Method for filling dense film defects

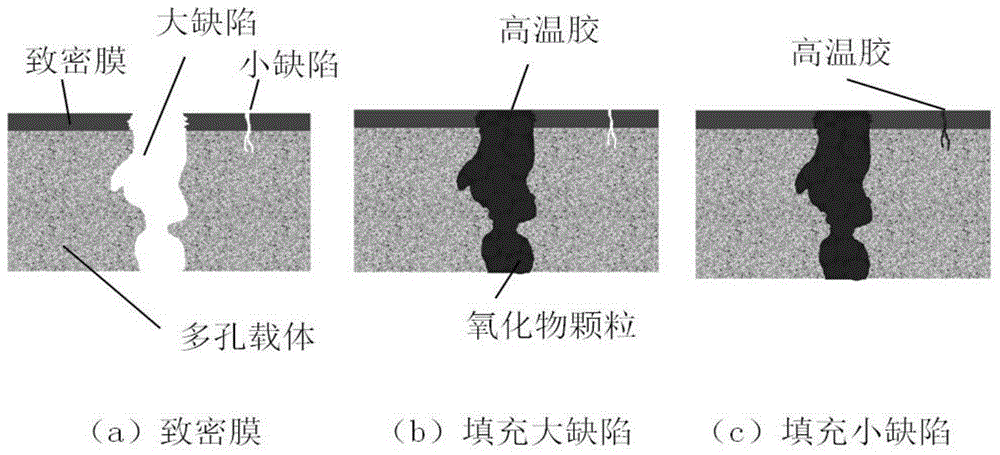

A dense film and defect technology, which is applied in the field of dense film defect filling, can solve the problems of affecting the performance of palladium film, complicated operation, and adding organic matter removal steps, etc., and achieves the benefits of recycling, good repeatability, and improved leveling performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Three kinds of Al with an average particle size of 0.5 μm, 0.3 μm and 0.2 μm 2 o 3 particles and 20nm TiO 2 In order to fill the particles into a suspension in deionized water, add high-temperature glue to prepare a composite modification solution A, in which each particle size Al 2 o 3 The mass volume concentration is 1g / mL, TiO 2 The mass volume concentration of the high-temperature glue (specifically: sodium silicate) is 10 g / mL. Use the prepared defect modification solution to modify the defects of the palladium membrane (length 80mm, outer diameter 12.5mm) prepared by conventional electroless plating. The pressure difference between the inner and outer sides of the dense membrane is 0.80-0.99MPa (the modified dense membrane is a tubular membrane , the ceramic particles or high-temperature glue in the defect filling solution are introduced into the defects on the surface of the film from the outside of the dense film by negative pressure method), the residence t...

Embodiment 2

[0022] Three kinds of Al with average particle size of 0.5 μm, 0.3 μm and 0.2 μm 2 o 3 particles and 20nm TiO 2 Add in deionized water to make a suspension, add high-temperature glue to prepare defect modification solution A, wherein each particle size Al 2 o 3 The mass volume concentration is 1g / mL, TiO 2The mass volume concentration of the high-temperature glue (specifically: sodium silicate) is 10 g / mL. Use the prepared defect modification solution to modify the defects of the palladium alloy film (length 80mm, outer diameter 12.5mm) prepared by conventional electroless plating (the modified dense film is a tubular film, and the ceramic particles in the defect filling solution are filled by negative pressure method) Or high-temperature glue is introduced from the outside of the dense film into the defect on the surface of the film), the pressure difference on both sides of the dense film is 0.80-0.99MPa, the residence time of the dense film in the defect modification so...

Embodiment 3

[0026] Three kinds of Al with average particle size of 0.5 μm, 0.3 μm and 0.2 μm 2 o 3 particles and 20nm TiO 2 In order to fill the particles into a suspension in deionized water, add high-temperature glue to prepare a defect modification solution A, in which each particle size Al 2 o 3 The mass volume concentration is 1g / mL, TiO 2 The mass volume concentration of the high-temperature glue (specifically: sodium silicate) is 20 g / mL. Use the prepared defect filling solution to fill the defects of the palladium film (length 80 mm, outer diameter 12.5 mm) prepared by conventional electroless plating (the modified dense film is a tubular film, and the ceramic particles in the defect filling solution or The high temperature glue is introduced from the outside of the dense film into the defect on the surface of the film), the negative pressure method condition is to keep the pressure difference between the two sides of the dense film at 0.80-0.99MPa, the time for the dense film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com