Patents

Literature

31 results about "Protolith" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A protolith is the original, unmetamorphosed rock from which a given metamorphic rock is formed (proto-: first; lithos: rock; both Greek). For example, the protolith of a slate is a shale or mudstone. Metamorphic rocks can be derived from any other kind of non-metamorphic rock and thus there is a wide variety of protoliths. Identifying a protolith is a major aim of metamorphic geology.

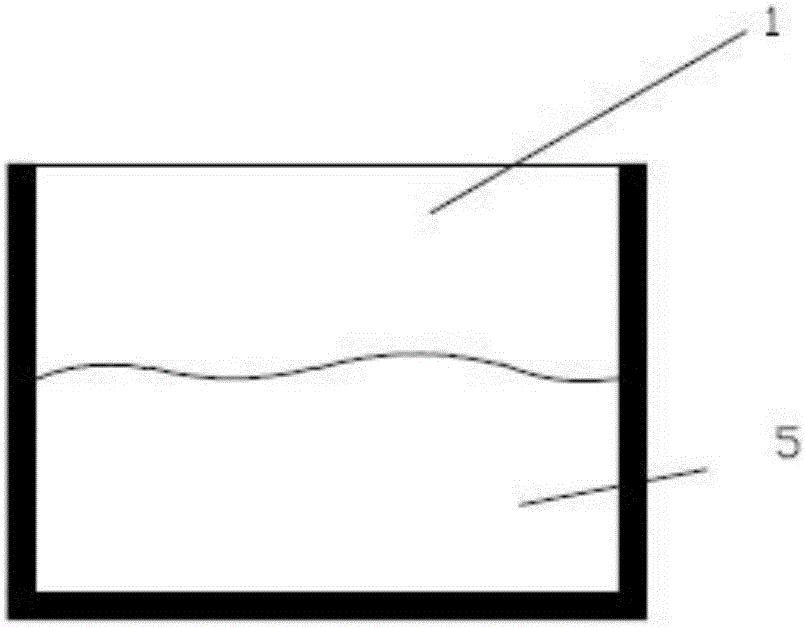

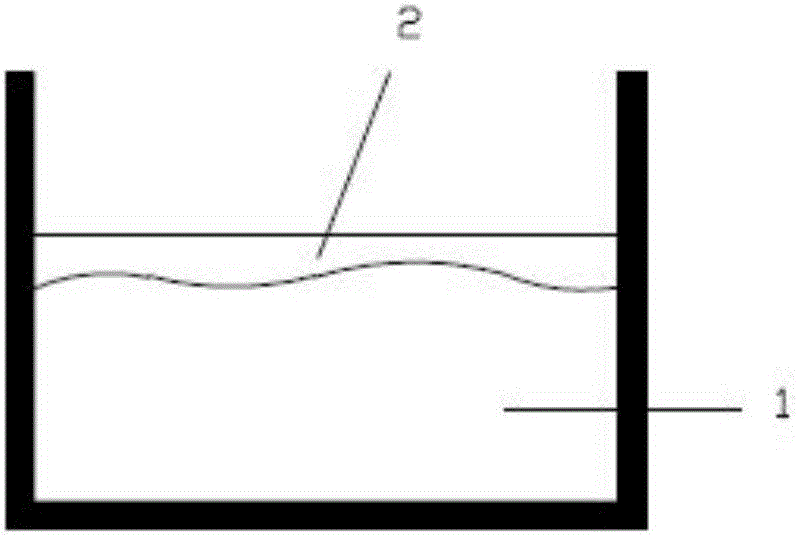

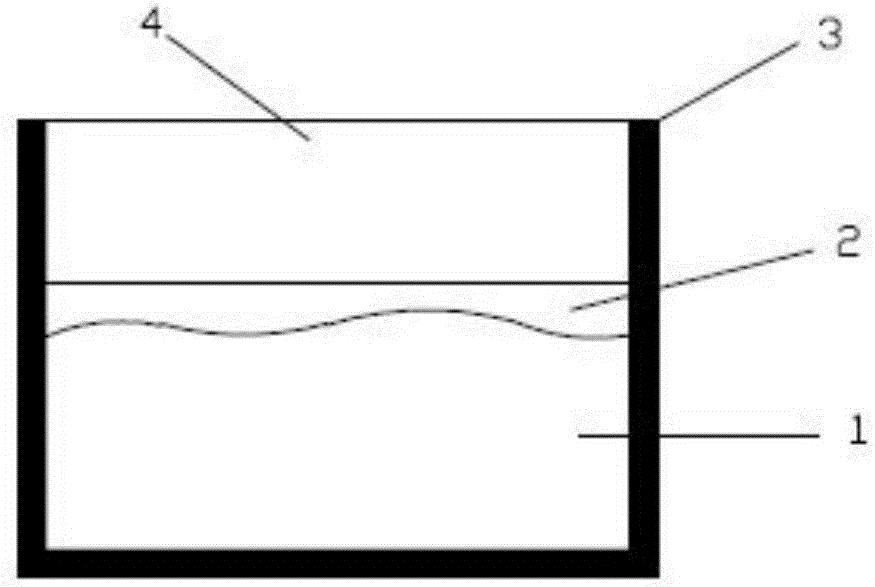

Method for manufacturing transparent rock model structure face test piece

ActiveCN106248454AGood surface roughness coefficientIncrease credibilityPreparing sample for investigationMaterial strength using tensile/compressive forcesEpoxyEngineering

The invention discloses a method for manufacturing a transparent rock model structure face test piece. The method comprises the following steps that 1, a protolith structural face is manufactured; 2, the structural face is placed in a stainless steel mold; 3, a silica gel opposite model of the protolith structural face is manufactured; 4, transparent epoxy resin is weighed and placed in a container; 5, a curing agent is added into the container in the step 4, and bubbles in the stirred mixed solution are removed through light vibration in the vacuum negative pressure environment; 6, the silica gel opposite model manufactured in the step 3 is placed in the mold in the step 2; 7, the mixed solution prepared in the step 5 is slowly poured into the mold in the vacuum negative pressure environment, and pouring is stopped after the solution reaches a certain position; 8, a transparent epoxy resin cube body custom-made in a factory is placed in the mixed solution which is not cured, the two parts are horizontally bound, and a simulation structural face capable of being used for a rock visualization experiment is obtained. The fine surface form of the structural face is effectively and truly reflected, and good transparency and repeatability are achieved.

Owner:SHAOXING UNIVERSITY

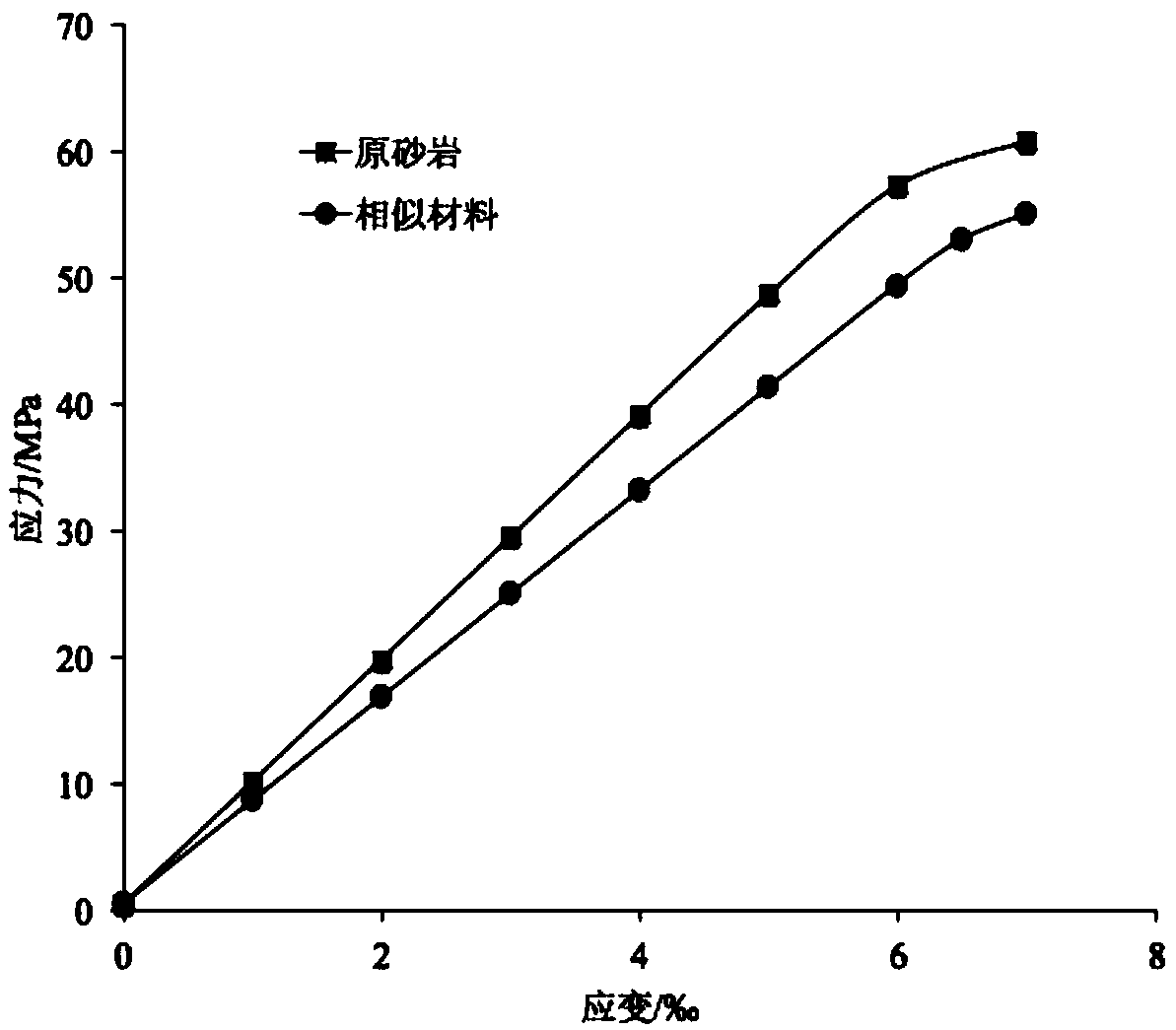

Sandstone similar material and preparation method thereof

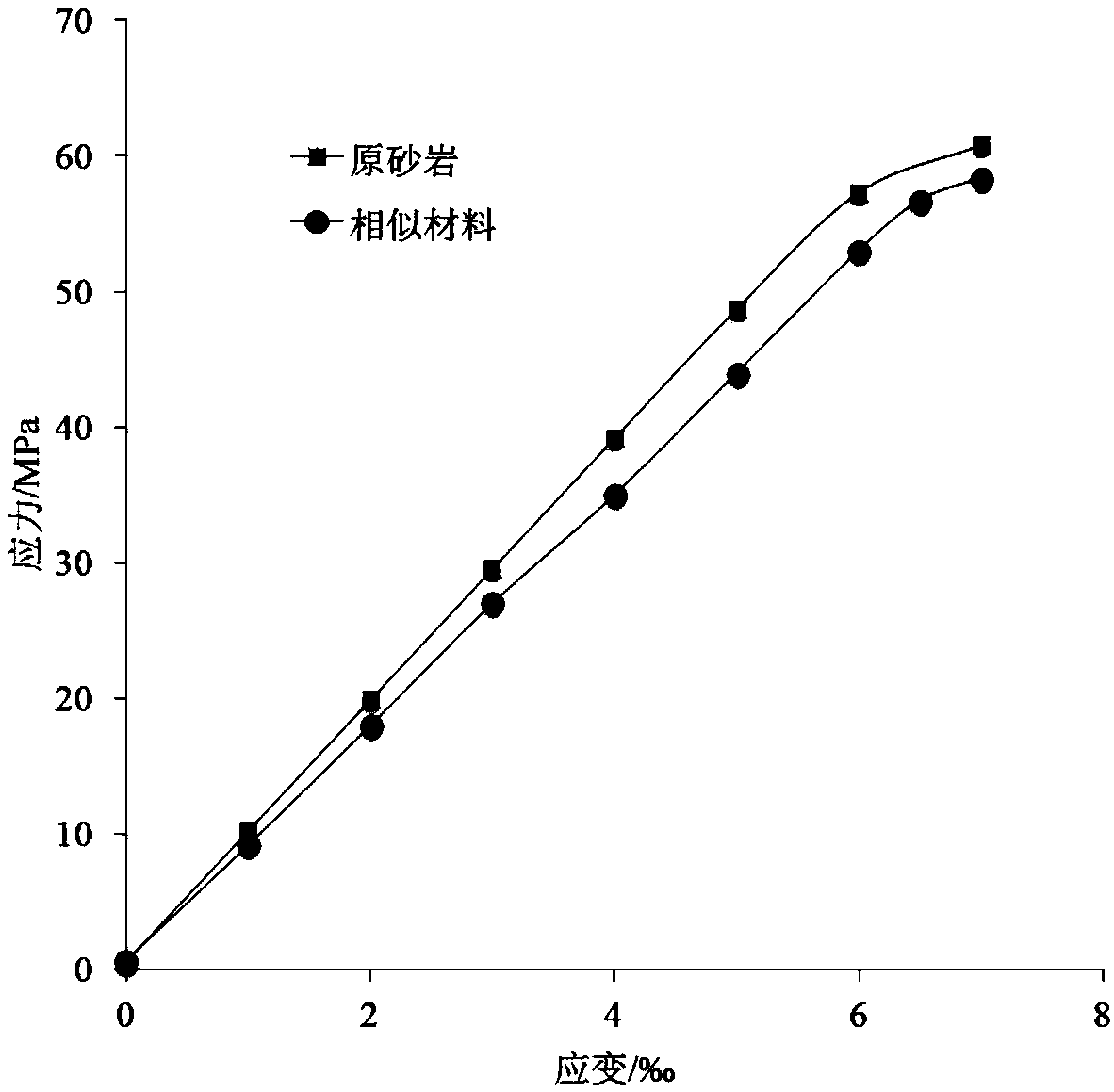

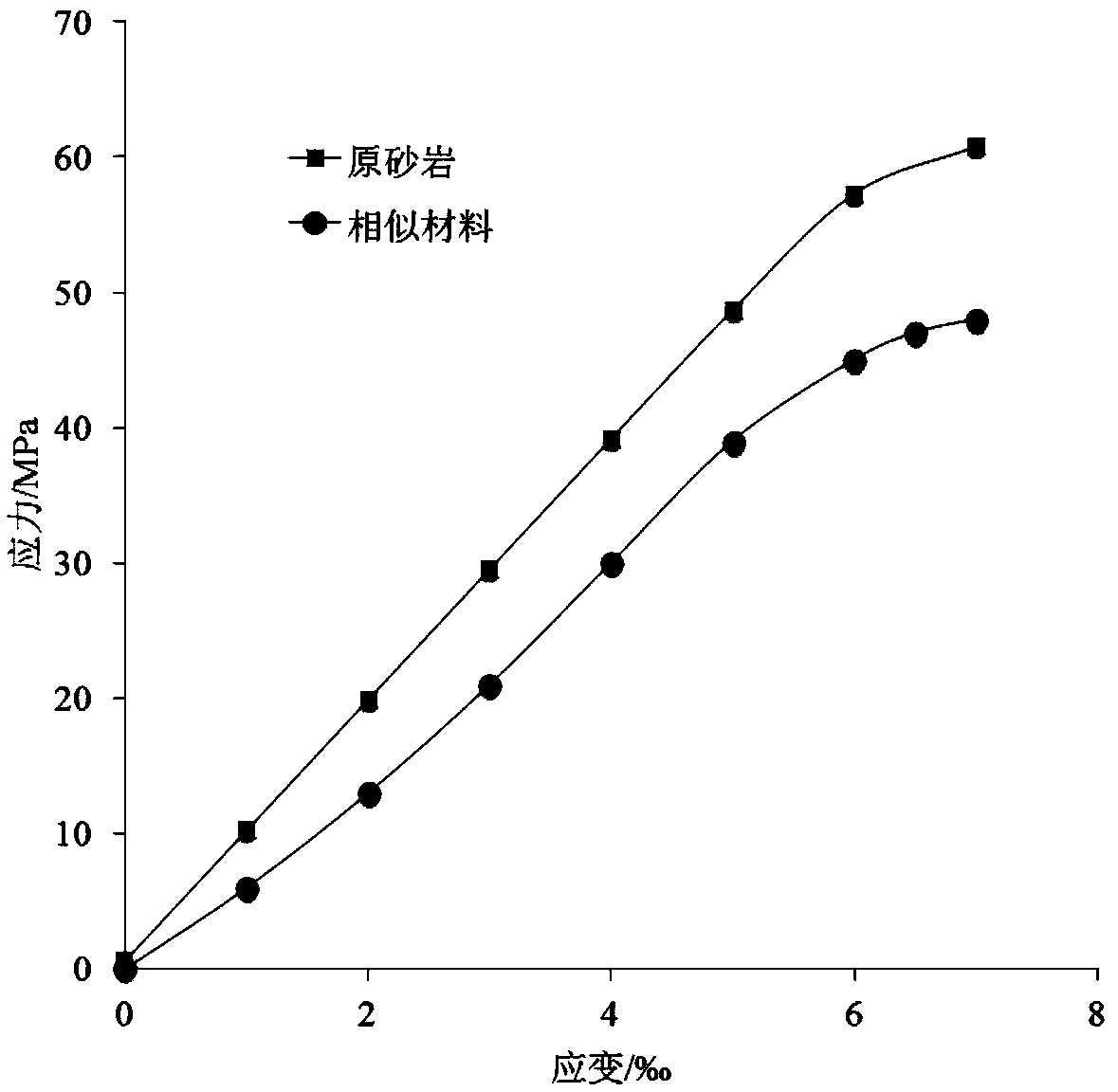

InactiveCN109020364AImprove brittlenessHigh strengthSolid waste managementPreparing sample for investigationMechanical propertyWater reducer

The invention provides a sandstone high-strength high-brittleness similar material and a preparation method thereof. Raw materials comprise quartz sand, silicon powder, cement, distilled water and a water reducer. based on physical and mechanical properties and microscopic features of protolith, a method of regulating material properties by using aggregate is adopted, quartz sand is selected to improve brittleness of the material, and silicon powder is selected to raise strength of the material. Thereby, brittleness and strength of the sandstone similar material are achieved, and main physicaland mechanics parameters (density, elastic modulus, cohesion, internal friction angle, uniaxial compressive strength, tensile strength and Poisson's ratio, etc.) of the similar material and protolithmeet the similarity theory. Features of sandstone in rock slope of Xinjiang Tianshan highway are successively simulated. The types of required materials are less, and the cost is low. The manufactureefficiency is high. The material of the invention has wide practicality.

Owner:HUBEI ENG UNIV

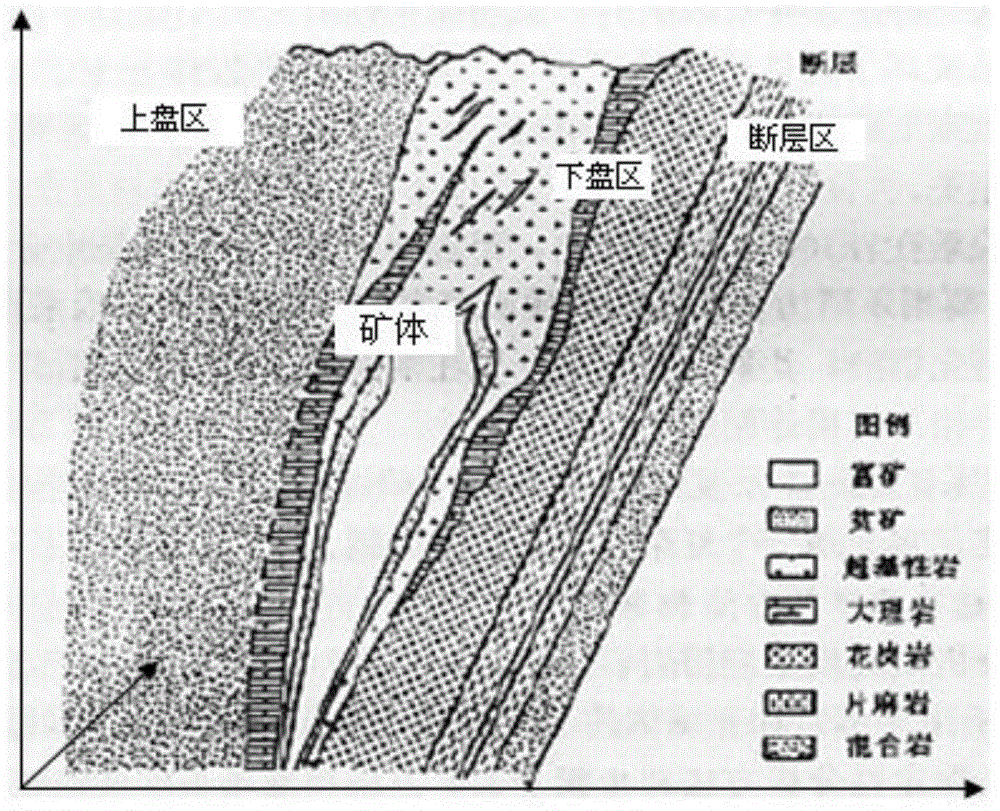

Cross-scale complicated geologic body ground stress field identification method and device

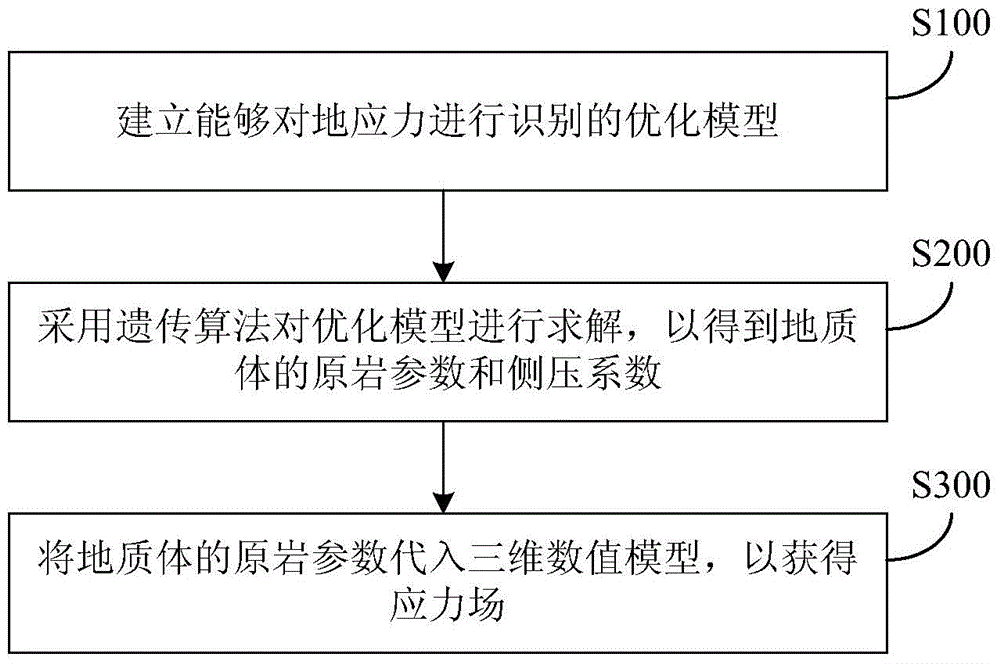

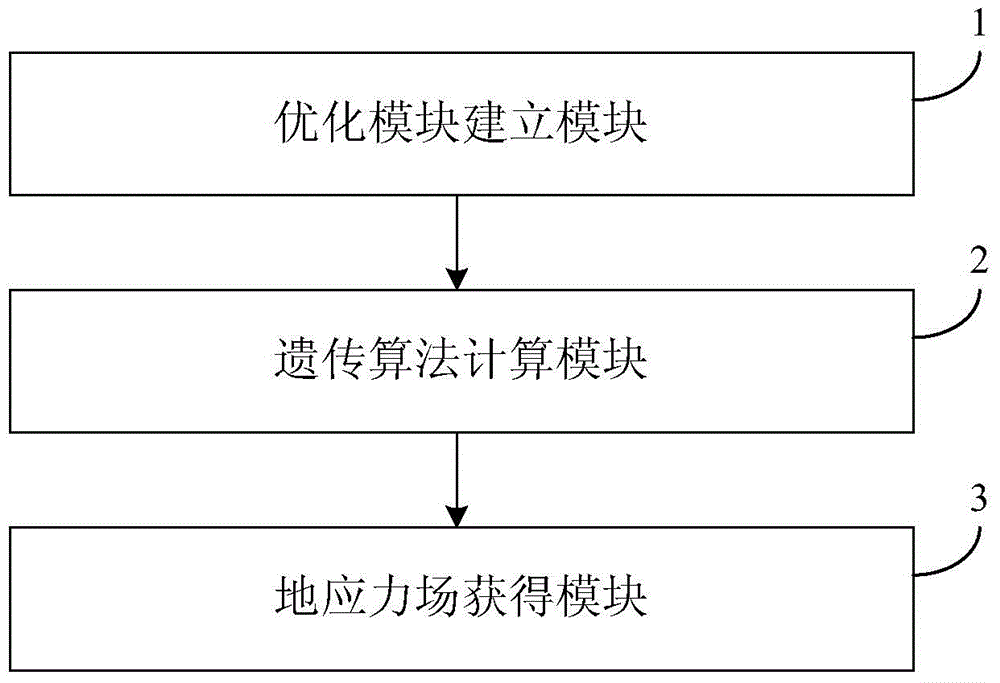

InactiveCN103605900ARealize the effect of geostressSolve the difficulty of giving a display functionSpecial data processing applicationsGenetic algorithmNumerical models

The invention relates to a cross-scale complicated geologic body ground stress field identification method, and belongs to the technical field of geological engineering, rock mass engineering and numerical analysis. The cross-scale complicated geologic body ground stress field identification method comprises the following steps: an optimization model capable of identifying ground stress is established; a genetic algorithm is adopted for solving the optimization model so as to obtain protolith parameters and side pressure coefficients of a geologic body; the protolith parameters of the geologic body are substituted into a three-dimensional numerical model to obtain a stress field. A device used for implementing the method comprises an optimization model establishing module, a genetic algorithm calculation module and a ground stress field obtaining module, wherein the optimization model establishing module is used for establishing the optimization model capable of identifying the ground stress; the genetic algorithm is used for solving the optimization model to obtain the protolith parameters and the side pressure coefficients of the geologic body; the ground stress field obtaining module is used for substituting the protolith parameters of the geologic body into the three-dimensional numerical model so as to obtain the ground stress field. According to the cross-scale complicated geologic body ground stress field identification method and device, the initial ground stress field in the geologic body can be obtained, so that the problem that existing ground stress inversion theories and methods are limited by ground stress inversion of a cross-scale complicated geologic body.

Owner:JINCHUAN GROUP LIMITED +1

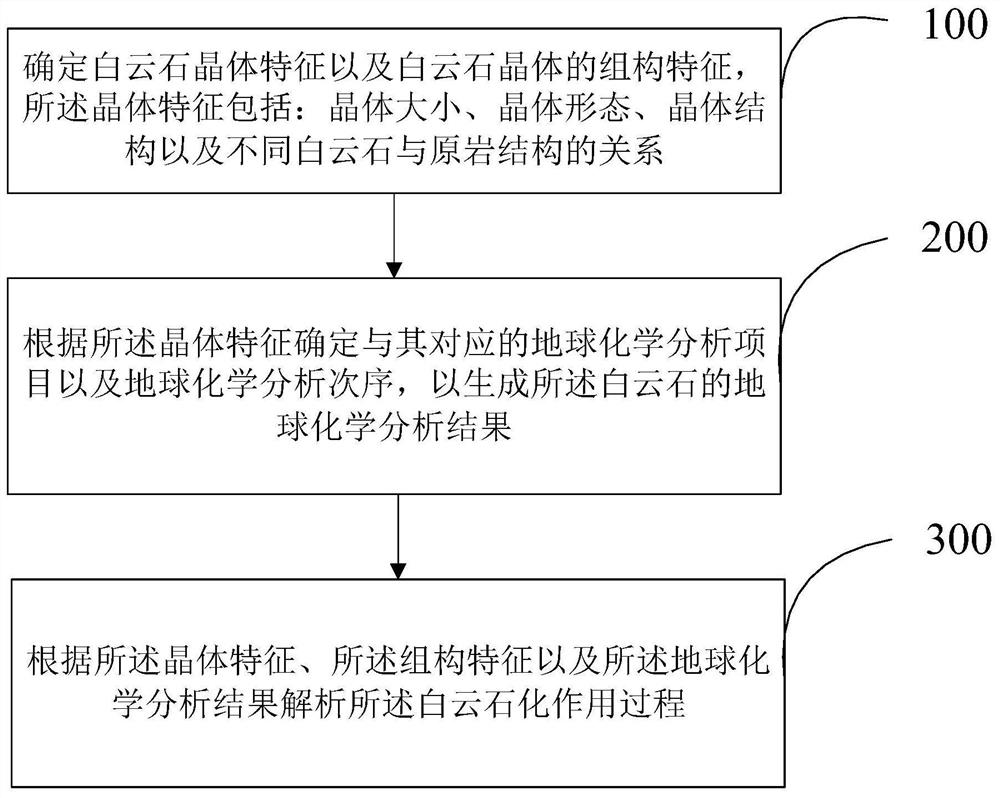

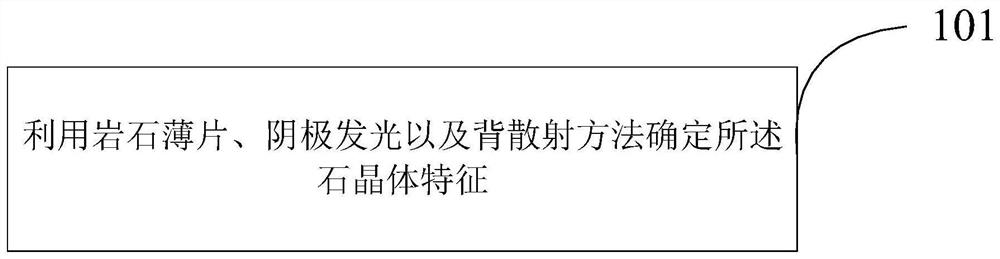

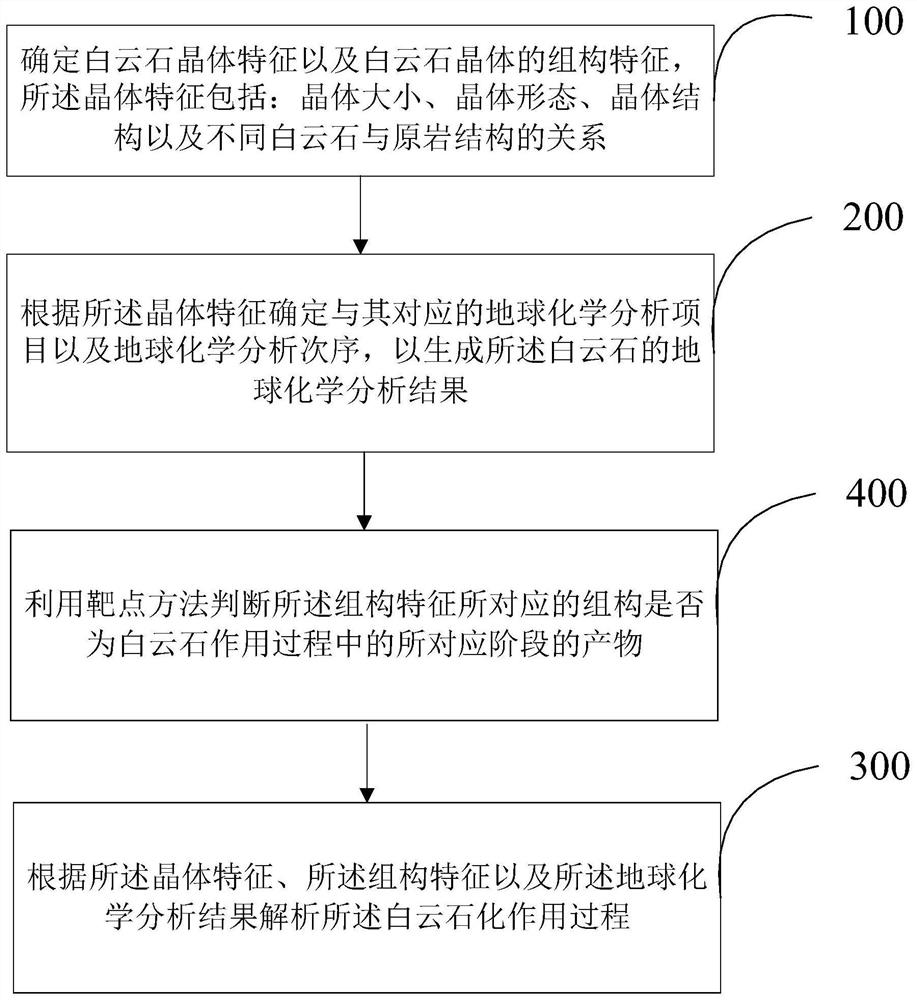

Method and device for identifying dolomite petrifaction action process

ActiveCN113791189AMaterial analysis using wave/particle radiationInvestigating crystalsDolostoneCrystal morphology

The invention provides a method and device for identifying the dolomite petrifaction action process, and the method comprises the steps: determining the characteristics of a dolomite crystal and the structure characteristics of the dolomite crystal, the crystal characteristics comprising the crystal size, the crystal form, the crystal structure and the relation between different dolomite and a protolith structure; determining a geochemical analysis project and a geochemical analysis sequence corresponding to the crystal characteristics according to the crystal characteristics so as to generate a geochemical analysis result of the dolomite; and analyzing the dolomite petrifaction process according to the crystal characteristics, the fabric characteristics and the geochemical analysis result. According to the dolomite petrifaction process identification method and device provided by the invention, the dolomite formation period and the dolomite petrifaction process can be reliably known.

Owner:PETROCHINA CO LTD

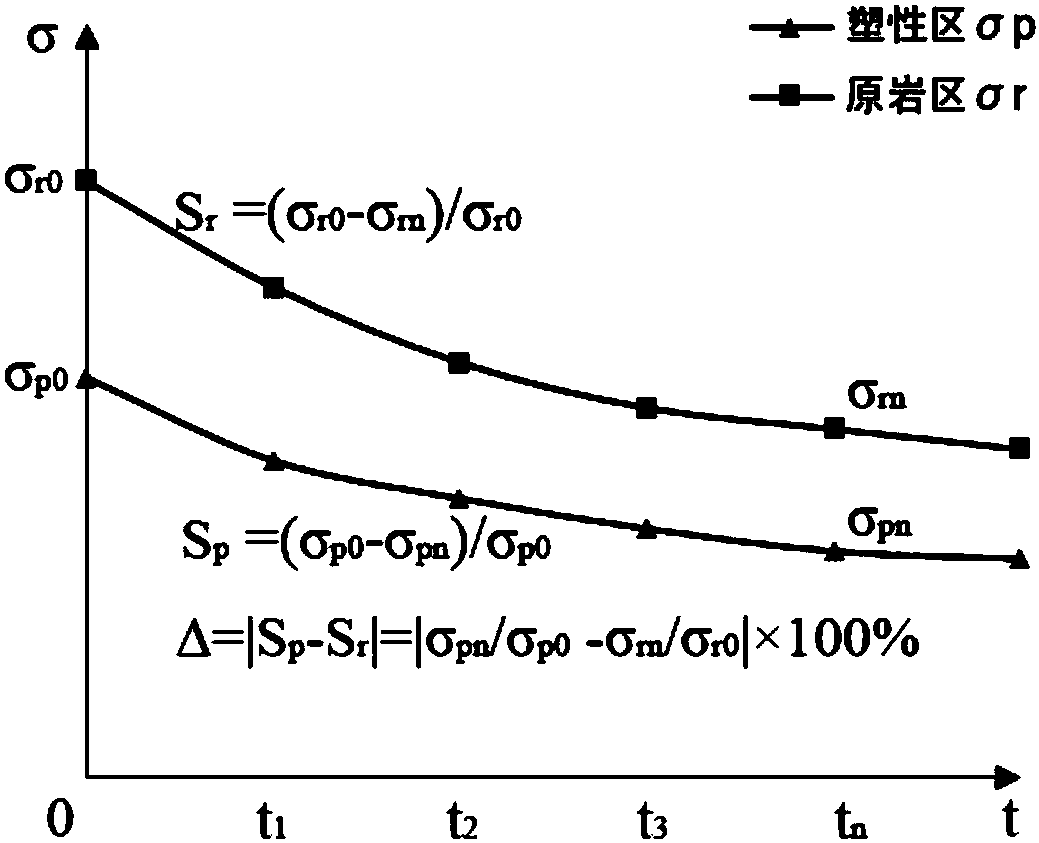

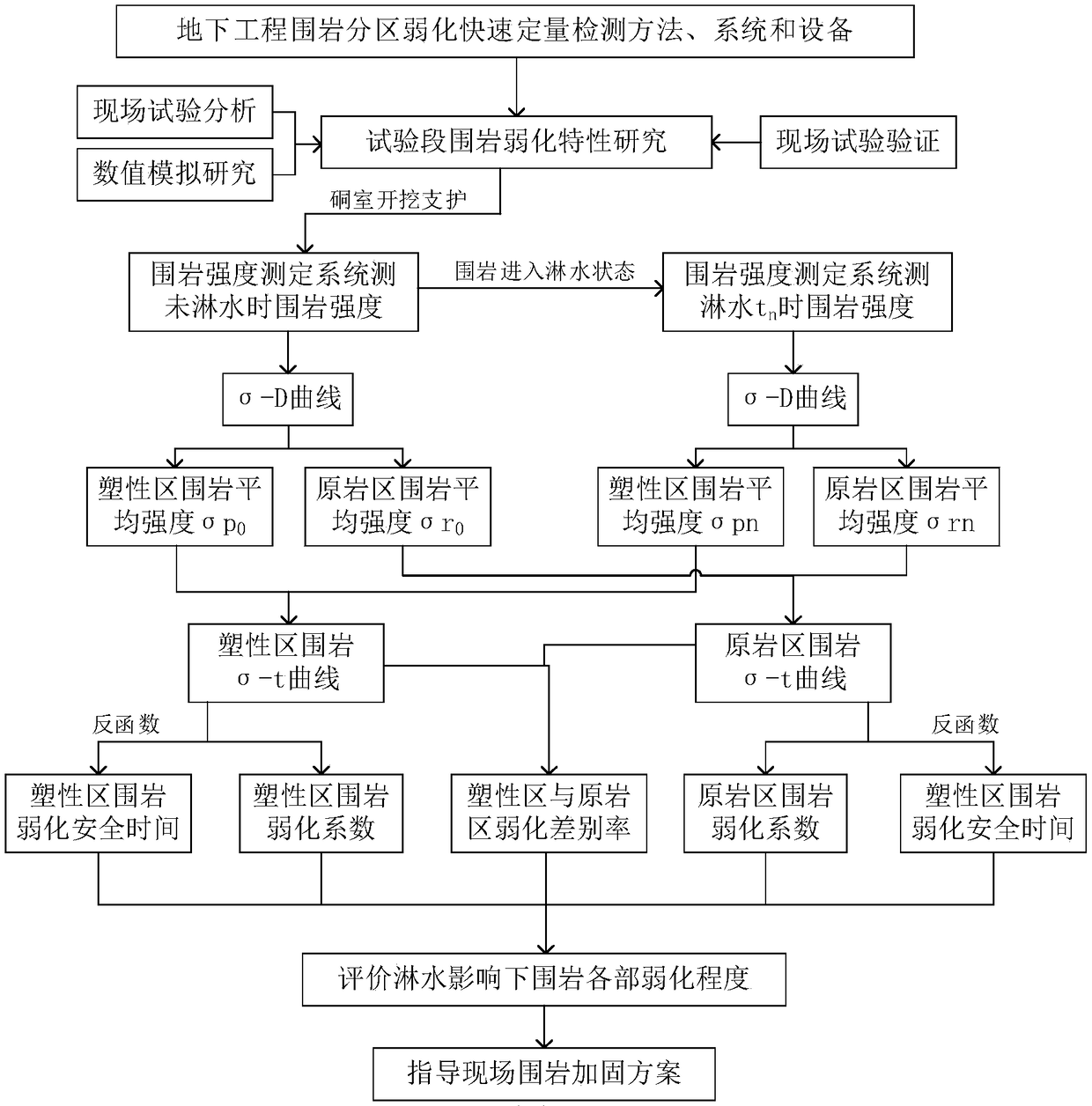

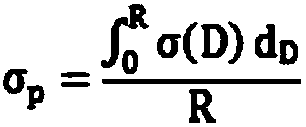

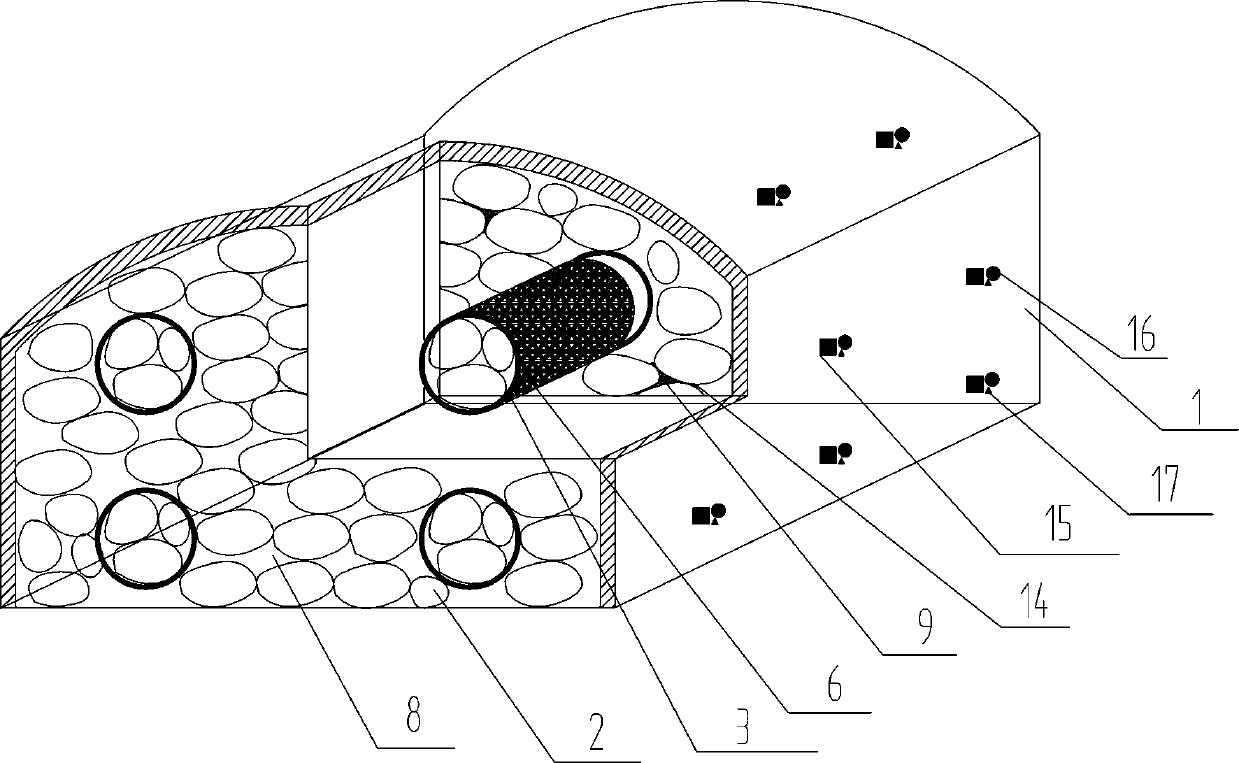

Method, system and device for rapidly and quantitatively detecting zonal weakening of surrounding rock of underground engineering

ActiveCN108414724AThe degree of weakening truly reflectsAvoid the disadvantages of long time intervalsEarth material testingGeomorphologyMechanical index

The invention discloses a method, a system and a device for quickly and quantitatively detecting the zonal weakening of the surrounding rock of underground engineering. The method comprises the following steps: onsite obtaining the weakened surrounding rock strength of an excavation body at different depths in a preset observation area, and calculating the average strength of the weakened surrounding rock; and detecting the weakening degree of the surrounding rock according to the change of the average strength of the weakened surrounding rock relative to the initial average strength of the surrounding rock and / or the change of the average strength of the weakened surrounding rock with time. The surrounding rock is disturbed with the excavation of a chamber in the construction process of the underground engineering forms a protolith zone surrounding rock and a plastic zone surrounding rock, and the surrounding rocks are weakened to a certain degree with the passage of time. The strength of the surrounding rock is obtained onsite, the direct obtaining of the mechanical indexes of the surrounding rock tending to be weakened in every zone is accelerated, and obtained data does not deviate from the original occurrence environment, stress field, temperature and other constraints, and can well represent the self strength of the rock.

Owner:SHANDONG TIANQIN ENG TECH CO LTD +1

Tunnel step-by-step excavation simulation device and using method

ActiveCN111337644AControllable dissolution rateThe size is easy to controlPreparing sample for investigationEarth material testingClassical mechanicsSound wave

The invention discloses a tunnel step-by-step excavation simulation device and a using method. The tunnel step-by-step excavation simulation device comprises a simulation tunnel of a hollow structure,and a rock mass simulation layer for simulating protolith strength is arranged in the simulation tunnel; an electromagnetic layer is arranged at the affected boundary in sections during blasting, anda magnet is arranged at the boundary of the simulation tunnel and the rock mass simulation layer and matched with the electromagnetic layer to work to form a blasting simulation device; the organic glue is filled between the contact surfaces; the expansion cement is filled in rock mass gaps outside the organic glue, so the rock mass is stressed; a pressure sensor, a strain gauge and a multi-pointdisplacement meter are arranged at the selected monitoring position; meanwhile, the sound wave instrument is used for monitoring the internal integrity; the monitoring device is used for monitoring data such as stress, deformation, strain, creep deformation and displacement of other positions of the simulated tunnel under the influence of disturbance generated in the whole simulated excavation process. The method can provide a basis for determining the rationality of design parameters and determining whether the selected construction method can ensure the stability of the tunnel surrounding rock, and has wide engineering practice significance and application prospects.

Owner:CHINA THREE GORGES UNIV

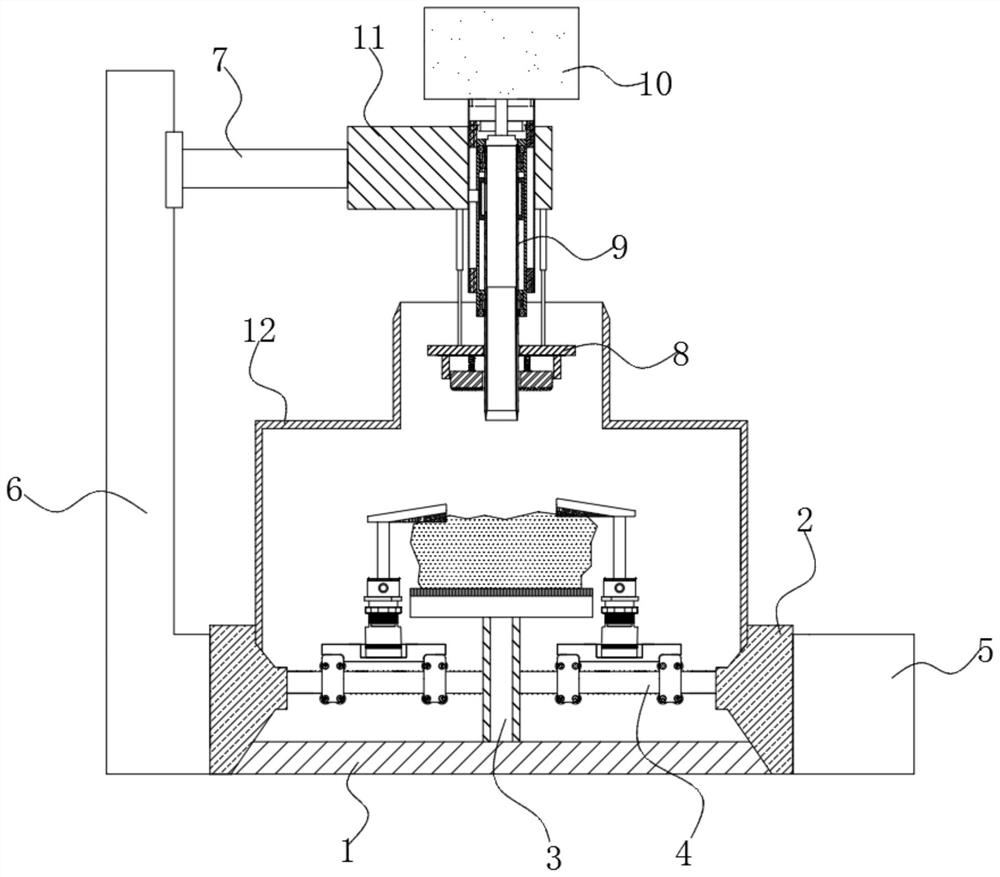

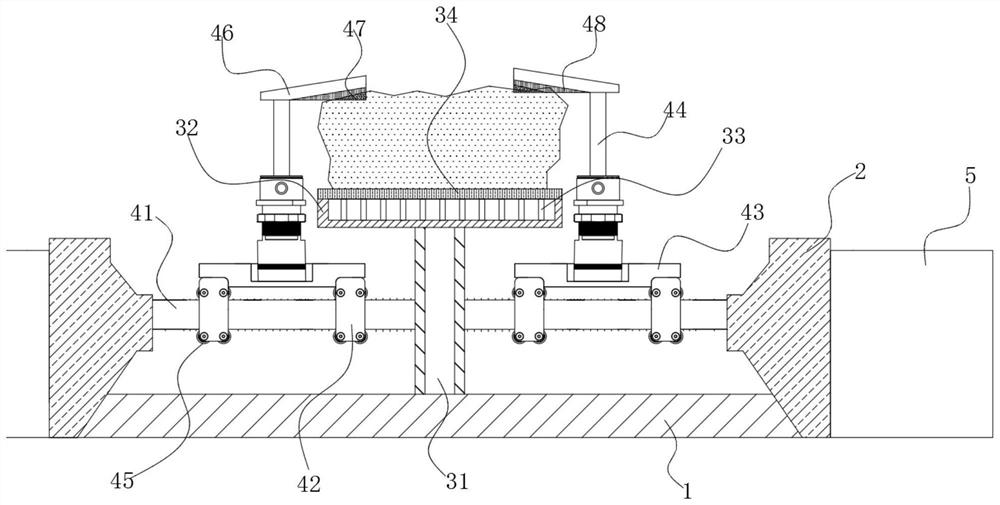

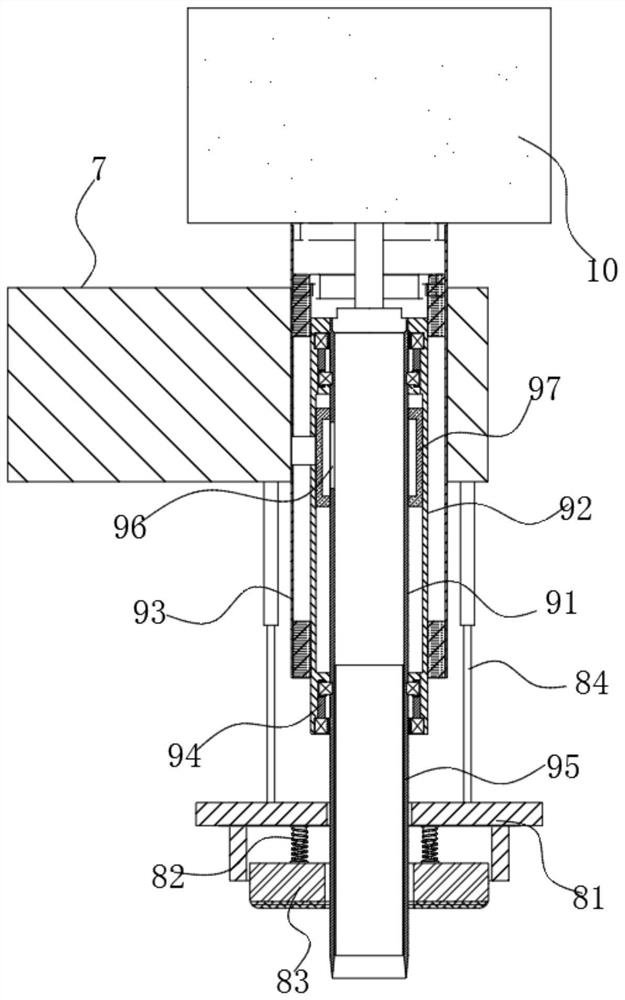

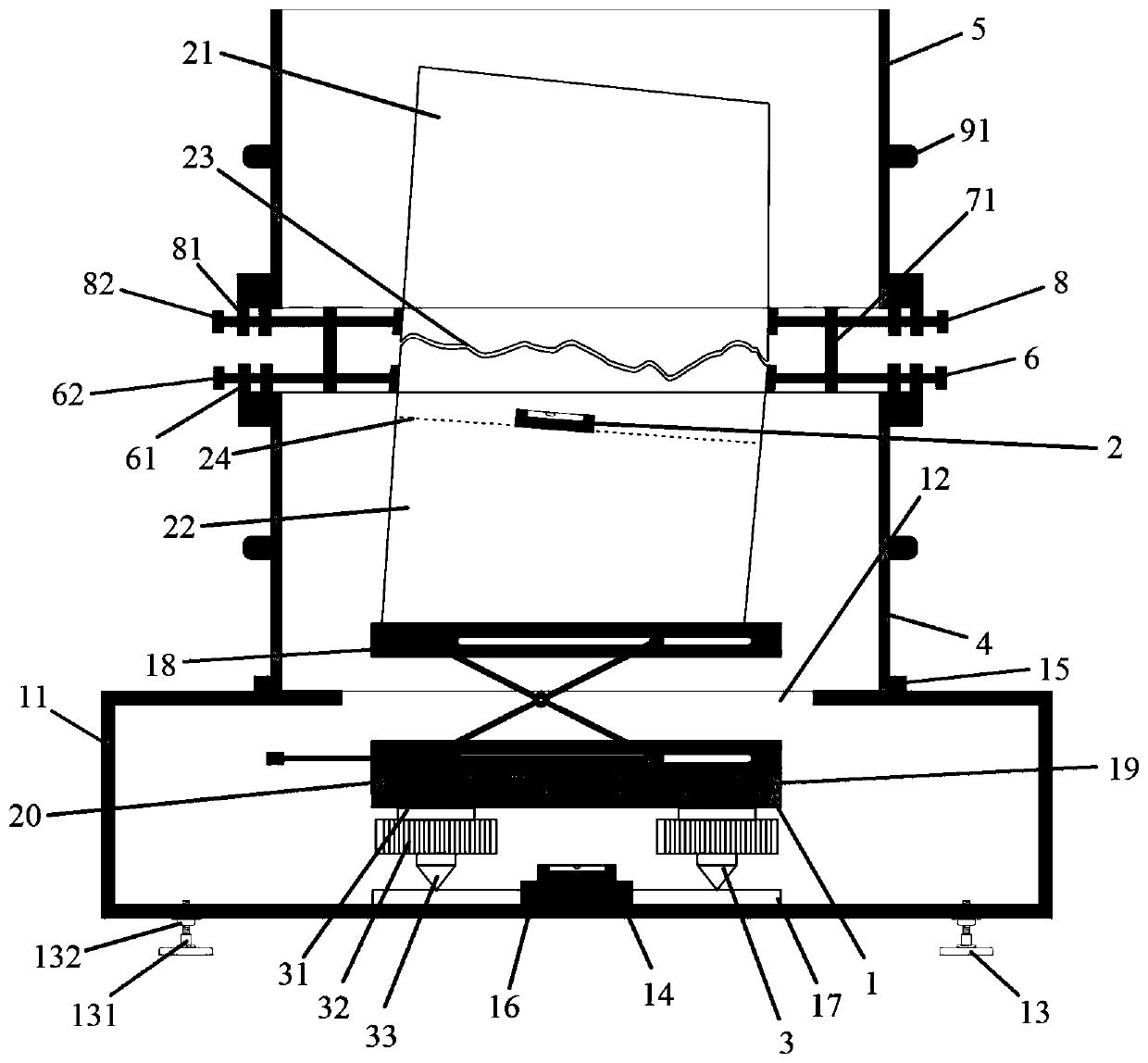

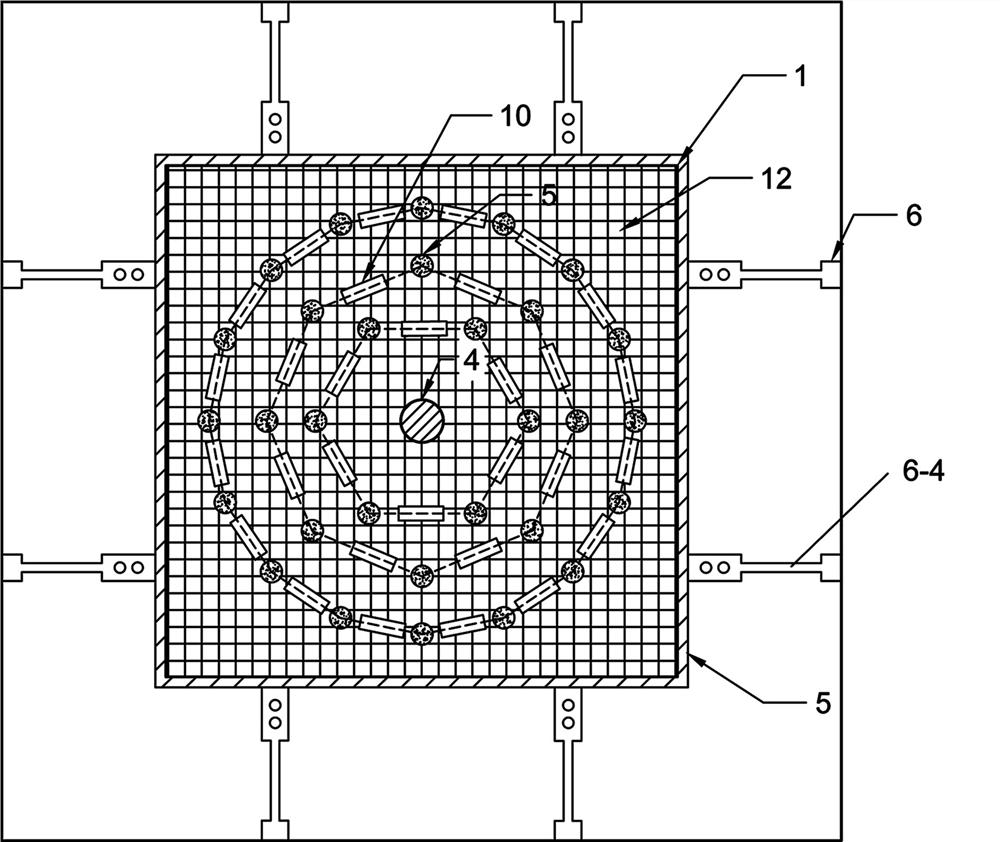

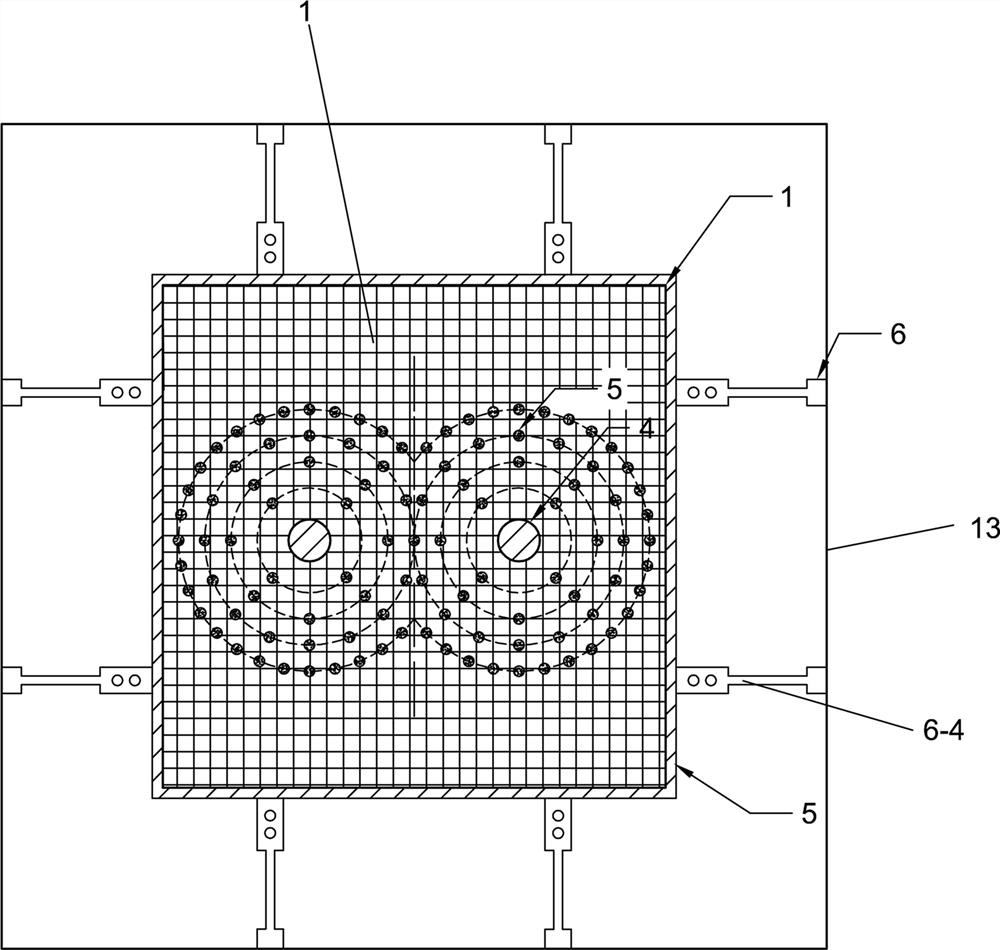

Large-size experimental model preparation device and method based on geotechnical materials

The invention relates to a large-size experimental model preparation device and method based on geotechnical materials and belongs to the field of indoor experimental model making for geotechnical engineering and geological engineering. The large-size experimental model preparation device is mainly composed of a high temperature kettle, a molding chamber, a complete molding assembly, a bidirectional fracturing structure, an axial pressure structure, a cutting knife, a telescopic knife holder, a fluid pressure sensor, a separating and metering structure, a sensor control unit and a fixing module. According to the device and method provided by the invention, large-size high-simulation rock experimental models can be provided for indoor scale experiments in geotechnical engineering and geological engineering, the physical and mechanical properties and mineral constituents of the made models can be infinitely close to those of protolith, the strength is far higher than that of a model madethrough 3D printing, and making contents cover undistorted models of common engineering objects such as side slope, tunnels, foundation pits or underground spaces, foundations and the like. Moreover,generation and distribution of faults, fractures and structural surfaces can be manually controlled, and water and rock coupled chemical reaction experiments can be conducted under different temperature and pressure conditions.

Owner:SUN YAT SEN UNIV

Efficient sampling device of organic-matter-rich mudstone section

ActiveCN111665083ARealize all-round lockingImprove stabilityWithdrawing sample devicesPreparing sample for investigationSoil scienceOrganic matter

The invention discloses an efficient sampling device of an organic matter-rich mudstone section. The device comprises a base, an annular pedestal, a sample placing assembly, a supporting arm and a connecting arm. The sample placing assembly is arranged in the middle of the base and used for placing an original rock sample to be sampled, the annular pedestal is further fixed to the base, the supporting arm is fixed to one side of the annular pedestal, and the connecting arm is connected to the supporting arm in an up-down moving mode; a sampling assembly is arranged at the other end of the connecting arm through a mounting base, a sampling end of the sampling assembly is cylindrical, and a columnar sample can be separated from an original rock sample by driving the sampling end to rotate sothat subsequent mechanical testing is facilitated; and the annular pedestal is further provided with a plurality of sets of flexible clamping assemblies, the flexible clamping assemblies can flexiblypress the original rock sample downwards from the upper portion of the original rock sample, the original rock sample can be kept in the state that the original rock sample is jointly clamped by theflexible clamping assemblies and the sample placing assembly, and stability of the original rock sample in a sampling process is improved.

Owner:HENAN POLYTECHNIC UNIV

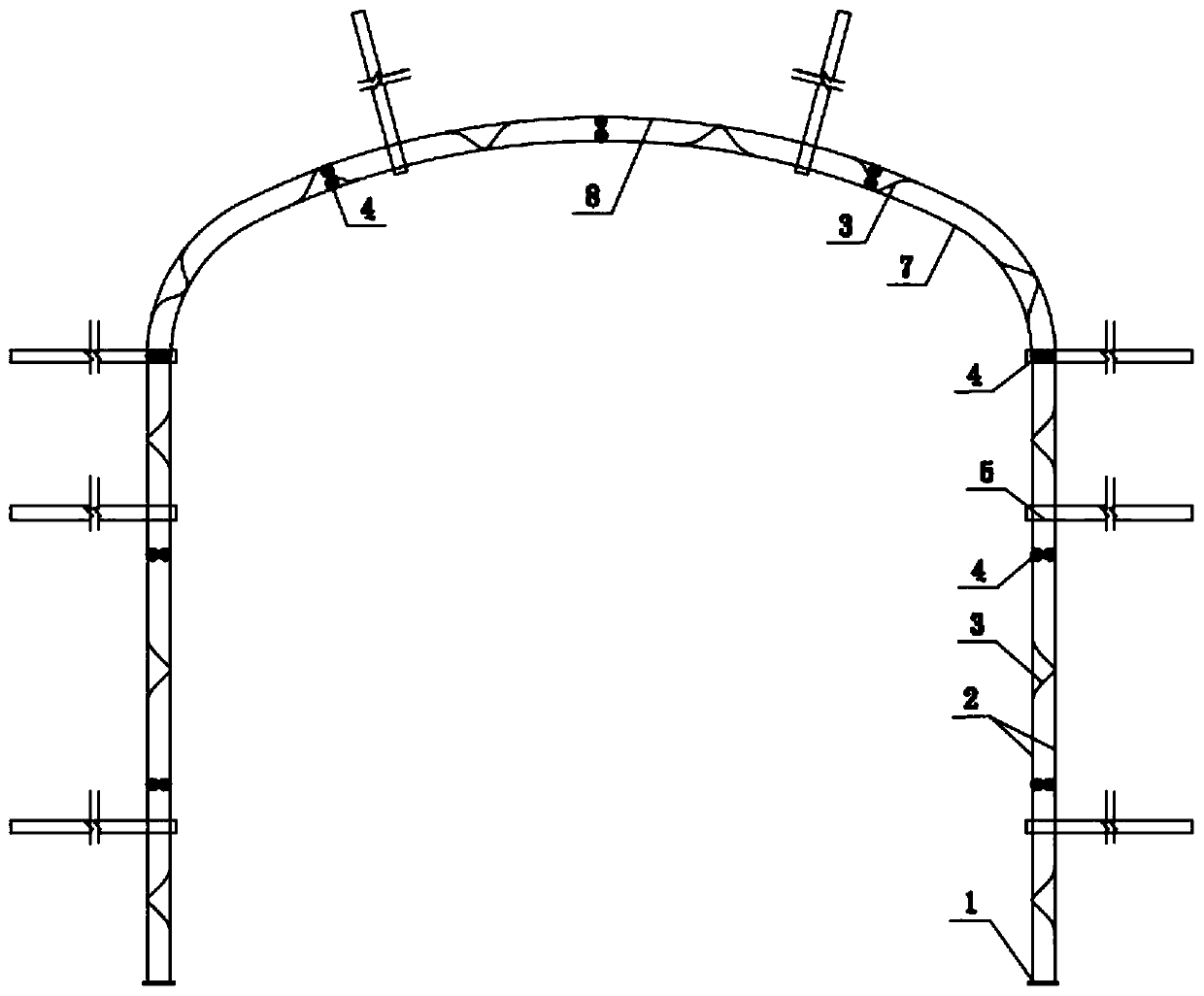

Arch frame for underground tunnel and roadway engineering support and rapid support method of arch frame

InactiveCN110735654AGive full play to carrying capacityMeet the construction support strength requirementsUnderground chambersTunnel liningUnderground tunnelArchitectural engineering

The invention discloses an arch frame for underground tunnel and roadway engineering support and a rapid support method of the arch frame. Firstly, initial spraying is carried out on an excavating tunnel or a roadway, bottom plate dross at the tunnel or roadway support arch part is cleaned, prefabricated dual arch frame bodies are assembled according to the designed position, the dual arch frame bodies are welded to form the complete arch frame, steel bar meshes are tightly attached to the outer contour of the arch frame, the arch frame is fixed with anchor rods according to the designed positions, and the arch frame and the meshes are fixed according to the requirements; the steel arch frame is fixed with the positioning arch rods, and the two sides of the steel arch frame are horizontally supported and connected; and through concrete spraying support, the arch frame and protolith are integrated, and the stability of surrounding rocks is enhanced. Dual arch frame steel bar mesh concrete support is adopted, support arch frame steel bar mesh concrete and the surrounding rocks become an organic whole, the bearing capacity of the surrounding rocks is given full play to, the bearing capacity is high, the requirements of construction support strength are met, the support effect is good, construction is convenient and fast, the speed is high, the labor intensity is low, and the support cost is saved.

Owner:周伟永

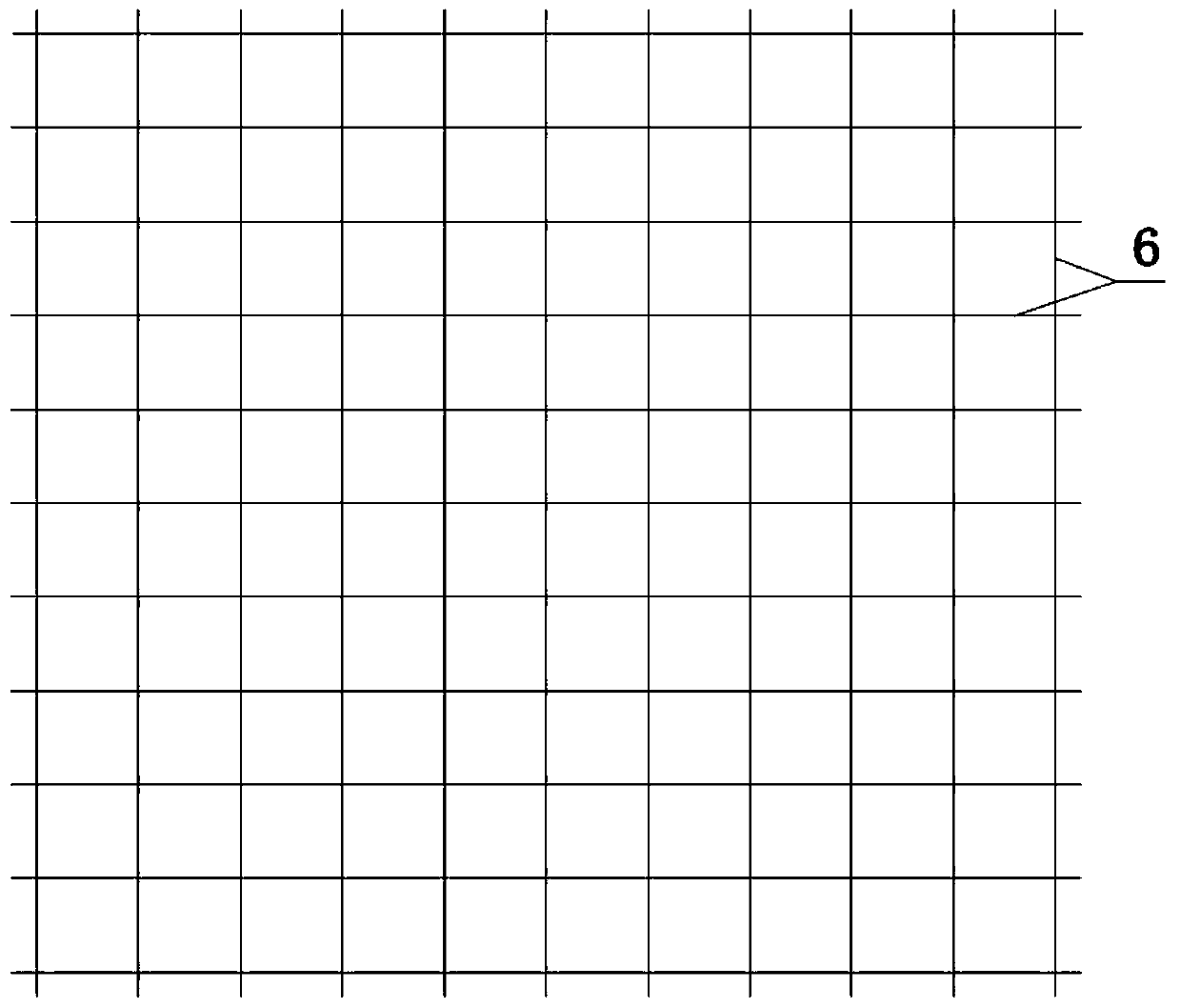

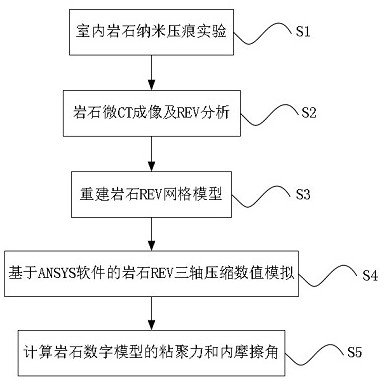

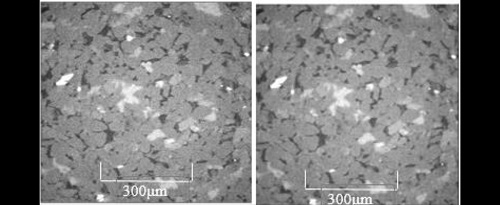

Rock cohesive force-internal friction angle calculation method based on digital core technology

InactiveCN112525684ABuild connectionMaterial analysis using wave/particle radiationPreparing sample for investigationEngineeringFriction angle

The invention discloses a rock cohesive force-internal friction angle calculation method based on a digital core technology. The method comprises the following steps: obtaining micro-scale mechanicalparameters of an original rock sample as input parameters of numerical simulation based on a rock nanoindentation experiment result; carrying out a micro-CT scanning test on the rock core to obtain arock micro-pore structure image, and reconstructing a three-dimensional grid model of the rock sample RVE; carrying out triaxial compression numerical simulation research of a rock sample RVE model based on a Moore Coulomb criterion; and obtaining the maximum compressive strength under different confining pressures according to a triaxial compression numerical simulation result, drawing an optimalrelation curve of the axial stress sigma 1 and the confining pressure sigma 3, and then solving the cohesive force and the internal friction angle of a rock matrix on the basis of the principle of aleast square method.

Owner:SOUTHWEST PETROLEUM UNIV

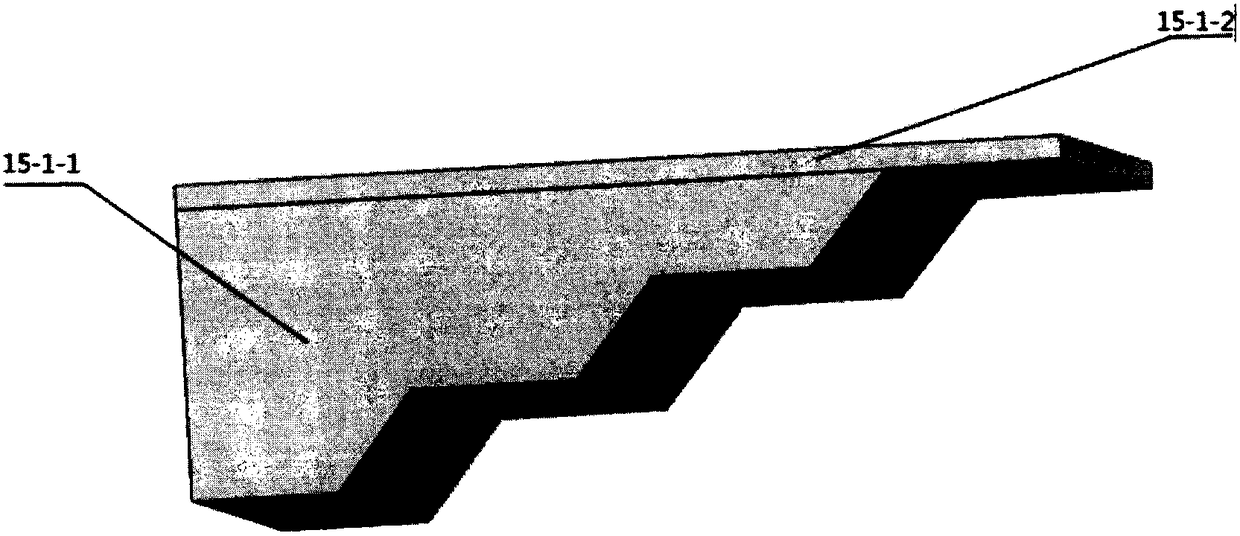

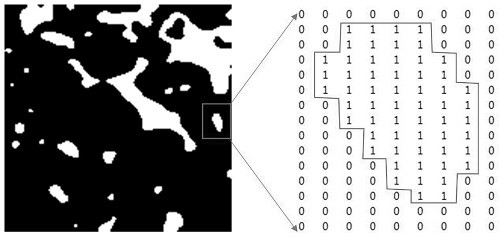

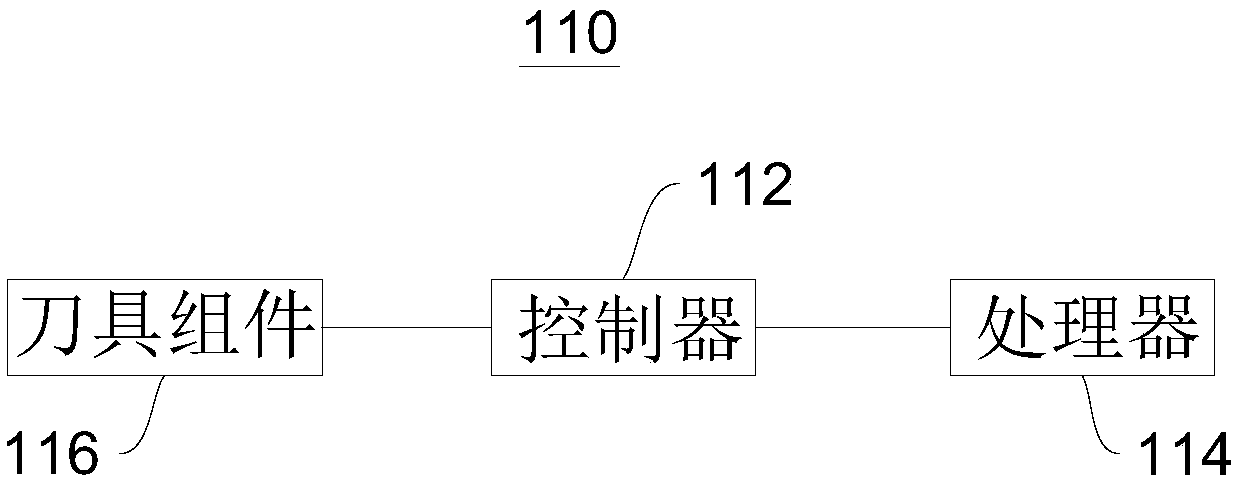

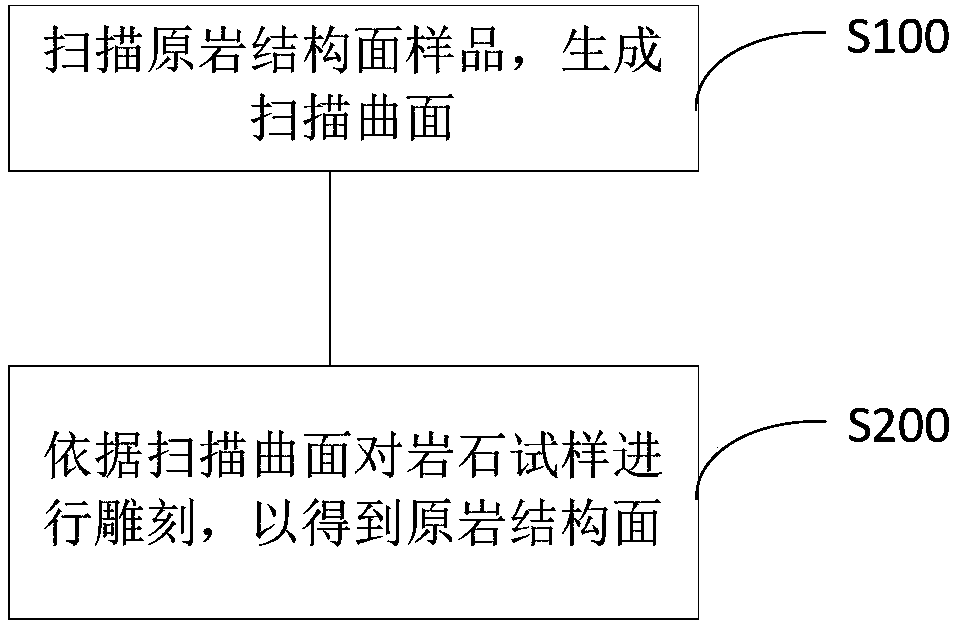

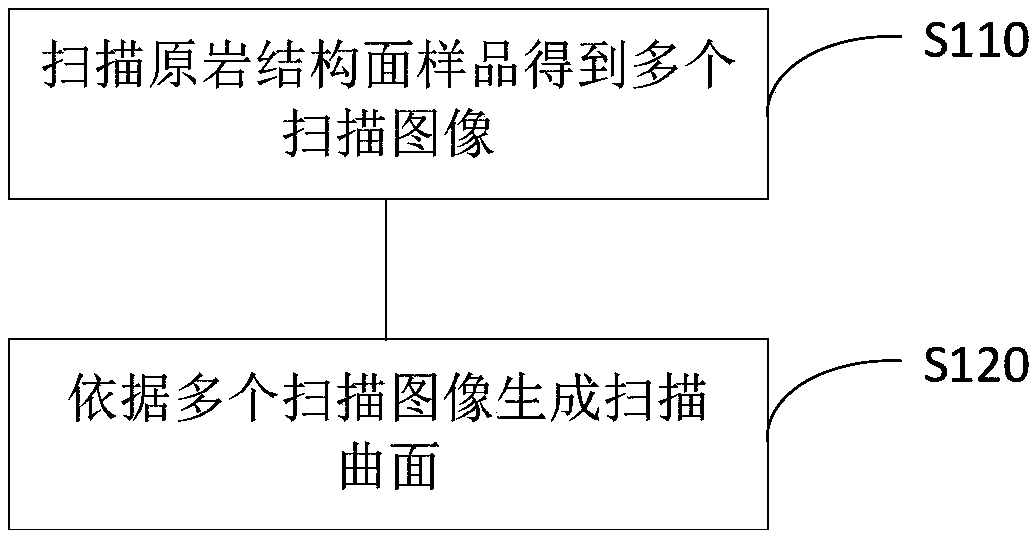

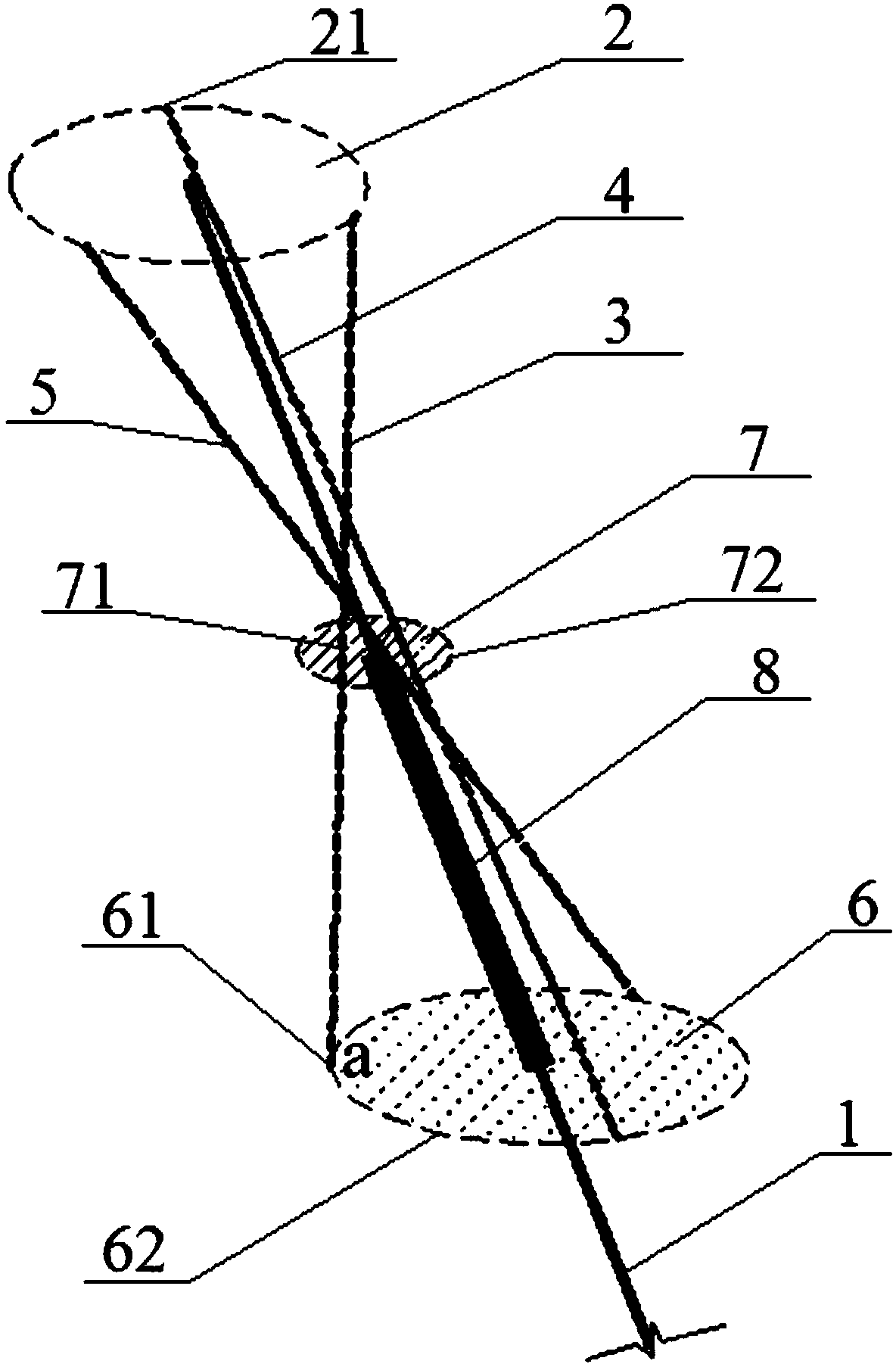

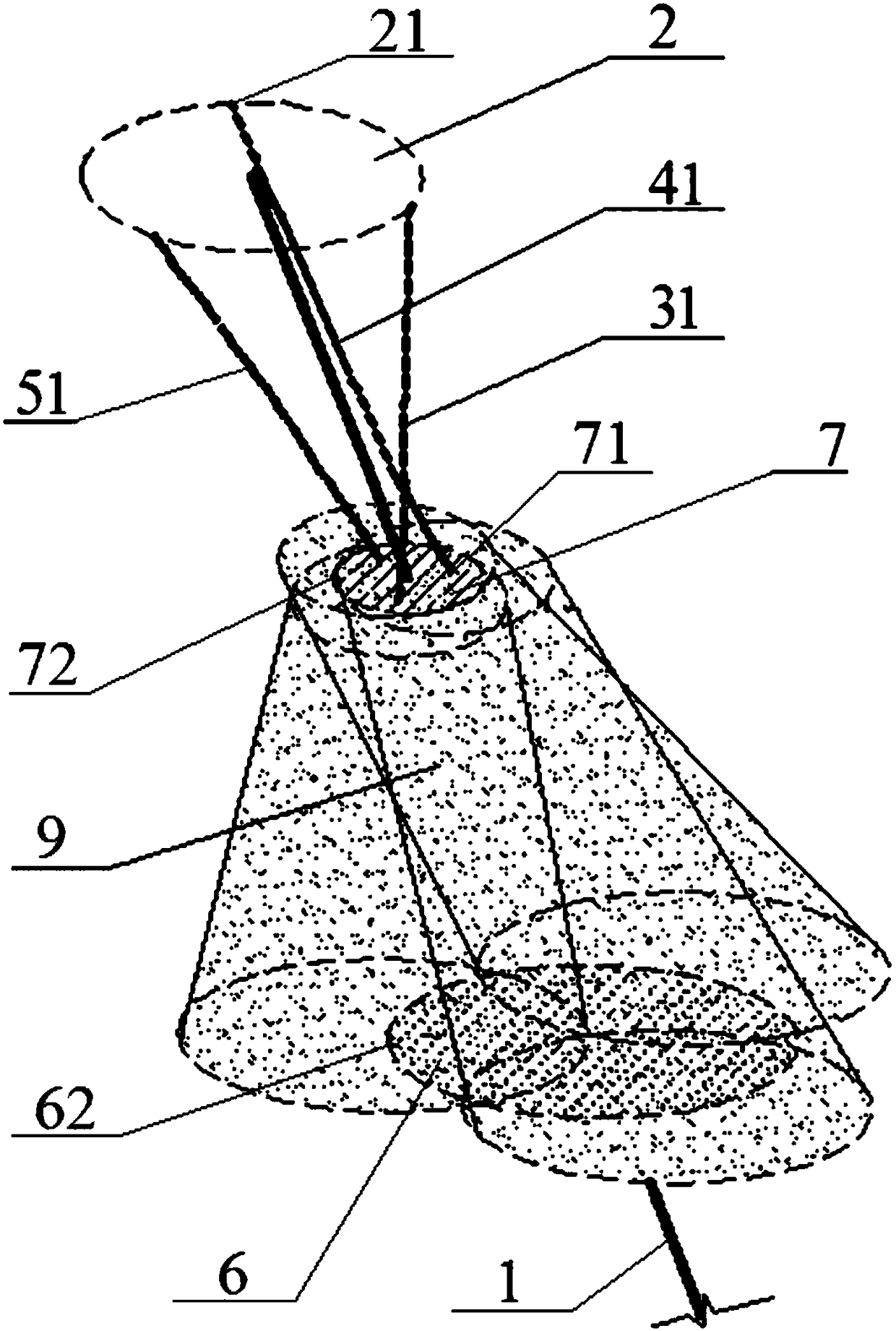

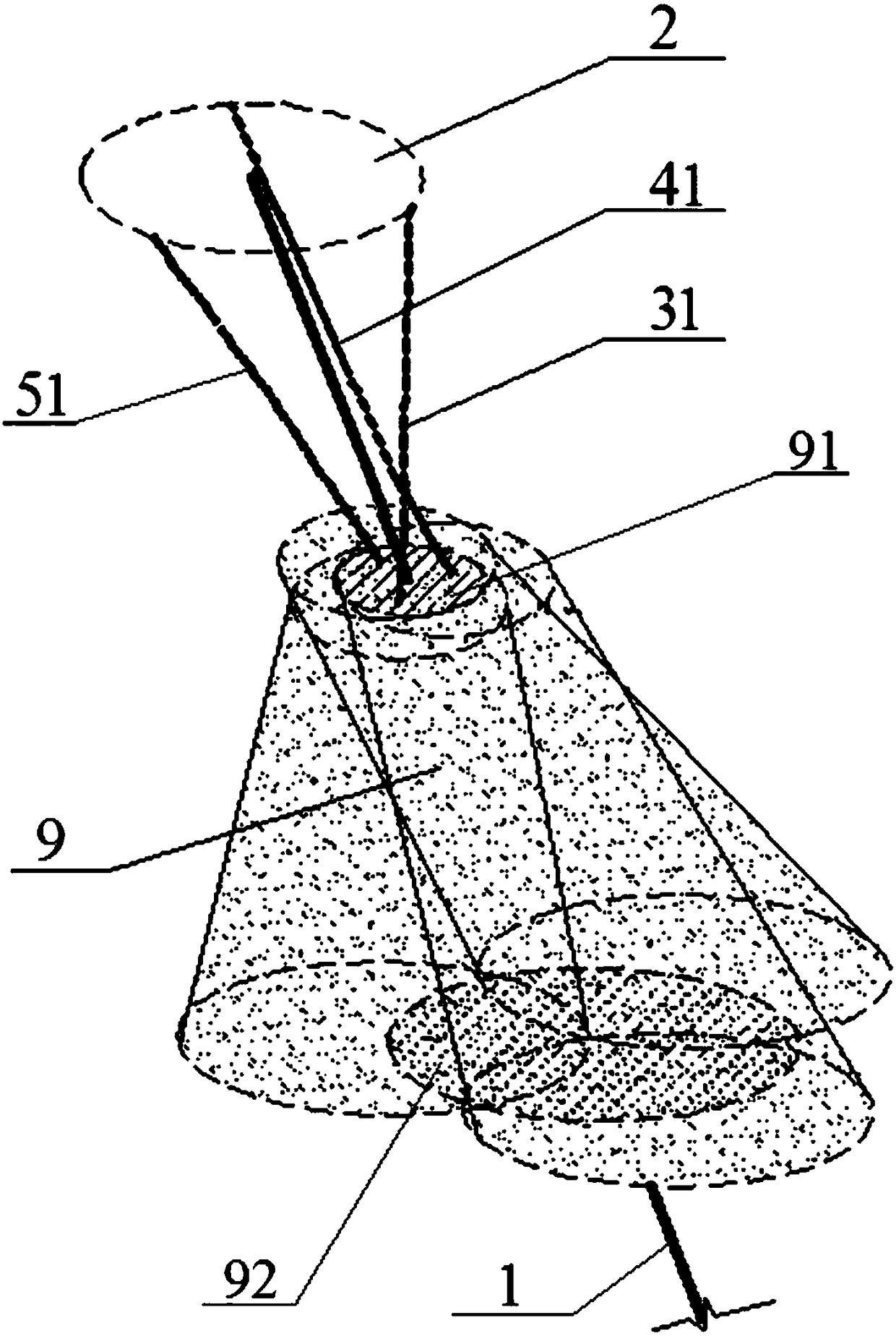

Protolith structural surface manufacturing method and device and protolith structural surface

The invention provides a protolith structural surface manufacturing method and device and a protolith structural surface, and relates to the field of rock mechanics. The protolith structural surface manufacturing method comprises the steps of scanning a protolith structural surface sample to generate a sweep surface; carving the protolith structural surface sample according to the scanning hook face to obtain the protolith structural surface. According to the protolith structural surface manufacturing method disclosed by the invention, the scanning hook face of the protolith structural surfacesample is obtained at first, and then a rock sample is carved according to the scanning hook face to obtain the protolith structural surface. Therefore, surface characteristics of the protolith structural surface are the same as surface characteristics of the protolith structural surface sample. Physical properties of the protolith structural surface are the same as physical properties of the protolith structural surface sample, so that accuracy of the protolith structural surface in a shearing test process is improved.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

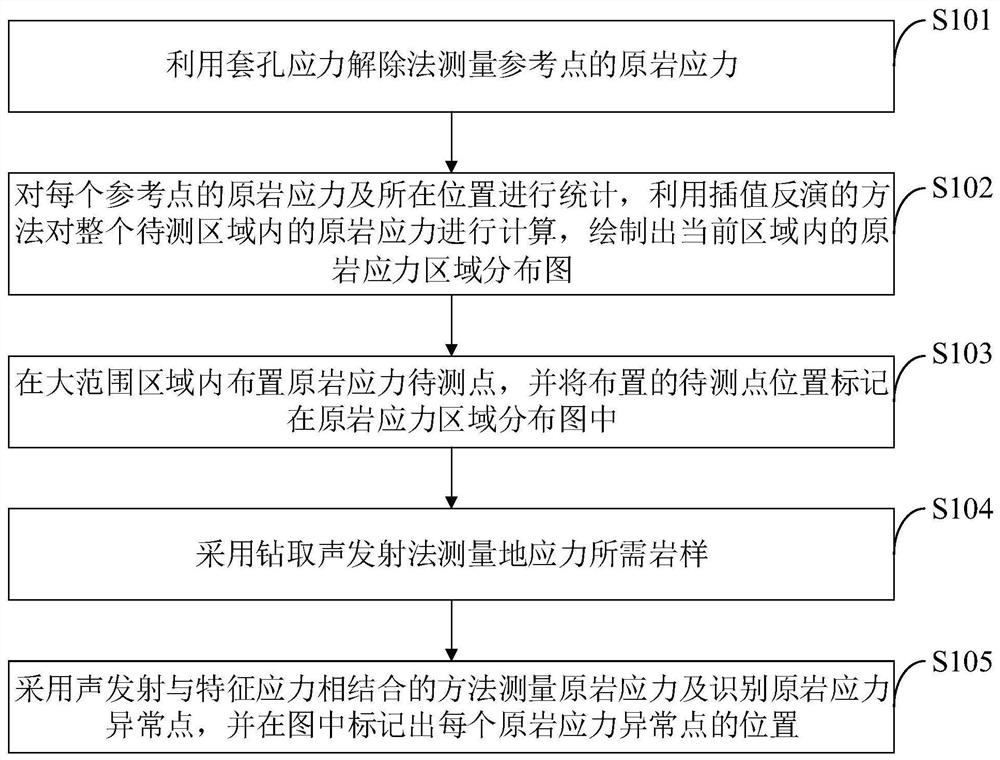

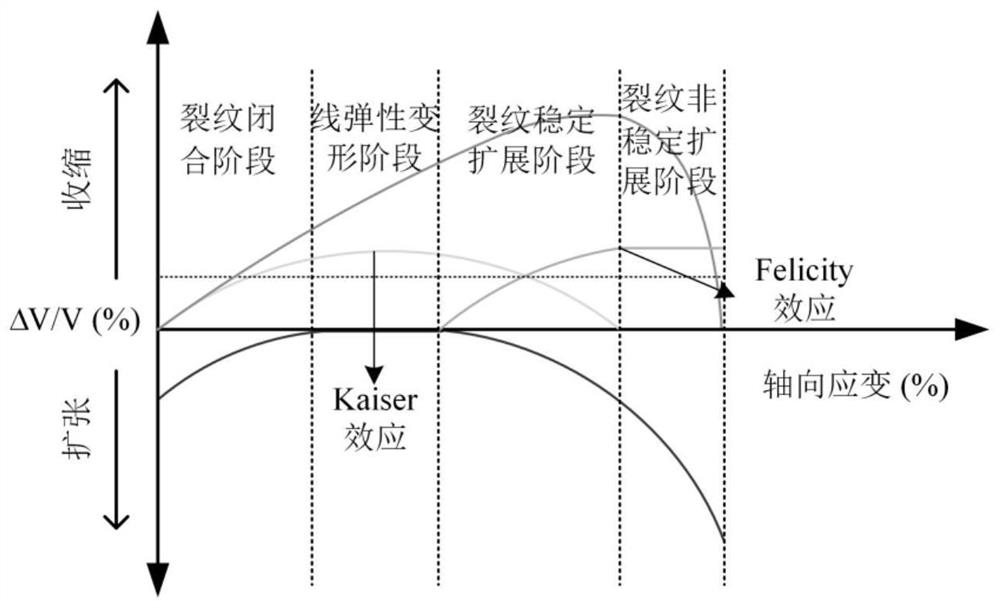

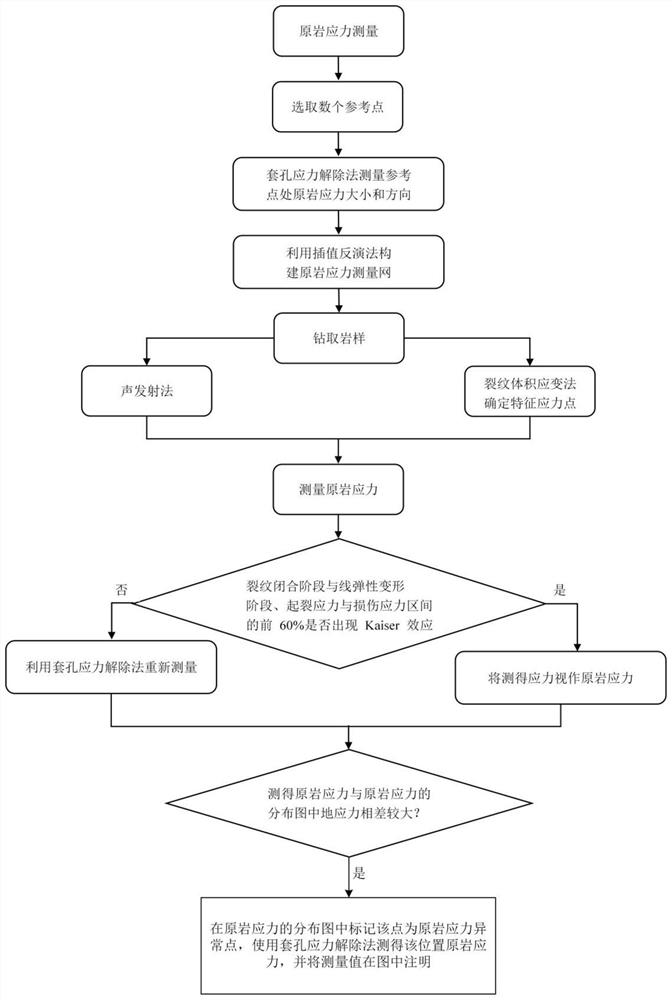

Novel method for identifying crustal stress abnormal area and measuring crustal stress in large range

ActiveCN112100842AHigh precisionImprove reliabilityMaterial analysis using acoustic emission techniquesDesign optimisation/simulationRock engineeringAcoustic emission

The invention belongs to the technical field of protolith stress measurement, and discloses a novel method for identifying a crustal stress abnormal area and measuring crustal stress in a large range,which comprises the following steps of: measuring protolith stress of reference points, calculating protolith stress of each reference point and the position of each reference point, and calculatingthe protolith stress in the whole area to be measured, drawing a protolith stress region distribution diagram in the region; marking the positions of the arranged to-be-measured points in the protolith stress area distribution diagram; drilling rock samples in different directions required for measuring crustal stress by an acoustic emission method; measuring the protolith stress by adopting a method of combining acoustic emission and characteristic stress, if the difference between a measurement result and an interpolation inversion result is large, recording the point as a protolith stress abnormal point, and measuring the protolith stress of the point by using a trepanning stress relieving method. The method is low in economic cost, high in technical applicability and simple in construction environment, the economic cost and workload can be effectively reduced, and basic data can be provided for design optimization and stability calculation of underground rock engineering.

Owner:JIANGXI UNIV OF SCI & TECH

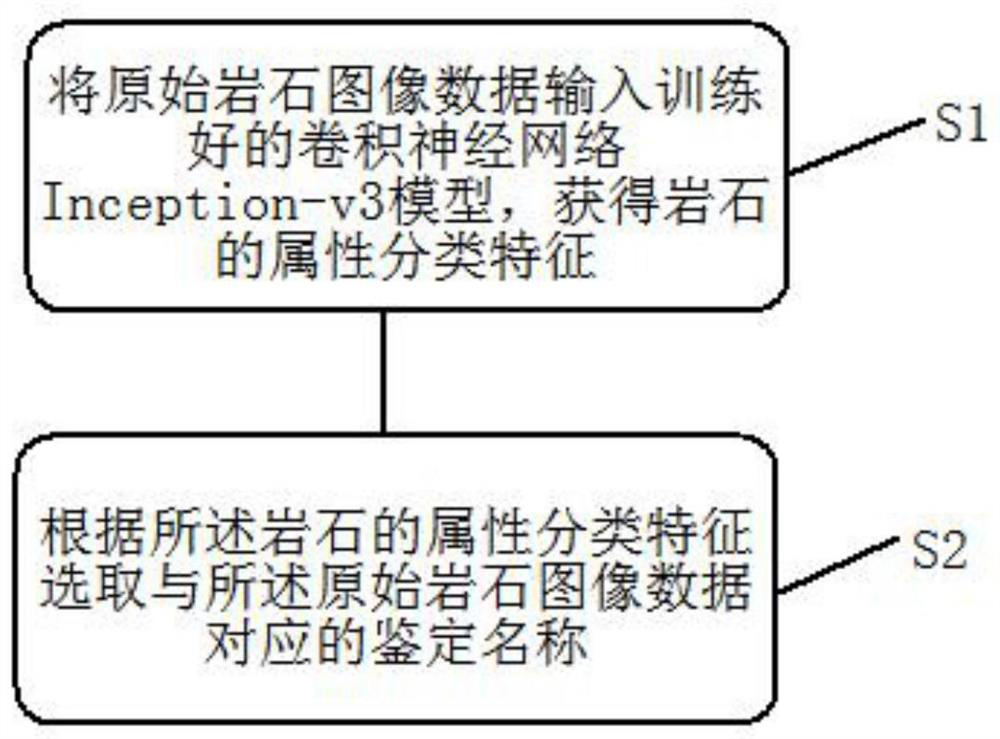

Artificial intelligence-based rock lithology rapid classification and identification method and device

InactiveCN112801213AReal-time data processingReal-time output classification and recognition resultsCharacter and pattern recognitionNeural architecturesLithologyImaging data

The invention discloses an artificial intelligence-based rock lithology rapid classification and identification method and device, and the method comprises the steps: inputting original rock image data into a trained convolutional neural network Inception-v3 model, and obtaining the attribute classification features of rock; selecting an identification name corresponding to the original rock image data according to the attribute classification features of the rock; according to the invention, rocks can be quickly classified and identified on a field operation site.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

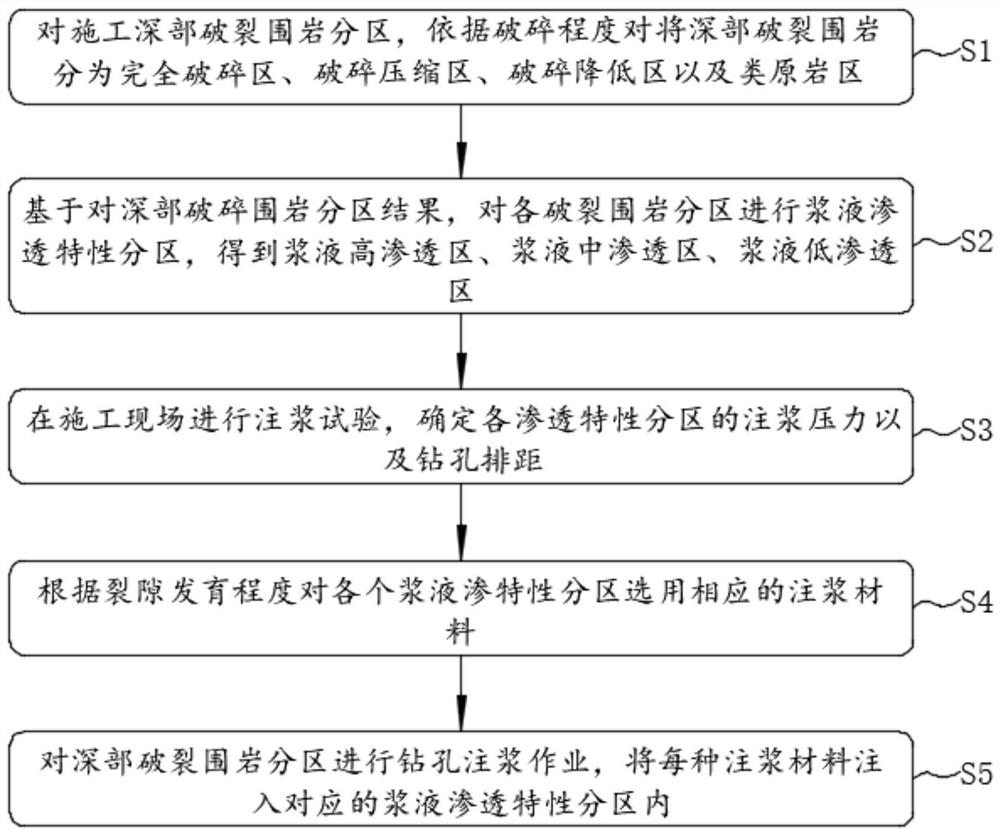

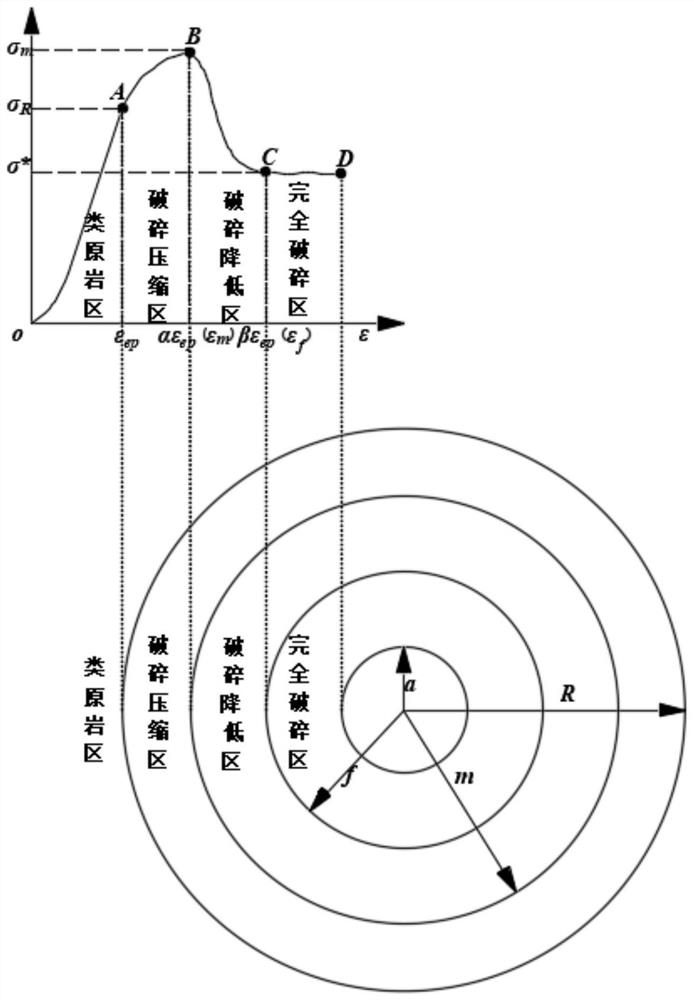

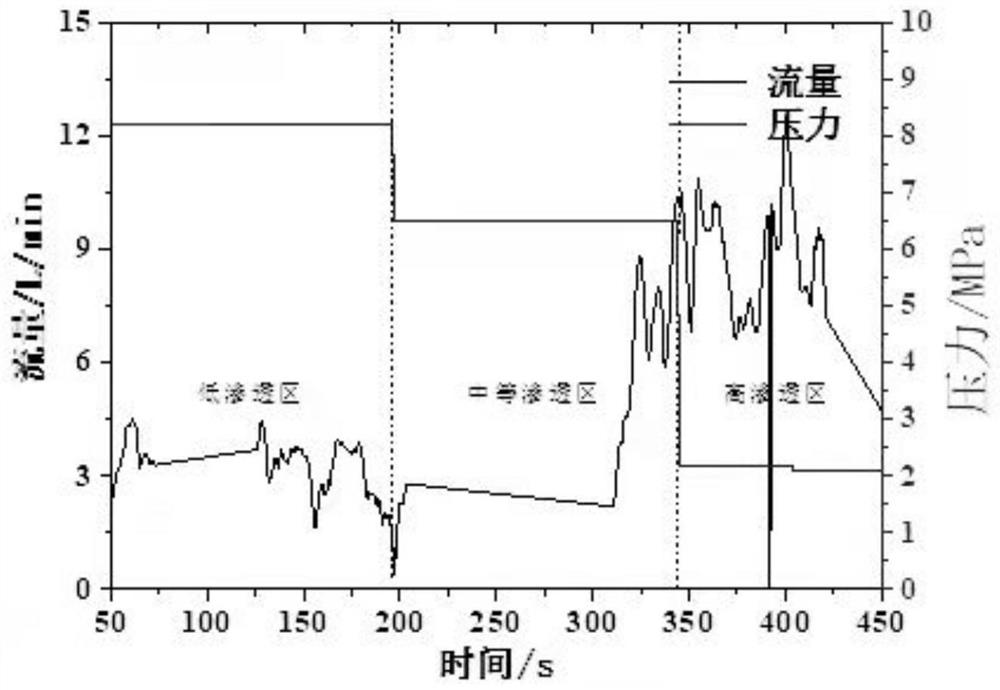

Deep fractured surrounding rock composite grouting reinforcement method

The invention discloses a deep fractured surrounding rock composite grouting reinforcement method which comprises the following steps: S1, partitioning a deep fractured surrounding rock, and dividing the deep fractured surrounding rock into a completely fractured region, a fractured reduction region, a fractured compression region and a protolith-like region according to the degree of fracture; S2, based on the zoning result of the deep broken surrounding rock, performing slurry permeability characteristic zoning on each broken surrounding rock zone to obtain a slurry high-permeability zone, a slurry medium-permeability zone and a slurry low-permeability zone; S3, performing a grouting test on the construction site, and determining the grouting pressure and the drilling row pitch of each permeability characteristic subarea; S4, selecting a corresponding grouting material for each grout permeability characteristic subareasaccording to the fracture development degree; and S5, conducting drilling and grouting operation on the deep fractured surrounding rock subareas, and injecting each grouting material into the corresponding grout permeability characteristic subareas. According to the method, surrounding rocks form a net-shaped structure with interlaced slurry veins through multiple grouting modes and grouting materials, and the mechanical property of a consolidated body is greatly improved.

Owner:CCTEG COAL MINING RES INST

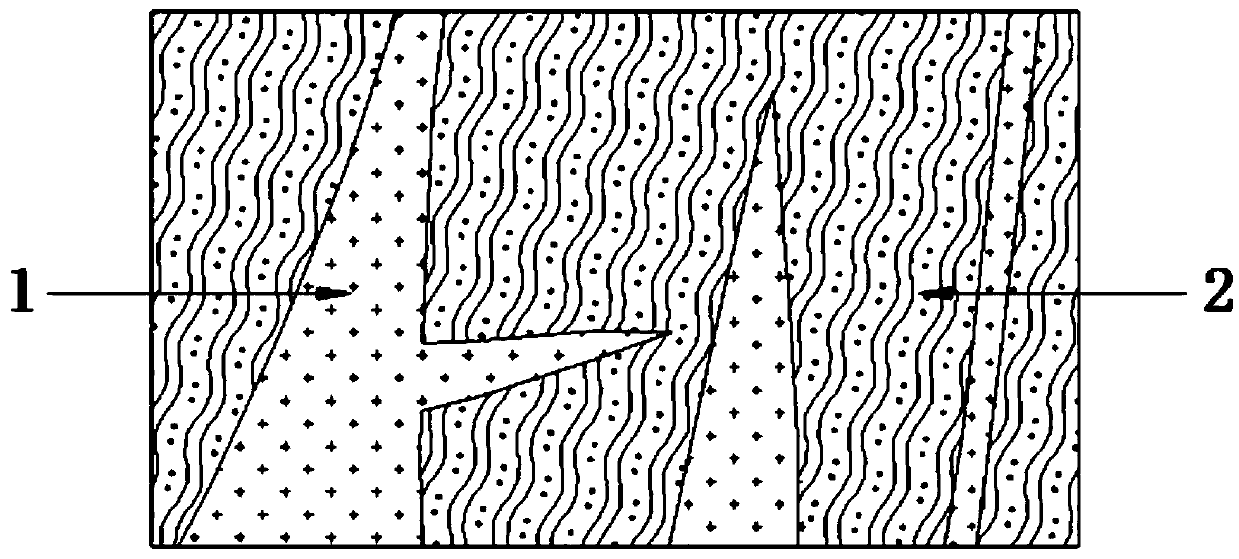

Method for classifying complicated engineering geological formation complexes interspersed with irregular intrusive rocks and veins

ActiveCN110646864AQuick classificationEarth material testingGeological measurementsLongitudinal waveClassical mechanics

The invention discloses a method for classifying complicated engineering geological formation complexes interspersed with irregular intrusive rocks and veins for solving the problem of extremely irregular shapes of intrusive rocks 1 and veins in an extension direction. The invention proposes a method for quickly classifying the complicated engineering geological formation complexes with the interspersed with irregular intrusive rocks 1 and veins by using the comprehensive longitudinal wave velocity that reflects the comprehensive geological characteristics of the formation complexes, in viewof such complicated engineering geological formation complexes in the later stage, the engineering geological classification of the complicated engineering geological formation complexes can be quickly performed just by testing the longitudinal wave velocities of the intrusive rocks 1 and protoliths in the formation complexes, a foundation and a support are provided for the engineering suitabilityevaluation of a large number of such complicated engineering geological formation complexes in the later stage, and meanwhile, a powerful basis is provided for the design of engineering treatment plans for such complex engineering geological rock groups in the later stage.

Owner:POWERCHINA CHENGDU ENG

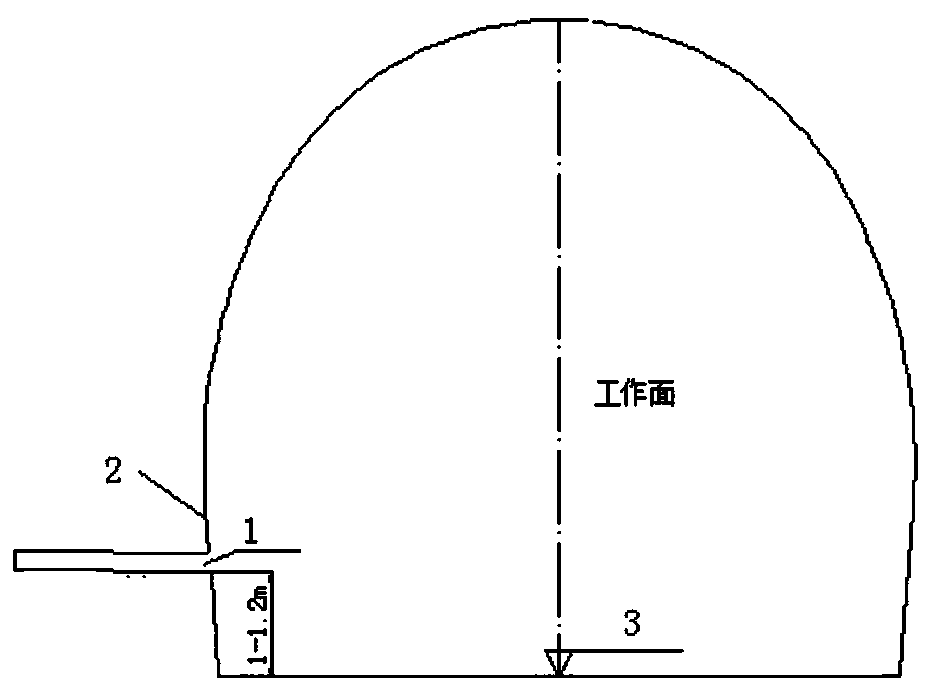

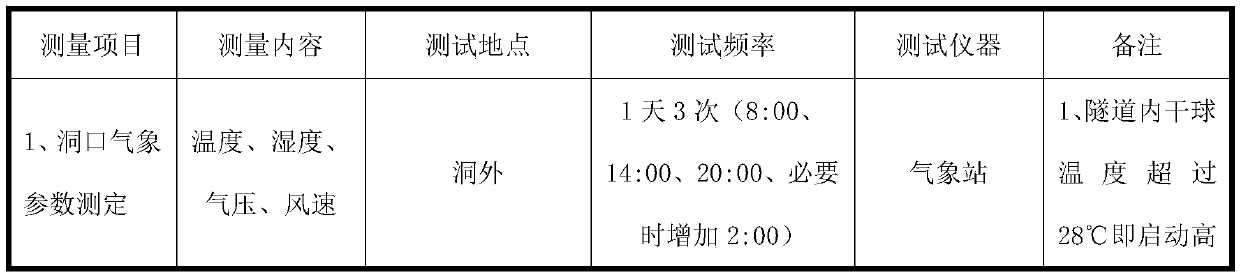

Tunnel excavation detecting method in high ground temperature state

InactiveCN110487443AThermometers using electric/magnetic elementsIndication of weather conditions using multiple variablesGround temperatureMeasuring instrument

The invention discloses a tunnel excavation detecting method in a high ground temperature state, and solves the problem of lacking of a determined detection method in the aspect of ground temperaturediscrimination and detection in the prior art. The detecting method comprises the steps of measuring rock temperature in a tunnel, environment in the tunnel, surrounding rock ground temperature, environment outside the tunnel and / or water temperature in the tunnel. The specific method for measuring the rock temperature in the tunnel comprises the steps of: drilling a hole by means of a pneumatic drill in a side wall 50 m away from an excavation face and in the surrounding rock which is 1.0-1.2 m high away from the tunnel bottom plate, blowing the hole with high-pressure air, and drilling a hole upwards and obliquely at 5-10 degrees, wherein the drilling depth is larger than or equal to 3 m, the hole diameter is larger than or equal to 42 mm; and sealing the hole opening after drilling, placing a probe of a temperature measuring instrument into the bottom of the hole after the drilled hole is balanced for 1.5-2.5 h, carrying out reading after an output value of the thermometer is stable, and acquiring a final temperature reading of the temperature measuring probe, namely, the protolith temperature of the measuring place where the temperature measuring probe is located.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Non-closed borehole sealing process and structure

InactiveCN108708687ASmall horizontal spreadLarge horizontal spreadSealing/packingStructure of the EarthSlurry

The invention discloses a non-closed borehole sealing process and structure. All designed grouting hole tracks are mutually overlapped and surrounded in space, a sand-clock-type grouting-hole-series model which is of a structure with two thick ends and a thin middle can be formed, the part, with the thin middle, of the grouting-hole-series model corresponds to a sealing position top plate, the stratum of the sealing position top plate is an intensely weathered zone, the extension range of fractures is small, and therefore, the horizontal diffusion range of slurry is small; the part, with the thick lower end, of the grouting-hole-series model corresponds to a sealing position bottom plate, and is generally a weak weathering zone, unweathered protolith or a transitional zone between the weakweathering zone and unweathered protolith, the extension range of the fractures is large, and the horizontal diffusion range of the slurry is large. By means of the non-closed borehole sealing process and structure, slurry diffusion features in different stratas are fully utilized, the slurry diffusion superposition rate within a certain sealing range is increased, a cone-shaped waterproof curtain can be obtained based on the structures, and boreholes are effectively sealed.

Owner:首钢滦南马城矿业有限责任公司

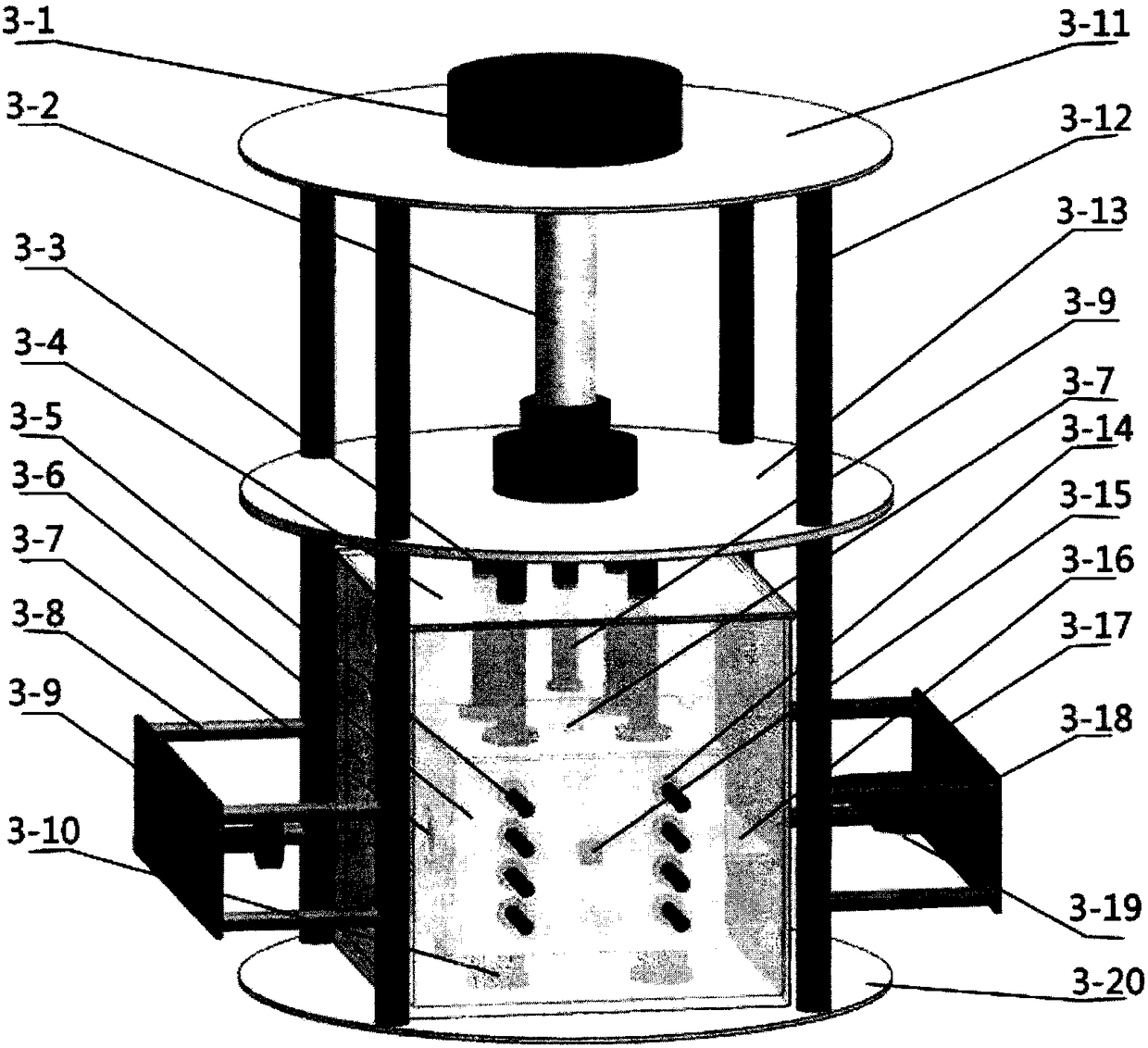

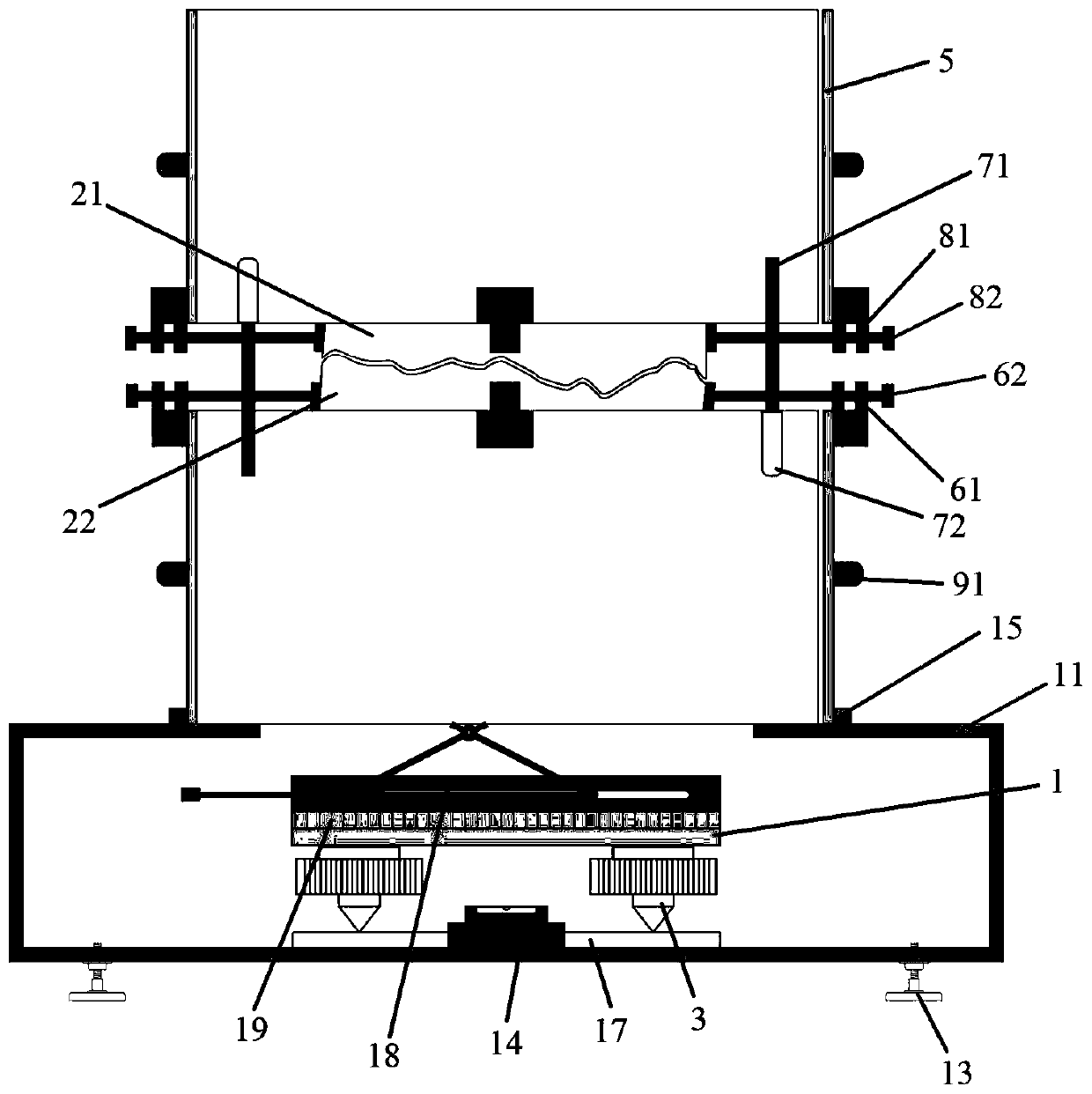

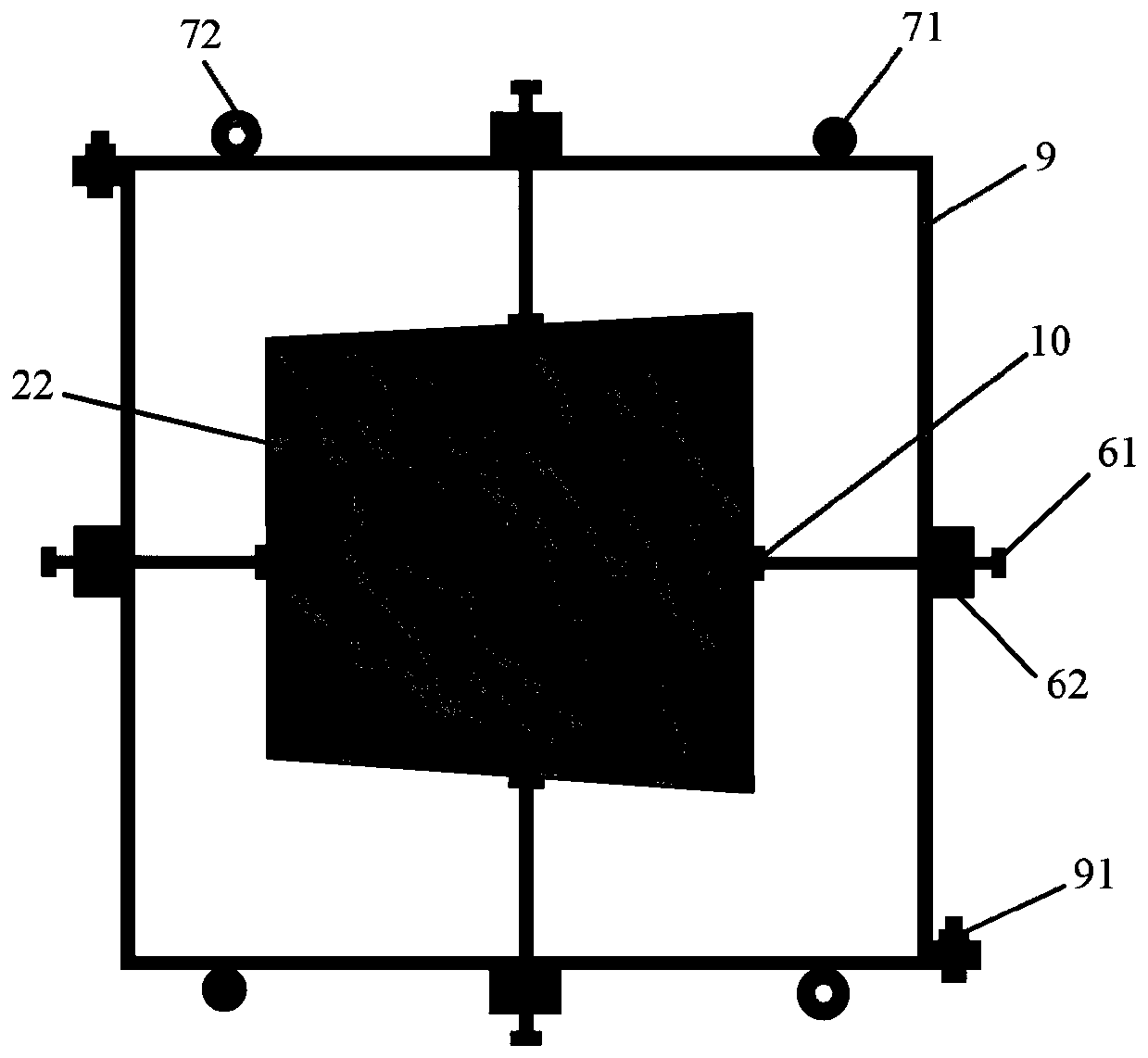

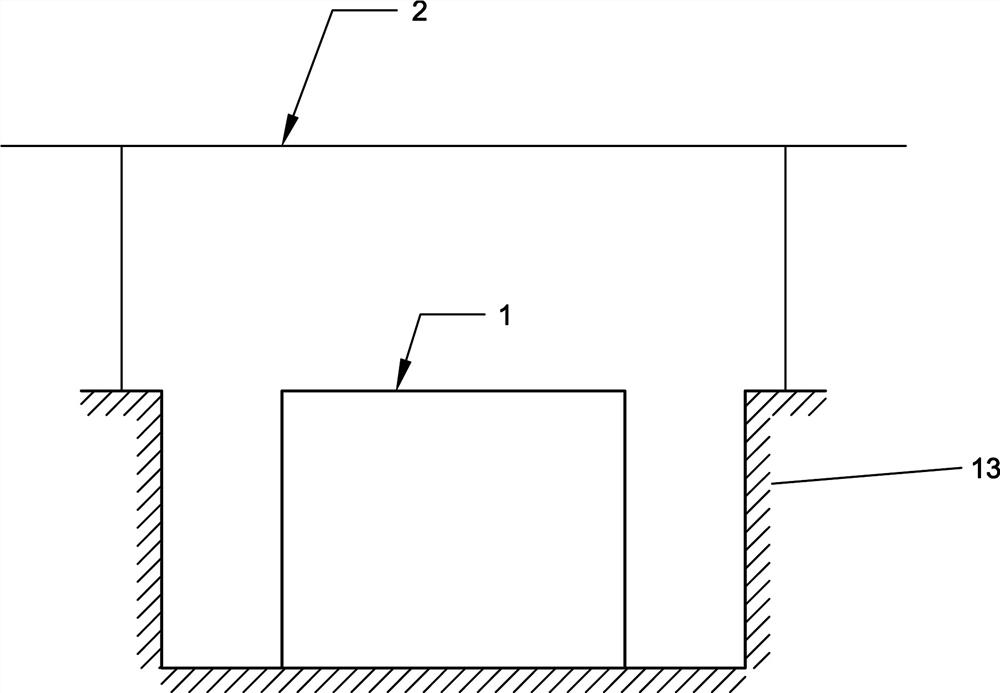

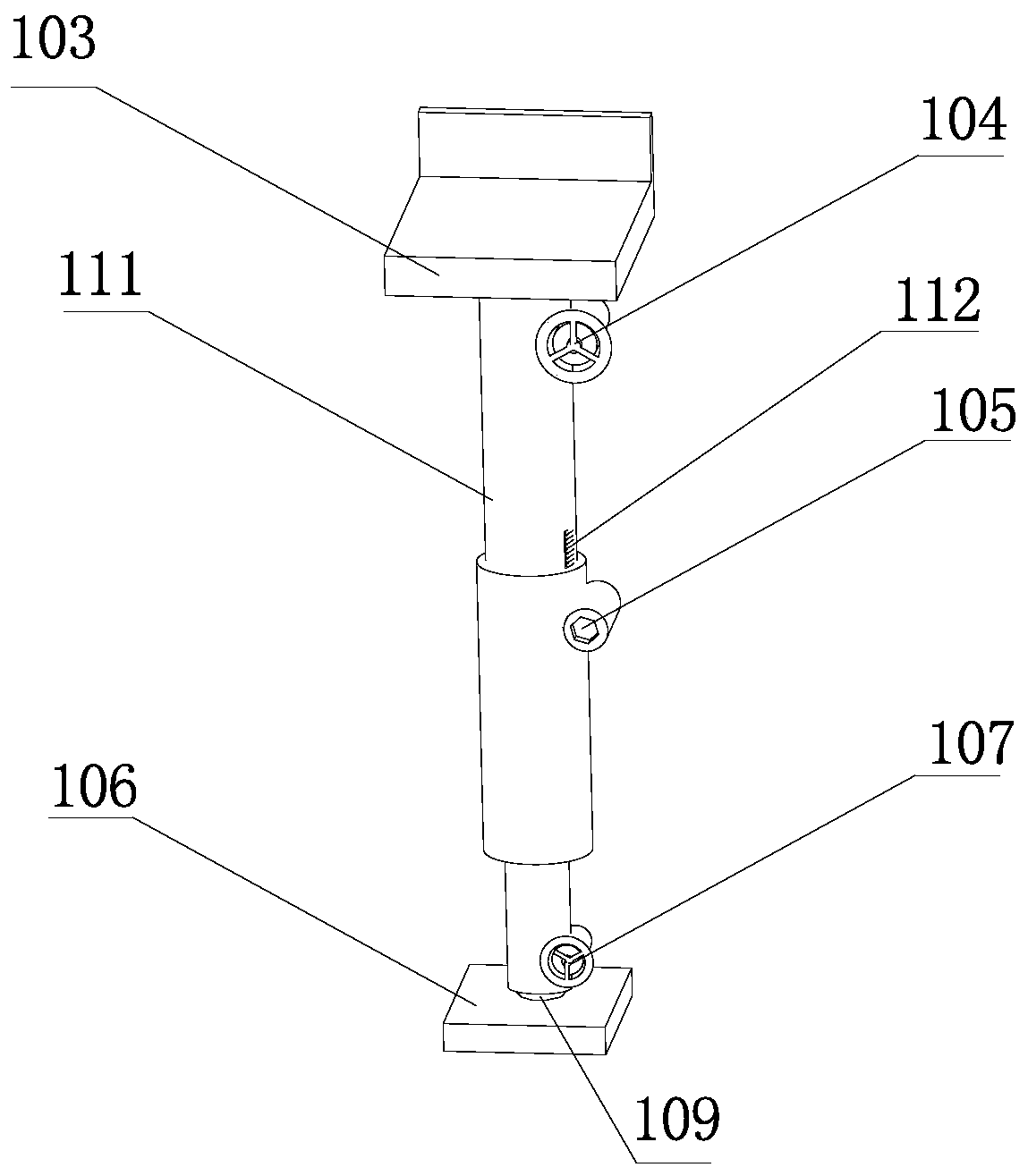

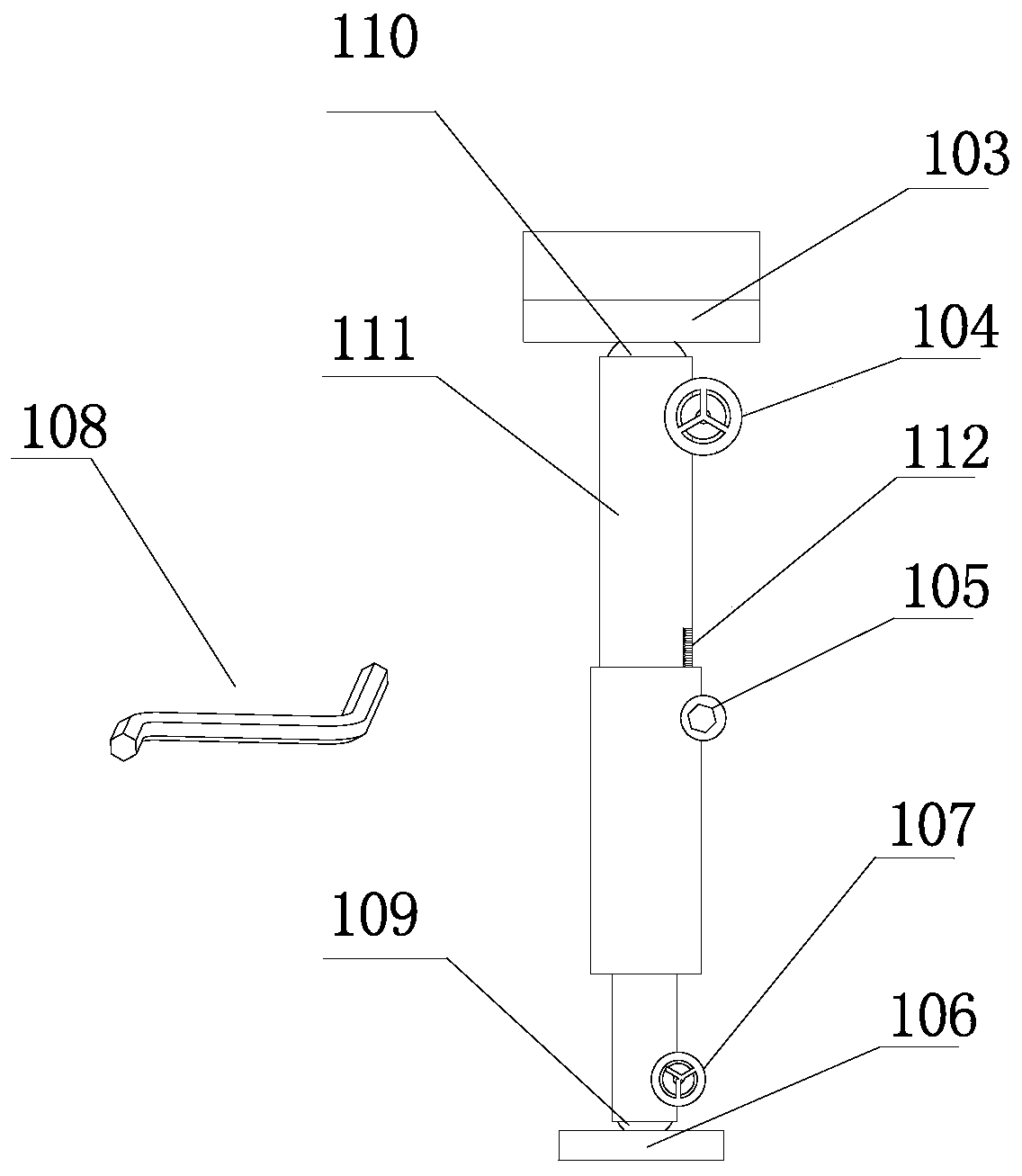

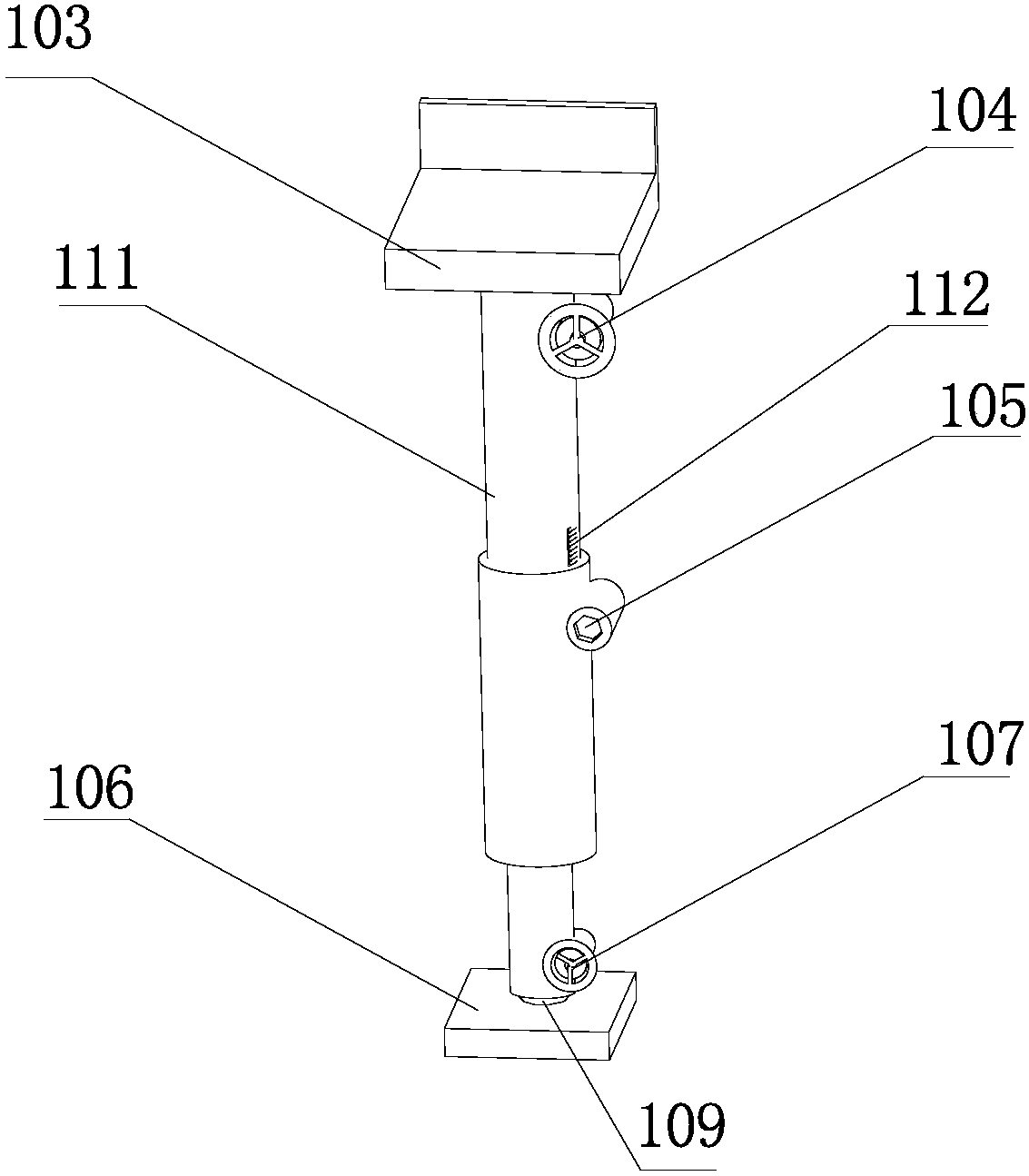

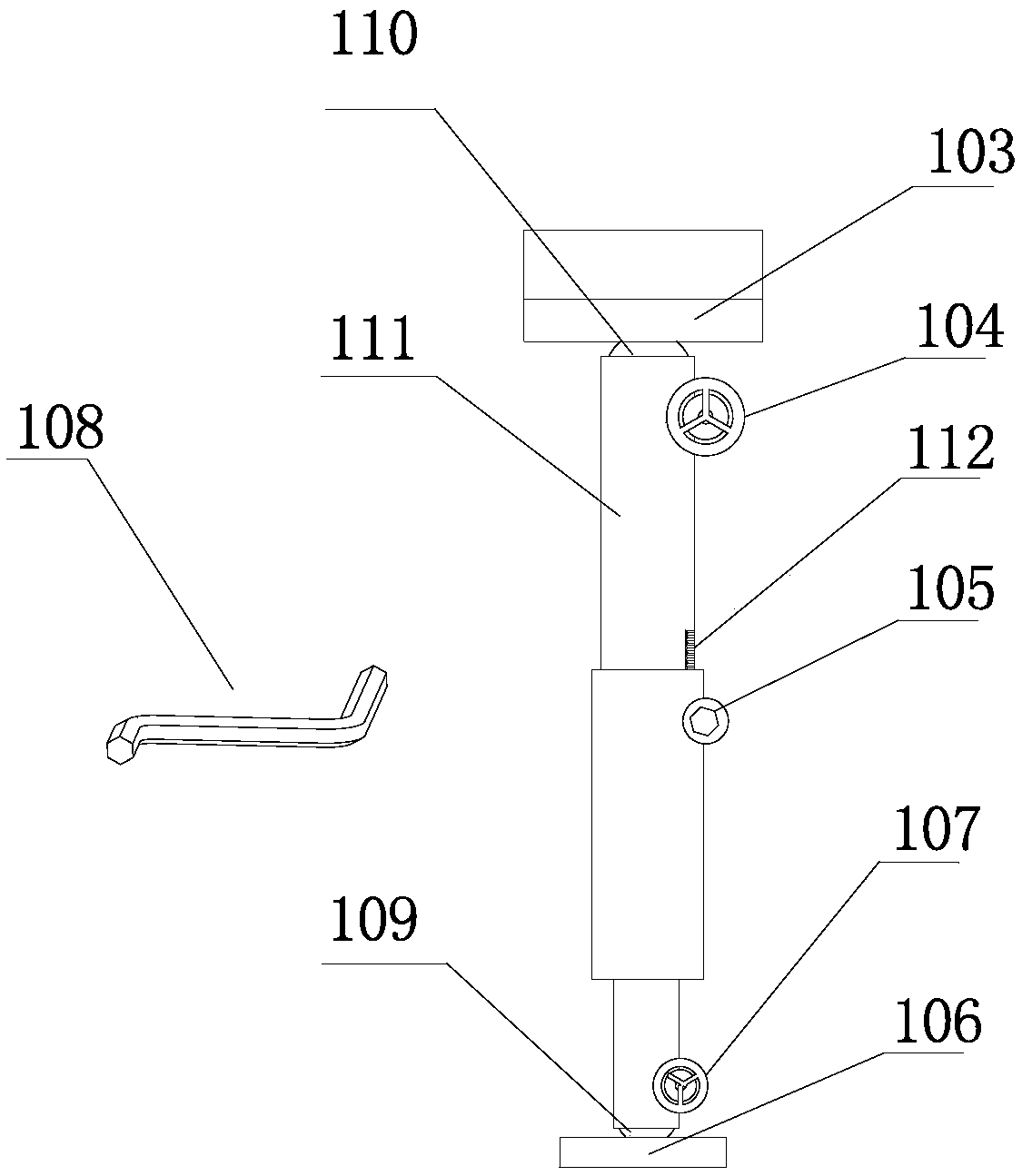

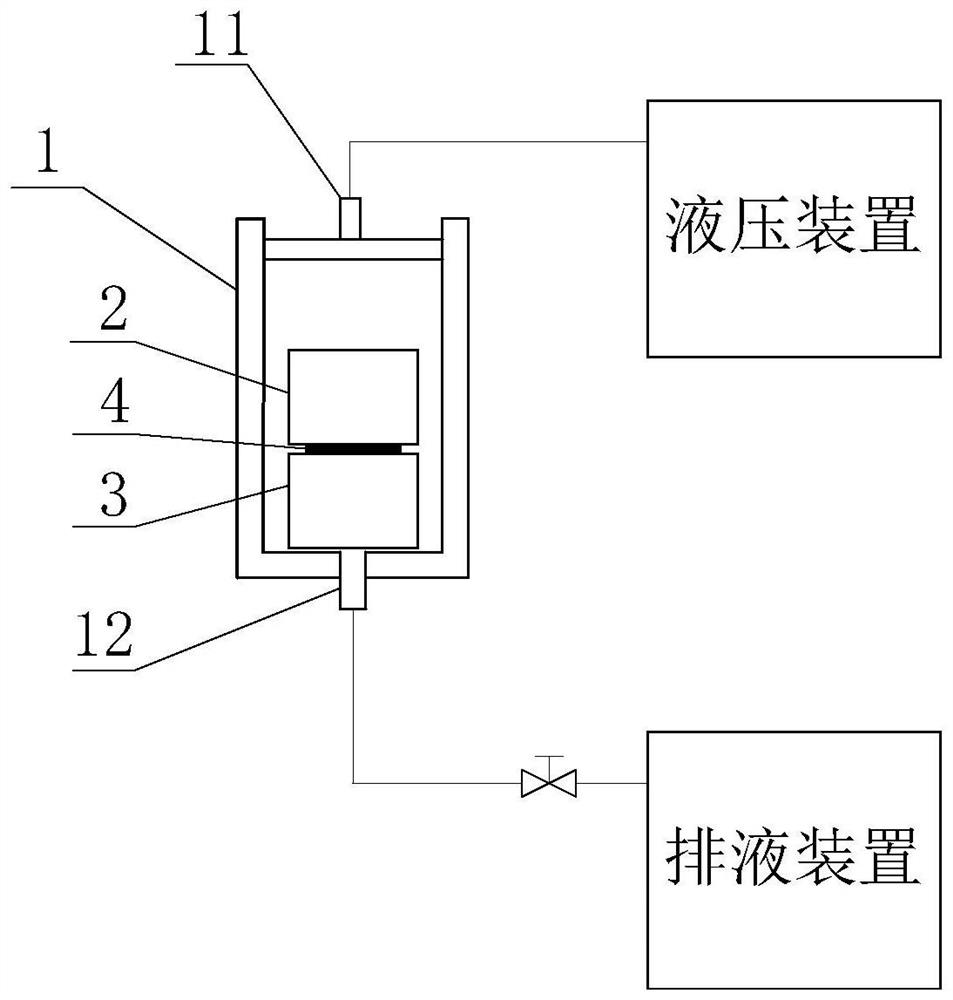

Protolith structural plane sample manufacturing device and manufacturing method

PendingCN111307547AFacilitates the application of normal forcePreparing sample for investigationStrength propertiesEngineeringMechanical engineering

The invention provides a protolith structural plane sample manufacturing device and manufacturing method. A bearing table is used for bearing a structural plane lower disc, a first level gauge is usedfor being installed on the side wall of the structural plane lower disc, and a plurality of first height adjusting pieces are used for adjusting the first level gauge to be in a horizontal state; a lower disc die and an upper disc die are arranged in a square tube shape and extend in a vertical direction, the lower disc die is used for being installed on the periphery of the structural surface lower disc, and a lower fixing piece is used for fixing the structural surface lower disc. A supporting assembly comprises a supporting rod and a supporting cap, the supporting rod extends in the vertical direction, the supporting rod and the supporting cap are fixed to the outer side wall of the lower disc mold and the outer side wall of the upper disc mold respectively, the supporting rod matchesthe supporting cap to install the upper disc mold above the lower disc mold, the upper disc mold is opposite to the lower disc mold; and an upper fixing piece is used for fixing a structural surface upper disc. The protolith structural plane sample manufacturing device has the following beneficial effect: a problem of how to determine the horizontal state of the structural plane on the premise ofensuring that the structural plane upper disc and the structural plane lower disc of the sample are matched is solved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for quickly constructing stress-saturated protolith crustal stress test standard part

ActiveCN111999148AIncrease diversityAccurate measurementPreparing sample for investigationForce transducersClassical mechanicsStructural engineering

The invention discloses a method for quickly constructing a stress-saturated protolith crustal stress test standard part. The method comprises the following steps that 1, a field protolith sample is prepared; 2, a stress main hole and a monitoring auxiliary hole are drilled; 3, a plurality of auxiliary hole pressure sensors are evenly arranged; 4, color marking is conducted on each stress main hole, and a plurality of main hole pressure sensors are evenly arranged in each stress main hole in the hole depth direction; 5, each stress main hole is backfilled; 6, a constraint boundary layer of thelateral confinement stiffness rock-like material is formed; and 7, stress locking components are installed on the other faces, except the face where the stress main hole and the monitoring auxiliaryhole are located, of the field protolith sample. The technical problem to be solved by the invention is to provide a method for quickly constructing the stress-saturated protolith crustal stress teststandard part, and the method can solve the problems that the sample preparation time is long and the test precision and accuracy cannot be ensured.

Owner:CHINA THREE GORGES UNIV

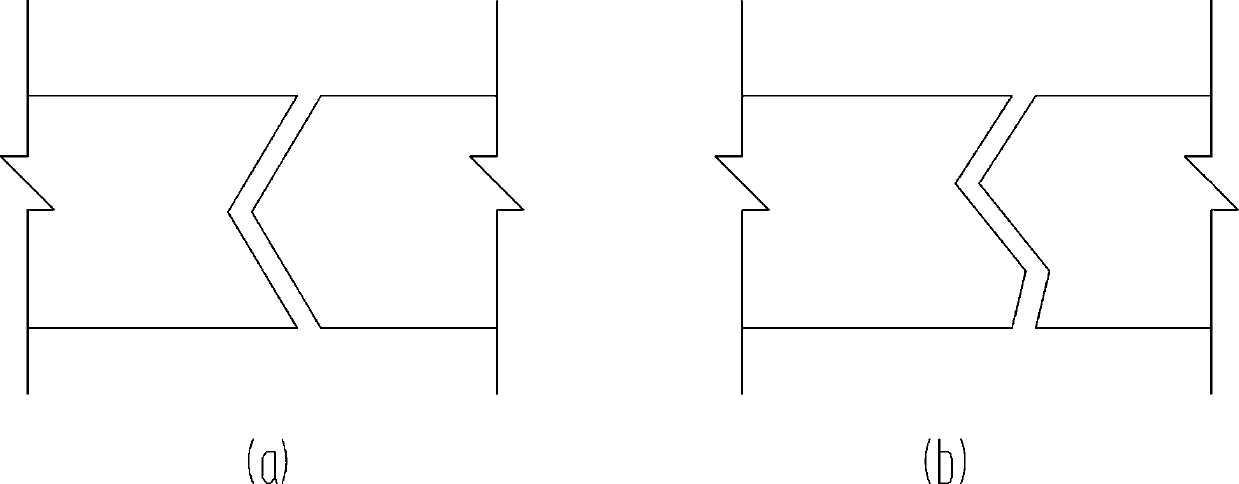

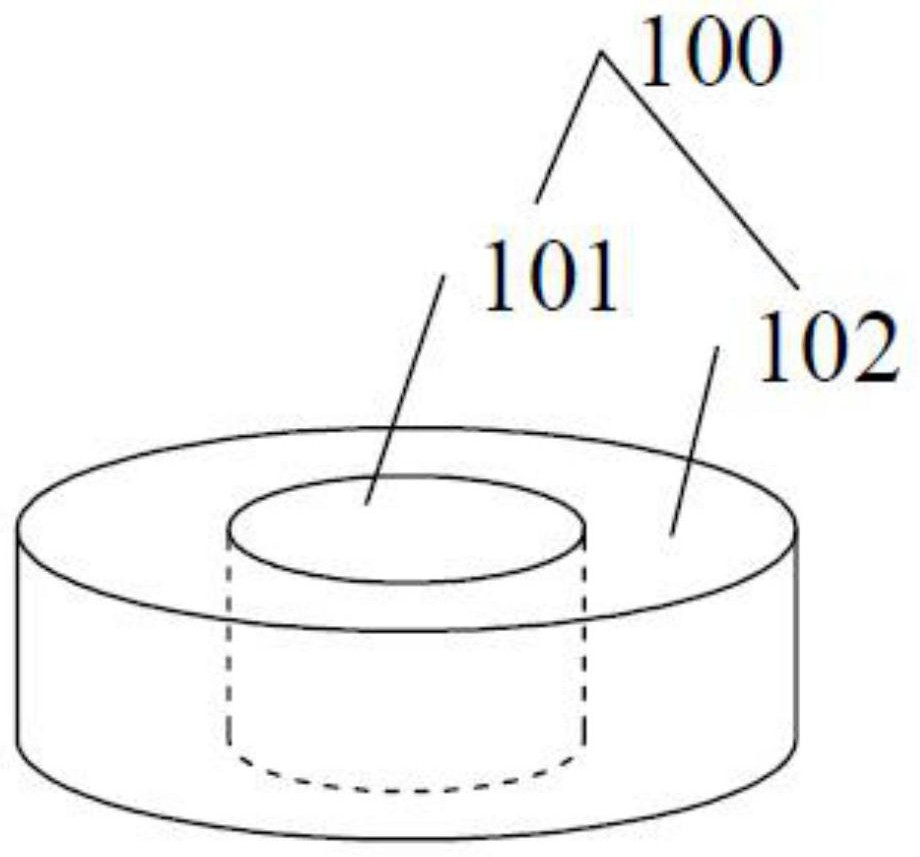

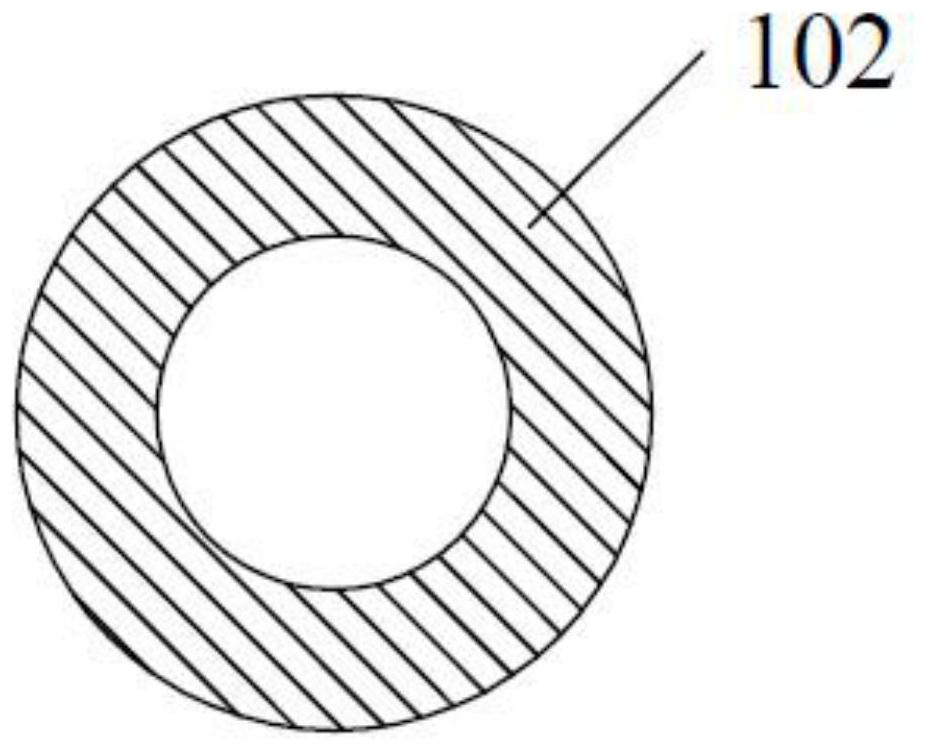

Device for simulating dynamic friction process of protolith and manufacturing method thereof

PendingCN113267447AAids in the study of dynamic friction propertiesSimple geometryUsing mechanical meansMaterial analysisEngineeringMechanical engineering

The invention provides a device for simulating the dynamic friction process of protolith and a manufacturing method thereof. The device comprises a first simulation piece for simulating the dynamic friction process of protolith, a second simulation piece used for being matched with the first simulation piece to work; the first simulation piece and the second simulation piece can be compactly nested in a relatively movable manner, and the upper surfaces or the lower surfaces of the first simulation piece and the second simulation piece are flush after the first simulation piece and the second simulation piece are nested. The first simulation piece and the second simulation piece can be mutually and compactly nested, the dynamic friction process of protolith under different confining pressures under different crustal stress conditions is simulated, and the dynamic friction performance of fragile materials such as rock under different additional conditions can be researched. The device is simple in geometric structure, reasonable in design, convenient to manufacture and use, capable of simulating rock dynamic friction under different confining pressures, good in using effect and convenient to popularize.

Owner:TIANJIN UNIV

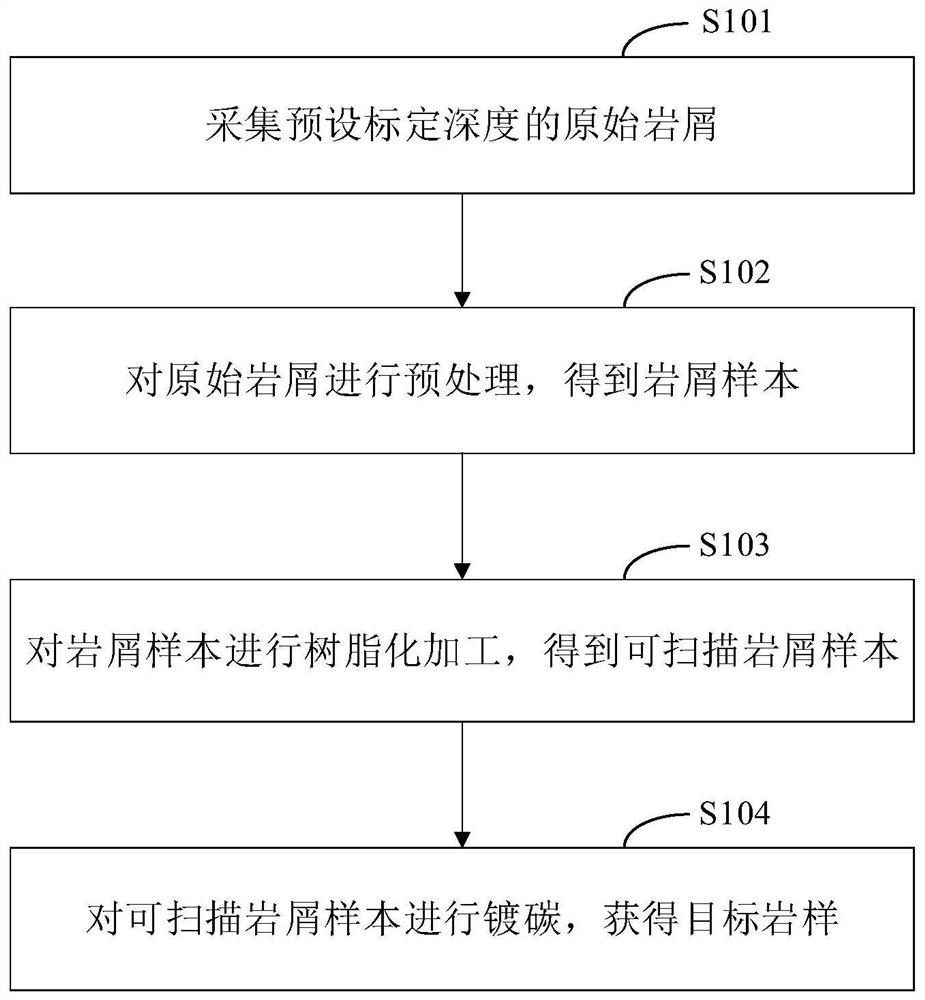

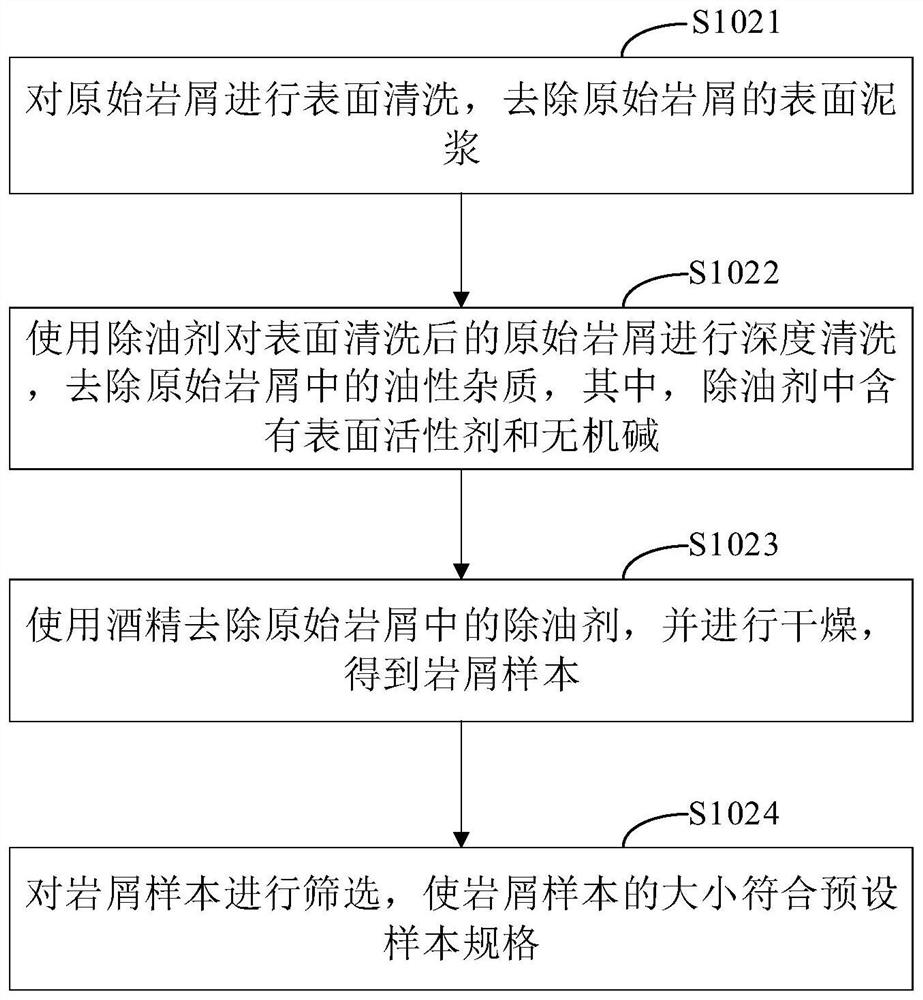

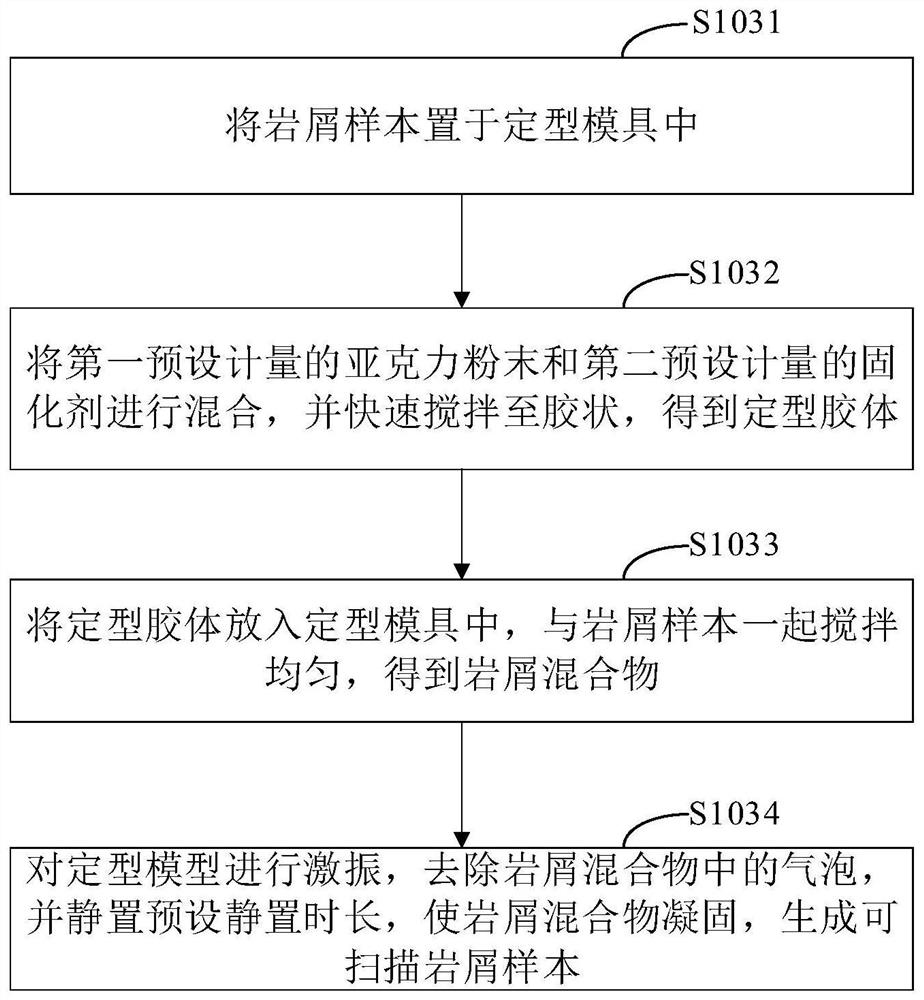

Rock sample preparation method and system for mineral element analysis

The embodiment of the invention provides a rock sample preparation method and system for mineral element analysis. The method comprises the steps: collecting original rock debris with the preset calibration depth; preprocessing the original rock debris to obtain a rock debris sample; performing resinification processing on the rock debris sample to obtain a scannable rock debris sample; and carrying out carbon plating on the scannable rock debris sample to obtain a target rock sample. As the real original rock debris is adopted for processing, the scannable rock debris sample is generated andsubjected to carbon plating processing, the target rock sample can be directly scanned and analyzed, the test analysis data are more real and effective, and the mineral element analysis accuracy and message existence are improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

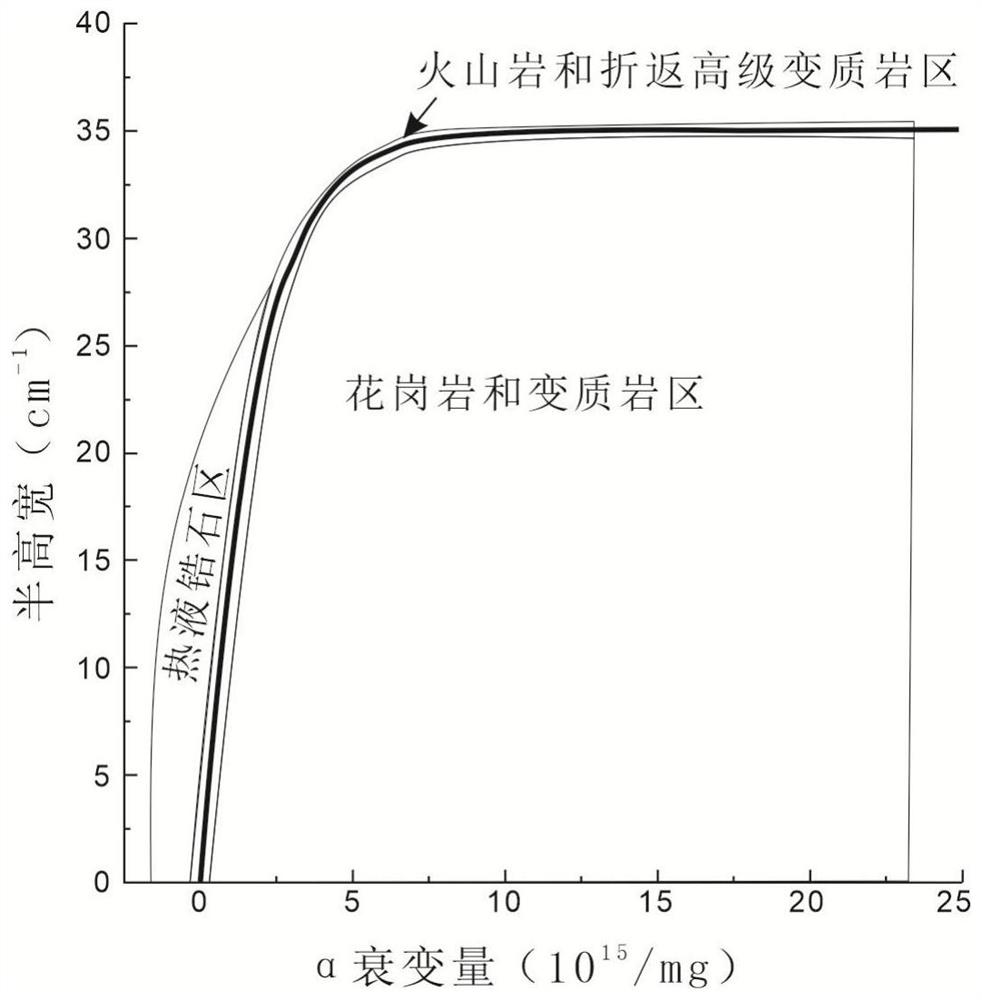

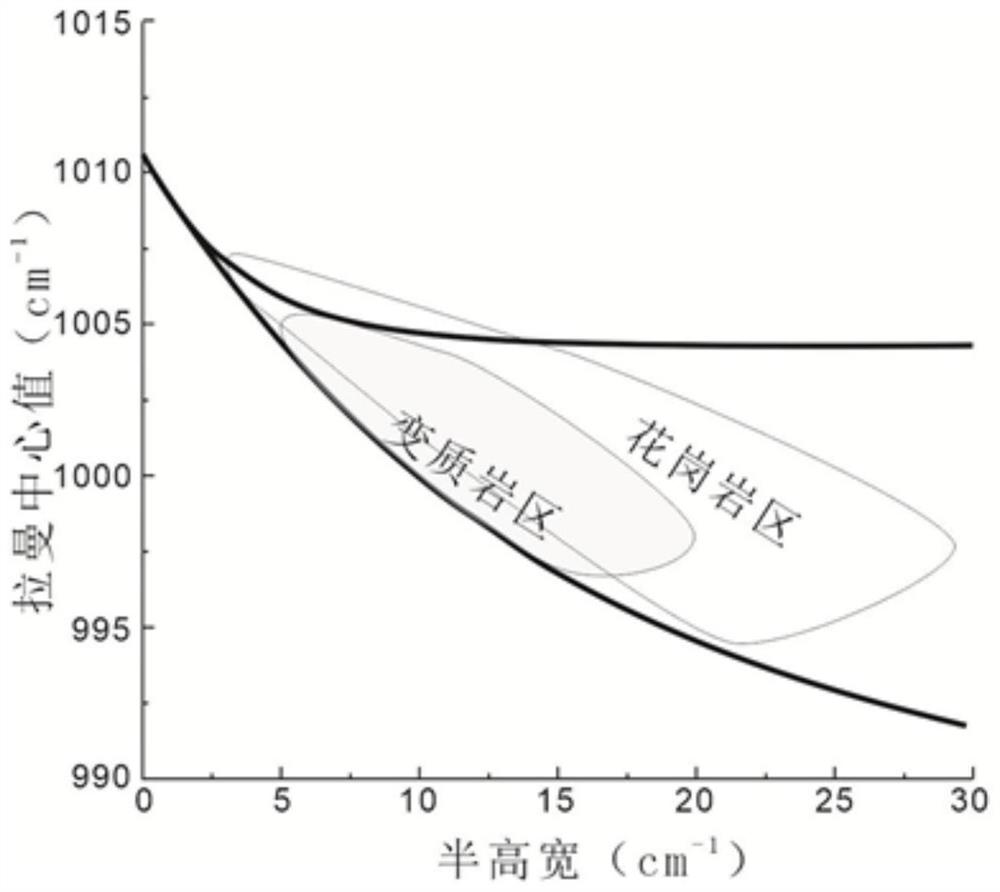

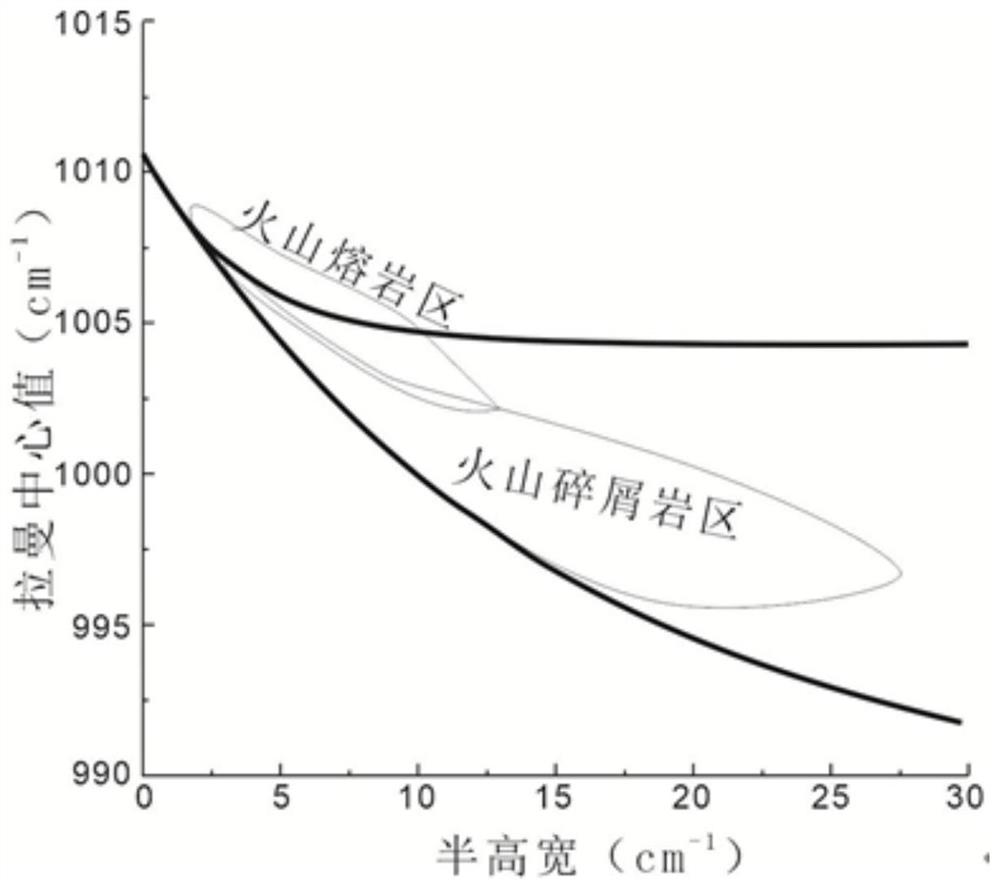

Method for discriminating zircon protolith type by using zircon lattice damage

ActiveCN114295598AEasy to operateEasy to learnNuclear energy generationMaterial analysis by electric/magnetic meansVisual observationCrystallinity

The invention discloses a method for judging the type of zircon protolith by using zircon lattice damage. The method comprises the following steps: S1, determining the U-Pb age, U content and Th content of the zircon by using a dating technology, and calculating the theoretical alpha decay amount of the zircon through the tested U-Pb age and U content and Th content according to a decay formula; s2, measuring the crystallinity of the zircon by using a laser Raman instrument, and calculating the full width at half maximum and the peak position of a zircon Raman vibration peak according to the crystallinity of the zircon; s3, performing projection on the alpha decay amount, the Raman spectrum peak full width at half maximum and the peak value to judge the protolith type of zircon; from the principle of lattice damage, a functional relationship is established with zircon protolith and a cause process. According to the method, a probability statistical algorithm is utilized to establish a discrimination formula, a probability value belonging to zircon protolith is given, the method is a parent user type discrimination method, the discrimination method has simple projection discrimination and is convenient for visual observation, and meanwhile, higher judgment accuracy is obtained in a probability mode.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

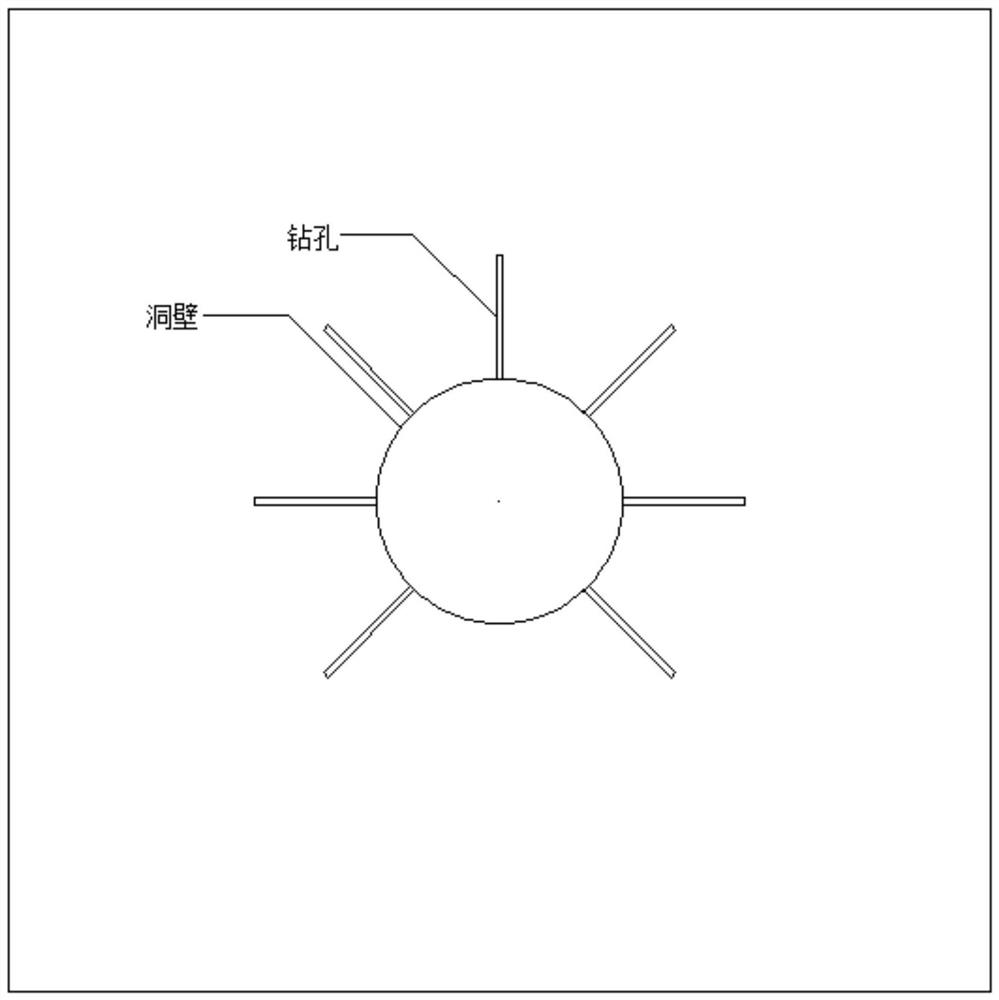

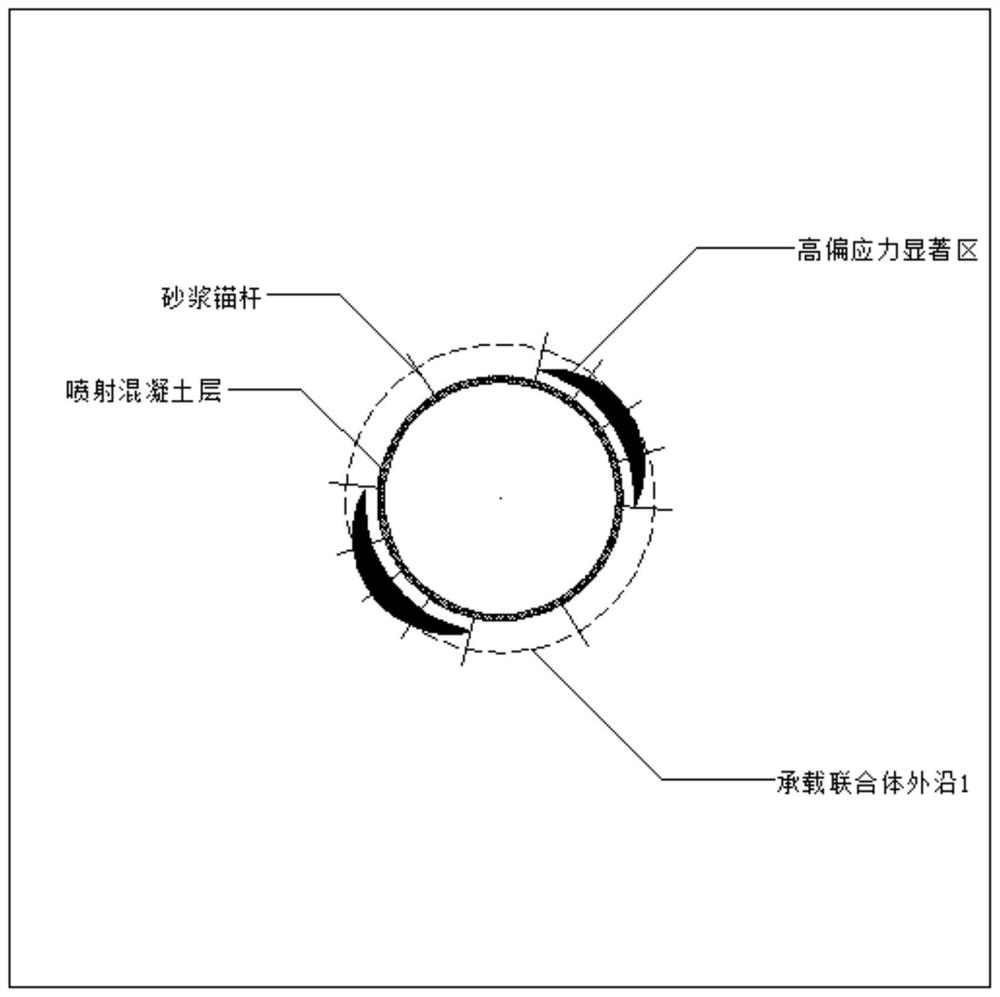

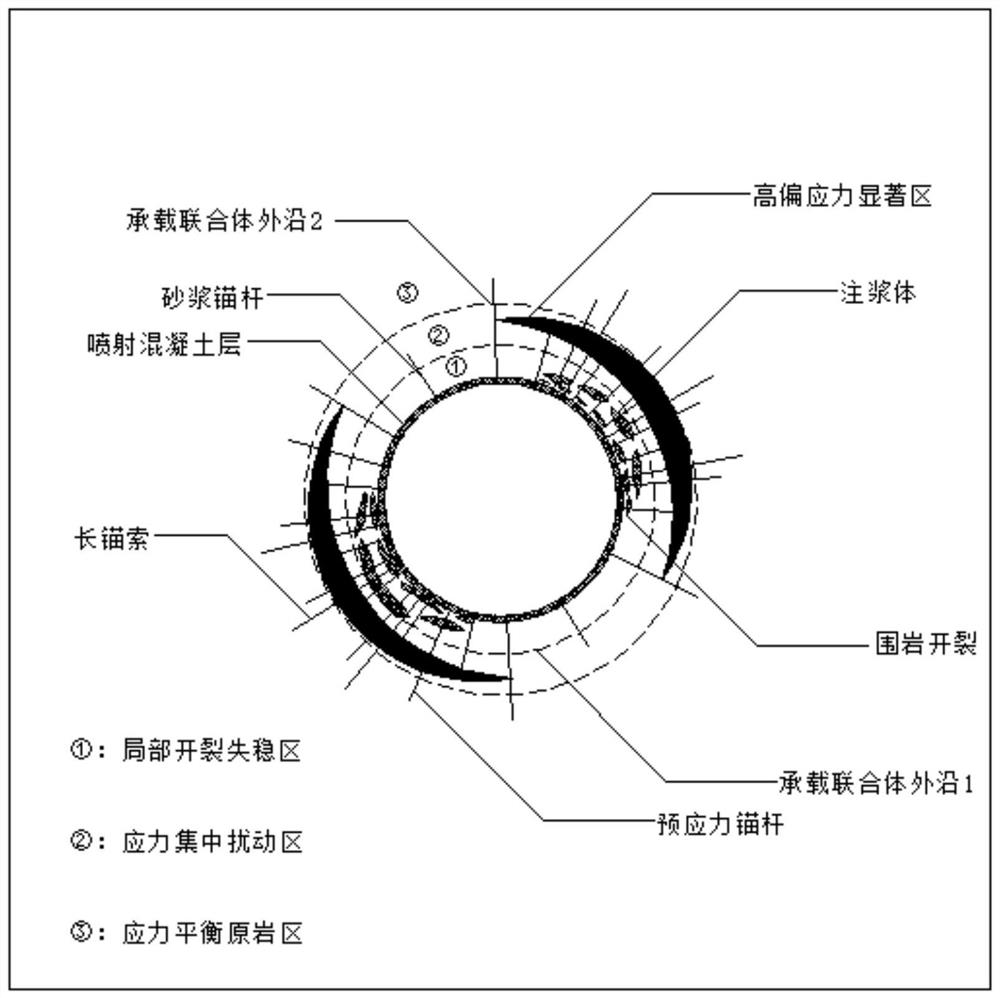

Underground engineering surrounding rock-stress double-target mutual feedback joint regulation and control method

PendingCN114233393AGive full play to carrying capacityActive control integrityMining devicesUnderground chambersStress concentrationClassical mechanics

The invention belongs to the technical field of underground engineering design, and particularly relates to an underground engineering surrounding rock-stress double-target mutual feedback combined regulation and control method. According to the underground engineering surrounding rock-stress double-target mutual feedback joint regulation and control method provided by the invention, the cracking coefficient CDI of a local cracking instability area, the pressure equalizing coefficient PEI of a stress concentration disturbance area and the bearing coefficient BCI of a stress balance protolith area of surrounding rock are calculated and obtained through in-situ drilling television camera, a rock stress meter and an acoustic wave testing technology on the section of the underground engineering; and the excavation layering height of the underground engineering and the supporting types, supporting opportunities and supporting lengths of three key links of shallow supporting and surface fixing, ring expanding and cost strengthening and combined bearing are determined, the completeness degree of shallow surrounding rock and the deviation stress increasing degree of deep surrounding rock are actively controlled, and the overall bearing capacity of the shallow surrounding rock and the overall bearing capacity of the deep surrounding rock are fully exerted.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

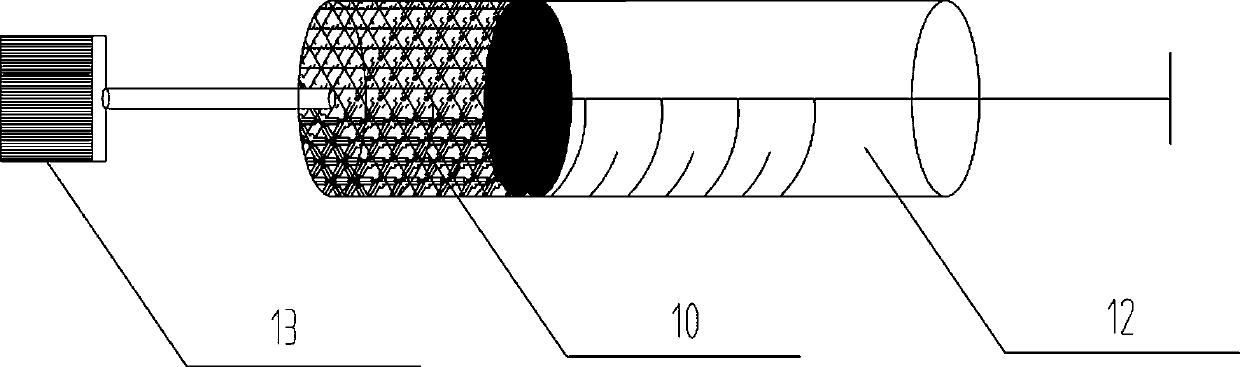

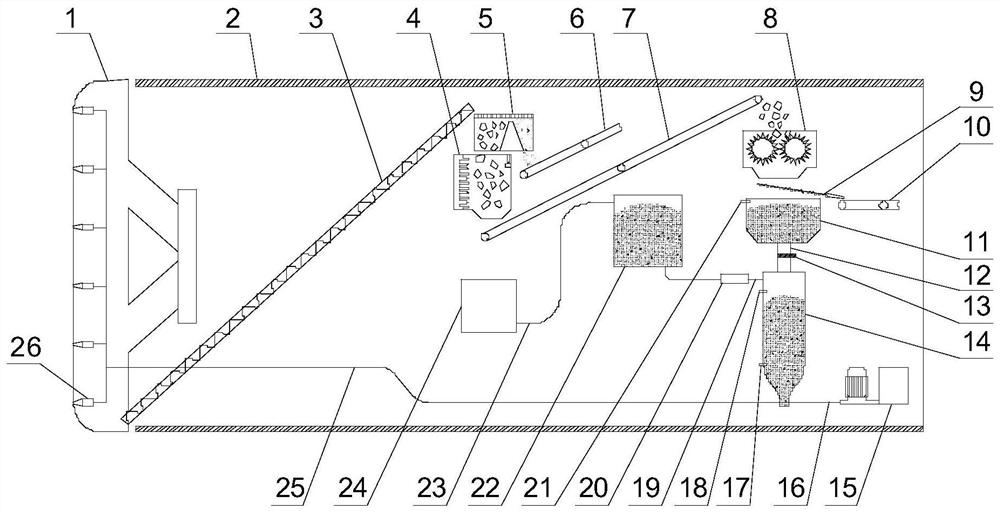

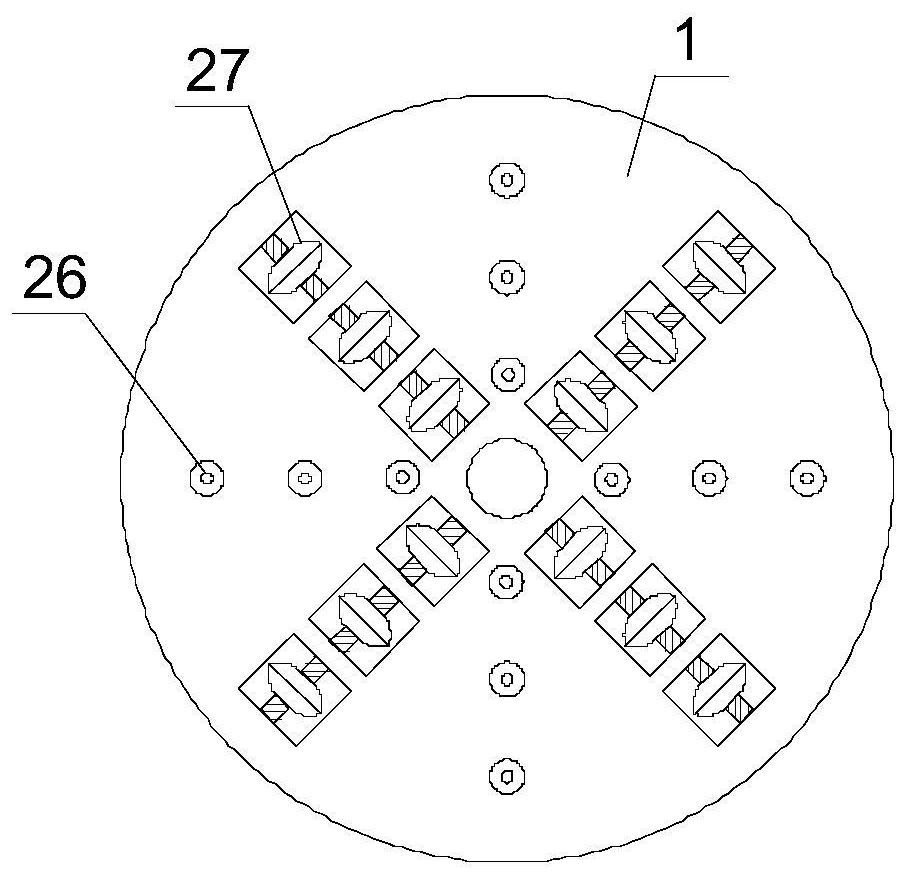

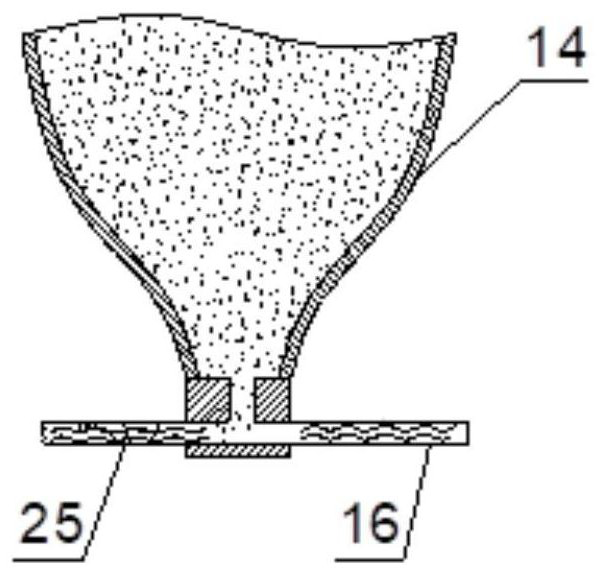

Protolith abrasive water jet construction equipment in tunneling process

PendingCN113216998ARealize continuous feedingReduce usage costsTunnelsEnvironmental engineeringProtolith

The invention provides protolith abrasive water jet construction equipment in a tunneling process. The protolith abrasive water jet construction equipment comprises a sand storage tank, a rock slag treatment assembly, a water pump and a nozzle, and the sand storage tank is provided with a first inlet, a second inlet and an outlet; the rock slag treatment assembly is connected with the first inlet of the sand storage tank and used for inputting abrasives made of rock slag into the sand storage tank; the water pump is connected with the second inlet of the sand storage tank; and the nozzle is connected with the outlet of the sand storage tank. The protolith abrasive water jet construction equipment in the tunneling process has the beneficial effects that the protolith waste (namely the rock slag) is used for manufacturing the abrasives, continuous feeding of abrasive water jet can be achieved, the use cost of traditional abrasives can be saved, the construction cost is reduced, and the working performance is stable and controllable.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

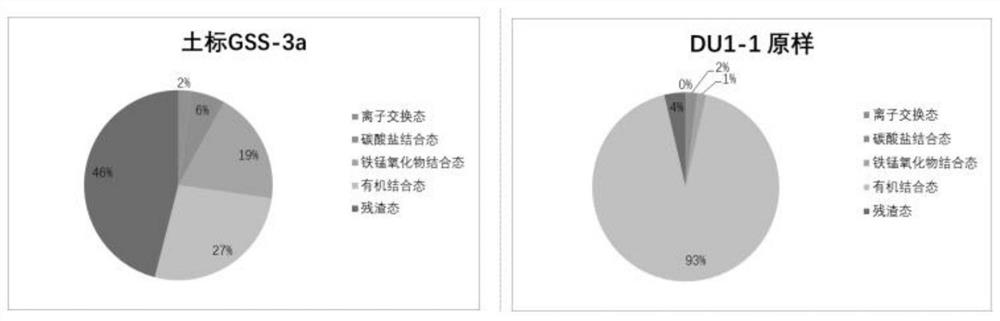

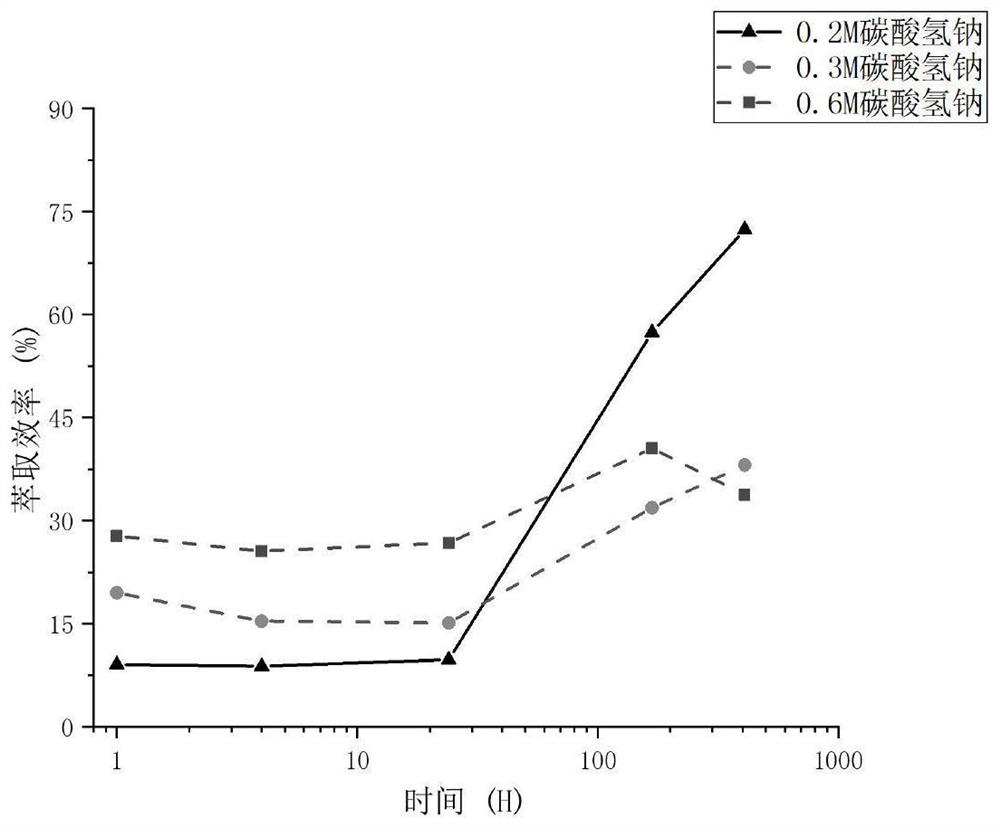

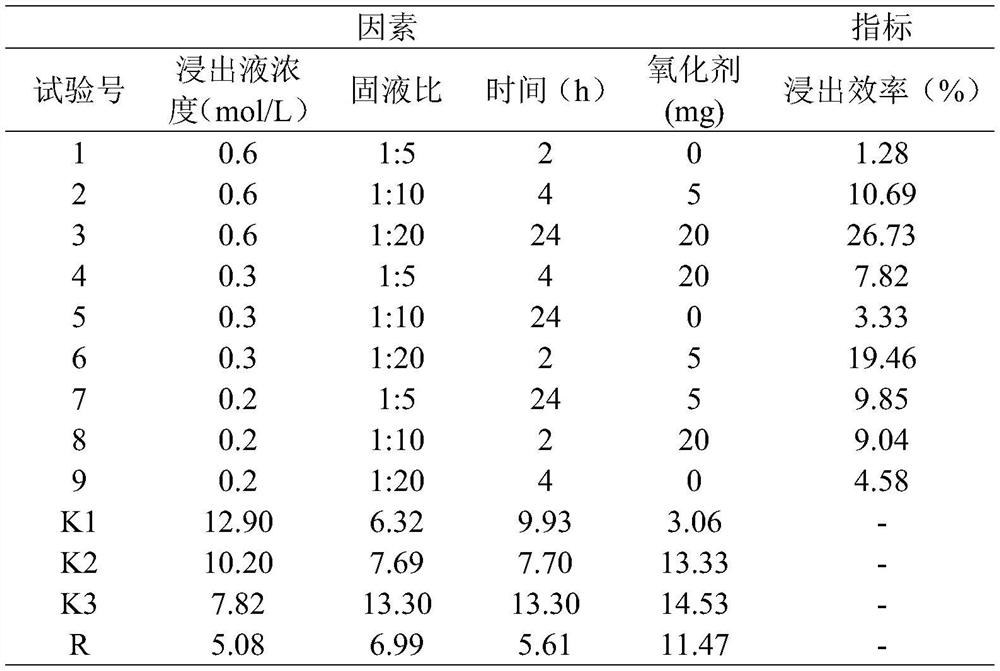

Method for removing uranium in gravel-containing protolith loose sand

PendingCN114653739AClear combinationReduce loss rateContaminated soil reclamationSoil scienceSoil remediation

The invention discloses a method for removing uranium in gravel-containing protolith loose sand, and belongs to the technical field of contaminated soil remediation. The method comprises the following steps: adding a leaching agent and an oxidizing agent into the gravel-containing protolith loose sandy soil, oscillating at normal temperature, separating the sandy soil from supernate through centrifugation, washing the separated sandy soil twice, merging the supernate, filtering, and detecting the filtrate; wherein the oxidizing agent is potassium permanganate or hydrogen peroxide, and the mass ratio of the oxidizing agent to the gravel-containing protolith loose sandy soil is (0.005-0.02): 3. Compared with biological decontamination and physical decontamination methods, the method has the advantages of simplicity in operation, low treatment cost, wide uranium concentration range, high uranium extraction rate and the like.

Owner:63653 FORCES PLA

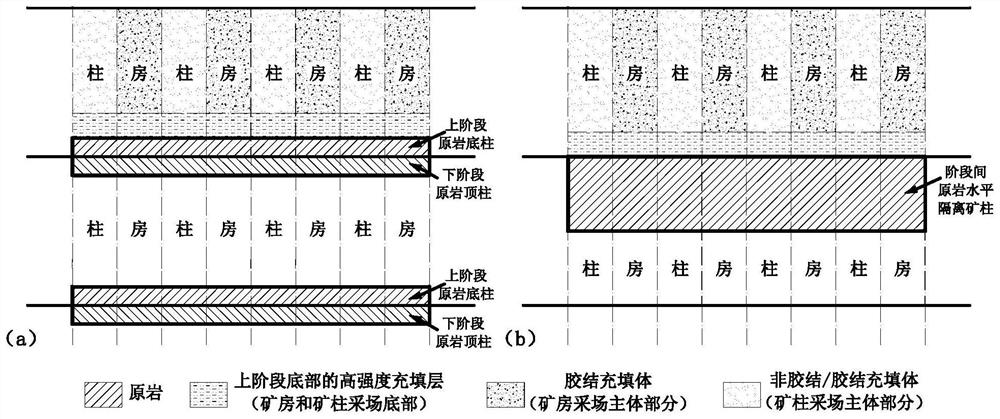

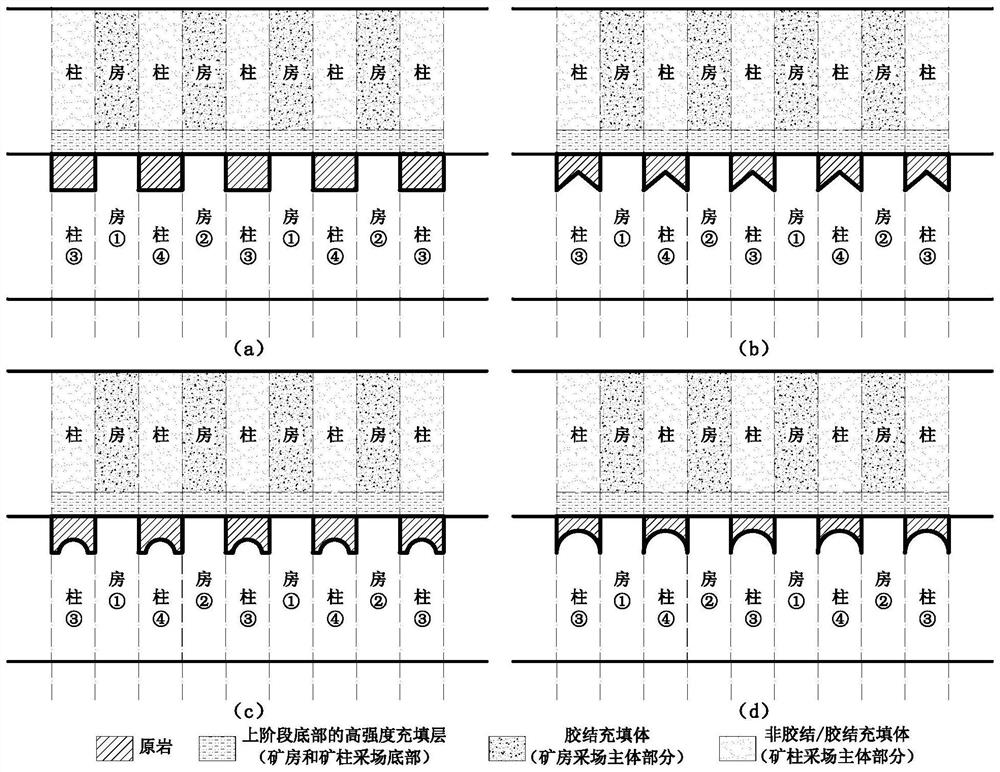

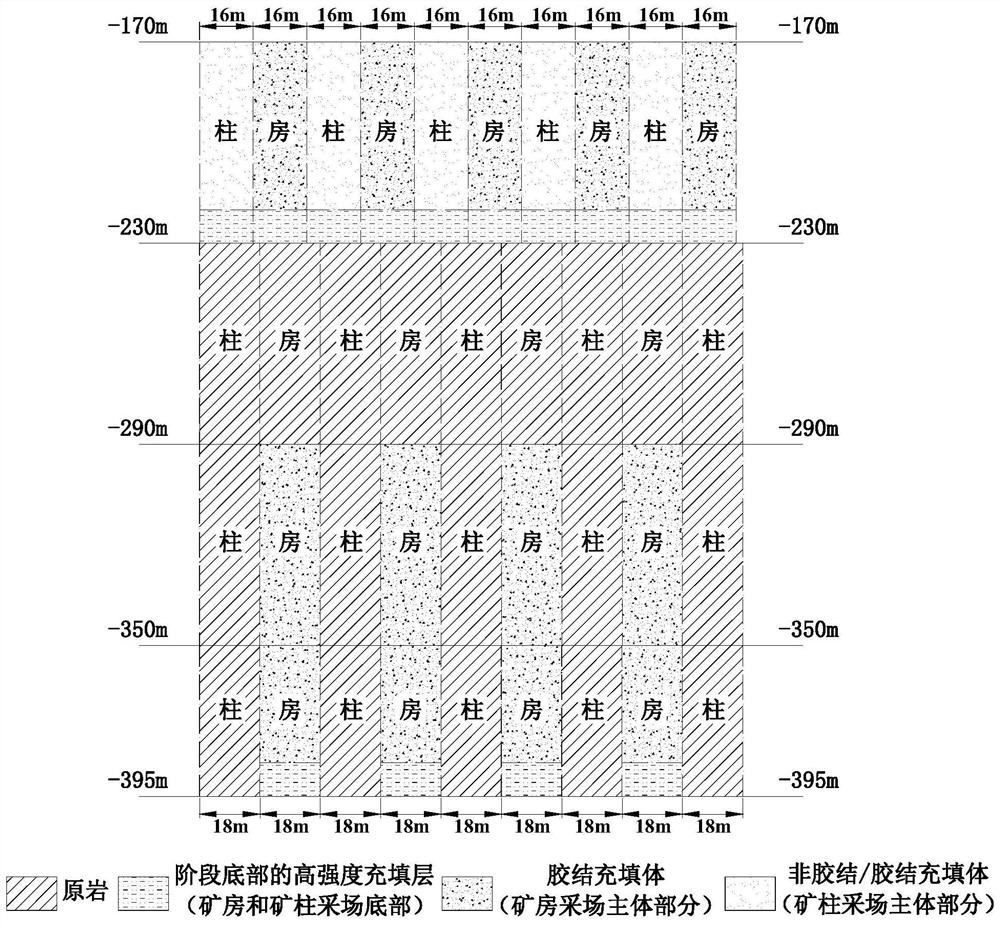

Underfill Mining Method with Only Serrated Ore Pillars

ActiveCN110295909BReduce oreImprove one-time high-efficiency recovery rateUnderground miningSurface miningMining engineeringMechanical engineering

The invention discloses a filling body under mining method with only toothed jambs left. Mining of a one-step chamber stope and mining of a two-step jamb stope are sequentially carried out, cemented filling is adopted in the chamber stope, and non-cemented filling or cemented filling is adopted in the jamb stope. Coal extraction is carried out on the chamber stope below a filling body in one steptill coal extraction is carried out on the bottom face of the filling body, after coal extraction of the stope is finished, mine rock of the adjacent jamb stope is located on the two sides of a dead zone, the filling body is located at the top, and cemented filling is carried out after ore removal is completed; and coal extraction is carried out on the jamb stope below the filling body in two steps, the bottom face of the filling body is not exposed, and mine rock of a certain height is reserved below the filling body and is not subjected to coal extraction. After coal extraction of a stage mine body below the filling body is completed according to the above manner, no complete protolith horizontal jambs are reserved, only the toothed jambs small in mine quantity are formed, the quantity of the protolith horizontal jambs between stages is reduced, the one-time efficient coal extraction rate of resources in a normal exploitation unit is improved, and then economic benefits of exploitation of mine enterprises are increased.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

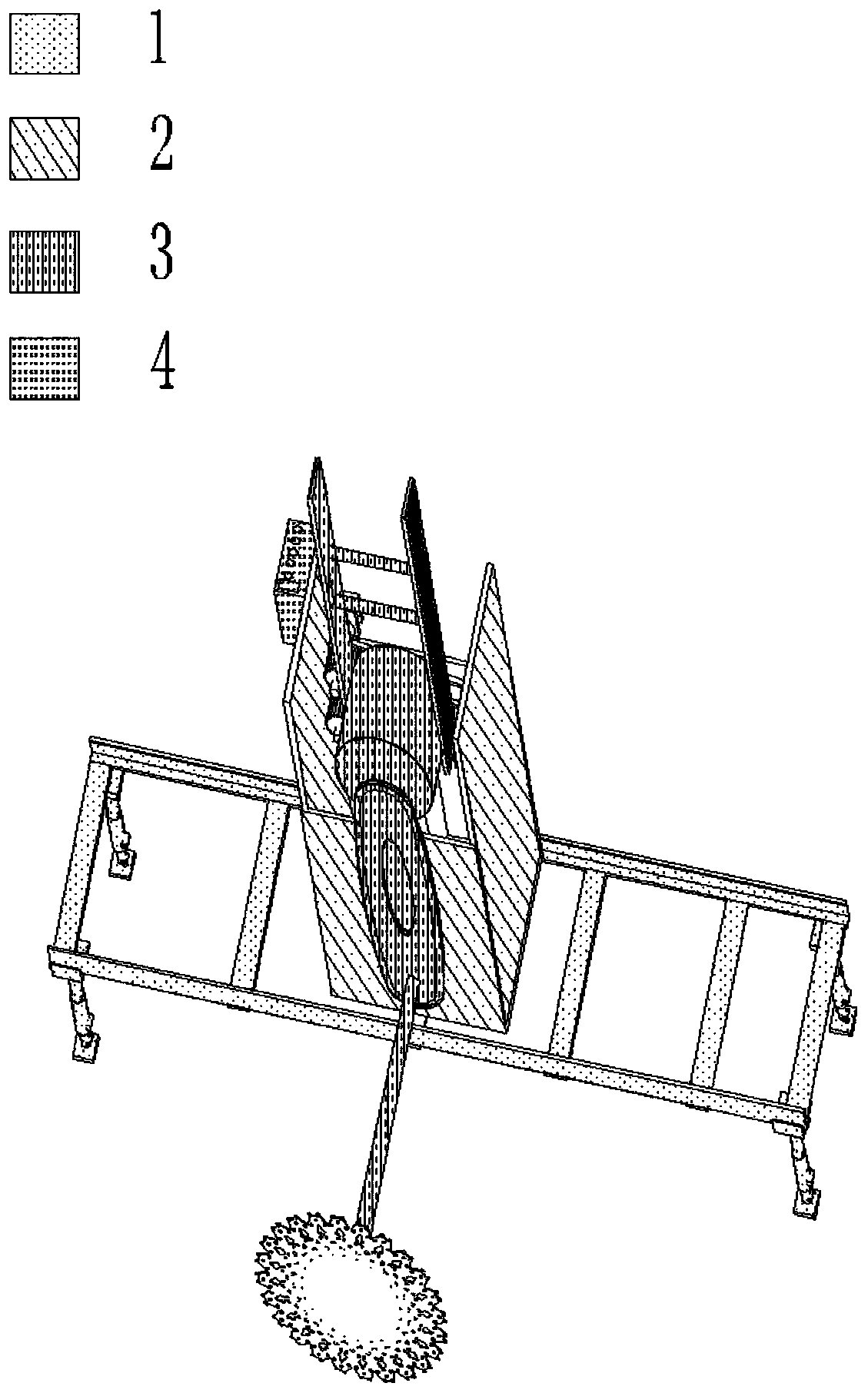

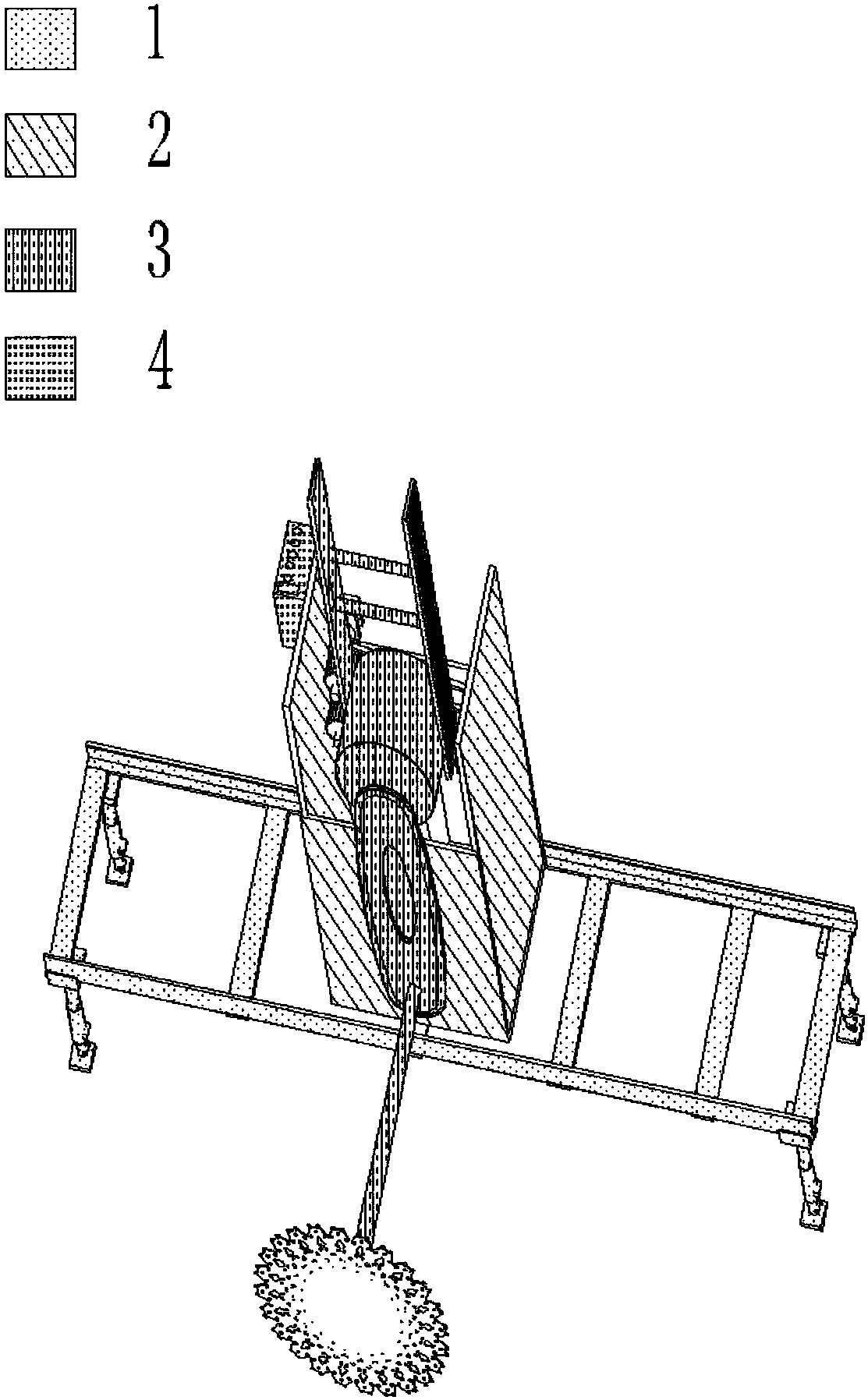

A method for fast and intelligent cutting of field rock structural planes with multiple working faces

The invention provides a method for quickly and intelligently cutting field protolith structure faces from multiple working surfaces and relates to the field of rock structure faces. The method comprises the steps: stably erecting an intelligent device for cutting the field protolith structure faces from multiple working surfaces on a rock body; starting a cutting power system, making a rock cutting chain saw cut the zy2 surface along the z axis in the negative direction, making a rock cutting shaft cut the xz1 surface along the z axis in the negative direction and making a rock cutting sheetcut the zy1 surface along the z axis in the negative direction; making the rock cutting chain saw cut the zy2 surface along the y axis in the negative direction, making the rock cutting shaft cut thexy1 surface along the y axis in the negative direction and making the rock cutting sheet cut the zy1 surface along the y axis in the negative direction; making the rock cutting shaft cut the xz2 surface along the z axis in the positive direction, making the rock cutting chain saw cut the zy2 surface along the z axis in the positive direction and making the rock cutting sheet cut the zy1 surface along the z axis in the positive direction. The method disclosed by the technical scheme of the invention has the beneficial effects of multi-working-surface cutting, high-efficiency cutting, accurate cutting, wide cutting range, automatic cutting process and the like.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for quickly and intelligently cutting field protolith structure face from multiple working surfaces

The invention provides a method for quickly and intelligently cutting field protolith structure faces from multiple working surfaces and relates to the field of rock structure faces. The method comprises the steps: stably erecting an intelligent device for cutting the field protolith structure faces from multiple working surfaces on a rock body; starting a cutting power system, making a rock cutting chain saw cut the zy2 surface along the z axis in the negative direction, making a rock cutting shaft cut the xz1 surface along the z axis in the negative direction and making a rock cutting sheetcut the zy1 surface along the z axis in the negative direction; making the rock cutting chain saw cut the zy2 surface along the y axis in the negative direction, making the rock cutting shaft cut thexy1 surface along the y axis in the negative direction and making the rock cutting sheet cut the zy1 surface along the y axis in the negative direction; making the rock cutting shaft cut the xz2 surface along the z axis in the positive direction, making the rock cutting chain saw cut the zy2 surface along the z axis in the positive direction and making the rock cutting sheet cut the zy1 surface along the z axis in the positive direction. The method disclosed by the technical scheme of the invention has the beneficial effects of multi-working-surface cutting, high-efficiency cutting, accurate cutting, wide cutting range, automatic cutting process and the like.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

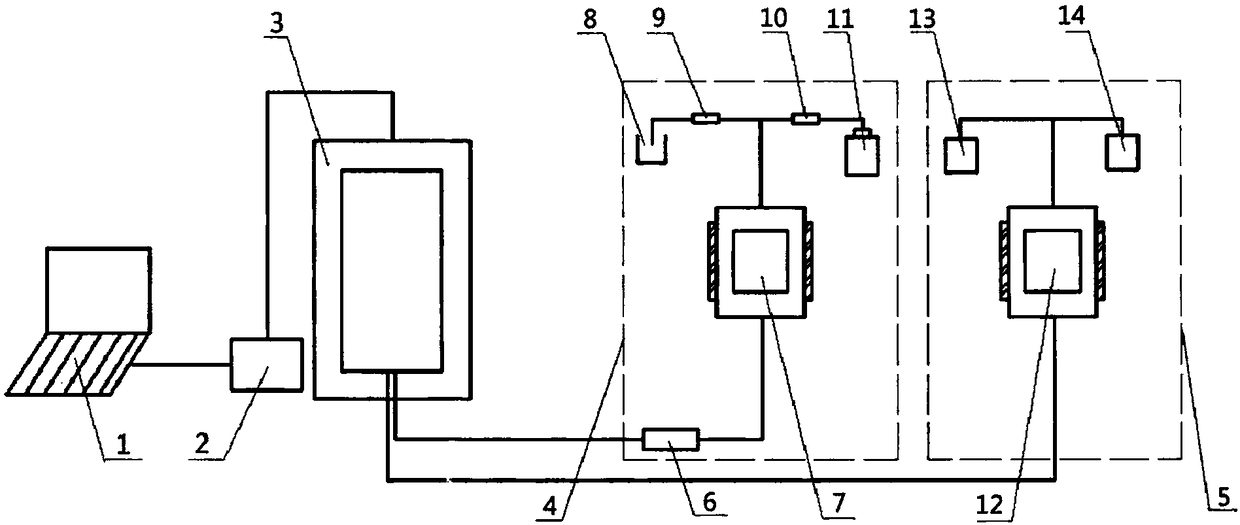

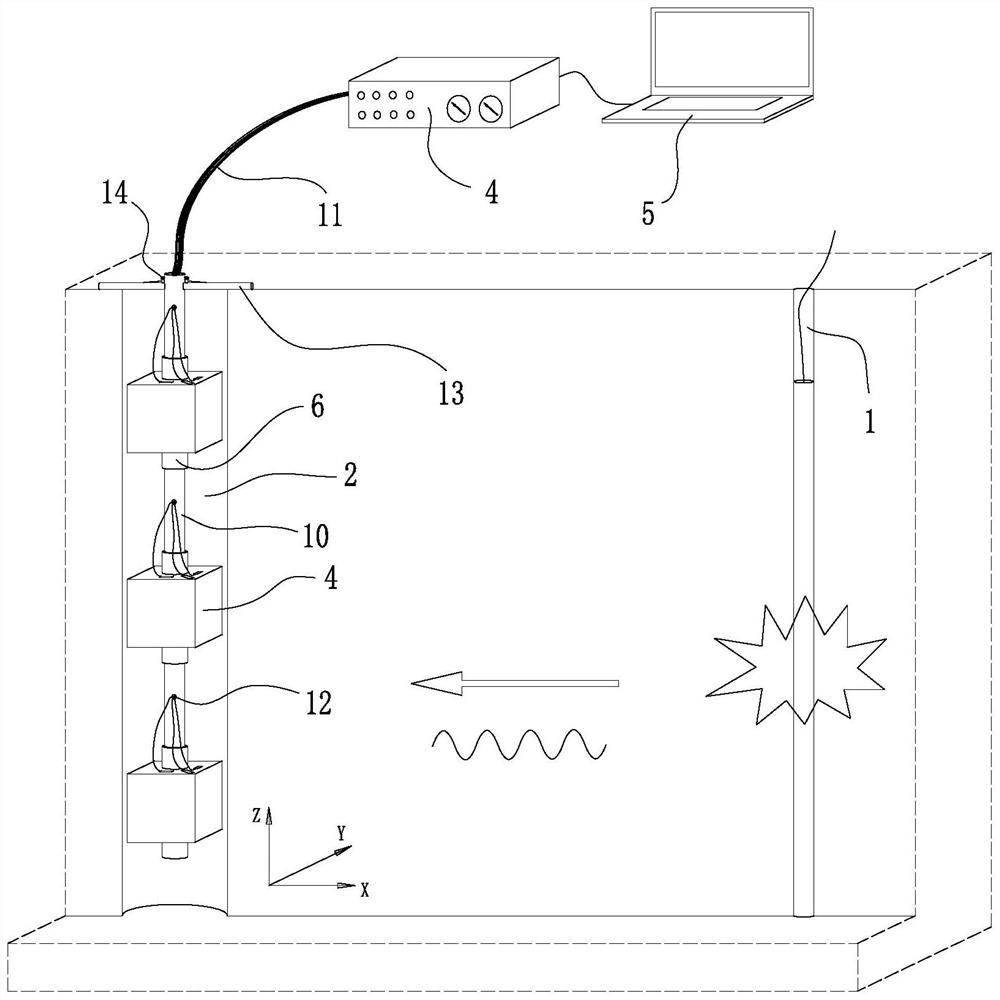

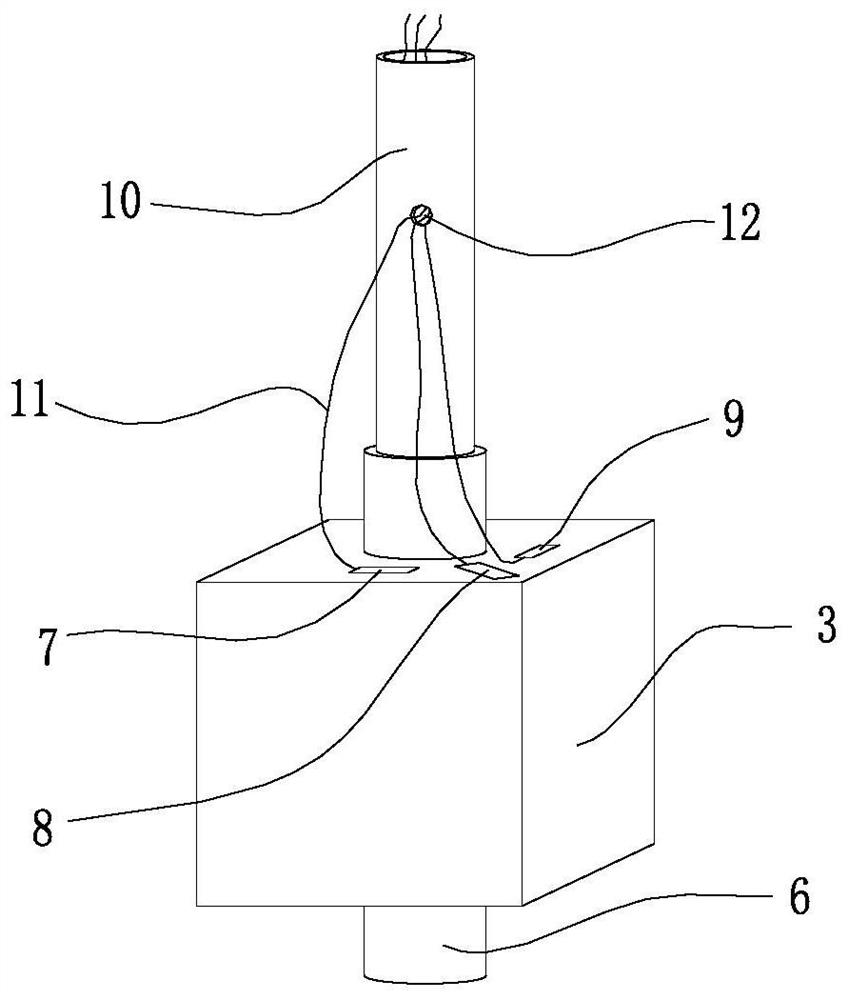

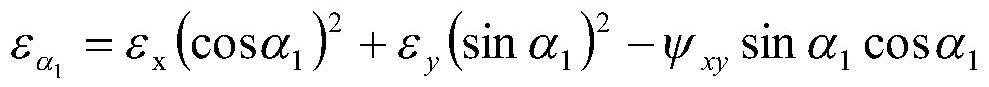

Method for testing dynamic strain in protolith

PendingCN113866025AGuarantee authenticityGuaranteed reliabilityStrength propertiesClimate change adaptationDetonatorMortar

The invention relates to a method for testing dynamic strain in protolith, which comprises the following steps of: preparing a measuring hole in an explosive shock wave action area taking a blast hole as a center; preparing a set of mold with a cube-shaped cavity, pouring mortar into the mold, and preparing a test block for simulating physical properties of protolith; pasting a strain gauge on the surface of the prepared test block; preparing a super-dynamic strain tester and a computer, connecting the strain gauges on the surface of the test block with the super-dynamic strain tester through wires, and connecting the super-dynamic strain tester with the computer; feeding the test block into a specified position in the measuring hole and fixing the test block; and controlling the detonators in the blast holes to detonate, collecting data measured by the strain gauges by the super-dynamic strain tester after explosive shock waves pass through the measuring holes, analyzing the collected data by the computer, and automatically calculating stress data. According to the method, the protolith environment and the protolith structure are reserved, the three-way high ground stress field is maintained, the strain measurement error is small, and data are real and reliable.

Owner:LIAONING TECHNICAL UNIVERSITY

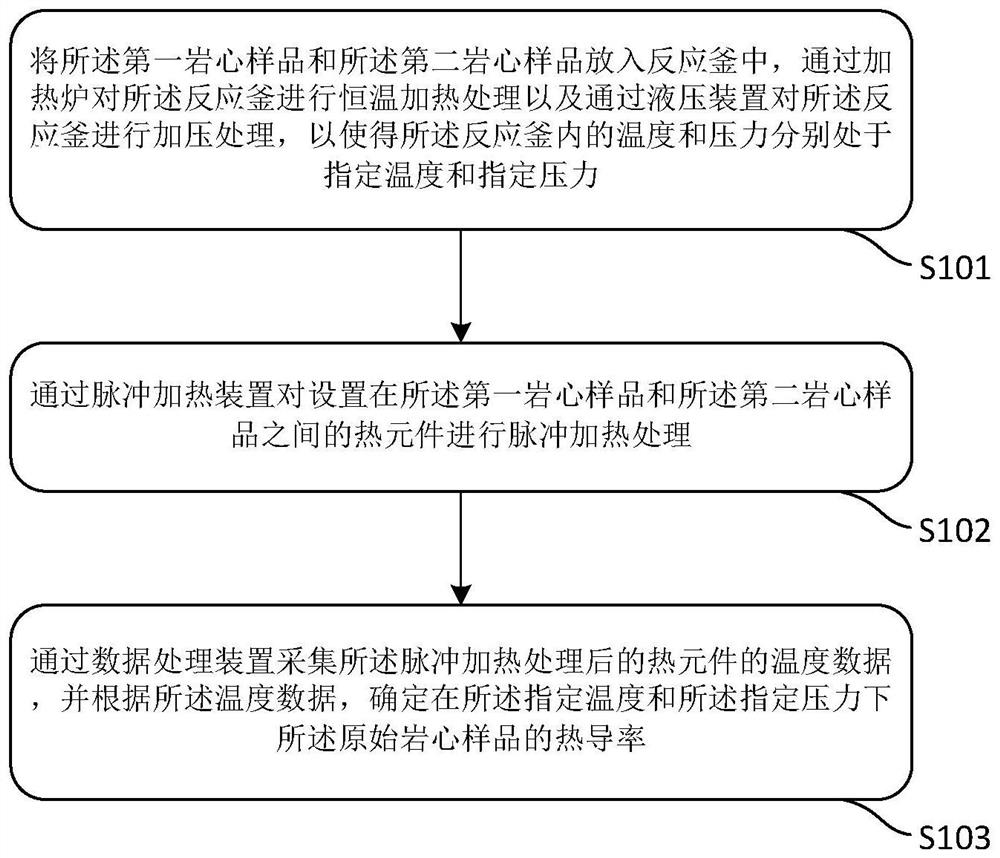

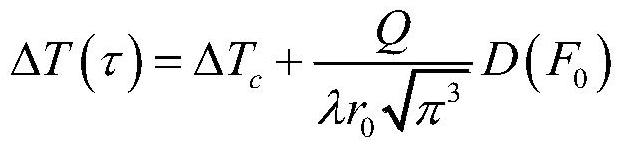

A method and system for determining thermal conductivity of rock

ActiveCN108562610BDetermine thermal conductivityEffective determination of thermal conductivityMaterial thermal conductivityMaterial heat developmentRock coreEngineering

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com