Patents

Literature

116results about How to "Give full play to carrying capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

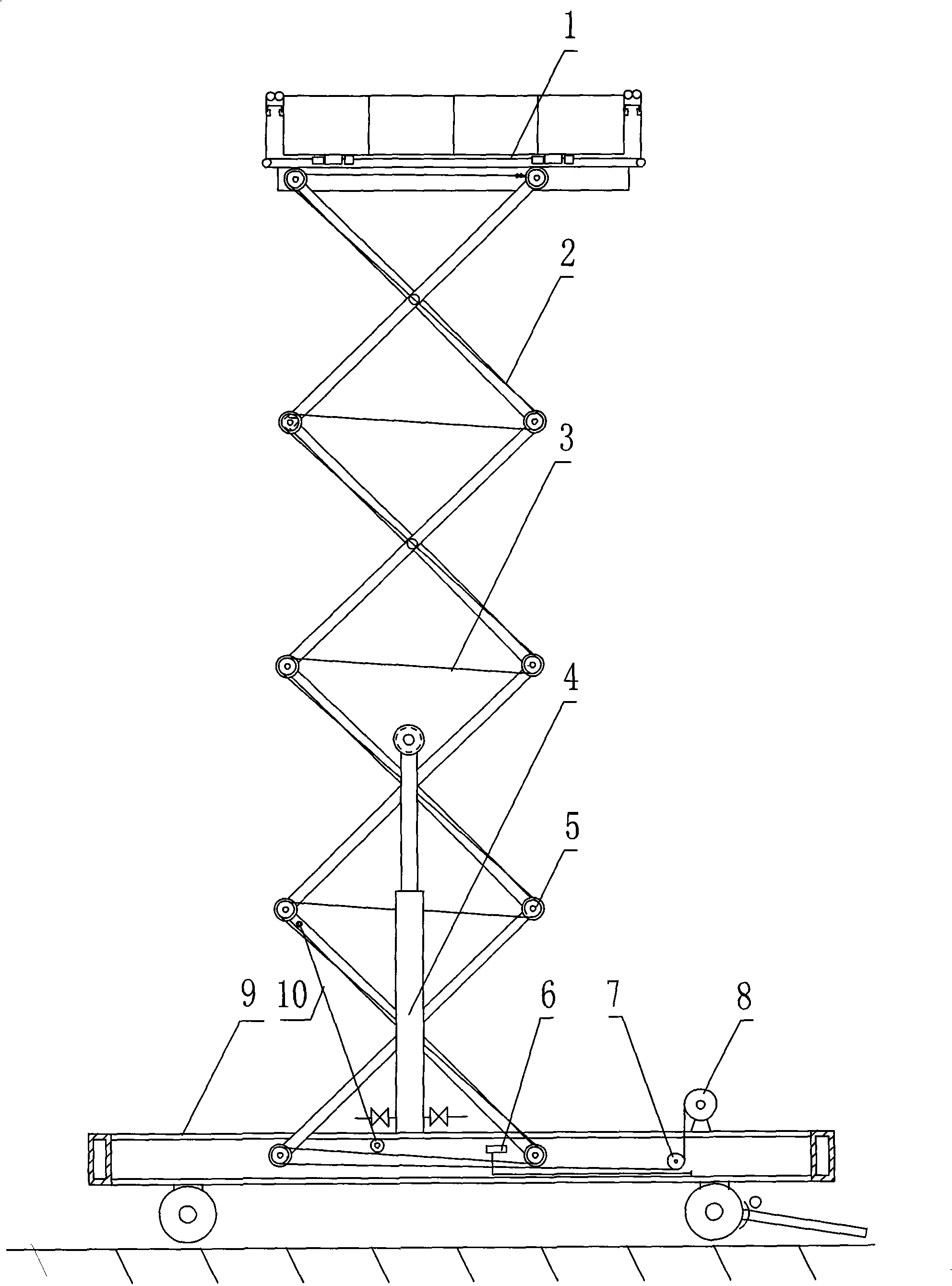

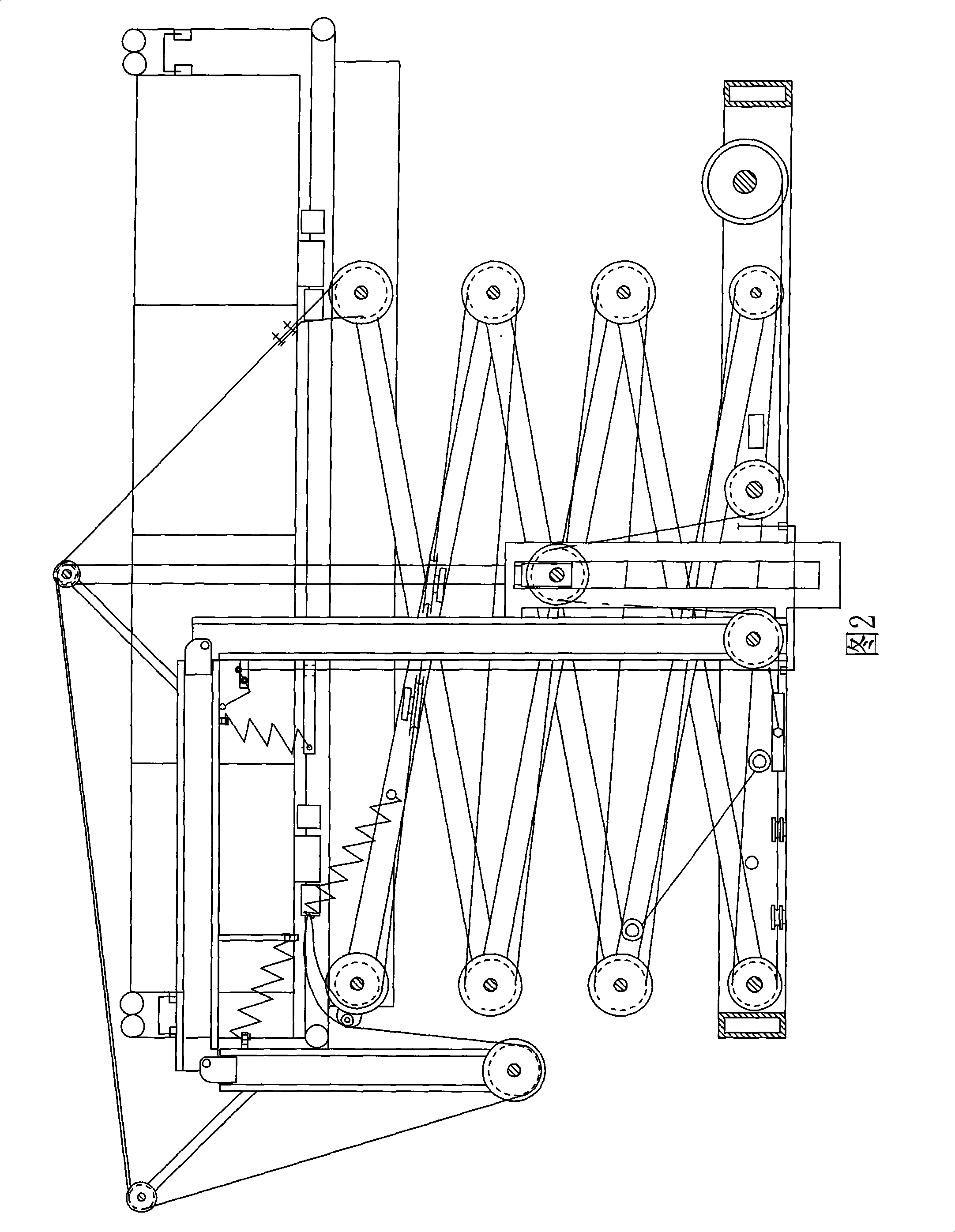

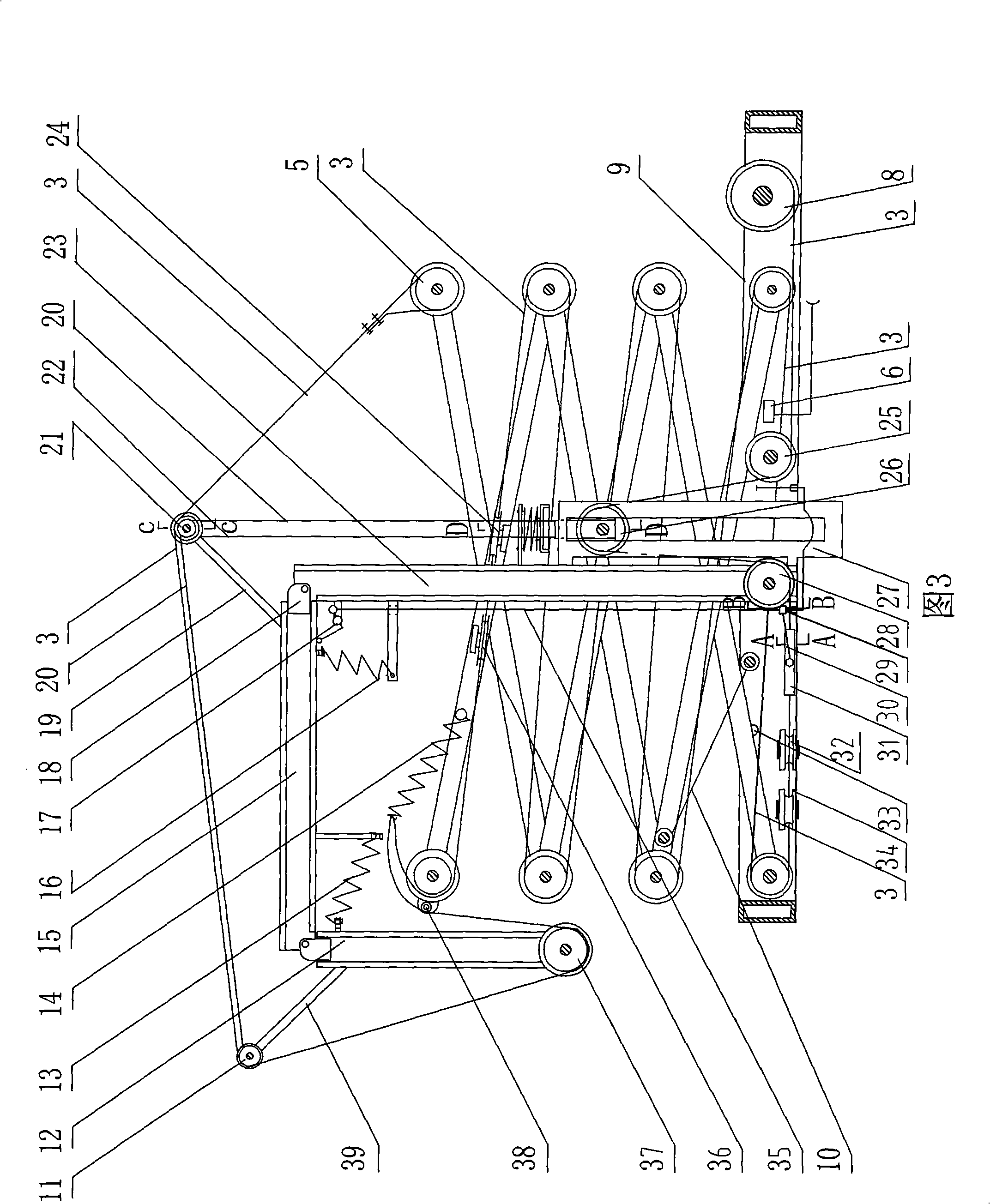

Mobile hoistable platform and labor-saving apparatus

InactiveCN101402440AImprove the unfavorable situationRelief of very unfavorable conditionsLifting devicesHydraulic cylinderEngineering

The invention discloses a mobile lifting platform labor-saving device, which consists of a chassis, a platform, a shearing fork rod, a pulley, a wire rope, and a wire rope loop cylinder, and is characterized in that the chassis of a vehicle is provided with the labor-saving device; when the mobile lifting platform is lifted initially, the labor-saving device is lifted firstly, and lifts the shearing fork rod through the wire rope with small force on an advantageous position, or pushes the shearing fork rod to lift through a hydraulic cylinder to increase the included angle on the ends of the shearing fork rod and reduce the stress of the shearing fork rod; and then the shearing fork rod gets rid of contacting the labor-saving device and is stressed in full load to lift. The various labor-saving devices improve the factor that the prior device is stressed adversely in initial lifting, and greatly reduce the stress of the shearing fork rod in the initial lifting. When the mobile lifting platform has the same load as the prior mobile lifting platform, the stress applied on the shearing fork rod in the initial lifting is about one fifteenth of that of the prior platform in the initial lifting, and the self weight of equipment can be reduced more then twice; and the labor-saving device has the advantages of simple operation and time conservation.

Owner:白天海

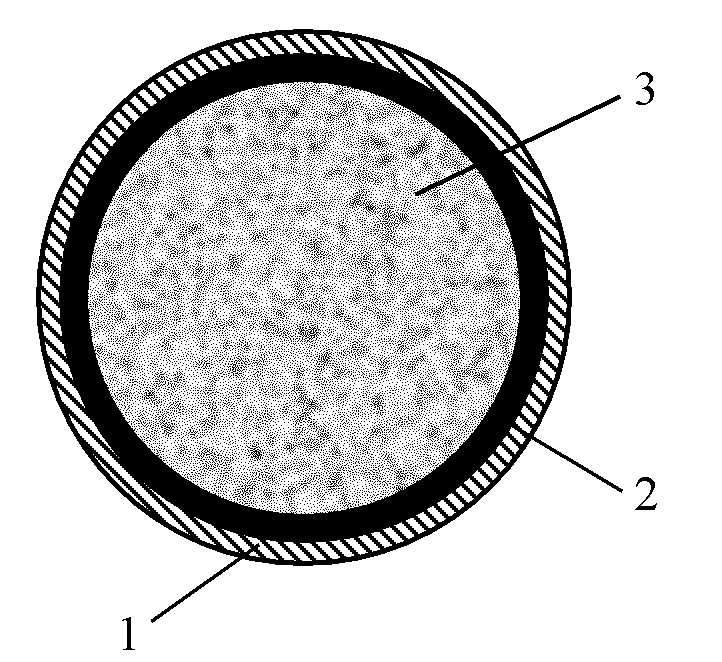

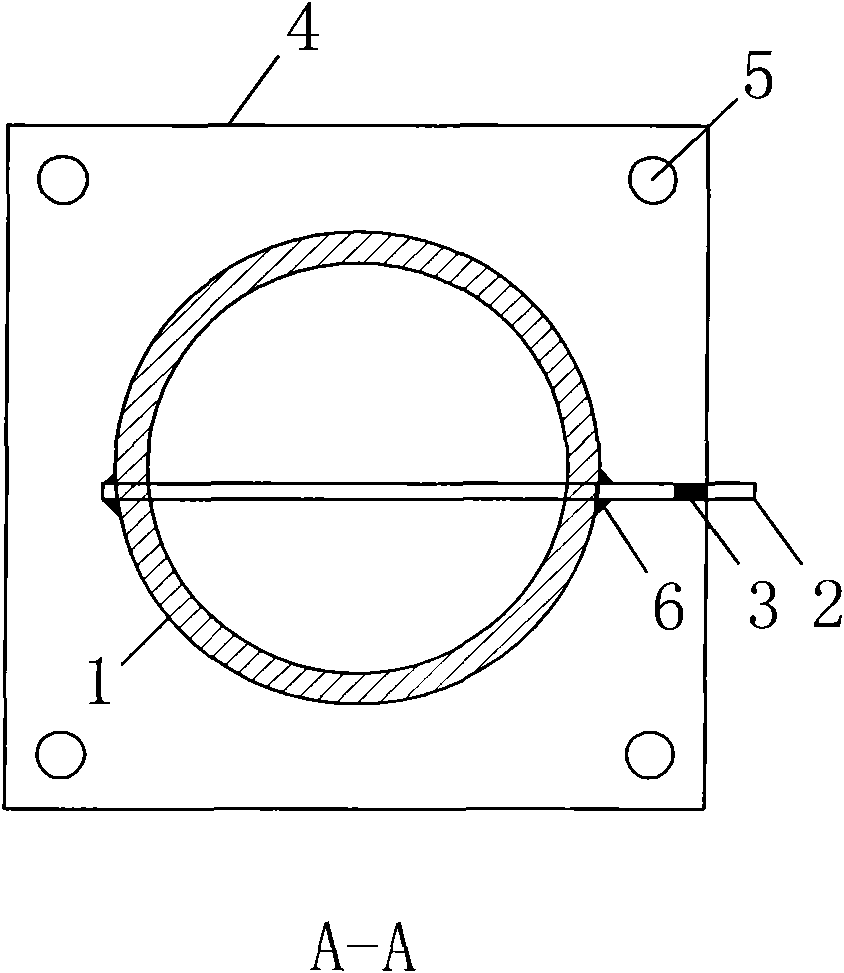

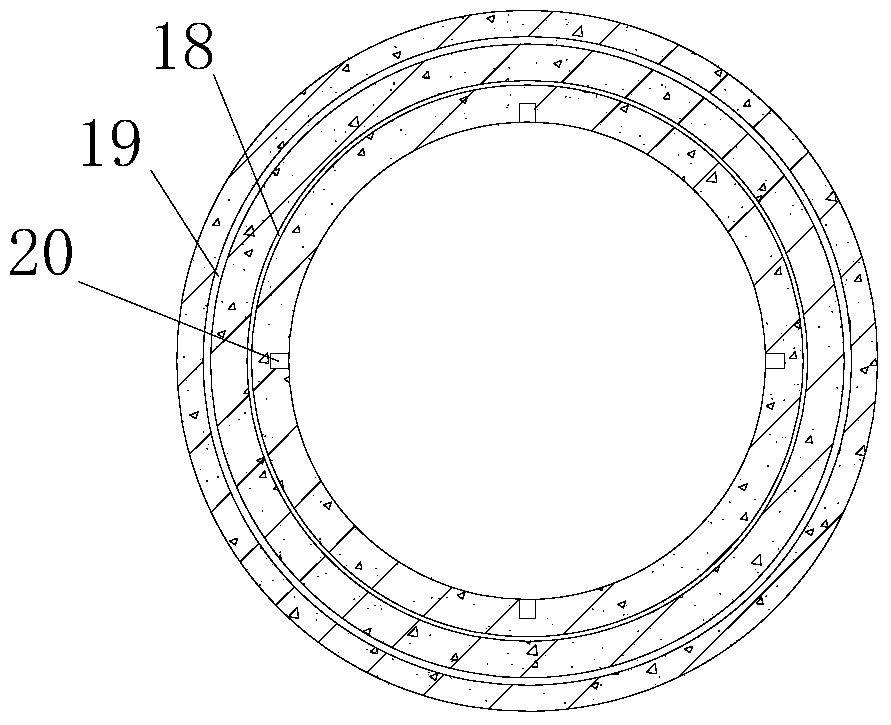

FRP (fiber reinforced plastic)-steel composite tube concrete column

InactiveCN101985851AGive full play to carrying capacityPersistent Circumferential ConstraintStrutsBridge structural detailsFiberYarn

The invention discloses an FRP (fiber reinforced plastic)-steel composite tube concrete column and relates to a civil engineering structural element, the composite tube concrete column consists of an FRP-steel composite tube and concrete filled therein and is characterized in that the FRP-steel composite tube is formed by compounding a steel tube as an inner wall with an FRP tube as an outer wall, the steel tube is formed by welding a steel plate, the FRP tube is prepared by winding continuous fiber yarn on the outer surface of the steel tube, and the solid concrete is poured in the composite tube. The FRP-steel composite tube concrete column can fully play the respective advantages of three composition materials of FRP, steel and concrete and has the characteristics of high bearing capacity, corrosion resistance, excellent aseismic performance and the like, thereby providing a new choice for civil engineering construction.

Owner:DALIAN UNIV OF TECH

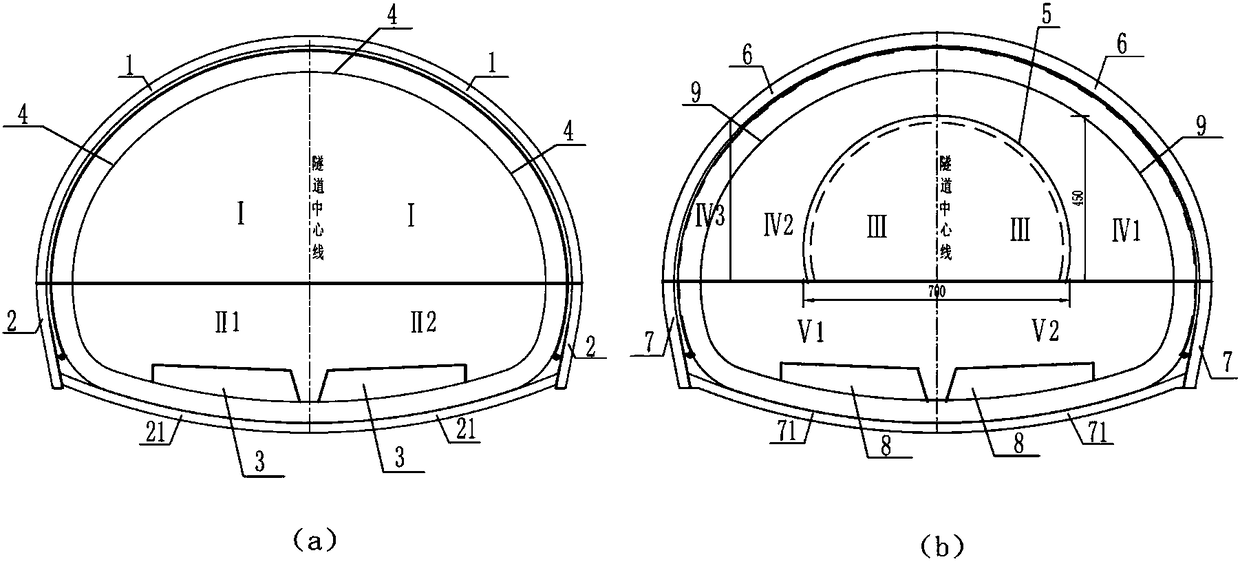

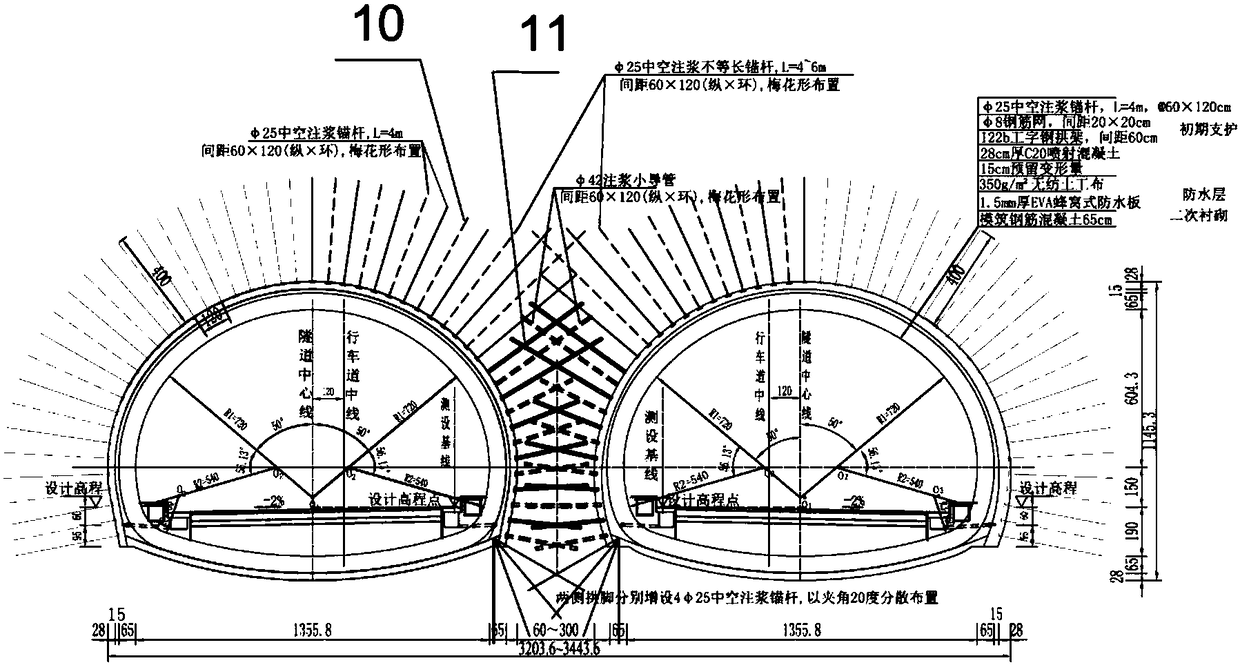

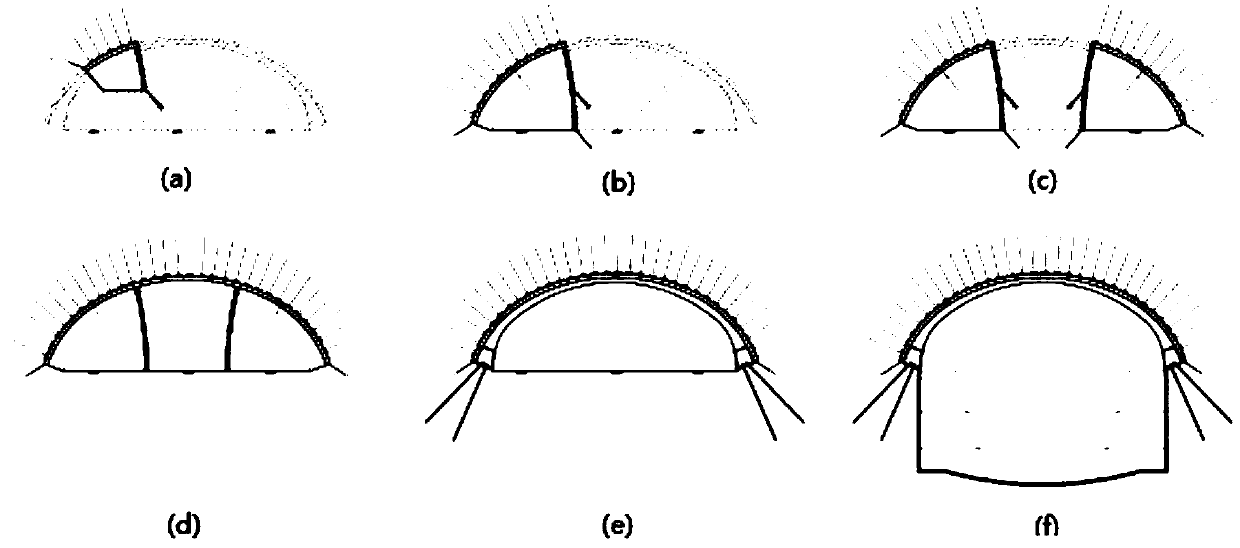

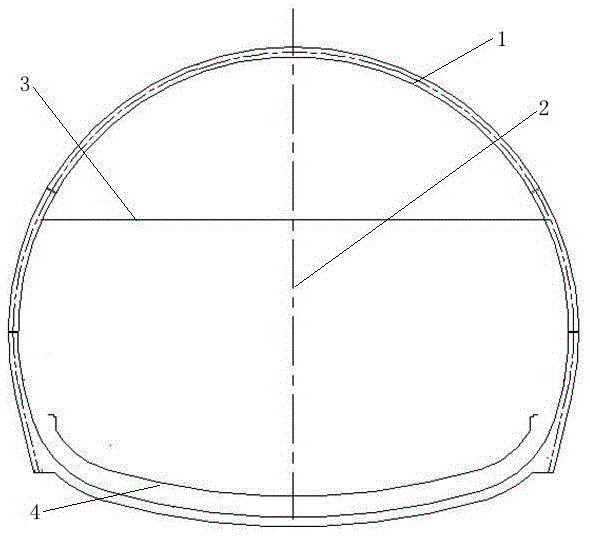

Out-of-pit tunneling construction method for minimum spacing tunnel

ActiveCN108533272ASolve the inconvenience of constructionReduce disturbanceUnderground chambersBlastingIndustrial engineeringTunnel construction

The invention provides an out-of-pit tunneling construction method for a minimum spacing tunnel, and belongs to the technical field of out-of-pit tunneling construction of small spacing tunnels. The out-of-pit tunneling construction method comprises the following steps that a left line upper step section is excavated, and a left line lower step left section and a left line lower step right sectionare excavated separately; a left line inverted arch and a left line filling layer are constructed, and a left line secondary lining is piled in a staggered mode; a right line small guide hole sectionis excavated, a right line upper step right section, a right line upper step left middle section and a right line upper step left edge section are excavated in an expanded mode, and a right line upper step primary support is constructed; a small guide hole primary support is removed, a right line lower step left section and a right line lower step right section are excavated, and a right line lower end face primary support is constructed; and a right line inverted arch and a right line filling layer are constructed, and a right line secondary lining is subjected to overall model-building. According to the out-of-pit tunneling construction method, an advanced tunnel is subjected to one-way out-of-pit tunneling, so that the problem that cliff construction of the exit section is inconvenientis solved; after a left tunnel is excavated, a middle rocky column is reinforced, the left line secondary lining is piled in the staggered mode, a right tunnel adopts an advanced small guide hole forout-of-pit tunneling, the section is excavated in an expanded mode, the construction risk is reduced, and tunnel construction safety is ensured.

Owner:GUIZHOU HIGHWAY ENG GRP +1

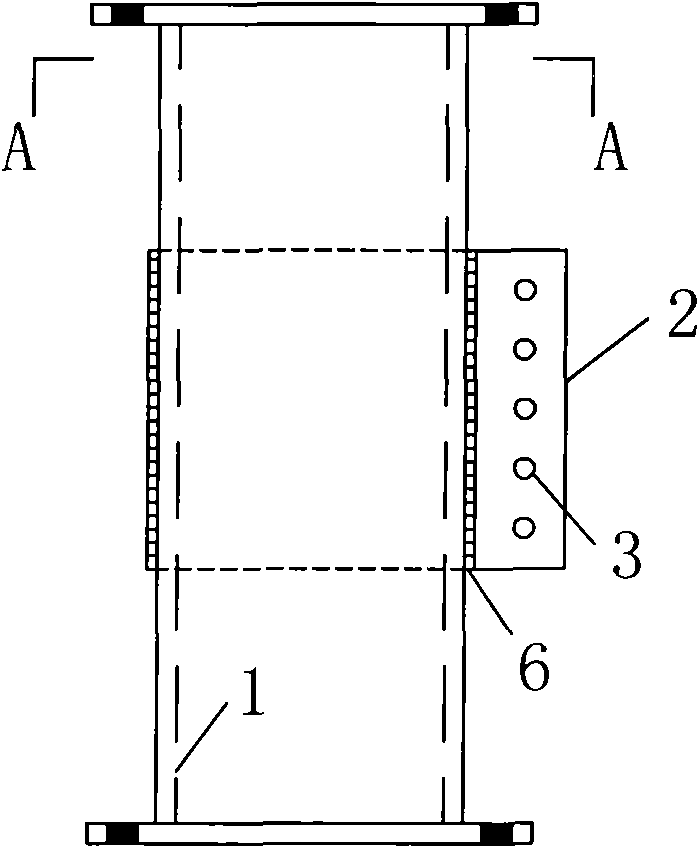

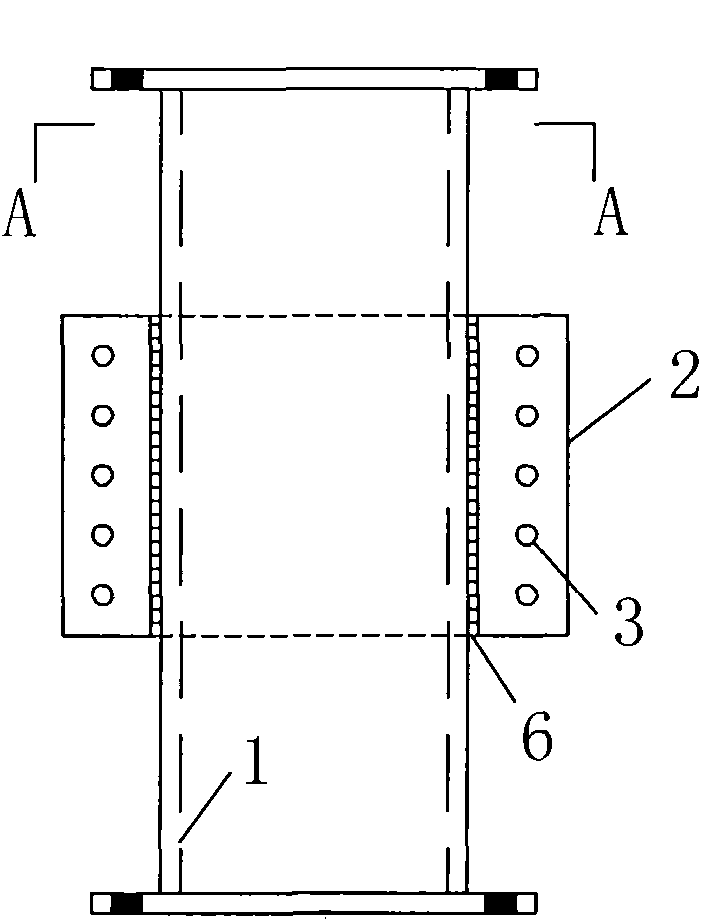

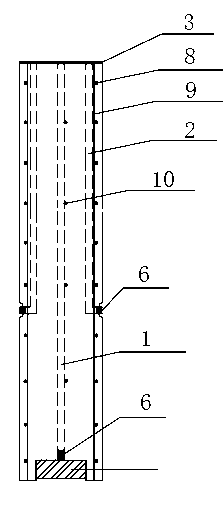

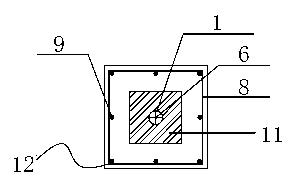

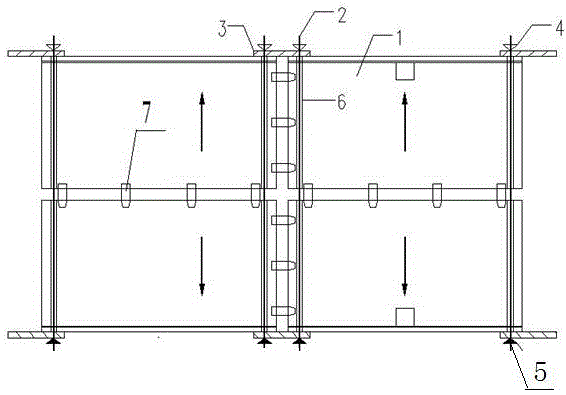

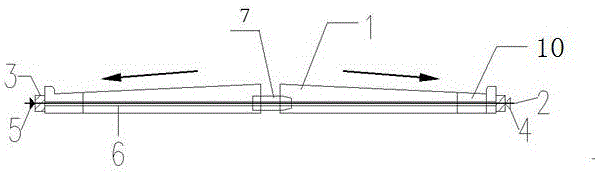

Standardized node connector of steel structure

InactiveCN101922183ADifficulty of SimplificationIncrease productivityBuilding constructionsCarrying capacityAgricultural engineering

The invention discloses a standardized node connector of a steel structure, comprising a steel column and a connection board. The connection board is fixedly connected on the side surface of the steel column; the free end of the connection board is a bolt connector; both ends of the steel column are fixedly connected with a flange on which a connection hole is arranged; the steel column is provided with a vertical through seam matched with the connection board; the connection board penetrates through the vertical through seam; and the connection board is fixedly welded with the penetrated part of the steel column. The invention has standard structure and convenient use as well as strong carrying capacity, can be applied in industrialized production and is very beneficial to promotion and application.

Owner:HENAN AUSPIC TECH

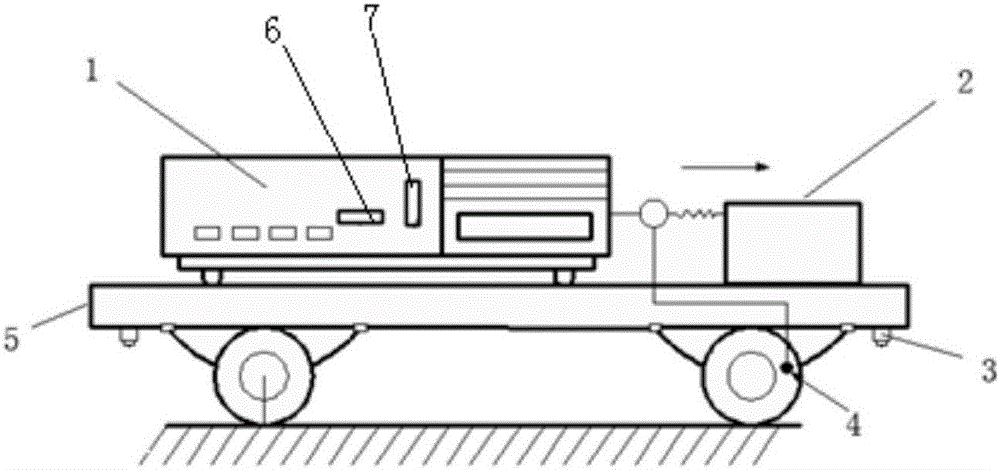

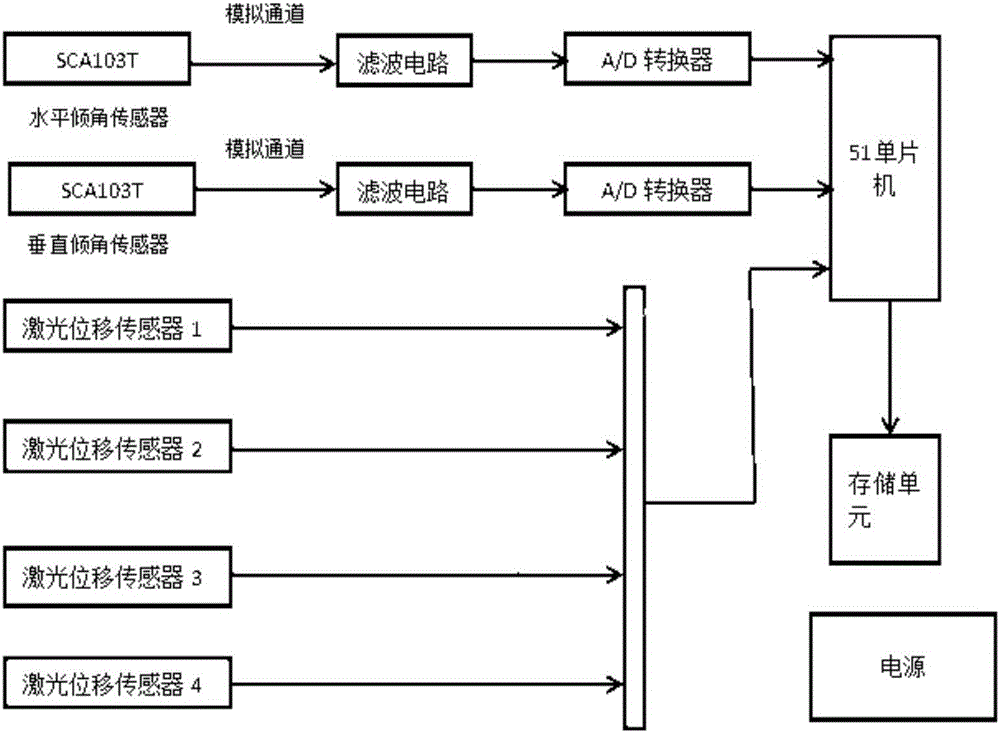

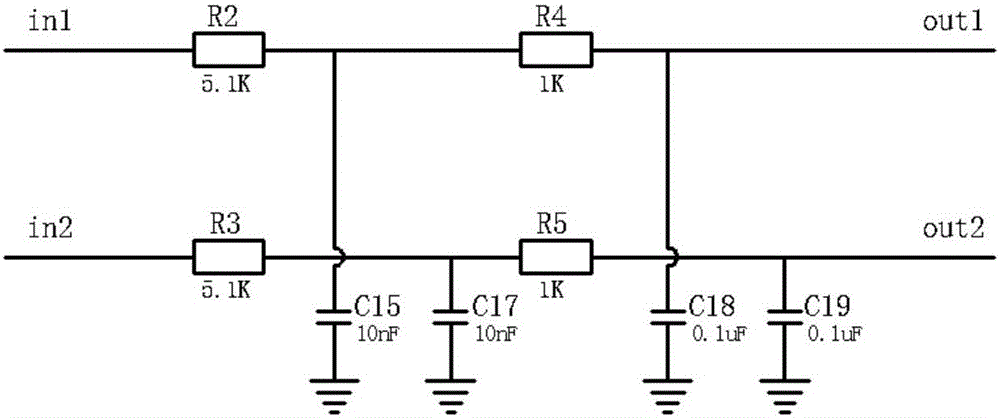

Measuring apparatus and method for flexibility line shape of bridge structure

InactiveCN105067206AFast sensingEasy to implementRoads maintainenceElasticity measurementMeasurement deviceFully developed

The invention discloses a measuring apparatus and a method for the flexibility line shape of a bridge structure. The measuring apparatus is not fixedly arranged on a bridge, the equipment is simple, the realization is easy, the cost performance is high, the operation is convenient, the flexibility line shape of the bridge can be rapidly, objectively, and intelligently sensed and reproduced, the flexibility of the bridge is measured, the overall flexibility change of the bridge can be reflected via the change of line shapes in different times, bridge management workers can be informed of the current flexibility line shape of the bridge in time, especially the flexibility change state, the health and safety condition of the bridge can be analyzed, the bearing ability of the bridge can be fully developed, load limit and the falling of the bridge are reduced, and the practical engineering value is very high.

Owner:CHANGAN UNIV

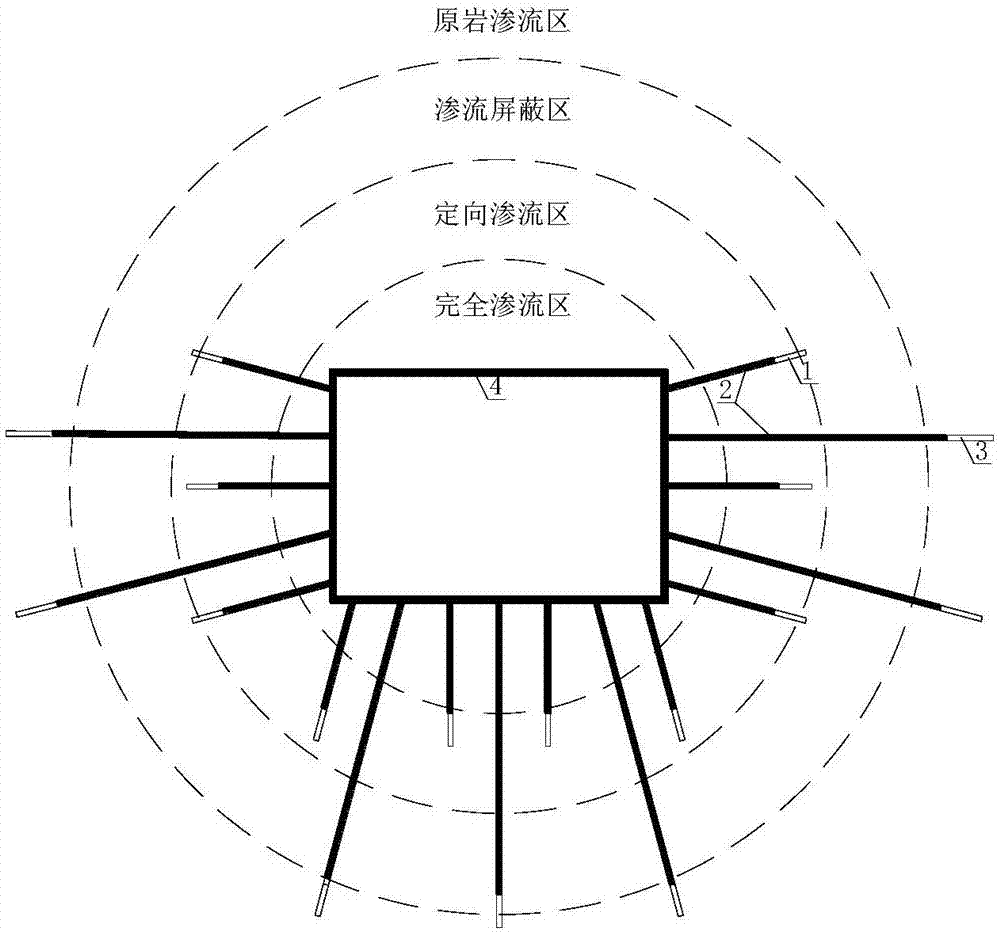

Argillaceous soft rock roadway partition multi-granularity grouting reinforcement method

ActiveCN107083977AEffectively closedPrevent weatheringUnderground chambersTunnel liningGranularityLarge deformation

The invention provides an argillaceous soft rock roadway partition multi-granularity grouting reinforcement method. A corresponding geological state is evaluated according to geological information data of a specific roadway, drilling points of shallow grouting holes and deep grouting holes are designed in the roadway according to the evaluated geological state, along with tunneling of the roadway, the periphery of the roadway is anchored, and a concrete and silica sol spray layer is arranged; the shallow grouting holes are constructed in the sides and a top plate and a bottom plate of the roadway, hole sealing grouting is carried out, the deep grouting holes are constructed in the pre-designed drilling points of the deep grouting holes, hole sealing grouting is carried out, and therefore grout is effectively sealed and reinforced in a deep virgin rock region. Shallow broken region surrounding rock is reinforced, water molecules, air molecules and crack water are prevented from entering a channel of a jet-grouted solid, the anti-deformation capacity and durability are improved, and the problems that after an argillaceous soft rock roadway encounters water, prominent non-linear large deformation, remarkable rheology and disturbance are generated are solved.

Owner:CHINA UNIV OF MINING & TECH

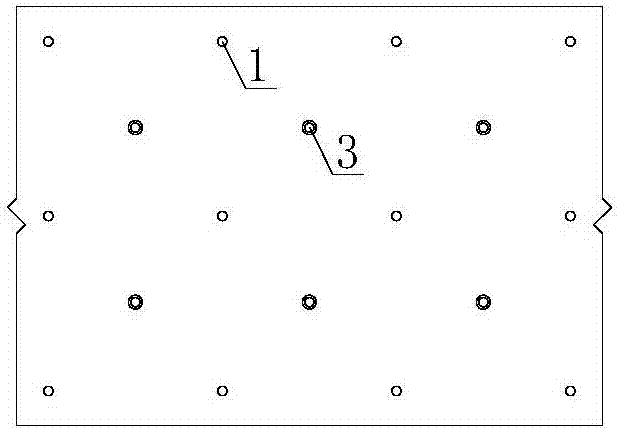

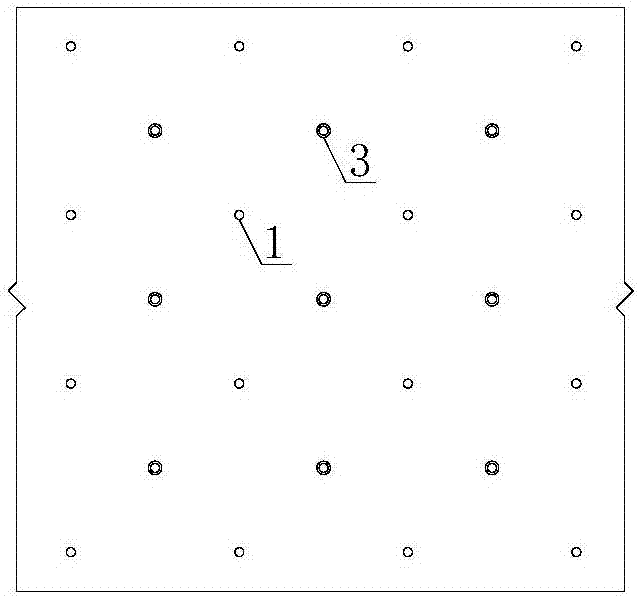

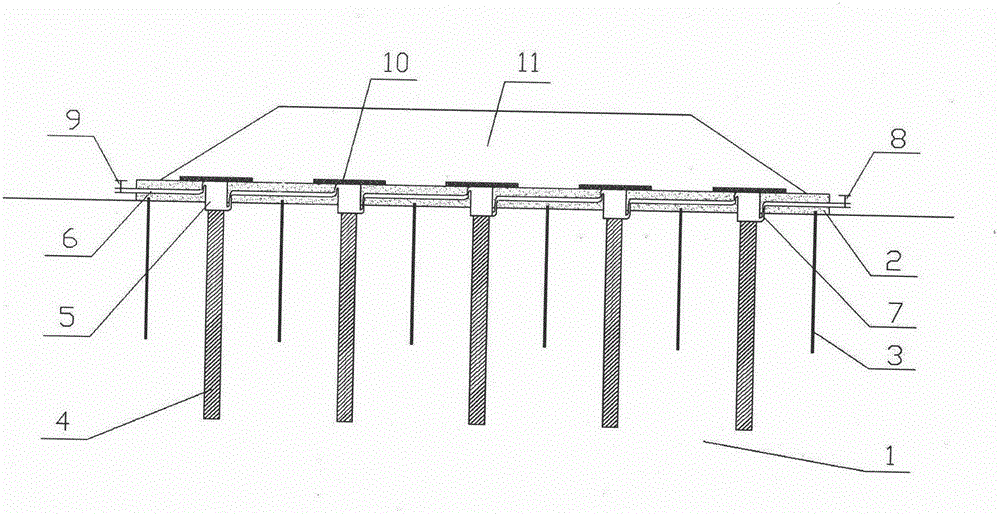

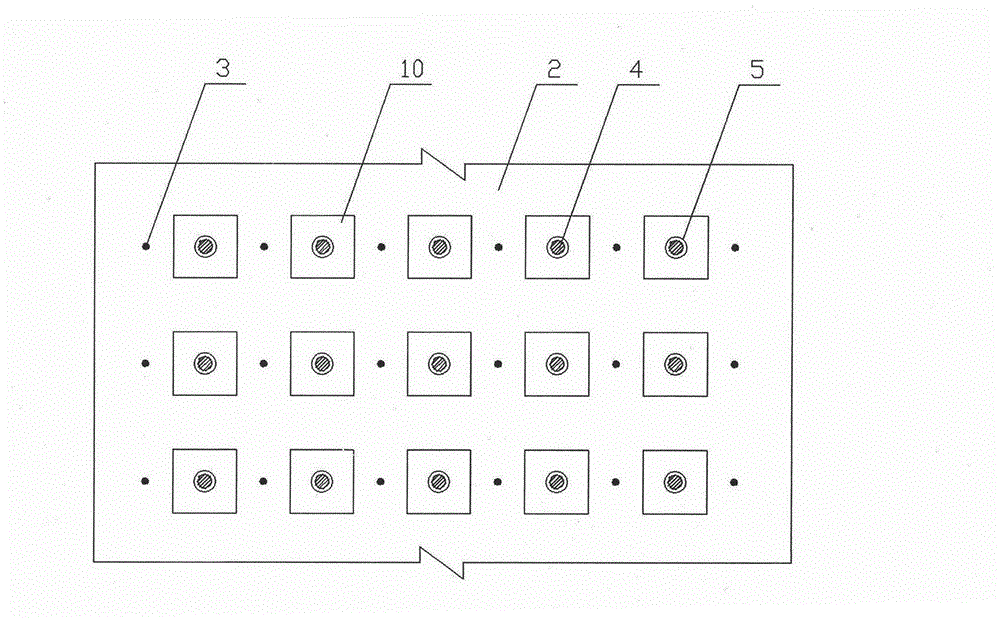

Post-grouting capped rigid pile and drainage unit combined foundation treatment technology

Disclosed is a post-grouting capped rigid pile and drainage unit combined foundation treatment technology. The post-grouting capped rigid pile and drainage unit combined foundation treatment technology comprises paving horizontal drainage units on the surface of a soft foundation and constructing vertical drainage units inside the foundation, wherein the horizontal drainage units and the horizontal drainage units are communicated to form drainage channels; constructing rigid piles inside the soft foundation, arranging grouting bags and reinforced concrete pile caps at the tops of the piles to form a controllable support system. When being filled with water and stabilized, the grouting bags can be extruded under the action of upper load to drain water and retract, the load born by the rigid pile can be relatively low, and after water drainage and solidification under the action of the upper load, the bearing capacity of foundation soil can be improved; when the grouting bags are filled with grout and solidified, the rigid piles, the grout and the pile caps form rigid support to bear more upper load and accordingly to reduce the loading pressure of the foundation soil. The post-grouting capped rigid pile and drainage unit combined foundation treatment technology can give full play to the bearing capacity of the foundation soil and reduce the consumption of the rigid pile to reduce the economic input, and meanwhile, can effectively control afterward settlement of a project to reduce upper structural deformation and damage due to overlarge settlement.

Owner:北方国际合作股份有限公司

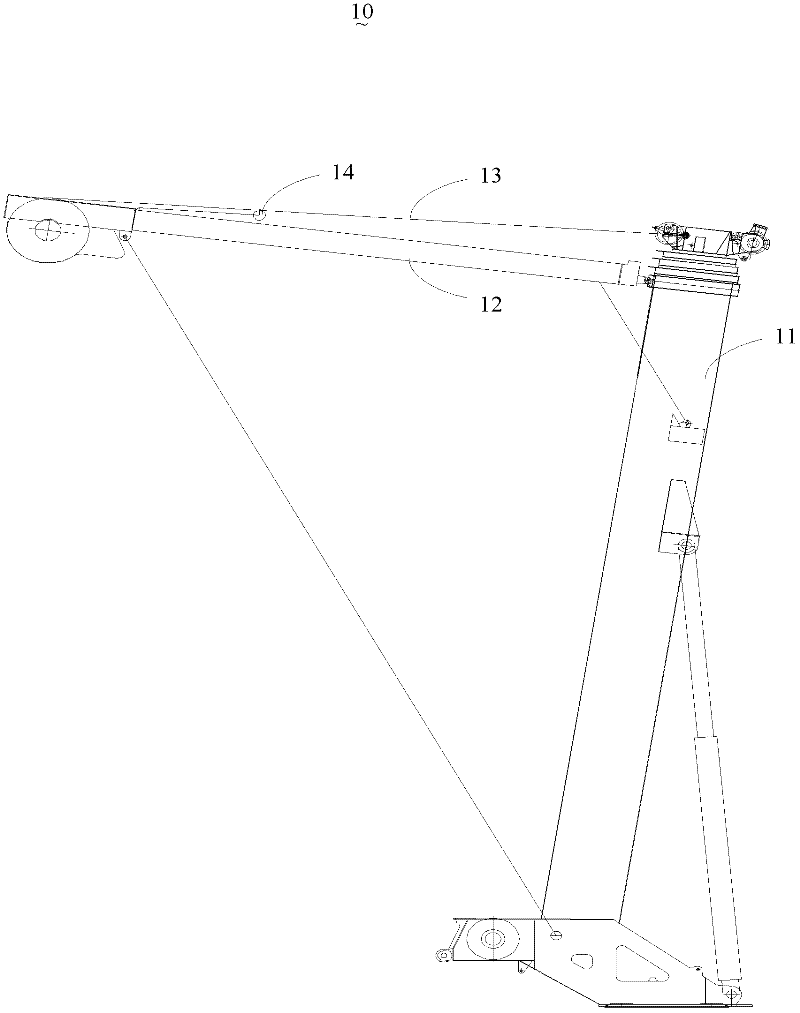

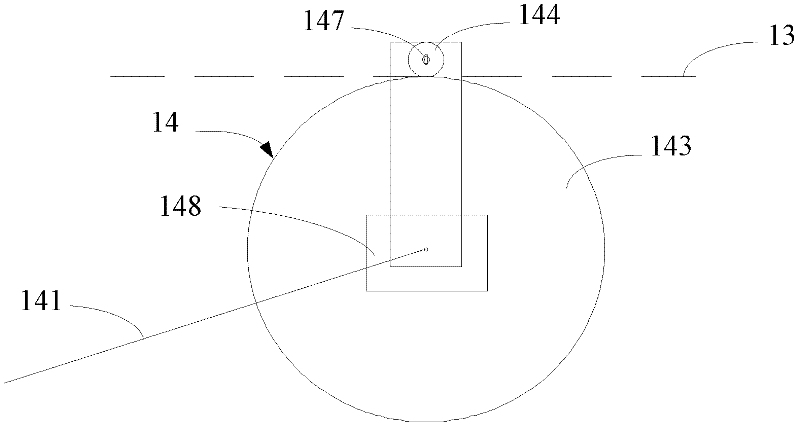

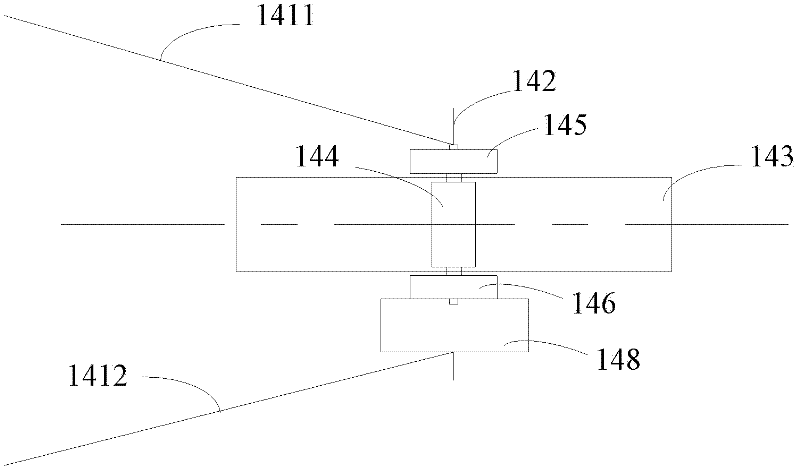

Crane and wire cable length measuring device thereof

ActiveCN102530741AImprove lifting performanceControl lengthMeasurement devicesCranesEngineeringPulley

The invention provides a crane and a wire cable length measuring device of the crane. The measuring device comprises a base comprising two brackets, wherein one end of the each bracket is connected with a mast of the crane; a rotating shaft, wherein both ends of the rotating shaft are respectively connected with the other end of each bracket; a head pulley mounted on the rotating shaft, wherein a wire cable winds around the head pulley; a roller bearing matched with the head pulley for clamping the wire cable; two connectors mounted on the rotating shaft and respectively located at both sides of the head pulley and the rotating shaft for connecting the head pulley with the roller bearing so that the wire cable can roll relative to the head pulley without relative sliding; and a counter connected with one end of the rotating shaft for measuring the length of the wire cable. The discharge length of the wire cable is measured in real time through above way to control the length of the wire cable under different working conditions, so as to bring the bearing property of the wire cable into full play. In this way, the lifting property of the crane is improved.

Owner:ZOOMLION HEAVY IND CO LTD

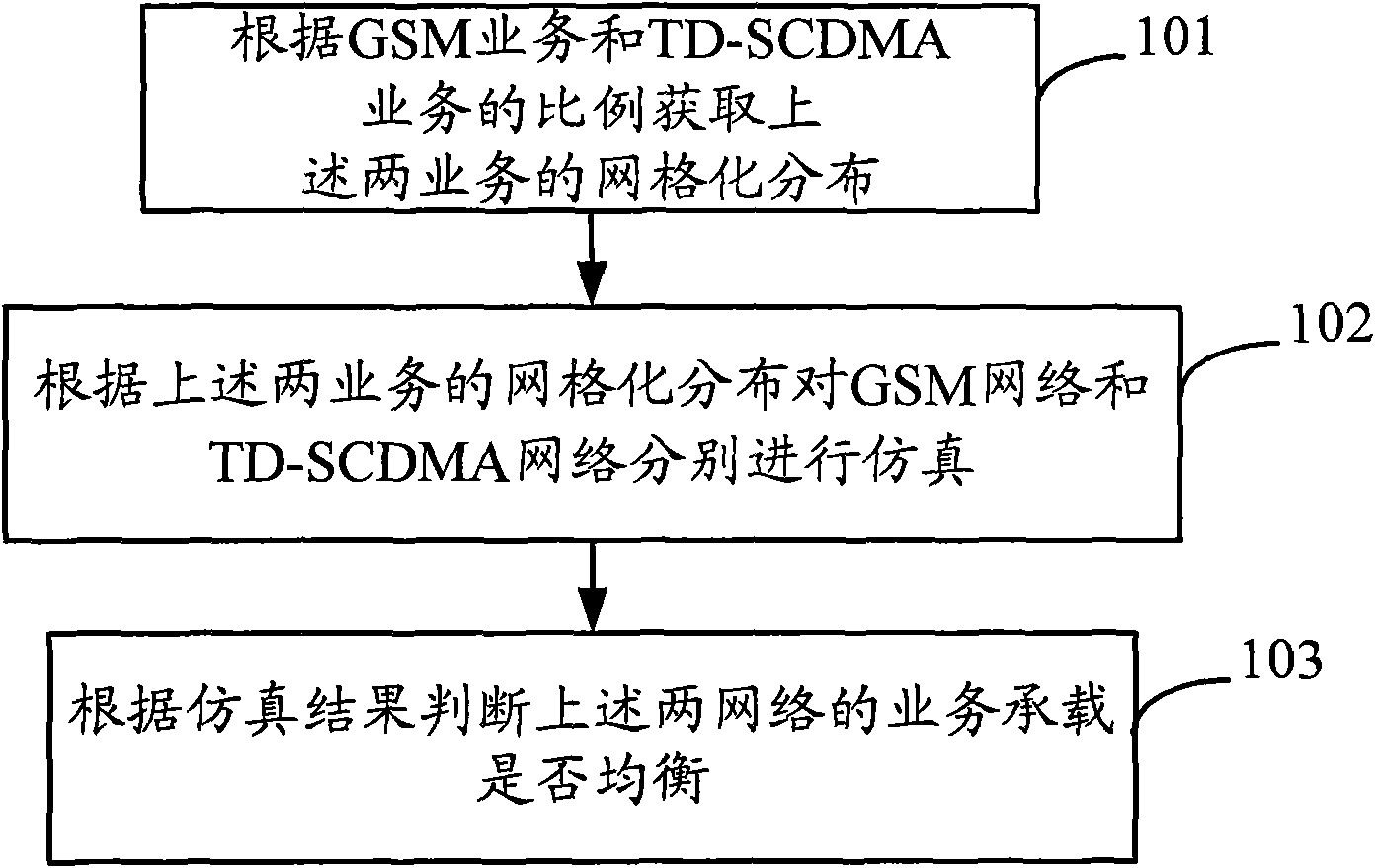

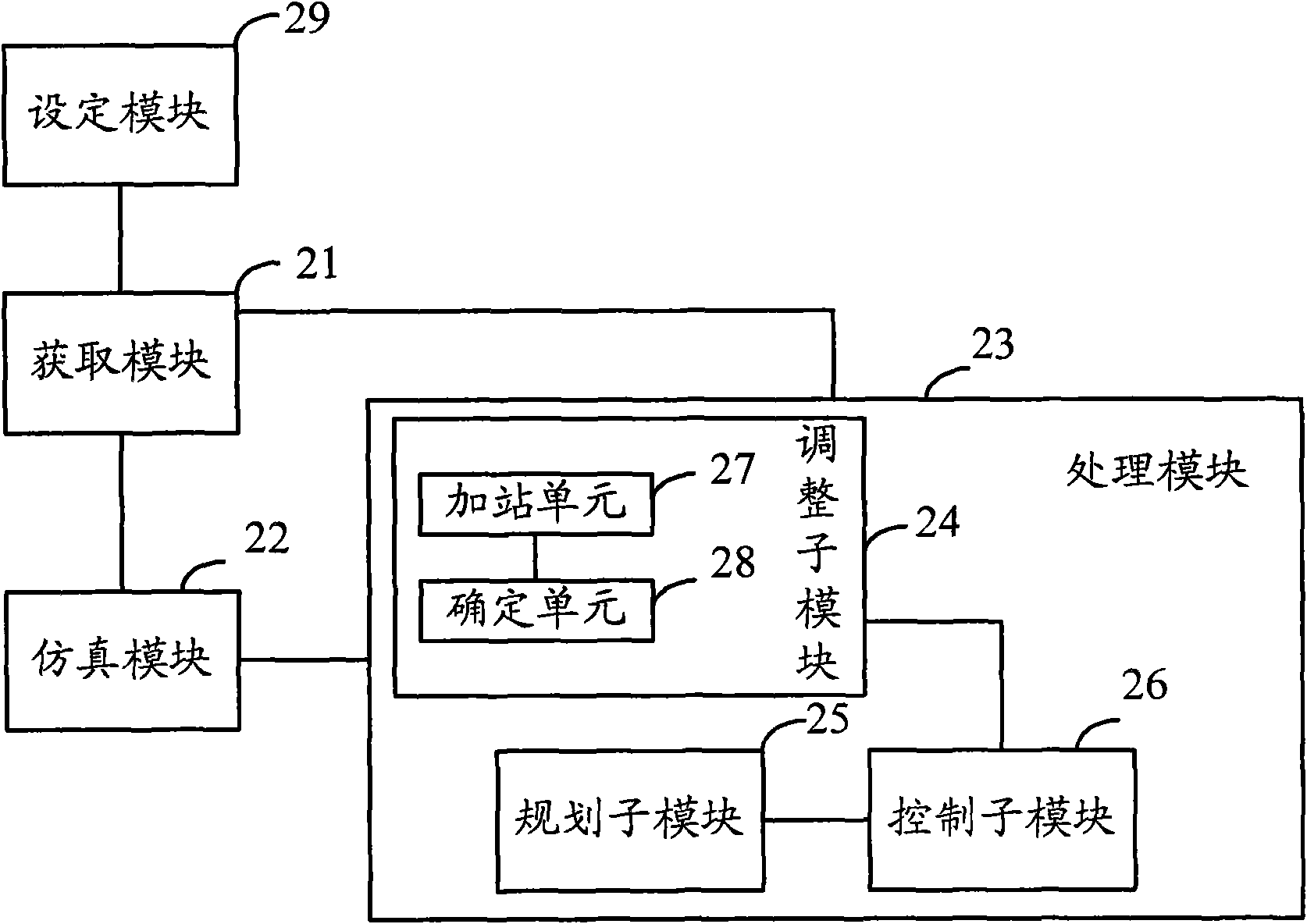

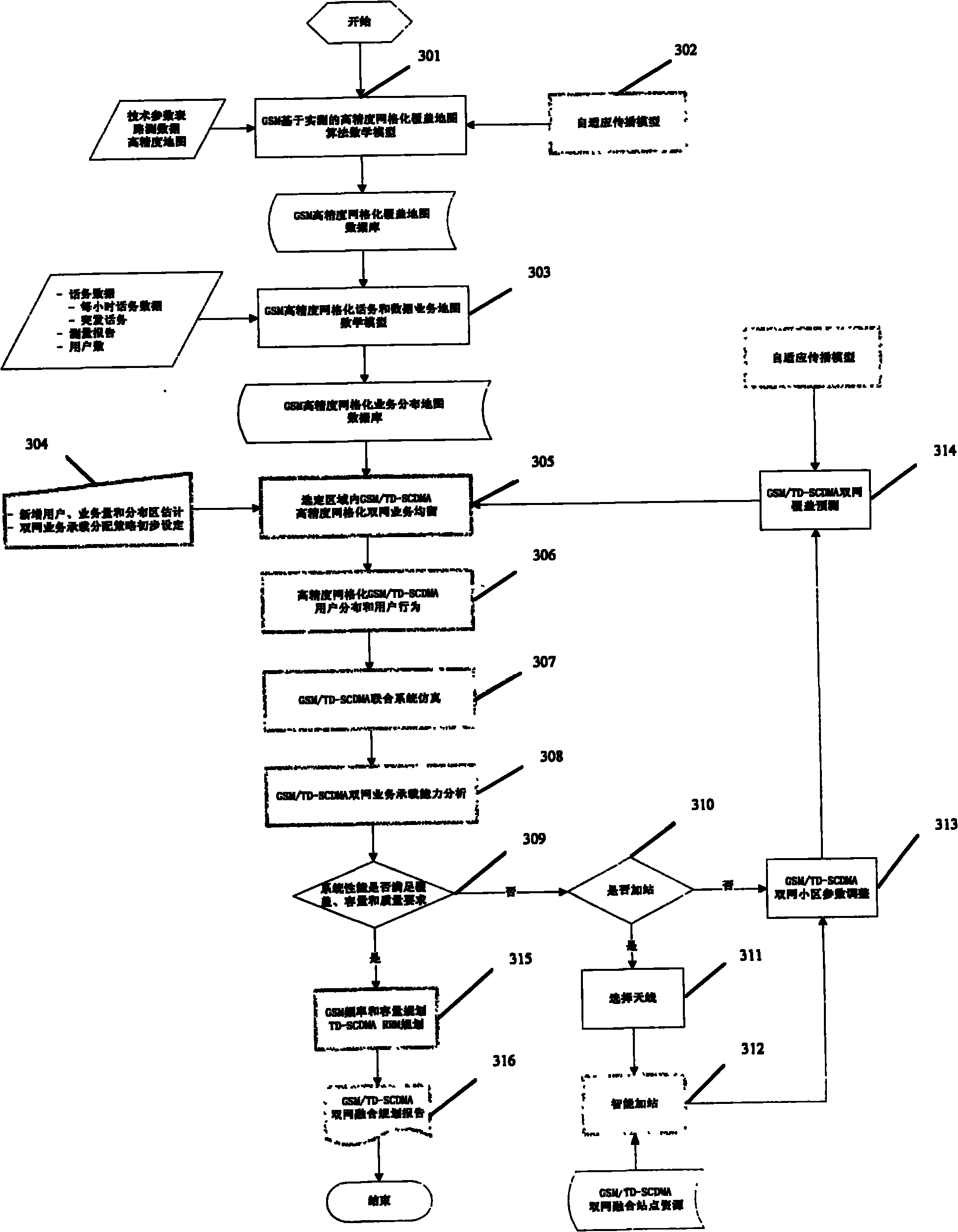

Planning method and device of wireless network

InactiveCN102083076AReduce construction costsGive full play to carrying capacityNetwork planningWireless mesh networkSynchronization code division multiple access

The invention provides a planning method and device of a wireless network, belonging to the field of mobile communications. The method comprises the following steps: acquiring gridding distribution of a global system for mobile communication (GSM) service and a time division-synchronization code division multiple access (TD-SCDMA) service in accordance with the proportion of the GSM service to the TD-SCDMA service; respectively emulating a GSM network and a TD-SCDMA network in accordance with the gridding distribution of the two services; and judging whether the service bearing of each of the two networks is balanced or not in accordance with an emulation result. According to the embodiment of the invention, the network construction cost can be reduced, and the efficiency and the accuracy of network planning are improved. The technical scheme of the embodiment in the invention can be widely applied to the planning field of the wireless network.

Owner:CHINA MOBILE GRP GUANGDONG CO LTD

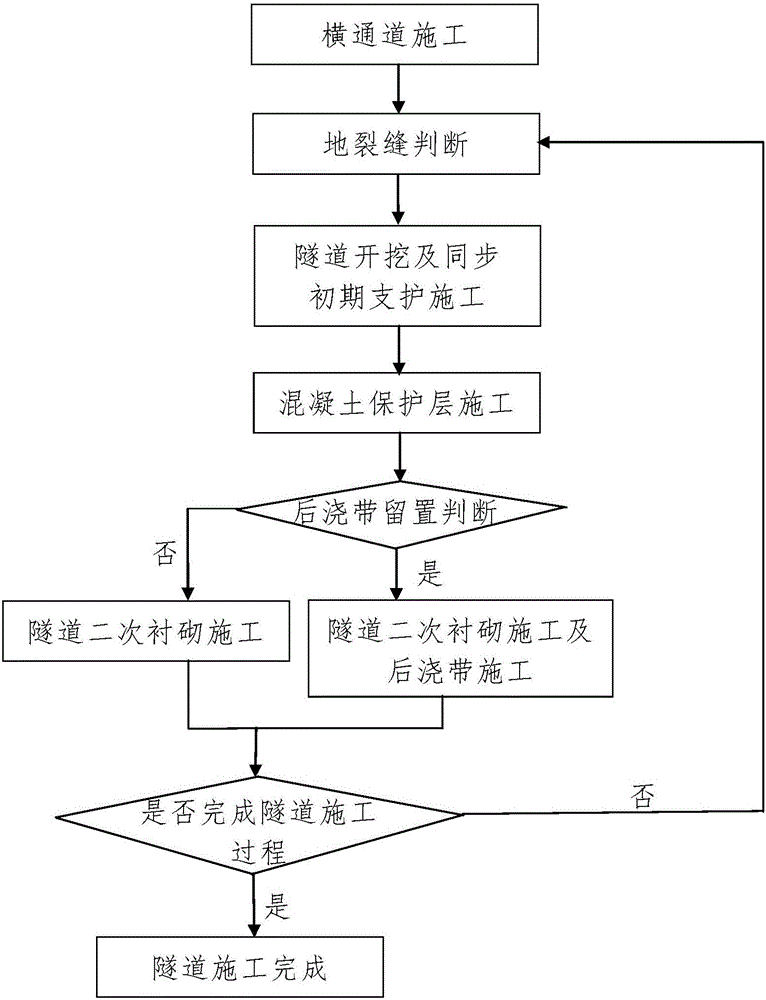

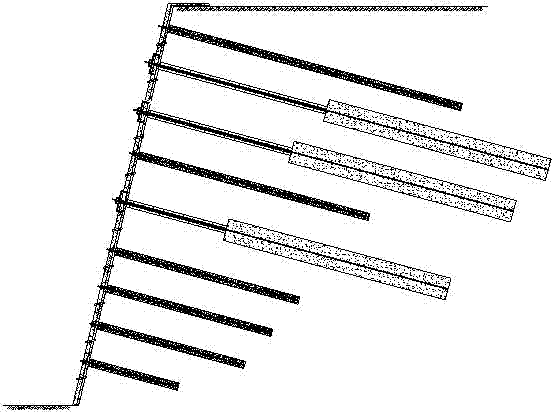

Ground fracture crushed zone passing construction method for shallow-buried tunnel excavation

ActiveCN106437726AThe method steps are simpleReasonable designUnderground chambersTunnel liningProtection layerTunnel construction

The invention discloses a ground fracture crushed zone passing construction method for shallow-buried tunnel excavation. A constructed shallow-buried excavation tunnel comprises a left line tunnel and a right line tunnel which are communicated through a transverse channel. During construction of the constructed shallow-buried excavation tunnel, the method comprises the steps that 1, transverse channel construction is performed; 2, tunnel construction is performed, wherein the two tunnel sections of the left line tunnel and the right line tunnel are constructed through the transverse channel, the construction is performed in the mode of multiple tunnel sections in the longitudinal extending direction of the tunnel from back to from during construction of any one tunnel section, and the construction of any one tunnel section includes the processes of ground fracture judgement, tunnel excavation and synchronous preliminary bracing construction, concrete protection layer construction, post-cast strip retention judgement, secondary tunnel lining construction and post-cast strip construction. The method includes simple steps and is reasonable in design, convenient to construct, good in construction effect, capable of simply and conveniently completing the shallow-buried tunnel excavation construction process of a ground fracture crushed zone and safe and reliable in construction process.

Owner:中铁二十局集团第五工程有限公司

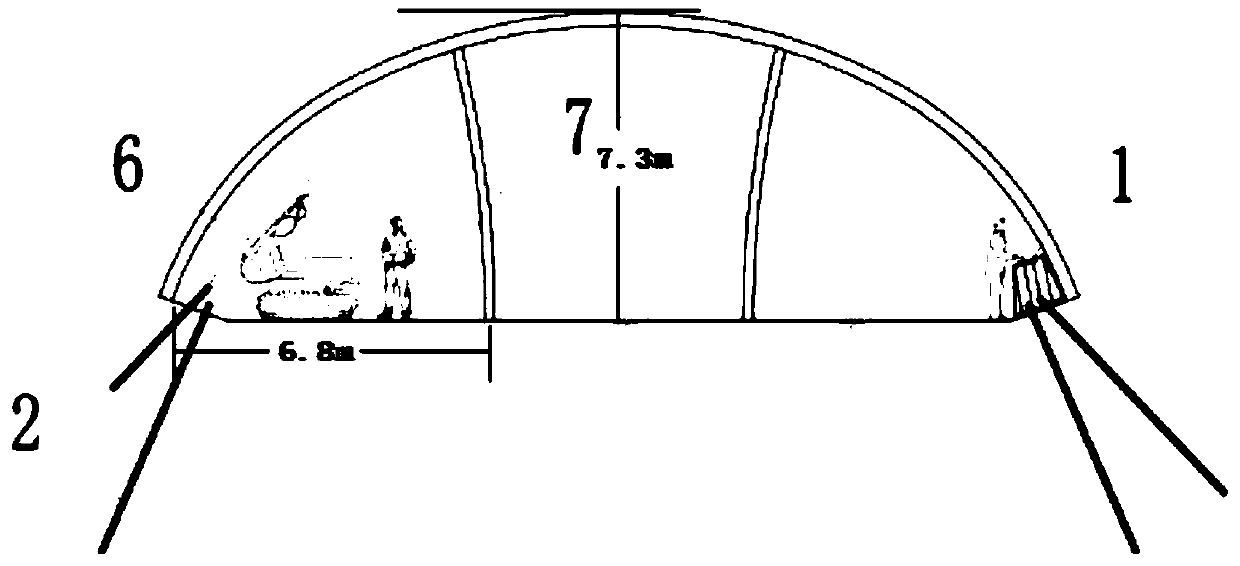

Reinforcement structure for arch-covering-method underground excavation subway station arch feet and construction method

PendingCN109538246AEasy to controlIncrease stiffnessUnderground chambersTunnel liningSubway stationStructural integrity

The invention discloses a reinforcement structure for arch-covering-method underground excavation subway station arch feet and a construction method. The reinforcement structure for the arch feet comprises two layers of arch cover supports, arch foot piles distributed at the arch feet of the left and right sides of subway station arch cover bodies and arch foot longitudinal beams, the arch foot longitudinal beams and the arch foot piles are integrally connected, and pile bodies of the arch foot piles are distributed along the tangent line of the arch feet; each arch foot pile is composed of asection steel framework and fine aggregate concrete which is poured into the section steel framework and pile holes. The reinforcement structure is a reinforcement system combining the arch foot pileswith the longitudinal beams, the longitudinal beams are connected with the arch foot piles and the first and second layers of arch cover supports, the structural integrity is good, the capacity of resisting local stress and deformation is high, and deep and thick smashed surrounding rock at the arch feet can be effectively reinforced and protected; in addition, according to the construction method of the reinforcement structure for the arch feet, the reinforcement range and implementation objects are flexibly selected, rock layers of the arch feet for supporting arch covers are smashed, the integrity influence cannot be caused, and the advantages of an arch-cover method in the aspects such as project cost, construction working period, implementation efficiency and mechanical operation cannot be influenced.

Owner:中铁科学研究院有限公司

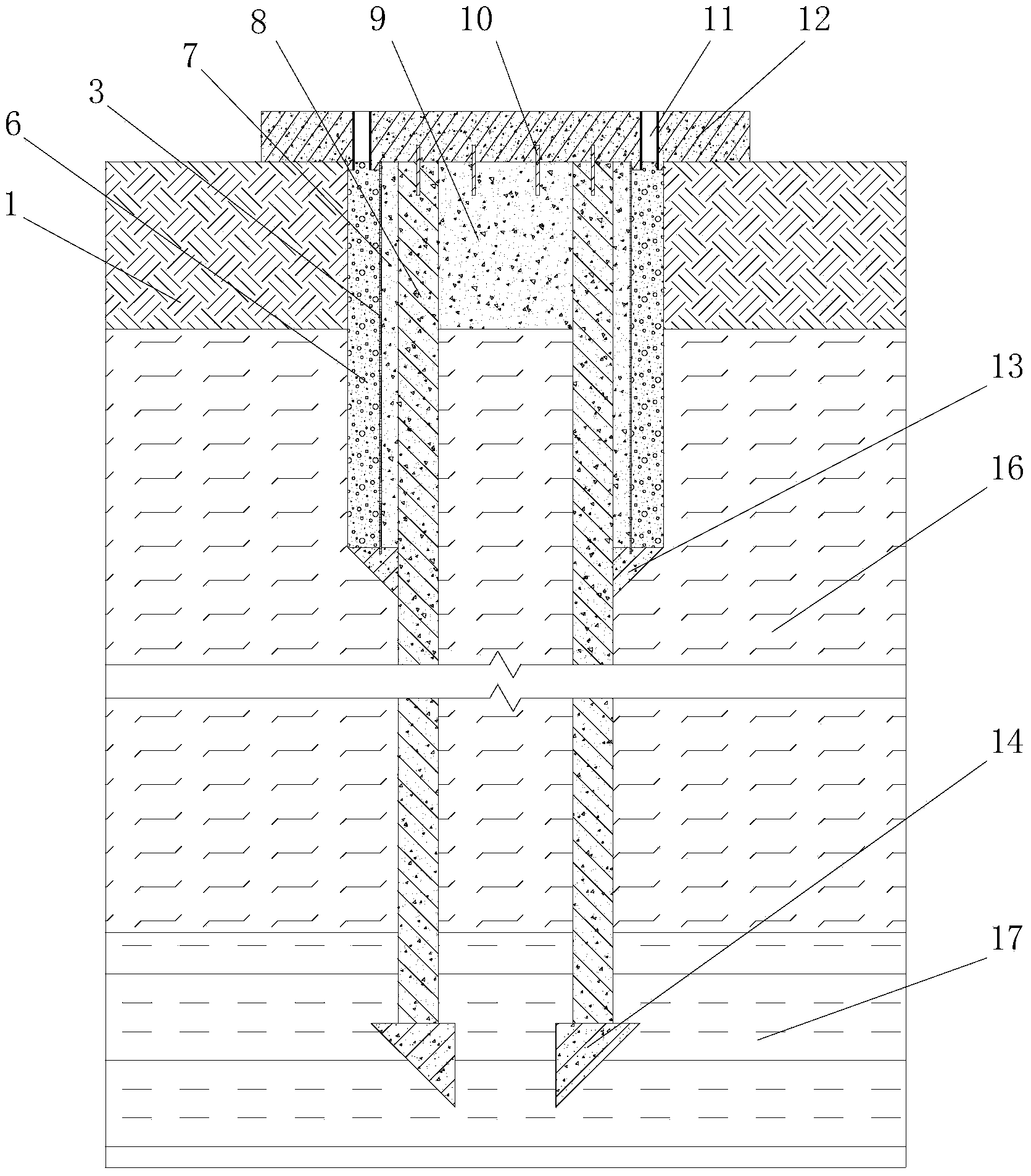

Top-reinforced cast-in-place concrete thin-wall pipe pile and construction method

ActiveCN103510511AImprove carrying capacityReduce disturbanceBulkheads/pilesEconomic benefitsEarth surface

The invention relates to a top-reinforced cast-in-place concrete thin-wall pipe pile, and further discloses a construction method of the top-reinforced cast-in-place concrete thin-wall pipe pile. The top-reinforced cast-in-place concrete thin-wall pipe pile is characterized in that the pile body of a thin-wall pipe pile body is formed by cast-in-place of double-layer steel immersed pipes. The pile diameter of the upper portion of the pile body is enlarged, and a plastic casing pipe and a vertical drainage body are sequentially arranged on the outer side of a concrete pile body of the pile-diameter-enlarged section from inside to outside; the pile-diameter-enlarged section is connected with an upper precast pile tip, and the bottom of the pile body is connected with a lower precast pile tip; the soil body, on the upper portion of the thin-wall pipe pile, around the pile is solidified to be a solidified soil layer; connection ribs are arranged between the top of the thin-wall pipe pile and a pile core closed section and a pile top cover plate; a drainage channel communicated with the vertical drainage body is formed in the pile top cover plate. The top-reinforced cast-in-place concrete thin-wall pipe pile improves pile body casting quality, can improve the mechanical property of the upper-portion pile body and the mechanical property of the soil body around the pile and prevent the pile body from deforming when mud cakes are taken out of the earth surface and has good technical and economic benefits.

Owner:HONGSHA CONSTR

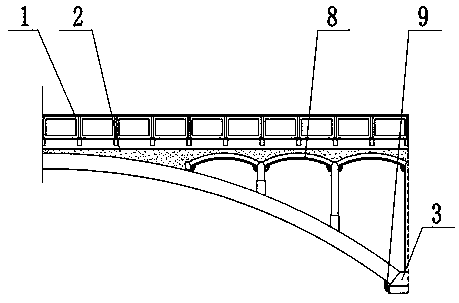

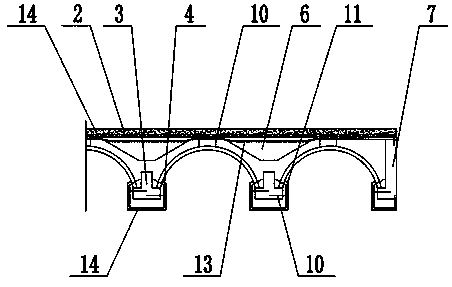

A method for reinforcing a double-curved arch bridge with a corrugated arch plate

ActiveCN109137762AImprove the bearing capacity of the structureGuaranteed safety and durabilityBridge erection/assemblyBridge strengtheningMaterial consumptionBending moment

A method for reinforcing a double-curved arch bridge with a corrugated arch plate comprises pouring a main arch ring arch rib reinforcement layer on the outside of the main arch ring supply rib, pouring a main arch plate reinforcement layer on that main arch ring arch plate, the main arch plate reinforcement layer and an arch plate groove area forming a cavity. Compared with the reinforcement method of directly filling the groove area on the arch plate in the prior art, the invention increases the bending moment of inertia of the section, at the same time, the material consumption is small, which is favorable for the stress of the structure before the newly poured concrete reaches the strength standard value. The invention does not change the characteristics of the double-curved arch bridge, and retains the historical style and features of the bridge. The invention also replaces the original filler with the lightweight filler, lightens the dead weight of the structure, reduces the stress level under the action of the original structure under the dead load, makes the load shared by the reinforcement layer larger, and gives full play to the bearing capacity of the reinforcement layer.

Owner:CHONGQING JIAOTONG UNIVERSITY

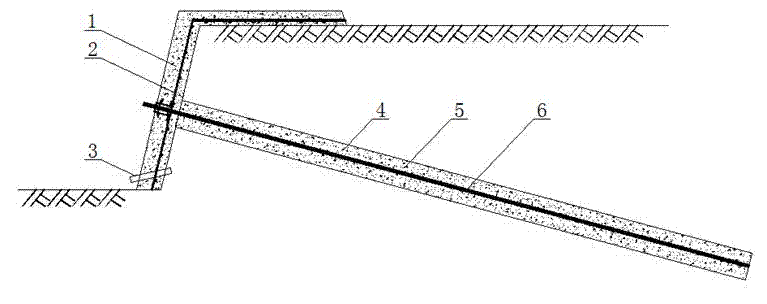

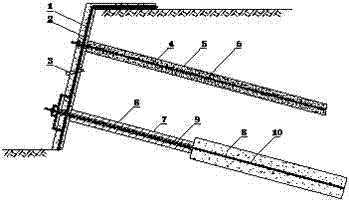

Foundation ditch composite concrete nail supporting structure and method

ActiveCN104727318AImprove stability and securityAvoid failureExcavationsBulkheads/pilesShotcretePunching

The invention relates to a foundation ditch composite concrete nail supporting structure and method. The method comprises the steps that concrete nails or anchoring rods are arranged, and a surface layer reinforcing mesh is laid; concrete is injected till the concrete covers the surface layer reinforcing mesh; a lower nail bearing structure is installed; micro-prestress is exerted on the concrete nails, and the concrete nails are locked through nuts; concrete is sprayed to form a block concrete surface layer, and a concrete nail supporting layer is formed; a lower anchor bearing structure is installed; low prestress is exerted on the anchoring rods, and the anchoring rods are locked through anchoring tackles; concrete is injected to form a block concrete surface layer, and an anchoring rod supporting layer is formed; the concrete nail supporting or the anchoring rod supporting is repeated till the supporting reaches the bottom of a foundation ditch, the concrete nail supporting layers and the anchoring rod supporting layers are formed, and the supporting structure is formed. The defects that prestress cannot be exerted on the concrete nails and the nail heads are prone to generating piercing damage to the surface layers are overcome through the lower nail bearing structure of the nail heads of the concrete nails; the problems of steel channel buckling damage and the anchoring head punching failure are solved through the lower anchor bearing structure of the anchoring heads; the defects that work of the concrete nails and work of the anchoring rods are inconsistent in the traditional joint supporting of the concrete nails and the anchoring rods is solved by exerting the micro-prestress on the concrete nails and exerting the low prestress on the anchoring rods.

Owner:DALIAN UNIV OF TECH

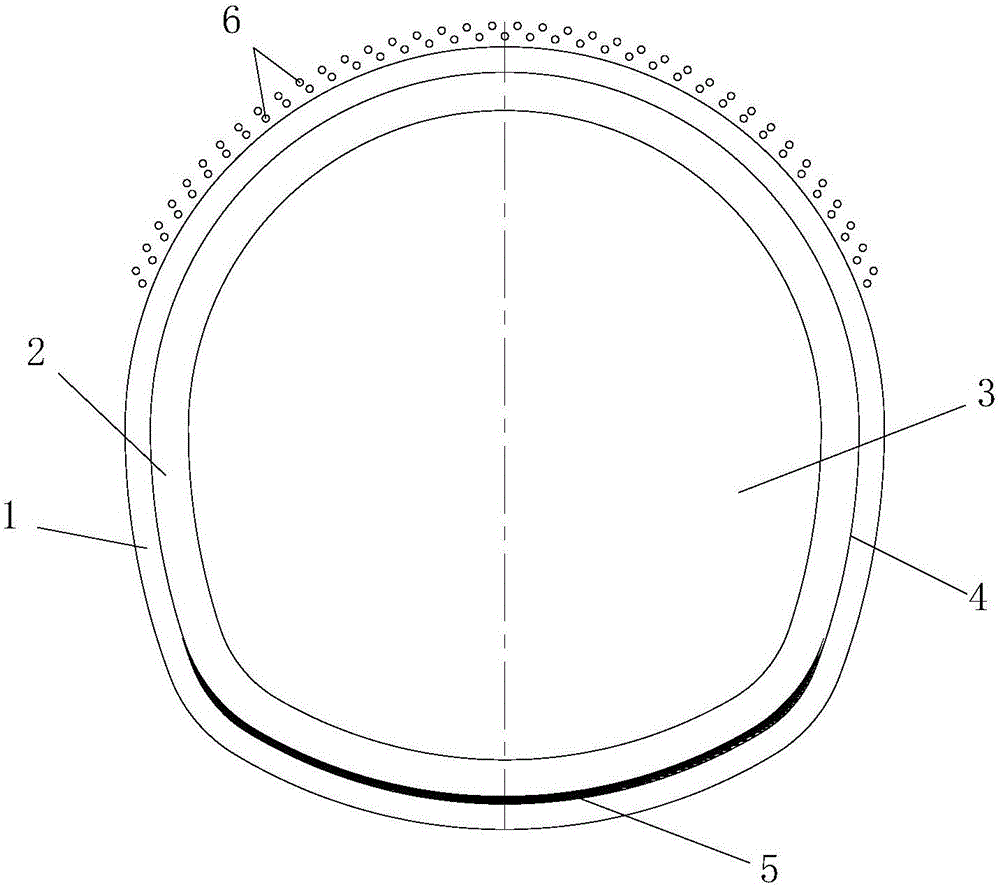

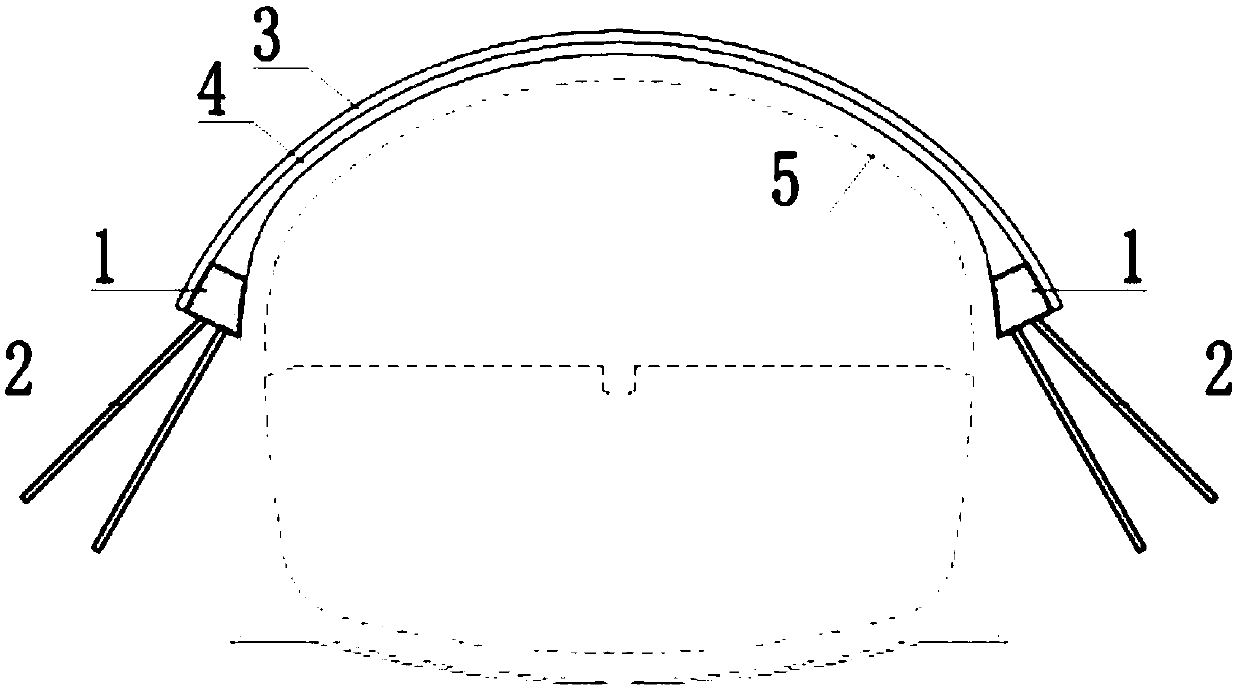

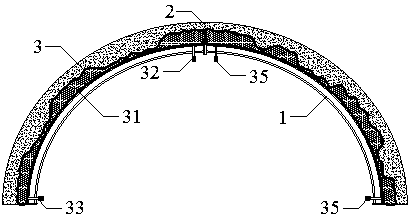

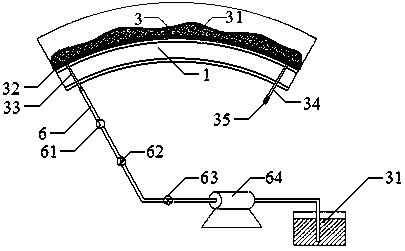

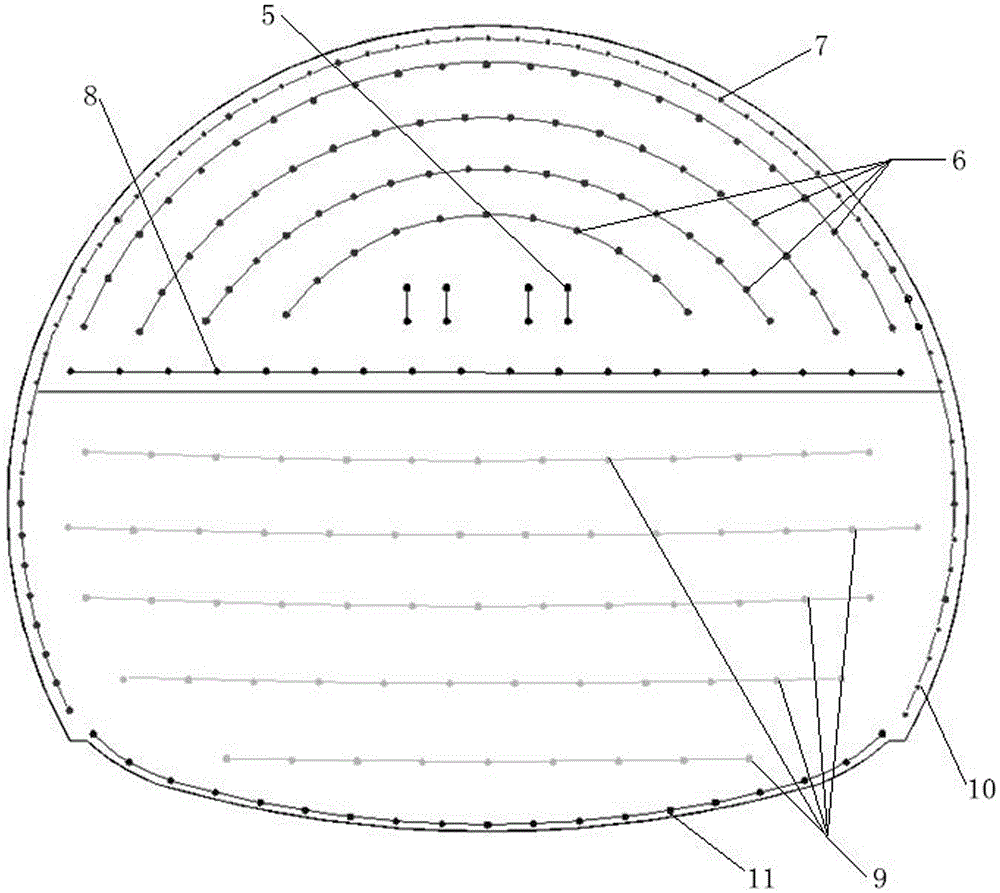

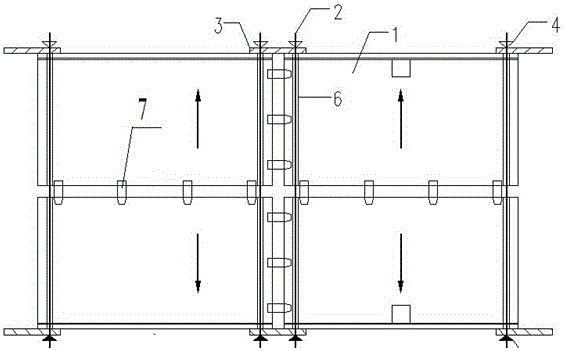

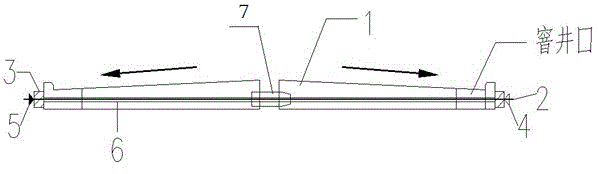

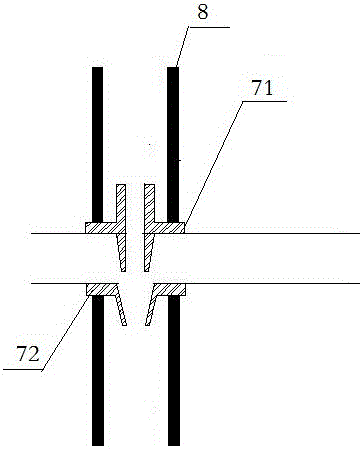

Tunnel arch frame with elastic grouting bags and mounting method thereof

The invention discloses a tunnel arch frame with elastic grouting bags and a mounting method thereof. The grouting bags are arranged on the face, making contact with surrounding rock, of the arch frame and made of flexible elastic materials; the grouting bags are bonded to the reverse side of the arch frame through glue; and after the arch frame is mounted, slurry is injected into the grouting bags, the grouting bags are expanded, gaps between the arch frame and the irregular surrounding rock are full of the grouting bags, and after the slurry is solidified, the arch frame and the surroundingrock are tightly attached. Compared with the prior art, the advantages of high bearing capacity, even stress, low cost, high construction speed, easy operation, safety and the like of the arch frame can be given into full play, and the tunnel arch frame can be widely suitable for various drill-blasting method tunnel construction.

Owner:陈胜玉

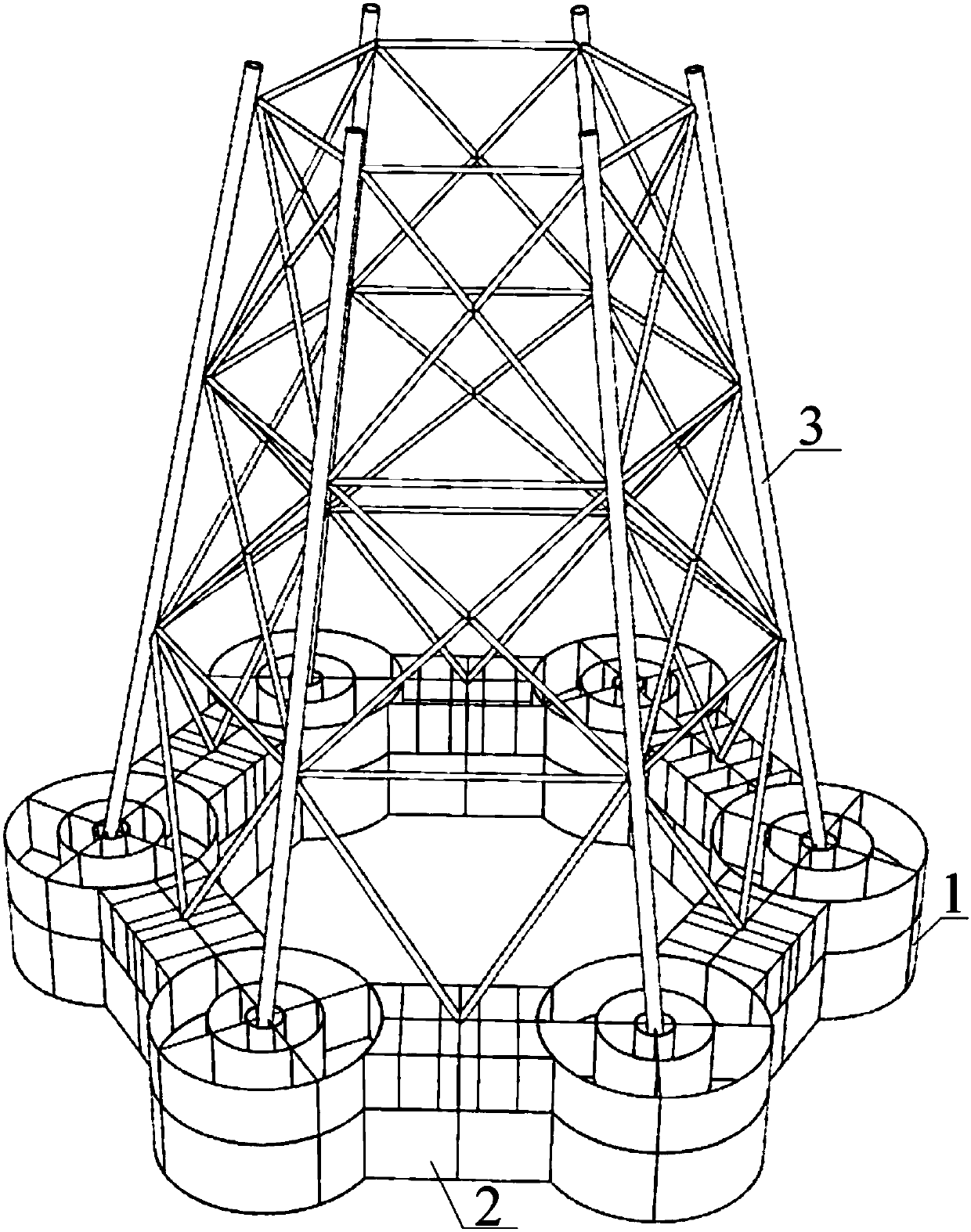

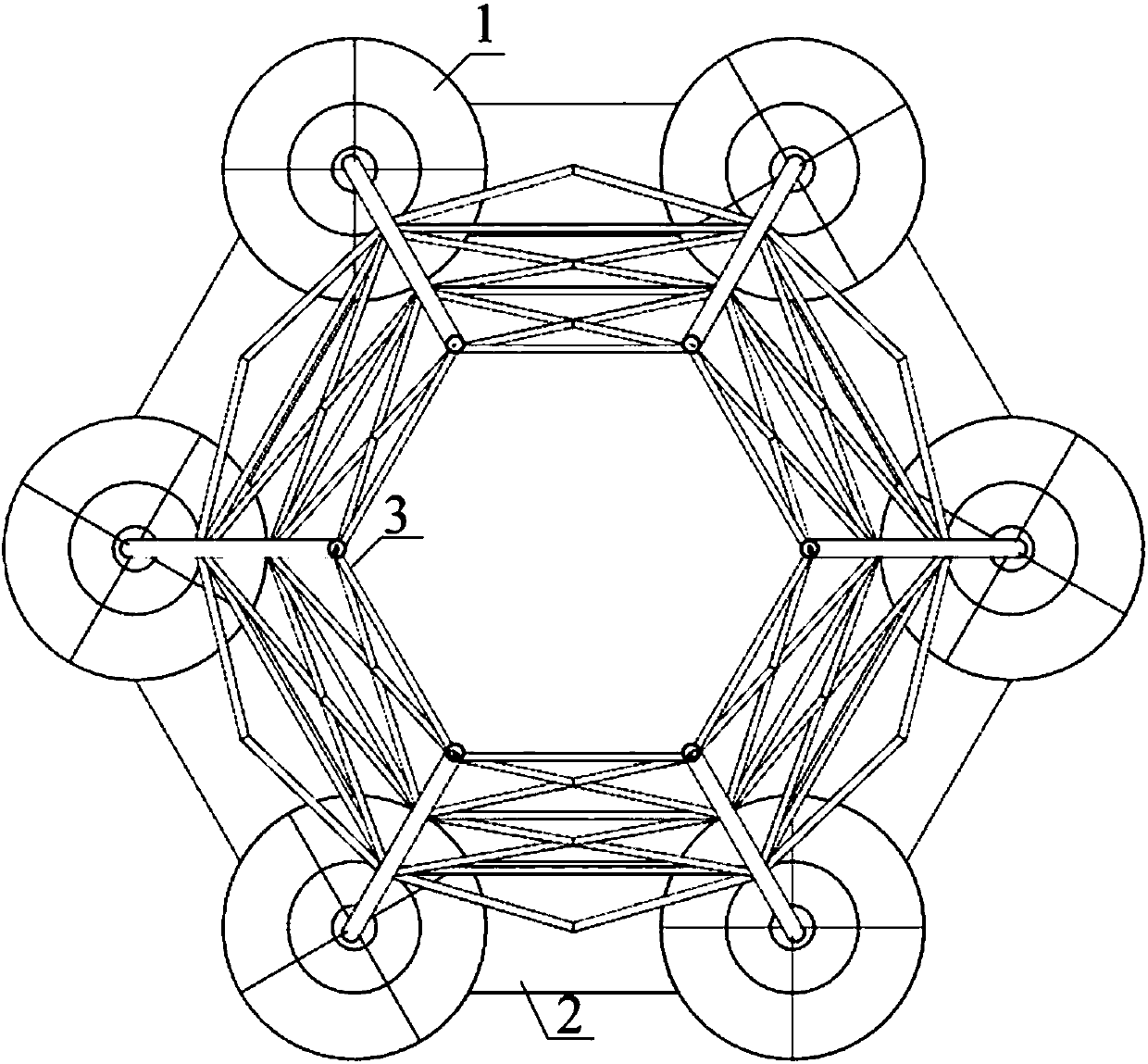

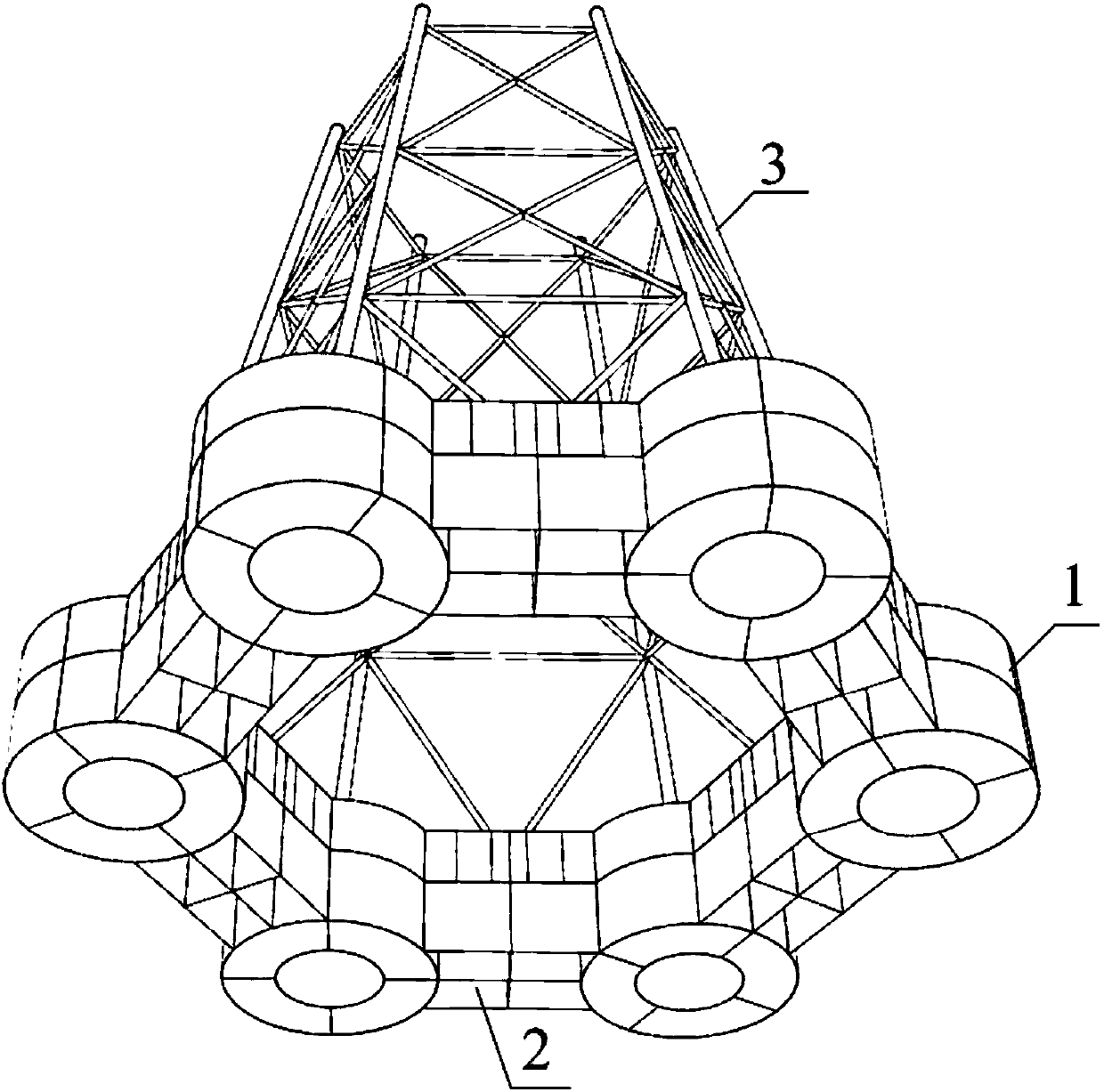

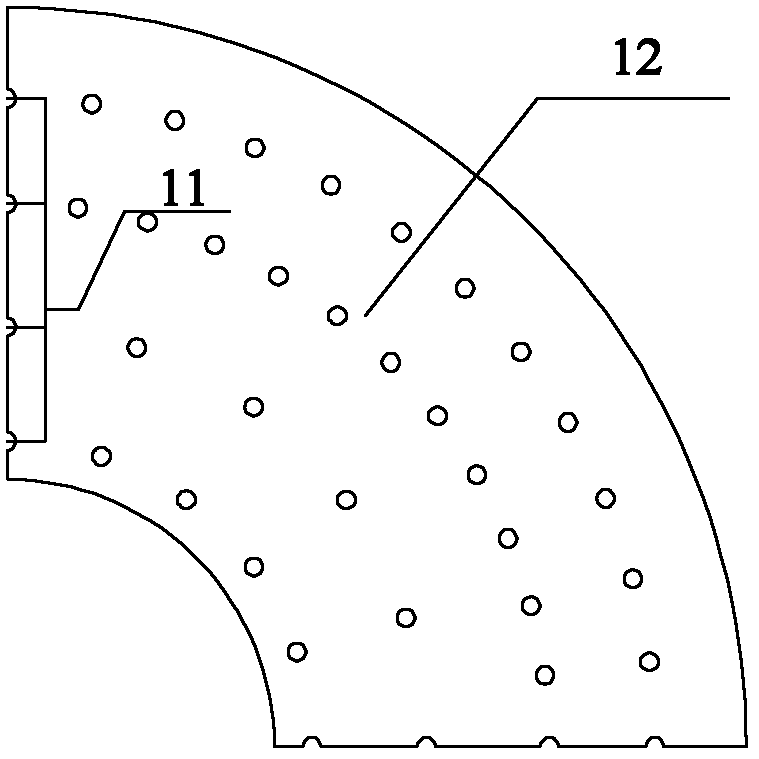

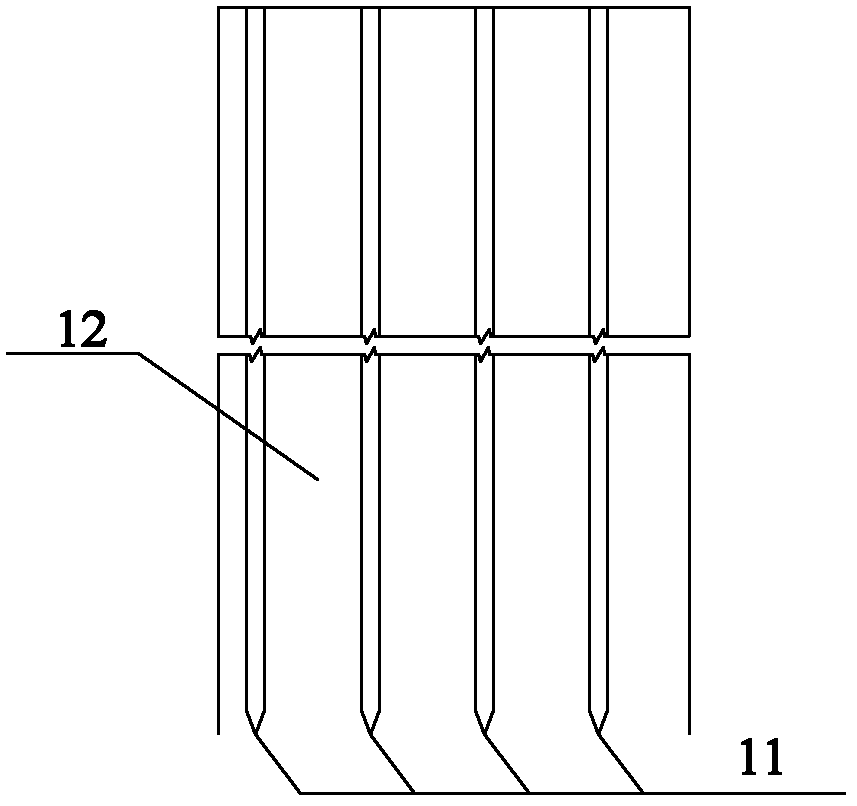

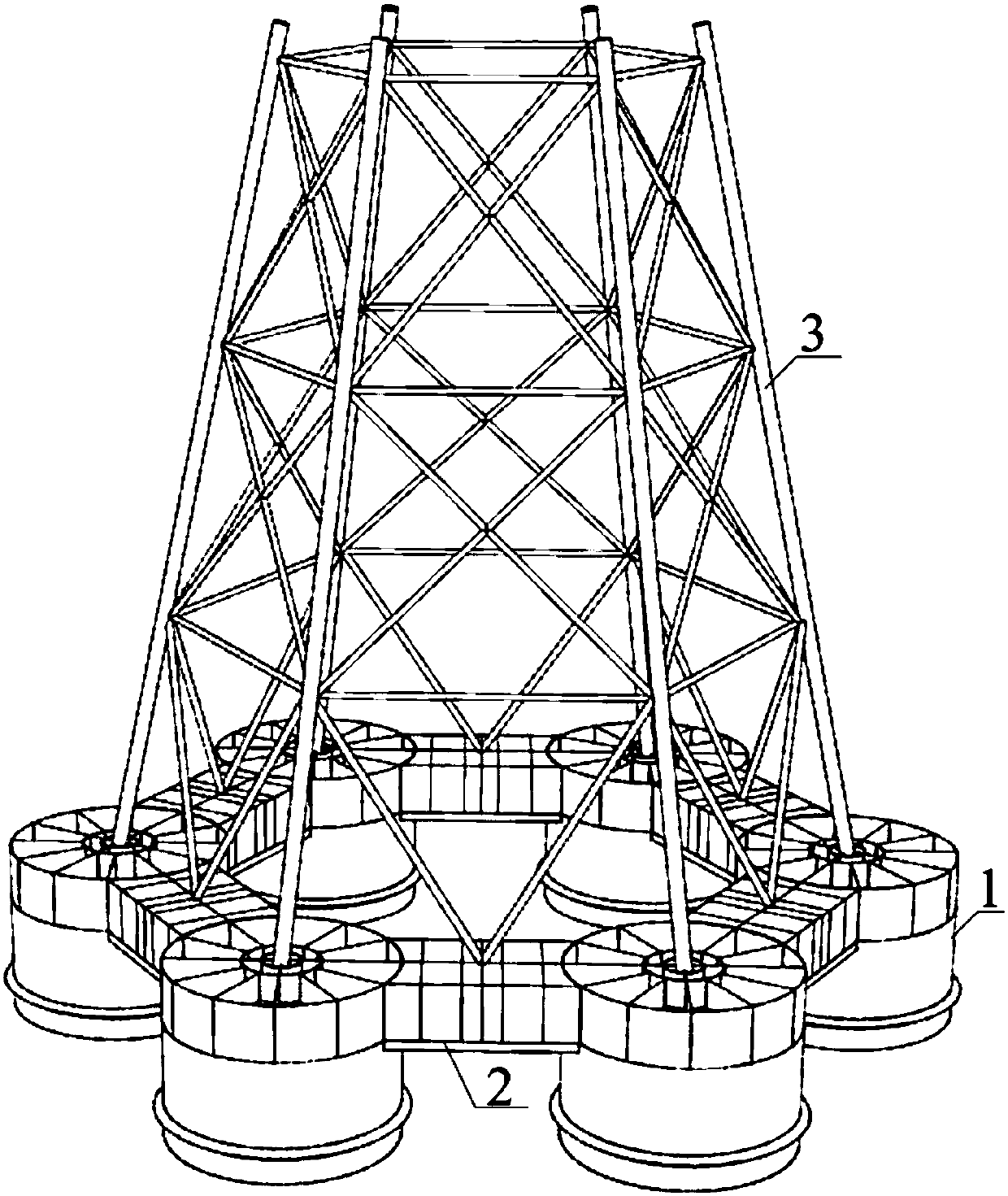

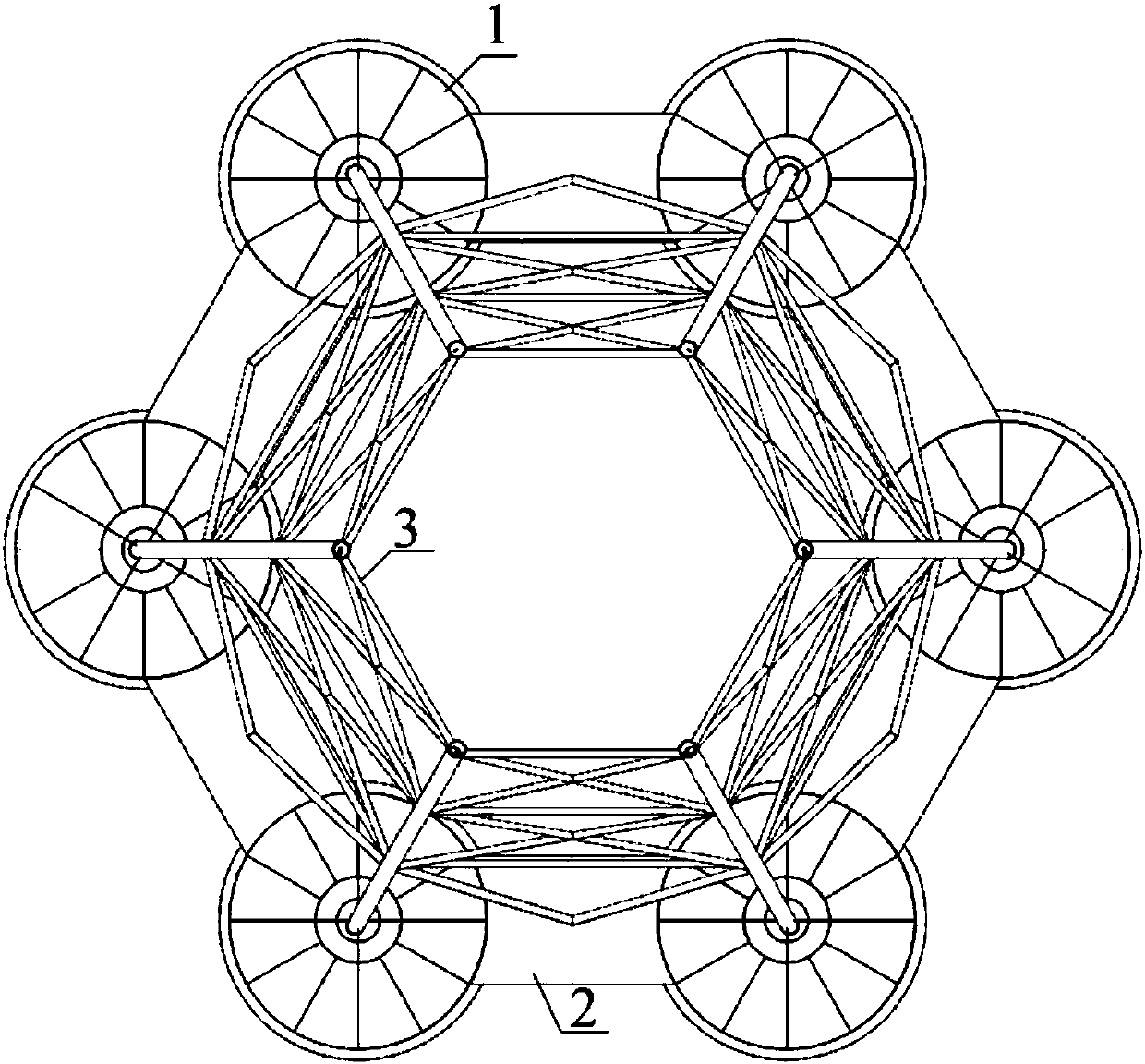

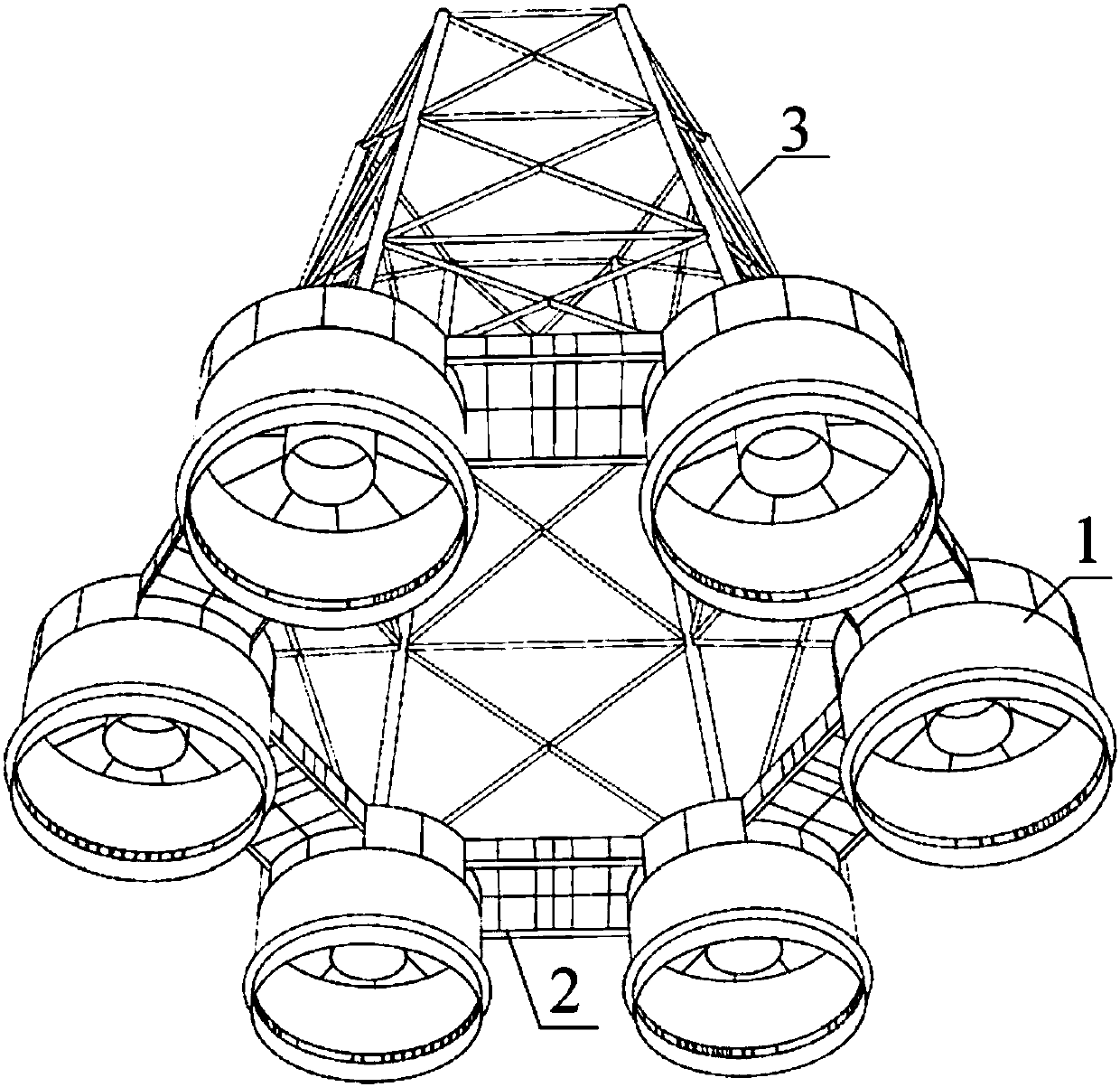

Combined marine six-pontoon floating box foundation structure and construction method thereof

PendingCN107653895AIncreased anti-slip stabilityEnhanced interactionFoundation engineeringFloating buildingsMarine engineeringWind power

The invention belongs to the technical field of foundation structures of marine engineering, and discloses a combined marine six-pontoon floating box foundation structure and a construction method thereof. The combined marine six-pontoon floating box foundation structure comprises six pontoons, wherein the six pontoons are arranged in the way that the six pontoons are connected in sequence in thehorizontal plane according to the center points of the six pontoons to define a regular hexagon. A floating box is connected between the every two adjacent pontoons. Each floating box penetrates through the axes of the corresponding pontoons at the two ends of each floating box along the center line of the length direction. The pontoons and the upper parts of the floating boxes are connected witha transition section tower frame. The transition section tower frame is used for being connected with upper wind power equipment. The construction method of the combined marine six-pontoon floating box foundation structure comprises the steps of structure prefabricating, initial adjustment preparation, water consignment, foundation water entry, negative pressure penetration, grouting ballasting, supper structure mounting and recycling and utilizing. The combined marine six-pontoon floating box foundation structure has the characteristics of having a gravity foundation and a suction-barrel-typefoundation, the bearing capacity is improved while the transporting and mounting method is simple and convenient, recycling and reusing can be achieved, and the construction cost is greatly reduced.

Owner:TIANJIN UNIV

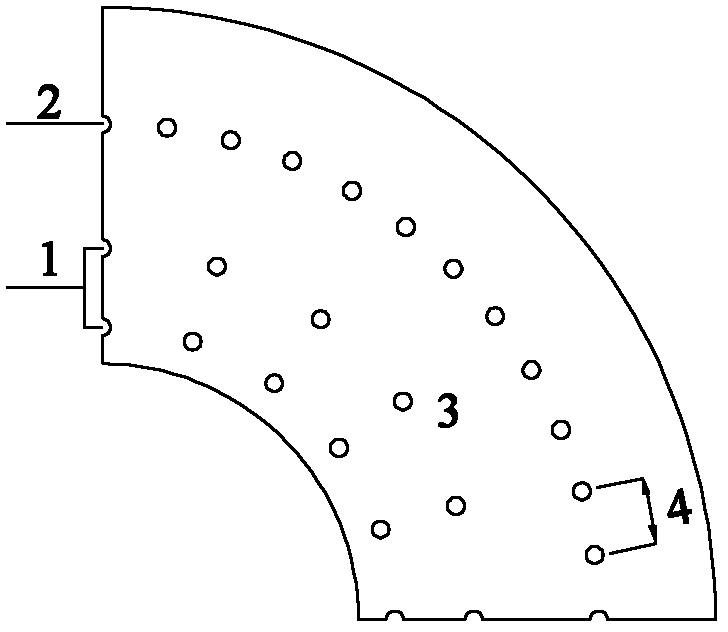

A Freezing Method of High Gradient Heterogeneous Freezing Wall

The invention discloses a method for freezing a high-gradient heterogeneous freezing wall. The mixed freezing mode of "salt water + liquid nitrogen" is adopted, and a freezing pipe is arranged at the place where the soil around the shaft needs to be frozen, and a brine freezing pipe is arranged inside the freezing wall. , and a liquid nitrogen freezing tube is arranged on the periphery. The liquid nitrogen freezing tubes are arranged in one row, and the brine freezing tubes are arranged in at least one row, and each row is arranged in a circular shape. When there are two or more rows of brine freezing pipes, the diameter of the ring in the innermost row should ensure that the temperature of the well side during excavation is not higher than the ideal value that is conducive to the stability of the well side; the brine temperature setting of the brine freezing pipes should ensure that It can form a temperature field that gradually decreases from the inside to the outside. The temperature field formed by the freezing tube layout method of the present invention has obvious high gradient non-uniformity. Compared with conventional brine freezing, under the same load conditions, the thickness of the frozen wall formed by this pipe layout is small but has a higher bearing capacity, which will reduce the amount of frost heaving and thawing, and reduce the amount of engineering work for freezing holes , The freezing period is shortened.

Owner:TONGJI UNIV

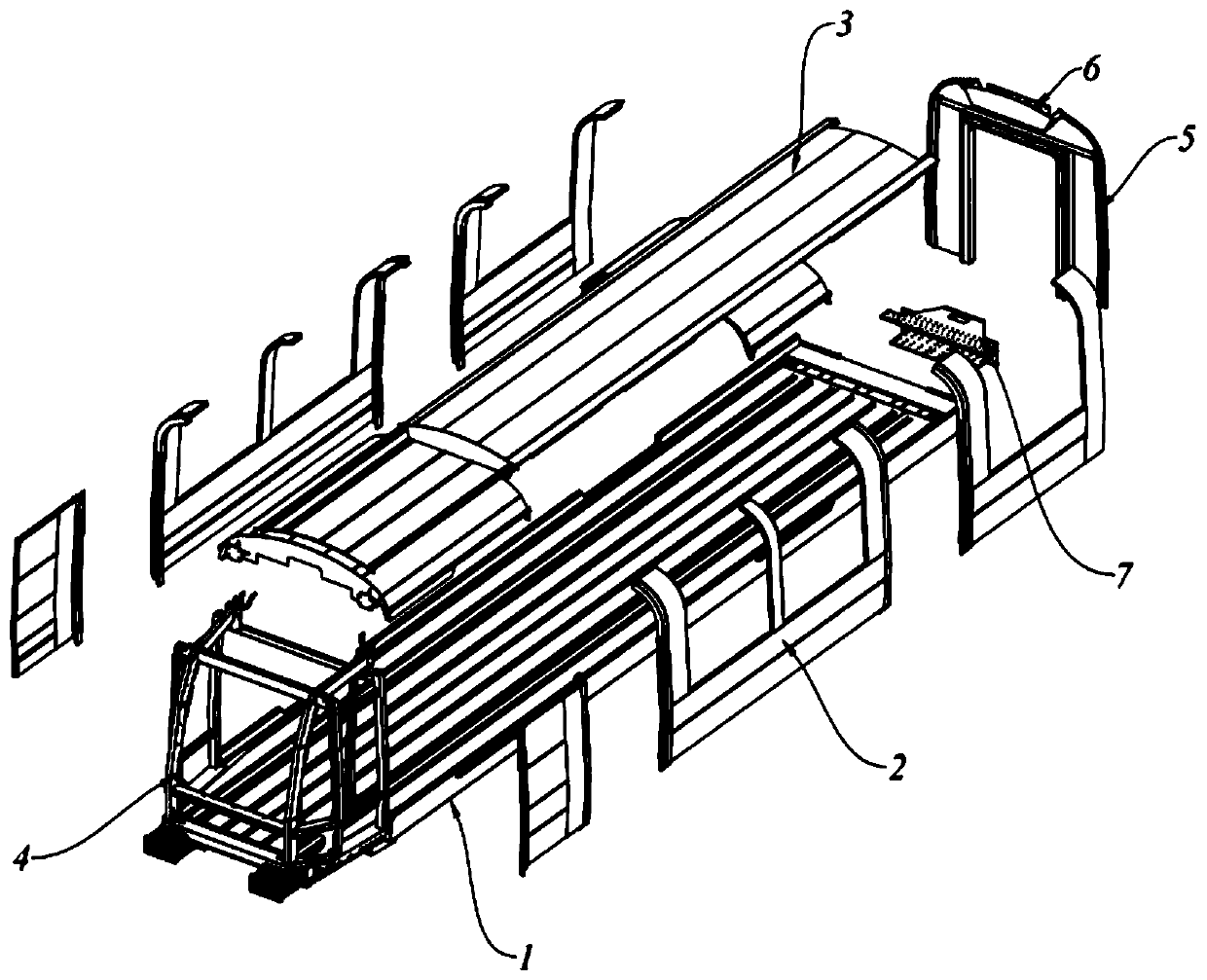

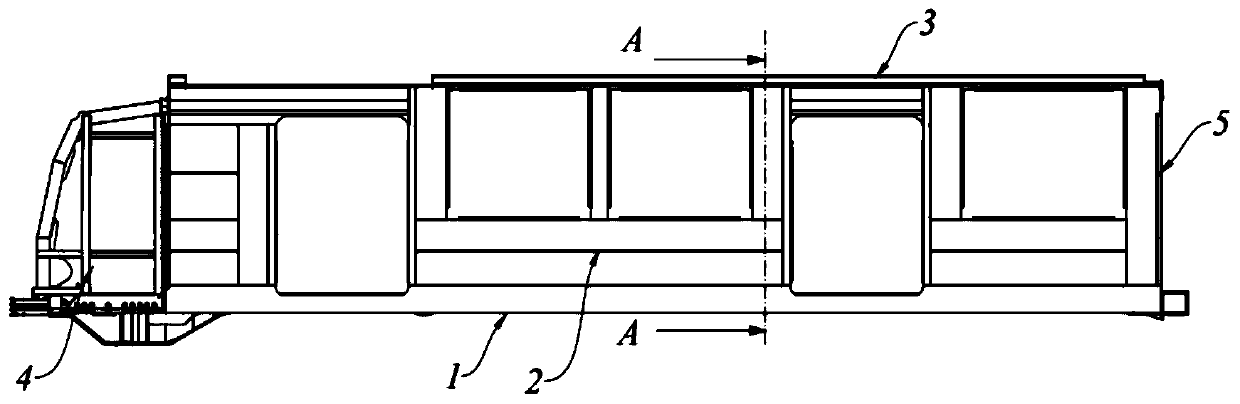

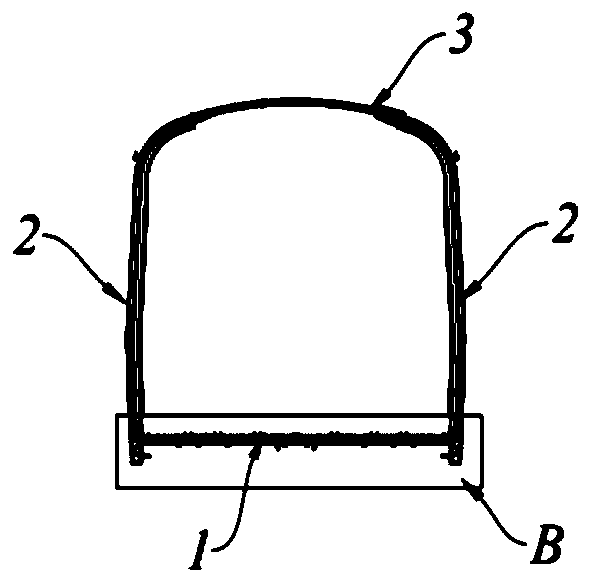

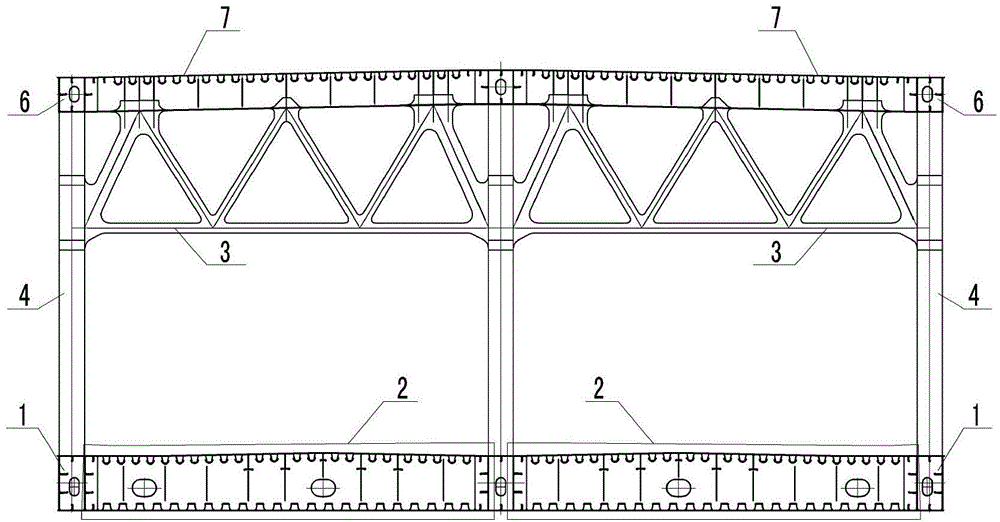

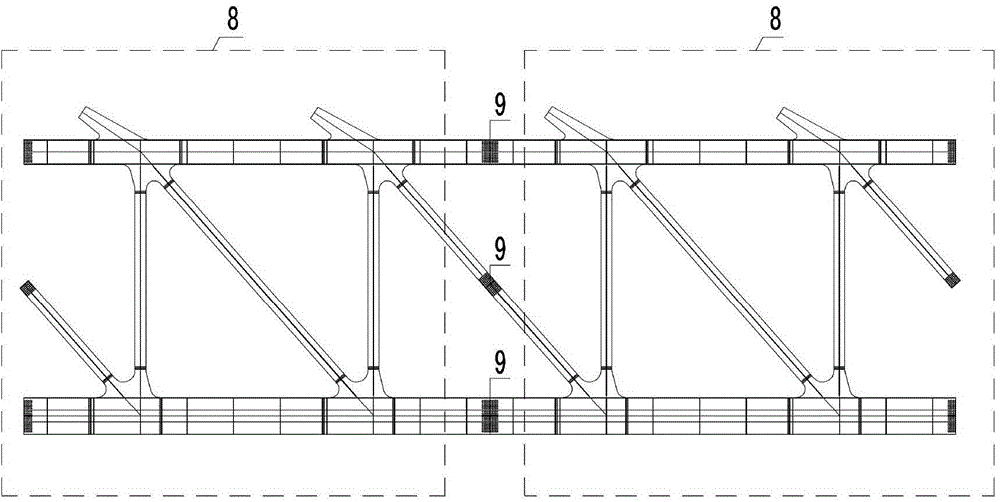

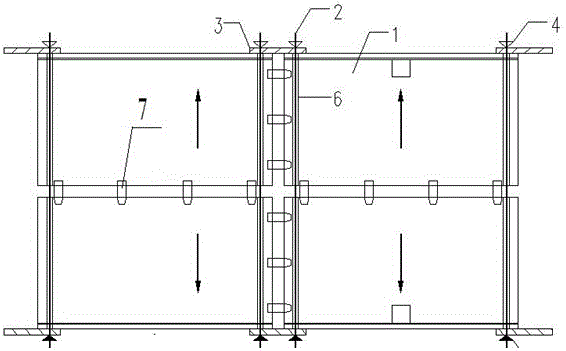

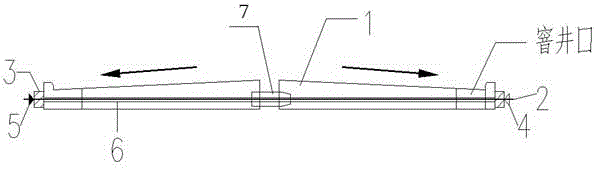

Head car body structure of high-floor tramcar

InactiveCN110667617AGive full play to carrying capacityReduce usageRailway roofsUnderframesBolt connectionAutomotive engineering

The invention discloses a head car body structure of a high-floor tramcar. The head car body structure comprises a base frame, side walls, a roof, a driver cab, an end wall, and an upper / lower hinge seat. The base frame, the side walls, the roof and the end wall are connected by welding, the driver cab is connected to the base frame and the roof by bolts, and the upper / lower hinge seat is rivetedto the end wall and the base frame respectively. The car body structure is mainly made by welding of hollow-section extrusion aluminum-type materials. In the manner, the car body structure has a goodlightweight effect and a good noise isolation performance while meeting the requirements of strength; and at the same time, window columns adopt an arc design, so that the area of a window frame is increased, and passengers can enjoy more wild field of vision to meet the needs of tour and sightseeing. In addition, the upper and lower hinge seats are riveted and cooperate with each other to effectively improve the connection strength with the car body. Even if the car body is larger than 12 meters, the car body structure can ensure sufficient connection strength.

Owner:中铁轨道交通装备有限公司

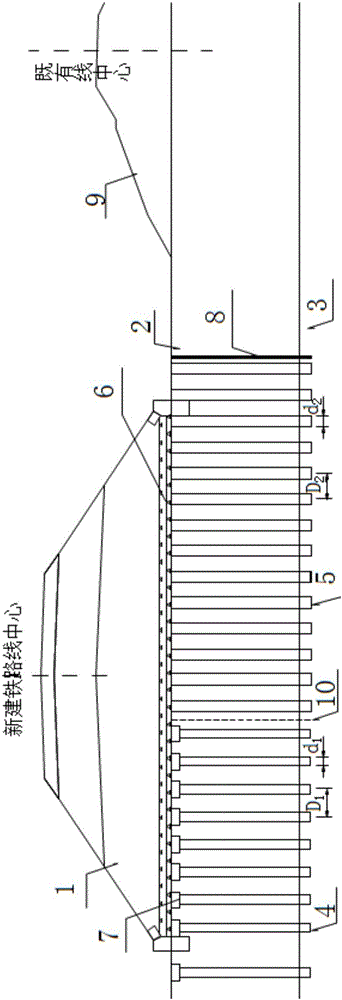

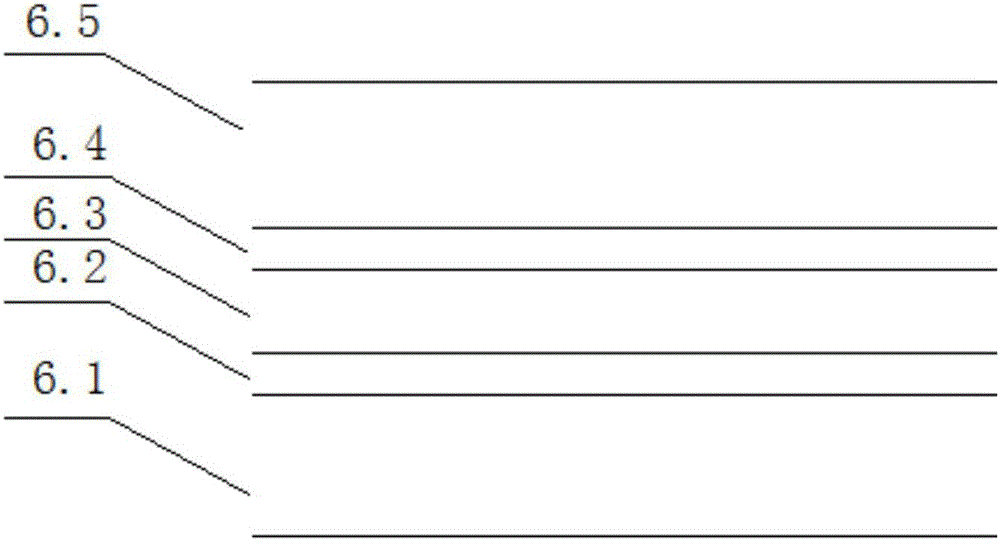

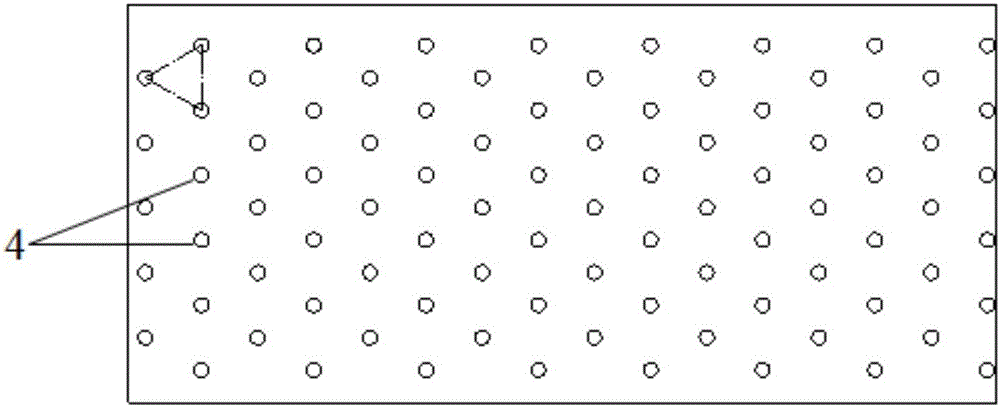

Construction method for treating adjacent existing railway line soft soil foundation and roadbed structure thereof

ActiveCN105696426AProtection securityConstruction Efficiency ProtectionRailway tracksBulkheads/pilesStructure of the EarthSoil horizon

The invention discloses a construction method for treating an adjacent existing railway line soft soil foundation and a roadbed structure thereof. The construction method comprises the steps of leveling the site, and longitudinally constructing a plurality of rows of rigid CFG piles along the line in the slope toe area of the side, away from an existing railway line, from a safety limit part to a designed newly-built roadbed; longitudinally constructing a plurality of rows of flexible jet grouting piles along the line in the slope toe area of the side, close to the existing railway line, from the safety limit part to the designed newly-built roadbed; longitudinally paving a mattress layer along the railway line above the rigid CFG piles and the flexible jet grouting piles and at the top of a soft soil layer; and paving a roadbed above the mattress layer according to the design. According to the construction method and the roadbed structure, the roadbed bearing capacity is effectively improved, the post-construction settlement of the roadbed is reduced, the stability of the soft soil foundation is guaranteed, and the negative impact to the safe operation of the existing railway line is avoided; and the roadbed reinforcement structure is simple in form, good in stratum adaptability, reasonable in technology, and economic in cost, and has relatively high popularization and application value.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Offshore six buoy and six buoyancy tank combined type foundation structure and construction method thereof

PendingCN107630462AIncreased anti-slip stabilityEnhanced interactionFoundation engineeringElectricityGravitation

The invention belongs to the technical field of foundation structures of oceanographic engineering, and discloses an offshore six buoy and six buoyancy tank combined type foundation structure and a construction method thereof. The foundation structure comprises six buoys arranged in a mode that the center points of the buoys are connected in sequence to define a regular hexagon shape on a horizontal plane, a buoyancy tank is connected between every two adjacent buoys, and the center line in the length direction of each buoyancy tank penetrates through the axes of the buoys on the two ends of the buoyancy tank; and a transition section tower is connected to the upper portions of the buoys and the upper portions of the buoyancy tanks, and the transition section tower is used for being connected with upper wind power equipment; and the construction method comprises the steps of structure prefabrication, primary adjustment preparation, overwater towage, water entrance of a foundation, negative pressure penetration, grouting and ballasting, upper structure installation and recycling. The foundation structure has the characteristics of a gravity type foundation and a suction barrel typefoundation, the bearing capacity is improved, and meanwhile, the transportation and installation modes are simple and convenient, the foundation structure can be recycled, and the construction cost isgreatly reduced.

Owner:TIANJIN UNIV

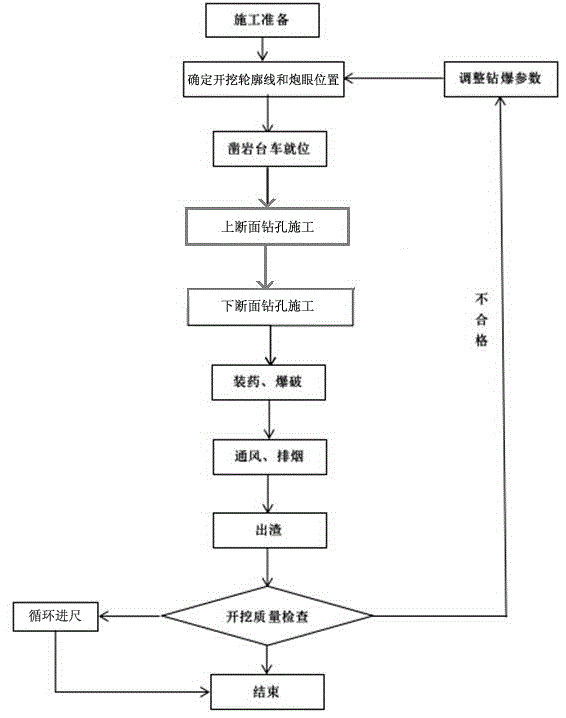

Method for blasting construction of upper and lower fracture surfaces in IV/V-class surrounding rock through three-arm jumbo drill

InactiveCN105627850APrecise positioningGive full play to carrying capacityBlastingGeomorphologyMechanical equipment

The invention belongs to the technical field of tunnel rock construction and particularly relates to a method for blasting construction of upper and lower fracture surfaces in IV / V-class surrounding rock through a three-arm jumbo drill. According to the method, the upper and lower fracture surfaces are excavated through smooth blasting, and the features of high speed, precise positioning and high security of the three-arm jumbo drill are fully utilized, so that the blasting drilling time is short and the angle of outward insertion is easy to control; steps of the upper and lower fracture surfaces are subjected to parallel crossing operation, it can be ensured that primary bracing is completed as early as possible by combination with the quick guniting technology of wet spraying machinery later, and the bearing capacity of the primary bracing is brought into full play; the construction quality is improved and the operation environment is perfected by means of matched mechanical equipment.

Owner:LIAONING TECHNICAL UNIVERSITY

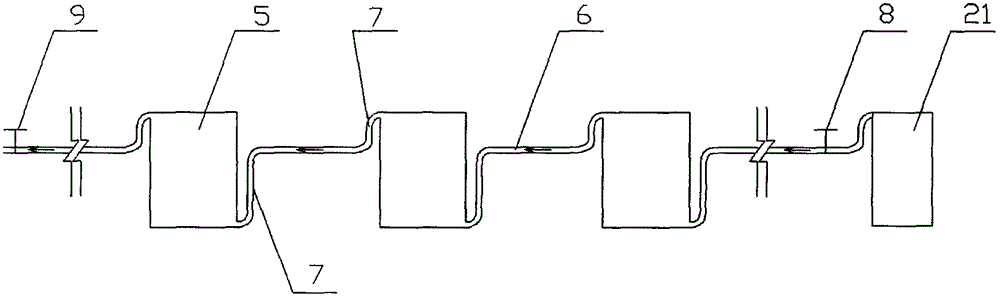

Concrete preassembled road high in rupture strength

InactiveCN105064160AImprove flexural strengthEasy to transportSingle unit pavingsPaving detailsStructural engineeringRoad surface

The invention discloses a concrete preassembled road high in rupture strength. The concrete preassembled road comprises four concrete precast slabs; the two sides of each concrete precast slab are provided with holes used for placing steel strands; adjacent concrete precast slabs are connected via the steel strands; the diameter of the steel strand is 15.50mm; the four sides of each concrete precast slab are provided with the holes used for placing the steel strands, and adjacent concrete precast slabs are connected via the steel strands; one road surface unit is formed from the four concrete precast slabs via the steel strands and steel connecting plates arranged on the outsides of the concrete precast slabs; connecting key structures are arranged between adjacent concrete precast slabs; each connecting key structure comprises a shearing-resistant convex key and a shearing-resistant concave key matching with each other. The concrete preassembled road is convenient for transportation, and rapid and convenient for installation; road slabs can be divided into a plurality of kinds and types according to the ratio of the short edges to the long edges; and the plurality of positioning shearing-resistant connecting keys are arranged on the joint interfaces of the precast slabs so as to ensure that rupture or breakage of the road slabs is not caused under repeated action of overload vehicles.

Owner:郭晓磊 +17

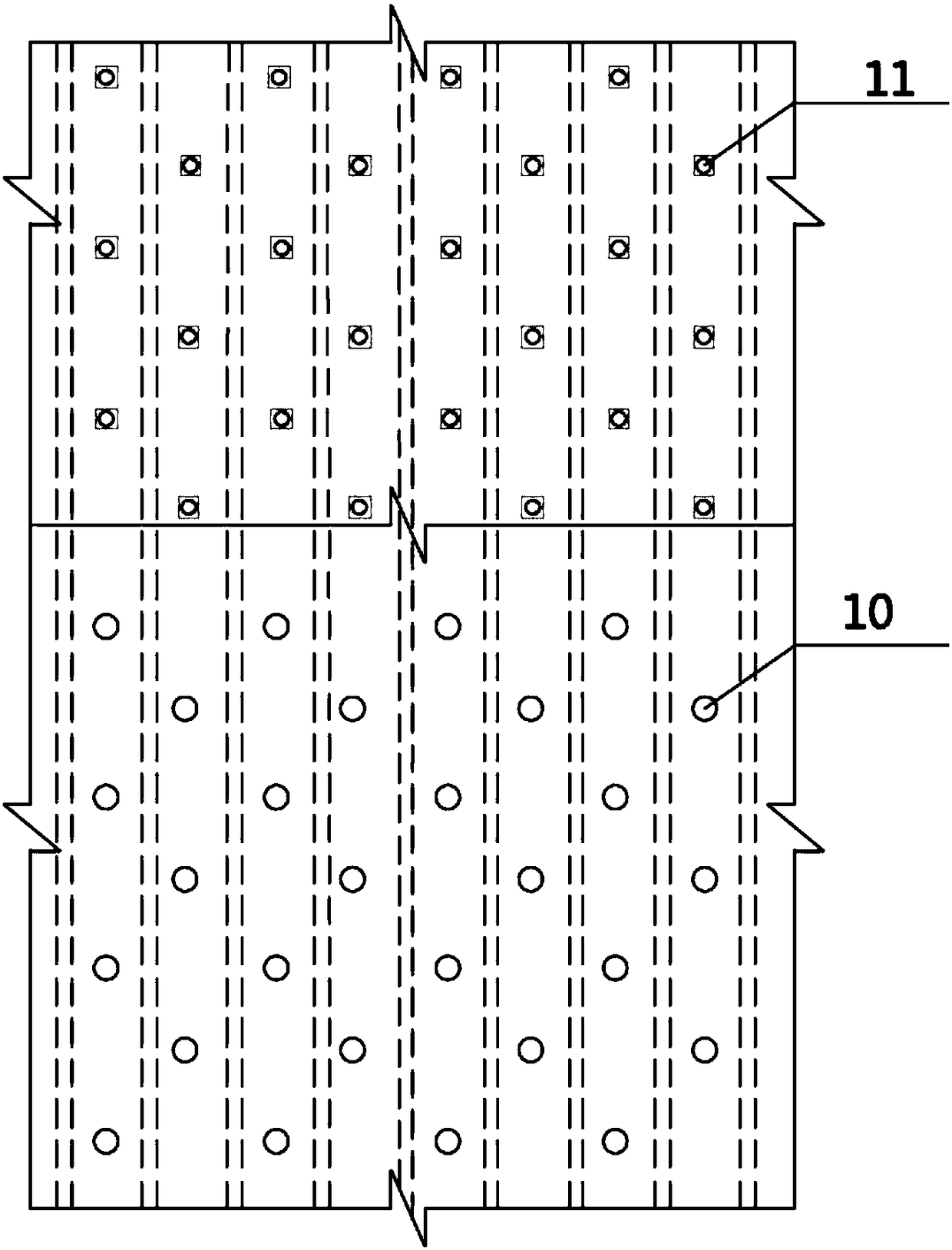

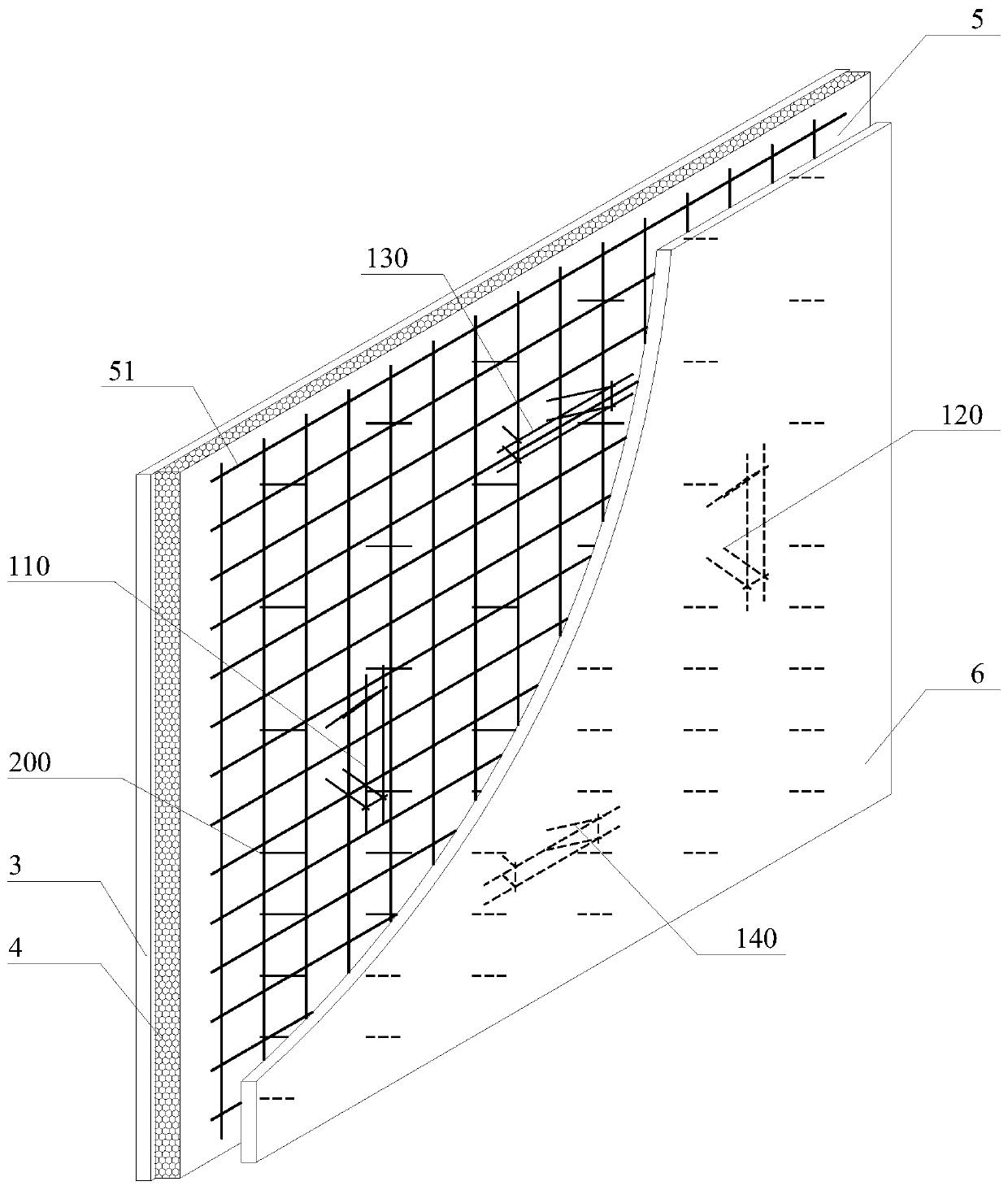

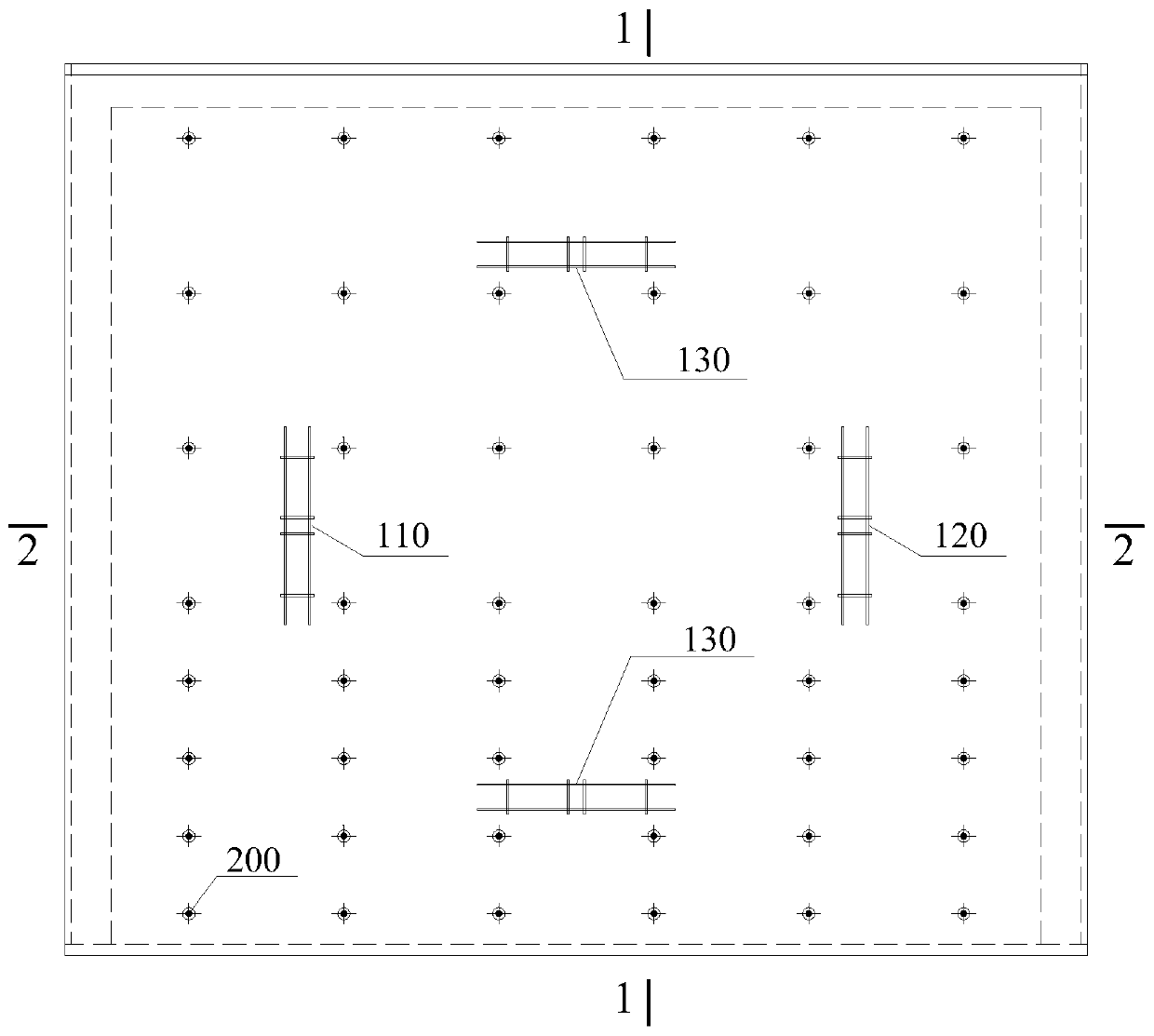

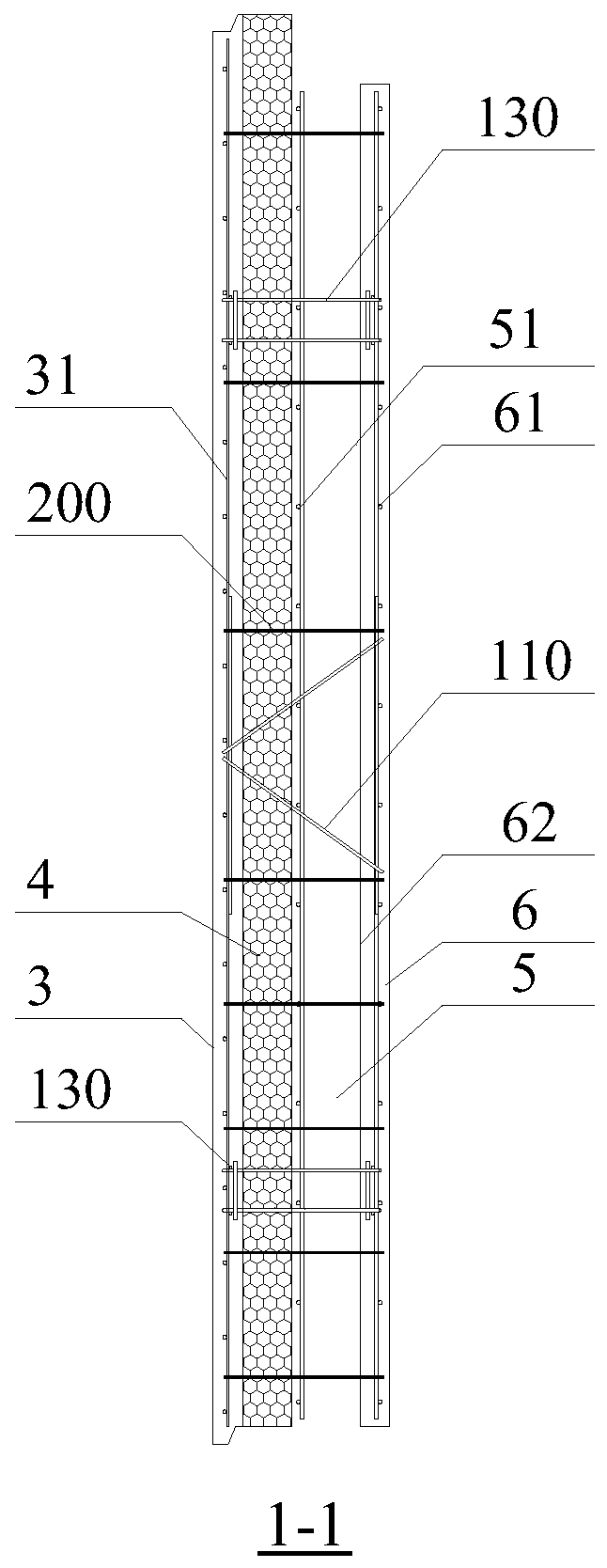

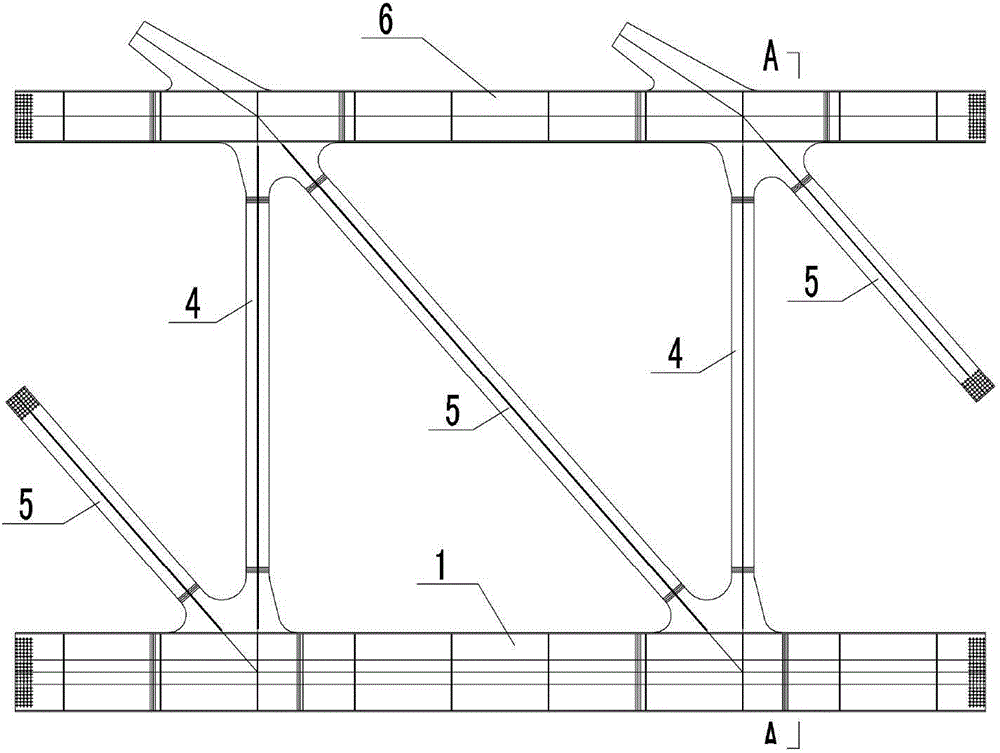

Sandwich heat preservation composite shear wall prefabricated part and manufacturing method thereof

PendingCN110978211AAvoid forceAvoid problems with unclear design calculationsWallsCeramic shaping apparatusInsulation layerMesh reinforcement

The invention discloses a sandwich heat preservation composite shear wall prefabricated part and a manufacturing method thereof. The prefabricated part comprises an inner concrete wallboard, an outerconcrete wallboard, a heat preservation layer, a cavity and a connecting piece system; the connecting piece system penetrates through the cavity and the heat preservation layer and extends into the inner concrete wallboard and the outer concrete wallboard; and the connecting piece system comprises at least four independent truss connecting pieces and a plurality of rod-shaped connecting pieces with the lengths distributed in a wall thickness direction. The manufacturing method comprises the following steps of: binding the reinforcing mesh of the outer concrete wallboard, and mounting the connecting piece system on the reinforcing mesh; pouring outer wallboard concrete, laying a heat insulation board, and mounting a reinforcing mesh in the cavity; binding and mounting the reinforcing mesh of the inner concrete wallboard, pouring concrete, keeping the inner concrete wallboard still, and integrally overturning other components by 180 degrees; and moving the overturned components towards the inner concrete wallboard, pressing the end portions of all the connecting pieces into the inner concrete wallboard and making the end portions of all the connecting pieces fully contact with the inner concrete wallboard. All components in the connecting piece system are stressed definitely, and the non-combined stress mode of a sandwich heat preservation composite shear wall is achieved.

Owner:CABR TECH CO LTD

All-welded box girder combination section constructing method

ActiveCN104018427AIncreased durabilityReduce post-maintenance workloadBridge erection/assemblyBridge engineeringBox girder

The invention relates to an all-welded box girder combination section constructing method. The method comprises the specific steps that a girder is divided by making the distance length of two sections serve as one novel box girder combination section, plate units of sectional unit parts are manufactured, a girder lower chord is welded to a lower bridge surface steel box, a girder upper chord is welded to an upper bridge surface panel, a transverse bracing system is welded to a girder vertical rod, the girder vertical rod and an inclined rod are welded to the girder lower chord and the girder upper chord, and the novel box girder combination sections are formed; trial splicing is performed on adjacent novel box girder combination sections on a preset trial assembly platform, and anticorrosion coating is performed on the outer surface. All-welded box girder combinations are welded in place according to a construction order on a bridging construction site. According to the method, the girder is designed into the all-welded box girder combination sections, few hanging units are used, durability of the girder is improved, maintaining workloads during the later period are reduced, site construction is simplified, work efficiency is improved, and an installation period is shortened; the appearance is beautiful, and durability is good. The method has been successfully applied to the Shanghai-to-Nantong railway Yangtze river highway-railway dual-purpose great bridge engineering.

Owner:CHINA MAJOR BRIDGE ENERGINEERING +1

Impacting-resistant and abrasion-resistant concrete prefabricated road

ActiveCN105113352AEasy to transportQuick installationPaving reinforcementsSingle unit pavingsBarium nitrateRoad surface

The invention discloses an impacting-resistant and abrasion-resistant concrete prefabricated road. The impacting-resistant and abrasion-resistant concrete prefabricated road comprises four prefabricated boards. Holes where steel strands are contained are formed in the two sides of the prefabricated boards respectively. The adjacent prefabricated boards are connected through the steel strands. The diameter of the steel strands is 14.50 mm. Or holes where the steel strands are contained are formed in the four sides of the prefabricated boards, and the adjacent prefabricated boards are connected through the steel strands. The four prefabricated boards form a road surface unit through the corresponding steel strands and steel connecting board bands on the outer sides of the prefabricated boards. Connecting key structures are further installed between the adjacent prefabricated boards. Each connecting key structure comprises a shearing-resisting convex key and a shearing-resisting concave key which are matched. The prefabricated boards are made of cement, coal ash, sand, water, nylon fibers, barium nitrate, calcium lignosulphonate, silicon carbide powder, sepiolite powder, alumina silicate fibers and gypsum.

Owner:惠州大亚湾市政基础设施有限公司

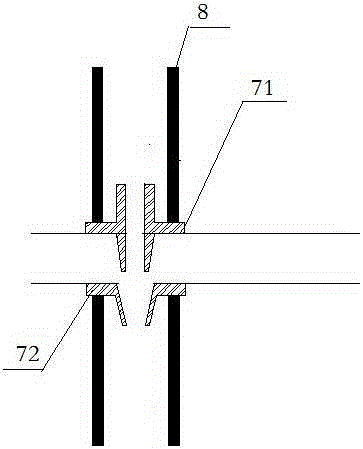

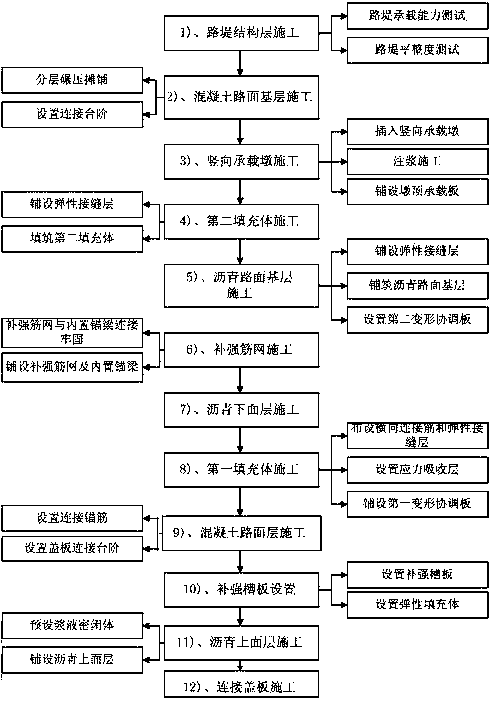

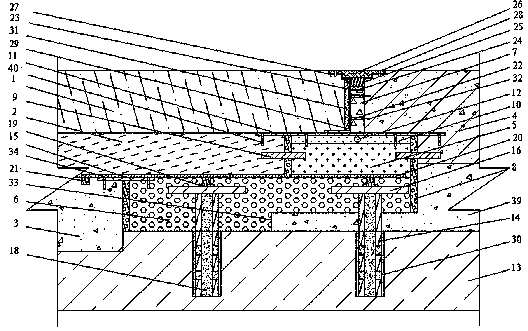

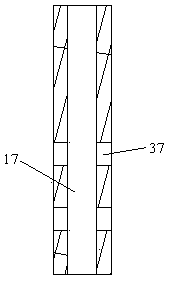

Asphalt pavement composite structure and construction method thereof

ActiveCN110067168AAchieve continuous transitionResolving sudden changes in stiffnessPaving reinforcementsIn situ pavingsTemperature stressRoad surface

The invention provides an asphalt pavement composite structure and a construction method thereof. One side of a pavement sequentially comprises an asphalt upper face layer, an asphalt lower face layer, an asphalt pavement base course and an embankment structure from top to bottom, the other side of the pavement sequentially comprises a concrete pavement layer, a concrete pavement base course and an embankment structure from top to bottom; and first filling bodies are arranged among the asphalt upper face layer, the asphalt lower face layer and the concrete pavement layer, second filling bodiesare arranged among the asphalt lower face layer, the asphalt pavement base course and the concrete pavement base course, and elastic filling bodies are arranged between the asphalt upper face layer and the concrete pavement layer. According to the asphalt pavement composite structure, through arrangement of the first filling bodies, the second filling bodies, the elastic filling bodies, a first deformation coordinating plate, a second deformation coordinating plate, an elastic joint layer and vertical bearing piers, the influences of temperature stress and differential deformation on a road structure can be effectively prevented and controlled, and a crack reflection channel is blocked.

Owner:中咨规划设计研究有限公司

Underwater pouring root type foundation with retaining wall and construction method thereof

ActiveCN103911989AHigh strength to mass ratioHigh stiffness-to-mass ratioBulkheads/pilesReinforced concreteUnderwater

The invention discloses an underwater pouring root type foundation with a retaining wall and a construction method thereof. The underwater pouring root type foundation with the retaining wall is characterized in that a retaining wall layer formed by pouring underwater quick set materials is arranged between a cast-in-place reinforcing concrete tubular column and the pore-forming inner wall, the side wall of the concrete tubular column is provided with root keys in the radial direction of the tubular column, the bottom of the concrete tubular column is provided with a concrete back cover, and a top cover is arranged on the top of the concrete tubular column in a pouring mode so that the underwater pouring root type foundation with the retaining wall can be formed. The underwater pouring root type foundation can be effectively applied to civil engineering, bridge buildings and water conservancy project structures, and the construction efficiency is improved.

Owner:ANHUI TRANSPORTATION HLDG GRP CO LTD

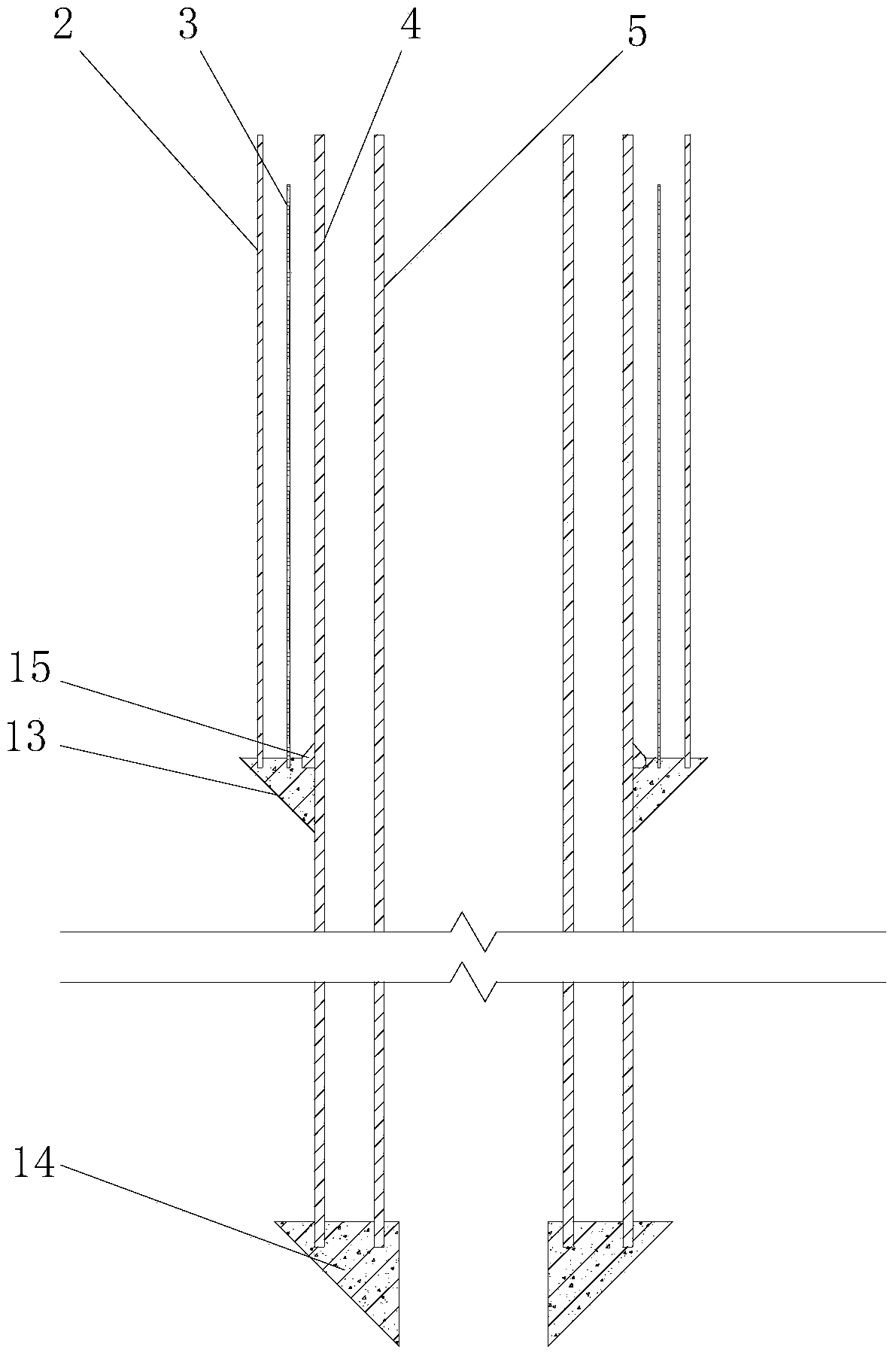

Precast concrete post grouting pile and grouting process

InactiveCN103015414ADimensions are easy to controlQuality controllableBulkheads/pilesCement pasteRebar

The invention discloses a precast concrete post grouting pile which comprises a post grouting pile body, a reinforcement cage framework, flanges, a post grouting tank, a post grouting pipe, a grouting hole and a pile bottom filler, wherein the reinforcement cage framework comprises longitudinal ribs and surrounding ribs; one end or two ends of the framework are welded with the flanges; at least one post grouting pipe runs through the center or the side edge position of the framework or the center and the side edge position of the framework; one end of the post grouting pipe is provided with the grouting hole; the grouting hole is positioned in the post grouting tank; and the post grouting tank is arranged on the post grouting pile body. In the constructing process, the post grouting pile is sunken and immediately, cement paste or powder paste with a specific surface area of 2,500 to 6,500kg / cm<2> is injected into the post grouting pile body by the grouting pipe, so that sufficient adhesion of the grouted paste and a soil layer around the pile is ensured. The precast concrete post grouting pile can realize improvement on rock and soil common resistance of soil and the pile so as to further play bearing capacity of the pile; and meanwhile, the number of the used piles can be reduced and engineering cost is reduced.

Owner:建华建材(四川)有限公司

Novel rapid-assembly type anti-shearing concrete pavement

InactiveCN105113353AEasy to installLow environmental impactSingle unit pavingsPrecast concreteRoad surface

The invention discloses a novel rapid-assembly type anti-shearing concrete pavement. The anti-shearing concrete pavement comprises a plurality of prefabricated plates, wherein holes for accepting steel strands are formed in two sides of each prefabricated plate; every two corresponding adjacent prefabricated plates are connected through steel strands; holes for accepting steel strands are formed in four sides of each prefabricated plate; every two corresponding adjacent prefabricated plates are connected through steel strands. The anti-shearing concrete pavement disclosed by the invention is prefabricated in a factory, and after being transported to a construction site, the prefabricated pavement is positioned and mounted; wet operation is not needed on the construction site, so that the pavement is convenient and rapid to mount, and the environmental influence on the pavement is small; standardized production of the prefabricated concrete pavement plates of fixed sizes are performed in factories and high production efficiency and quality are realized, and a great amount of manpower resources are saved; the prefabricated pavement plates are classified into multiple varieties and types according to bearing capacity and length, so that designers can conveniently select an appropriate prefabricated pavement plate type according to different use requirements; therefore, the road design is simple and convenient.

Owner:JIANGSU WANRONG ENG TECH CO LTD

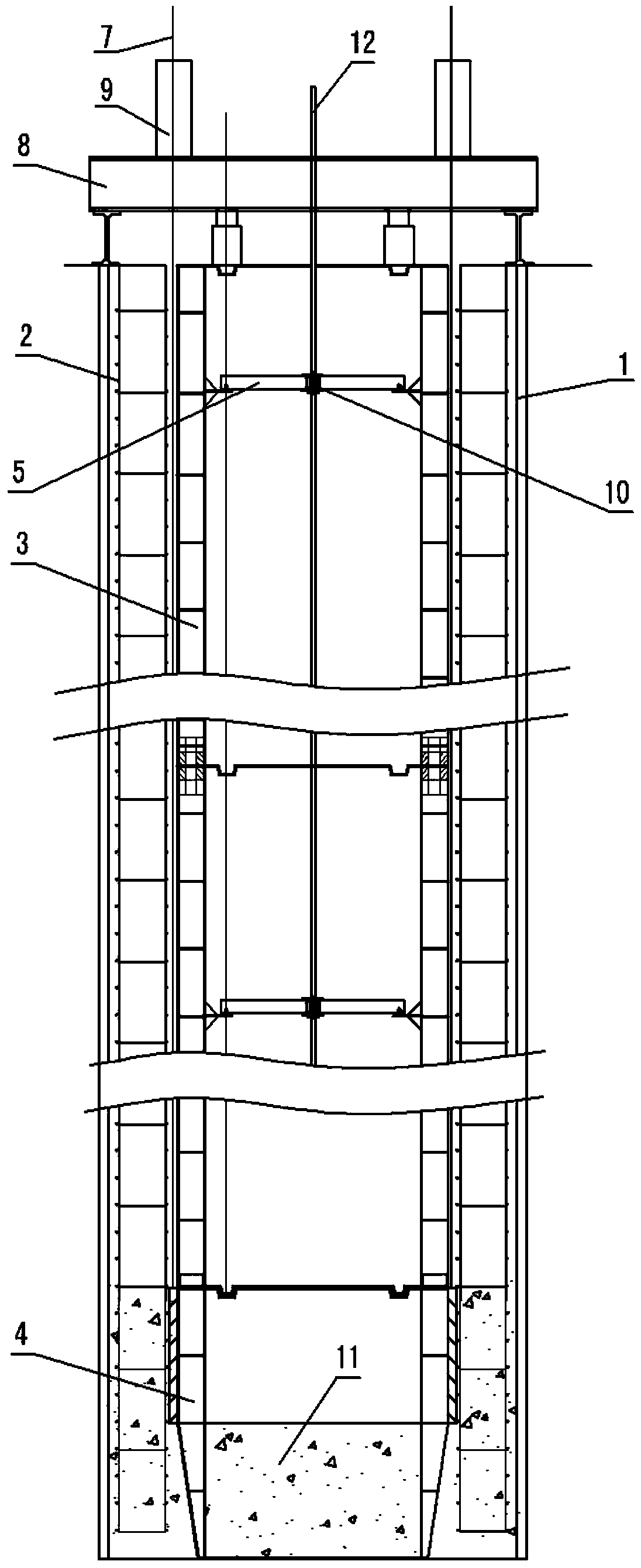

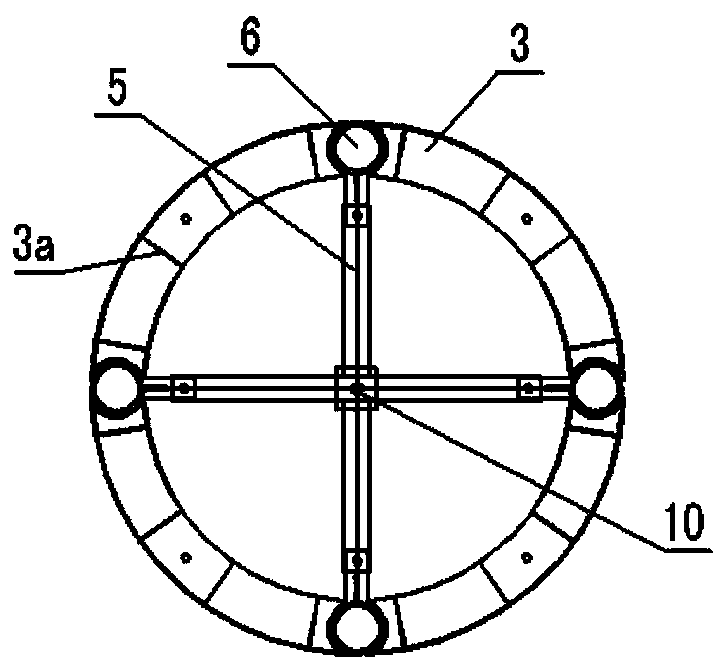

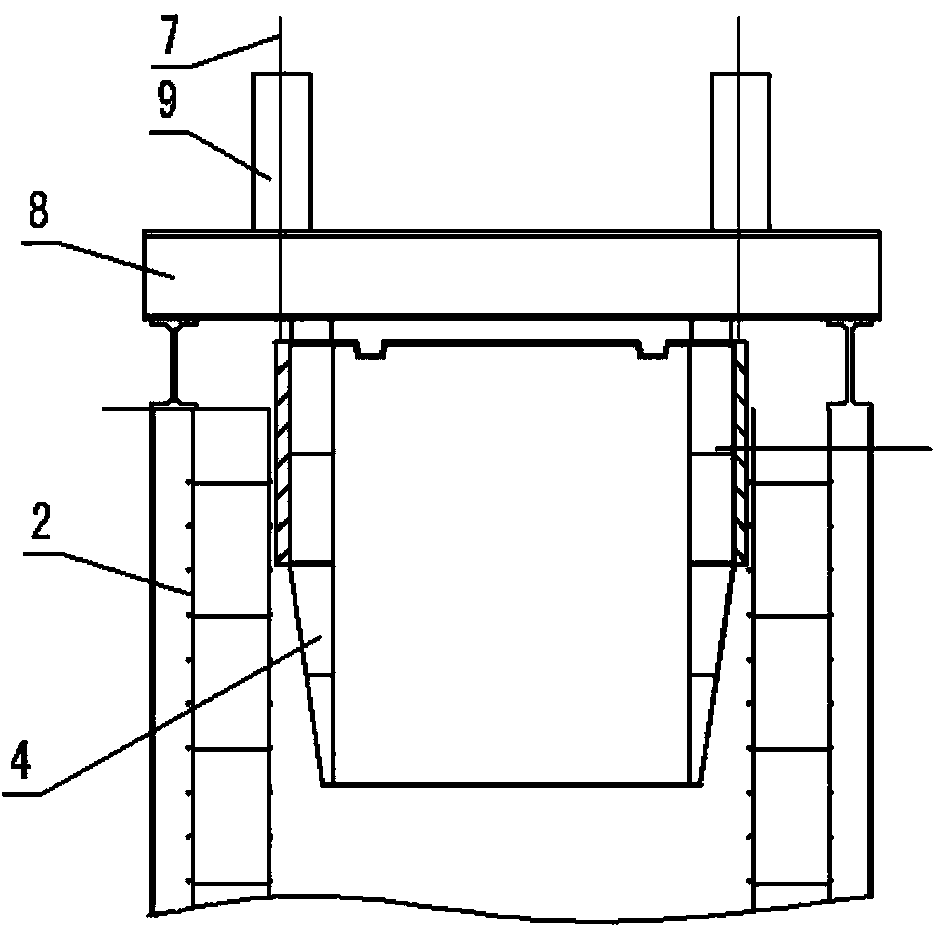

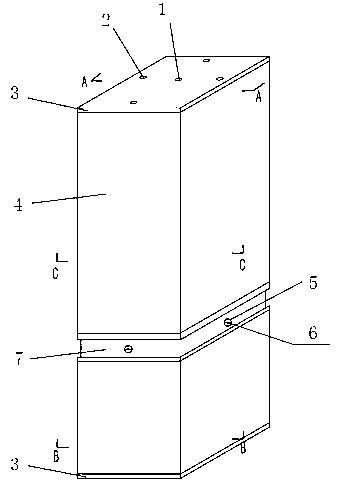

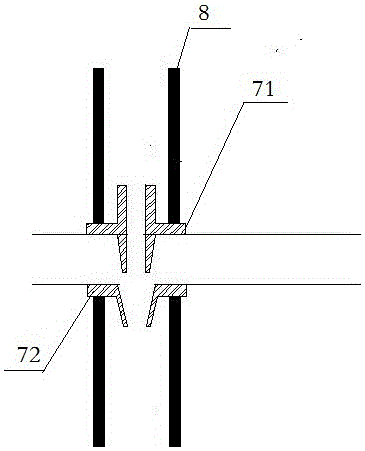

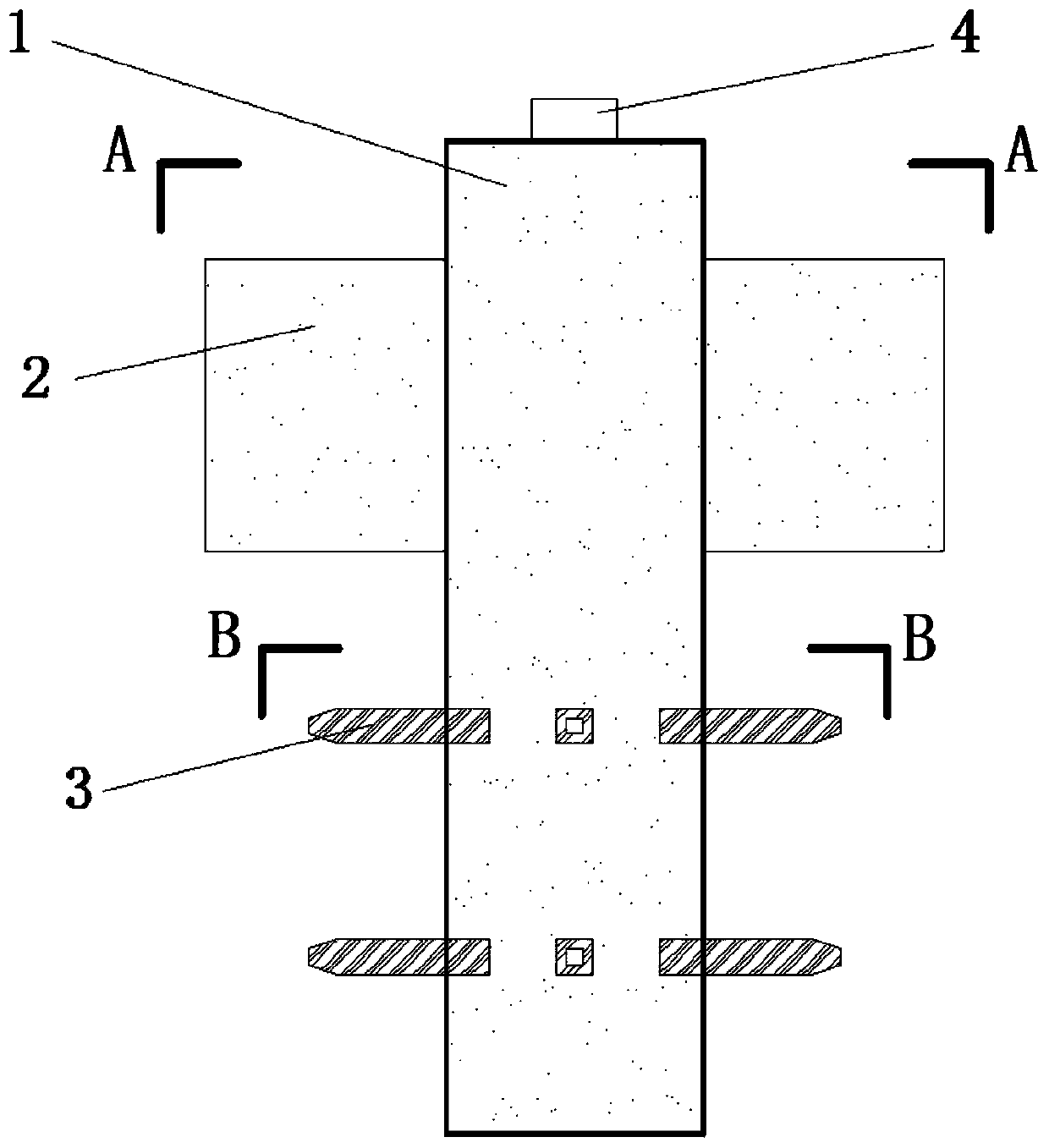

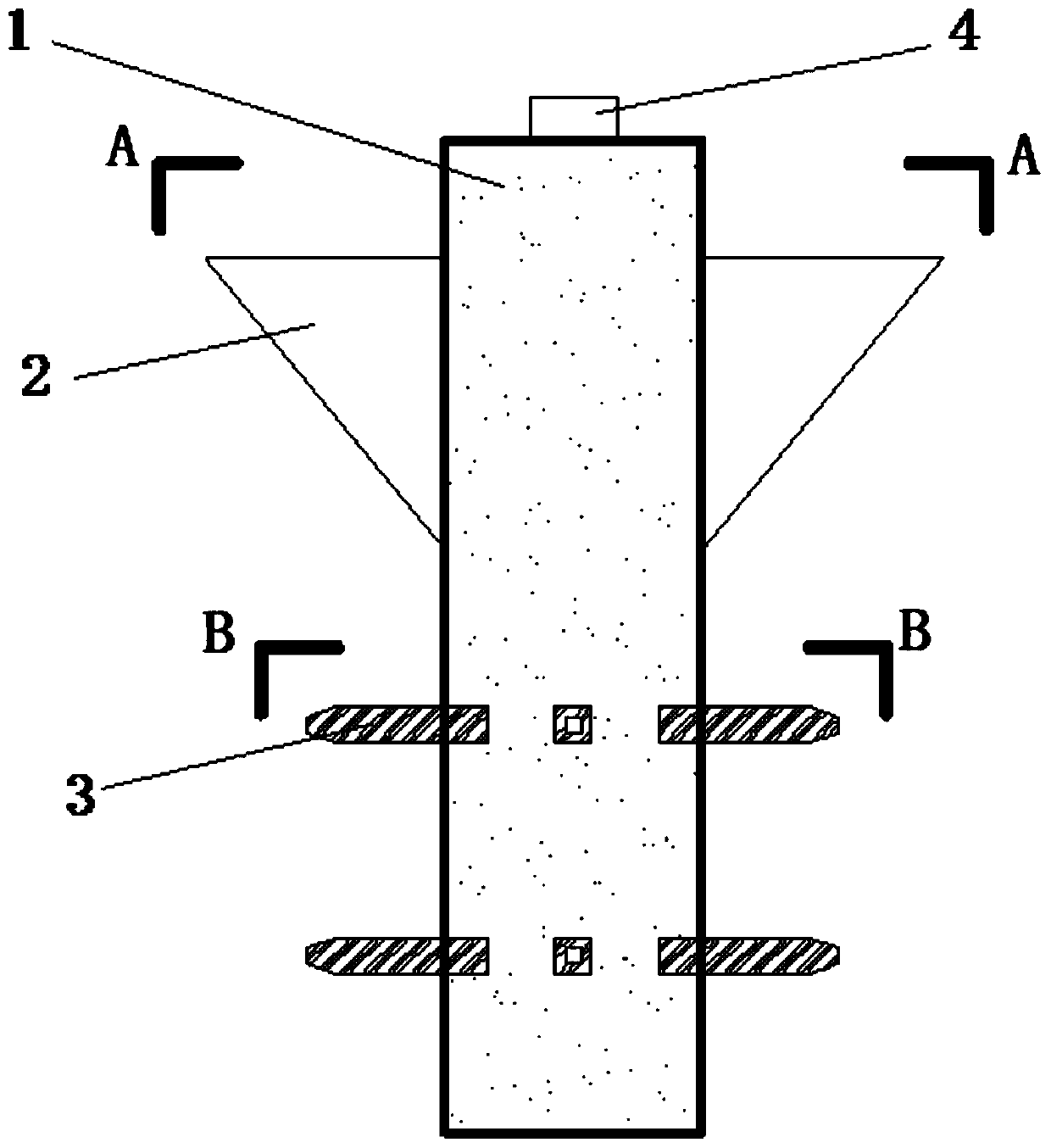

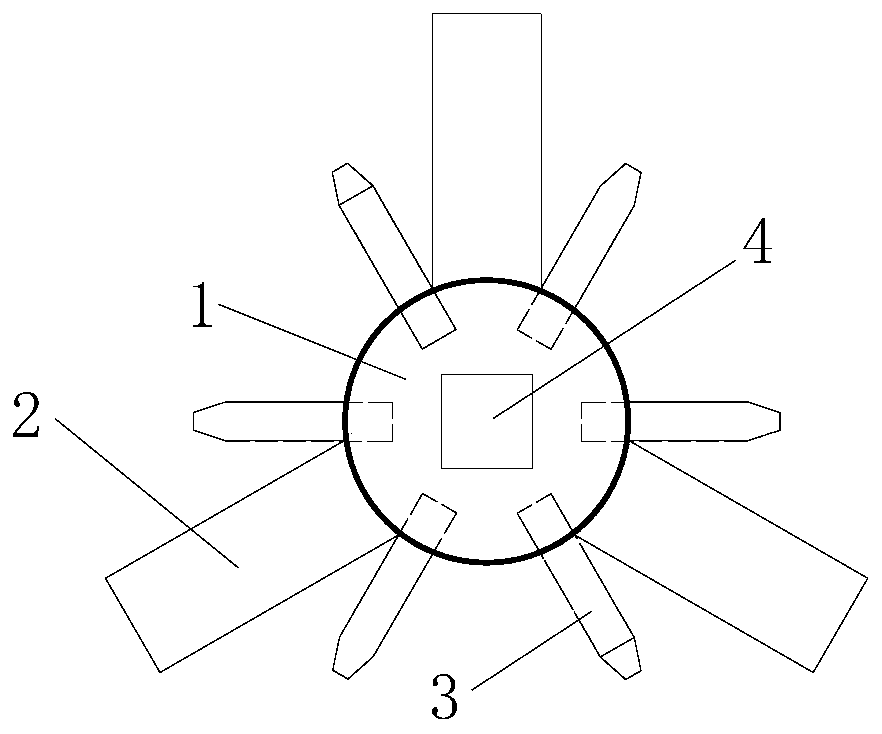

Construction method of prefabricated root key-type wing plate foundation

InactiveCN111485572AGood synergyGive full play to the role of bearingFoundation engineeringArchitectural engineeringStructural engineering

The invention discloses a construction method of a prefabricated root key-type wing plate foundation. A main concrete structure is included, and comprises a column body, wing plates and prefabricatedroot keys; an embedded part is connected to the top of the column body; the wing plates are uniformly arranged on the column body, and the wing plates and the column body are vertically intersected and close to the top; and a plurality of prefabricated root keys are vertically connected to the outer side of the column body, and the prefabricated root keys extend from the inside to the outside of the column body. According to the prefabricated root key-type wing plate foundation, the vertical and horizontal bearing capacity and lateral stiffness of the foundation can be effectively improved, the pile length and diameter of the pile foundation are reduced, the expansion of the conventional foundation is canceled, so as to reduce the safety risk, construction difficulty and engineering quantity of the foundation construction, the concrete transportation engineering quantity in mountainous is reduced, and the purposes of safety and reliability, cost saving and environmental protection areachieved.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com