Repairing method for defects of turbine guide blade

A technology for turbine guide vanes and defects, applied in welding media, welding/cutting media/materials, manufacturing tools, etc., can solve problems such as no improvement, unsuitable for repair, and non-compliance with technical standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

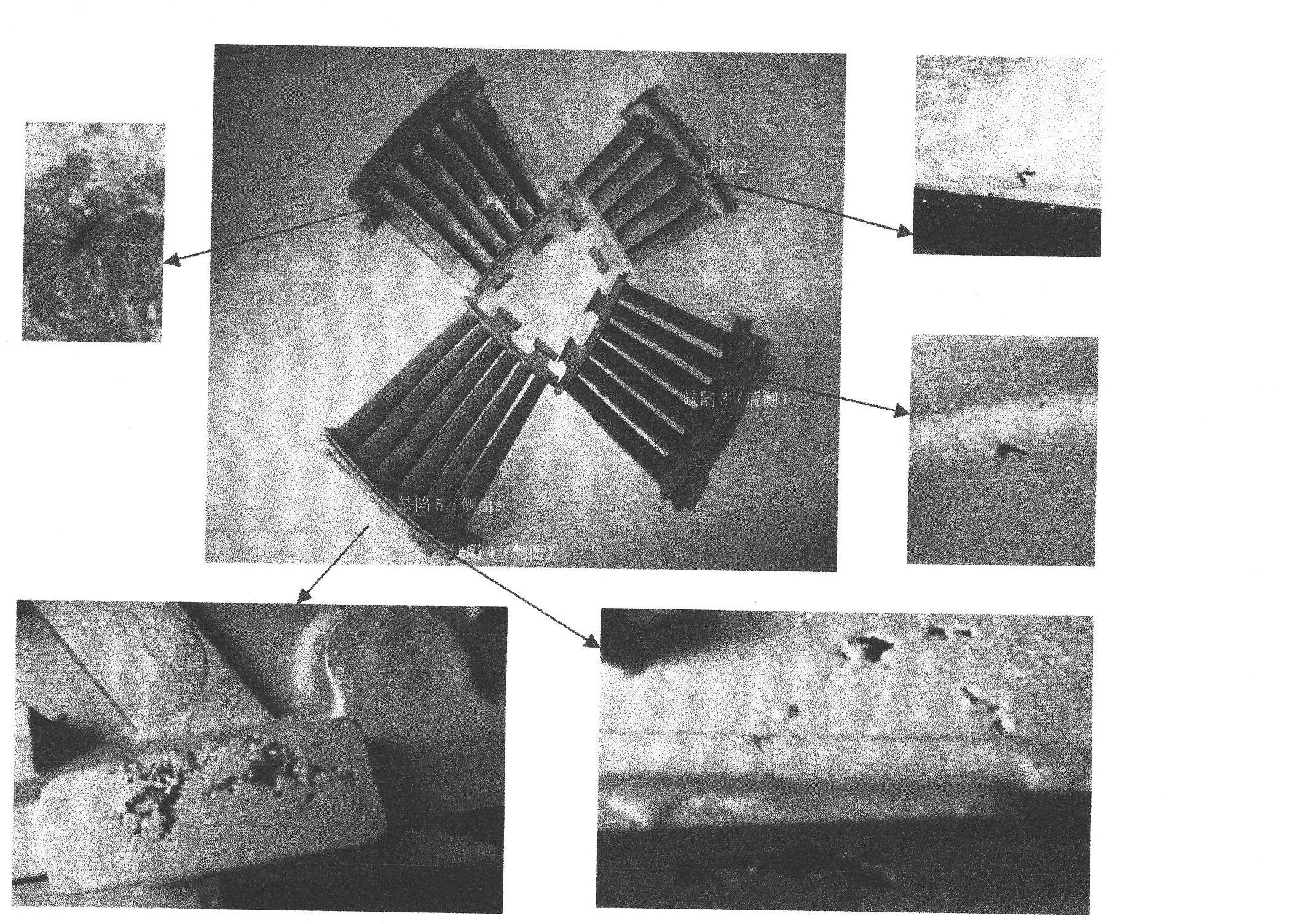

[0029] A method for repairing defects of turbine guide vanes: filling defects to be repaired with paste-like mixed powder (a mixture of solder, alloy powder, and binder) and performing vacuum brazing to repair defects of K417G turbine guide vanes. The specific requirements are as follows

[0030] 1. Preparation before welding

[0031] 1.1 Defect cleaning: Use mechanical processing methods to completely remove oxide slag inclusions, holes, and non-linear looseness that do not meet the standard requirements of cast blades.

[0032] 1.2 X-ray inspection: Use X-ray to inspect the position of the defect that has been removed, and the defect should be completely removed after inspection.

[0033] 1.3 Clean up the oxide skin: use a grinder equipped with an alloy grinding head to clean the oxide skin on the defect surface and its surroundings, and it should show a metallic luster after removal.

[0034] 2. Cleaning: Clean the blades with acetone.

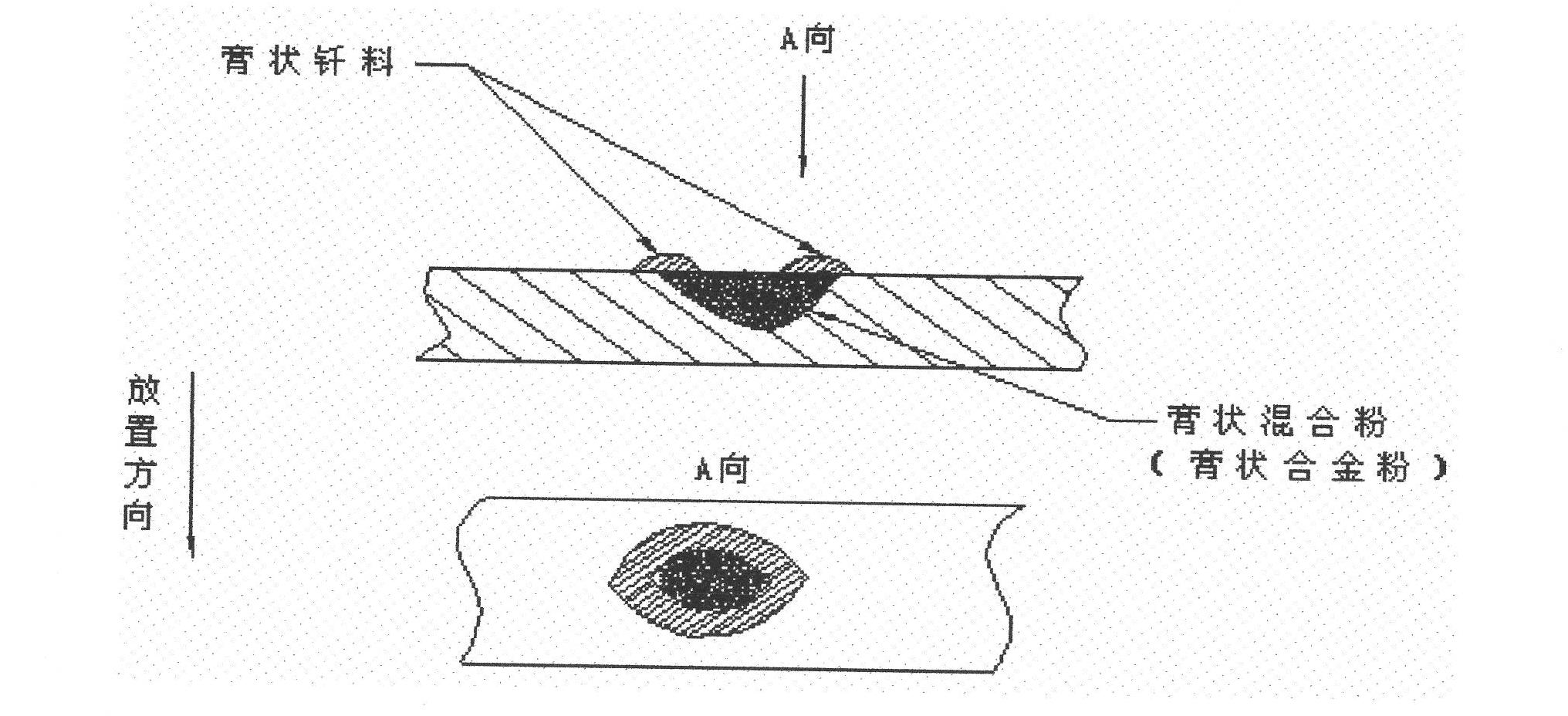

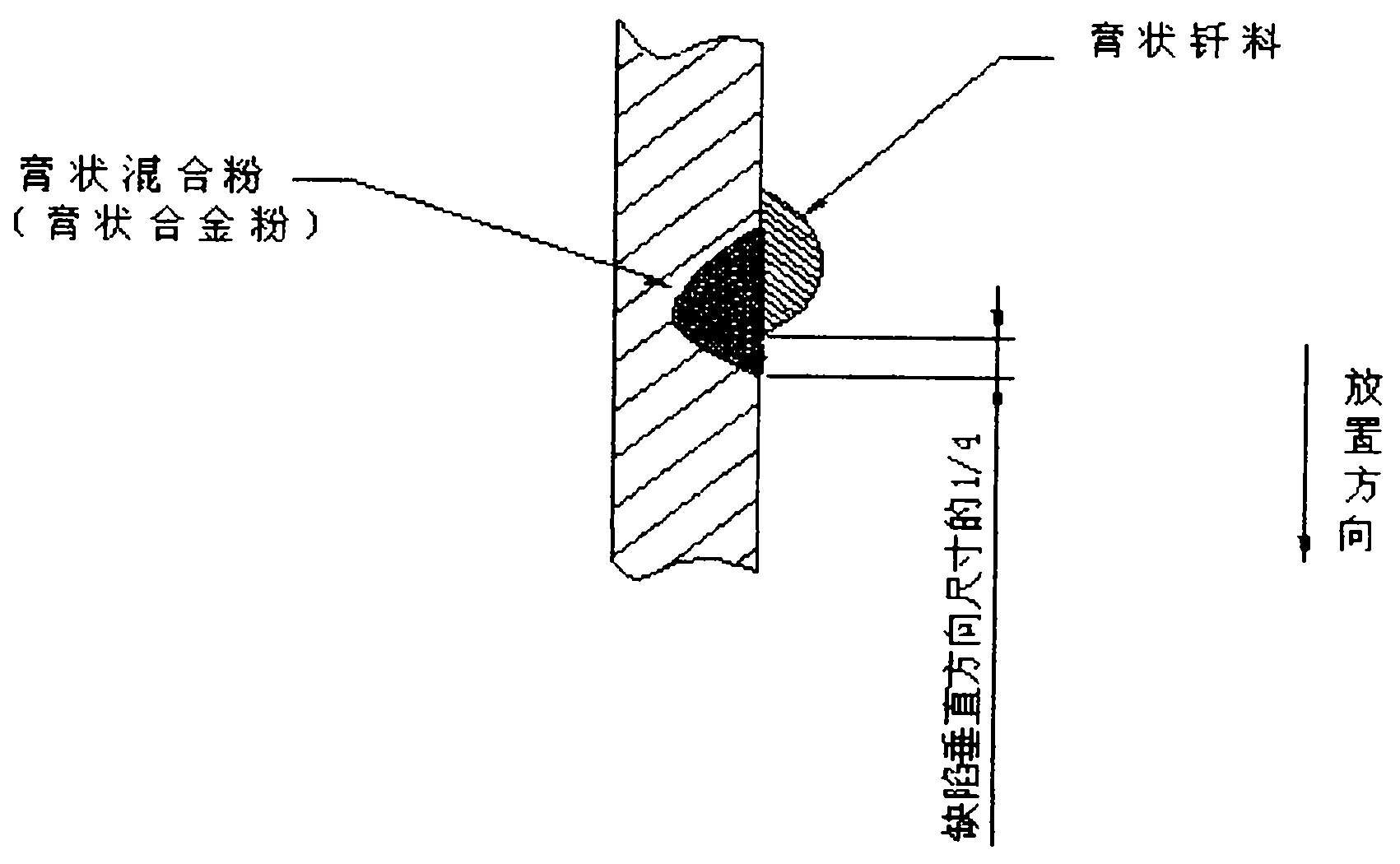

[0035] 3. Preset paste mixed powd...

Embodiment 2

[0053] The defects to be repaired are filled with paste alloy powder and vacuum brazing is used to repair the defects of K417G turbine guide vanes. The operation of repairing the blade in this embodiment is different from Embodiment 1 in two points:

[0054] One is that paste-like alloy powder is used to fill the defects to be repaired, and its proportion is 92% of FGH741 alloy powder and 8% of brazing binder; The thickness of the material is 1 / 2 to 3 / 4 of the defect depth.

[0055] The brazing quality of the repaired blades meets the standard requirements after inspection, and the shape, size and position accuracy meet the requirements of the design drawings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com