Capacitor manufacturing method

A manufacturing method and capacitor technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., and can solve problems such as capacitor breakdown and difficult dielectric layer coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

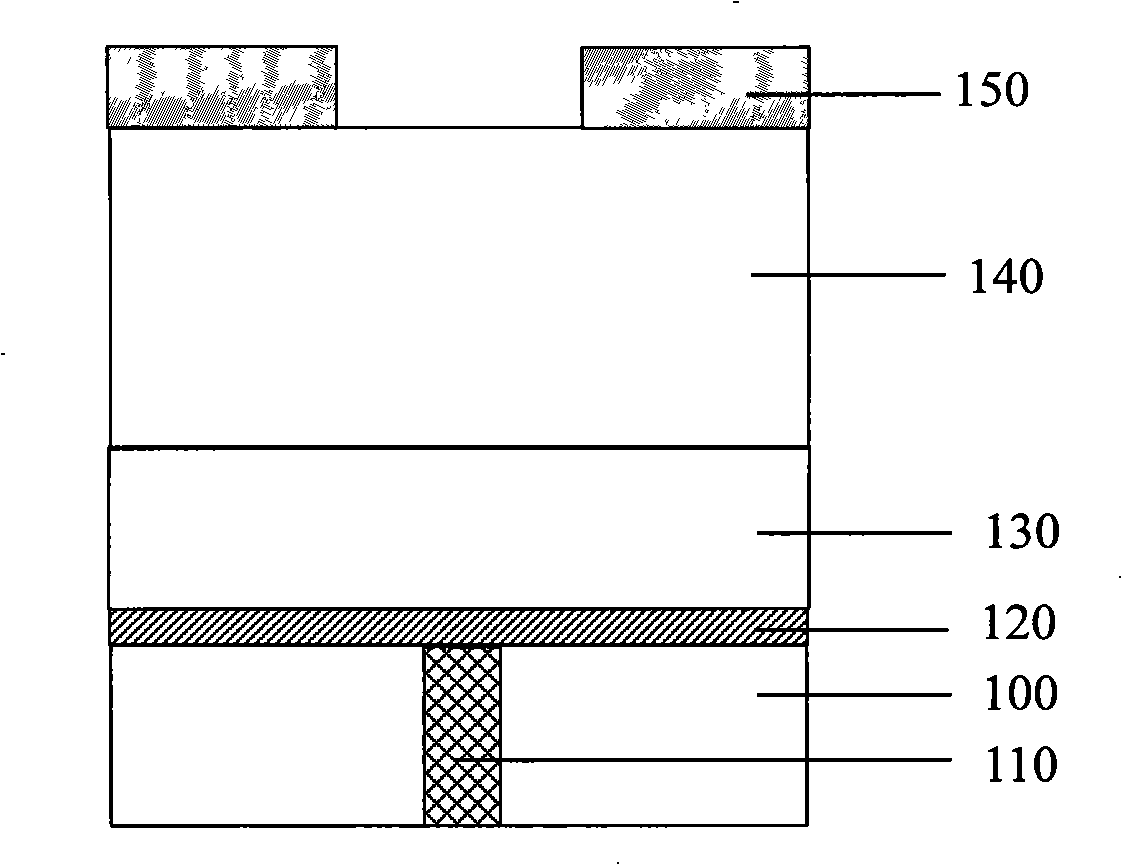

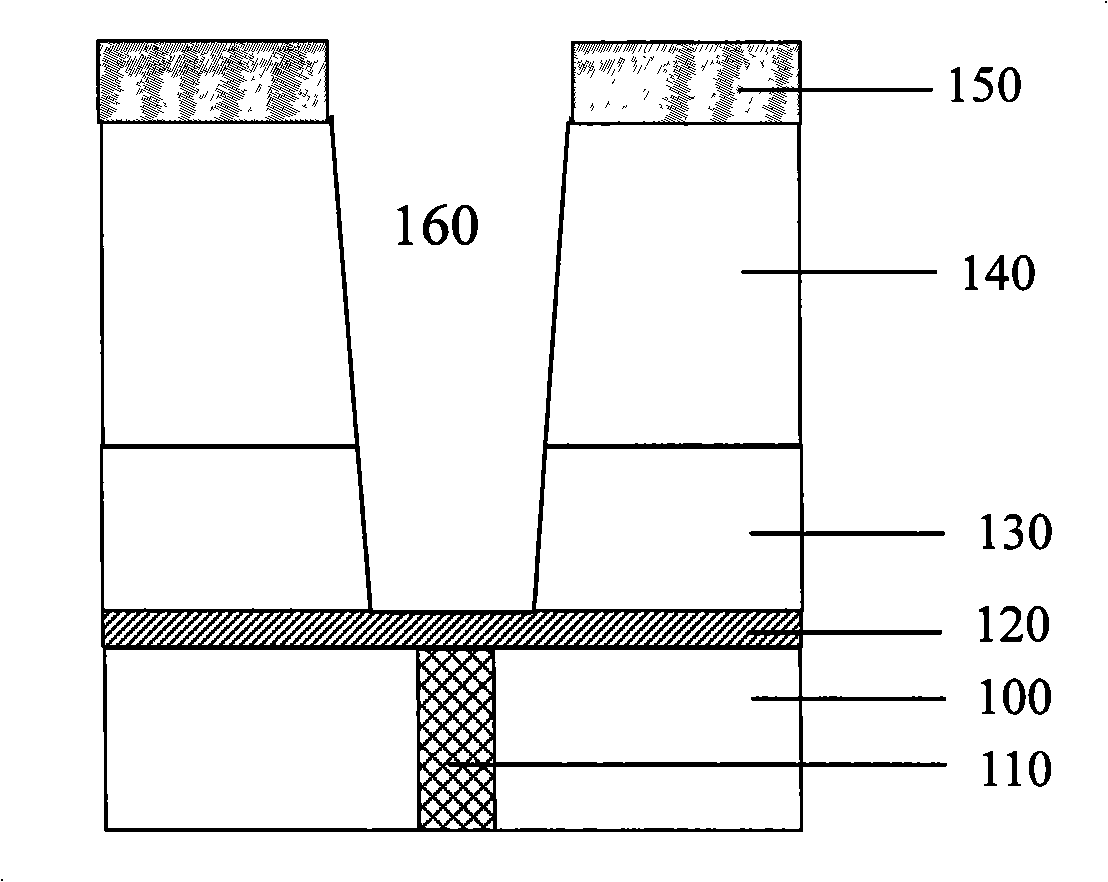

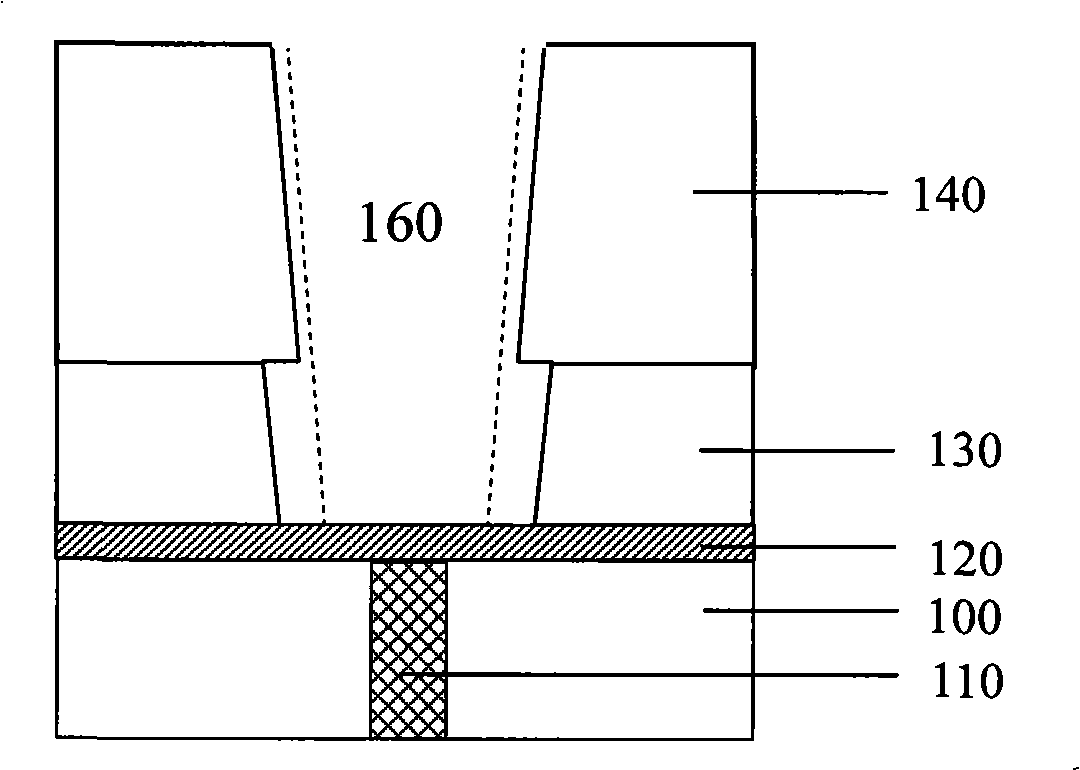

[0028] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] In order to solve the gap between two adjacent polysilicon hemispherical particles formed in the interface region of the first insulating layer and the second insulating layer in the prior art is too small, it is difficult to completely fill the dielectric layer material between the two hemispherical particles , the defect that the capacitor is easily broken down at the position, the present invention provides a new method for manufacturing a capacitor, and each step will be described in detail below in conjunction with the accompanying drawings. The method for manufacturing a capacitor includes:

[0030] Step S1: providing an interlayer dielectric layer and an interconnection structure passing through the interlayer dielectric layer;

[0031] Reference attached Figure 3A As shown, 300 in the drawings is an interlayer dielectric l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com