A Freezing Method of High Gradient Heterogeneous Freezing Wall

A freezing method and freezing wall technology, which is applied to earth drilling, shaft equipment, mining equipment, etc., can solve the problems of broken freezing pipes, large radial deformation of frozen walls, and long freezing construction period, and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

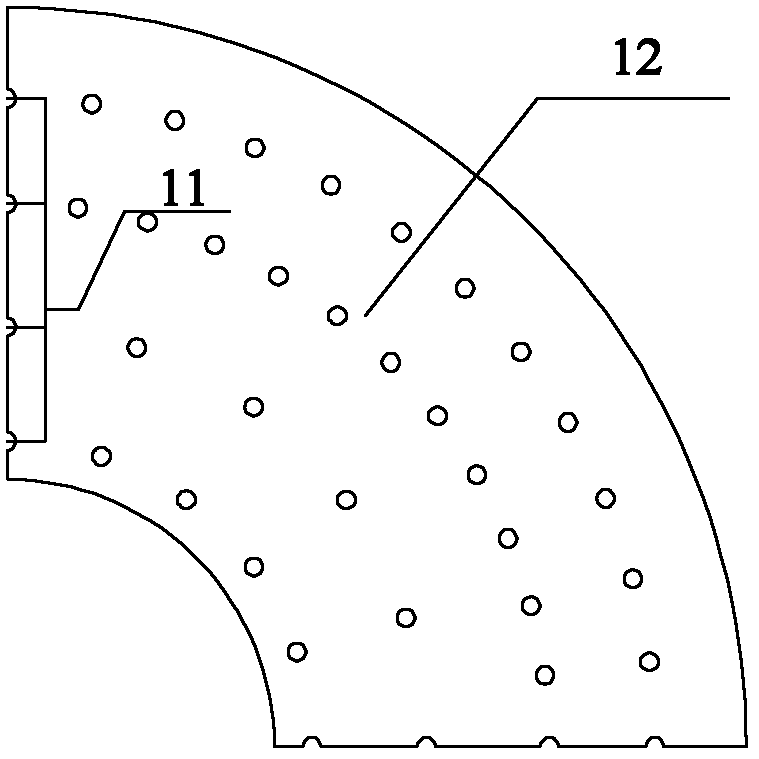

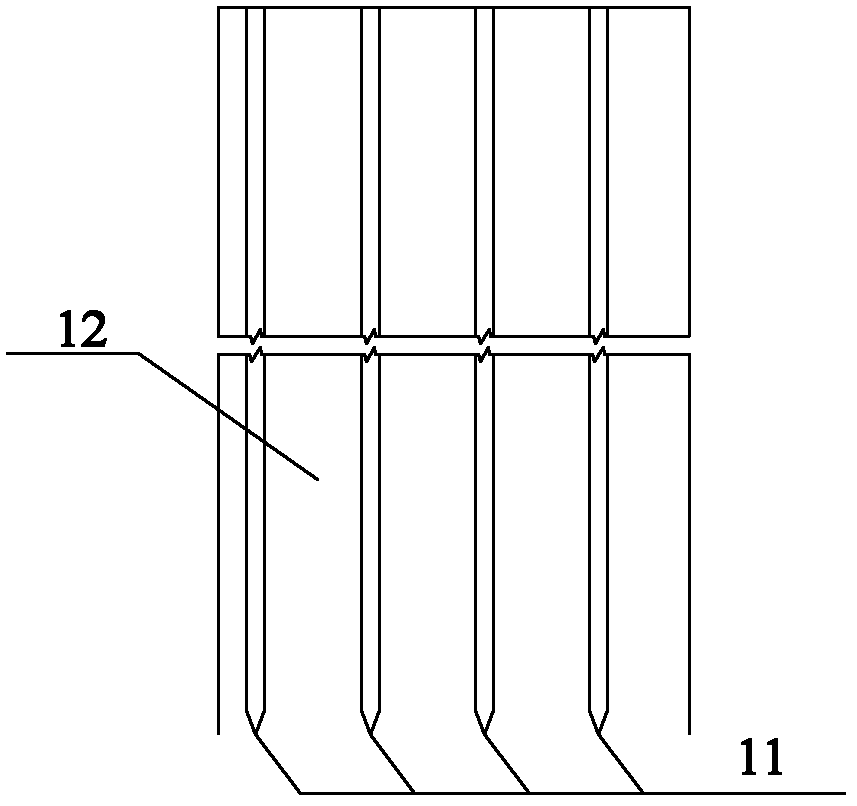

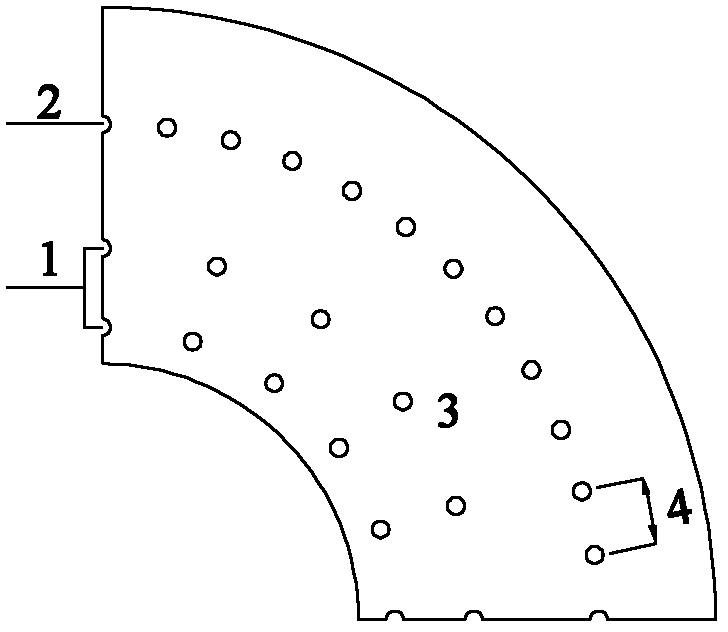

[0030] A method for freezing a heterogeneous freezing wall according to the present invention, in which brine freezing pipes and liquid nitrogen freezing pipes are arranged in a special manner, can form a high-gradient heterogeneous freezing wall 3 . It adopts the mode of brine freezing on the inner side of the freezing wall 3 and liquid nitrogen freezing on the outer side to form a temperature field in which the temperature of the freezing wall gradually decreases from the inside to the outside in the radial direction, that is, the temperature of the brine or the working temperature of nitrogen in each row of freezing tubes decreases step by step from the inside to the outside. , The temperature of brine is controlled in the range of -24~-34°C, and the working temperature of nitrogen is adjustable according to the needs, generally controlled ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com