Novel rapid-assembly type anti-shearing concrete pavement

A concrete pavement and prefabricated technology, which is applied to roads, roads, pavements paved with prefabricated blocks, etc., can solve the problems of long seasonal downtime, inability to reuse, long construction period, etc., and achieve upgrading and building industrialization Level, realize the industrialization of construction, and the effect of convenient and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

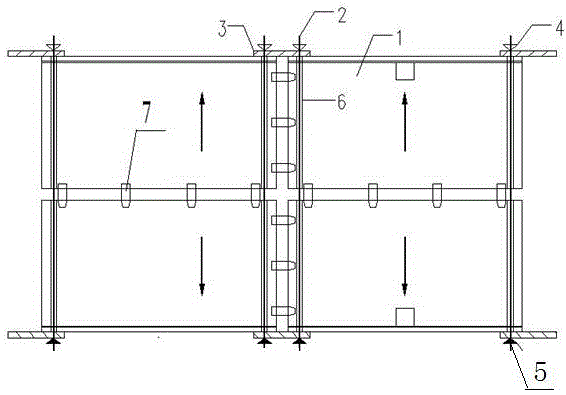

[0036] Attached below figure 1 The present invention is further described.

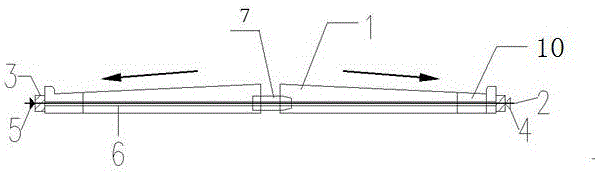

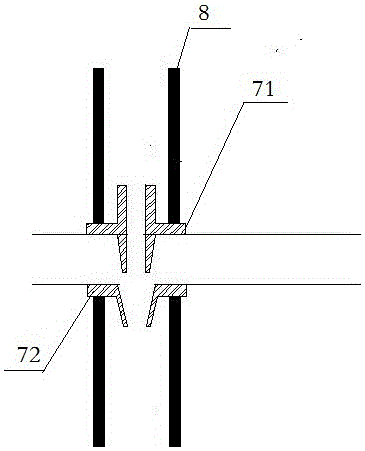

[0037] Such as Figure 1 to Figure 4 As shown, a new type of rapid-assembly shear-resistant concrete pavement is laid by a plurality of arranged pavement units. Each pavement unit includes 4 prefabricated slabs 1, and the four prefabricated slabs 1 use steel hinge lines and pass through the prefabricated slabs. The outer steel connecting plate strips 3 form a pavement unit. Both sides of the prefabricated slab 1 are provided with tunnels 6 for placing steel strands, and adjacent prefabricated slabs 1 are connected by steel strands 2 . In order to better increase the strength, the four sides of the prefabricated slab 1 are provided with tunnels 6 for placing steel strands, and the adjacent prefabricated slabs 1 are connected by steel strands 2, so that each prefabricated slab 1 has 3 to 4 steel strands 2 are connected to enhance the overall stability of the pavement unit,

[0038] When the prefabric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com