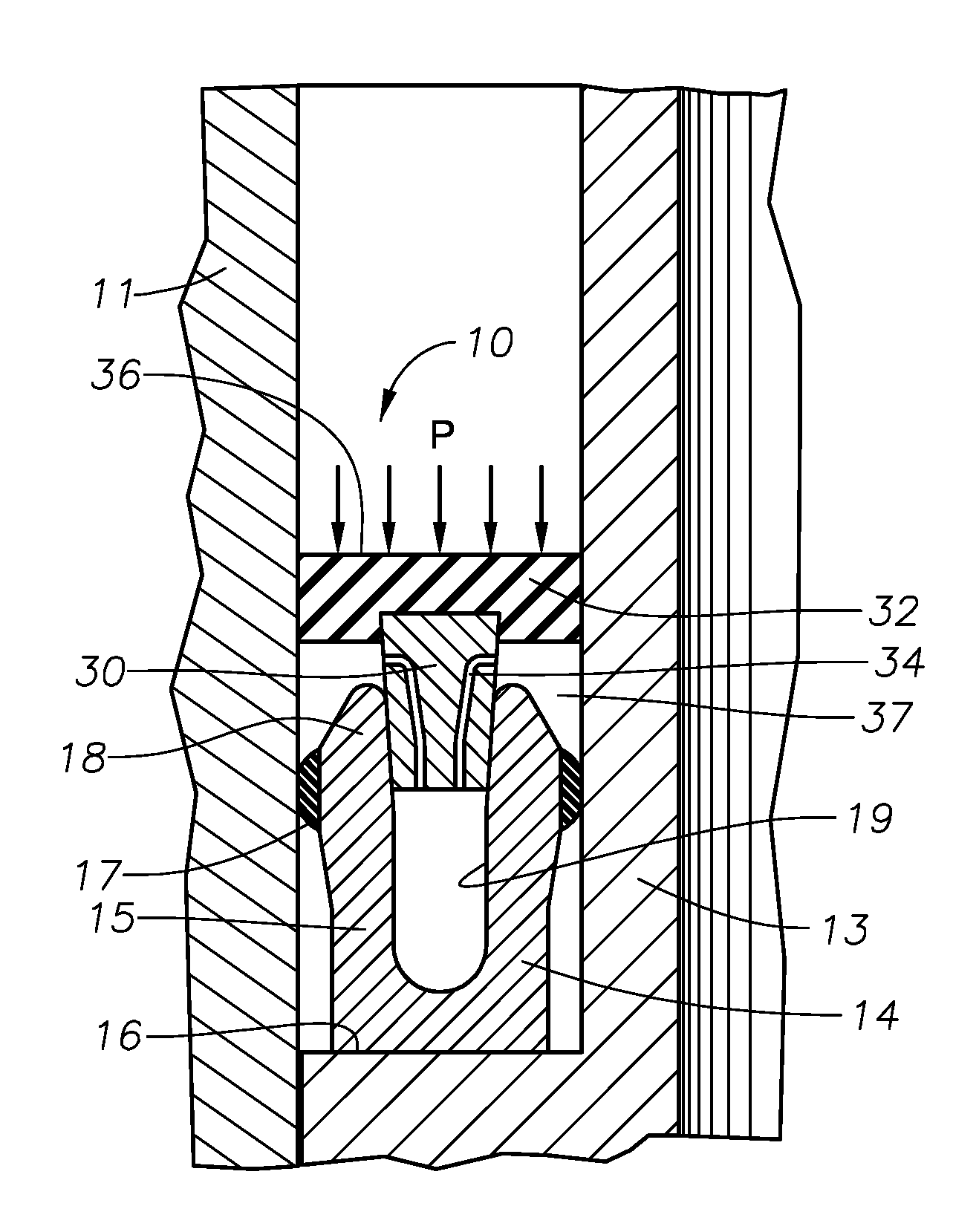

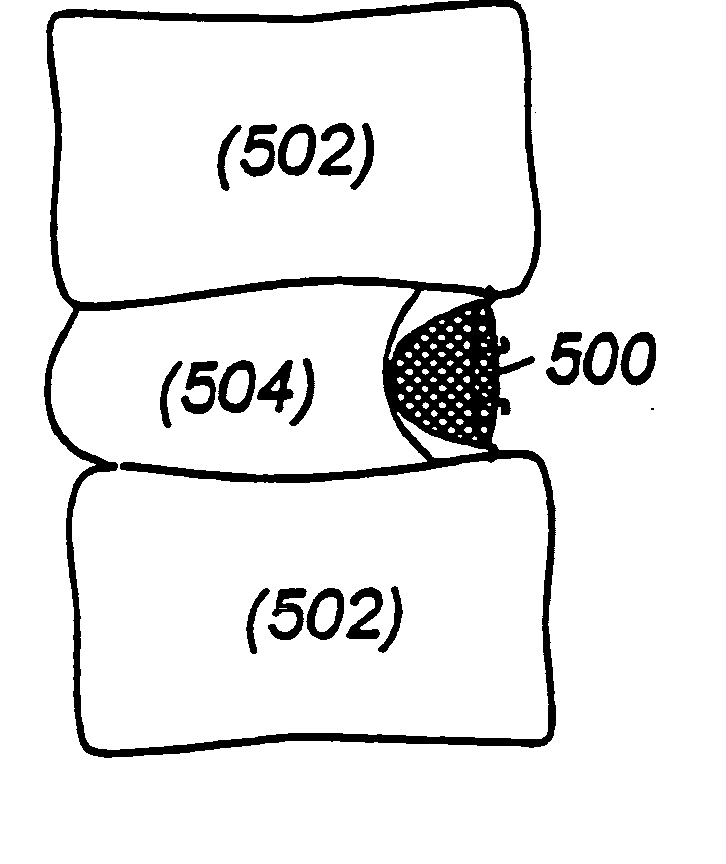

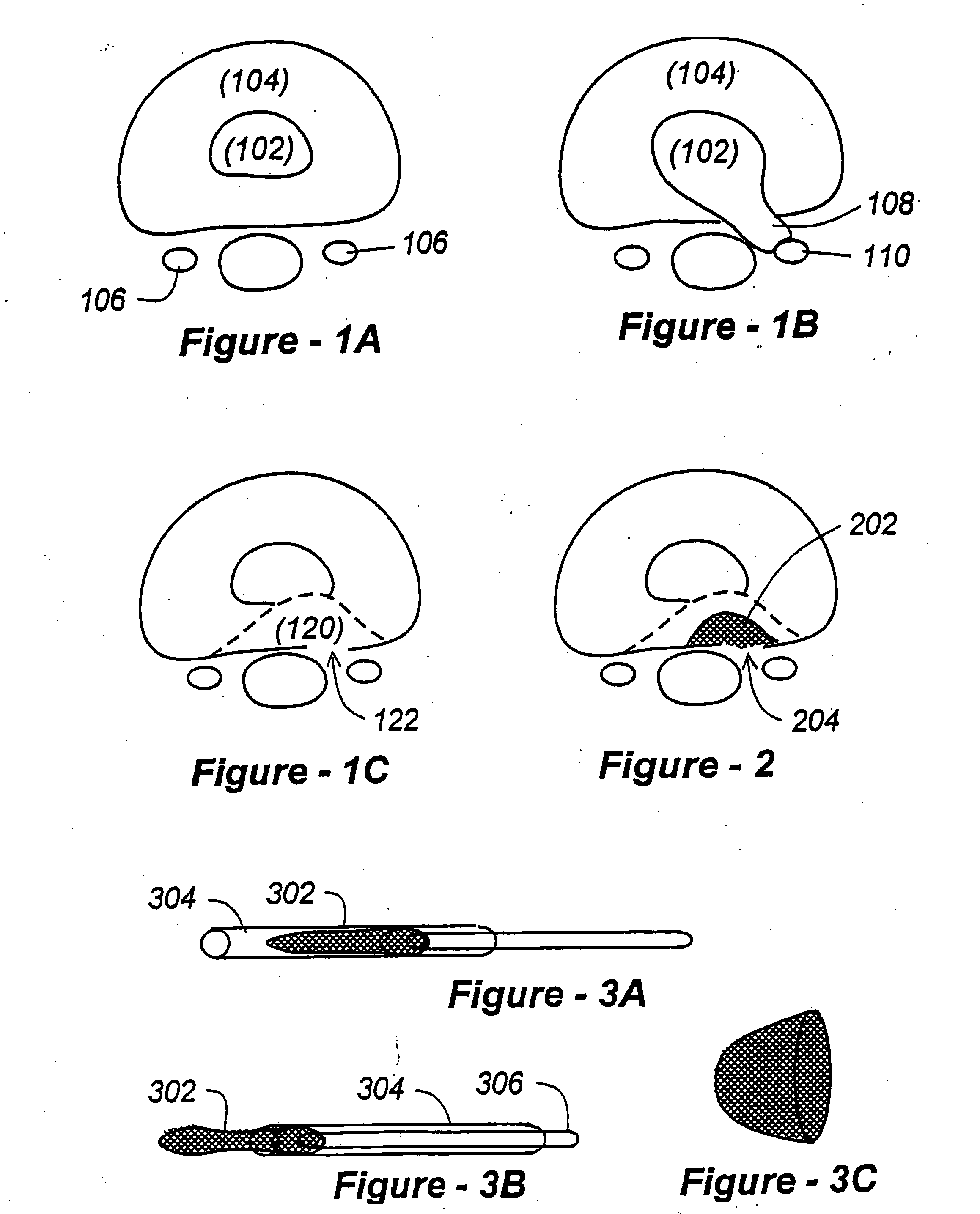

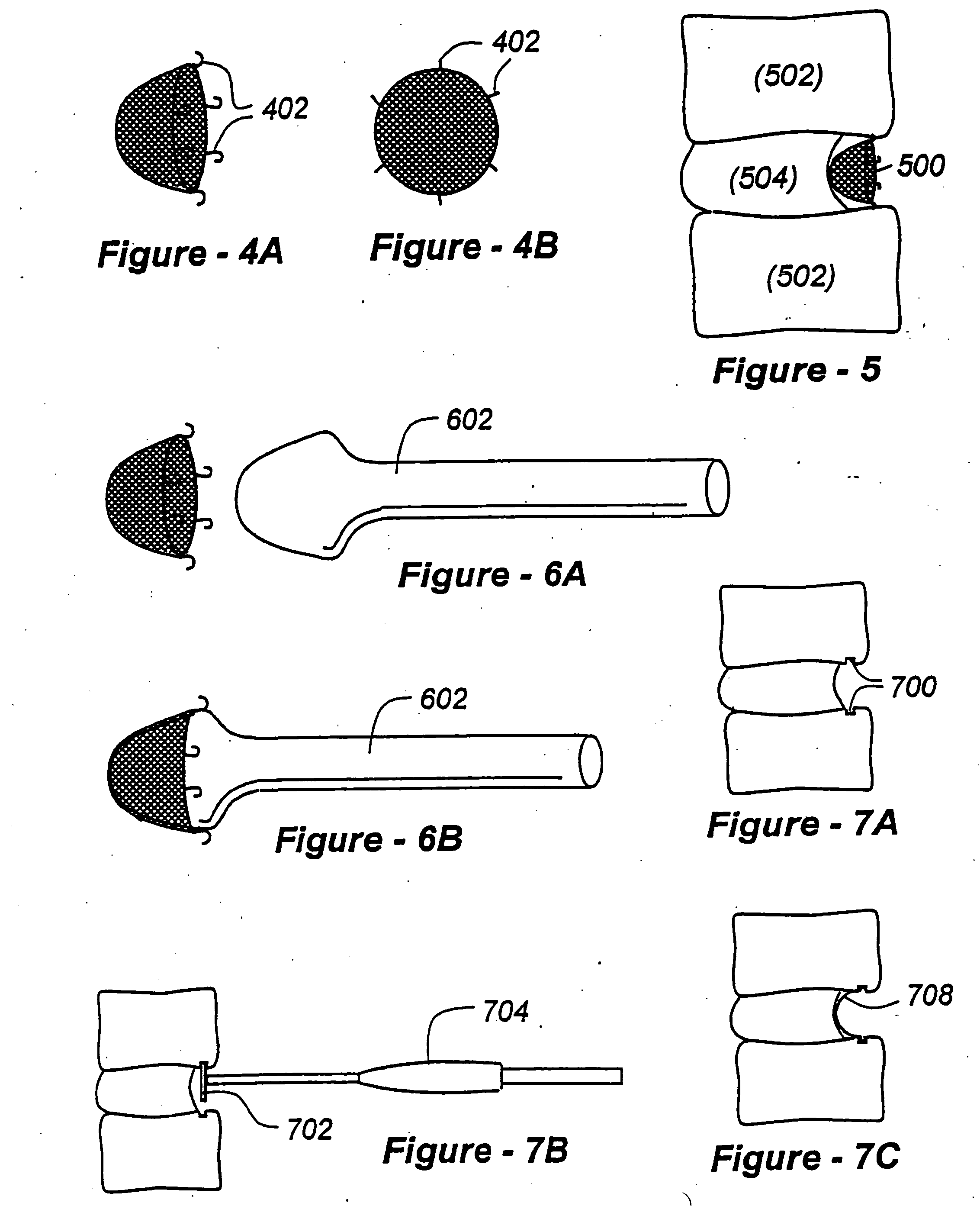

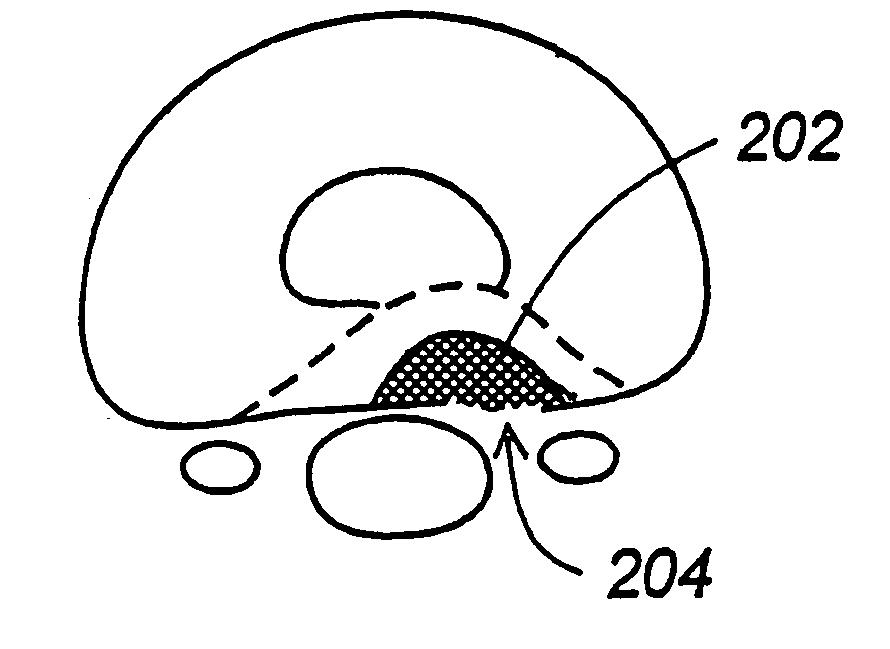

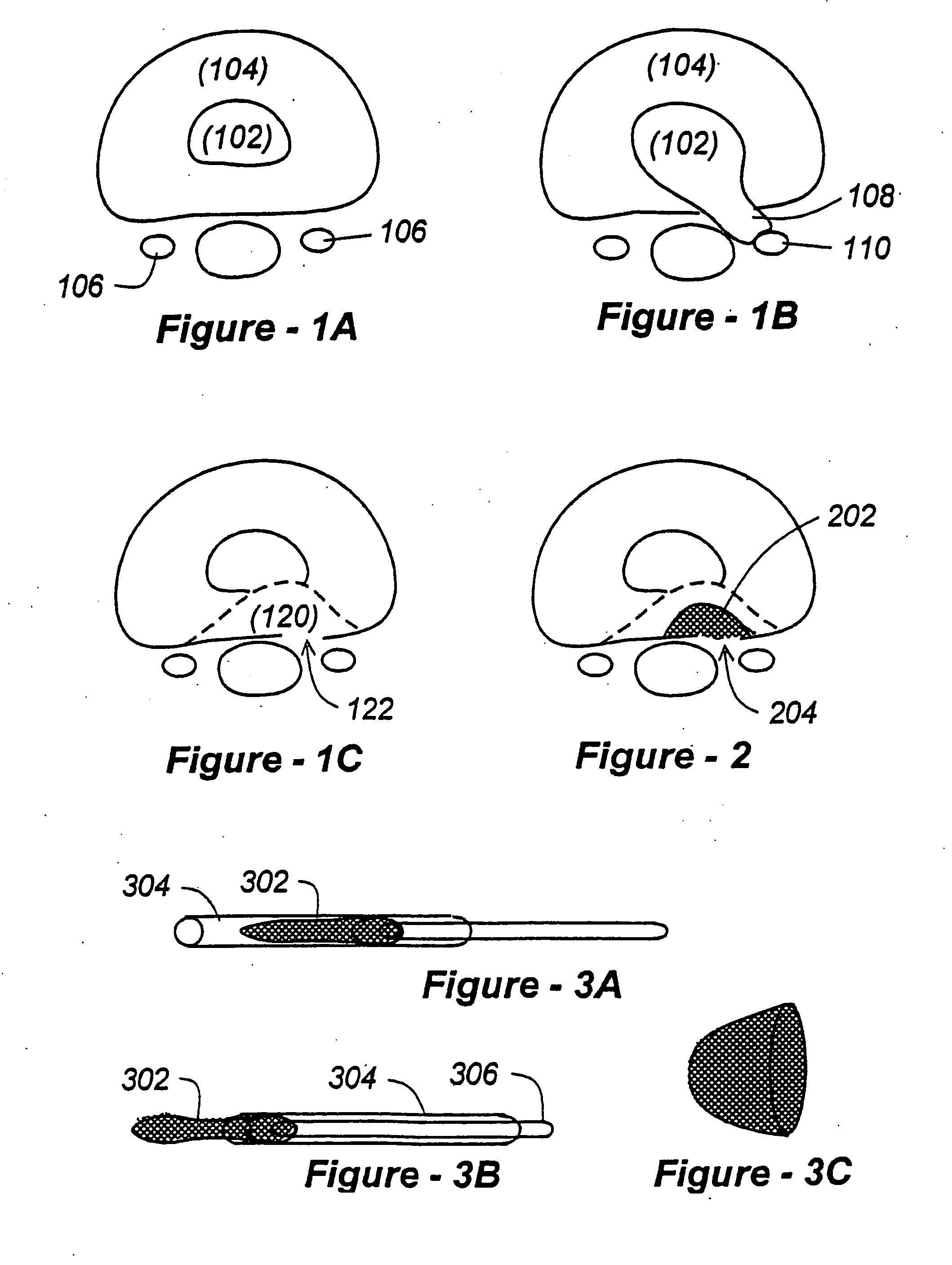

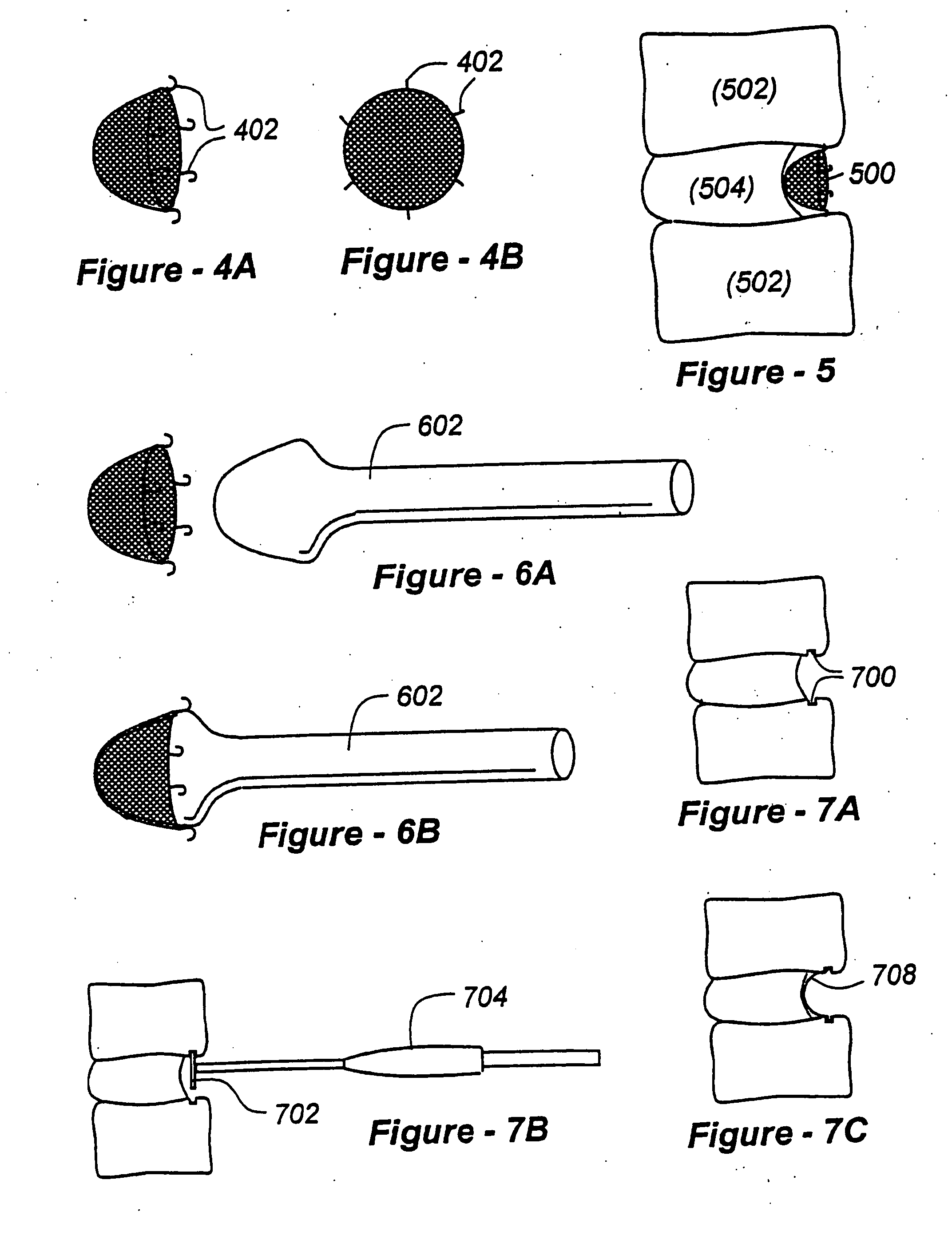

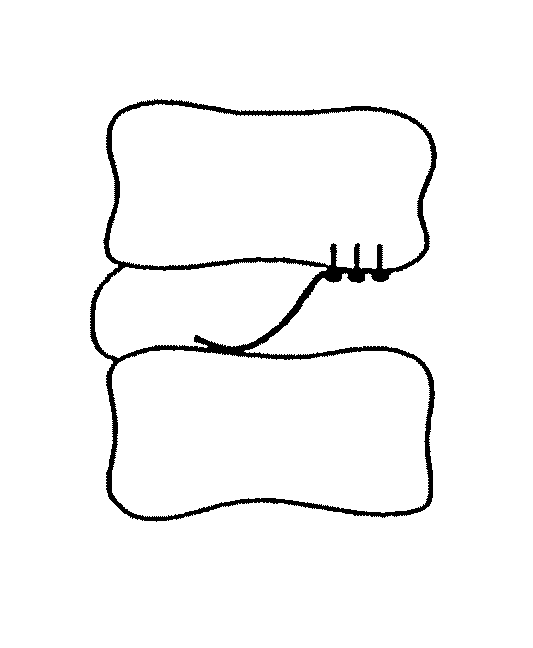

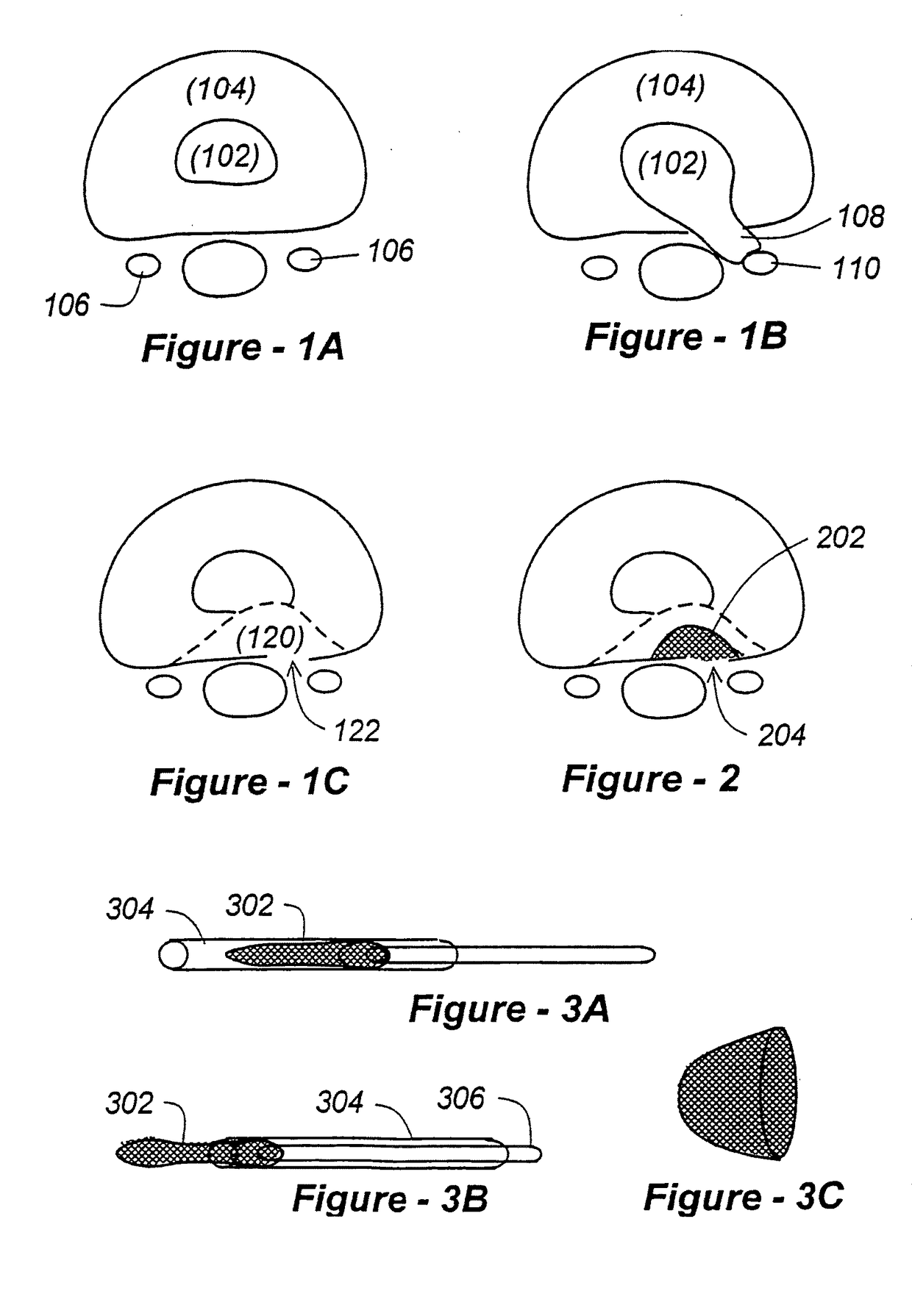

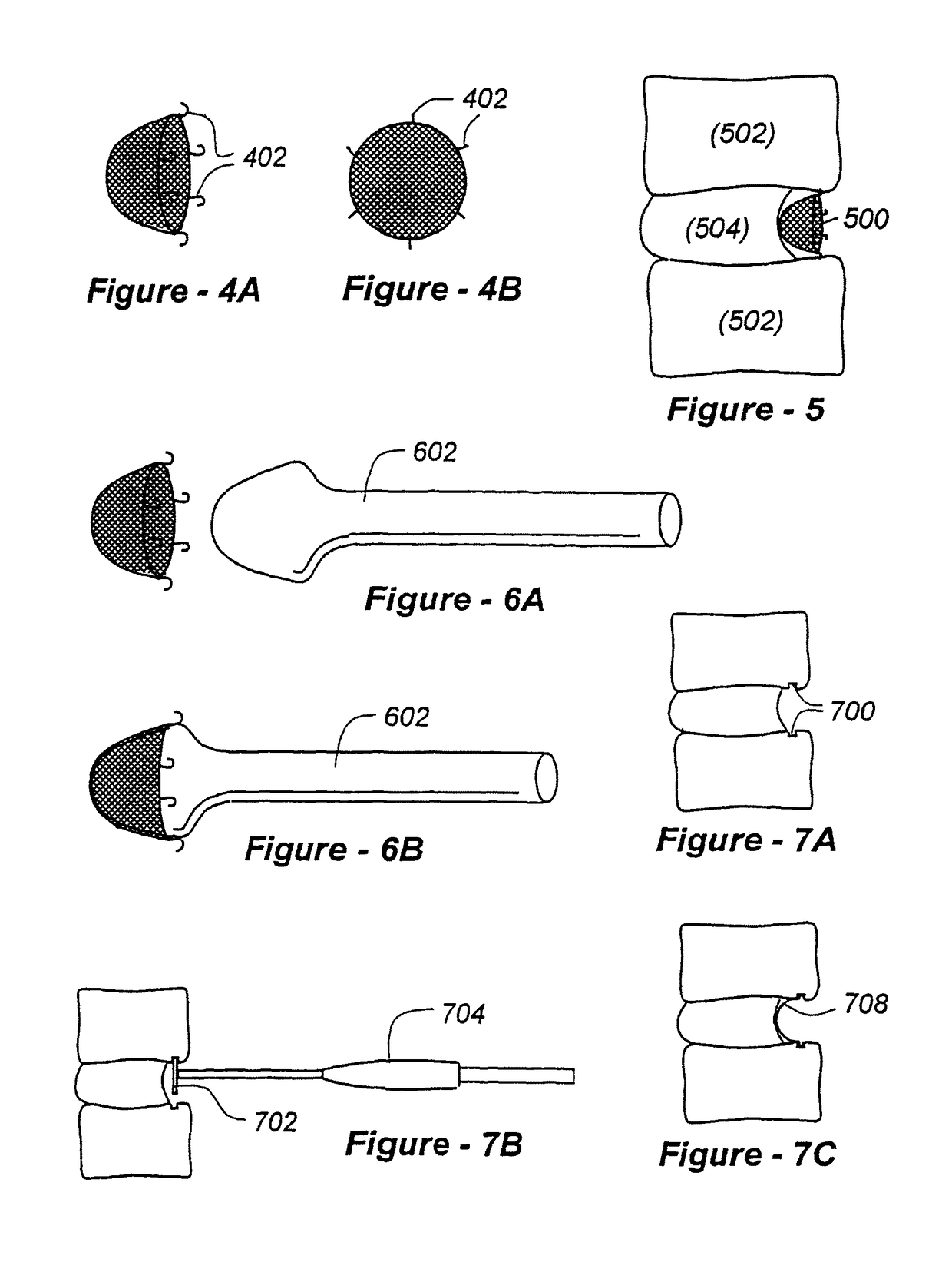

Methods for treating a defect in the annulus fibrosis

InactiveUS20070156152A1Minimized in sizeAvoiding delicateInternal osteosythesisBone implantFibrosisDiscectomy

Methods and apparatus for treating disc herniation provide a conformable device which assumes a first shape associated with insertion and a second shape or expanded shape to occlude the defect which typically follows partial discectomy. The device may take different forms according to the invention, including patches size to cover the defect or plugs adapted to fill the defect. In a preferred embodiment, however, the device is a gel or other liquid or semi-liquid which solidifies to occlude the defect from within the body of the disc itself. In another preferred embodiment, a mesh screen is collapsed into an elongated form for the purposes of insertion, thereby minimizing the size of the requisite incision while avoiding delicate surrounding nerves. Such a configuration also permits the use of instrumentation to install the device, including, for example, a hollow tube or sheath adapted to hold the collapsed screen, and a push rod to expel the collapsed device out of the sheath for use in occluding the disc defect. A device according to the invention may further include one or more anchors to assist in permanently affixing the device with respect to the defect.

Owner:ANOVA

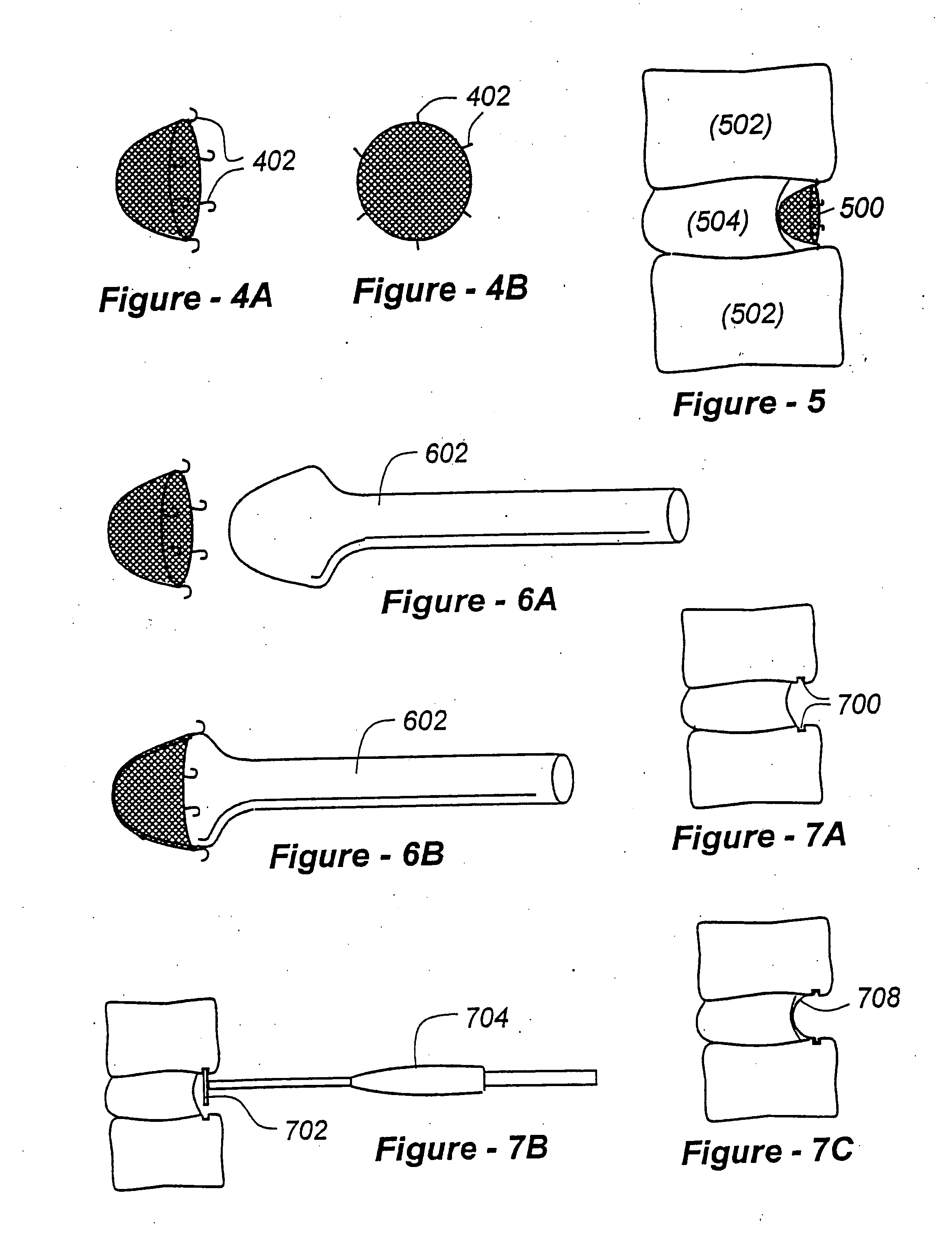

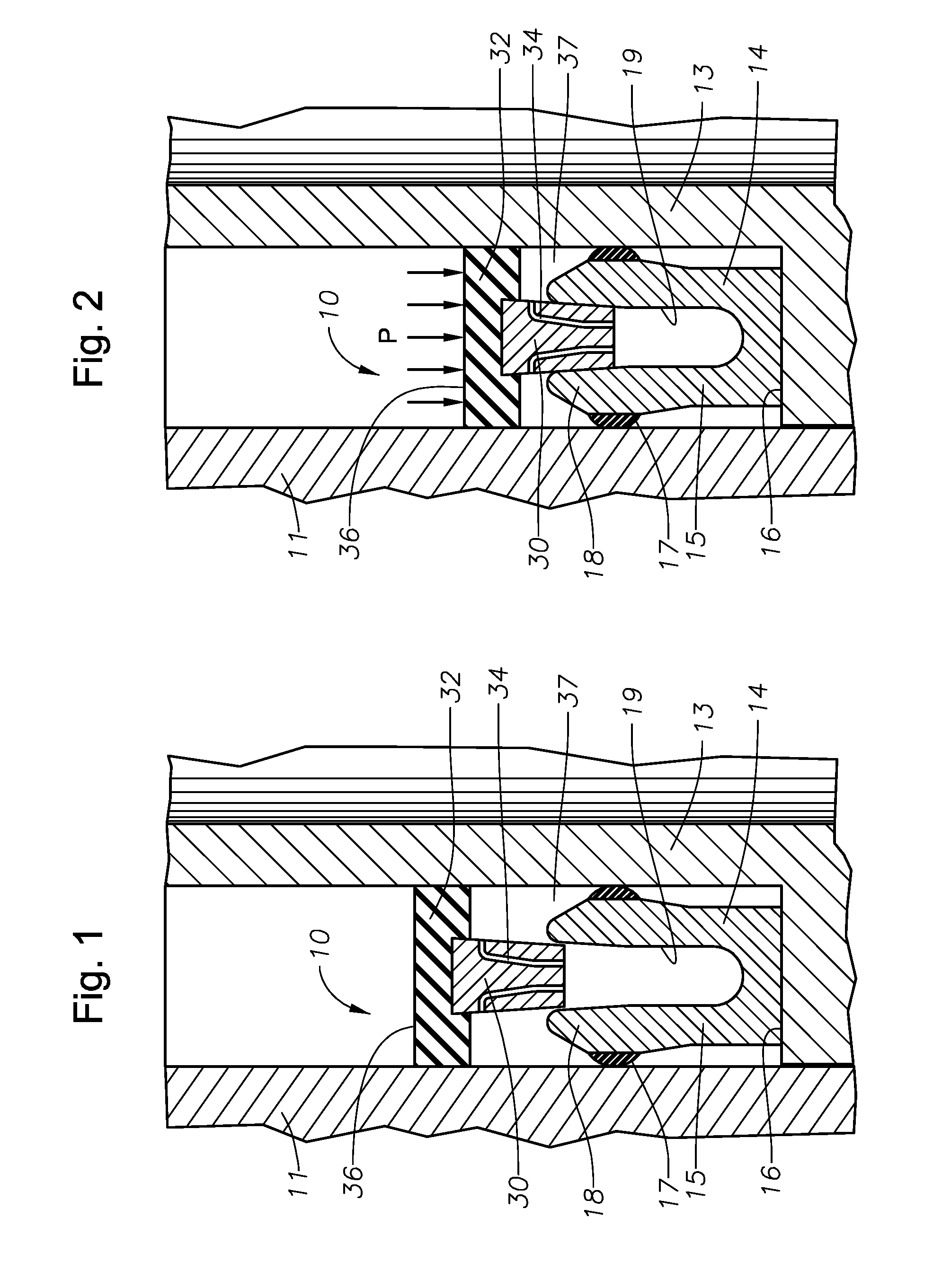

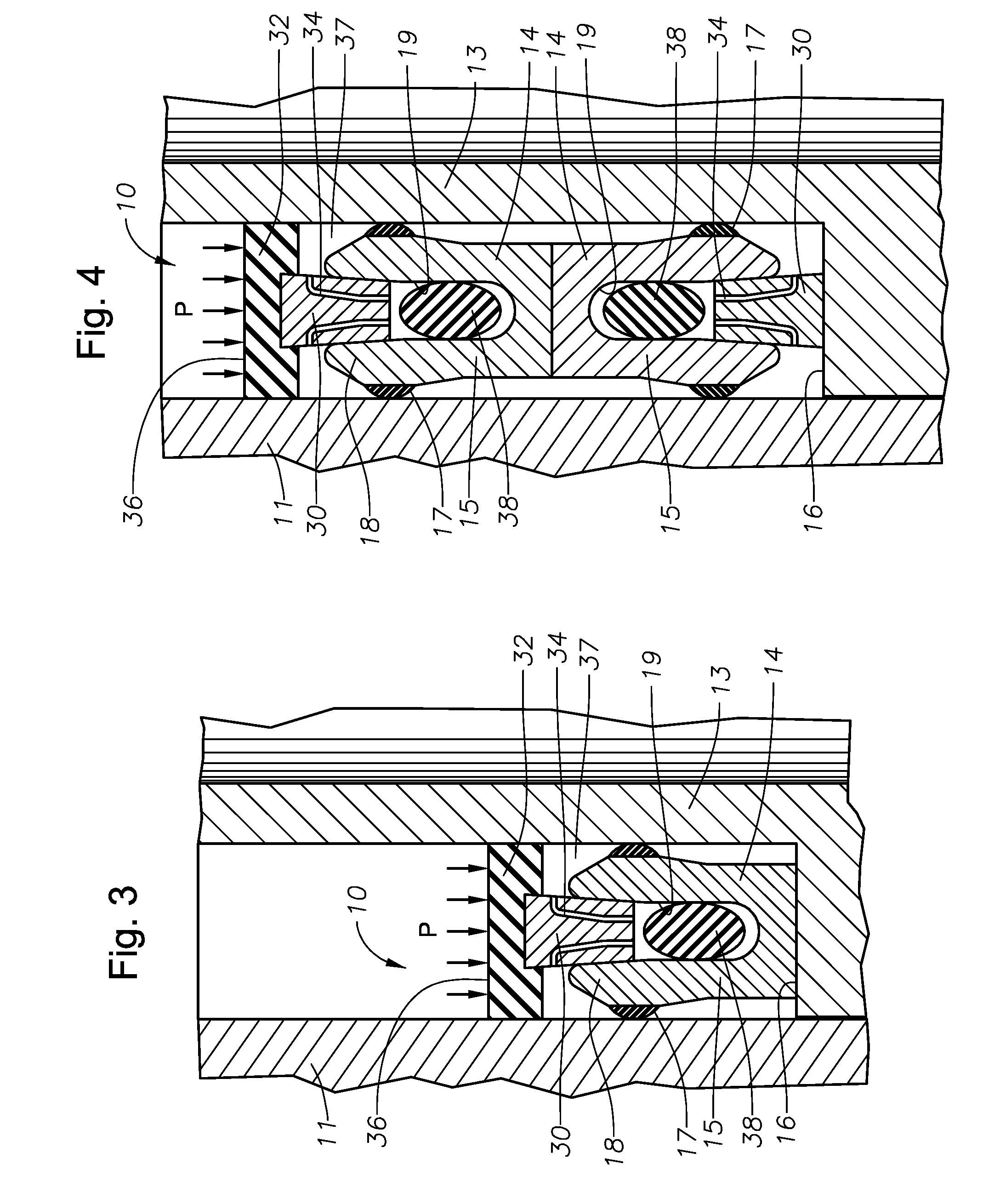

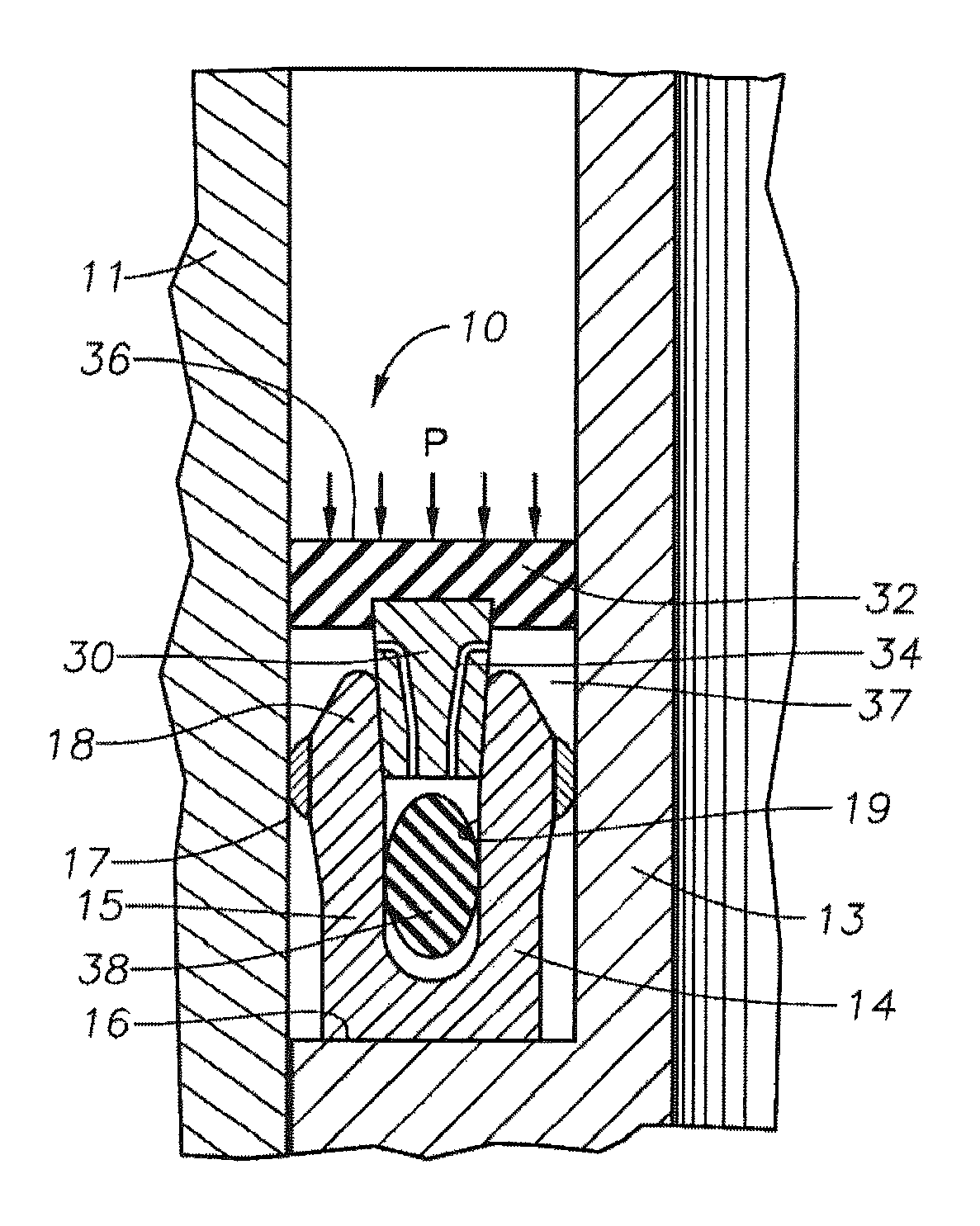

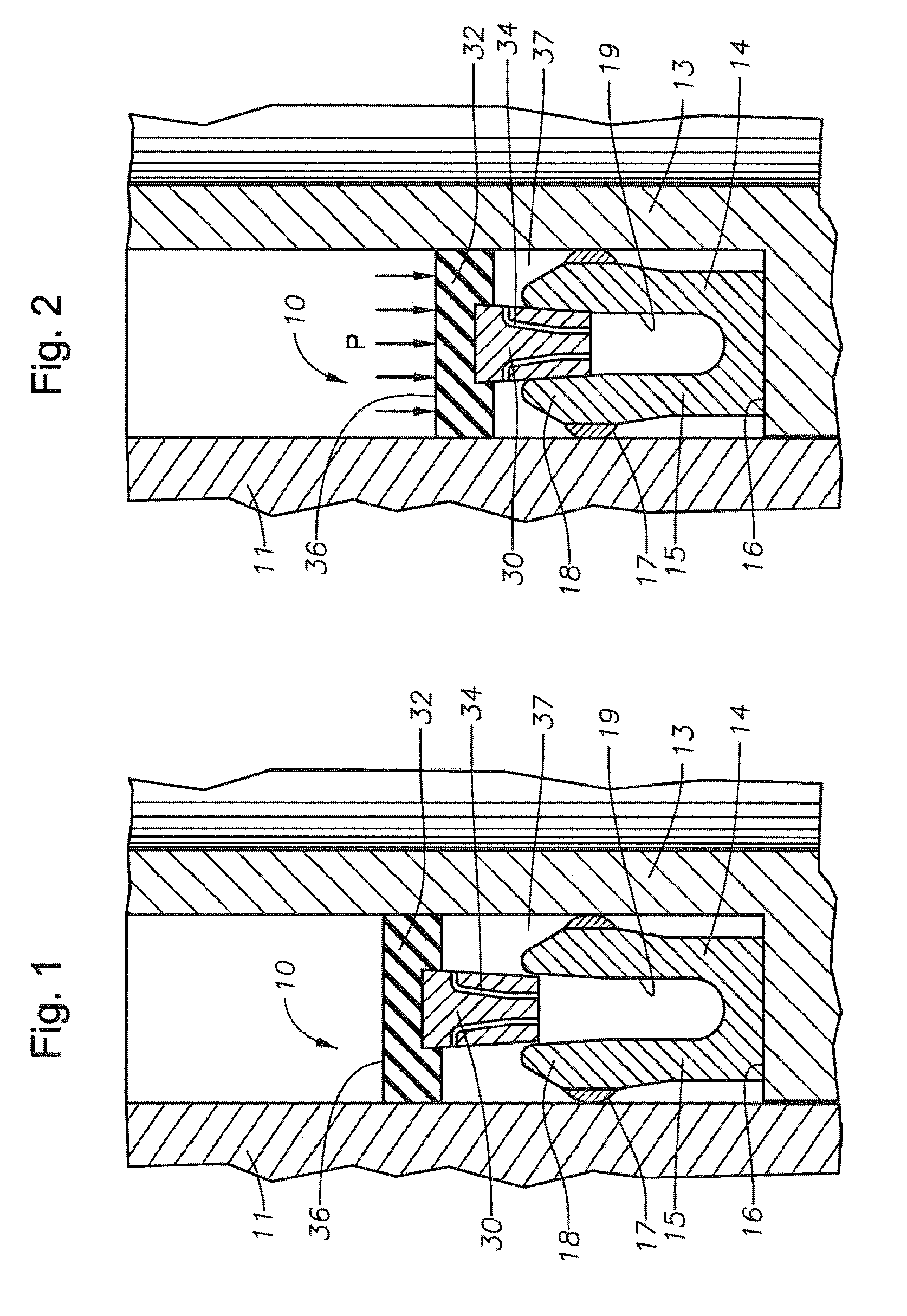

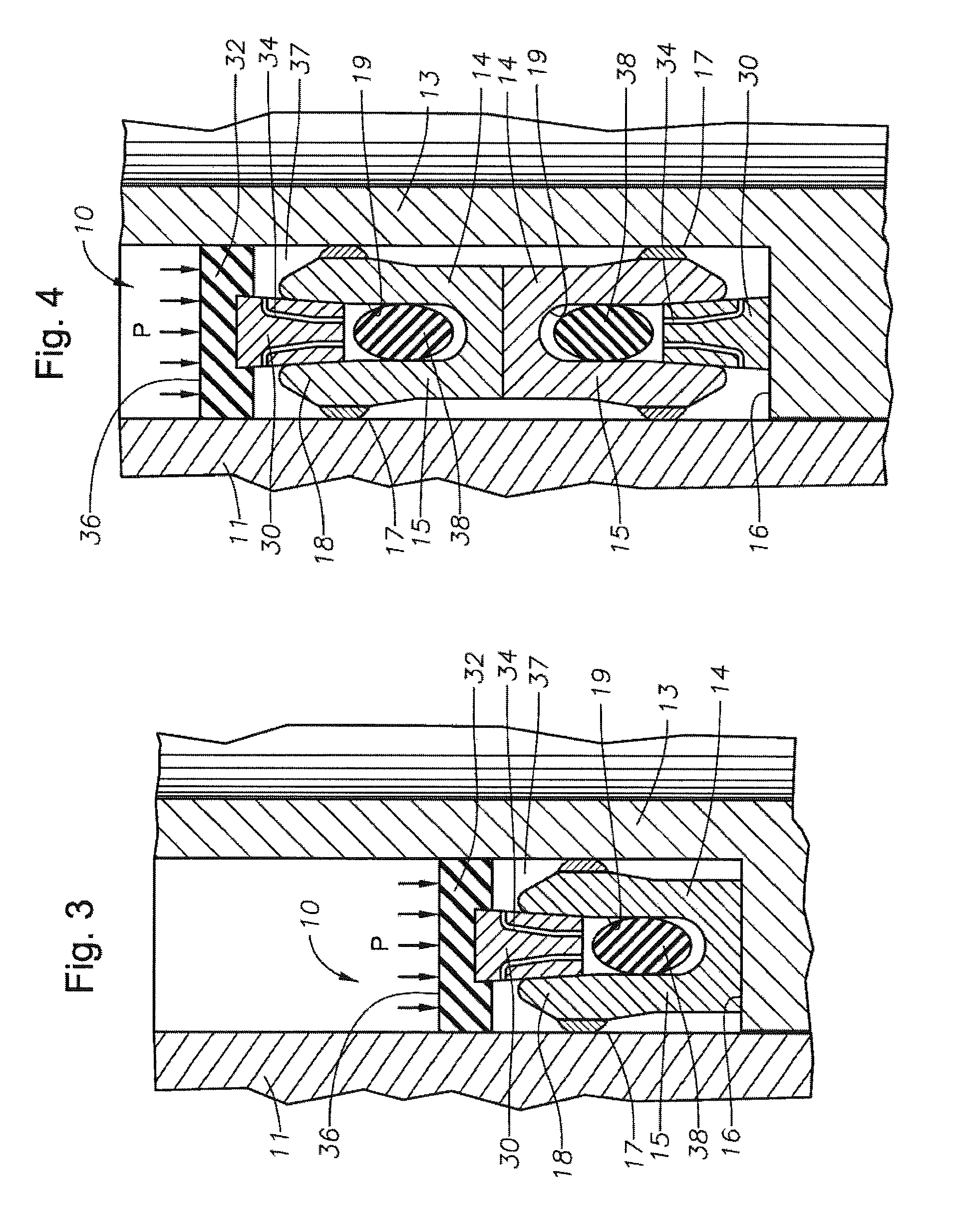

Bi-Metallic Annular Seal and Wellhead System Incorporating Same

ActiveUS20110180275A1Improve sealingImprove reliabilityConstructionsFluid removalEngineeringFilling defect

A wellhead seal assembly that forms a metal-to-metal seal between inner and outer wellhead members. A bi-metallic U-shaped seal with legs having a low yield metal on the outer portions. During installation of the seal assembly, the legs of the seal are forced outward against the surfaces of the wellhead members, by pressurization of a interim non-metallic seal which forces a wedge into the U-shaped seal, causing localized yielding of the low yield metal to fill defects on wellhead member surfaces.

Owner:VETCO GRAY

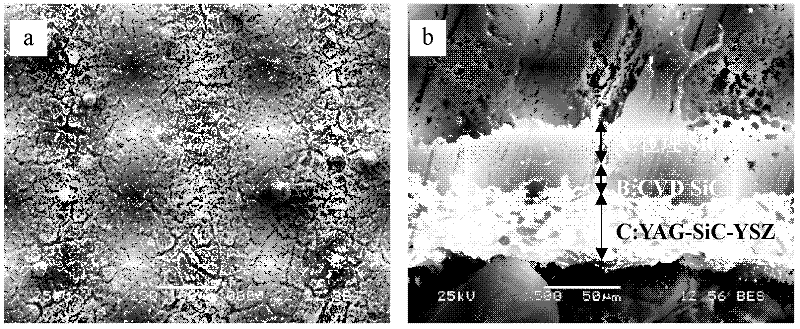

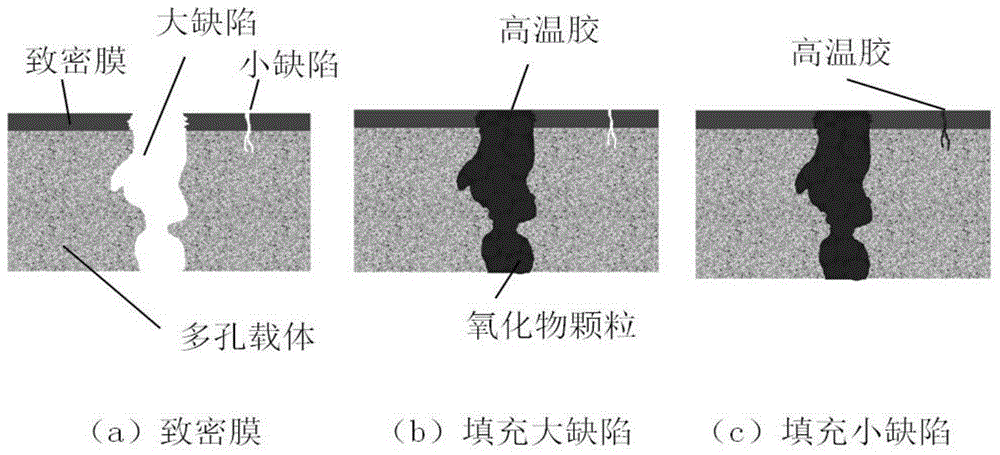

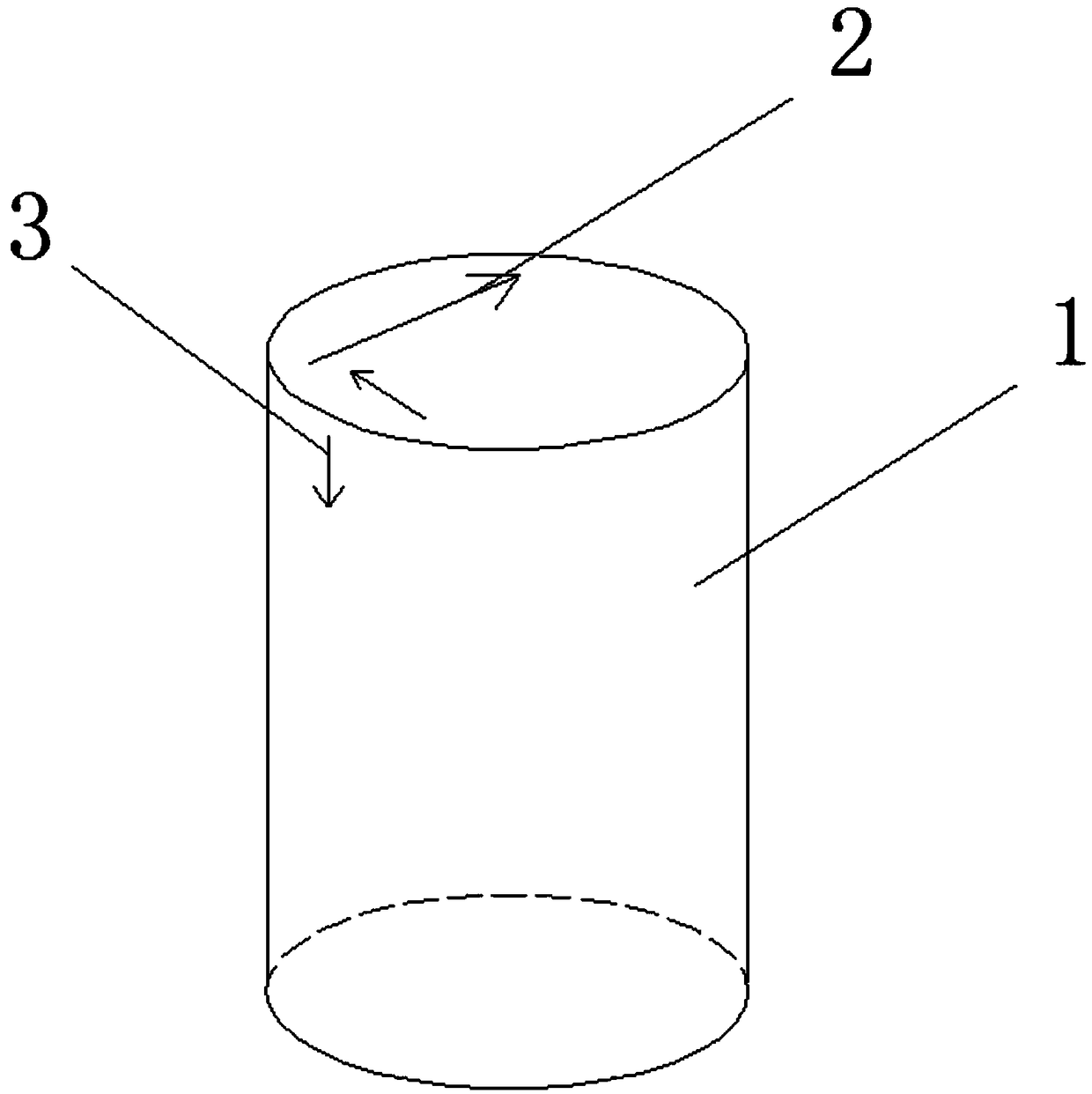

Long-term high-temperature oxidation-resistant multi-element composite ceramic coating for carbon/carbon composite material and preparation and application methods thereof

The invention provides a long-term high-temperature oxidation-resistant multi-element composite ceramic coating for a carbon / carbon composite material and preparation and application methods thereof. The long-term high-temperature oxidation-resistant multi-element composite ceramic coating is a composite coating on the surface of the carbon / carbon composite material and sequentially (from inside to outside) comprises a SiC connection layer prepared with an embedding method, a SiC sealing layer prepared with a chemical vapor deposition method and a SiO2-Y2Si2O7-ZrSiO4-Al2SiO5 ceramic layer prepared with a brush coating method and an in-situ oxidation reaction method, wherein the SiC connection layer is combined with a matrix and exerts the function of connecting the matrix, the SiC sealinglayer exerts the function of filling defects of an inner layer, and the outermost SiO2-Y2Si2O7-ZrSiO4-Al2SiO5 ceramic layer serves as an oxygen blocking layer and exerts the function of self-healing and oxygen blocking. The long-term high-temperature oxidation-resistant multi-element composite ceramic coating has the advantages of firmness in combination with the matrix, no run-through crack, long-term high-temperature oxidation resistance, and capability of being completely applied to the preparation of non-direct-ablation heat-resistant structural members around the head and of the wings ofa hypersonic aircraft and the preparation of a material for the tailpipe chamber of an aircraft engine.

Owner:CENT SOUTH UNIV

Methods and apparatus for treating disc herniation and preventing the extrusion of interbody bone graft

InactiveUS20060247665A1Minimized in sizeAvoiding delicateBone implantJoint implantsMedicineIntervertebral disc

Methods and apparatus for treating disc herniation provide a conformable device which assumes a first shape associated with insertion and a second shape or expanded shape to occlude the defect which typically follows partial discectomy. The device may take different forms according to the invention, including patches size to cover the defect or plugs adapted to fill the defect. In a preferred embodiment, however, the device is a gel or other liquid or semi-liquid which solidifies to occlude the defect from within the body of the disc itself. In another preferred embodiment, a mesh screen is collapsed into an elongated form for the purposes of insertion, thereby minimizing the size of the requisite incision while avoiding delicate surrounding nerves. Such a configuration also permits the use of instrumentation to install the device, including, for example, a hollow tube or sheath adapted to hold the collapsed screen, and a push rod to expel the collapsed device out of the sheath for use in occluding the disc defect. A device according to the invention may further include one or more anchors to assist in permanently affixing the device with respect to the defect.

Owner:ANOVA

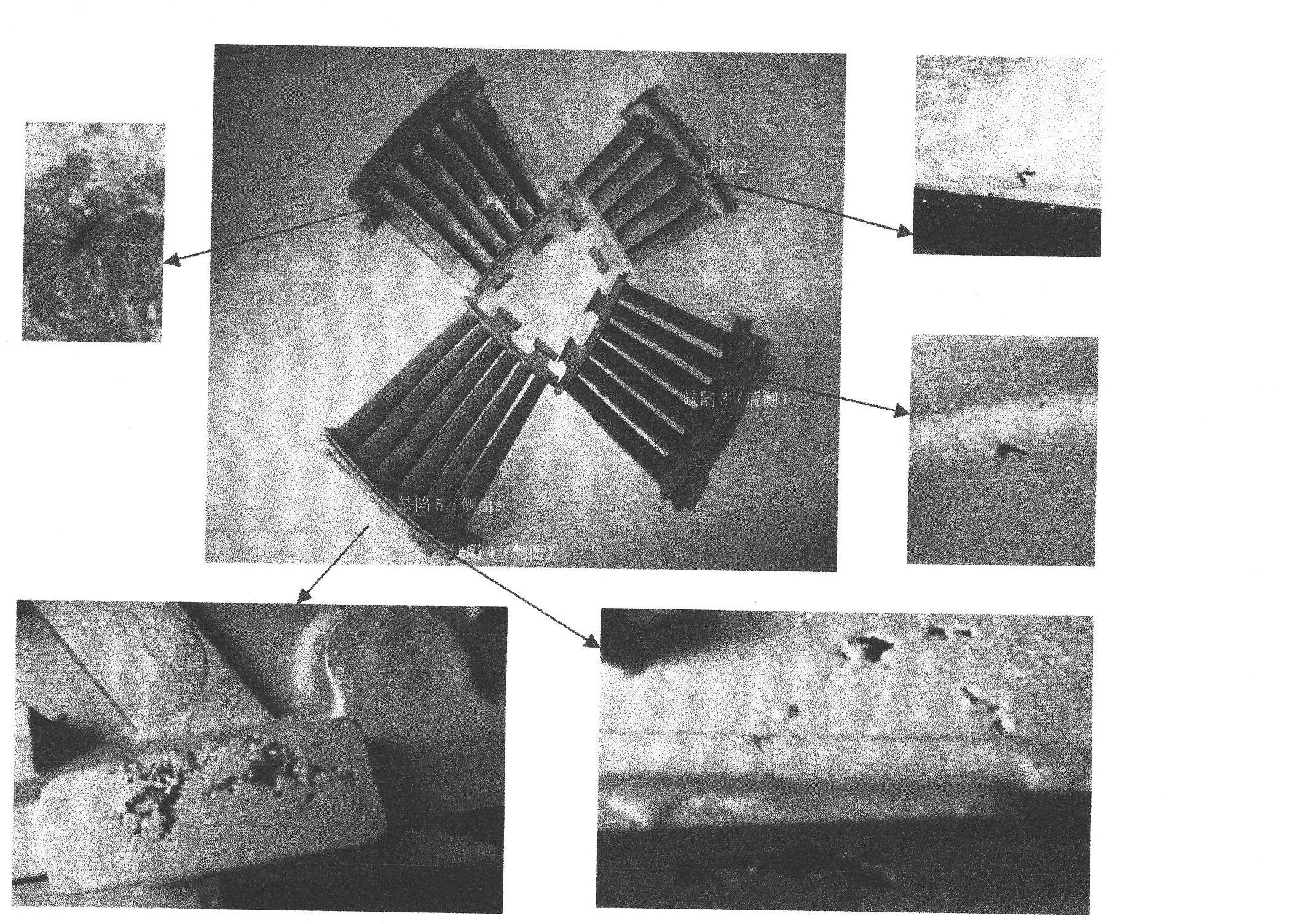

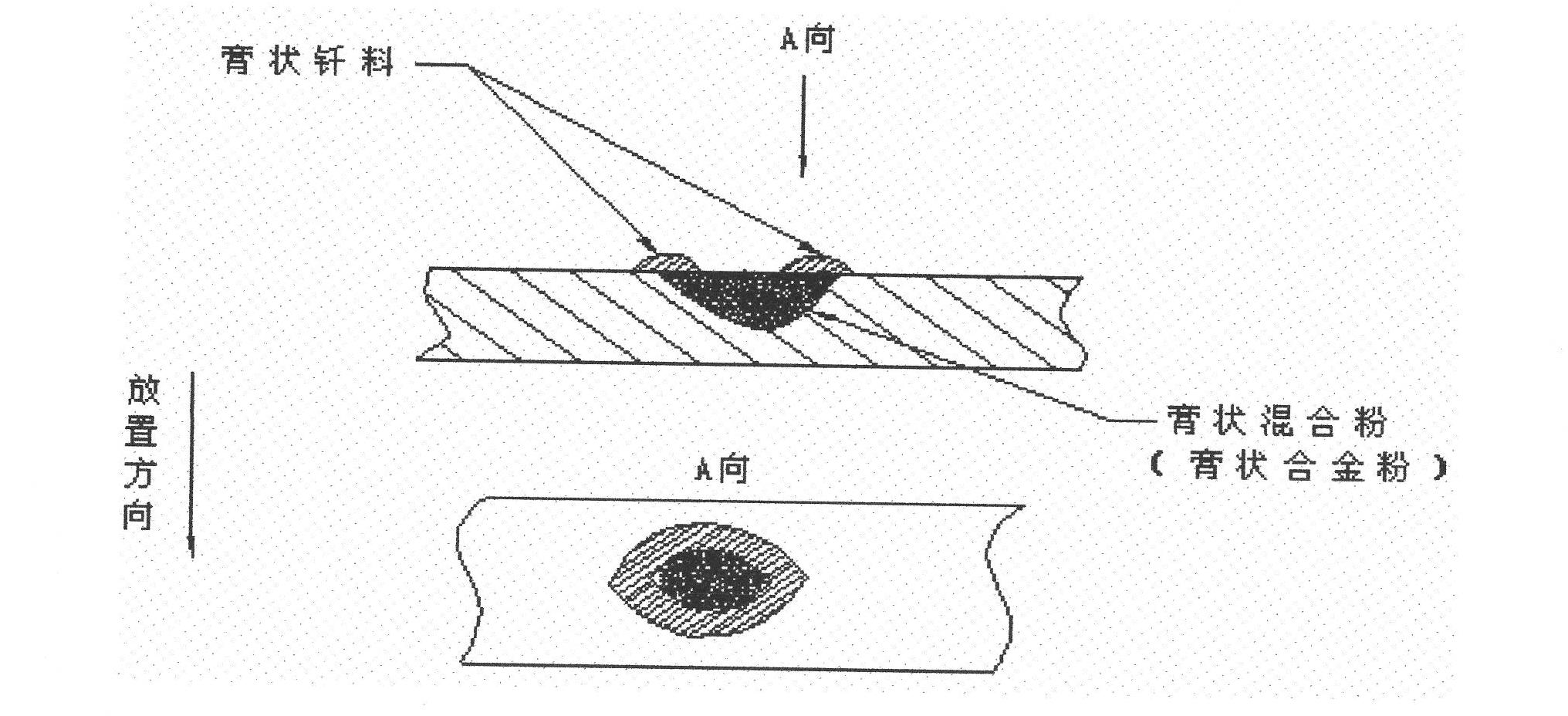

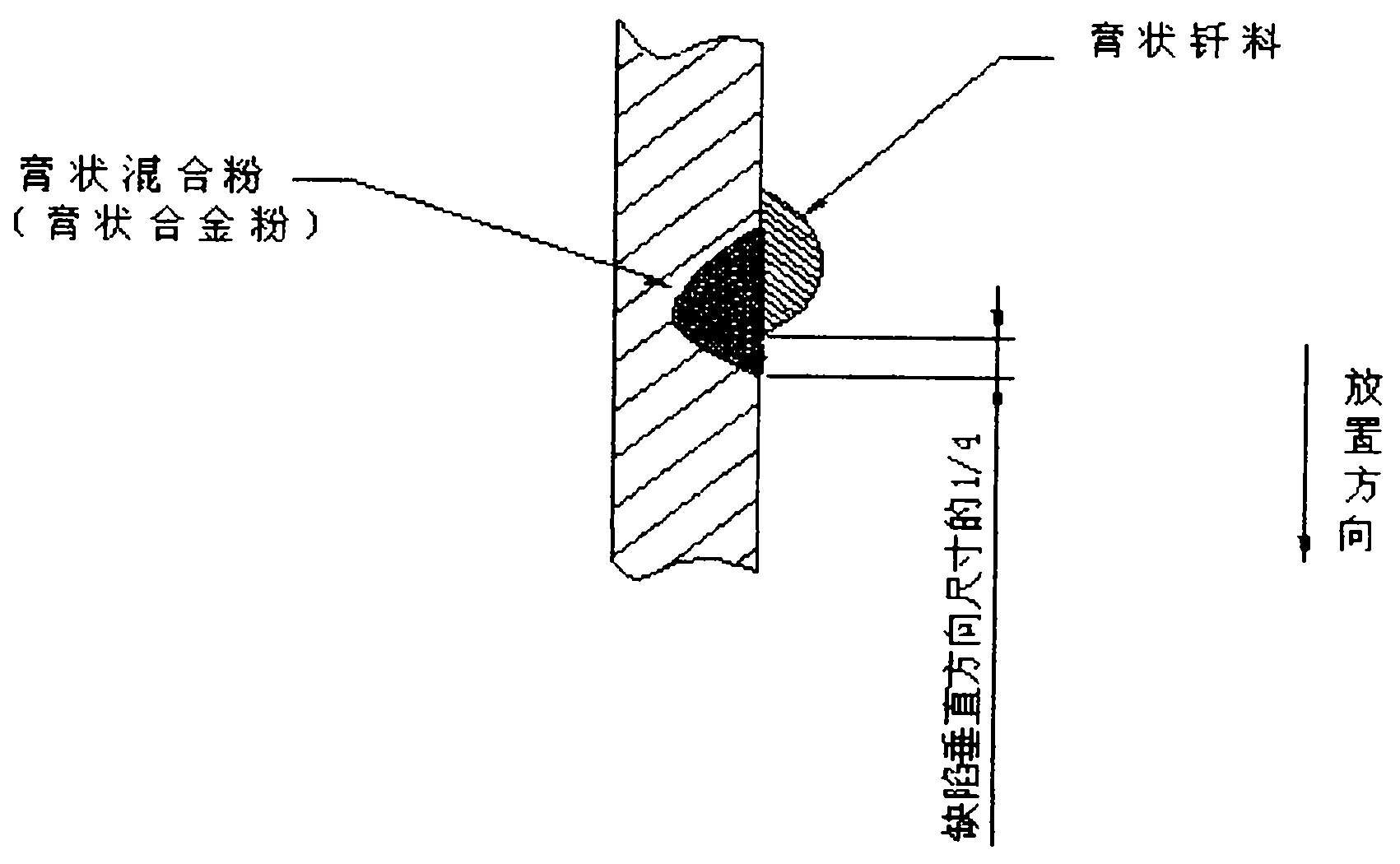

Repairing method for defects of turbine guide blade

ActiveCN102107306AImprove pass rateAvoid crackingWelding/cutting media/materialsSoldering mediaPass rateEconomic benefits

The invention relates to a repairing method for defects of a turbine guide blade. The method comprises the following steps: filling the defects with paste alloy powder or paste mixed powder; then coating paste brazing filler metal around the filled defects; drying the filler; and carrying out the repairing operation: putting the blade in a vacuum furnace, and performing repairing and brazing by adopting the vacuum brazing technology. The repairing method for defects of the turbine guide blade provided by the invention effectively prevents flaws; the property of the brazing technology and the mechanical property of the repaired parts meet the requirements; the molded surface of the blade and the accuracy of all sizes and positions completely meet the requirements. Therefore, the passing rate of the cast blades is improved, the cost is reduced, and remarkable economic benefits are created.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

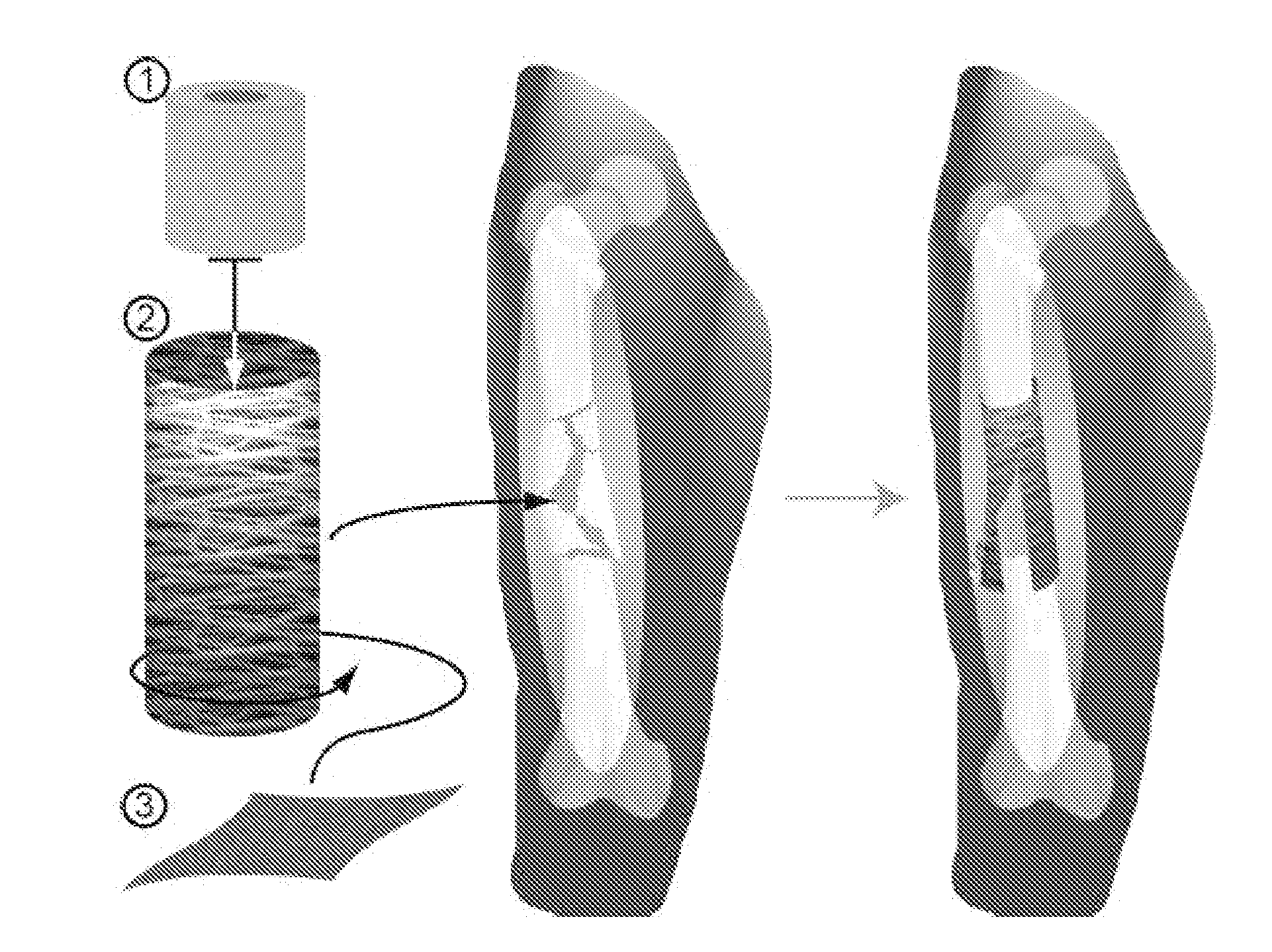

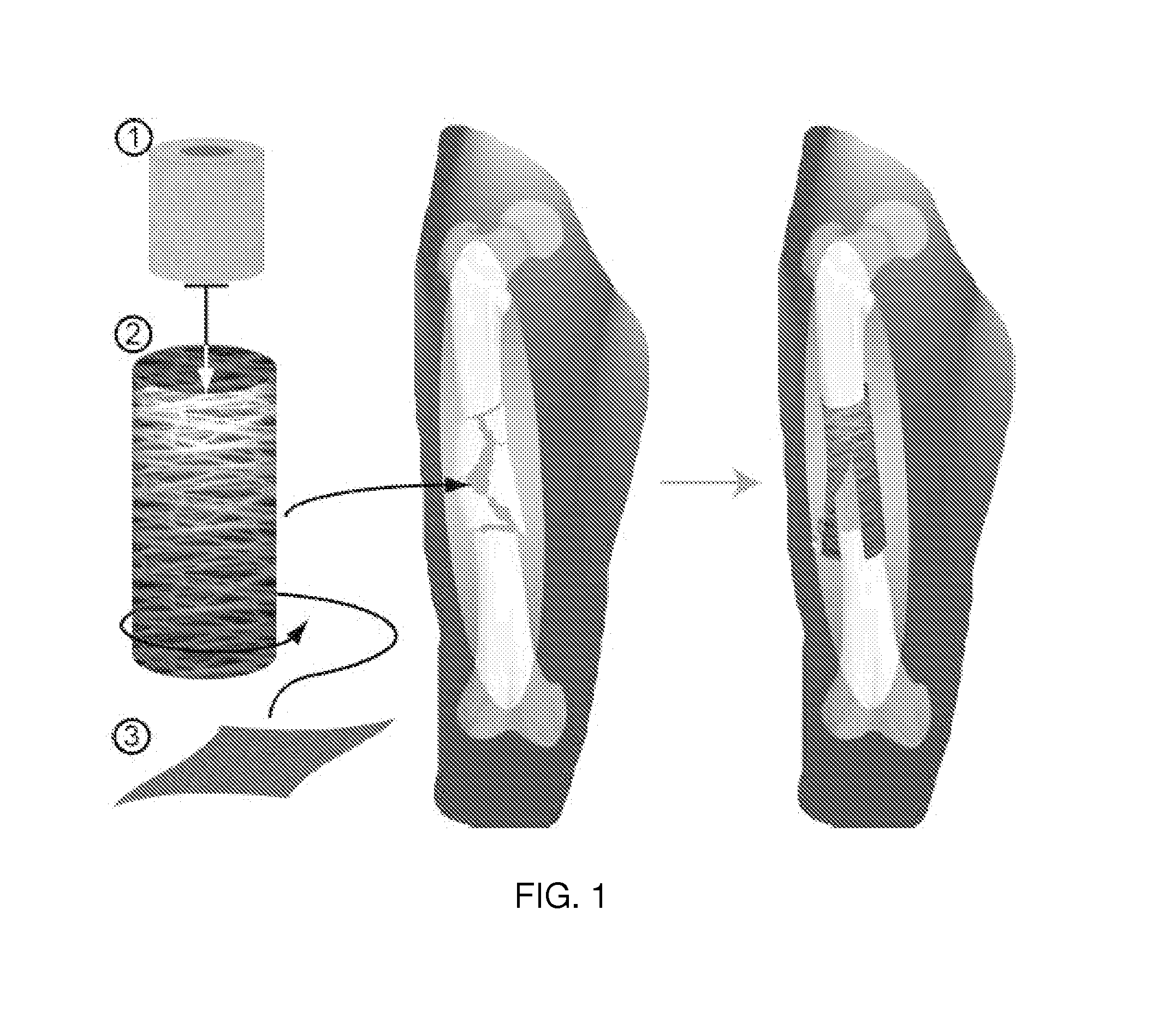

Shape-memory-actuated materials for accelerated healing of orthopedic injuries

ActiveUS20160135955A1Easy to operateClear processBone implantPharmaceutical delivery mechanismOsseointegrationBone defect

A three component system for repairing critically sized bone defects having a first shape memory polymer (SMP) component formed as a scaffold that fills the defects, a second SMP component formed as a restricting sleeve that stabilizes and supports osseointegration and osteoconduction, and a third SMP component formed as a two-dimensional cell culture substate for engineering periosteal grafts.

Owner:SYRACUSE UNIVERSITY

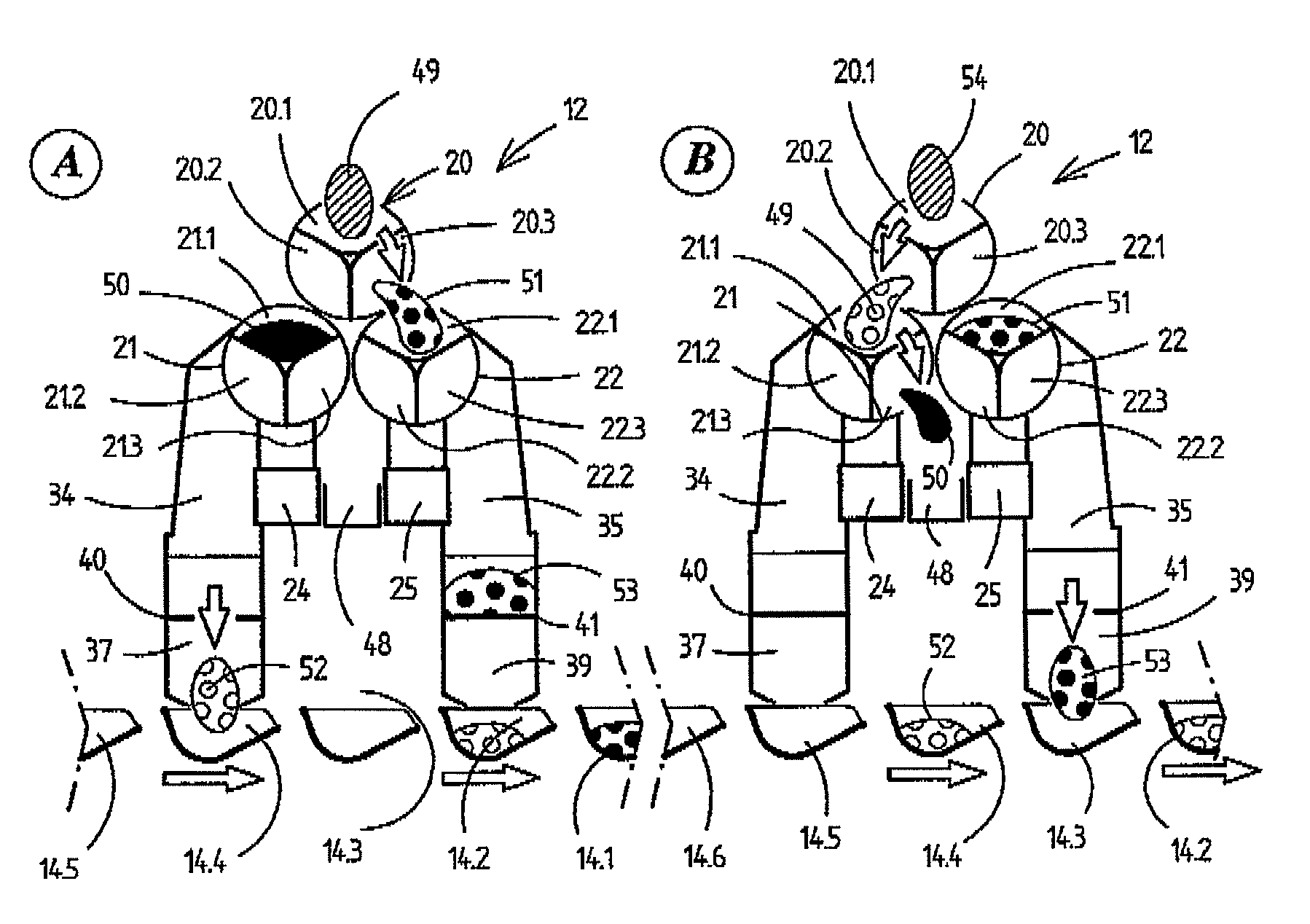

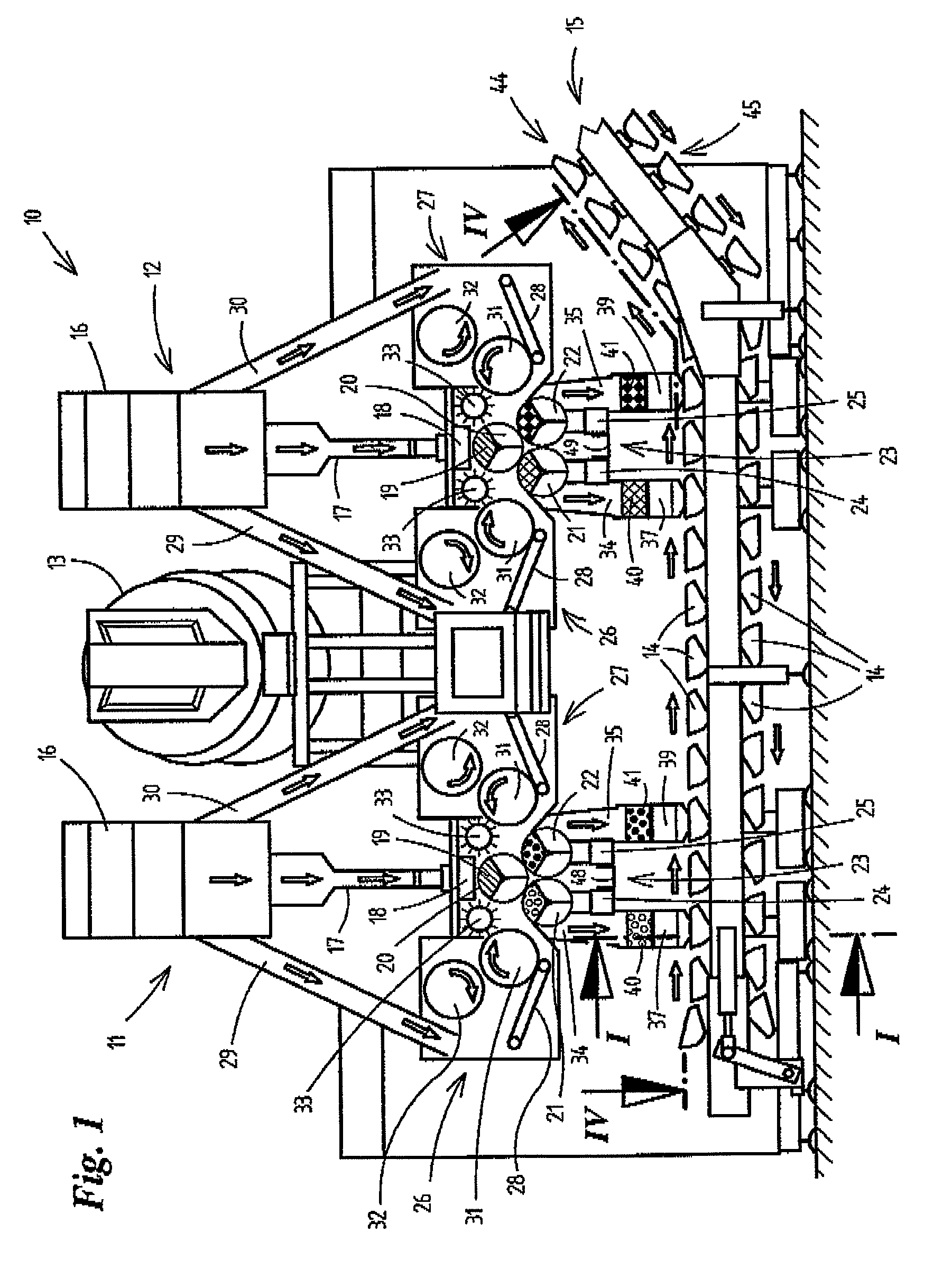

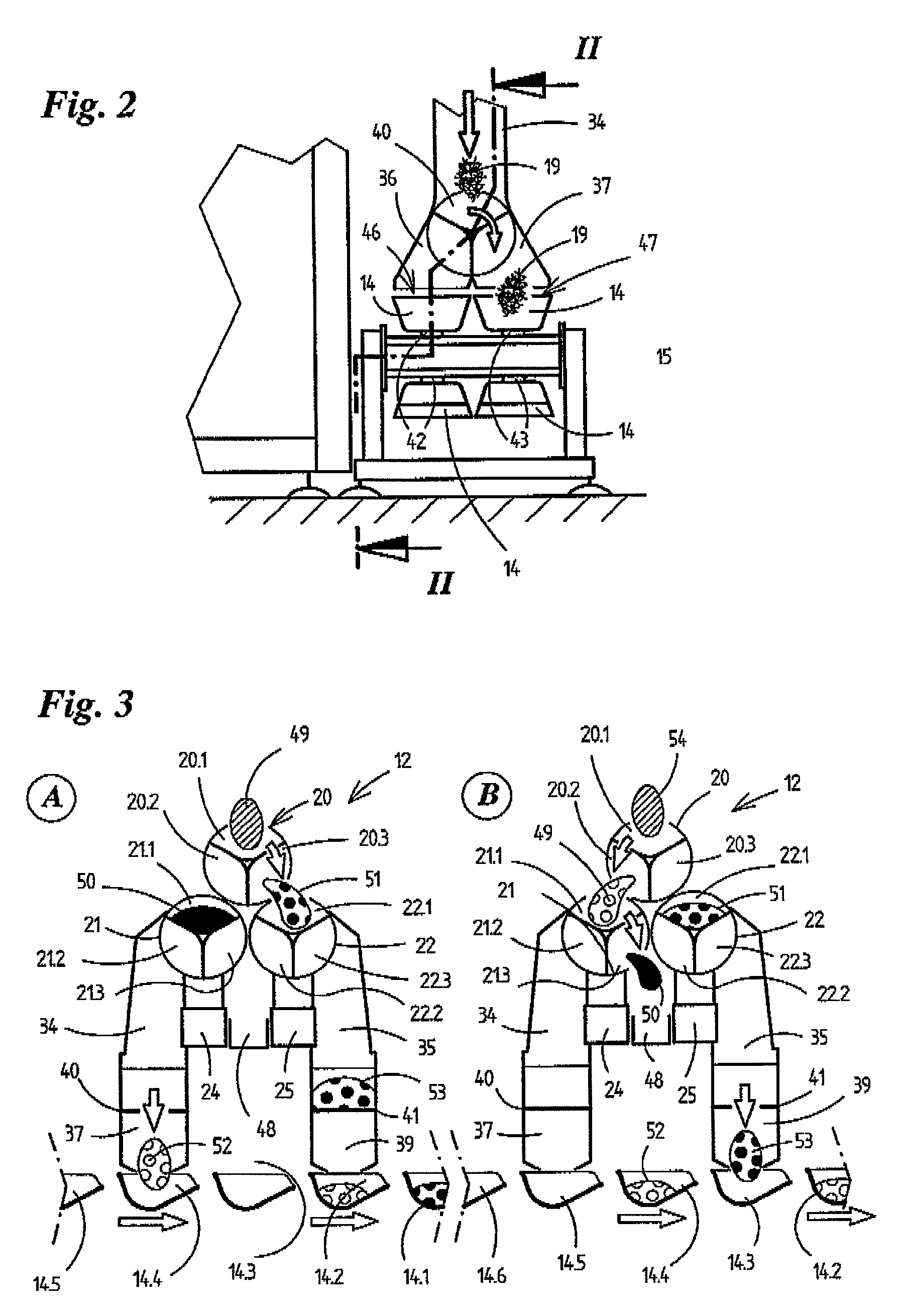

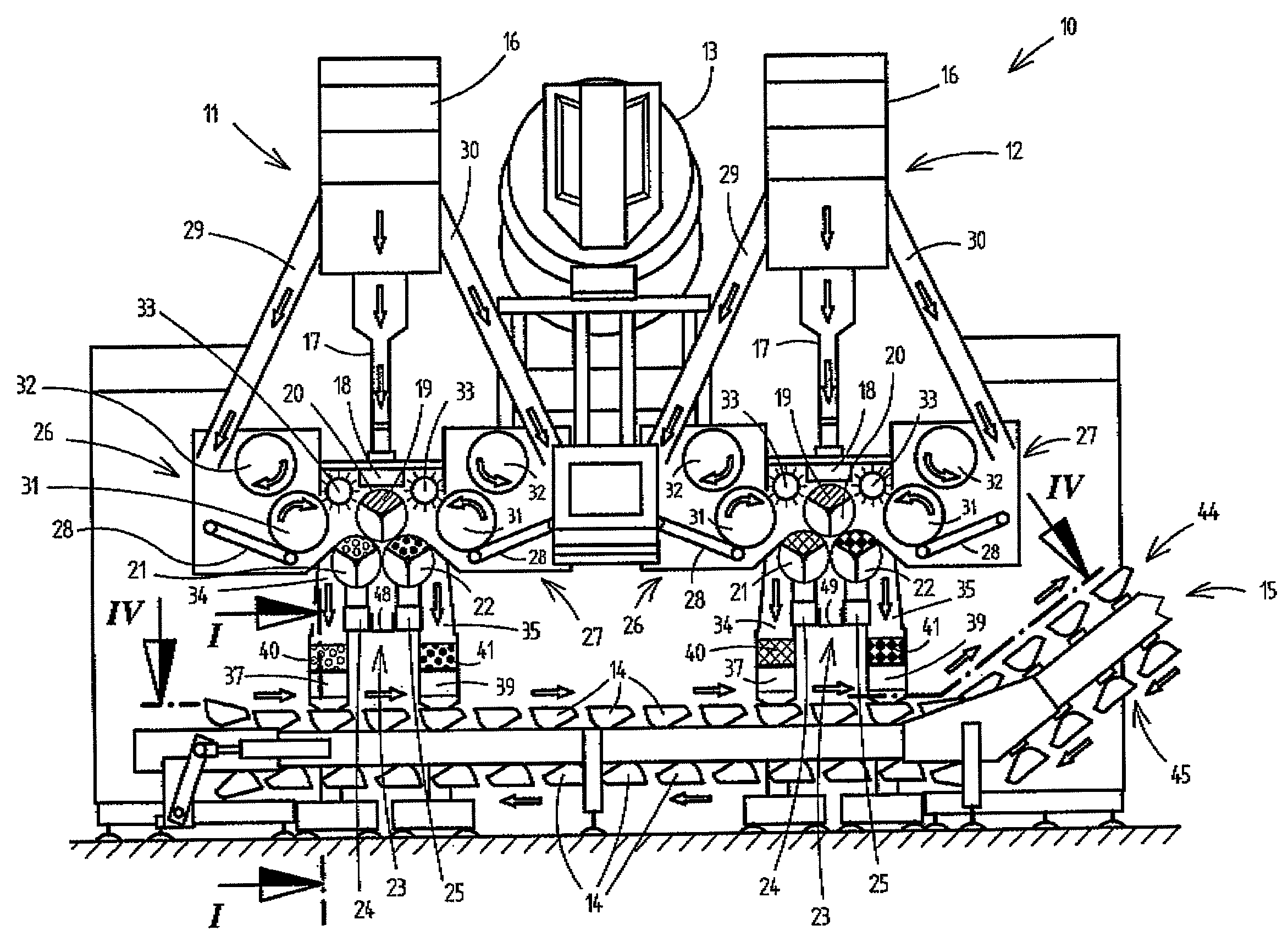

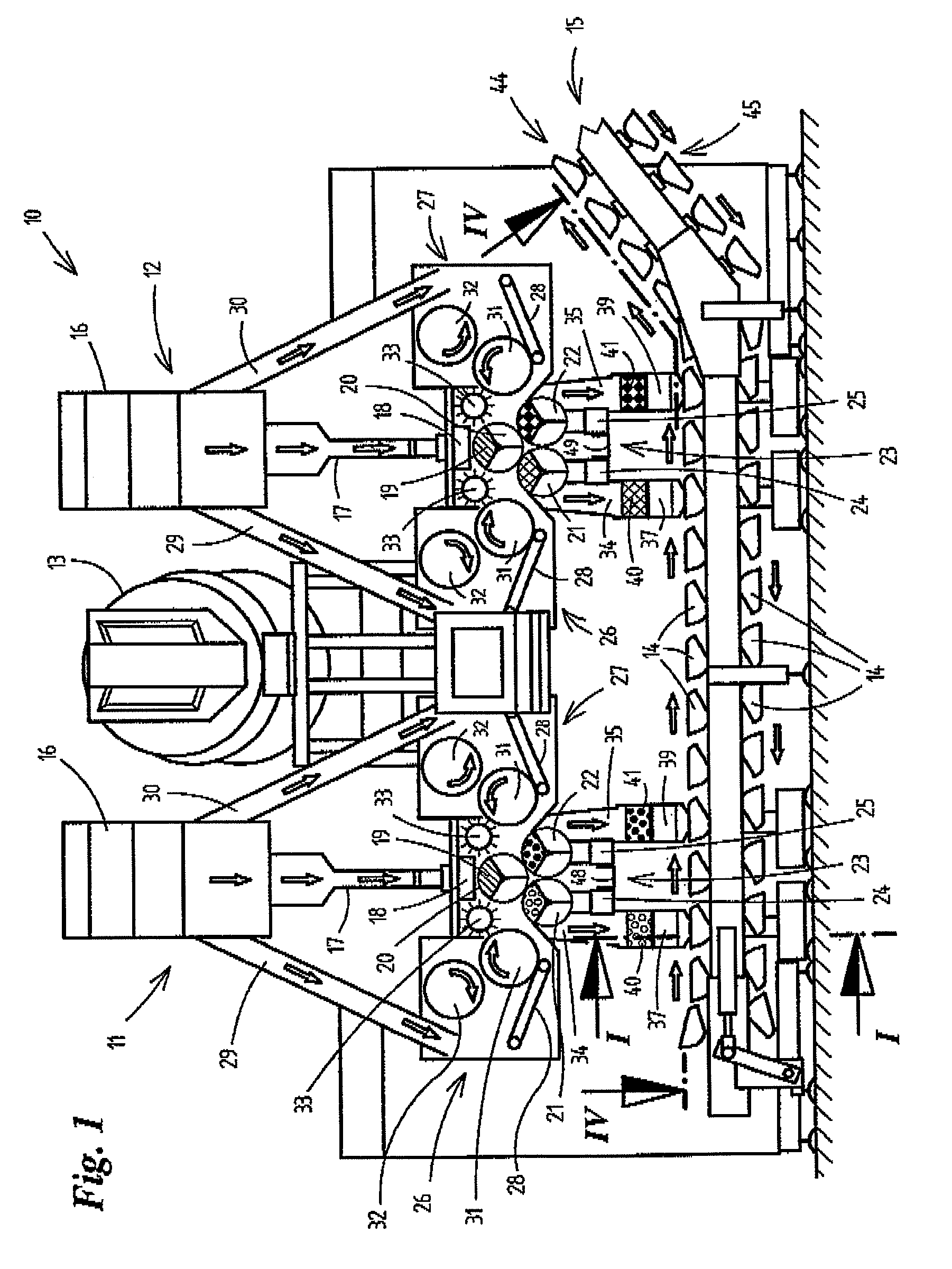

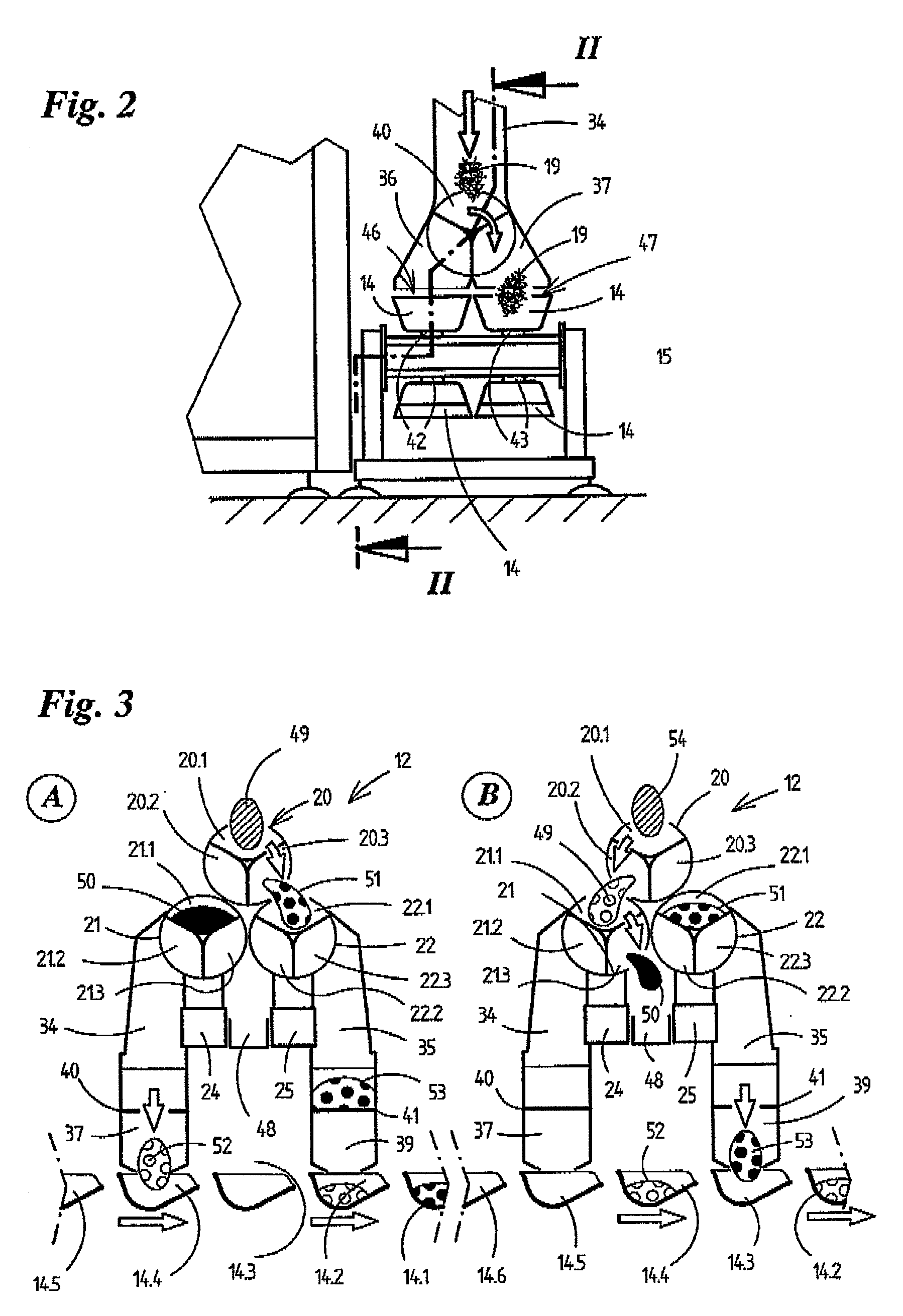

Method and apparatus for forming portions of fibrous material

Owner:FOCKE & CO (GMBH & CO KG)

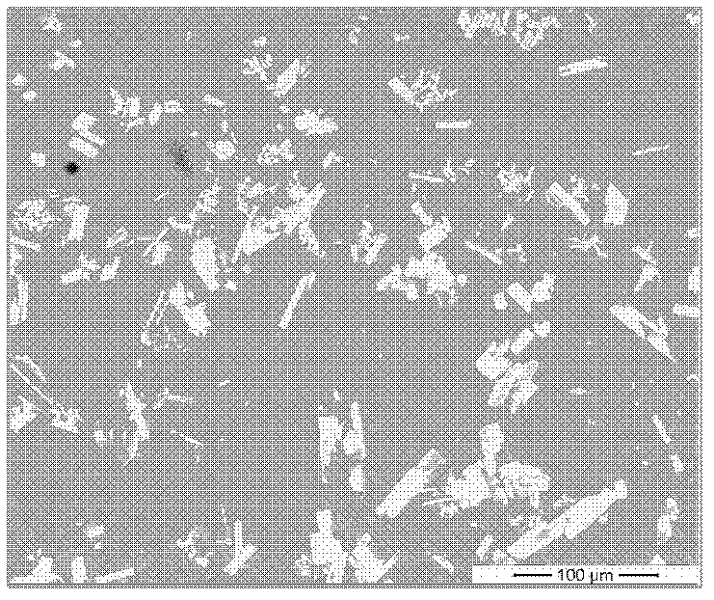

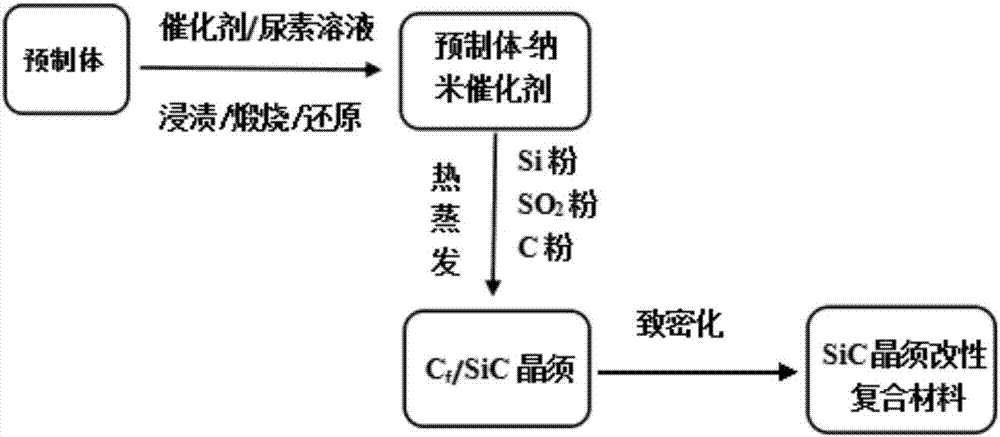

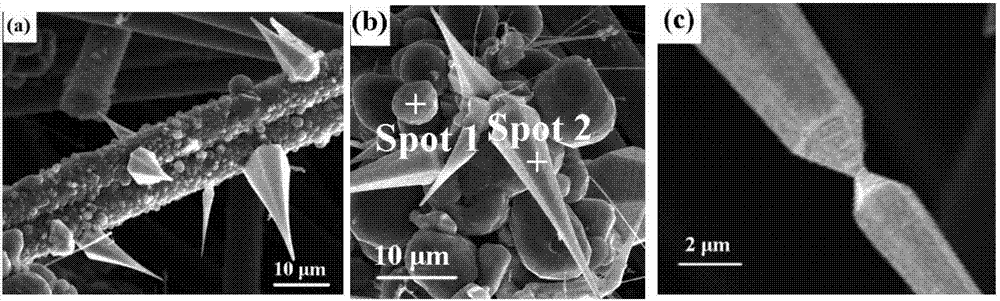

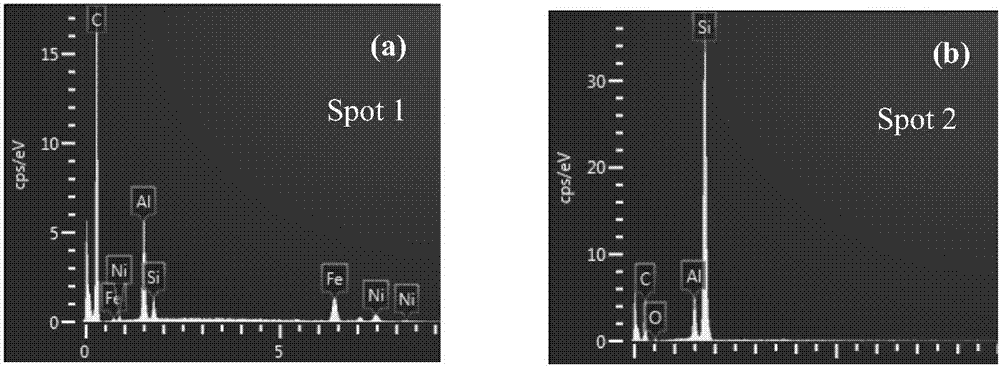

Preparation method for in-situ synthesizing of conical SiC crystal whisker through coprecipitation and thermal evaporation technology

ActiveCN107059129AImprove oxidation resistanceImprove fracture toughnessPolycrystalline material growthSingle crystal growth detailsNano catalystFiber

The invention relates to a preparation method for in-situ synthesizing of conical SiC crystal whisker through a coprecipitation and thermal evaporation technology. The preparation method comprises the steps of depositing a layer of carbon on a carbon fiber prefabricated body through a CVI method, filling defects on the surface of the prefabricated body and providing sufficient reaction raw materials; then putting the prefabricated body into a urea solution containing a catalyst to be dipped, calcining and reducing to obtain a nano catalyst; then suspending a sample containing the nano catalyst at the position of the top end in a graphite mold where silicon powder and carbon powder are loaded and evenly mixed and then obtaining the conical SiC crystal whisker through thermal treatment in certain temperature. The preparation method disclosed by the invention is simple, free of pollution, safe and stable, can effectively improve oxidation resistance, breaking tenacity and creep resistance of a composite material and combination strength between a base body and an enhanced body, can be applied to carbon / carbon, carbon / ceramic, magnesium-based and aluminum-based composite materials and has very good economical and social benefits.

Owner:无锡博智复合材料有限公司

Sealing wellhead members with bi-metallic annular seal

A wellhead seal assembly that forms a metal-to-metal seal between inner and outer wellhead members. A bi-metallic U-shaped seal with legs having a low yield metal on the outer portions. During installation of the seal assembly, the legs of the seal are forced outward against the surfaces of the wellhead members, by pressurization of a interim non-metallic seal which forces a wedge into the U-shaped seal, causing localized yielding of the low yield metal to fill defects on wellhead member surfaces.

Owner:VETCO GRAY

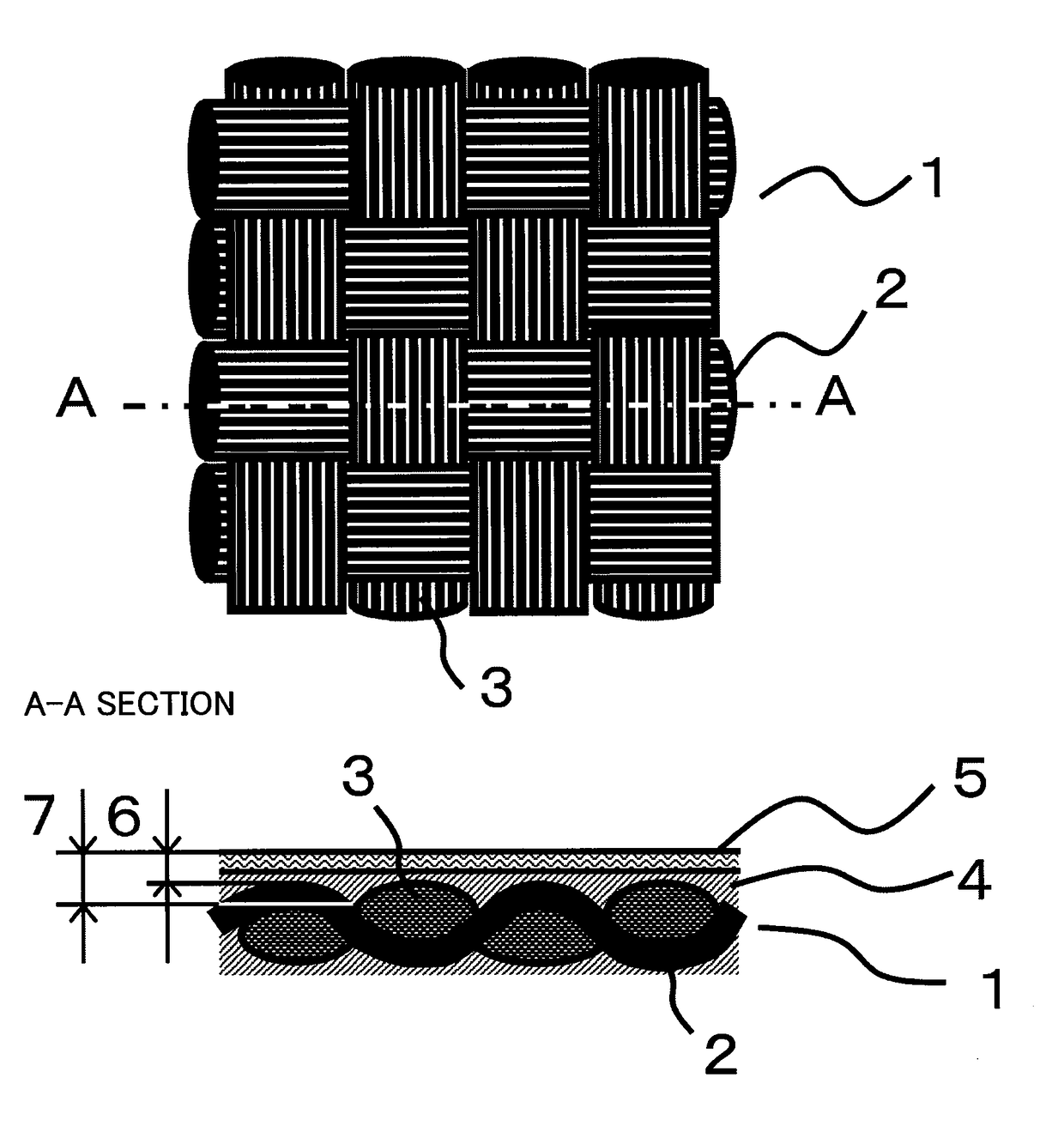

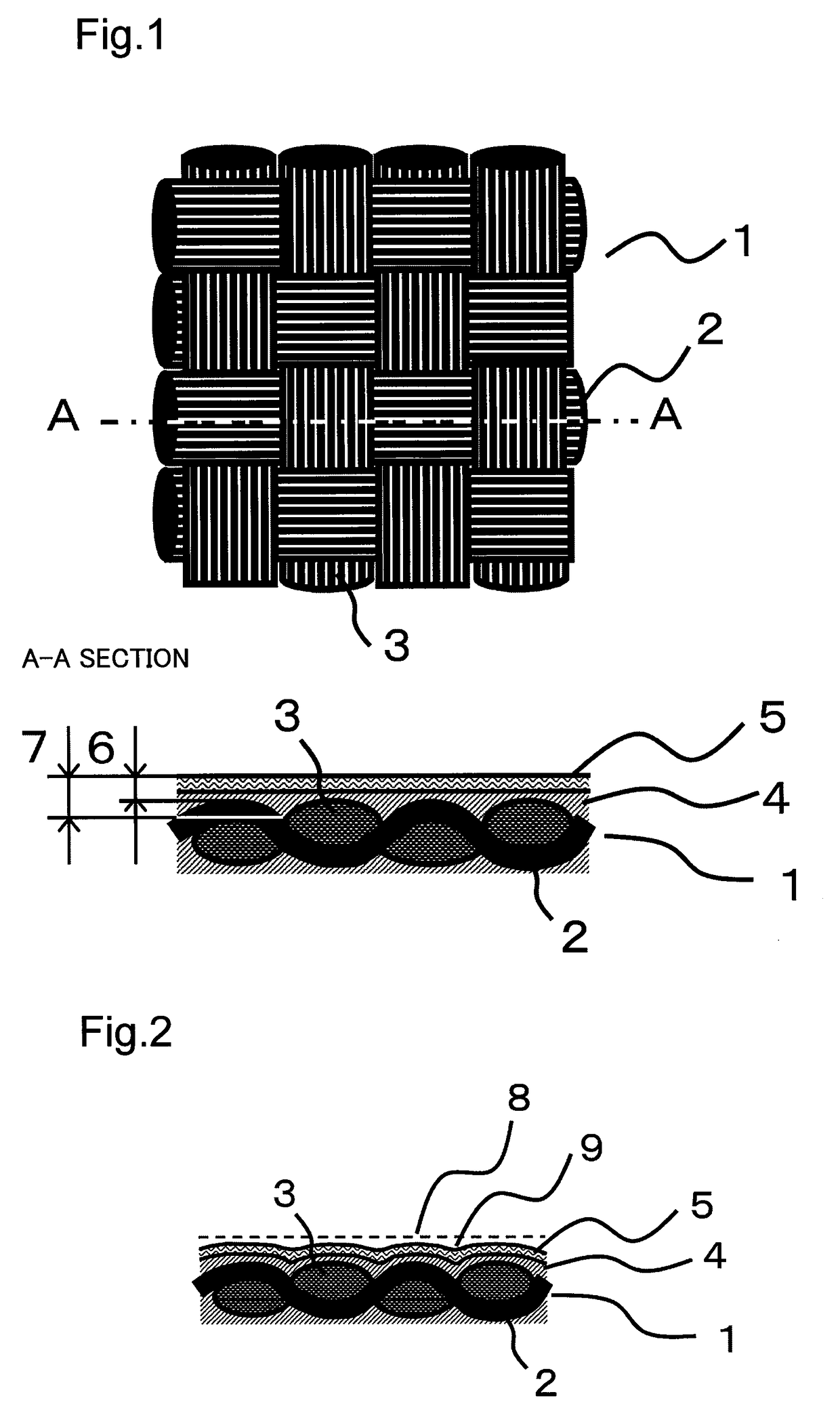

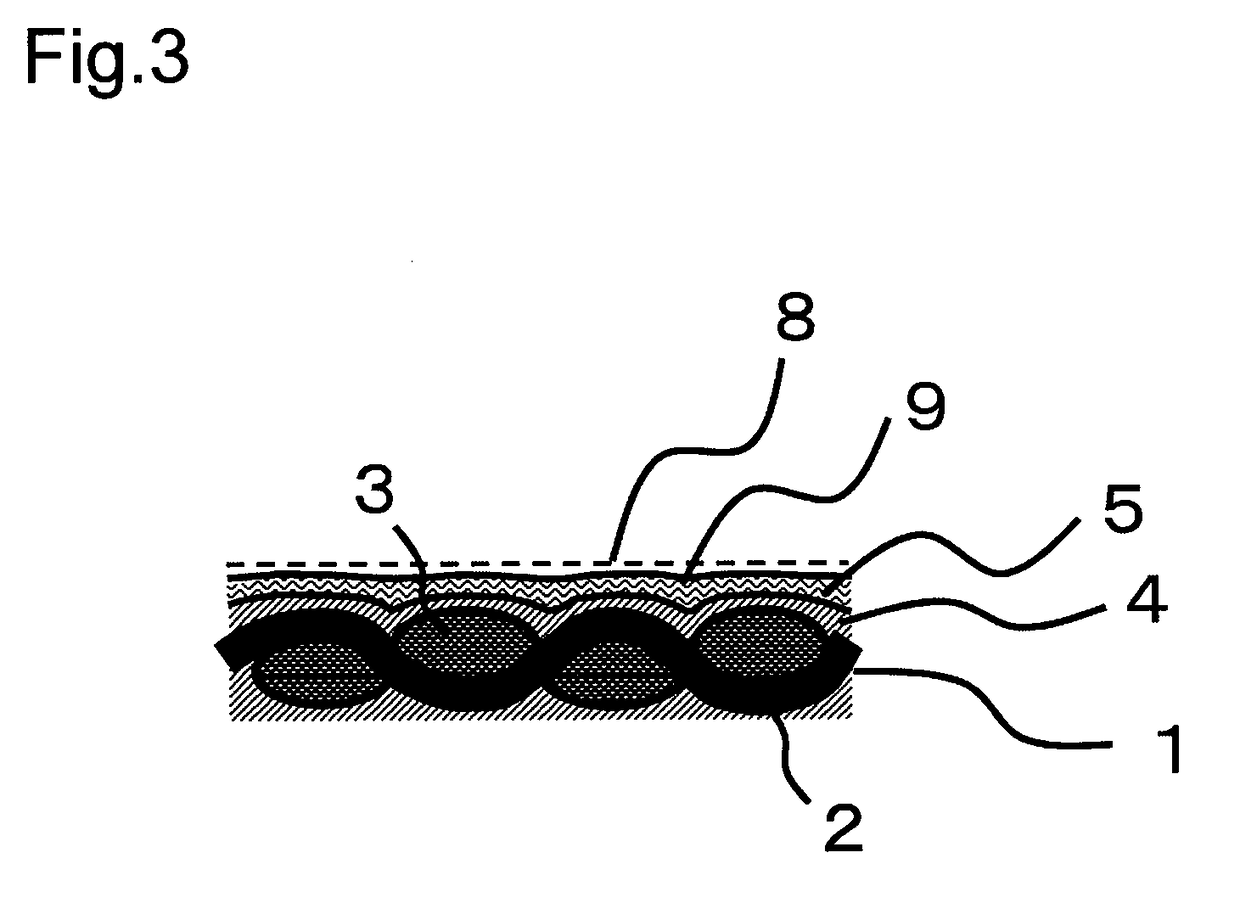

Coated fiber-reinforced resin molded article and manufacturing method of the same

An object is to provide a manufacturing method of a fiber-reinforced resin that significantly reduces a resin filling defect on the surface and surface irregularity caused by a temperature difference between a molding temperature (curing temperature) and ordinary temperature in the course of molding the fiber-reinforced resin, and a product manufactured by the manufacturing method. There is accordingly provided a manufacturing method of a coated fiber-reinforced resin molded article and a product manufactured by the manufacturing method. The manufacturing method comprises a first molding process that cures a matrix resin which a reinforcing fiber is impregnated with at a temperature T1(° C.) to obtain a fiber-reinforced resin molded article; and a second molding process that places the fiber-reinforced resin molded article in a cavity of a mold, sets the cavity to a temperature T2(° C.) that is lower than the temperature T1(° C.), injects a liquid coating layer-forming resin material into the cavity such as to coat at least part of a surface layer of the fiber-reinforced resin molded article, and cures the coating layer-forming resin material at the temperature T2(° C.), so as to obtain the coated fiber-reinforced resin molded article, wherein the mold is comprised of at least two pieces and has the cavity in a shape that is approximately same as a shape of the fiber-reinforced resin molded article.

Owner:TORAY IND INC

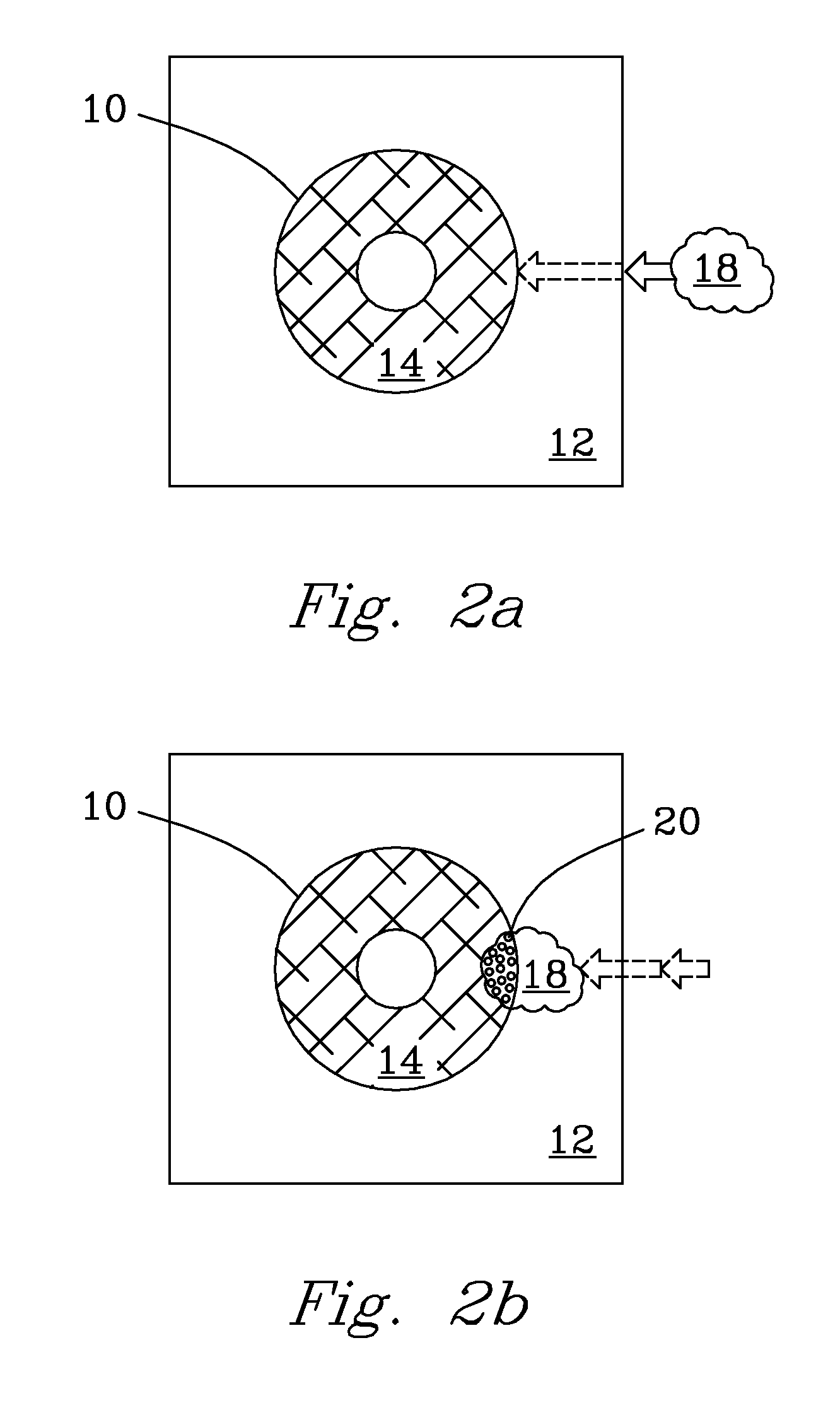

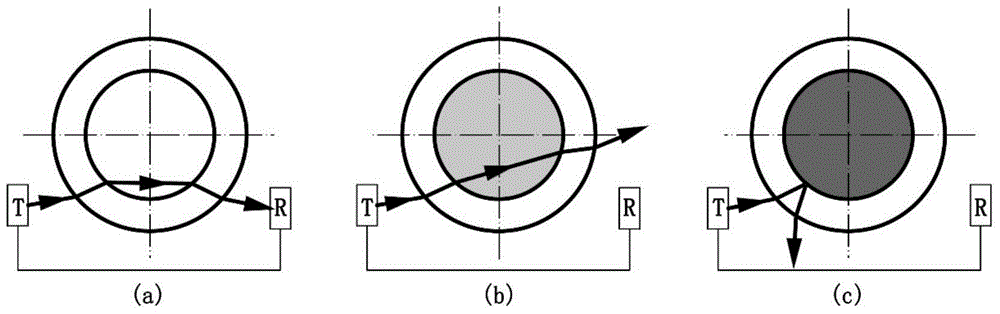

A visual detection method and a system for filling defects of a dry battery pulp layer paper

ActiveCN109146841AImprove detection accuracyImprove pass rateImage enhancementImage analysisFilling defectZinc

The invention discloses a visual detection method and a system for filling defect of a dry battery pulp layer paper. The detection method comprises the following steps: a detection camera is initialized; after the synchronization signal is captured, the visual light source is turned on to detect a frame of image collected by the camera and marked as P; gray linear stretching and Gaussian blur areapplied to the image P; using canny edge detection algorithm, the edge of the preprocessed image P is extracted; using a Hough algorithm, the position of zinc cylinder mouth is located, and the ROI image is set to filter the irrelevant area; the area A of the pulp layer paper is obtained by using the binary threshold and the area growth algorithm; the area A is compared with the standard value, and when the pulp sheet is defective, the dry cell is removed and the next dry cell is then detected. The system mainly includes an industrial intelligent camera and rejection device. The detection method and the system can not only detect the pulp layer paper in real time, but also have the advantages of high detection efficiency and low cost.

Owner:广州市讯思视控科技有限公司

Method of, and apparatus for, forming portions of fibrous material and removing the same

Owner:FOCKE & CO (GMBH & CO KG)

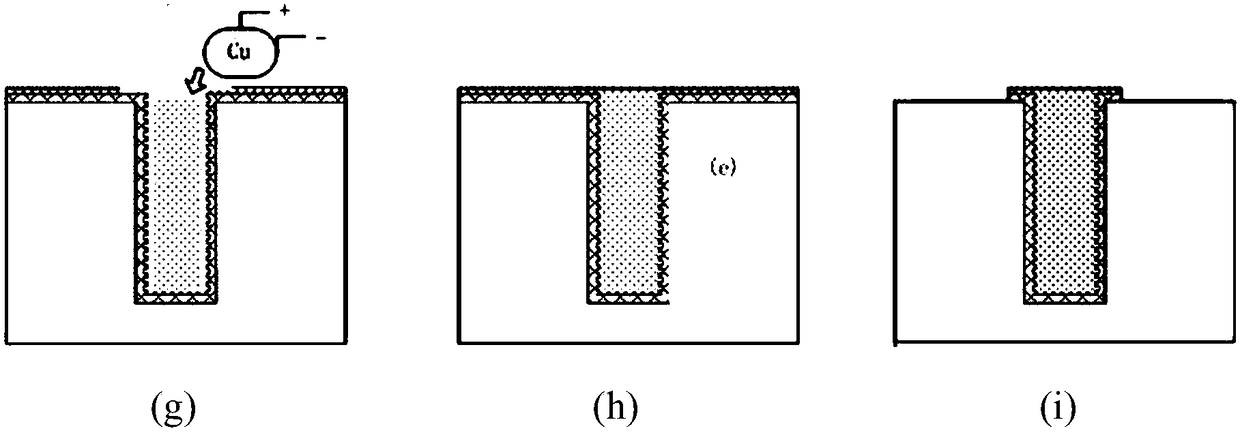

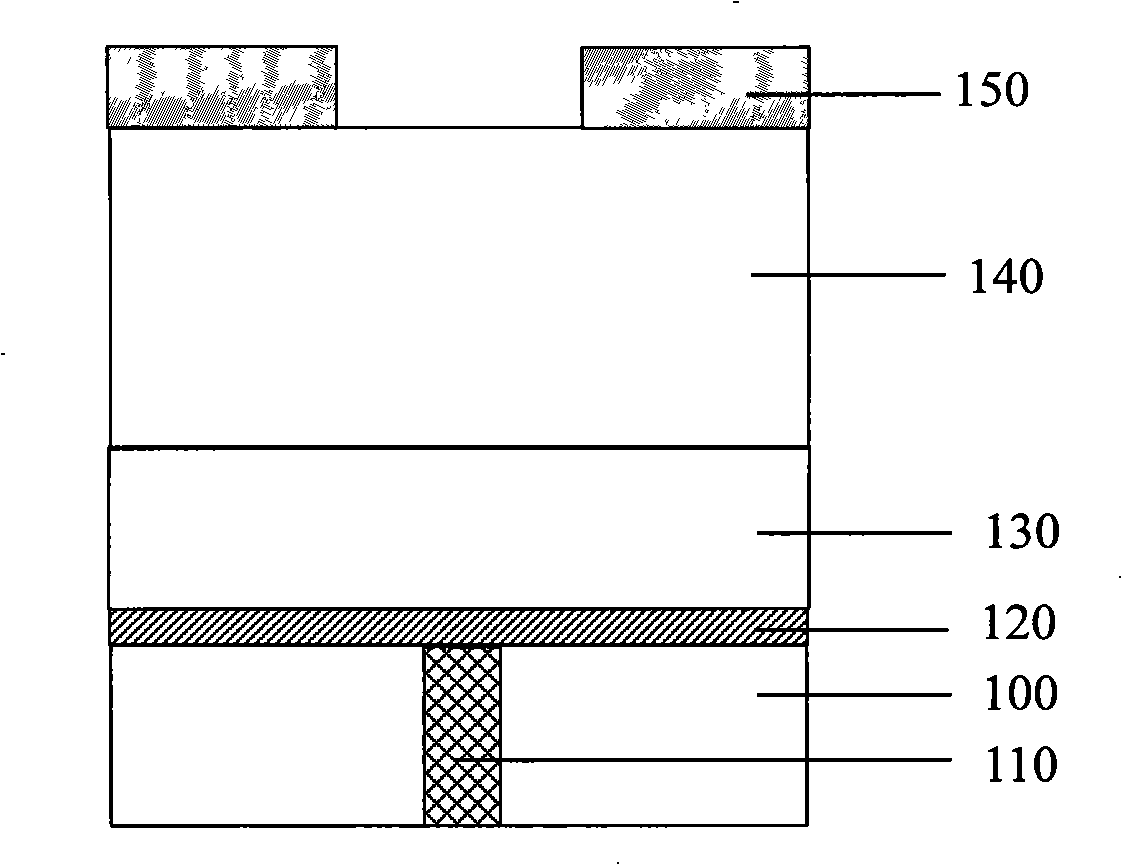

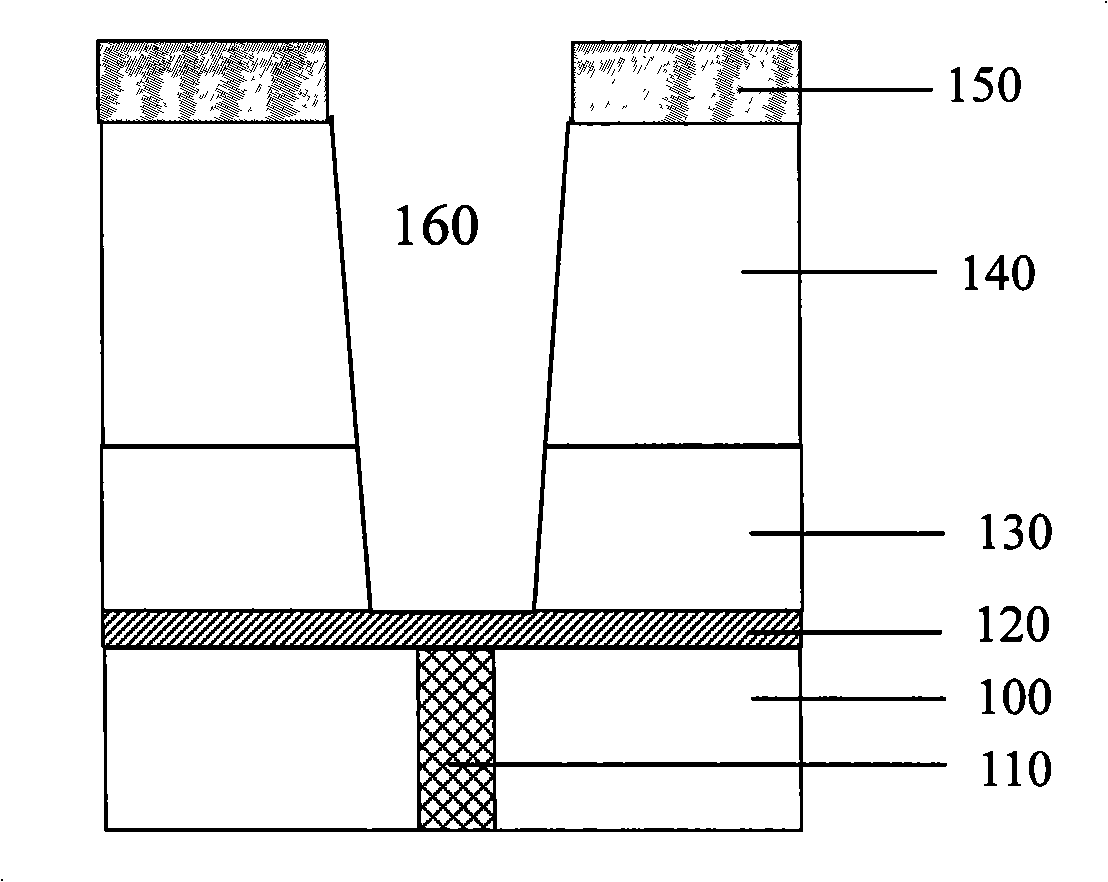

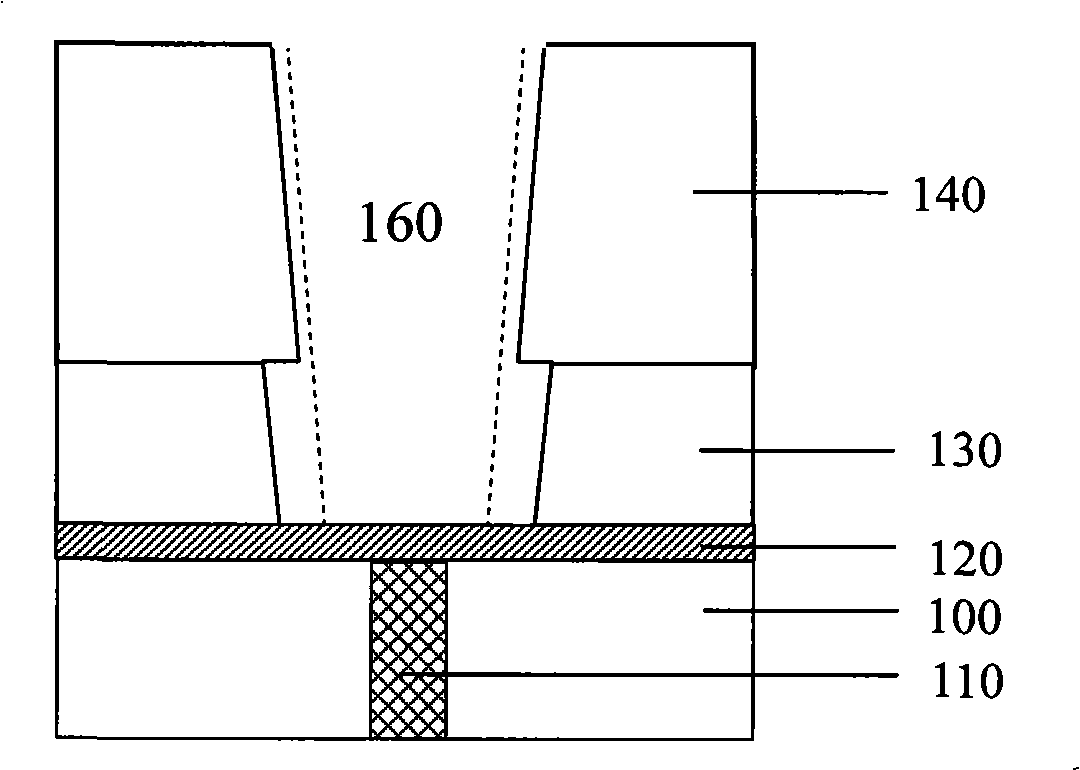

Composite material for filling vertical through silicon via (TSV) and filling method thereof

InactiveCN108109955AImprove reliabilityReduces the possibility of fracture failureSemiconductor/solid-state device manufacturingCopper atomFailure rate

The invention discloses a composite material for filling a vertical through silicon via (TSV) and a filling method thereof, wherein the composite material is mainly composed of diamond and copper, thediameter of the diamond is less than 1 [mu]m, and the diamond is monocrystal diamond or boron-doped diamond. The filling method comprises sputtering an adhesion layer, a barrier layer, and a seed layer in the TSV in advance, depositing the composite material by a composite electrodeposition method, and then attaching and depositing the copper atoms along a current direction to fully fill the TSVby energization so as to form a completely filled composite layer on a silicon wafer. By the key internal composition and structure of the composite material, the overall process flow design of the corresponding filling method, and the improvements in conditions and parameters of each step, and using a specific composite material as a TSV filling material and using a specific filling method, the reliability of the TSV can be improved and the failure rate of the TSV can be reduced to avoid filling defects.

Owner:HUAZHONG UNIV OF SCI & TECH

Metal nanometer lubrication oil

The invention discloses metal nanometer lubricating oil, comprising lubricating oil and nanometer metal powder which are mixed together. The weight proportion range of the metal powder and the lubricating oil is between 1 to 12000 and 1 to 3000; the nanometer metal powder in the metal nanometer lubricating oil can form a micro-bearing between the inner wall of a cylinder and a piston so as to change the sliding friction into rolling friction, decrease friction coefficient, and reduce the abrasion of the inner wall of the cylinder; and the tiny metal powder can fill defects and dimples at the wearing terrain of the inner wall of the cylinder to realize the self-repairing function and increase the airtightness of the cylinder, thereby ensuring that fuel oil is completely combusted, improving the powder, and reducing the emission of tail gas.

Owner:ZHUHAI ZHONGJIN NANO TECH

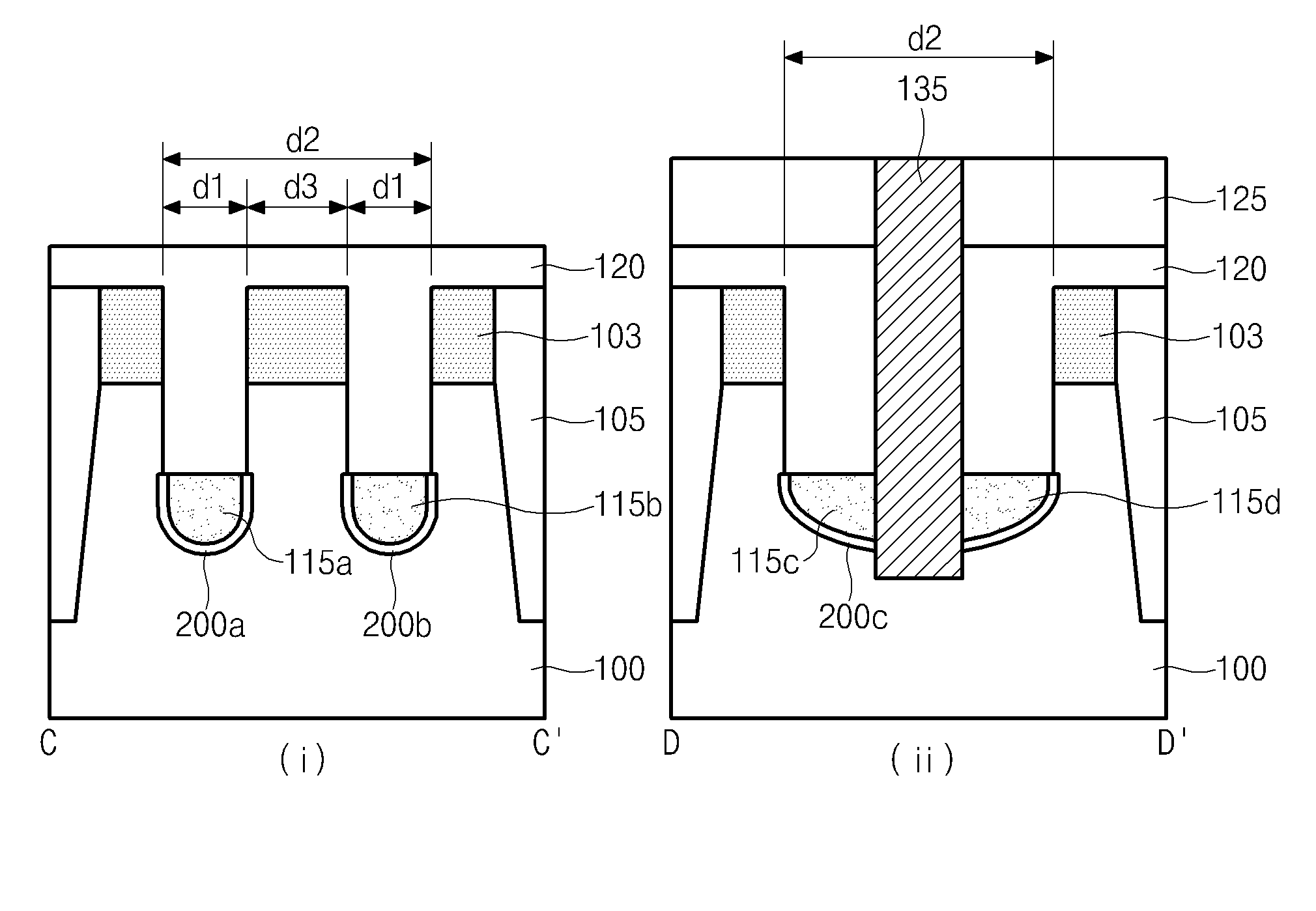

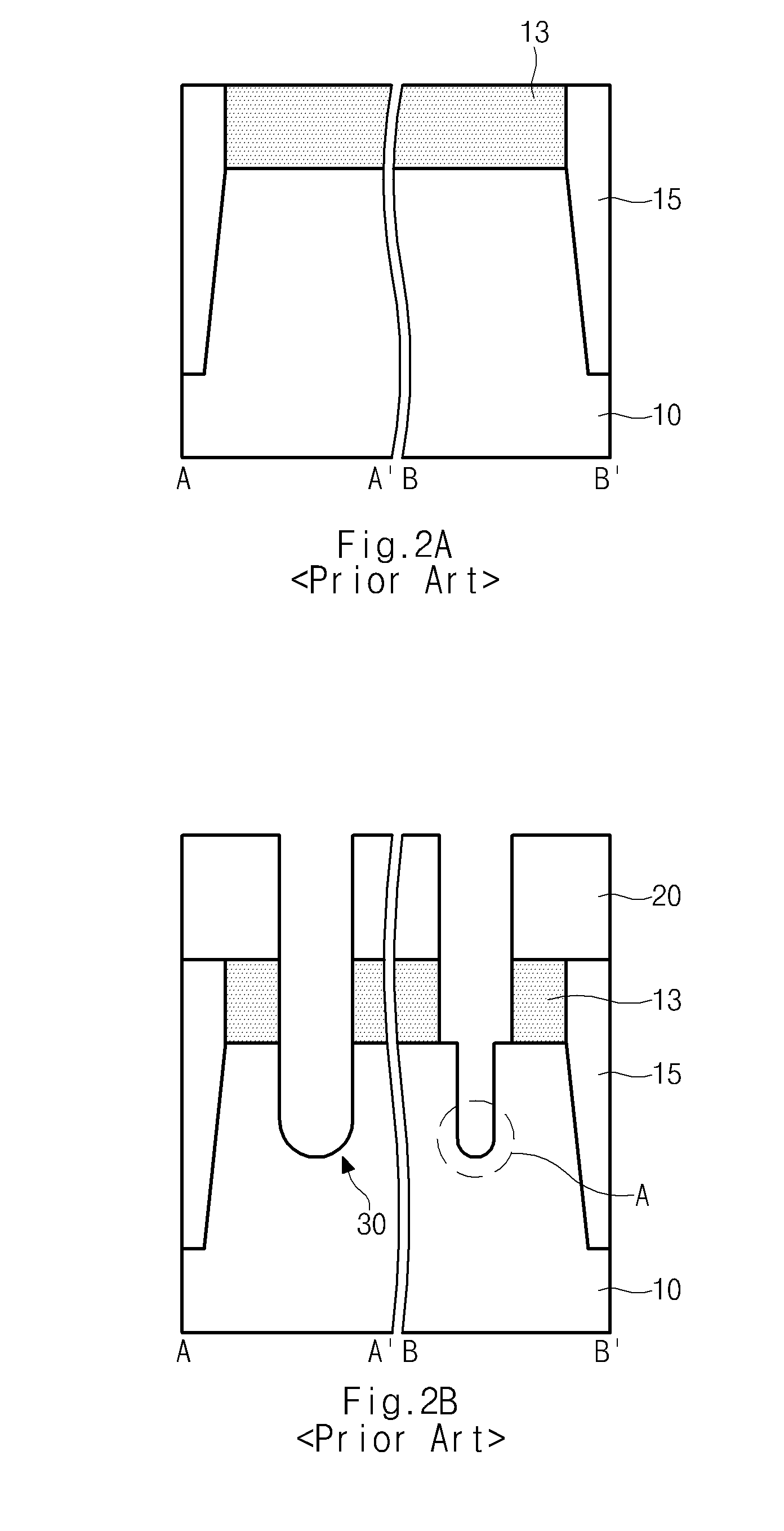

Semiconductor device and method for manufacturing the same

InactiveUS20130099298A1Improve operating characteristicsPattern size can be reducedTransistorSolid-state devicesEngineeringFilling defect

A semiconductor device comprises a buried gate formed in a mat and in an adjacent dummy region. A space larger than is conventional is formed in a dummy region of a mat edge where the buried gate is to be created. This larger space inhibits shortening of an end of a buried gate and reduction in pattern size attributable to lithographic distortion arising between patterned (mat) and unpatterned (dummy) regions. Device reliability is thereby improved by avoiding gap-fill defects of a gate material.

Owner:SK HYNIX INC

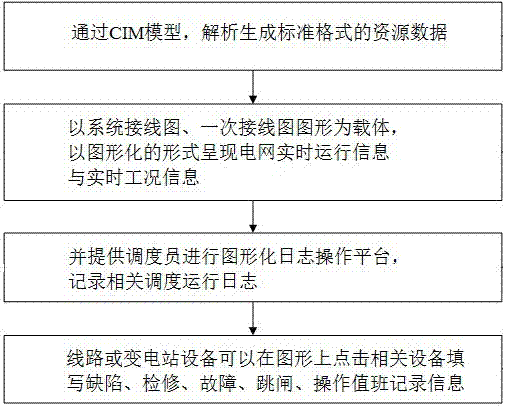

Graphical application method based on power grid operation management system

The invention relates to the graphical field of the electronic information, and especially relates to a graphical application method based on a power grid operation management system. The method comprises the following steps: analyzing to generate resource data in a standard format through a CIM model, displaying real-time operation information and real-time work-condition information in a graphical way by taking a system wiring diagram and a primary wiring diagram graph, and providing a dispatcher to perform a graphic log platform operation so as to record related dispatching operation log, wherein a line or transformation substation equipment can fill defects, overhauling, faults, tripping, and operation duty recorded information by clicking related equipment on the graph. The graphicalapplication disclosed by the invention has the features of being concise, visual and easy to use.

Owner:CHINA SOUTHERN POWER GRID COMPANY +1

Method and Composition for Protection of Refractory Materials in Aggressive Environments

InactiveUS20110033613A1High viscosityHigh melting temperatureLiquid surface applicatorsGasification processes detailsSlagRefractory

Owner:BATTELLE MEMORIAL INST

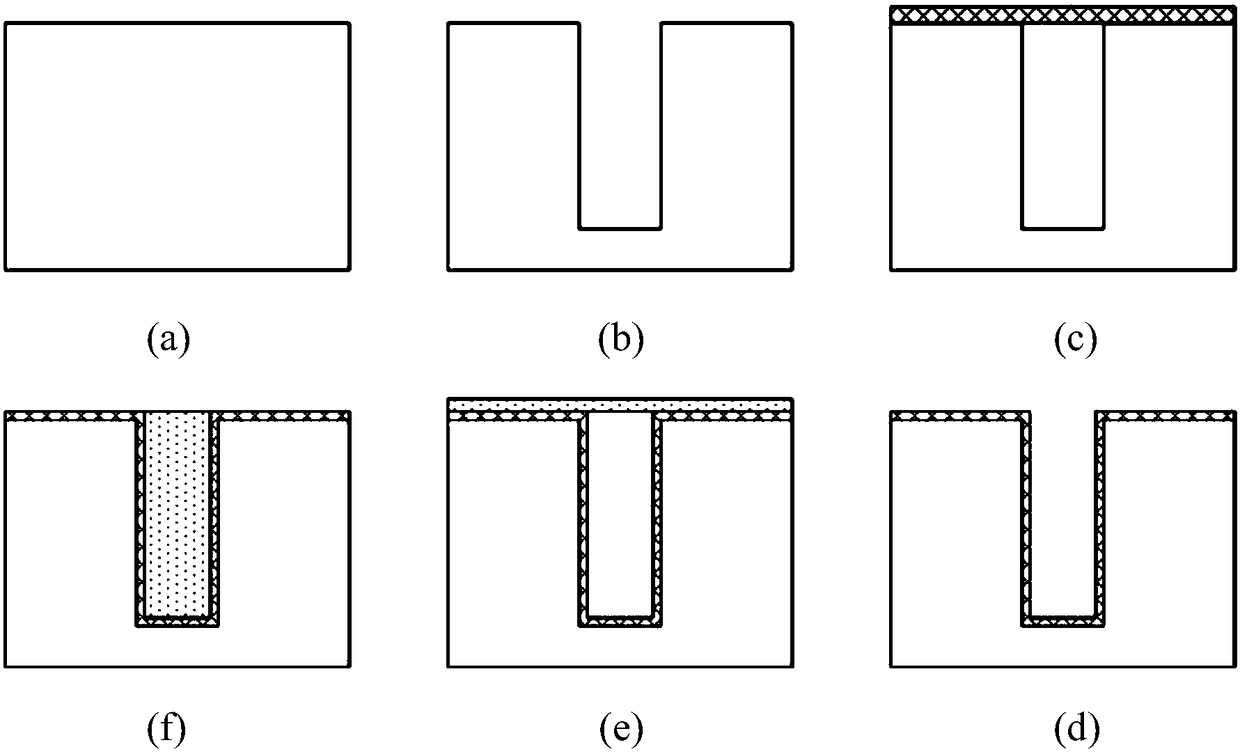

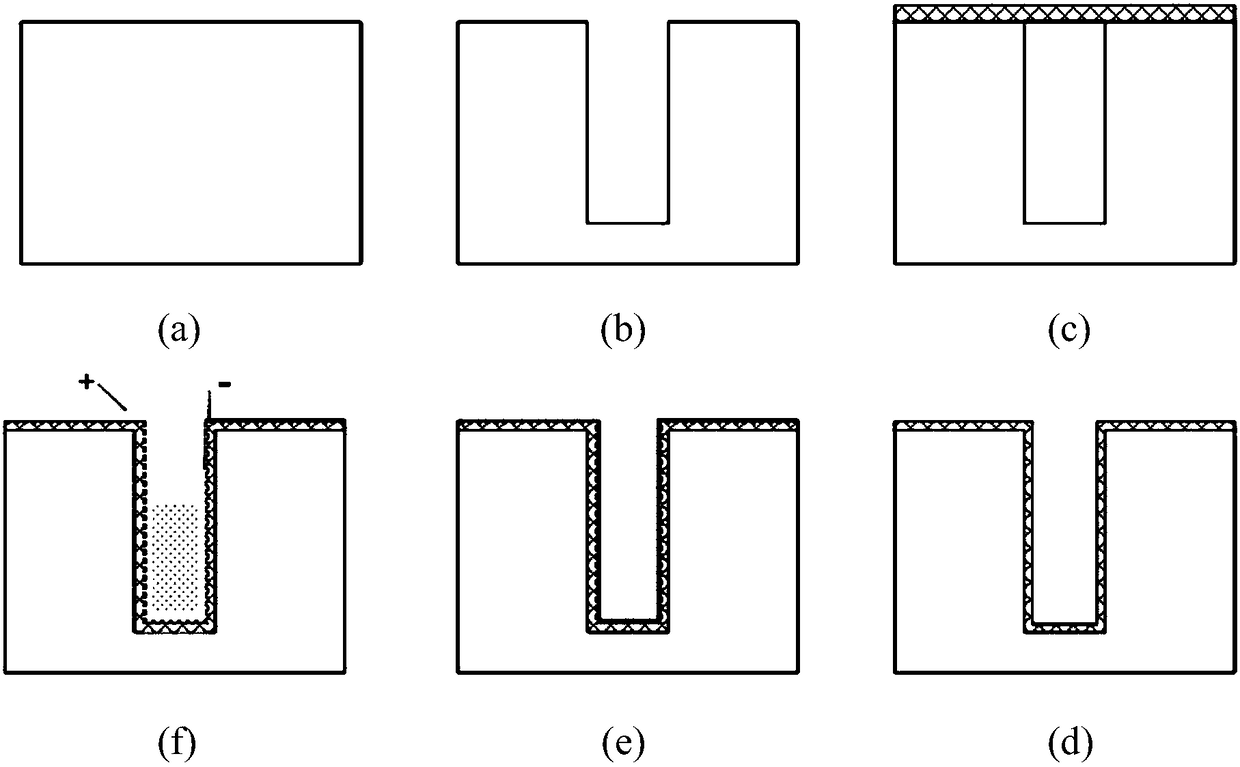

Capacitor manufacturing method

InactiveCN101989539AEvenly spacedIncrease spacingSemiconductor/solid-state device manufacturingGroove widthInter layer

The invention discloses a capacitor manufacturing method, which comprises the following steps: providing an inter-layer medium layer and an interconnection structure penetrating through the inter-layer medium layer; depositing an etching barrier layer, a first insulating layer, buffer layers and a second insulating layer on the inter-layer medium layer in turn; etching the second insulating layer, the buffer layer and the first insulating layer in turn to form grooves; etching the buffer layers through the grooves so as to increase the local widths of the grooves in the buffer layers; etching the grooves with a first etching agent, so that the bottom widths of the grooves approach to the top widths of the grooves; continuing to etch the grooves with a second etching agent, smoothening the closed angles at the interfaces between the second insulating layer and the buffer layers and between the buffer layers and the first insulating layer, and increasing the groove widths; removing the etching carrier layer; depositing polycrystalline silicon on the inner walls of the grooves and forming semi-spherical polycrystalline silicon particles serving as the lower electrode of the capacitor; and depositing a dielectric layer and an upper electrode on the lower electrode in turn. By using the method, the short circuit and the filling defect between the upper electrode and the lower electrode of the capacitor can be avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP

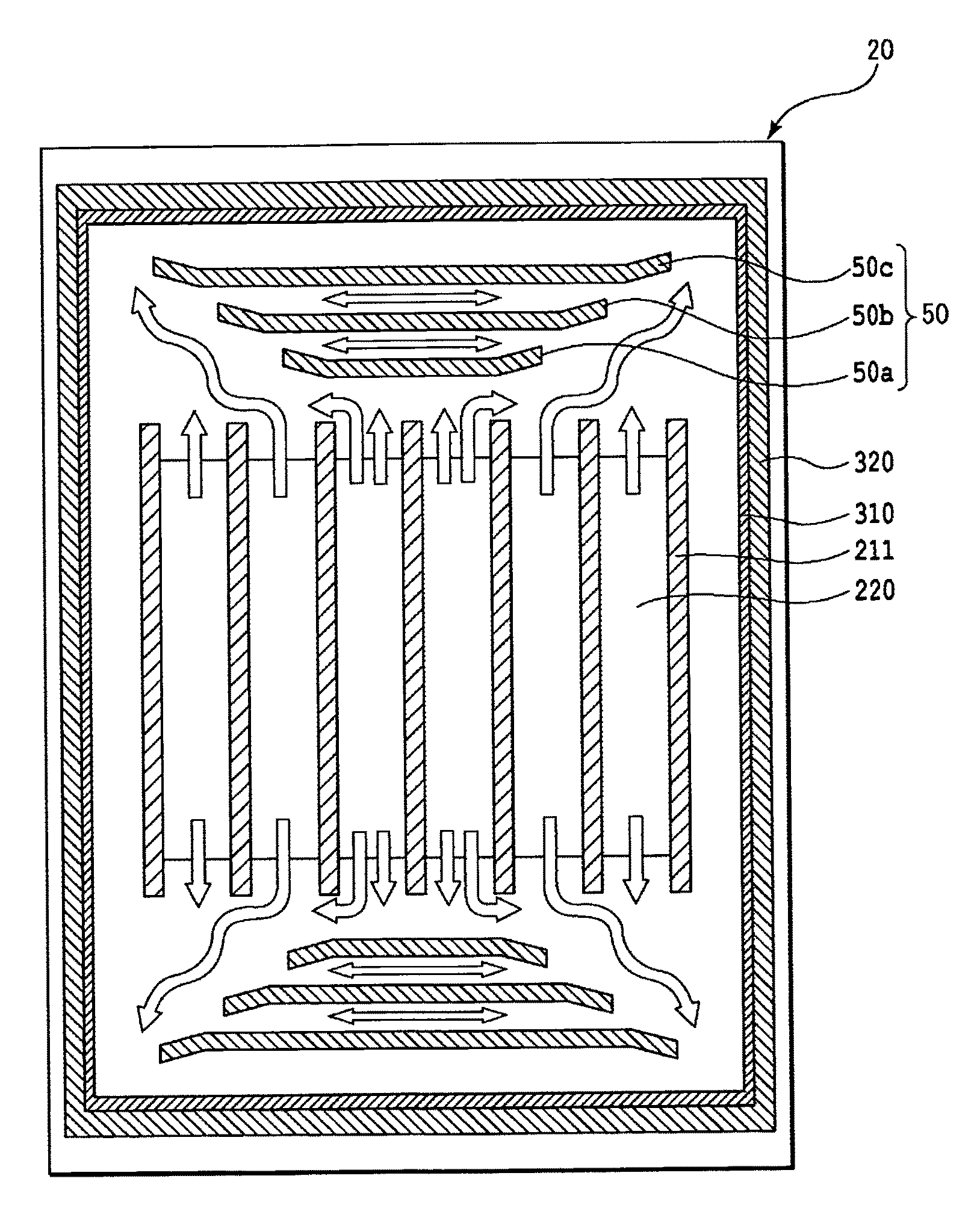

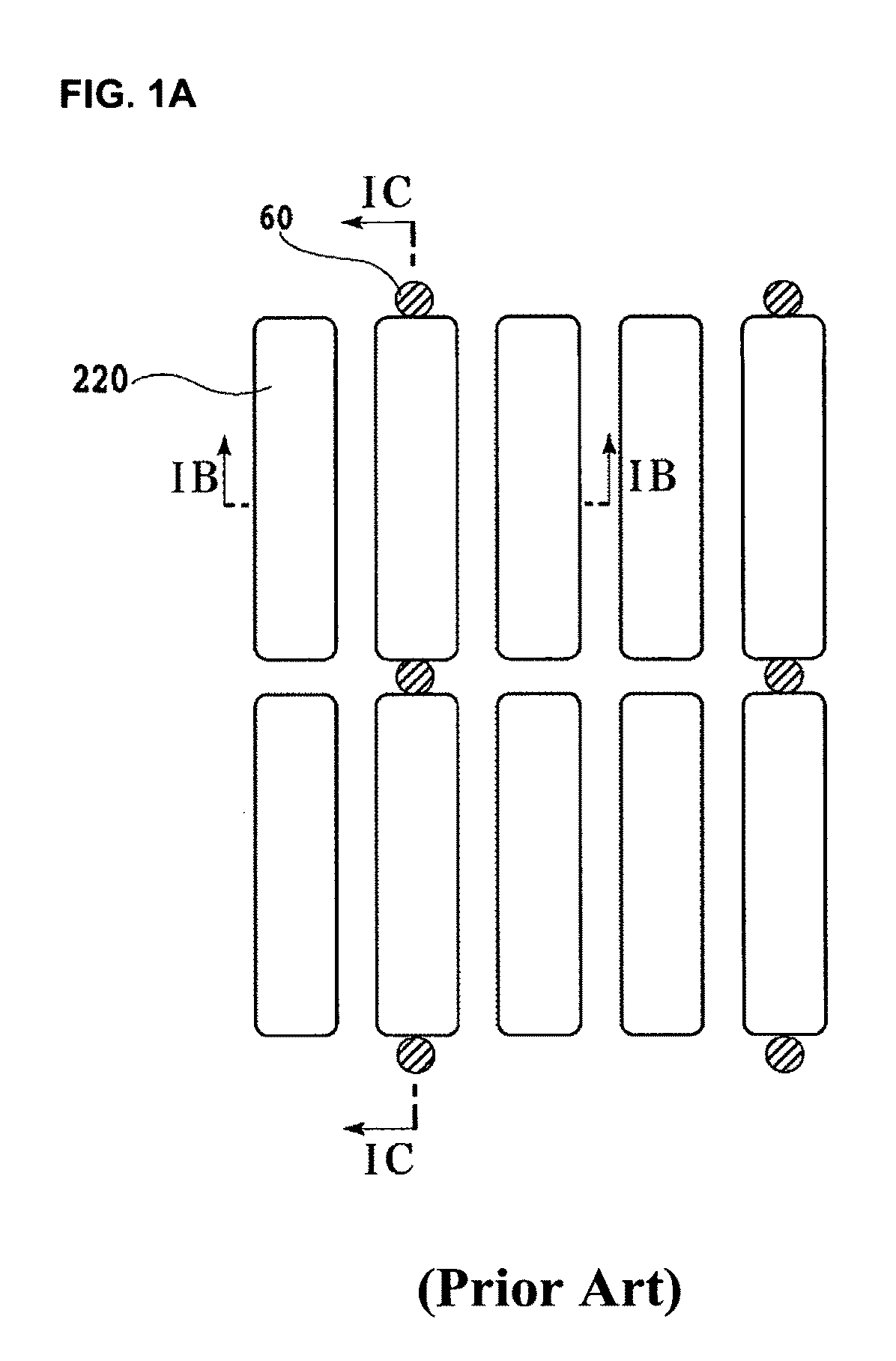

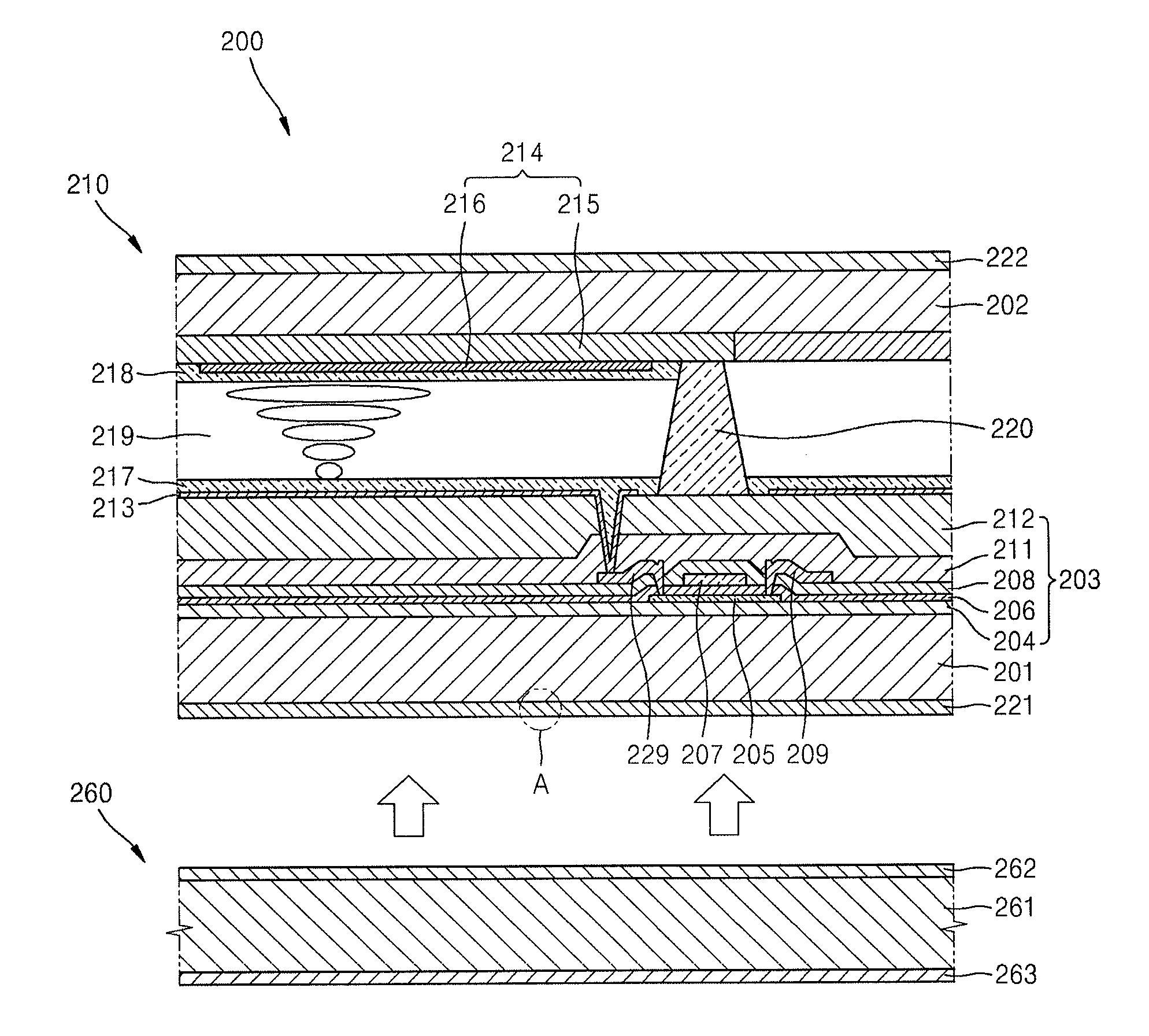

Organic EL display and method for manufacturing same

ActiveUS8629614B2Avoid inclusionsPrevent materialDischarge tube luminescnet screensElectric discharge tubesFilling materialsEngineering

An object of this invention is to provide a top-emission type organic EL display in which filling defects of a resin filler material are alleviated during bonding of an organic EL emission panel and a color conversion filter panel with the resin filler material, as well as to provide a method for manufacturing such an organic EL display. An organic EL display of this invention is characterized in having stripe-shaped barrier walls for inkjet application placed on a color conversion filter panel, and a filler material guide wall placed between the length-direction end portions of the barrier walls for inkjet application and a peripheral seal member.

Owner:SHARP KK

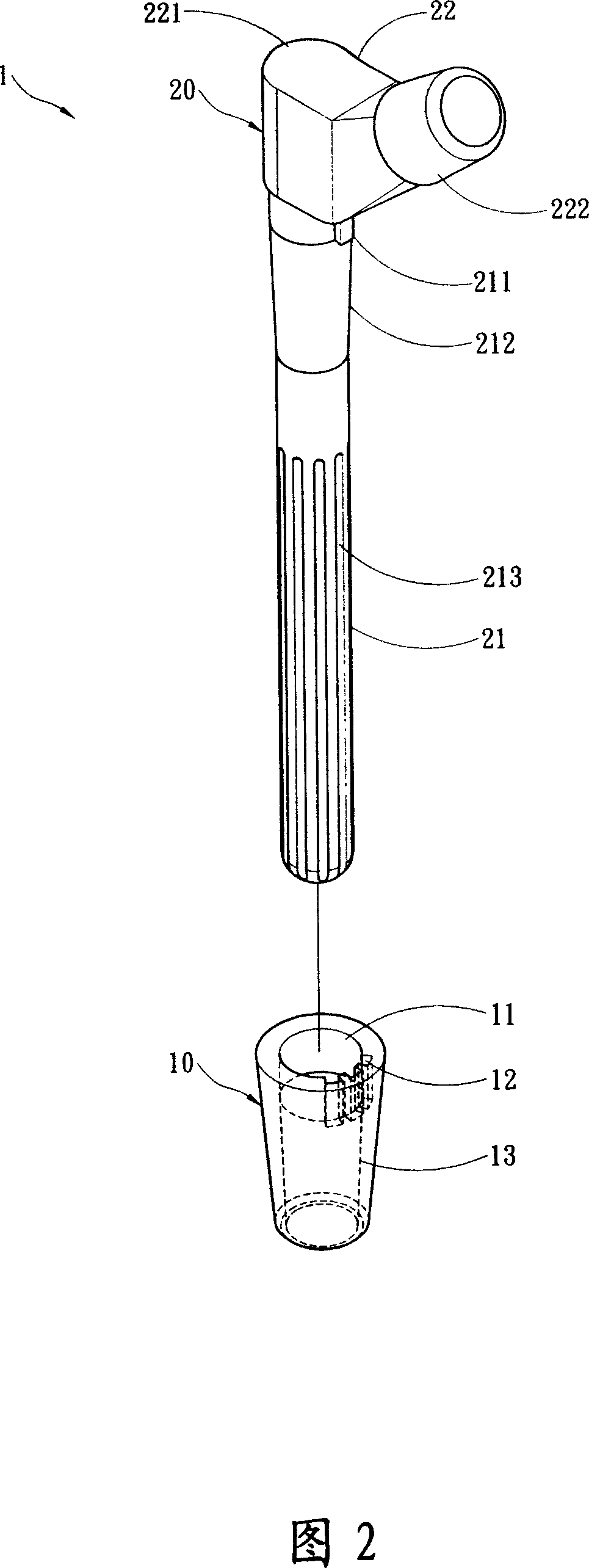

Artificial femur structure

InactiveCN101006946ASave storage spaceLower medical costsBone implantJoint implantsThighRight femoral head

The invention discloses an artificial femur structure, which comprises the following parts: chassis corresponding to fill defect, plural limit groove with hole on the periphery, support crank in the hole, joint end on one end of support crank, bone crank end on the other end with tapering segment, limit bond in the plural limit groove to define the position of joint end.

Owner:郑诚功

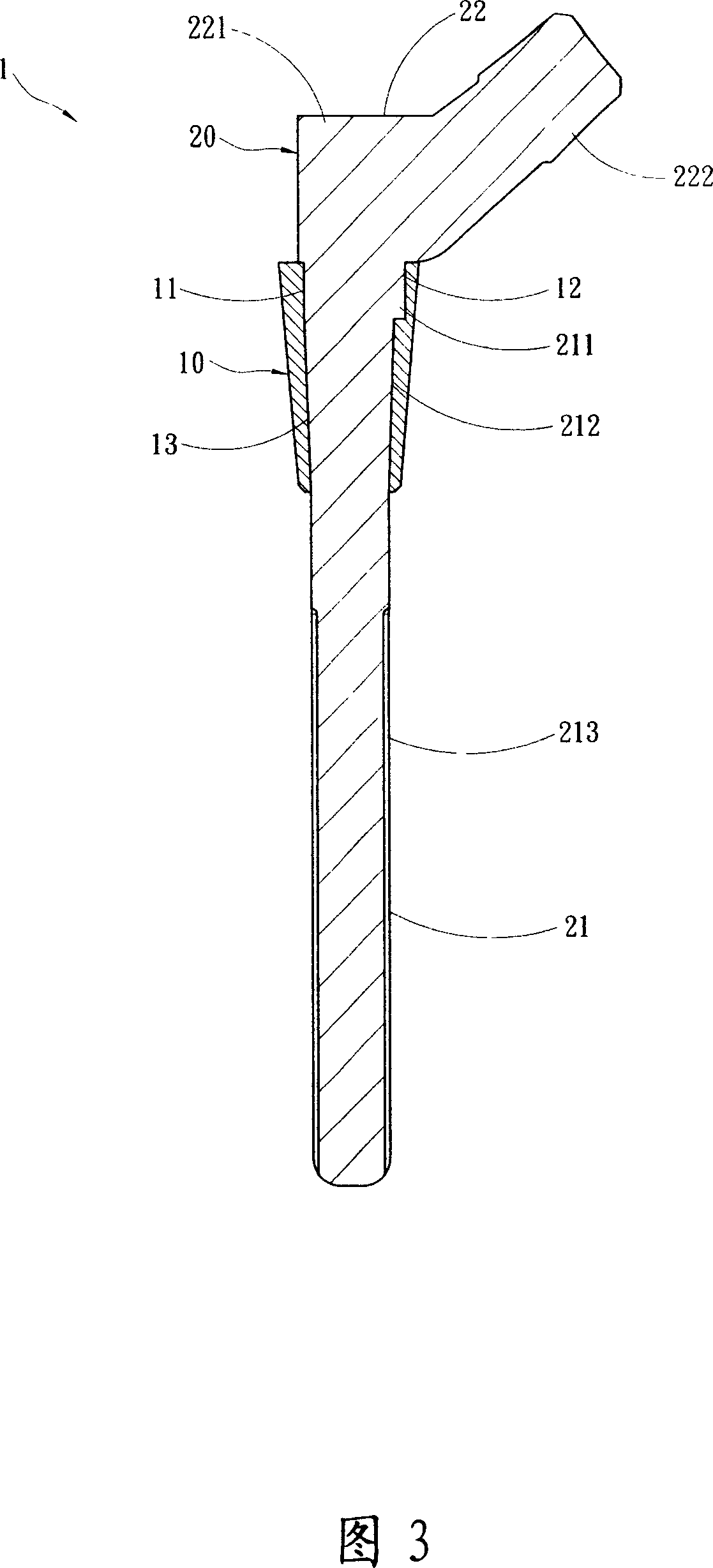

Method for filling dense film defects

ActiveCN106310956AAchieving a full range of retouchingImprove the level ofSemi-permeable membranesAdhesiveMetallurgy

High temperature glue and ceramic particles with certain particle size distribution are mixed to prepare a compound modification liquid to realize the full range (from a few nanometers to hundreds of microns) modification of defects on a dense film. The ceramic particles are used to modify large defects (such as more than 5nm) on the dense film, the high temperature glue is used to modify small defects (such as less than 5nm) on the dense film; in addition, by the use of the high temperature adhesive, the leveling performance of the compound modification liquid can be significantly improved, the ceramic particles can be bonded and toughened, and after-processing temperature is reduced. The compound modification liquid is used for coating and modifying the surface of the dense film with the defects, and the ceramic particles and the high temperature glue only fill defect parts and are not adsorbed on the surface of the dense film. The method can realize a defect filling ratio of nearly 100%, has the advantages of simple process and good repeatability, and is suitable for large-scale filling of the defects on the dense film.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Methods and apparatus for treating disc herniation and preventing the extrusion of interbody bone graft

InactiveUS20070038231A1Minimized in sizeAvoiding delicateBone implantJoint implantsIntervertebral discDiscectomy

Owner:FERREE BRET A

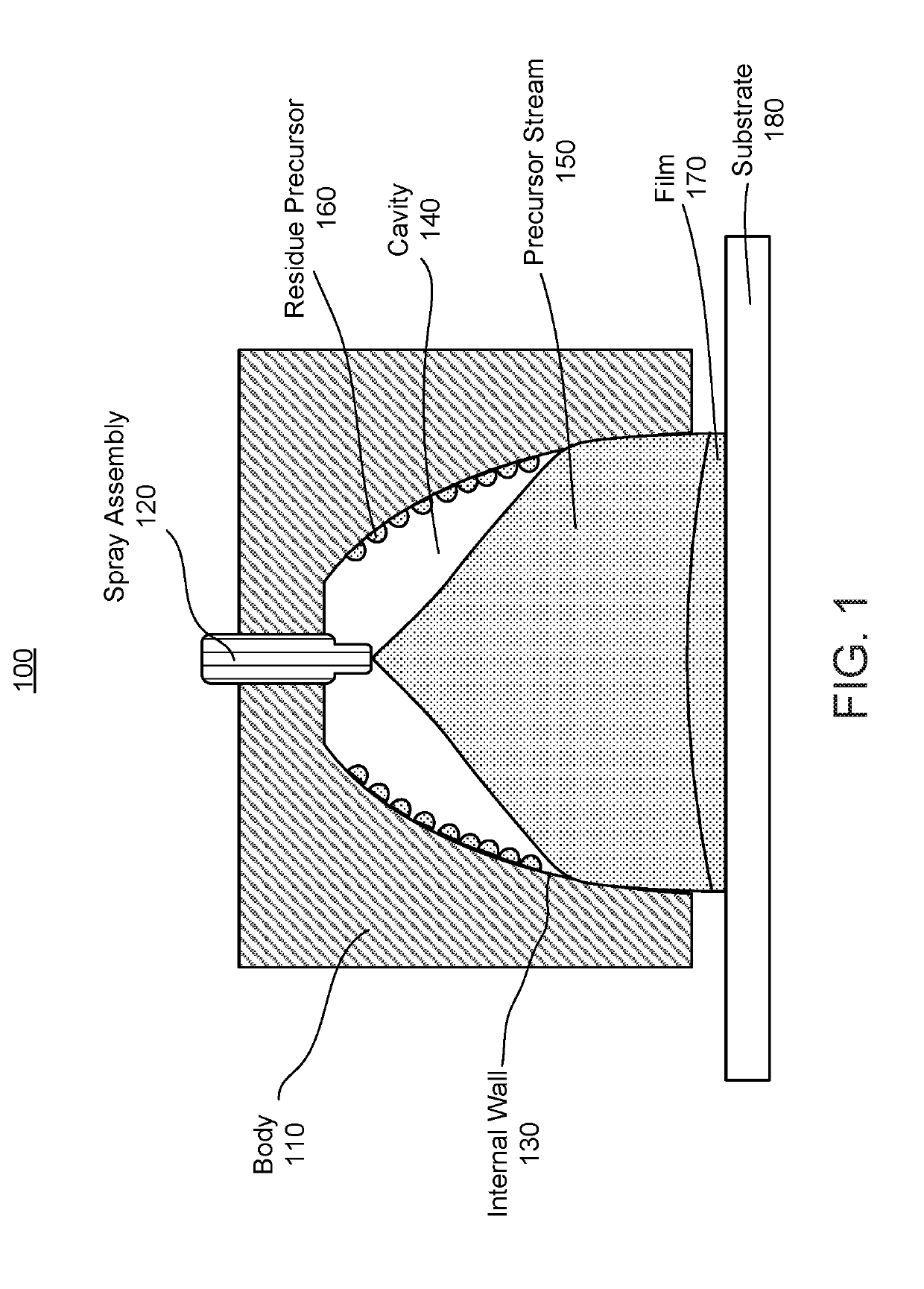

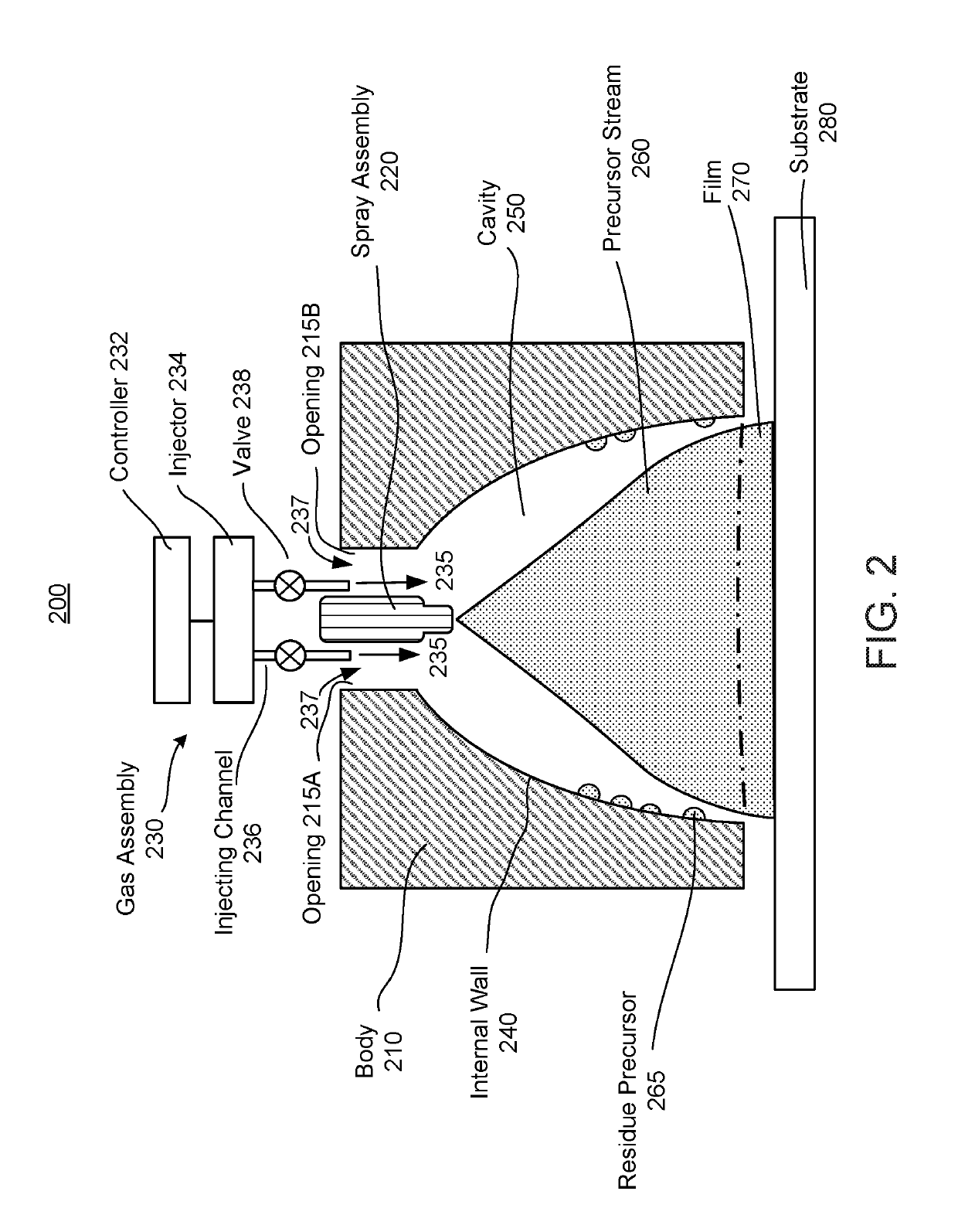

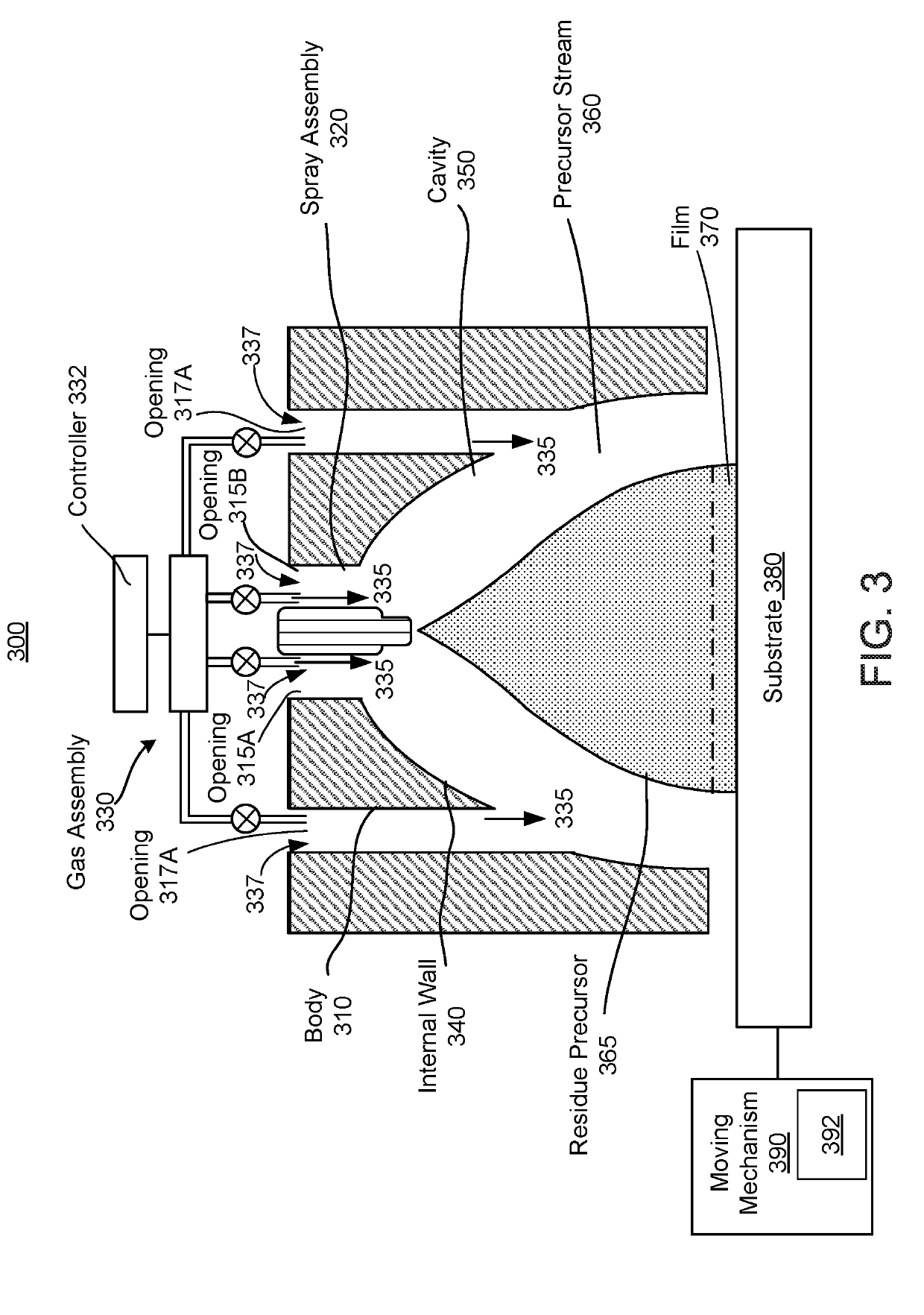

Film Deposition Apparatus With Gas Entraining Openings

ActiveUS20190292661A1Reduce the amount requiredImprove directionality and utilizationMolten spray coatingLiquid spraying apparatusPlasma generatorEngineering

A film deposition apparatus includes a body formed with openings and cavity, a spray assembly, and a gas assembly. The spray assembly sprays a precursor stream into the cavity for forming a film on a substrate. The gas assembly injects one or more gases into the cavity through the openings to shape the precursor stream and improve directionality and utilization of the precursor stream. The film deposition apparatus can operate with one or more plasma generators to form a laminated film on the substrate. The laminated film may have three layers of film: a first film formed through reaction of a first precursor with plasma, a second film being a composite of the first precursor and a second precursor, and a third film formed through sonification of the second precursor on top of the second film. The second precursor can infiltrate into the first film and fill defects therein.

Owner:NOVA ENG FILMS INC

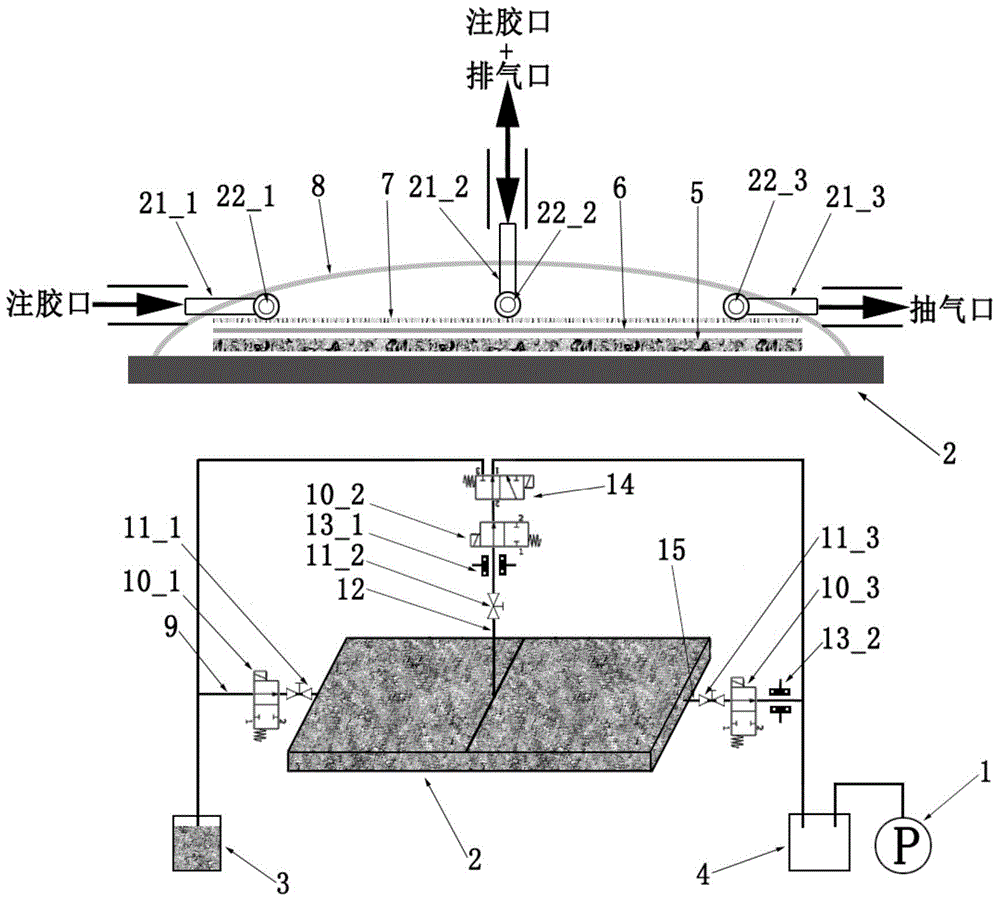

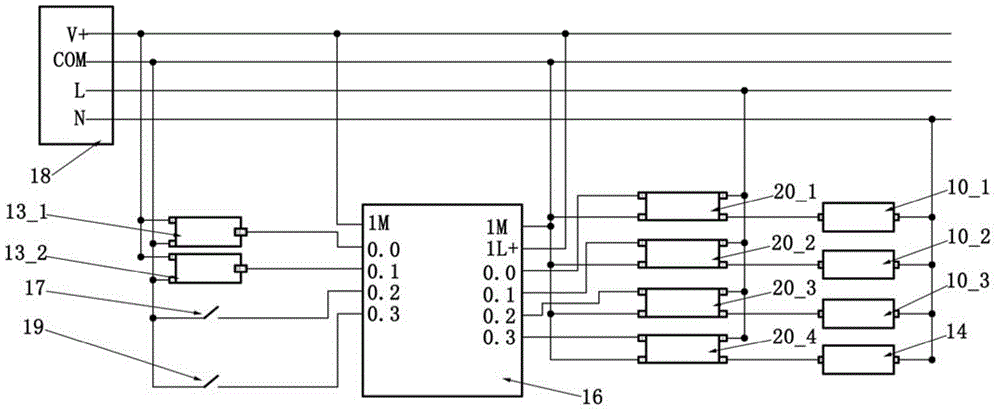

Fast resin wetting forming technology based on material flow prepeak monitoring

The invention discloses a fast resin wetting forming technology based on material flow prepeak monitoring on the basis of a traditional resin wetting forming technology. A system comprises a monitoring module, a vacuum pump, a vacuum tank, a sensor, electromagnetic valves A, electromagnetic valves B, a throttling valve, a die, a storage tank, filler, die releasing cloth, a flow guide net, a flow guide pipe, a pipeline connecting piece, sealing cloth, a feeding pipeline, a middle pipeline and a gas extraction pipeline. The technology process mainly includes the steps that the die is divided into multiple filling areas; the material flow prepeak position is monitored through the sensor in the monitoring module; sequential starting and stopping of all the pipelines are controlled in cooperation of a controller, and step-by-step filling is achieved for the different filling areas; and after all the areas are filled with sizing materials, curing forming is conducted, then die releasing is conducted, and a product can be obtained. Compared with a traditional technology, the fast resin wetting forming technology has the beneficial effects that sizing material prepeak lossless monitoring is achieved, and the automation degree is high; and the probability of filling defects such as incomplete wetting can be better lowered, and meanwhile the labor cost is reduced. The fast resin wetting forming technology is particularly suitable for processing and producing of various large thermosetting resin matrix composite materials of complex structures.

Owner:BEIJING UNIV OF CHEM TECH

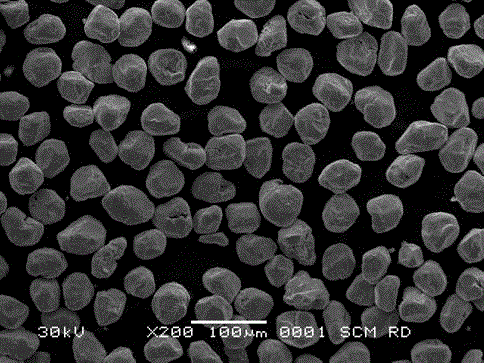

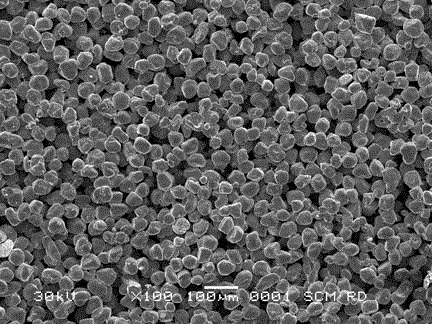

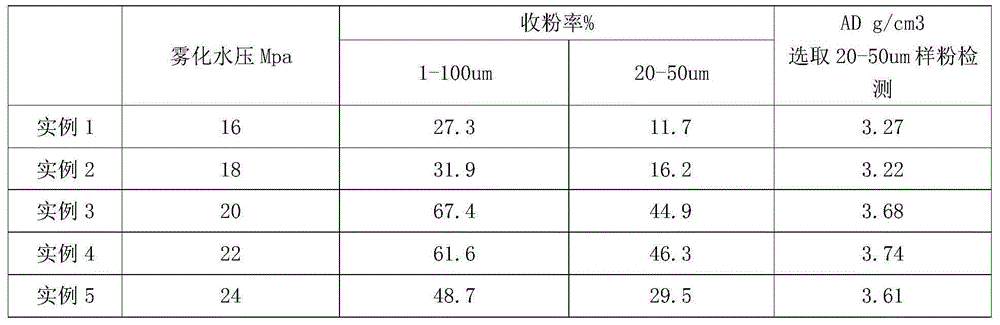

Copper powder used for ultrathin vapor chamber and manufacturing method thereof

The invention relates to copper powders and a manufacturing method thereof, and especially relates to copper powders used for an ultrathin vapor chamber and a manufacturing method thereof. The shape of a copper powder particle is spherical or spherical-like. The copper powder particles are in a single particle non-spheroidizing structure. Particle size range of the copper powders is 1-100 [mu]m. Apparent density of the copper powders is 2.0-5.0 g / cm<3>. The shape of the copper powder particle is spherical or spherical-like. The spherical copper powder has excellent mobility, and powders can be filled uniformly and densely without powder filling defects in a vapor chamber powder filling process. The copper powders have capillary organization in relatively high porosity. The porosity of the capillary organization is higher than 65%.

Owner:SCM METAL PROD SUZHOU

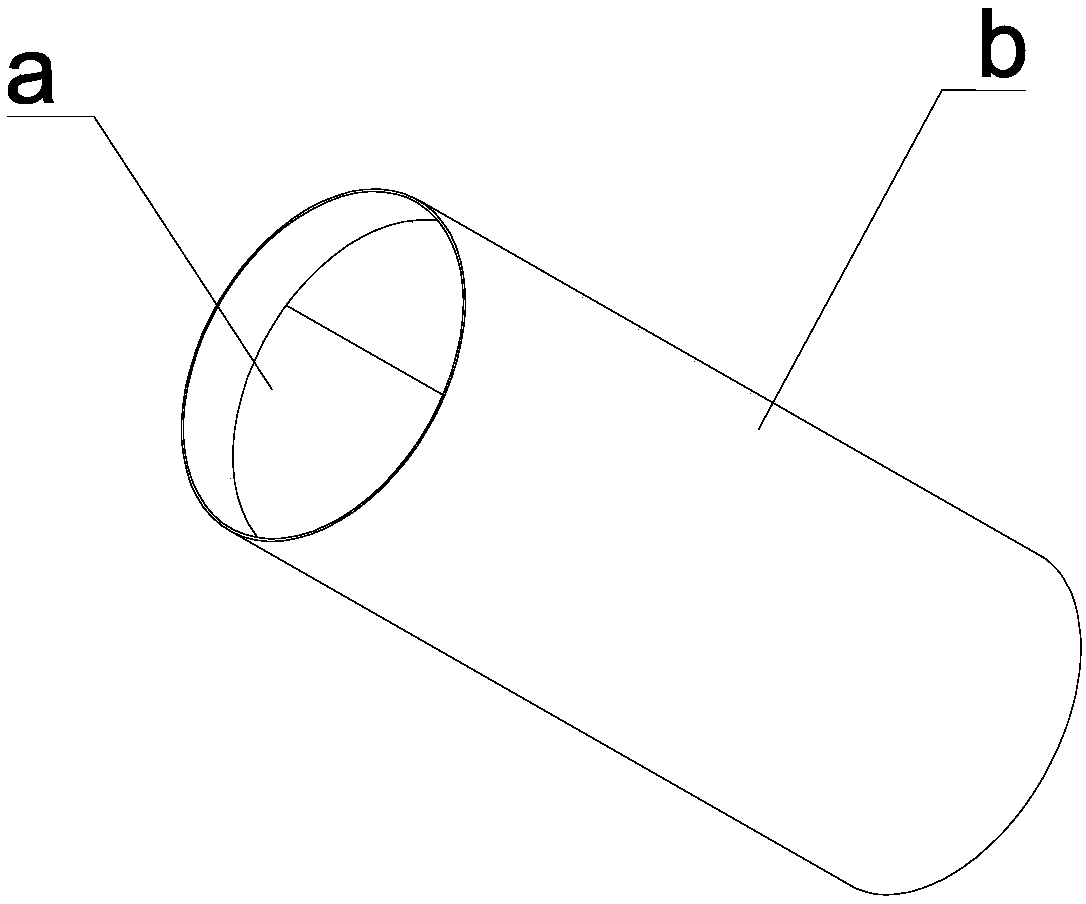

Methods and apparatus for treating disc herniation and preventing the extrusion of interbody bone graft

InactiveUS9592062B2Minimized in sizeAvoiding delicateBone implantPharmaceutical delivery mechanismDiscectomyFilling defect

Methods and apparatus for treating disc herniation provide a conformable device which assumes a first shape associated with insertion and a second shape or expanded shape to occlude the defect which typically follows partial discectomy. The device may take different forms according to the invention, including patches size to cover the defect or plugs adapted to fill the defect. In a preferred embodiment, however, the device is a gel or other liquid or semi-liquid which solidifies to occlude the defect from within the body of the disc itself. In another preferred embodiment, a mesh screen is collapsed into an elongated form for the purposes of insertion, thereby minimizing the size of the requisite incision while avoiding delicate surrounding nerves. Such a configuration also permits the use of instrumentation to install the device, including, for example, a hollow tube or sheath adapted to hold the collapsed screen, and a push rod to expel the collapsed device out of the sheath for use in occluding the disc defect. A device according to the invention may further include one or more anchors to assist in permanently affixing the device with respect to the defect.

Owner:ANOVA

Mineral-based chemical heat storage composite material and preparation method thereof

ActiveCN105567174AHigh activityHigh thermal conductivityHeat-exchange elementsFilling defectMaterials science

A mineral-based chemical heat storage composite material and a preparation method thereof are disclosed, the mineral-based chemical heat storage composite material having a chemical heat storage function is prepared by talcum powder modification, interlaminar ammonium ions of the mineral-based chemical heat storage composite material may enter talcum powder crystal lattices under the conditions of ambient temperature> 60 DEG C to absorb heat to form H-O and Mg-N bonds and fill defects, when the ambient temperature is below 20 DEG C, the H-O and Mg-N bonds formed with ammonium ions in the crystal lattices break and emit heat so as to achieve the effects of heat storage and heat release, and the mineral-based chemical heat storage composite material is stable in performance, large in heat storage amount, capable of being used repeatedly, mild in reaction conditions, easy to control, wide in range of sources of raw materials and suitable for low-temperature heat storage, and has broad market prospects.

Owner:辽宁卓仑科技有限公司

Method and device for ground stress testing reproducing wave velocity

PendingCN109406019ATake the hassle out of testingImpact testForce measurementAcoustic emissionAcoustic wave

The invention discloses a method and a device for ground stress testing reproducing wave velocity. Three-dimensional rock wave velocity is tested and calculated under an in-situ stress state on a borehole wall, and then an oriented rock test piece is taken back from protolith, and a maximum acoustic wave direction is processed, that is, a rock test piece in a maximum stress direction, and a compression test and an acoustic wave test are performed under side pressure. The pressure under which wave velocity of the test piece is equal to the maximum wave velocity of a drill hole is selected as maximum stress of borehole protolith, and a maximum acoustic wave direction is the maximum stress direction of the protolith. The method and the device utilize positive correlation between rock wave velocity and ground stress, and wave velocity variation under the ground stress is generally in a favorable condition of 5% to 20%, so as to ensure test accuracy of the ground stress and fill defects ofa rock acoustic emission ground stress test method. The test principle of the method and the device is simple, the device is light, and test accuracy of the ground stress can be improved from e orderof magnitude.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

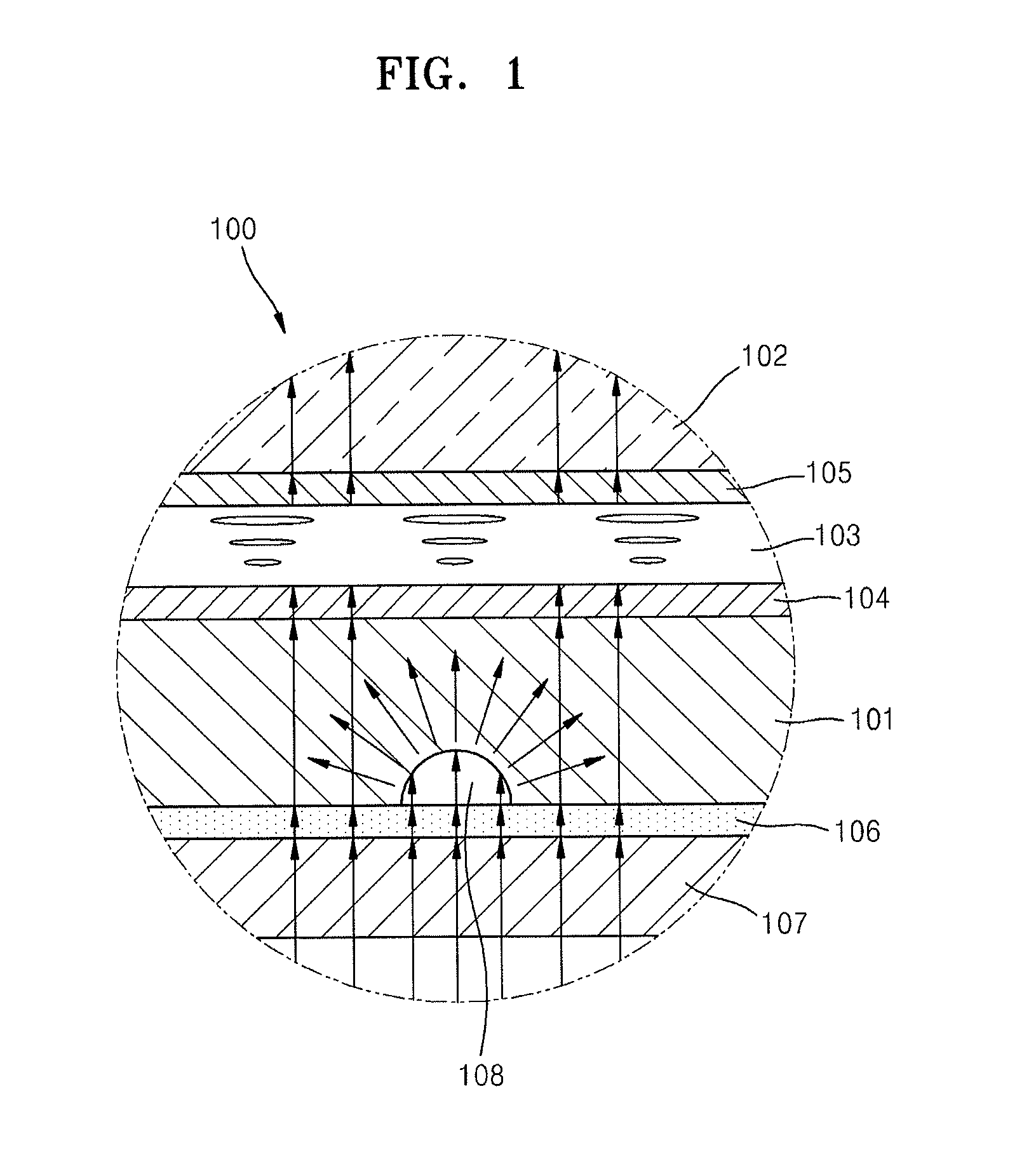

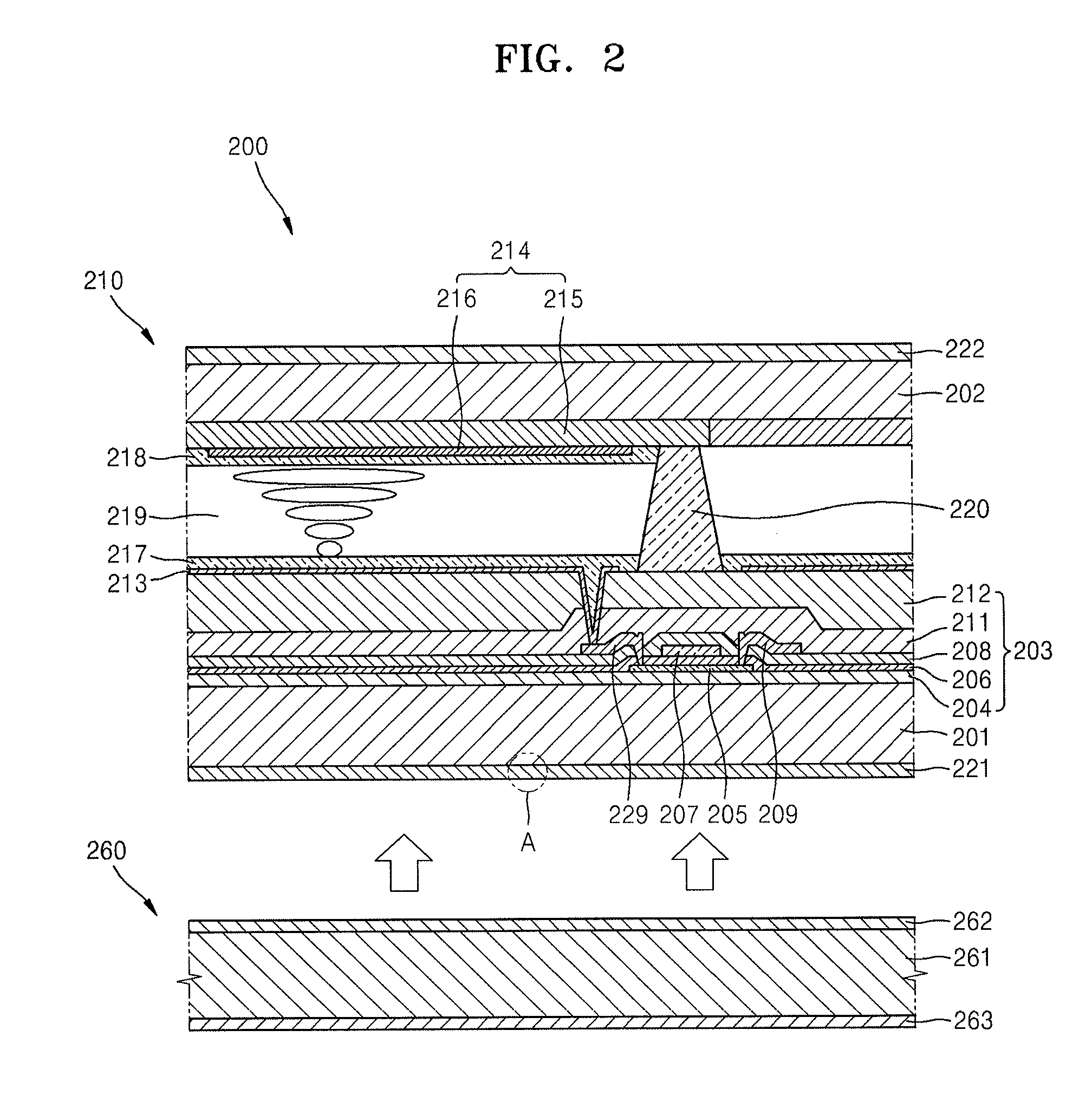

Liquid crystal display device and method of manufacturing the same

A liquid crystal display device and a method of manufacturing the same, the device including a liquid crystal display panel, the liquid crystal display panel including substrates facing each other and a liquid crystal layer therebetween; a backlight unit below the liquid crystal display panel, the backlight unit being for emitting light toward the liquid crystal display panel; a filling that fills defect holes on surfaces of the substrates, which surfaces are relatively remote from the liquid crystal layer, the filling having horizontally even surfaces with respect to the surfaces of the substrates, and a cover member disposed over the defect holes filled with the filling.

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com