Arch frame for underground tunnel and roadway engineering support and rapid support method of arch frame

A technology for underground tunnels and arches, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of unsatisfactory construction results, high cost, and long construction time, and meet the requirements of construction support strength and large bearing capacity , The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0042] The ore rocks in a mining area are developed with volcanic rocks. The footwall of the ore body is basalt and the hanging wall is tuff. The sprayed concrete support mode of the double-layer arch net of the present invention effectively utilizes the bearing capacity of the surrounding rock itself.

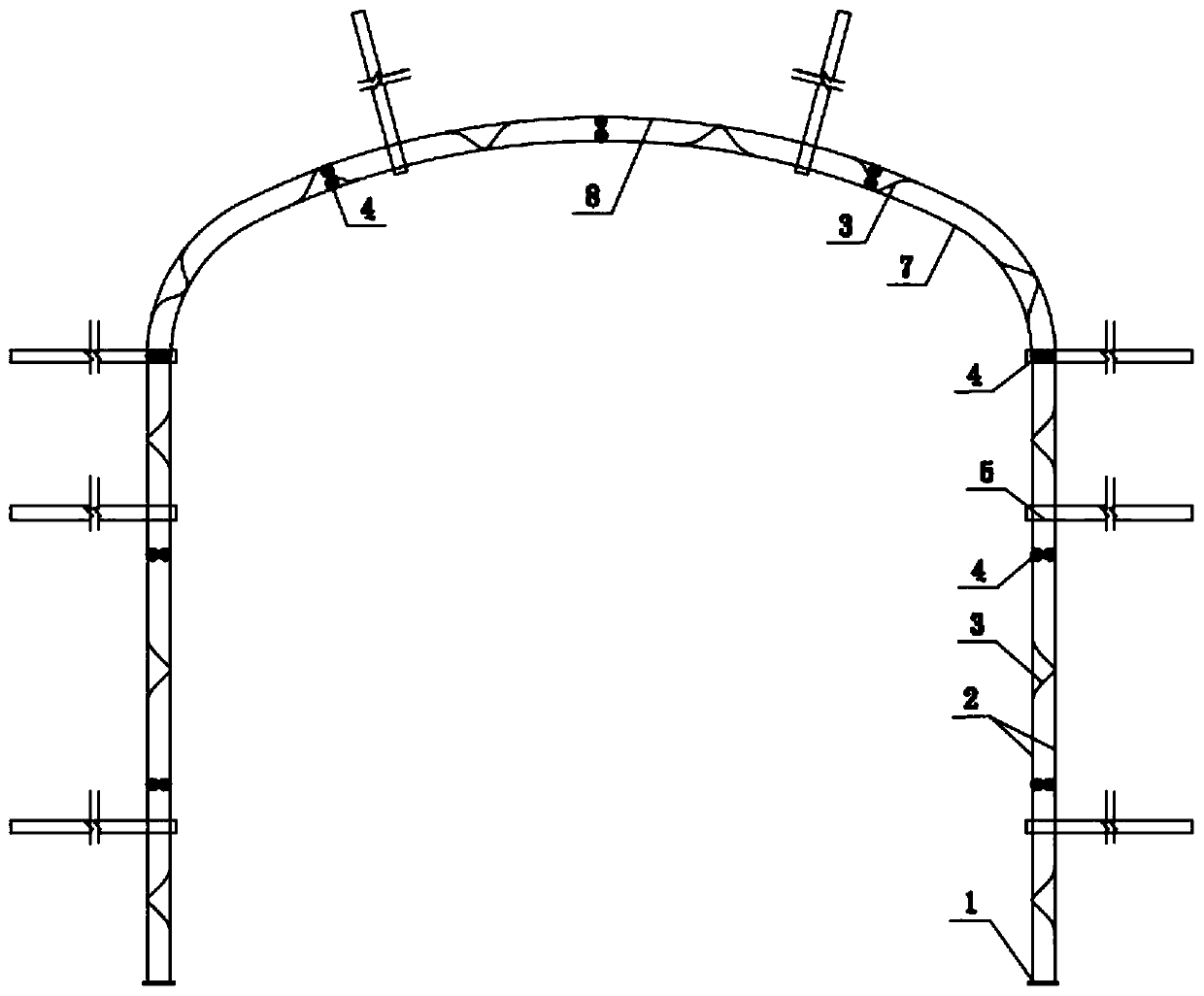

[0043] The parameters are as follows: the development ramp is excavated in tuff, its net section is 4.4m*4.3m (width*height), and it is supported by double-layer arch frame shotcrete, and the concrete thickness is 200mm. According to the stability requirements of the roadway, the rebar with a diameter of 22mm is selected, the length of the leg rebar 2 is 3200mm, the length of the inner arch 7 is 842mm, and the length of the outer arch 8 is 974mm. Two double-layer arches form an arch group, the distance between double-layer arches is 120mm, the distance between two arches is 150mm, and the distance between arch groups is 1200mm. The eight-shaped steel bars 3 are welded between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com