Patents

Literature

141 results about "Frozen temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Freezer Storage. Keep your freezer at zero degrees (0°) or below to maintain the quality of frozen foods. Most foods will maintain good quality longer if the freezer temperature is -10 to -20°F. At temperatures between 0 and 32°F, food deteriorates more rapidly.

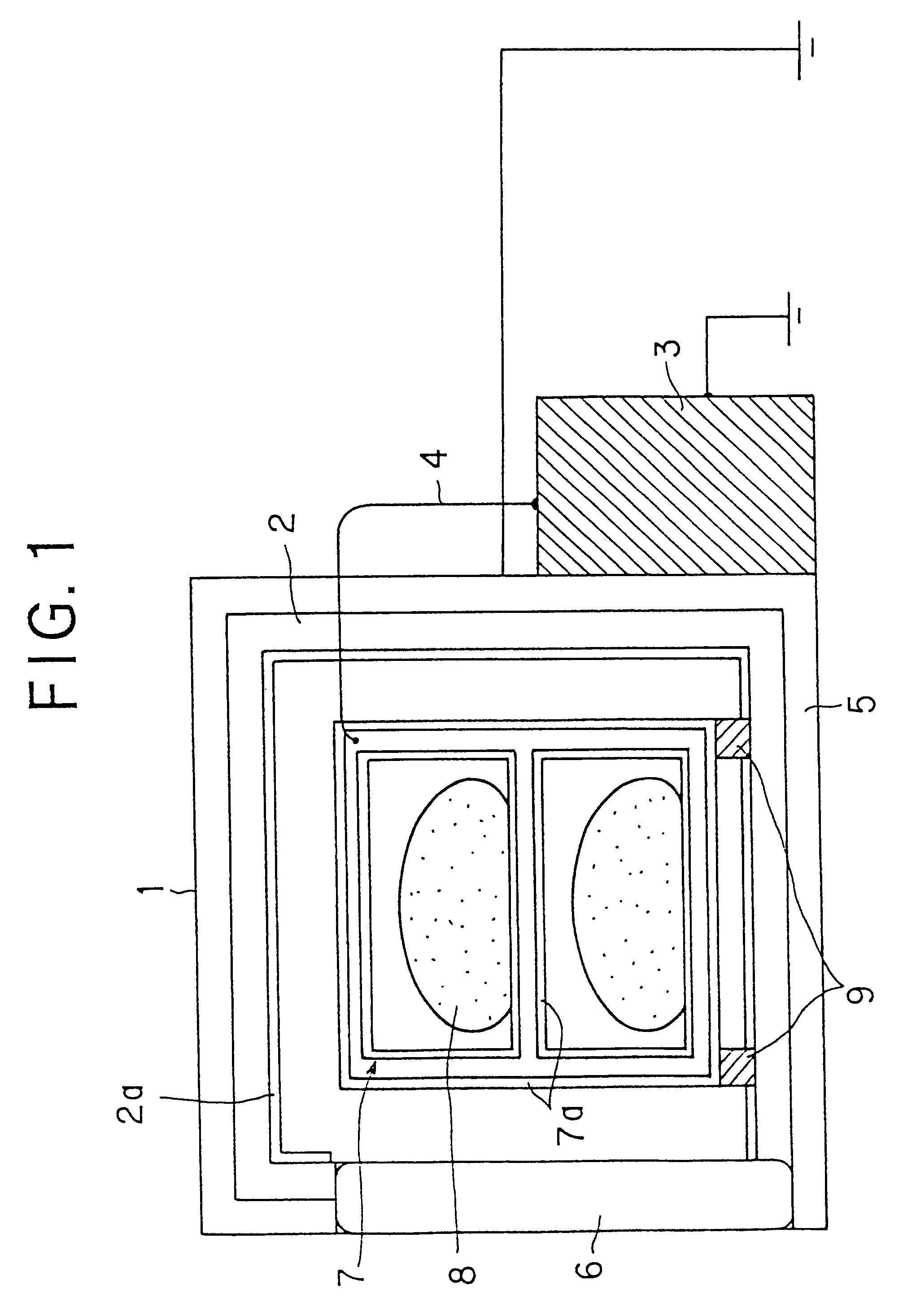

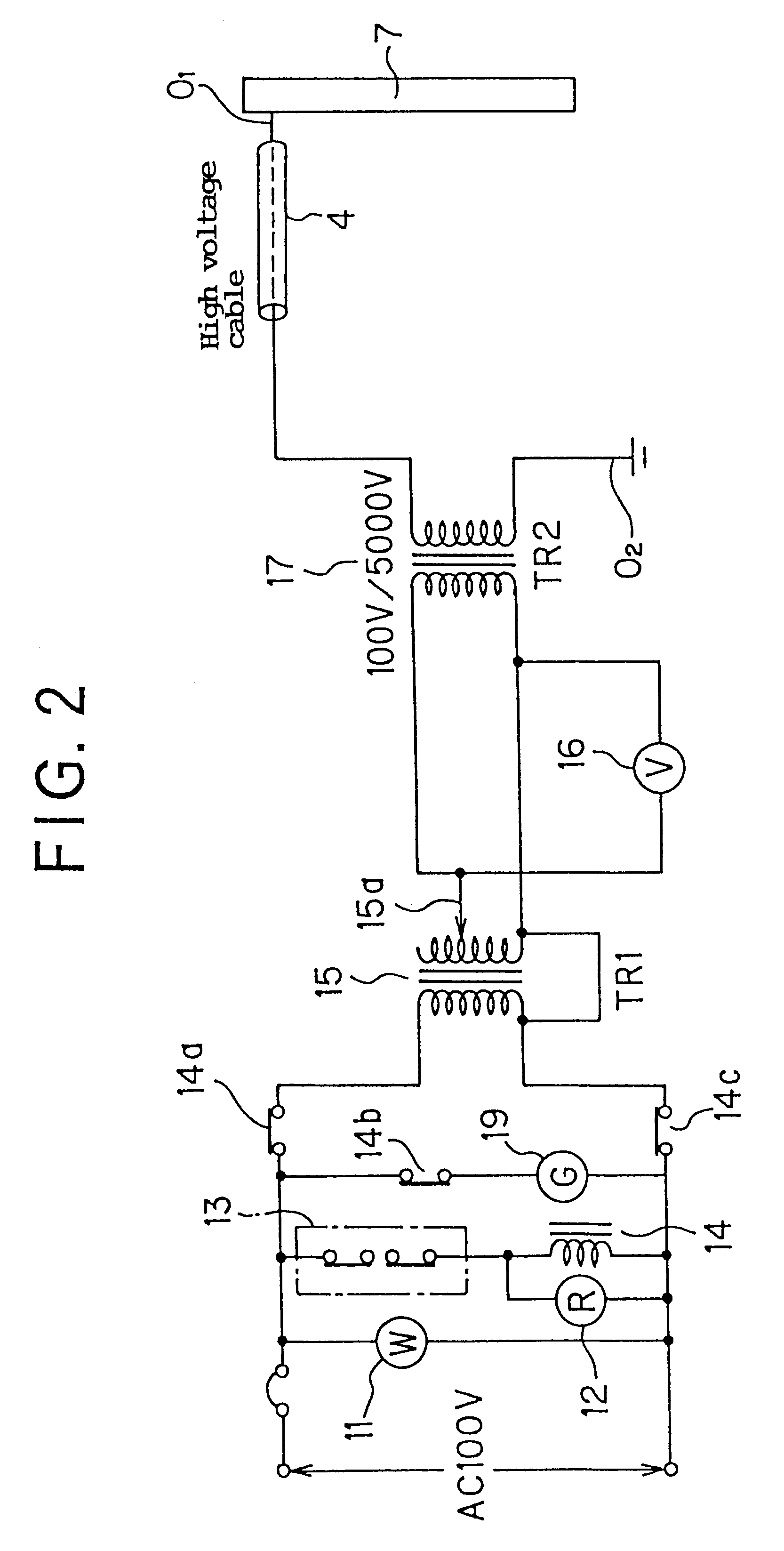

Method of treating a food object in an electrostatic field

Owner:MARS COMPANY

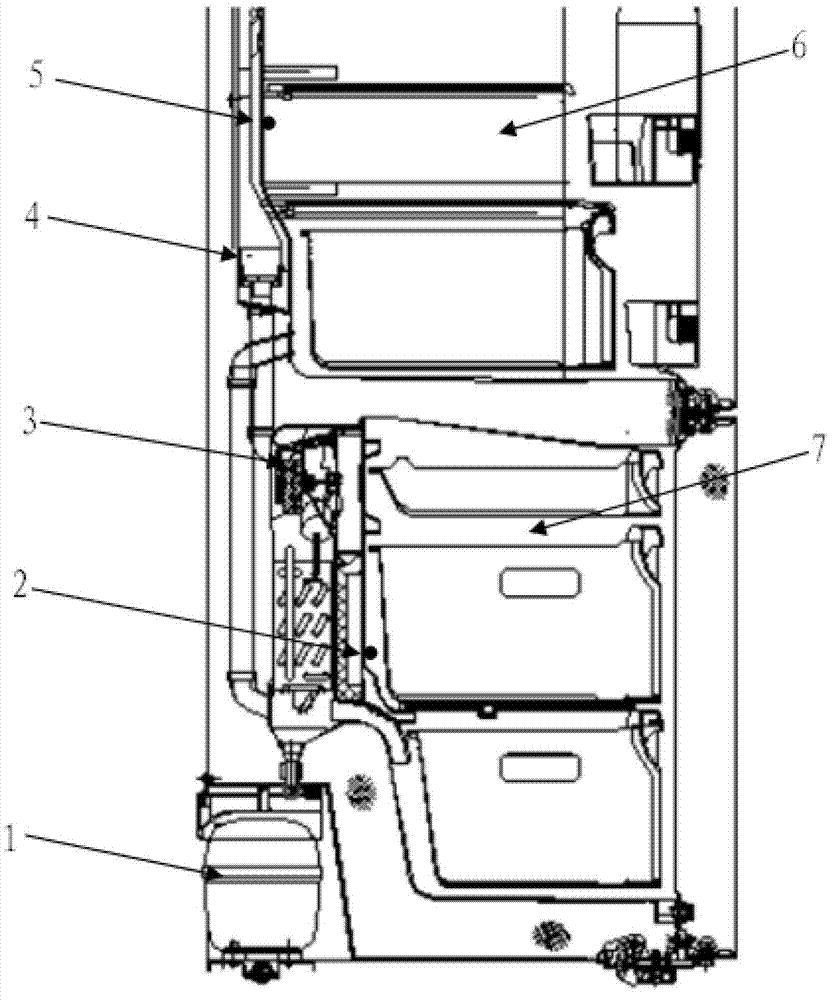

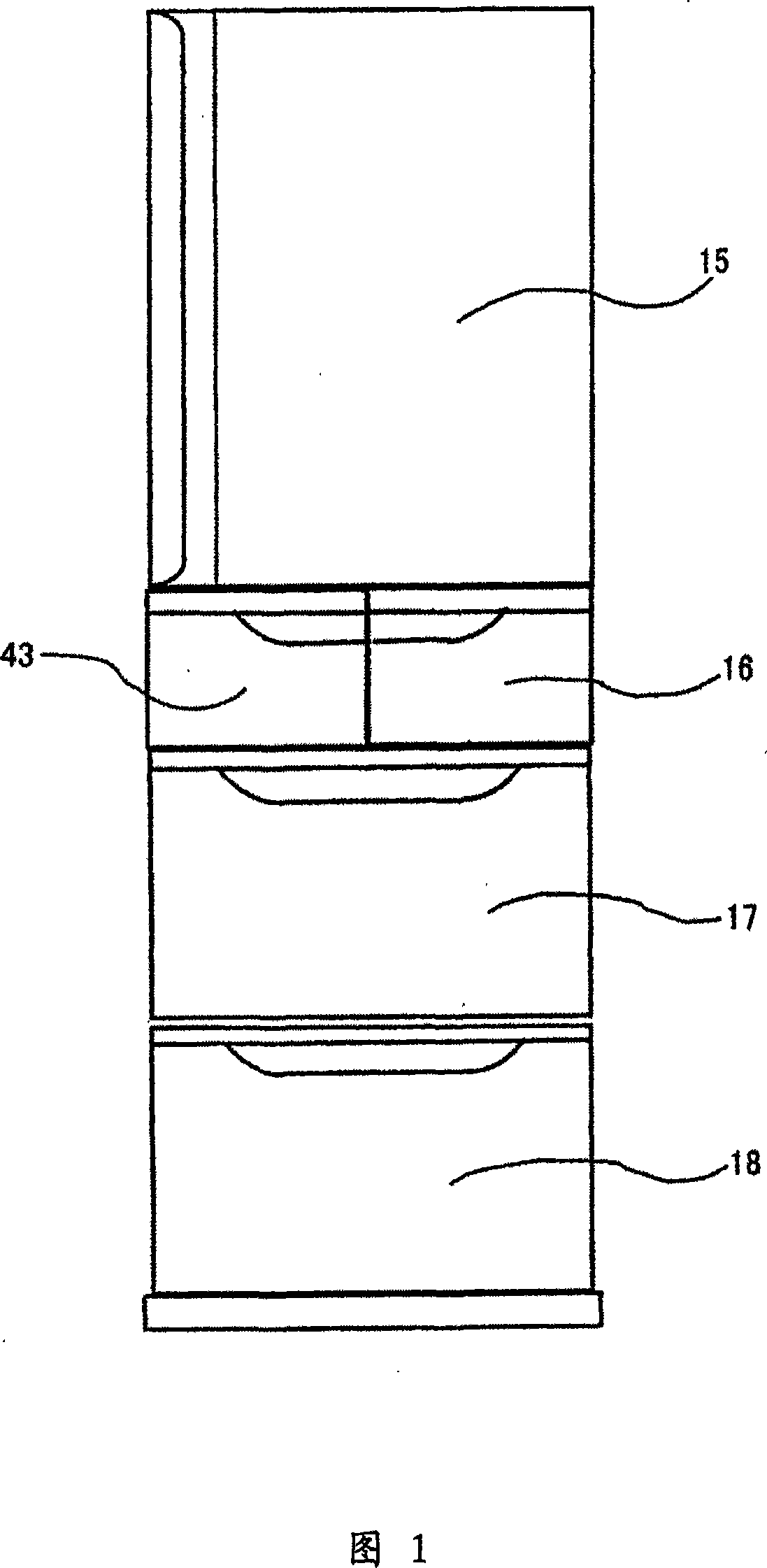

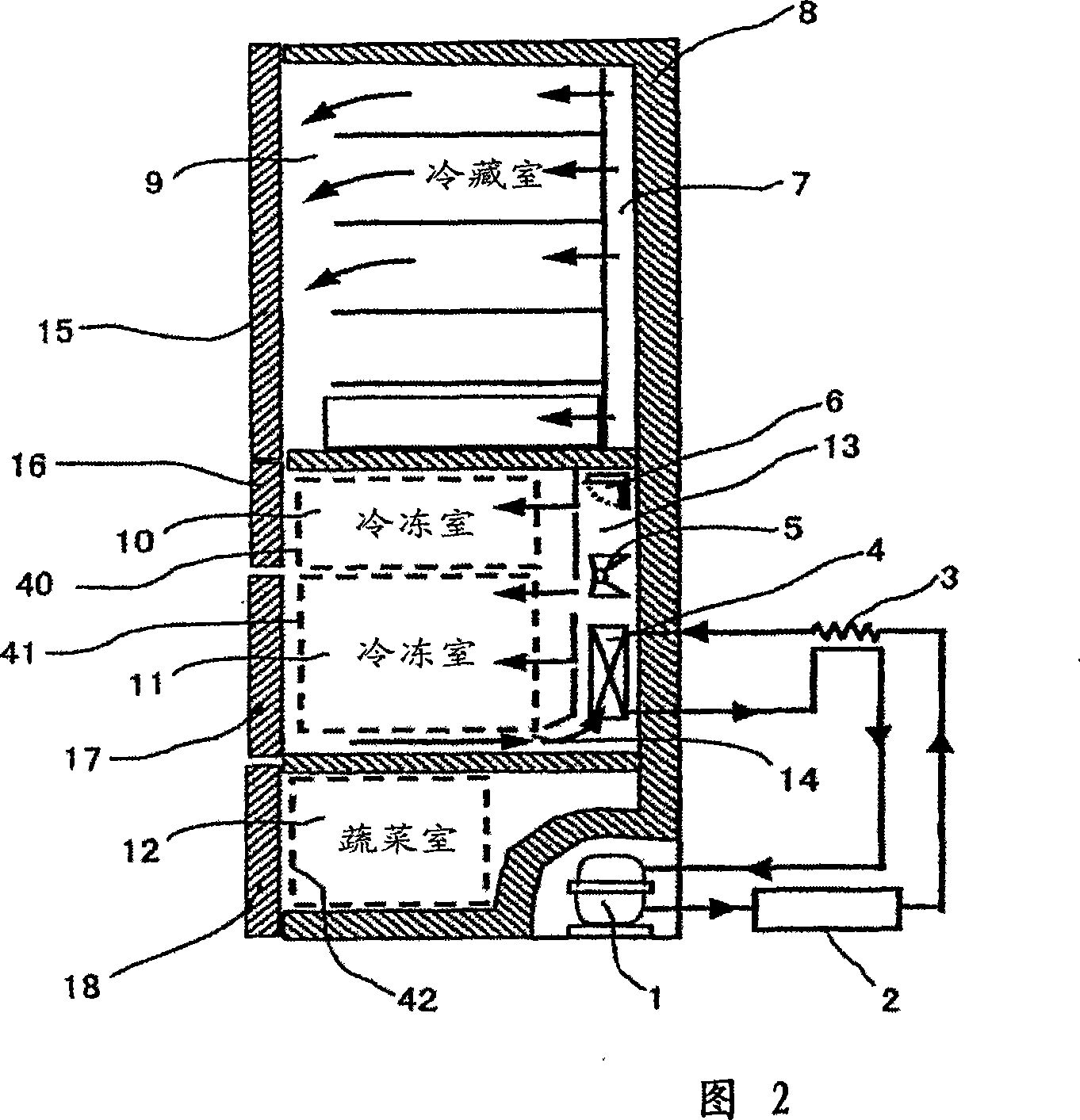

Refrigerator

InactiveCN1412509AEasy to useConvenient storage compartment layoutLighting and heating apparatusDomestic refrigeratorsPreserved FoodsUsability

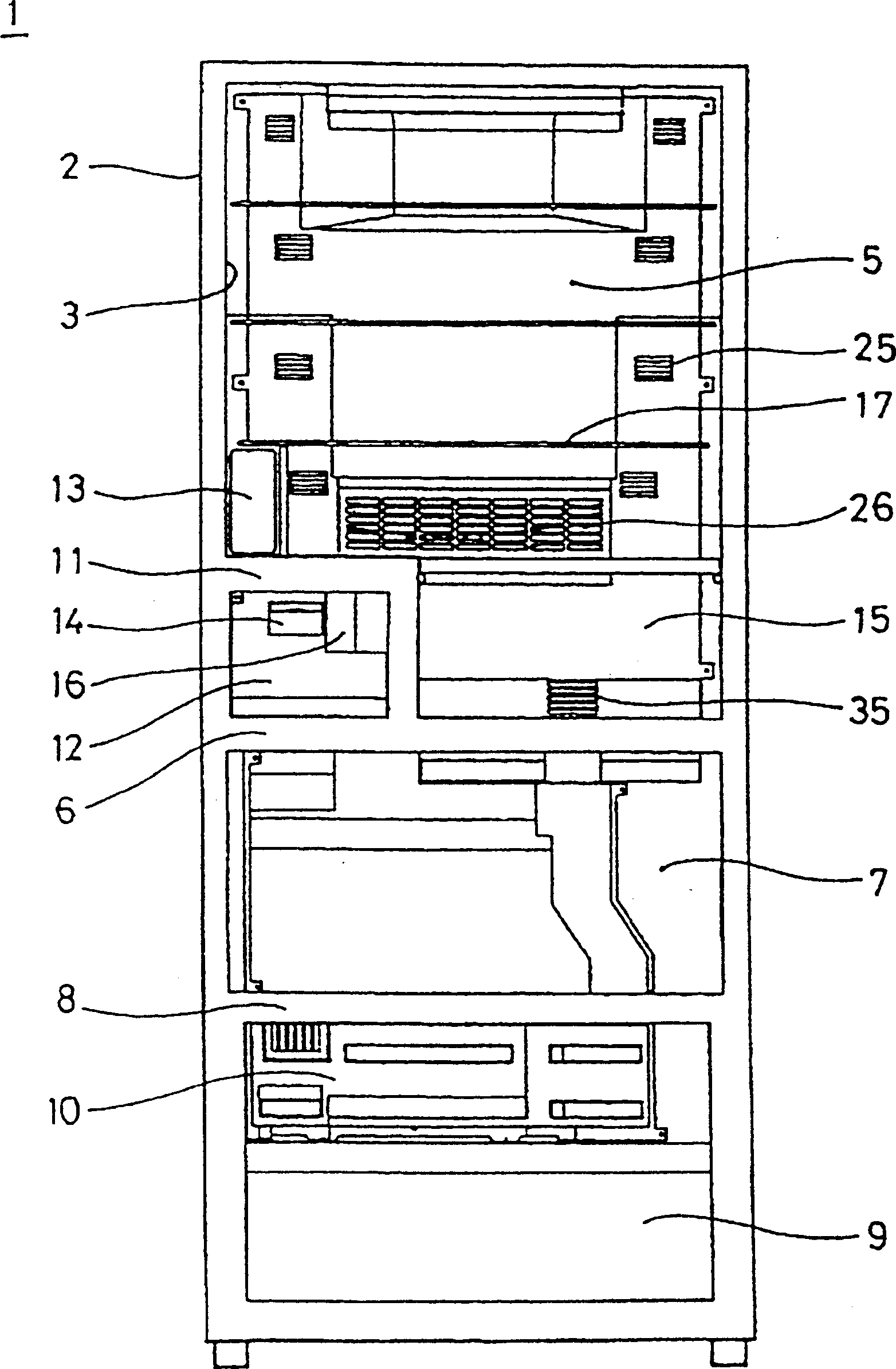

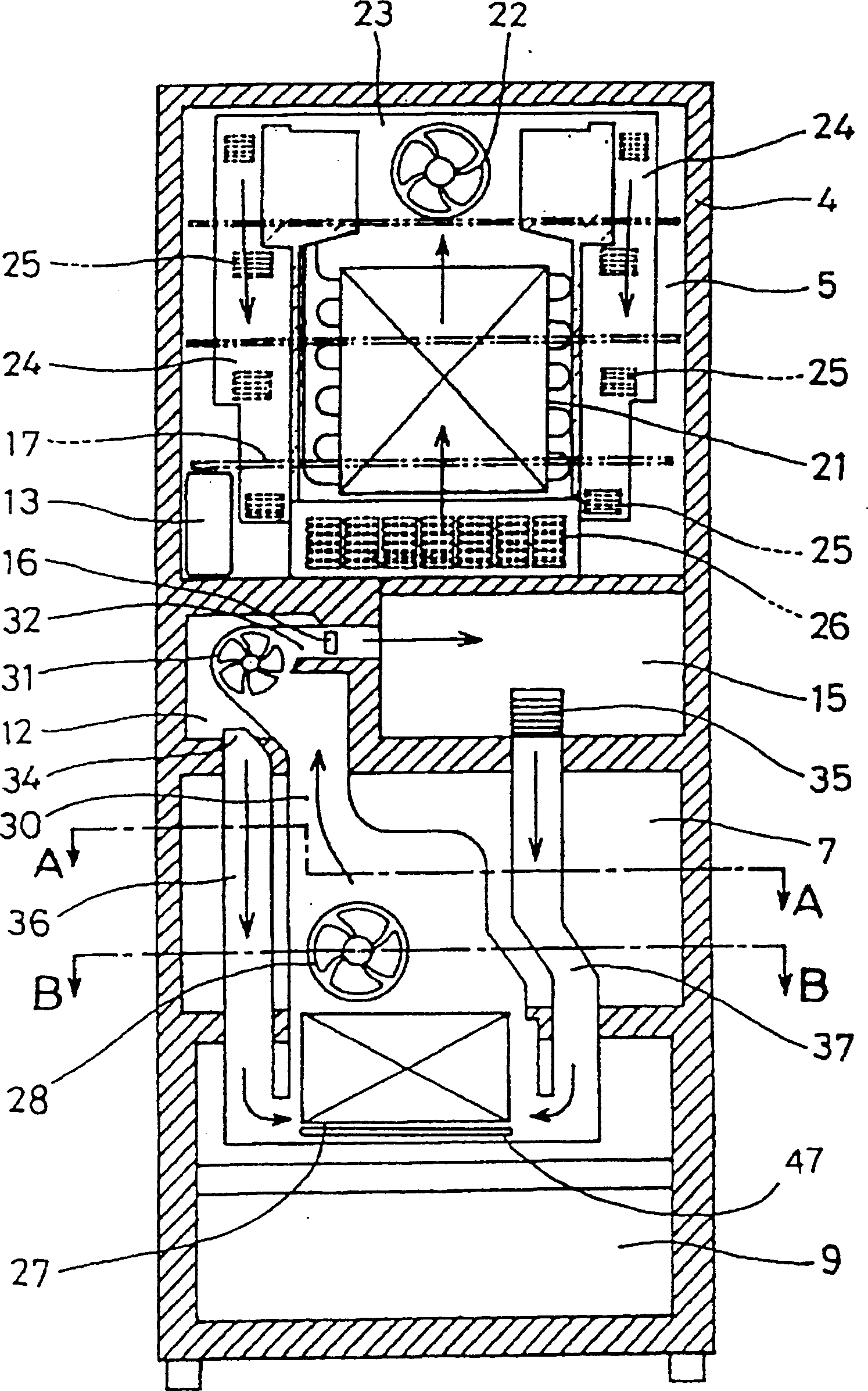

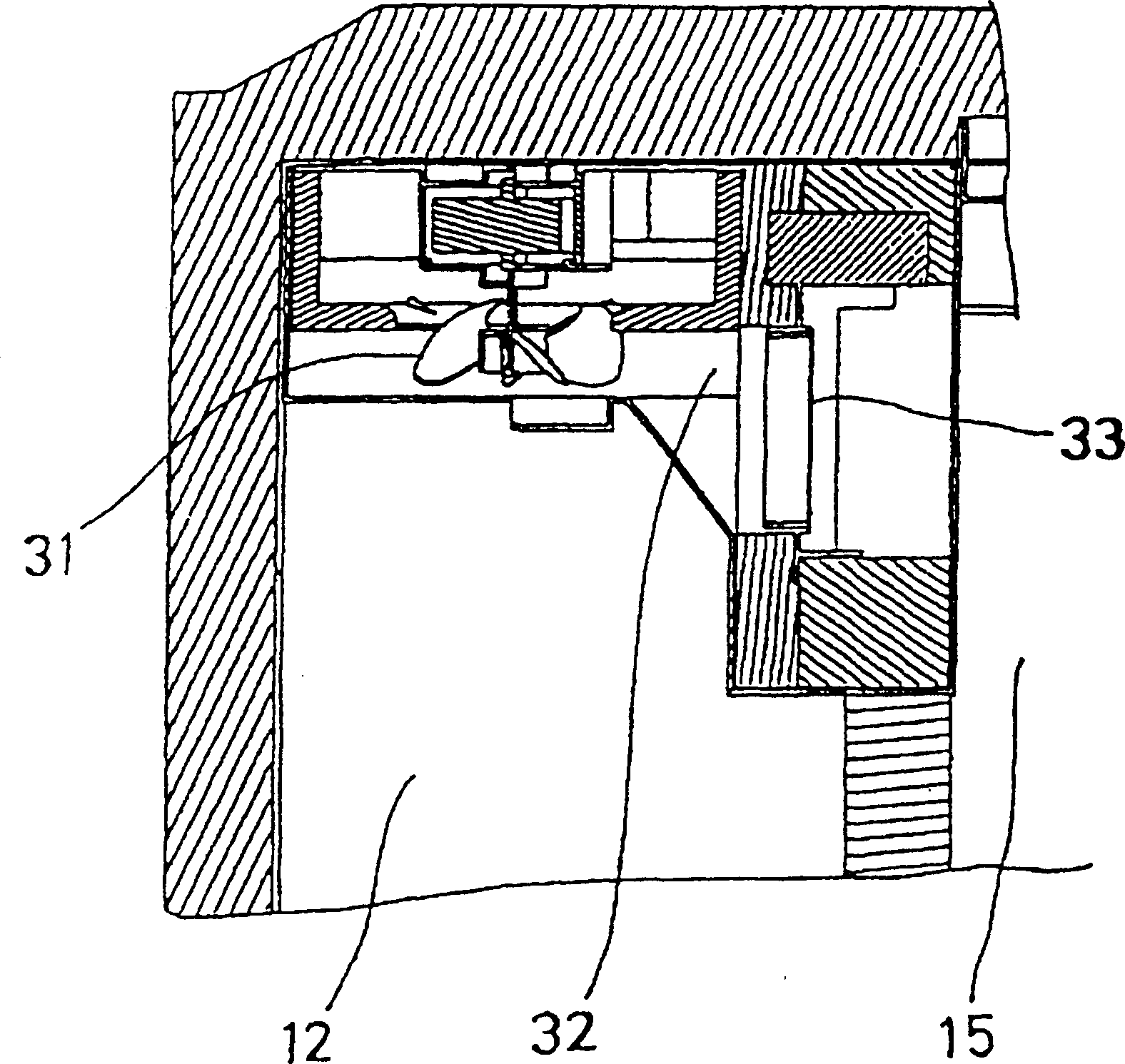

A refrigerator comprises a refrigerating room(5)disposed in the upper part of a refrigerator body; a freezing room (9) disposed in the lower part of a refrigerator body; a vegetable room(7) provided between the refrigerating room and the freezing room; the ice making room (12) disposed in the corner of the bottom part of the refrigerating room having an automatic ice making device; and an ice making fan(31) provided in the rear part of the ice making room; The cooling air produced by the refrigeration cooler is sent to the ice making room via a duct(30) and the ice making fan(31), and a cooling air duct including the freezing fan and a return duct from the ice making room are jointly provided in the rear surface of the vegetable room; A weak freezing chamber (6) is disposed in a freezing space (40), and a damper (37) is disposed in a back face of the weak freezing chamber (6). wall in a freezing space (40) and a damper (37) is disposed in a back face of the weak freezing chamber (6). When weak freezing is performed for food in the weak freezing chamber (6), the damper (37) is made into an open state, cooling air is forced to flow in, resulting in a rapid freezing operation up to a maximum ice crystal generation zone or lower. Subsequently, a heater (43) is initiated and the food is maintained in the weak freezing temperature zone. The present invention provides a layout of a storage room of a usability, Furthermore, it may maintain fresh degree and taste of food with weak frozen temperature when preserving food.

Owner:KK TOSHIBA

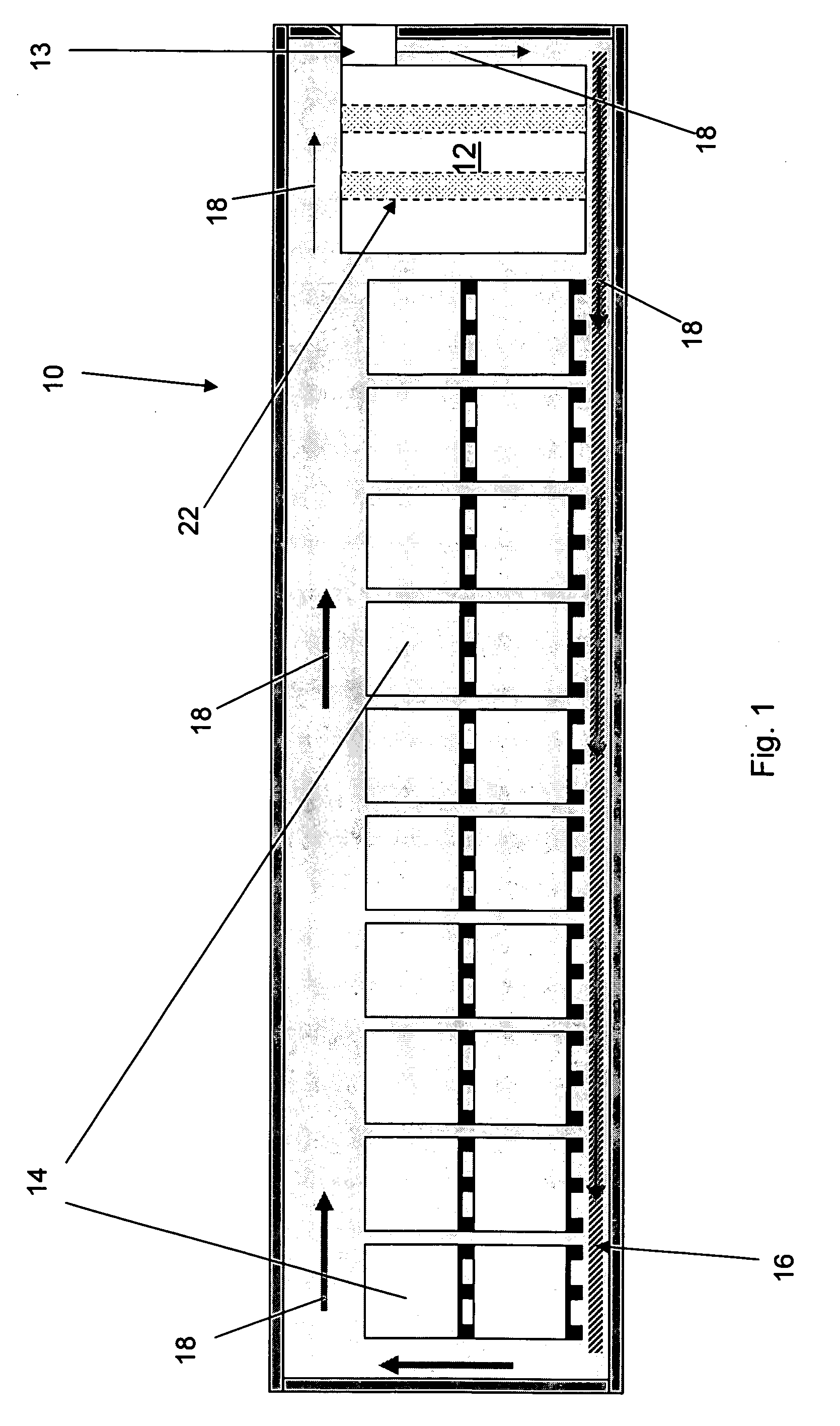

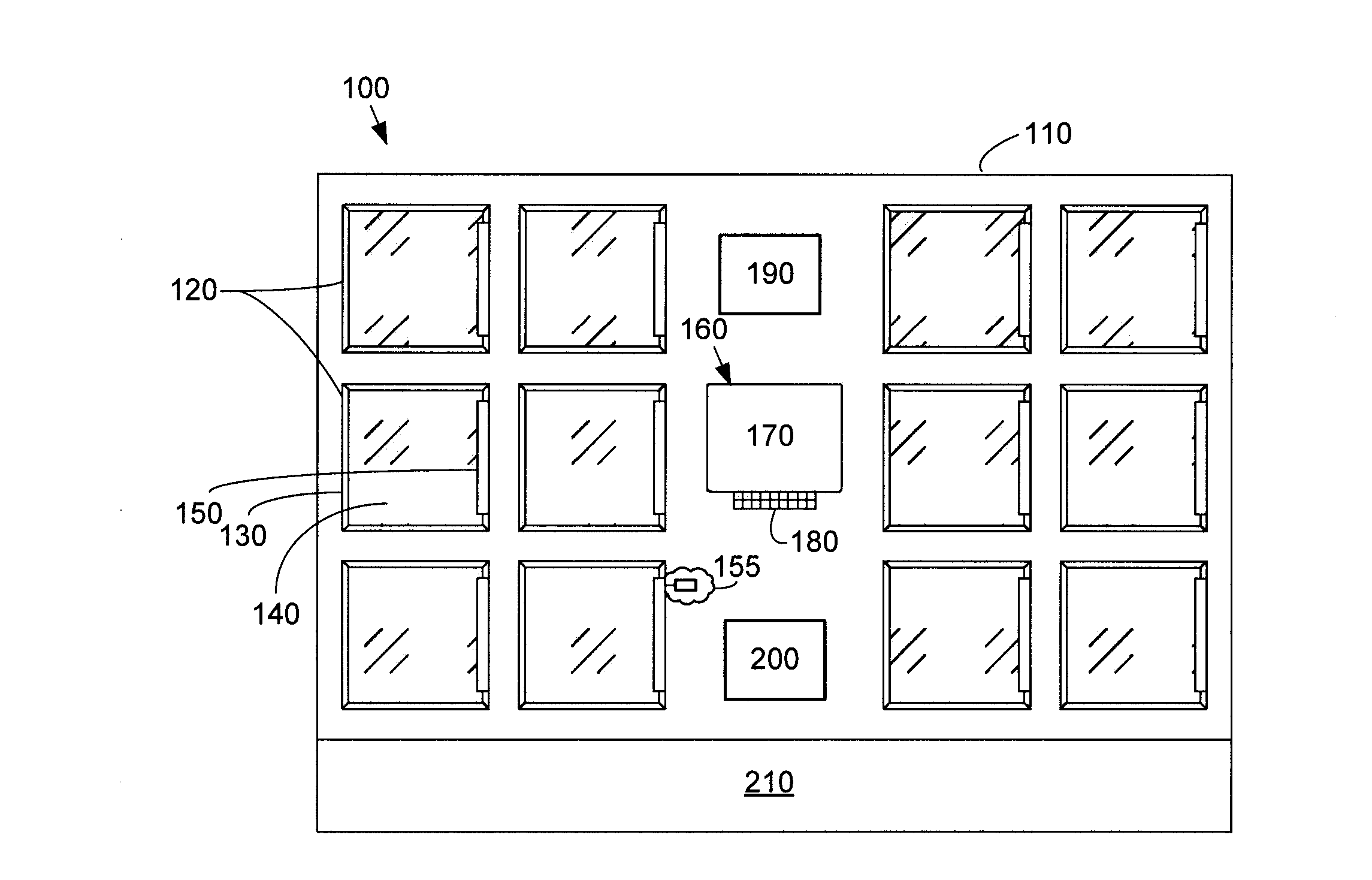

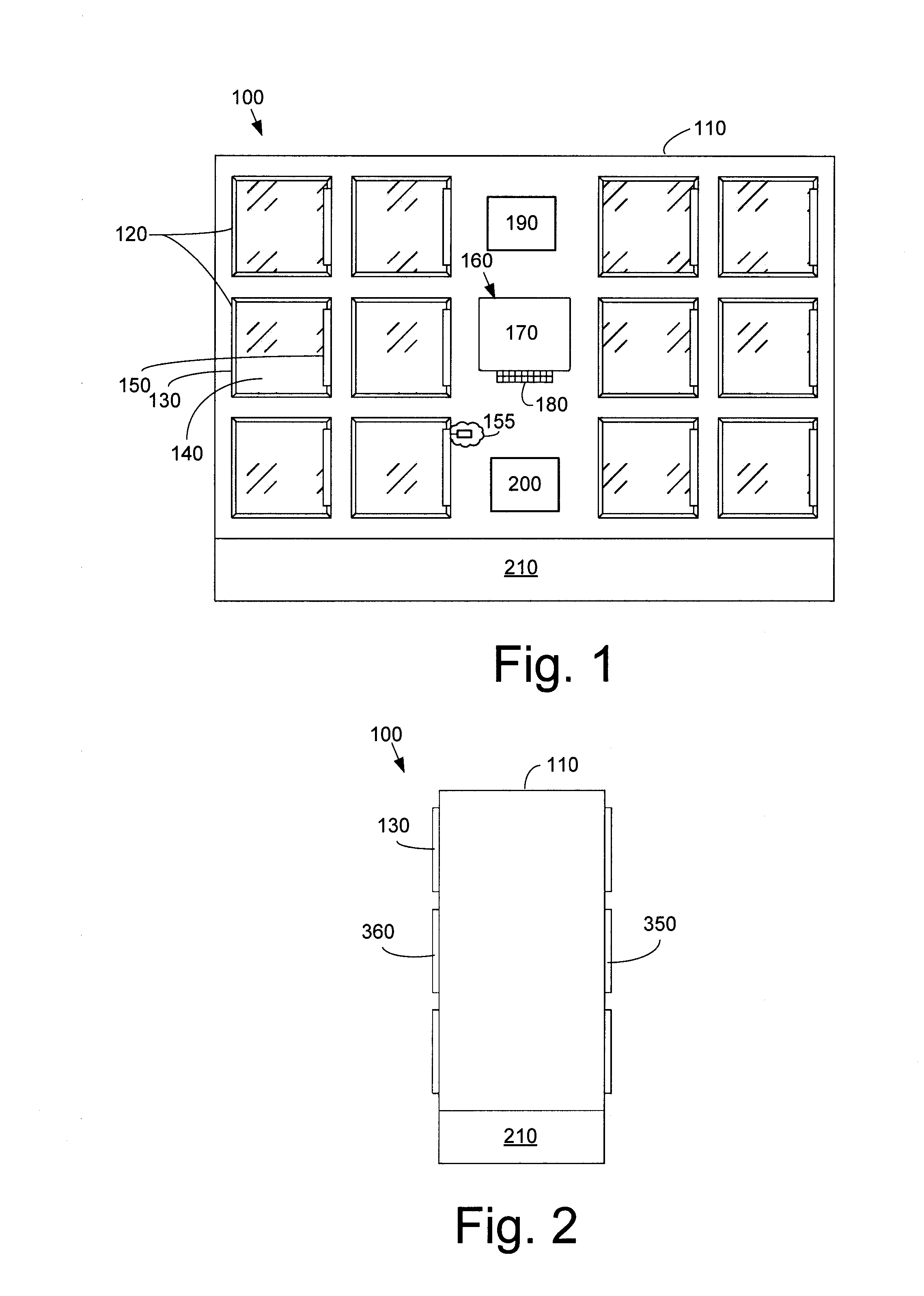

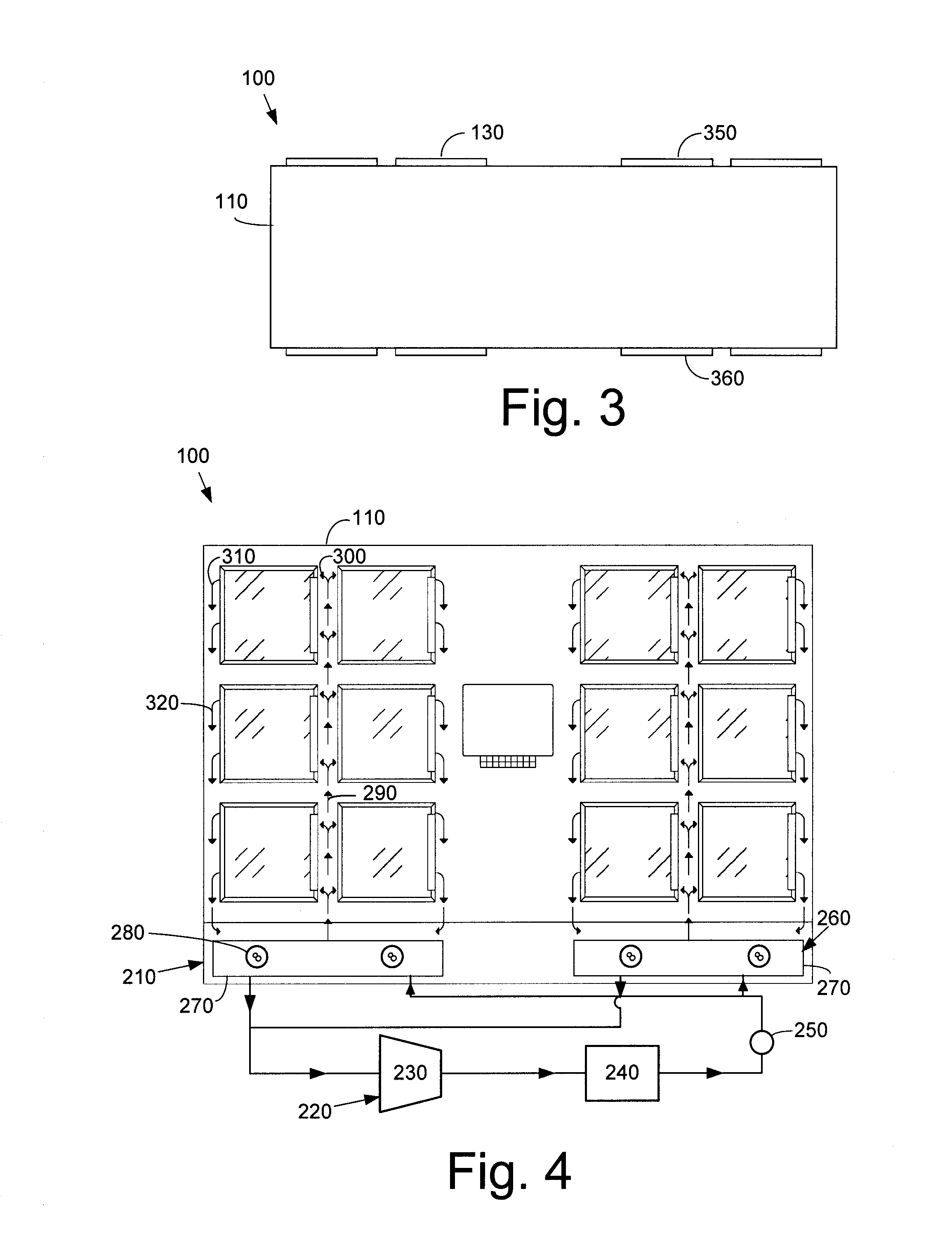

Locker system

ActiveUS20170215620A1Easy and fast switchingEasy to controlKitchen equipmentIndividual entry/exit registersTemperature controlEngineering

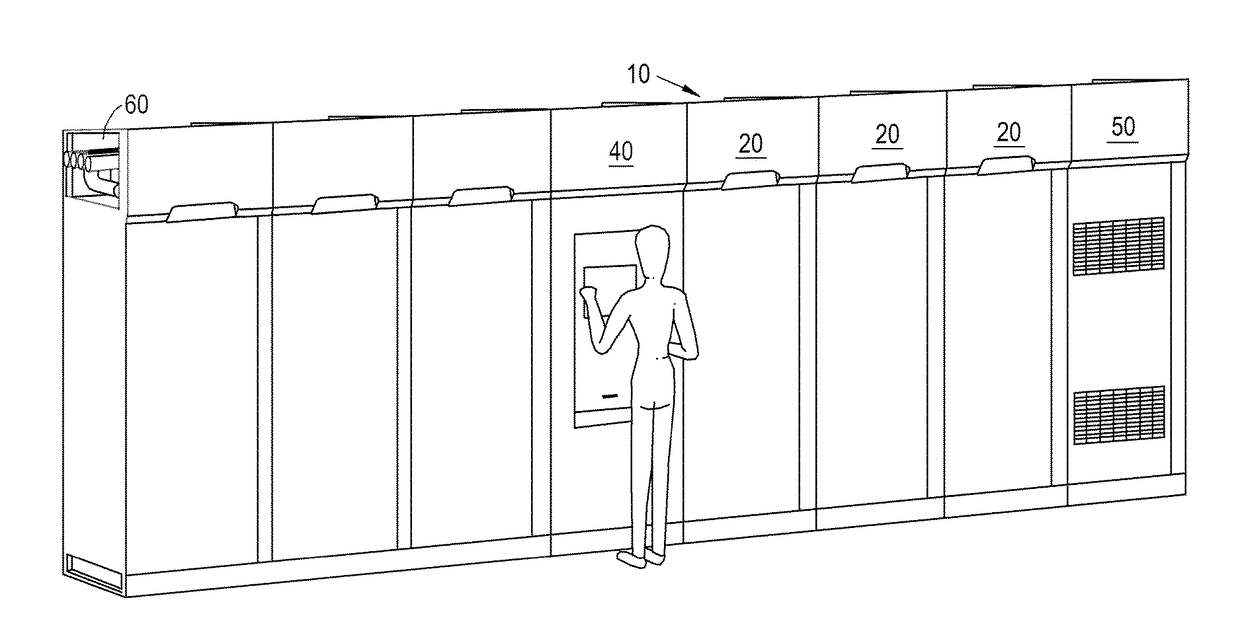

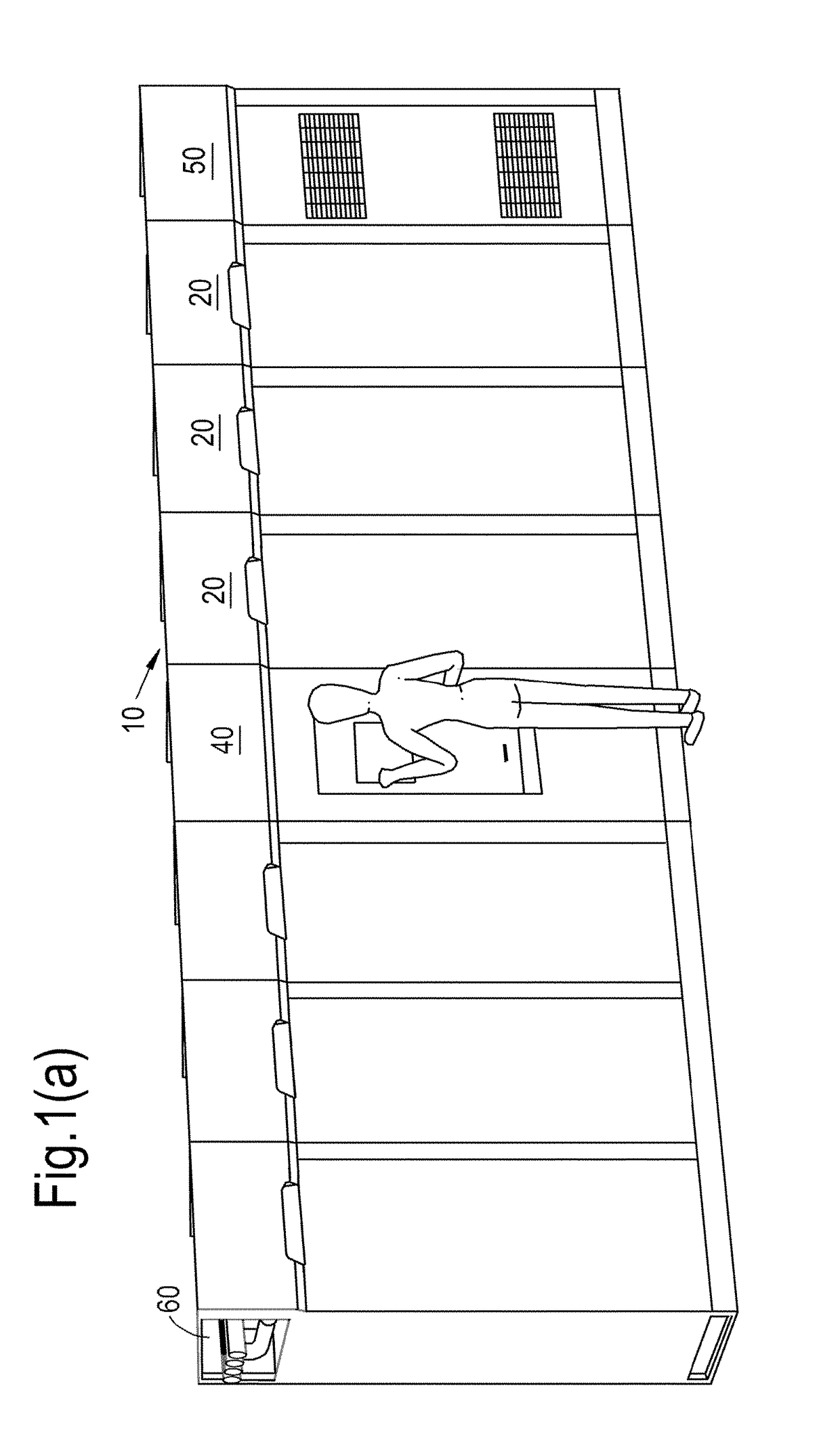

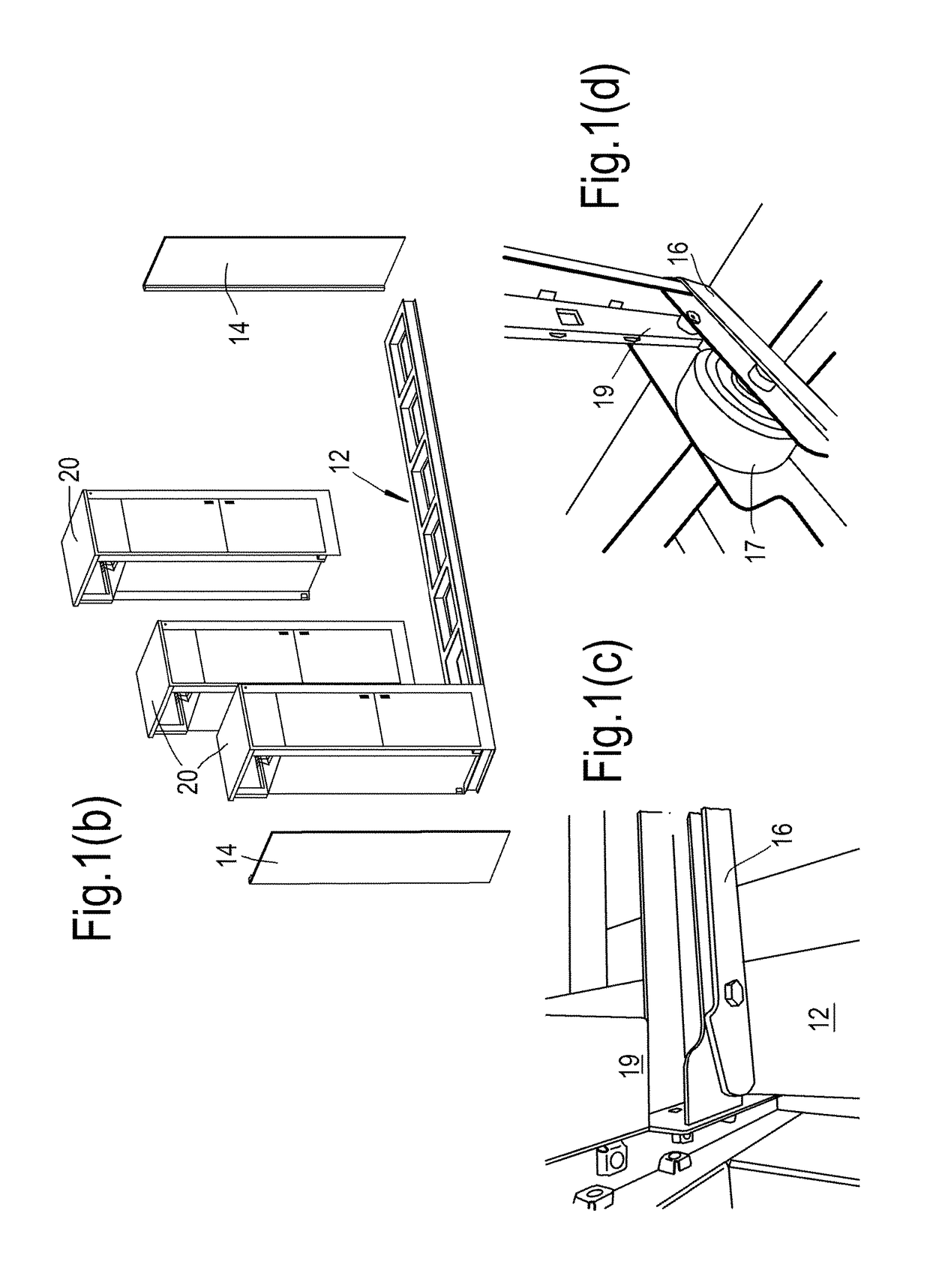

A temperature controlled storage apparatus 8(10), comprising; a plurality of lockable storage spaces, each of the plurality of lockable storage spaces comprising one or more compartments; in which the temperature of each of the one or more compartments is independently controllable to provide either one of: chilled temperature; or frozen temperature; and wherein access to the storage space is remotely programmable.

Owner:ILLINOIS TOOL WORKS INC

Frozen evaporator coil detection and defrost initiation

ActiveUS20150204589A1Mechanical apparatusCompression machines with non-reversible cycleTemperature controlEngineering

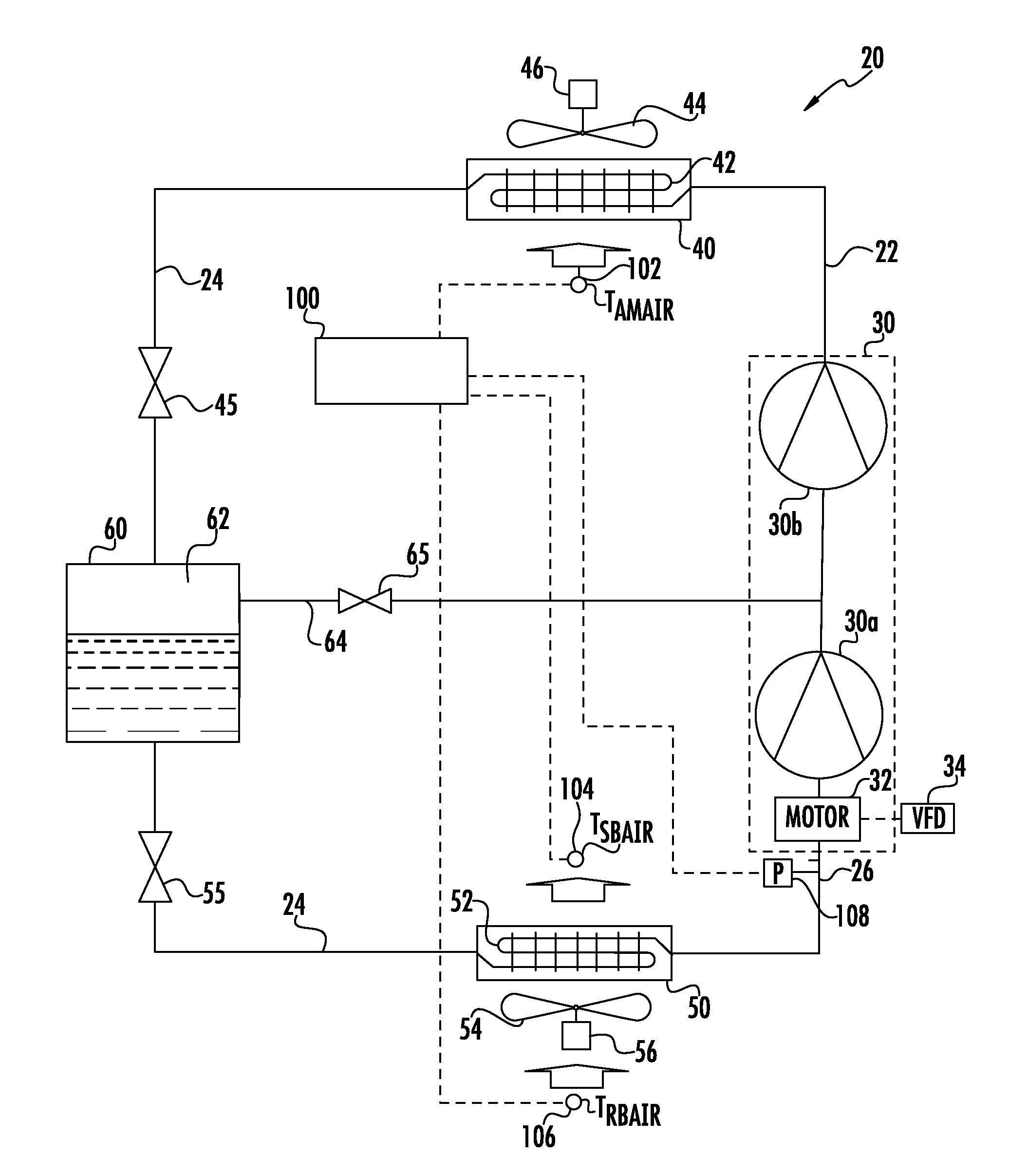

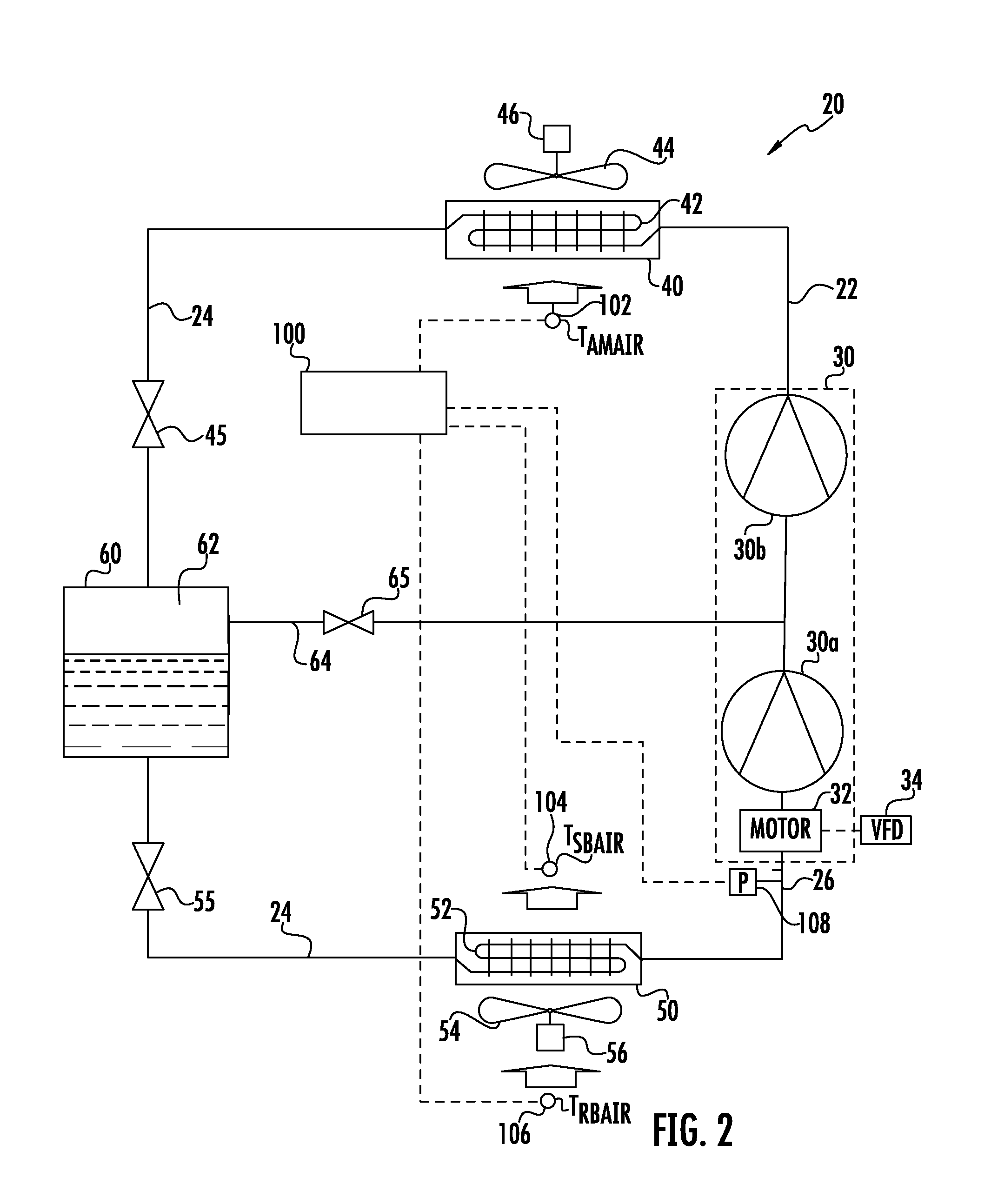

A method is disclosed or detecting a frozen evaporator coil of a refrigerant vapor compression system for supplying conditioned air to a temperature controlled space before ice build-up on the evaporator coil becomes so excessive as to result in an undesirable on-off cycling of the refrigerant vapor compression system compressor when operating to a frozen temperature maintenance mode. The method may also include initiating a defrost of a frozen evaporator coil of the refrigerant vapor compression system before ice build-up on the evaporator coil becomes so excessive as to result in an on-off cycling of the refrigerant vapor compression system compressor when operating to a frozen temperature maintenance mode.

Owner:CARRIER CORP

Method for drying blueberries by utilizing vacuum freezing technology

InactiveCN101518280AAnthocyanin content does not decreaseQuality assuranceFruit and vegetables preservationWorking pressureFreeze-drying

A method for drying blueberries by utilizing vacuum freezing technology comprises the following processing steps: 1) blueberries are washed, pulped and uniformly agitated to prepare pulp material; 2) the pulp material is put into a vacuum freezing room by a stone holder to be dried under the process condition with the working pressure of 30 Pa to 70 Pa, the freezing temperature of -10 DEG C to -30 DEG C, the freezing time of 4h to 5h, the sublimation temperature of 10 DEG C to 50 DEG C and the resolution temperature of 10 DEG C to 50 DEG C until the pulp material has a thickness of 4-8 mm; and 3) the dried pulp material is crashed by a vacuum freezing drying muller and sieved by a sieve of 80 meshes to 120 meshes to obtain powder which is dry blueberry products. The invention has the advantages that the method for drying blueberries by utilizing the vacuum freezing technology can effectively ensure the quality and the active ingredient of the blueberry, is applicable to different kinds of blueberries and easy to implement, has stable process conditions and is suitable for large-scale manufacturing production.

Owner:WODELV WORLD TIANJIN BIOLOGY TECH

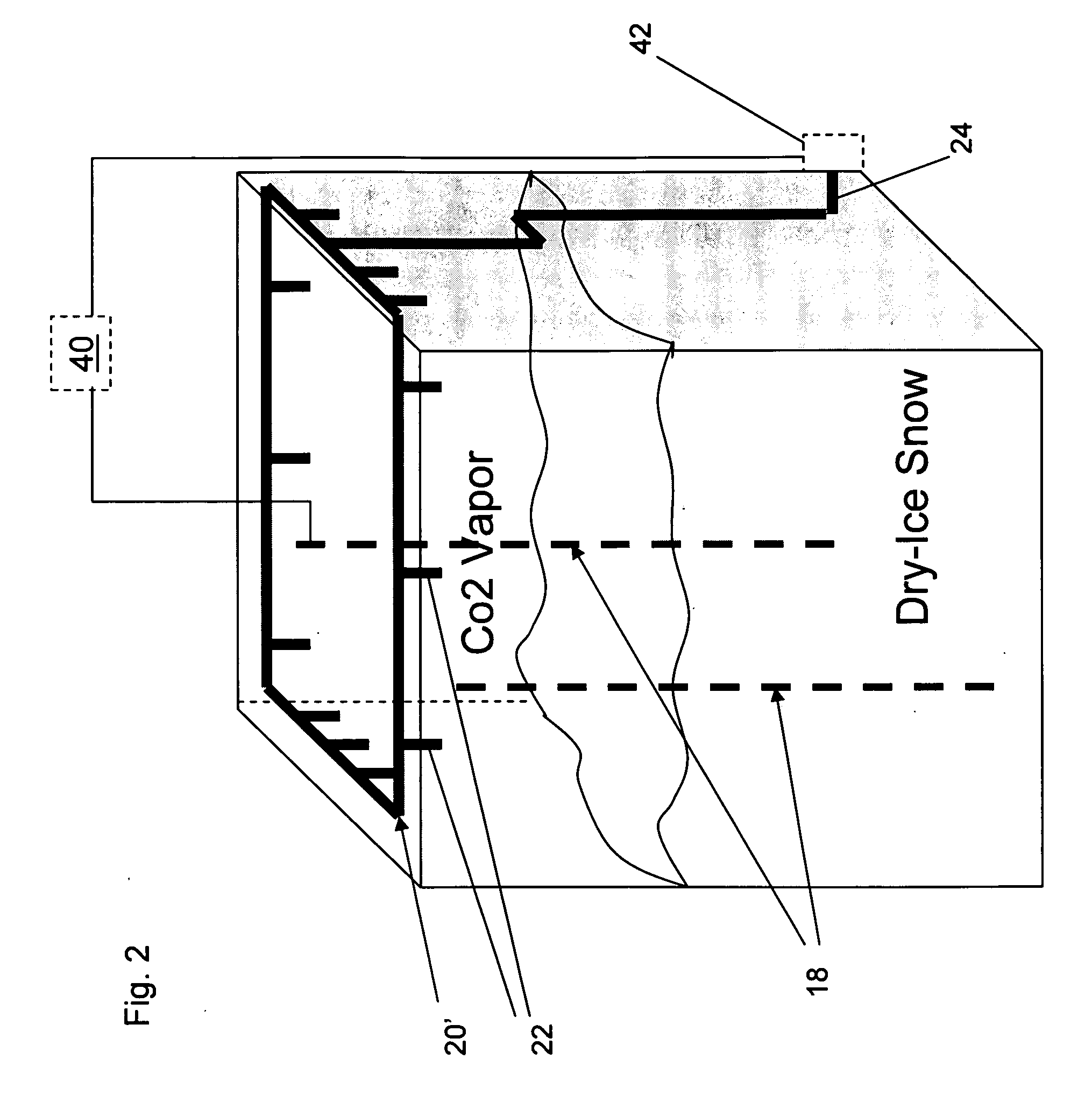

Refrigerated Container for Super Frozen Temperatures

InactiveUS20090183514A1Increase temperatureAir-treating devicesDomestic cooling apparatusEngineeringRefrigerant

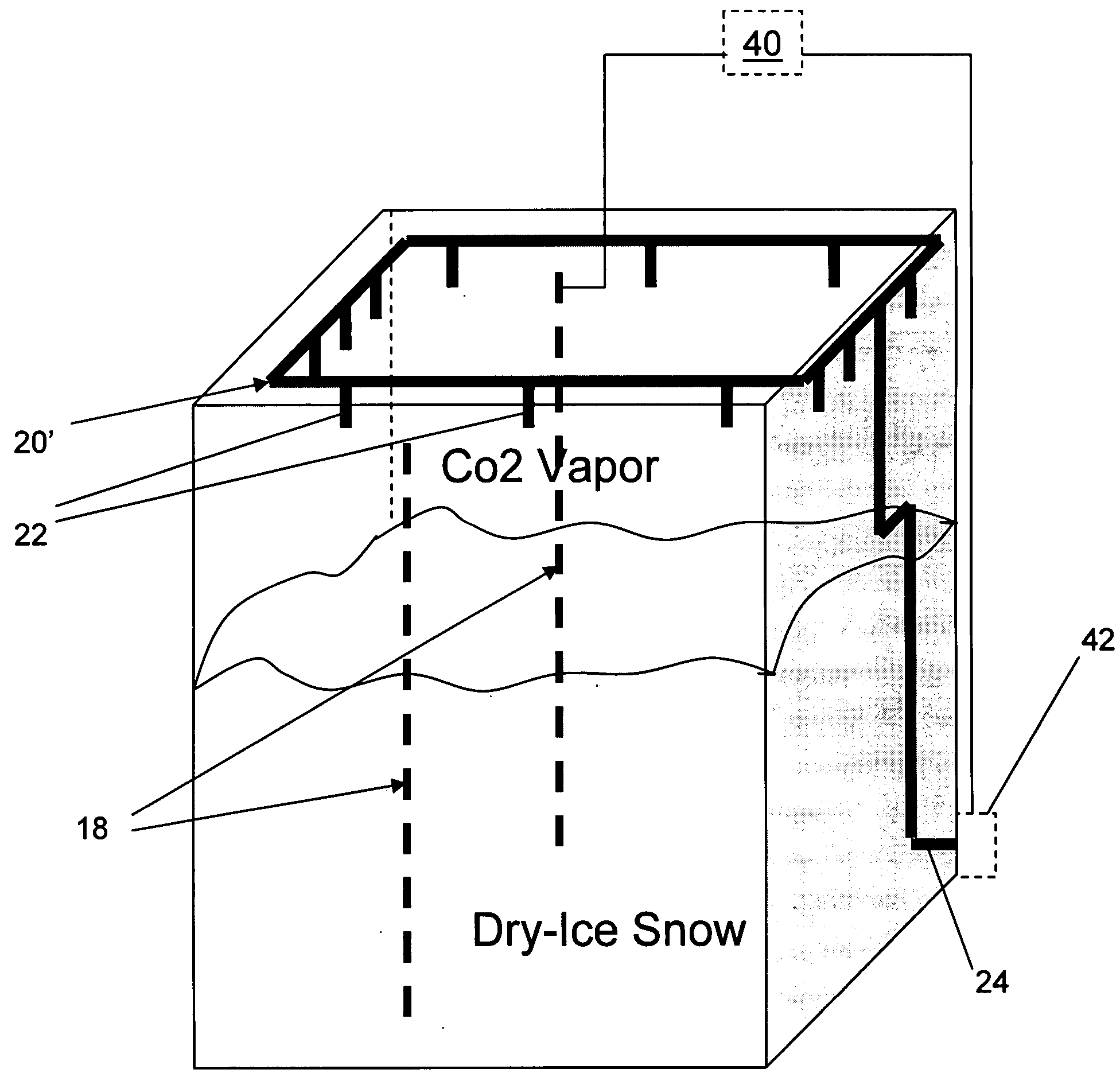

A refrigerated container and method capable of maintaining super frozen temperatures of about −50 degrees C. or less, includes container walls insulated to a value of at least about r-20, a cargo compartment configured for receiving cargo, and at least one refrigerant compartment configured for receiving refrigerant in the form of CO2 snow. The refrigerant compartment maintains the CO2 snow and vapor sublimating therefrom separately from the cargo compartment. The refrigerant compartment is located within the cargo compartment and configured to permit ambient atmosphere within the cargo compartment to contact at least three sides, and up to six sides, of the refrigerant compartment. The placement of the refrigerant compartment is also configured to generate a temperature gradient within the cargo compartment capable of generating convection therein, so that the super frozen temperatures are maintained within the cargo compartment without the use of external power sources.

Owner:COLDWAVE SYST

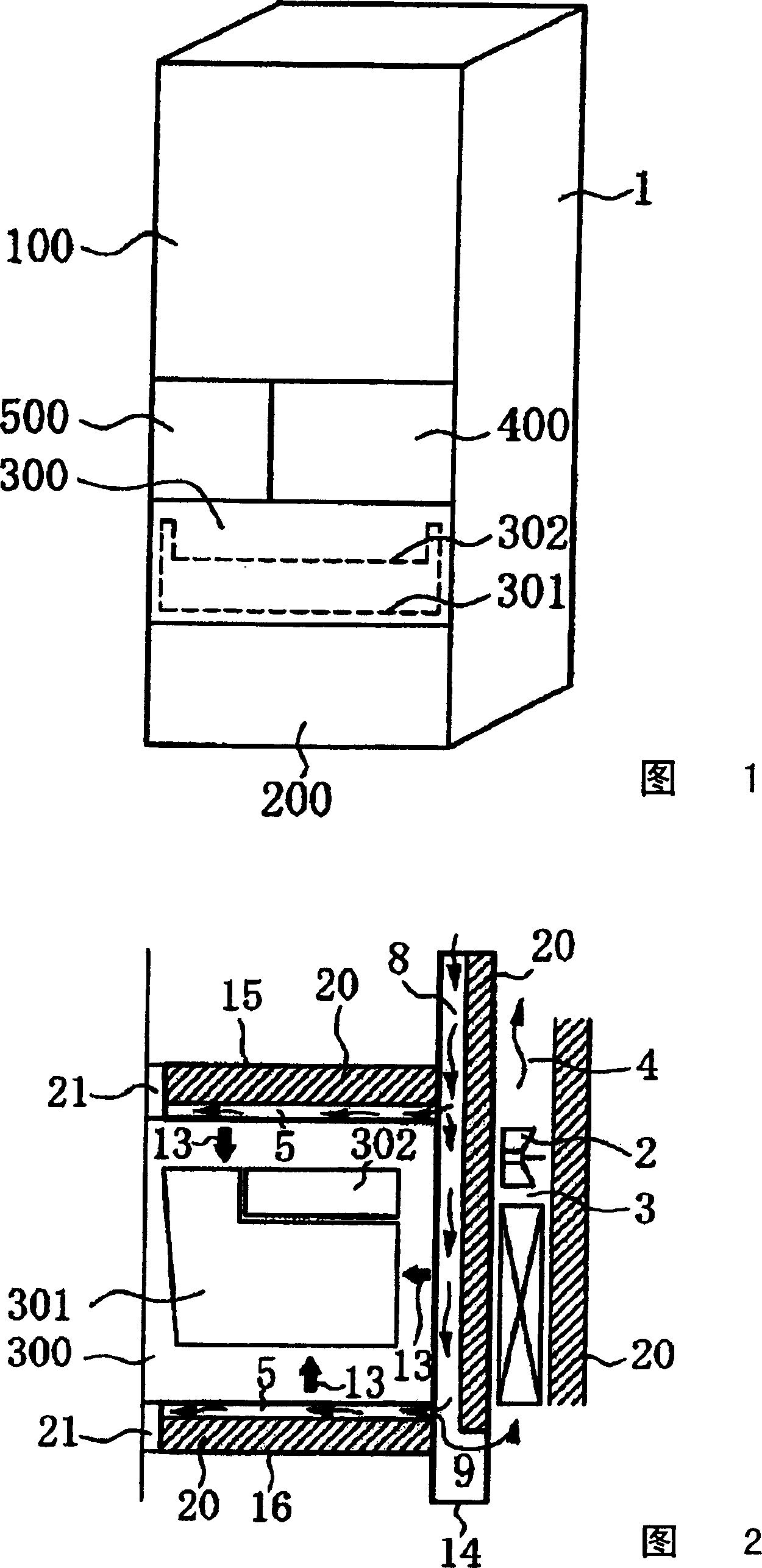

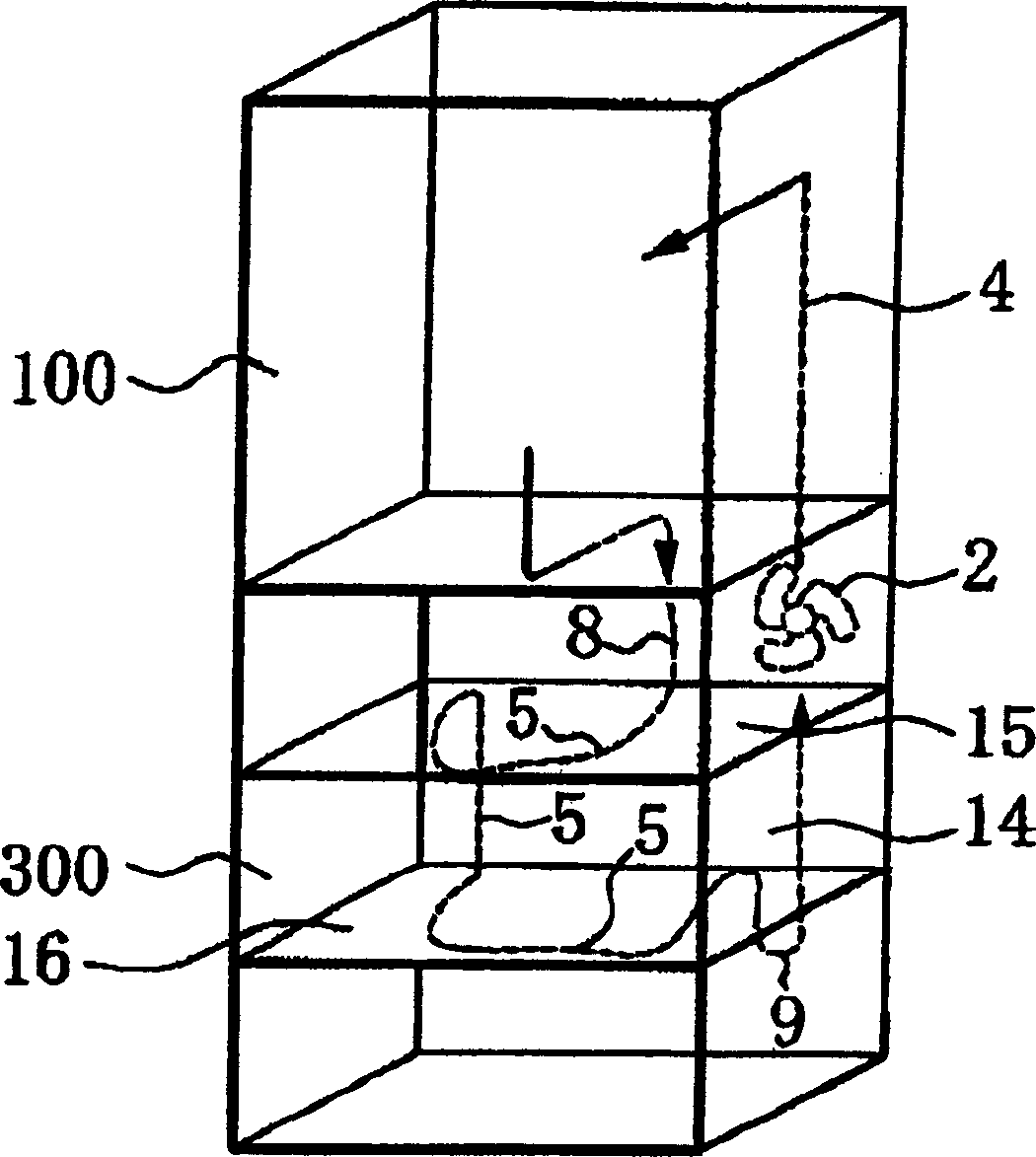

Refrigerator

InactiveCN1397780AImprove hydrophilicityIncrease humidityLighting and heating apparatusDomestic refrigeratorsDryingEngineering

A refrigerator which may allow vegetables kept more fresh by minimizing temperature fluctuations in a vegetable compartment. The refrigerator minimizes dehydration in food stored in the vegetable compartment, so that vegetables are kept fresh longer. The vegetable compartment is arranged so as to be surrounded by freezing temperatures, and cooled through radiation cooling without receiving blowing cool air thereto to minimize temperature fluctuations, so that vegetables may be keep more fresh. At the same time, the vegetable compartment is sealed so that convection does not occur thereby minimizing dehydration in food, so that food is allowed to be kept fresh longer. Furthermore, the refrigerator is provided with compartments whose temperatures may be set to freezing temperatures. The vegetable compartment is arranged so as to be surrounded by compartments whose temperatures are freezing temperatures via partition parts.

Owner:MITSUBISHI ELECTRIC CORP

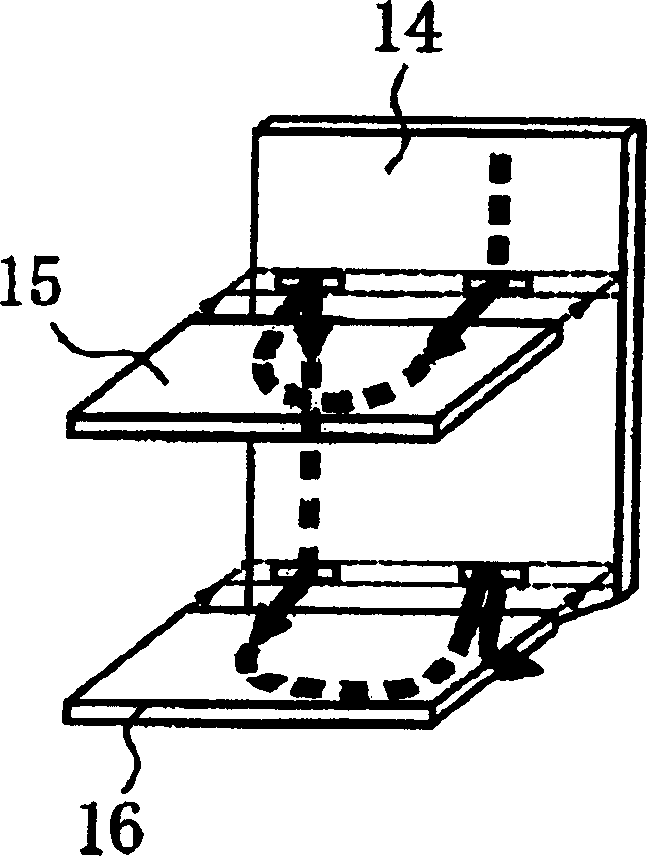

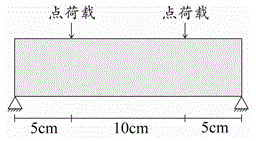

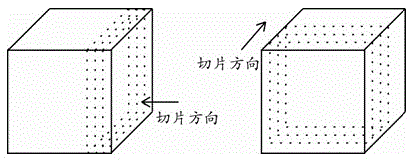

Method for obtaining three-dimensional stress field of rock mass model including complex structural plane

InactiveCN105608736AMaterial strength using steady shearing forces3D modellingModel testingRapid prototyping

The invention relates to a method for obtaining a three-dimensional stress field of a rock mass model including a complex structural plane by using a rapid prototyping technology. The method comprises: (1), a stress frozen fringe value of a rapid prototyping material is measured and an optimal frozen temperature is determined; (2), a rock mass structural plane network system and a rock mass CAD model are generated; (3), rock model checking and printing are carried out; (4), stress freezing is carried out; (5), model slicing is carried out and a stress fringe value is measured; and (6), a rock mass model stress field is reconstructed. According to the invention, on the basis of the complicated building technology of the 3D printer and the photo-elastic measuring technology, two limiting factors that a rock mass model including a complex structural plane can not be manufactured easily and distribution of inner stresses of the rock mass belongs to the black box in the prior art can be eliminated and thus observation and measurement can be carried out by using the common testing means, so that development of the model testing can be promoted. Therefore, the method has the important application value in researches of the rock mass mechanical behavior.

Owner:SHAOXING UNIVERSITY

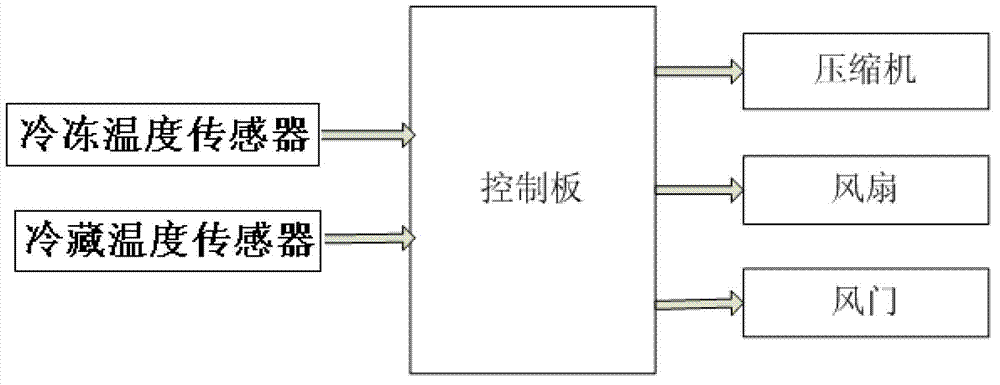

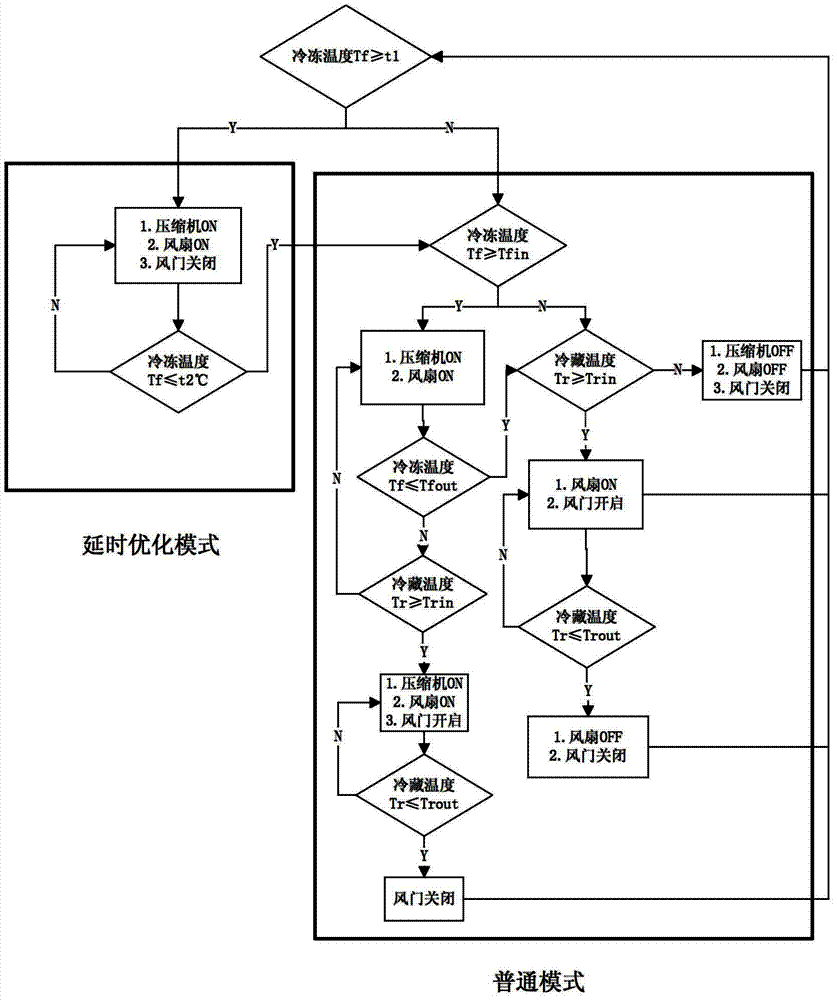

Control method of refrigerator applicable to high-temperature environment

InactiveCN102901320ASolve startupSolve runnabilityDomestic cooling apparatusLighting and heating apparatusIceboxCool storage

The invention relates to a control method of a refrigerator applicable to a high-temperature environment. The refrigerator comprises a refrigerating chamber and a chilling chamber, wherein the chilling chamber is internally provided with a compressor, a fan and a chilling temperature sensor; the chilling chamber is internally provided with a refrigerating temperature sensor; an air flue between the refrigerating chamber and the chilling chamber is internally provided with an air door; the compressor, the fan, the air door, the chilling temperature sensor and the refrigerating temperature sensor are connected with a control board arranged in the refrigerator; and the control method comprises the following steps that the control board selects a control mode of the refrigerator to be a common mode or a delaying optimized mode according to a chilling temperature detected by the chilling temperature sensor and then converts into the common mode. According to the control method disclosed by the invention, delaying optimized control is adopted at a high-temperature environment, and chilling and refrigerating load peak values are staggered, so that the total load peak value of the system is reduced, and the normal starting and operation of the compressor are guaranteed. Furthermore, on the premise of not increasing the cost, the starting and operation problems of the refrigerator under the high-temperature environment are solved, so that the stability and reliability of using the refrigerator are improved.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

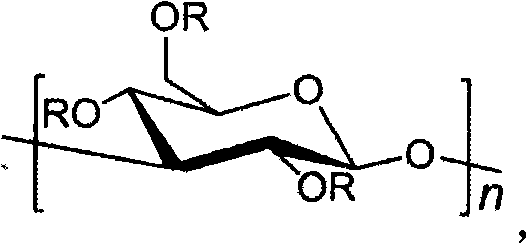

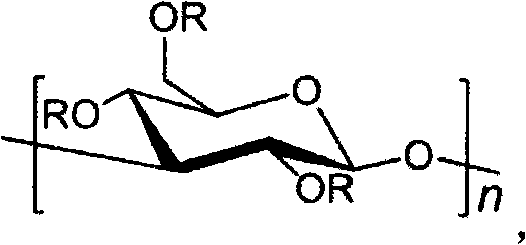

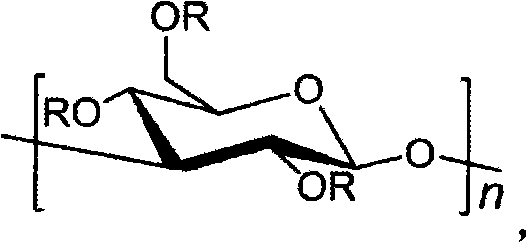

Carboxymethyl curdlan gum physical hydrogel and preparation method thereof

InactiveCN101602814AEasy to prepareIncrease the number of freeze-thaw cyclesFreezing thawingControl drugs

The invention provides a carboxymethyl curdlan gum physical hydrogel and a preparation method thereof, belonging to the technical field of high polymer material; the mass percent of the carboxymethyl curdlan gum physical hydrogel is 3-20% while the balance is water. The preparation method comprises the following steps: preparing carboxymethyl curdlan gum aqueous solution; regulating pH value and performing freeze-thaw treatment; compared with the prior art, the invention adopts the freeze-thaw treatment to prepare carboxymethyl curdlan gum physical hydrogel; the preparation method is easy and convenient and the strength of the hydrogel can be enhanced through increasing freeze-thaw circling times, reducing freeze temperature, prolonging freeze time and the like; no chemical cross-linking agent or organic solvent with poison and side effect to organism is introduced in the hydrogel preparation process with freeze-thaw treatment. The carboxymethyl curdlan gum has immunity activity and anti-tumor activity, so the physical hydrogel has potential application in biomedical sciences, such as being taken as sustained and control drug carrier, and has more advantages compared with other hydrophilic gums.

Owner:SHANGHAI JIAO TONG UNIV

Preparing method of vacuum freeze-dried strawberry products

ActiveCN104026214AGood microbial controlAvoid decompositionFruit and vegetables preservationDesorptionAdditive ingredient

The invention discloses a preparing method of vacuum freeze-dried strawberry products. The method comprises the following steps that: (1) strawberries are pretreated; (2) steam with the temperature of 121 to 125 DEG C is introduced to the strawberries, the acting time is 90 to 120 seconds, and the material center temperature is higher than or equal to 75 DEG C; (3) the strawberries are cooled to room temperature; (4) a mixed solution is prepared, the mixed solution contains 0.1 to 0.4 mass percent of konjac glucomannan and 25 to 35 mass percent of white granulated sugar, and the strawberries are soaked in the mixed solution for 30 to 45 seconds; (5) then, the strawberries are paved onto a disc and are fast cooled and frozen in parameter ranges that the frozen temperature is -20 DEG C to -25 DEG C, the freezing time is 10 to 15 minutes, and the disc paving thickness is 2 to 3cm; (6) finally, the vacuum freeze-drying is carried out in parameter ranges that the vacuum degree is 50 to 80 Pa; the cold trap temperature is -30 to -40 DEG C; the sublimation temperature is 50 to 60 DE GC; the time is 8 to 10 hours; the vacuum degree in a desorption drying process is 40 to 50 Pa; the drying temperature is 40 to 50 DEG C; and the time is 6 to 8 hours; and (7) packaging is carried out. The strawberry products prepared by the method provided by the invention have the advantages that the eating is convenient and simple; the original color, luster, shape and flavor of the strawberries are maintained; the nutritional ingredients are basically maintained; in addition, the sterilization is thorough; the secondary pollution can also be effectively prevented; and the shelf life is long.

Owner:福建立兴食品股份有限公司

Refrigerated Storage Case

InactiveUS20140318157A1Provide for selectionLighting and heating apparatusDomestic refrigeratorsWorld Wide WebUser interface

The present application thus provides a refrigerated storage case for storing pre-selected items. The refrigerated storage case may include a number of compartments, a user interface configured to receive an access code and to unlock a predetermined compartment with the pre-selected items therein, and an evaporator coil configured to maintain the compartments at a chilled and / or a frozen temperature.

Owner:HEATCRAFT REFRIGERATION PRODS

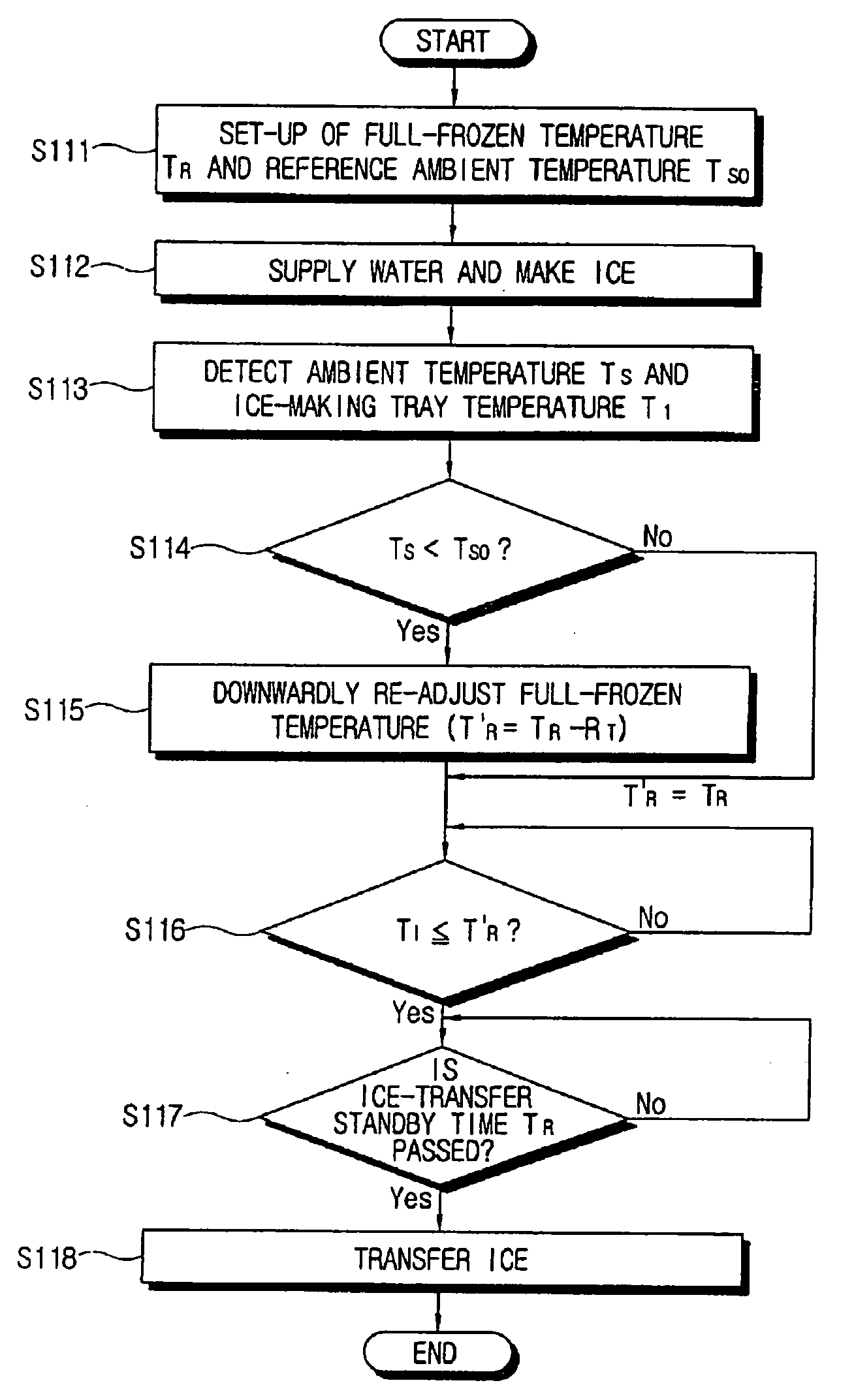

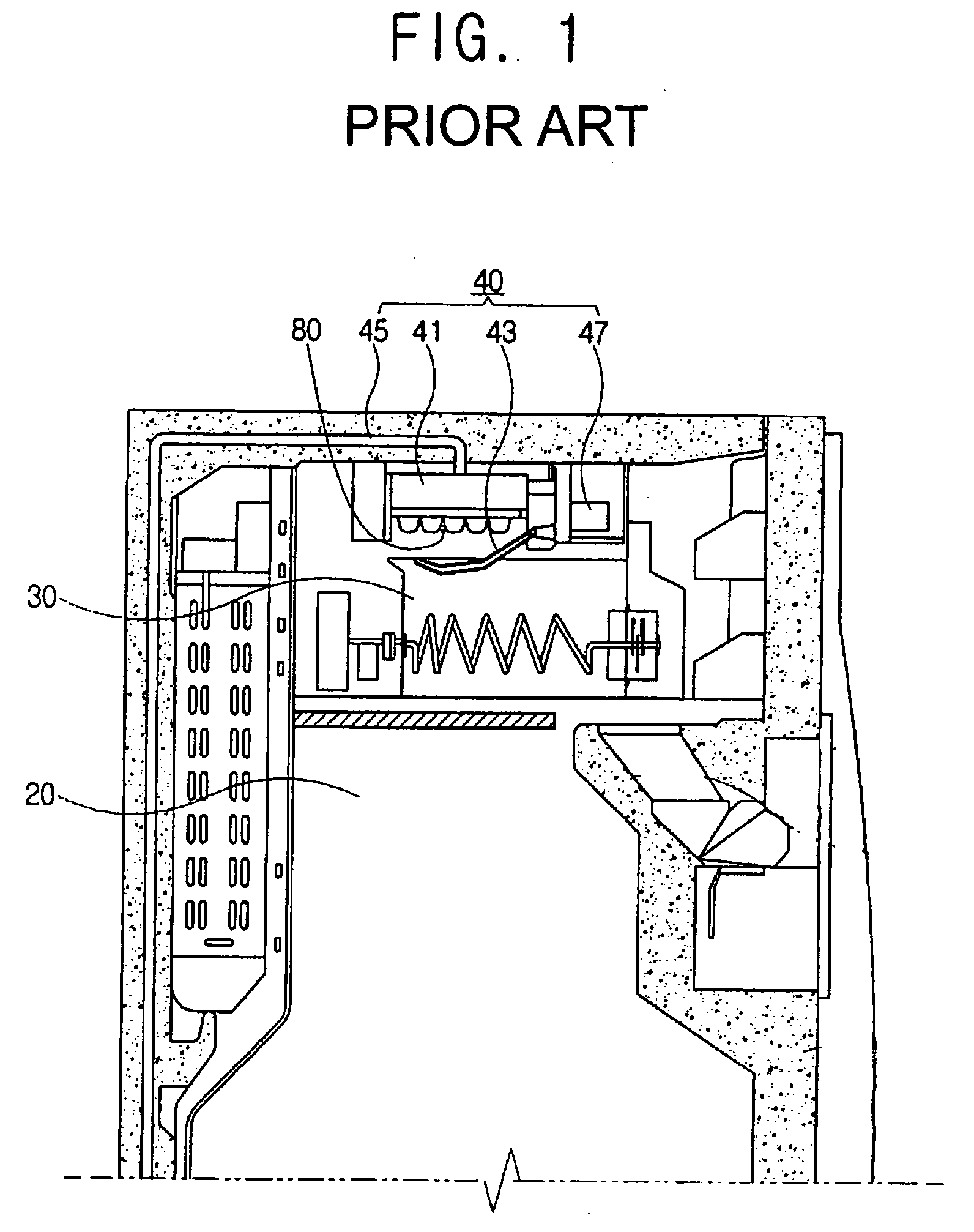

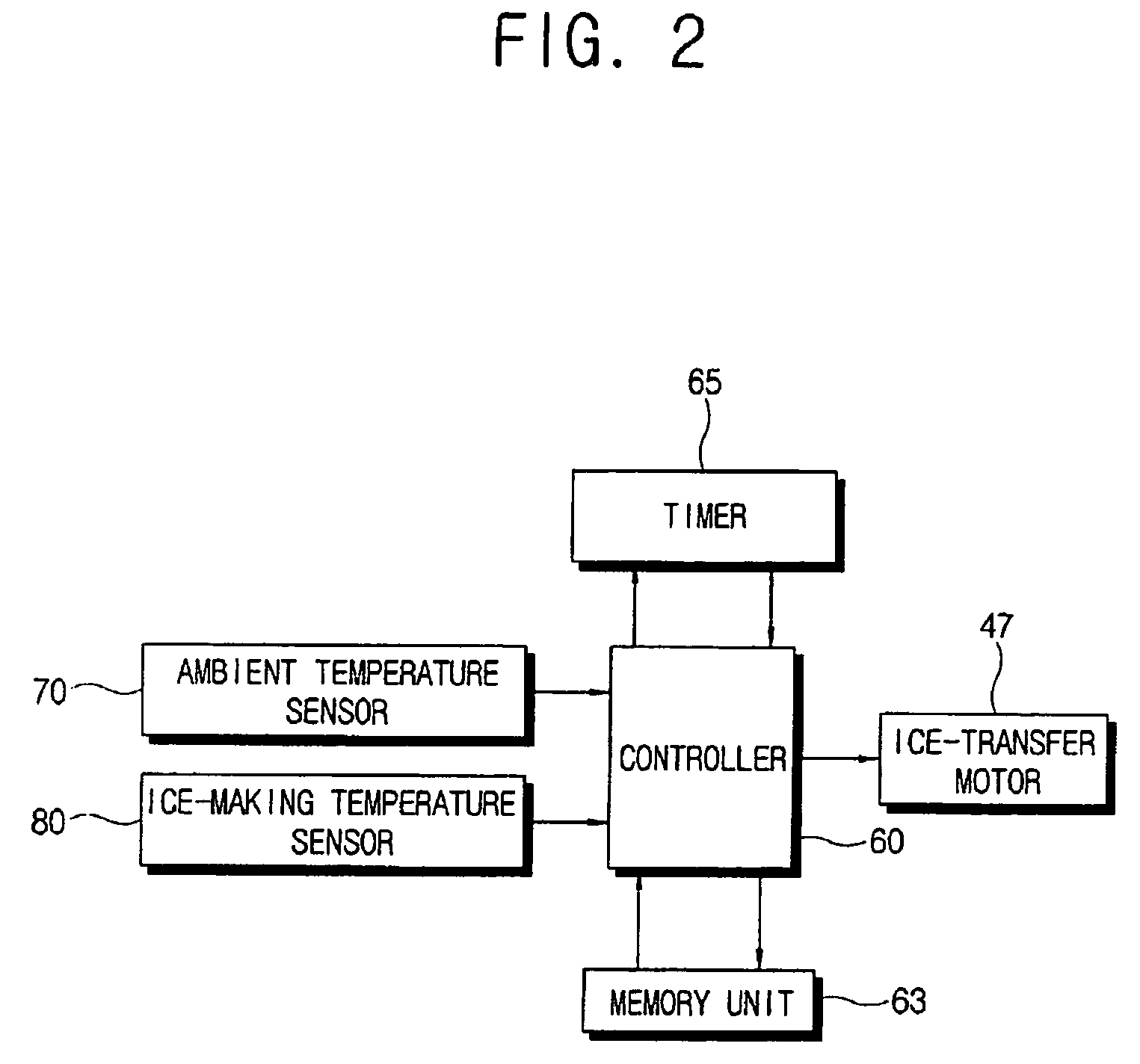

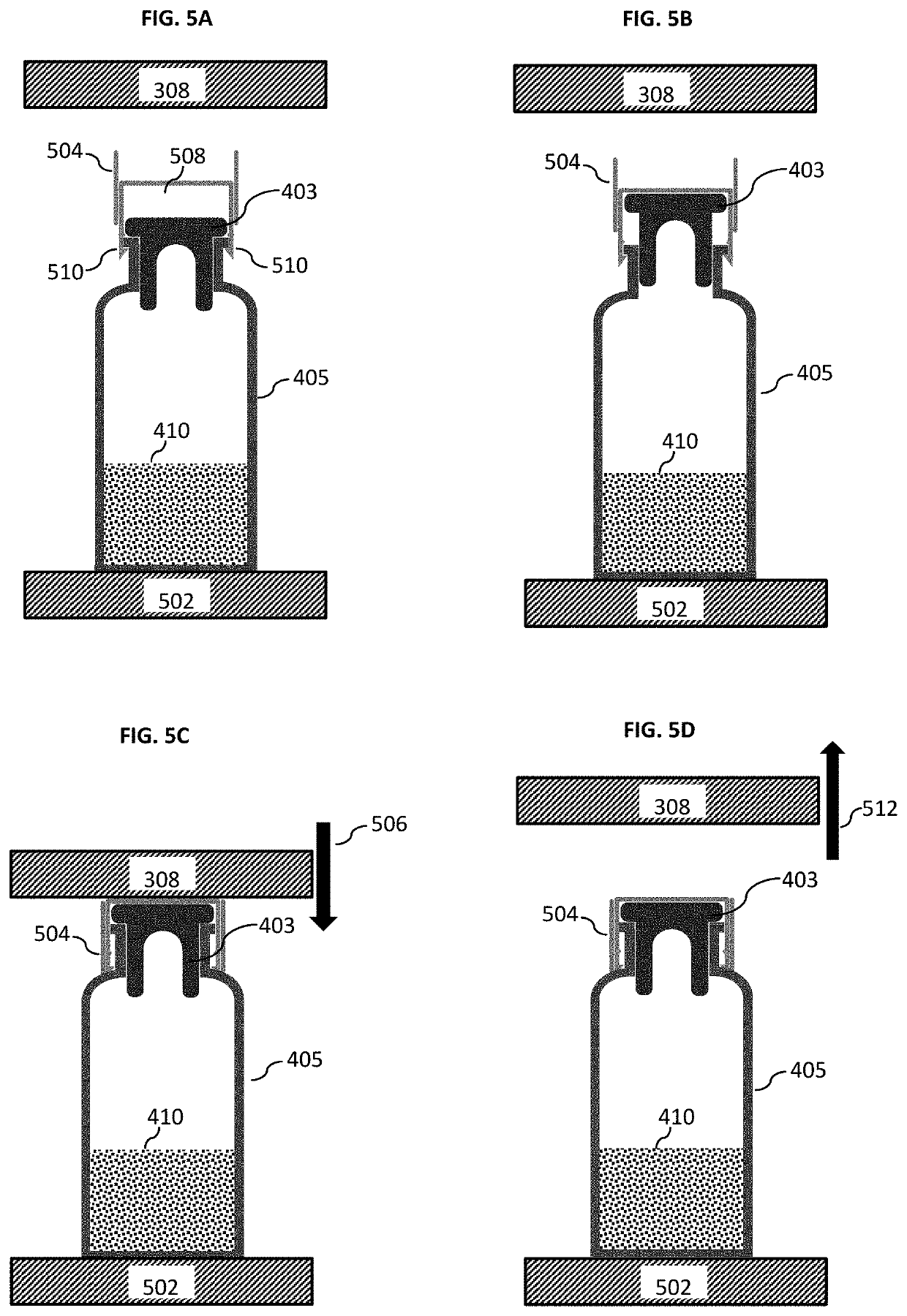

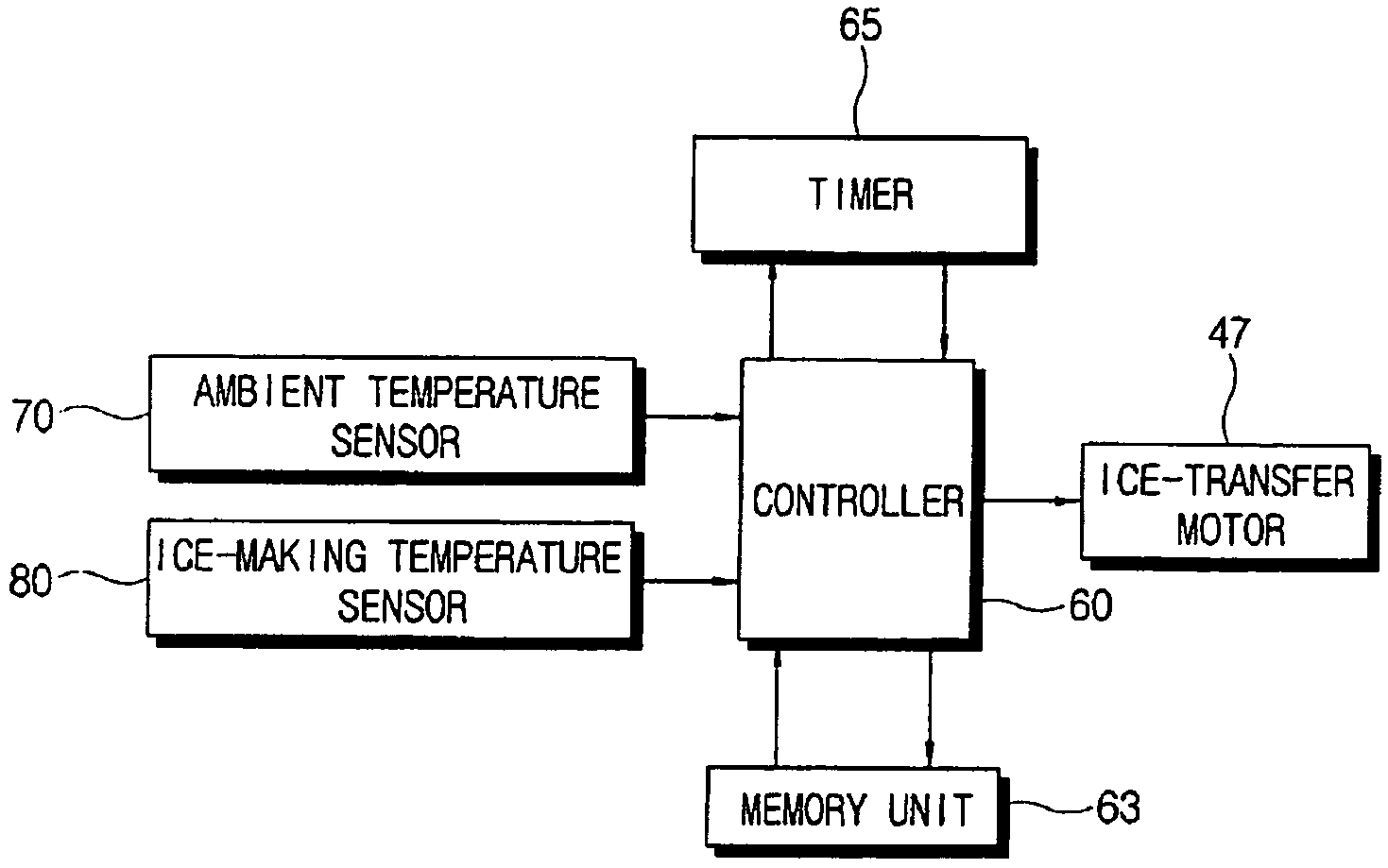

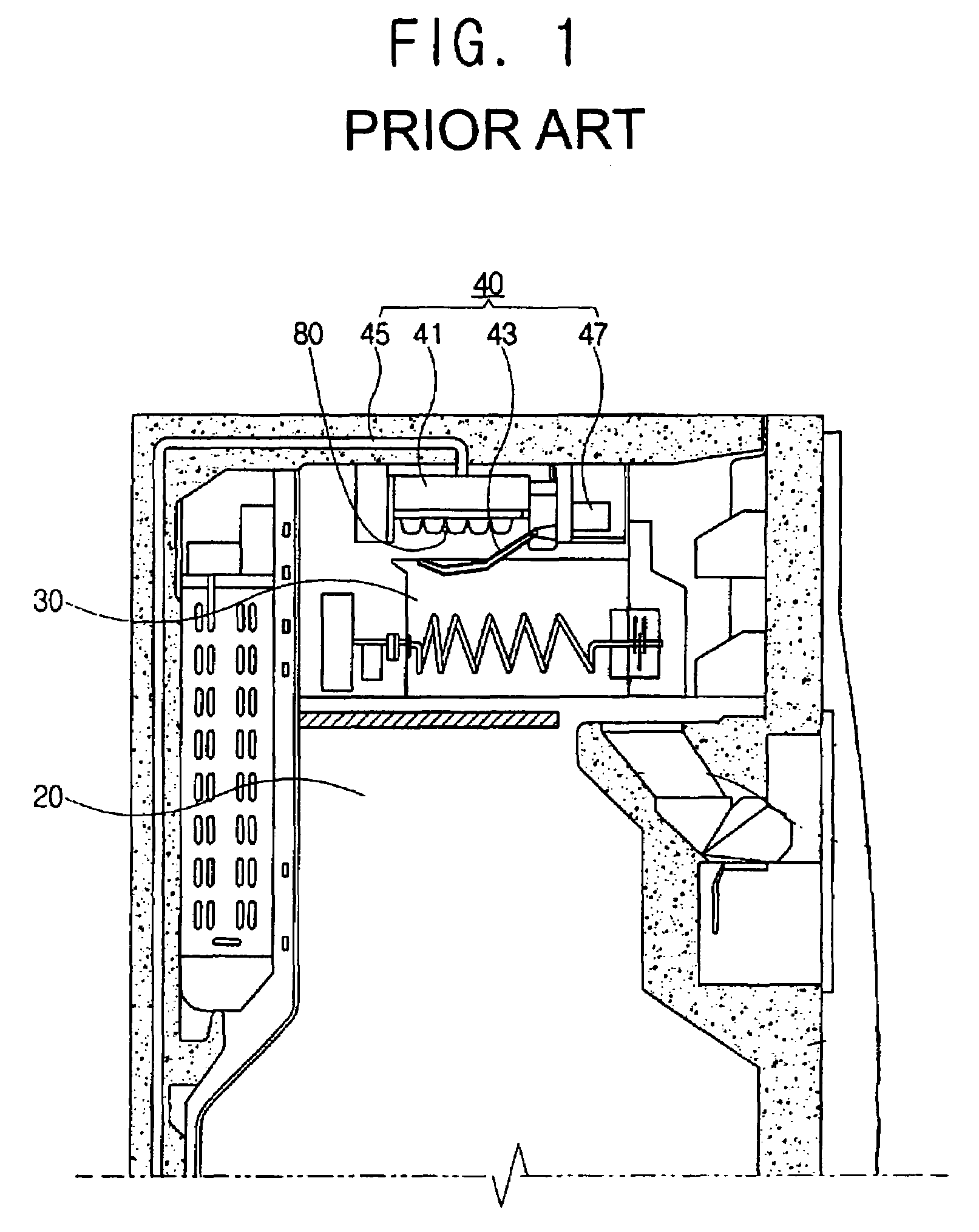

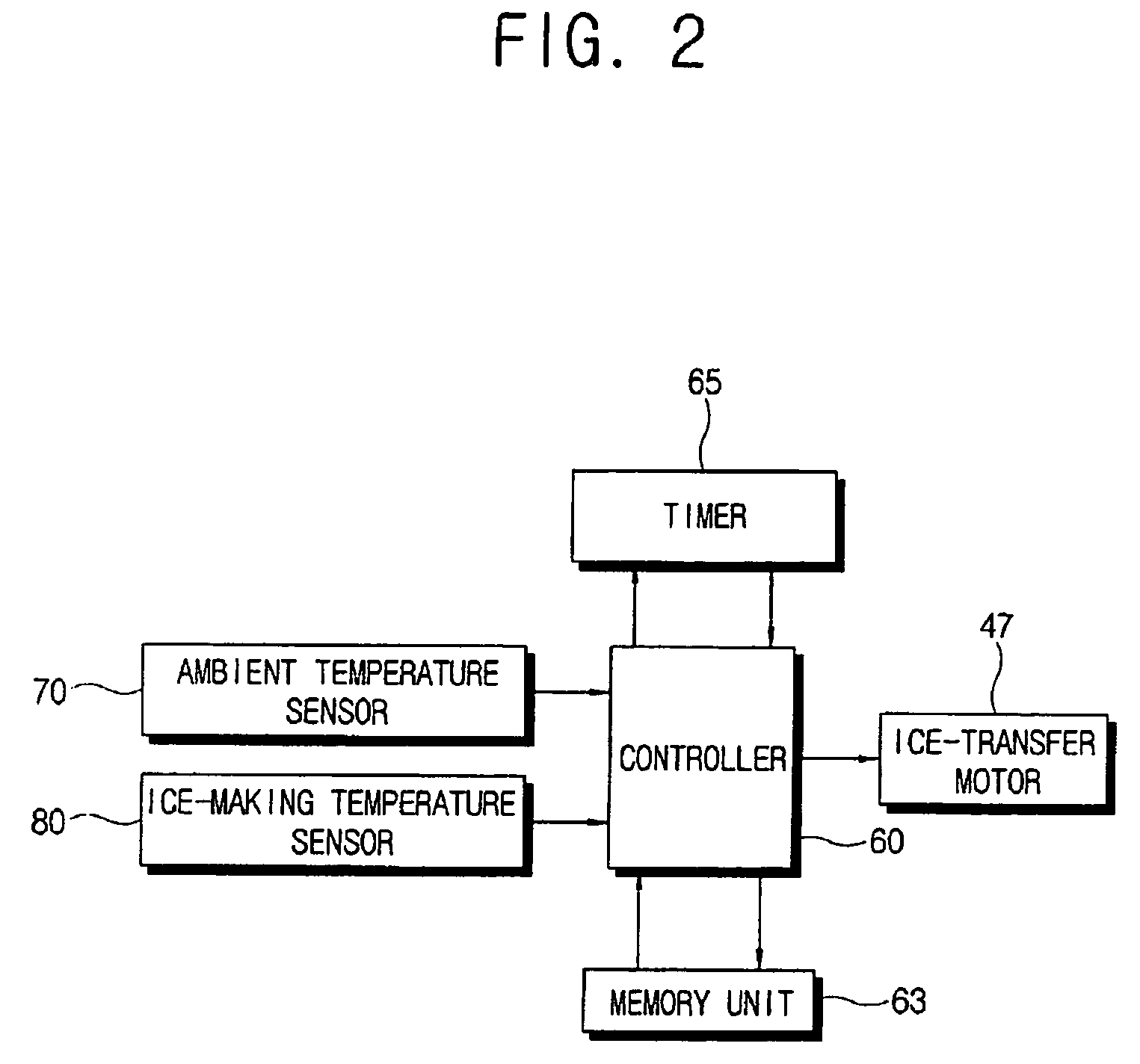

Method of fully freezing ice and refrigerator using the same

InactiveUS20060266056A1Improve ice qualityPreventing the ice from sticking togetherIce productionFluid circulation arrangementEngineeringRefrigerated temperature

A method of fully freezing ice in a refrigerator. The method includes setting a full-frozen temperature for determining whether ice is fully frozen, and a reference ambient temperature for re-adjusting the full-frozen temperature; supplying water to the ice-making tray to thereby perform ice-making; sensing ambient temperature; sensing temperature of the ice-making tray; re-adjusting the full-frozen temperature by comparing the sensed ambient temperature with the reference ambient temperature; and if the temperature of the ice-making tray reaches the re-adjusted full-frozen temperature, driving an ice-transfer motor to transfer full-frozen ice from the ice-making tray. Thus, not fully frozen ice is prevented from being transferred, to thereby improve ice quality and avoid sticking of ice, which may occur when not fully frozen ice is broken while being transferred. A refrigerator using such a method is also disclosed.

Owner:SAMSUNG ELECTRONICS CO LTD

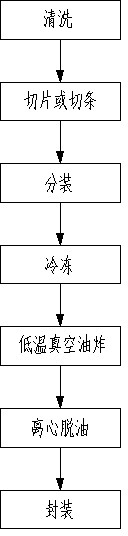

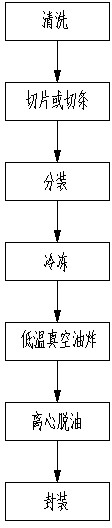

Method for preparing fried snack food at low temperature

InactiveCN102648741ADoes not affect processing efficiencyCrunchy taste does not affectFood preparationRoom temperatureSnack food

The invention relates to a method for preparing fried snack food at low temperature. The method comprises the following steps: cleaning the food raw material; cutting the cleaned food raw material into slices or strips; steaming and cooking the sliced or stripped food raw material to obtain the semi-finished product with 80 percent cooked; cooling the semi-finished product to the room temperature, and freezing the semi-finished product at the temperature of minus 17 DEG C to minus 20 DEG C for 24 to 48 hours to obtain the frozen semi-finished product; frying the frozen semi-finished product, which is not unfrozen, for 25 to 45 minutes at low temperature of between 78 and 98 DEG C and under the vacuum condition to obtain deoiled food; and packaging the deoiled food to obtain the finished product, namely, the fried snack food. By the method for preparing fried snack food at low temperature, the carcinogenic defect in the traditional process is eliminated, the application range is wide, and the process flow processing efficiency is high.

Owner:张镰斧

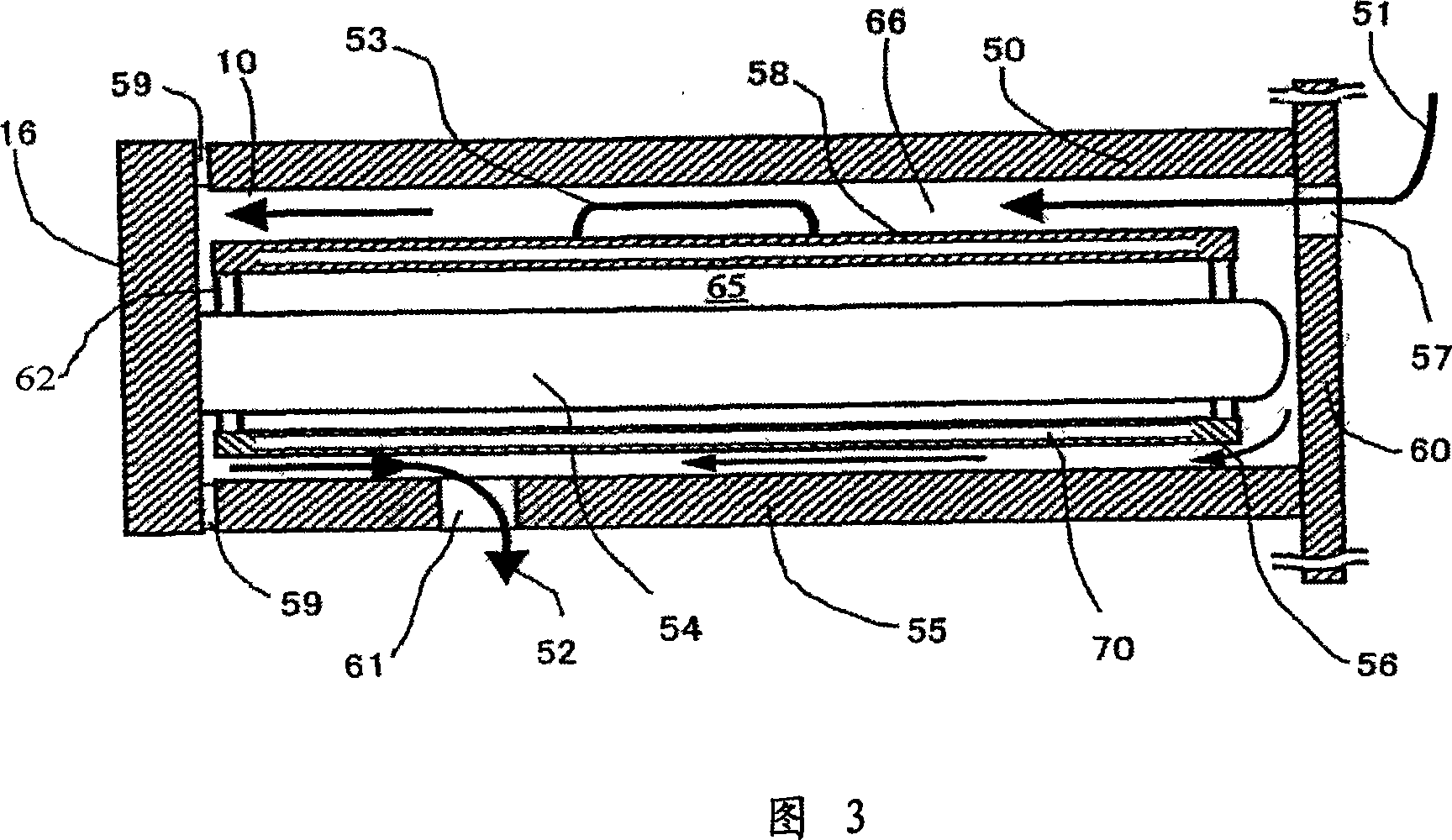

Refrigerator

InactiveCN101046345ALighting and heating apparatusCooling fluid circulationInsulation layerEngineering

When cooling drink water by using household refrigerator, it is insufficient to average cool gas in the refrigerator, internal temperature distribution of the drink water causes over cool release or the over cool is tend to be released. The invention provides a refrigerator having a storing chamber 10 cooling food stored in the space 65, which comprises a cool gas flow space 66 arranged around the space 65; a heat insulation layer 70 arranged between the space 65 and the cool gas flow space 66; a cool gas output port 57 outputting cool gas cooling temperature to the cool gas flow space 66 such that inside of the space 65 is cooled to cool temperature range lower than 0 DEG C to indirectly cool the food. The refrigerator, by the cooling mode, can restrain the generation of internal temperature distribution of the drink water such that drink water in over cool does not release over cool by chance.

Owner:HITACHI APPLIANCES INC

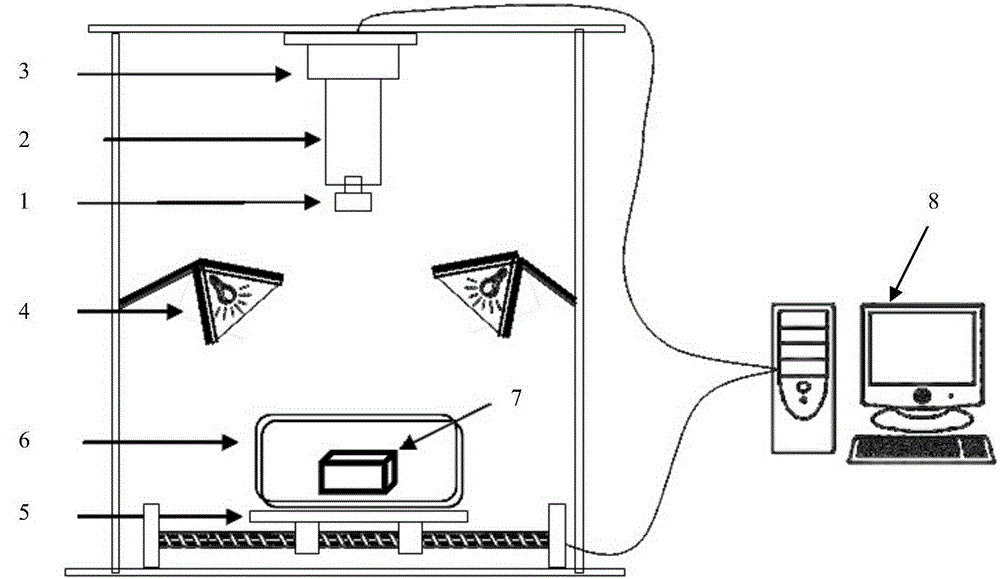

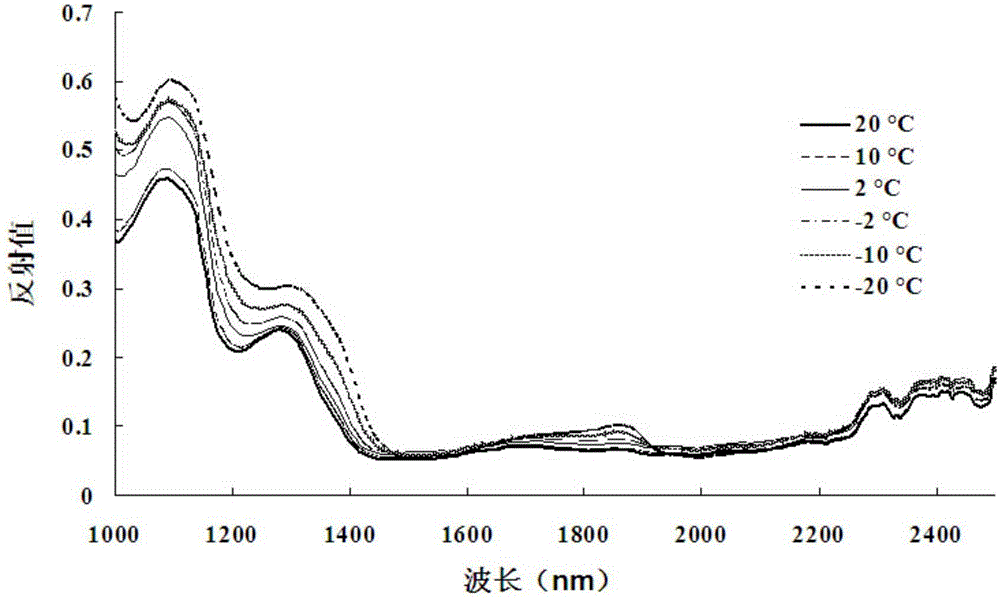

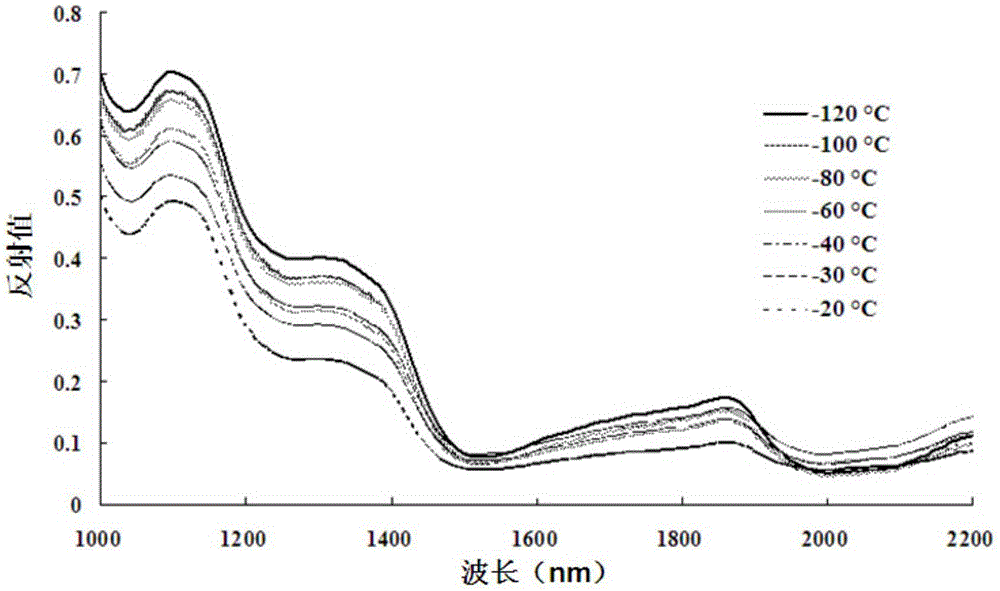

Method and device for measuring freezing parameters of frozen meat

ActiveCN105136709ARapid temperatureFast measuring methodMaterial analysis by optical meansFast measurementReflectance spectroscopy

The invention discloses a method for measuring freezing parameters of frozen meat; with utilization of difference of near infrared absorption and reflection spectra of different-particle-size and different-distribution ice crystals formed from moisture in a product in different temperatures and at different freezing rates, and through establishment of a chemometrics relationship model of the freezing parameters and the near infrared spectra, the method for rapidly measuring the freezing temperature and the freezing rate of the frozen product is realized. The method can rapidly, accurately and nondestructively measure the freezing temperature and rate, at the same time, breaks through conventional technical limitations that the freezing parameters of the product are required to be in the freezing process to be measured, and is applicable to monitoring and quality analysis of the freezing process of the frozen product.

Owner:SOUTH CHINA UNIV OF TECH

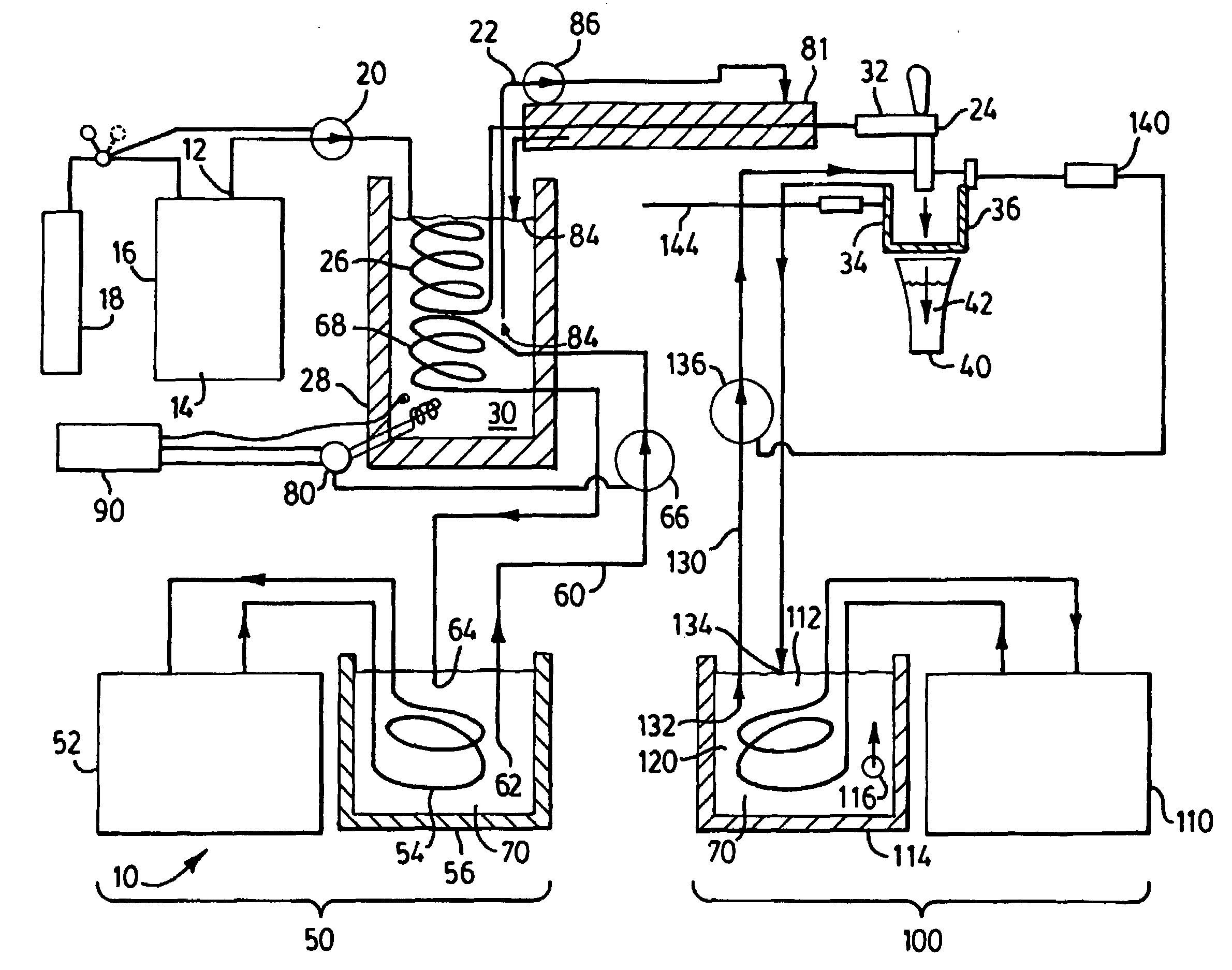

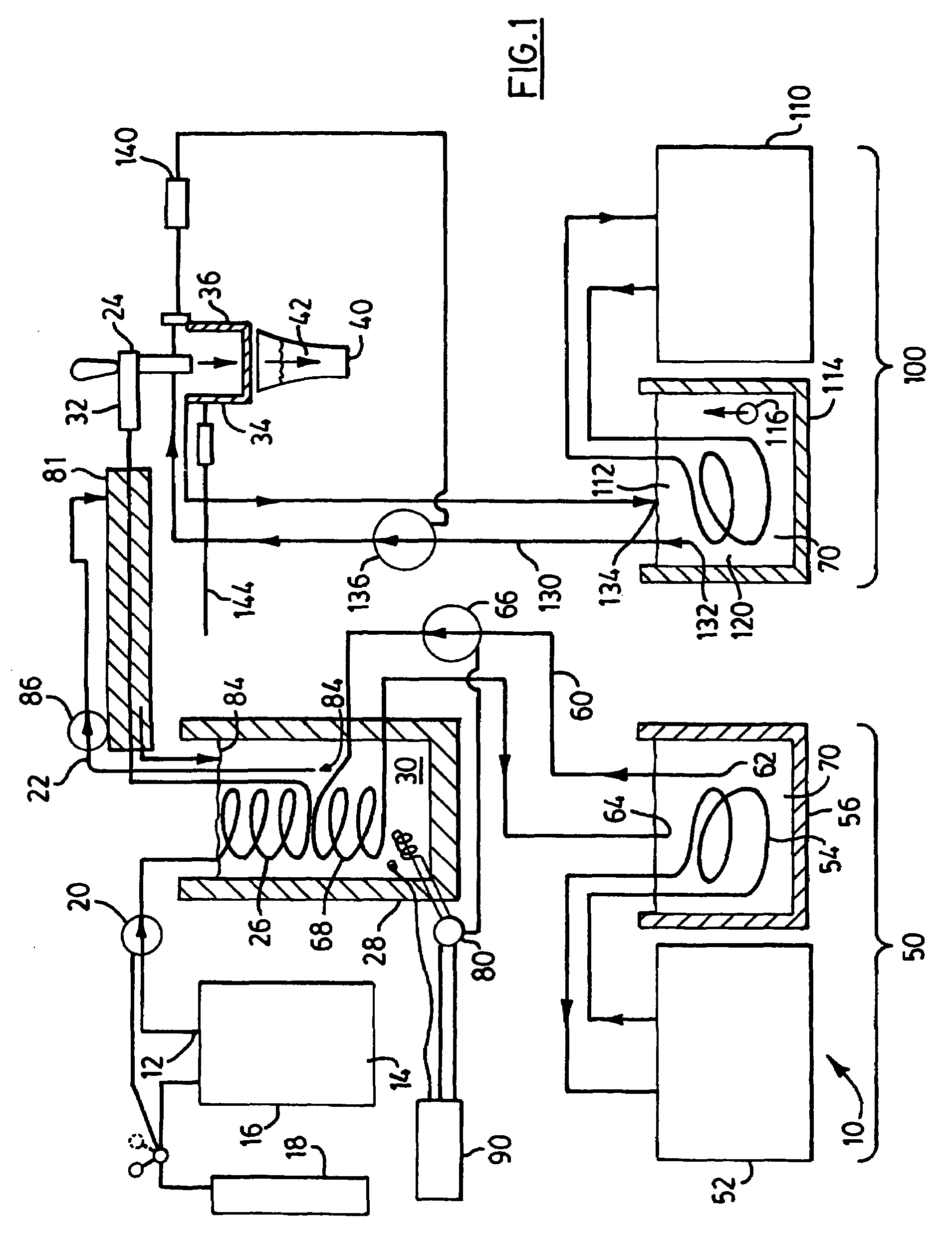

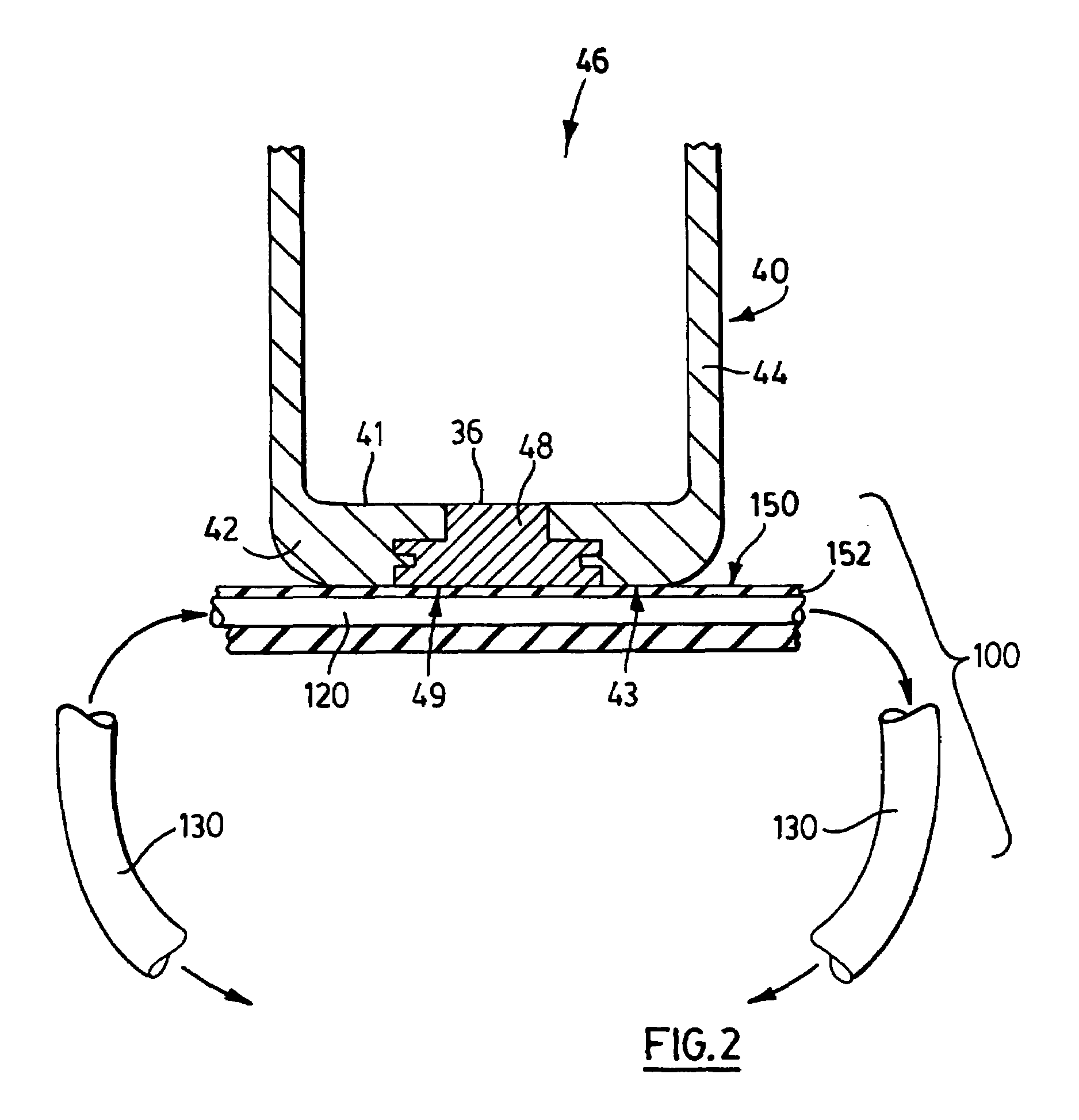

Method and apparatus for controlled ice crystal formation in a beverage

ActiveUS6928824B2Prevent splashLighting and heating apparatusIce productionSufficient timeEngineering

A method for producing a desired amount of ice crystal formation in a beverage comprising the steps of cooling said beverage to a temperature below its ordinary freezing temperature at atmospheric pressure to form a cooled beverage; maintaining said beverage at a pressure sufficient to inhibit freezing of said beverage; dispensing said cooled beverage into a vessel; obtaining a cooled surface, having a temperature sufficiently low to cause flash freezing of a portion of said cooled beverage which comes into contact therewith; and presenting said cooled surface to said beverage for a time sufficient to form a desired amount of said ice crystals in said beverage. An apparatus is provided for carrying out the method.

Owner:ICEFLOE TECH INC

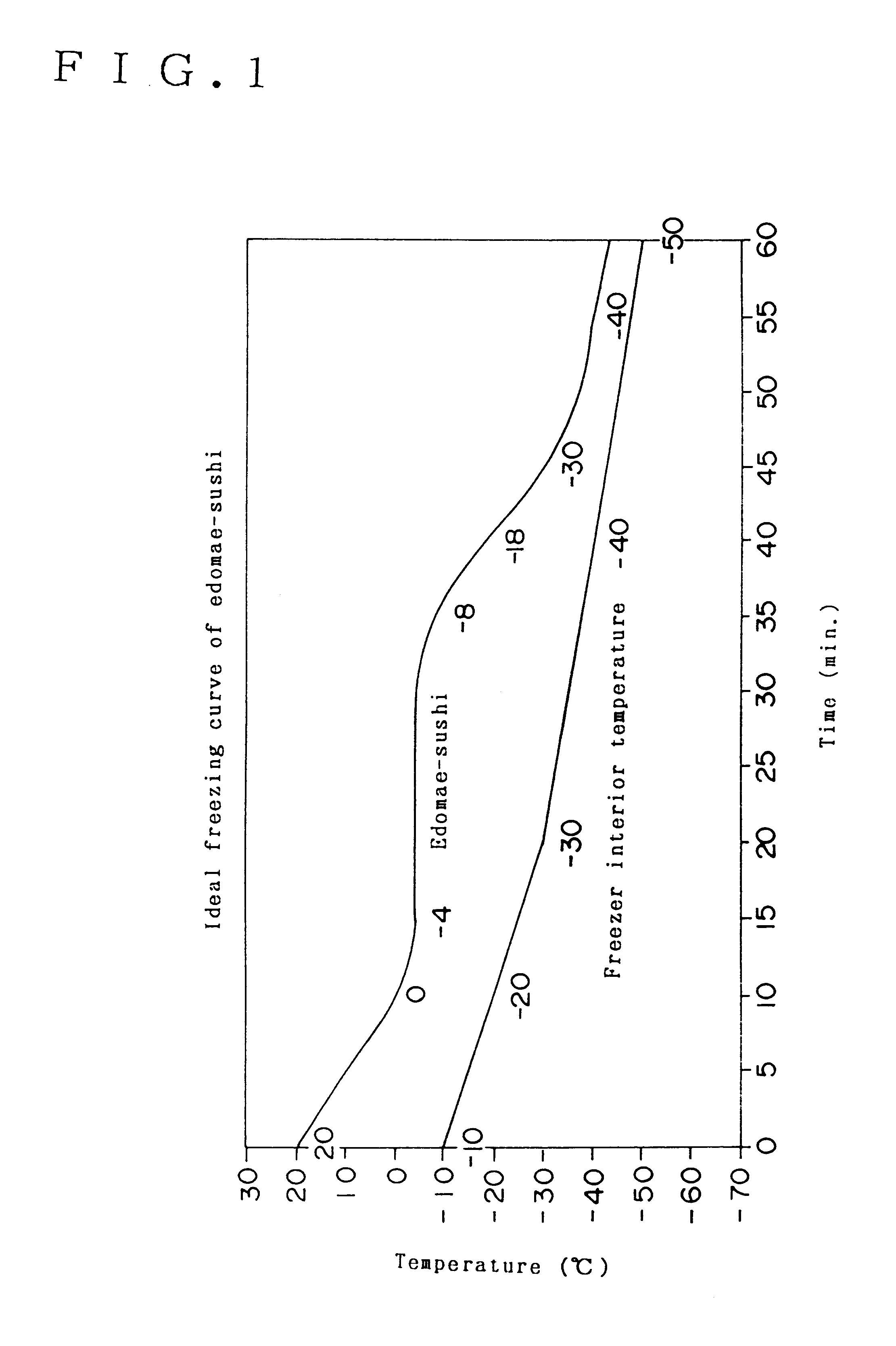

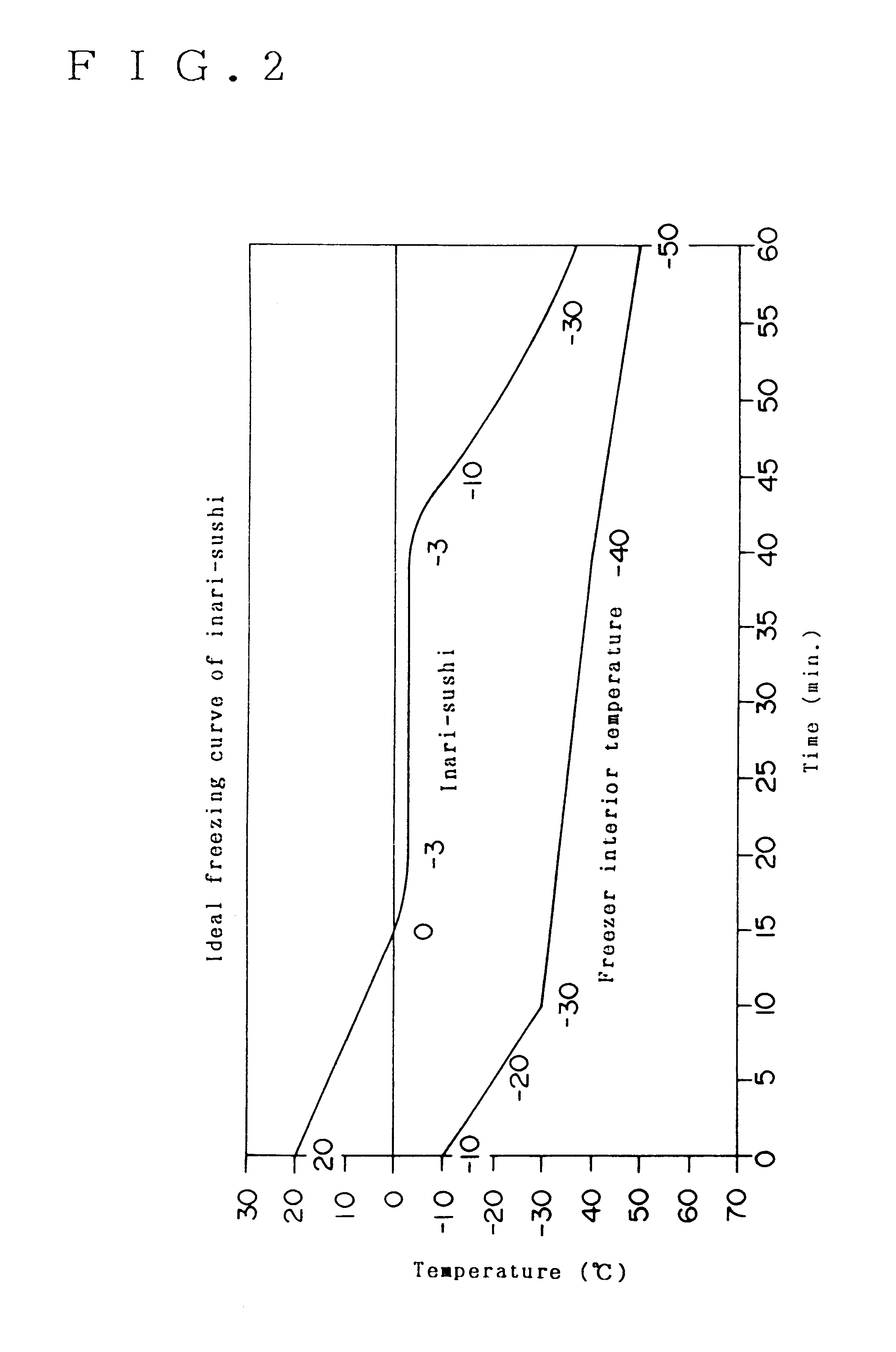

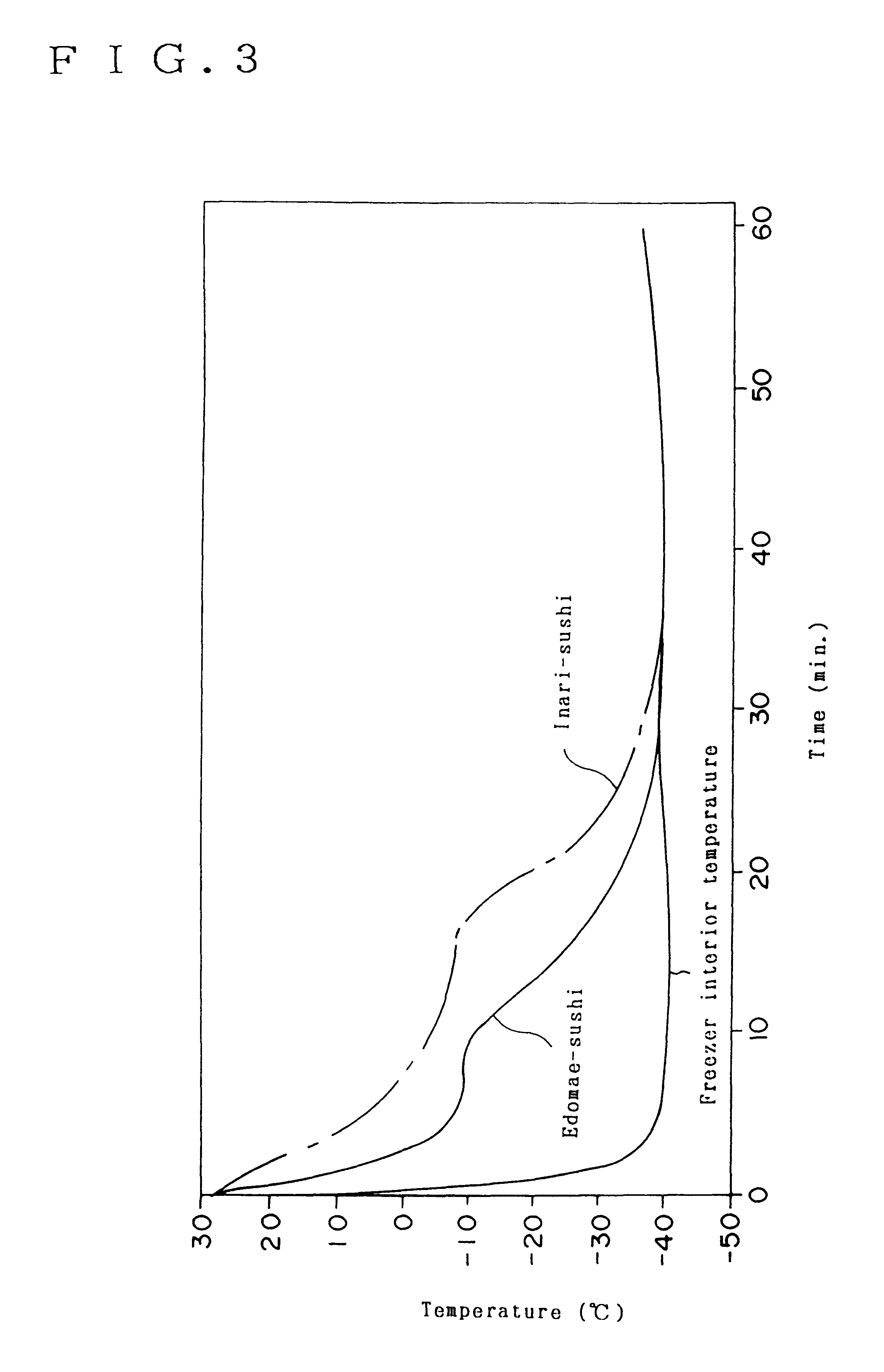

Process of freezing sushi, boiled rice or processed food with boiled rice as main component

A process of freezing sushi, boiled rice or processed food with boiled rice as the main component permits substantially the same quality offered before freezing to be obtained after natural thawing or thawing using an electric oven. When freezing nigiri-sushi at a normal temperature of about 20° C., the freezer temperature is first reduced from a preliminary cooling temperature of -10° C. to a temperature of -30° C. in about 20 min. with a temperature gradient of about 1 to 2° C. / min. The freezer temperature is then reduced from -30 to -40° C. with a temperature gradient of 1° C. / min. or below, preferably about 0.5° C. / min., over a time of 15 to 25 min., and preferably 15 to 20 min., until a maximum ice generation temperature range of 0 to -10° C. for the rice part of the sushi, specifically -3 to -6° C., is passed.

Owner:MAYEKAWA MFG CO LTD +1

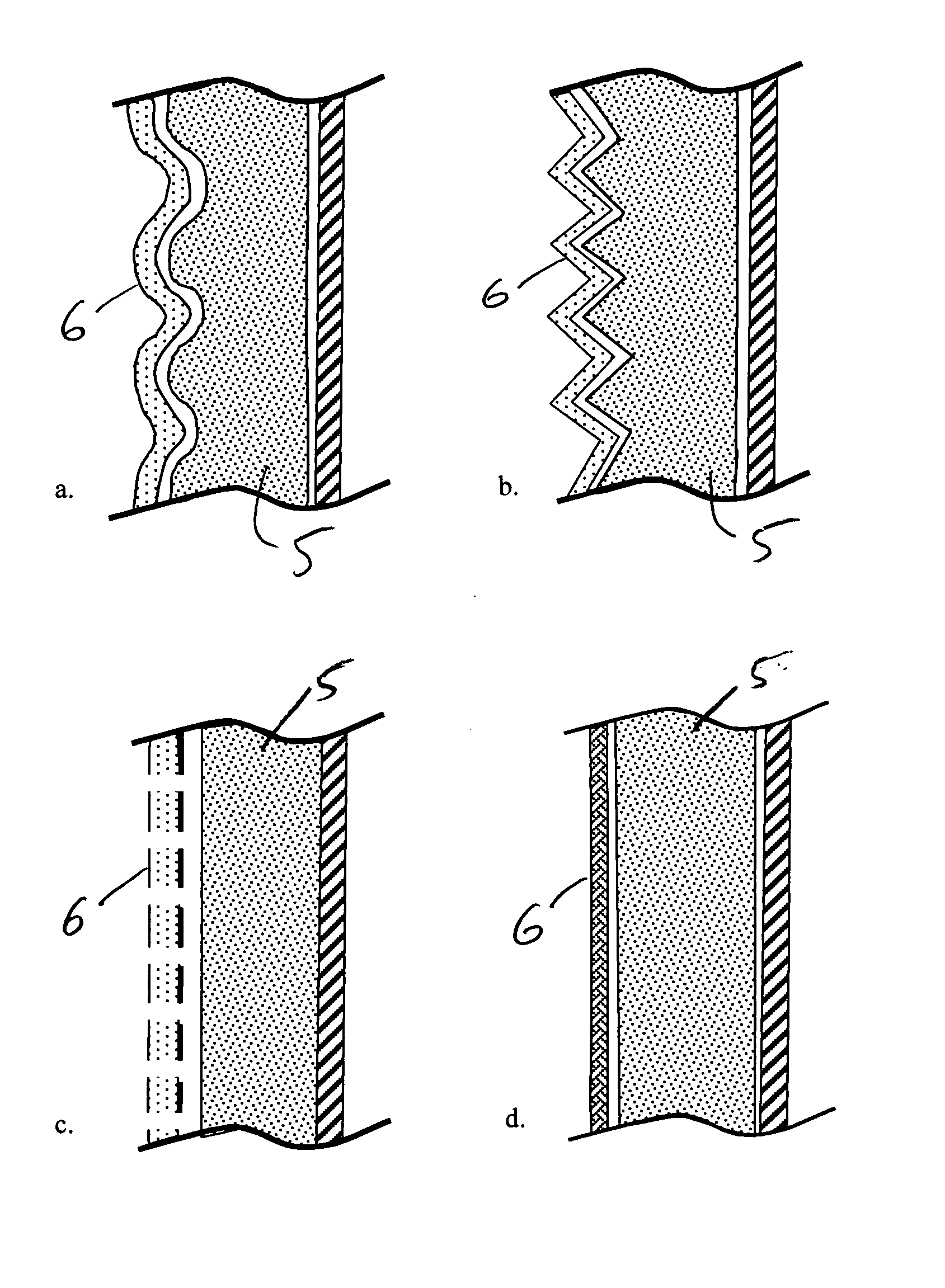

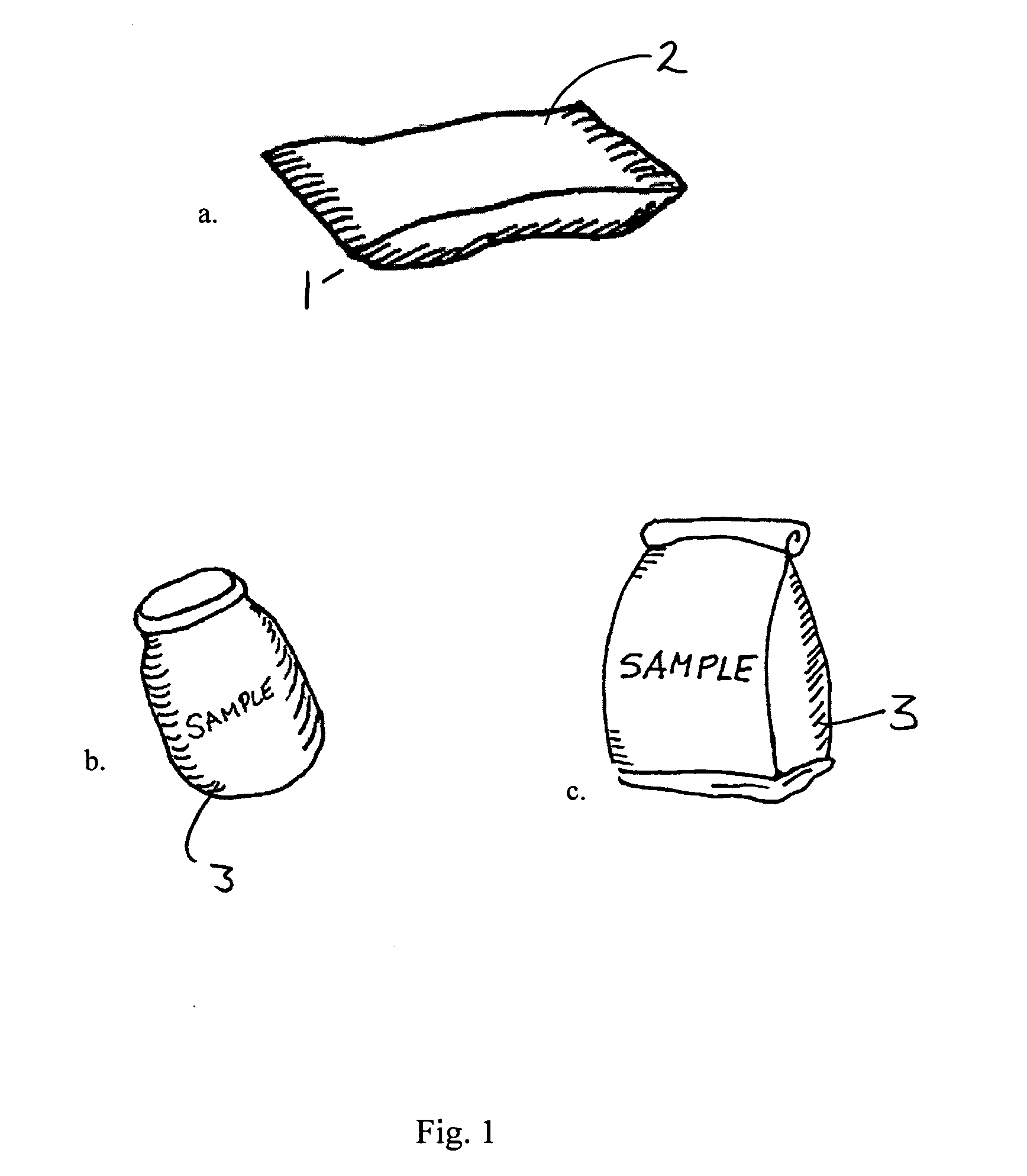

System for maintaining materials at freezer temperatures for shipping

InactiveUS20070180847A1Reduce conduction heat transferLighting and heating apparatusCooling fluid circulationTemperature controlControl system

At least one embodiment of the inventive technology relates to a frozen environmental sample temperature control system that comprises a frozen formulation having water in an amount from substantially 87% to 78% by weight of the formulation, and salt in an amount from substantially 13% to 22% by weight of the formulation, the system further including at least one container containing the frozen formulation; and a cooler having insulating material disposed between an outer wall and an inner surface that defines an inner chamber into which the at least one container and the at least one frozen environmental sample may be placed for storage and / or transport. Various embodiments may incorporate specific types of insulating material and / or adaptations to an inner surface of the cooler to enhance the insulation effected thereby.

Owner:UNIV OF WYOMING RES

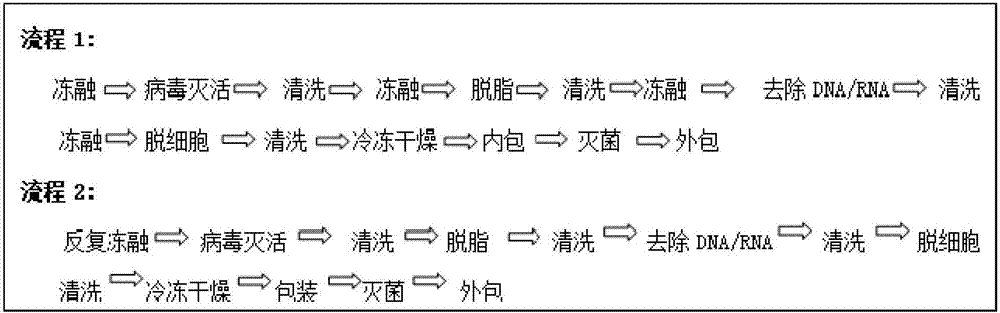

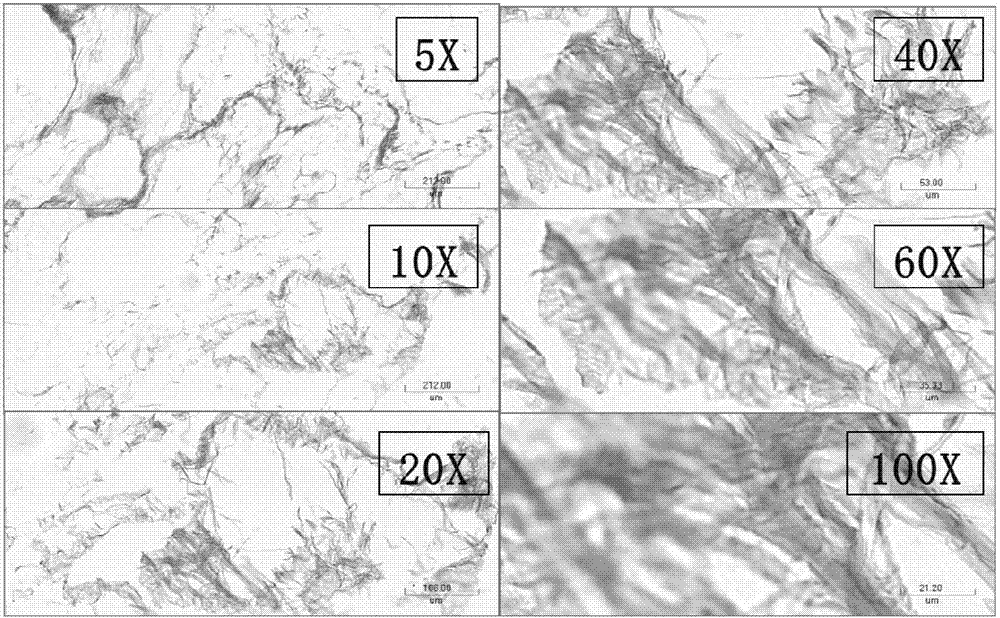

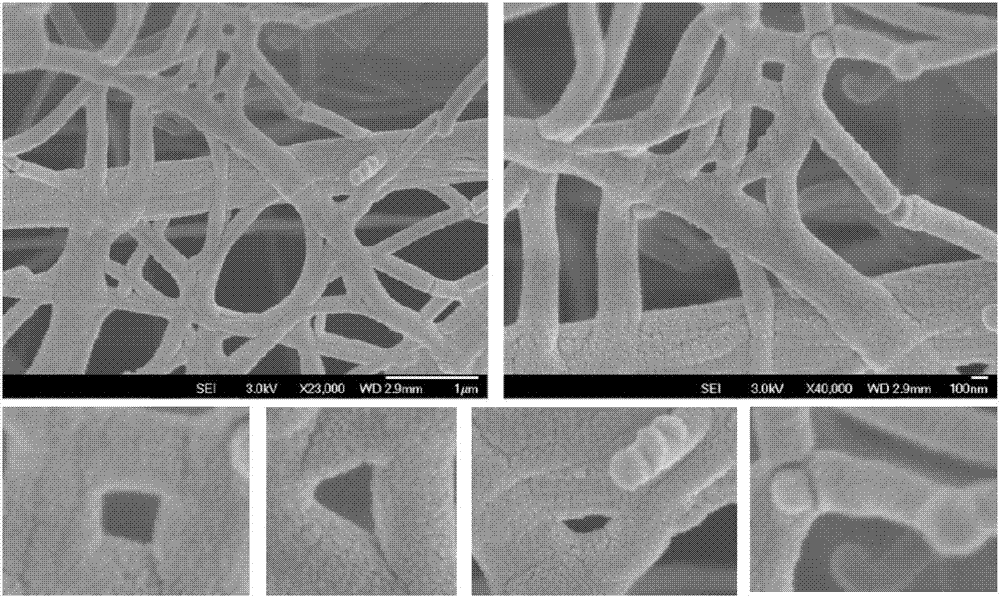

Animal bladder decellularizing matrix as well as preparation method and application thereof

ActiveCN107397978AEnsure Structural IntegrityReduce the risk of transmissionTissue regenerationProsthesisAntigenFreeze thawing

The invention provides a preparation method of an animal bladder decellularizing matrix. The preparation method comprises the steps of extracting a strata submucosum of an animal bladder, and carrying out virus inactivation, degreasing and decellularization, wherein the decellularization step sequentially comprises a repeated freeze thawing step and a decellularization solution decellularization step, the freezing temperature in the freeze thawing step is (-70)-(-90) DEG C, and the freezing time is 5-15 hours. The invention further provides the animal bladder decellularizing matrix prepared by virtue of the preparation method and the application of the animal bladder decellularizing matrix. According to the preparation method, the bladder decellularizing matrix is prepared by combining the repeated freeze thawing with the decellularization solution decellularization, elastic fibers and a collagen net structure of an extracellular matrix are furthest preserved, and meanwhile, antigens are thoroughly removed. The animal bladder decellularizing matrix can be applied to the repairing fields of bladders, urethrae and ureters.

Owner:BEIJING NATON TECH GRP CO LTD +1

Making method of green plum concentrated juice

InactiveCN105454937AAdvanced production methodsReduce energy consumptionFood scienceMetaboliteFruit juice

The invention discloses a making method of green plum concentrated juice. The method includes the following steps that 70-80% maturity green plums are selected, washed, denucleated and pulped to be frozen, the freezing temperature is minus 8DEG C-minus 10 DEG C, and the freezing time is less than three months; 2, after frozen fruit juice is unfrozen, enzymolysis factors are added for enzymolysis, the enzymolysis temperature is 40-60 DEG C, and when the acidity of citric acid reaches 100 g / kg or above, solid-liquid separation is conducted; 3, separated juice is subjected to dehydration and concentration under the vacuum state with the pressure intensity smaller than -0.08 MPa, the concentration temperature is smaller than or equal to 80 DEG C, when the weight percentage of the moisture is lower than or equal to 5%, the juice is sterilized, and a finished product is obtained. The whole process is free of a high temperature, and energy consumption is lowered; the nutritional ingredients of the green plum are maintained to the maximum degree, and the absorption effect of an organism is better improved; the variety of organic acid of the green plum is increased and reaches one hundred and forty or more, and the effective ingredients of the green plum are utilized to the maximum degree; no toxic substance is generated or discharged in the processing process, and toxic metabolite generated by the organism is neutralized to the maximum degree.

Owner:YANGZHOU YOUYUAN BIOTECH CO LTD

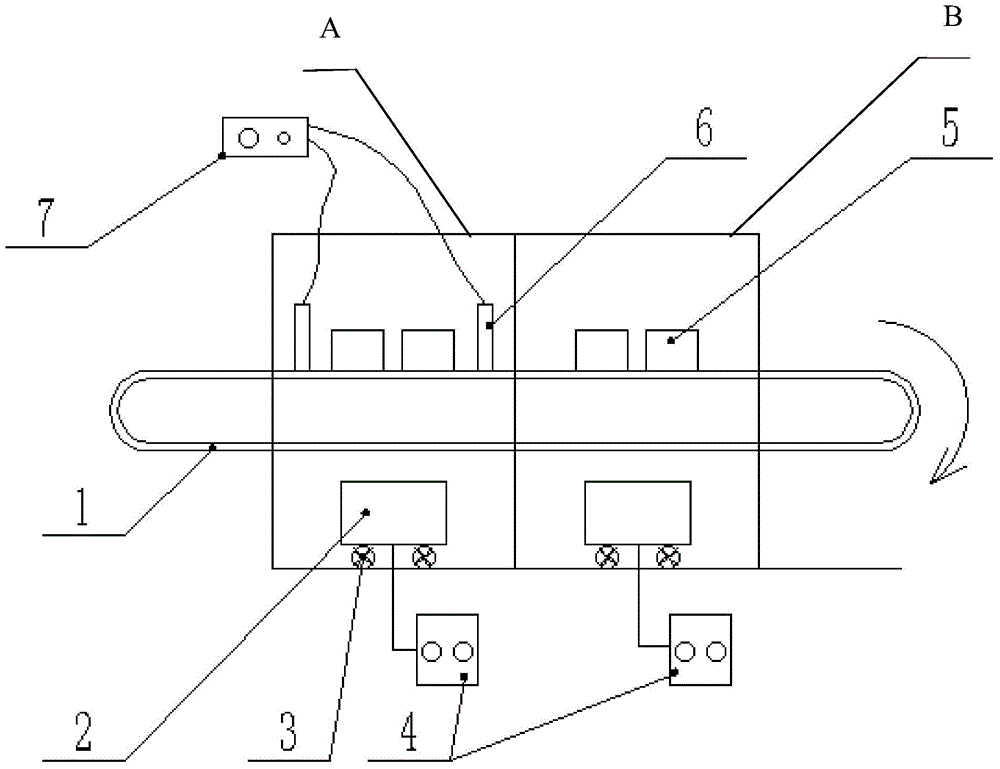

Microwave-combined electric field-assisted method for production of quickly-frozen convenient rice and refrigeration unit

The present invention discloses a microwave-combined electric field-assisted method for production of quickly-frozen convenient rice, comprising the steps of: (1) cleaning rice; (2) soaking the rice; (3) steaming and cooking with microwave; (4) cooling to room temperature and packing; ( 5) pre-cooling to 1-2 DEG C; (6) performing electric field-assisted freezing on the pre-cooled rice to complete crystallization, wherein the electric field-assisted freezing temperature is-18 to-20 DEG C; (7) freezing to freezing storage temperature in the absence of electric field; and (8) performing freezing storage. The microwave-combined electric field-assisted method can effectively inhibit linear chain molecule gelling, formed ice crystals are fine, and mainly distributed in the crystal cell, amylopectin molecular rearrangement is greatly prevented, and the convenient rice with good taste and good nutrition can be obtained.

Owner:SOUTH CHINA UNIV OF TECH

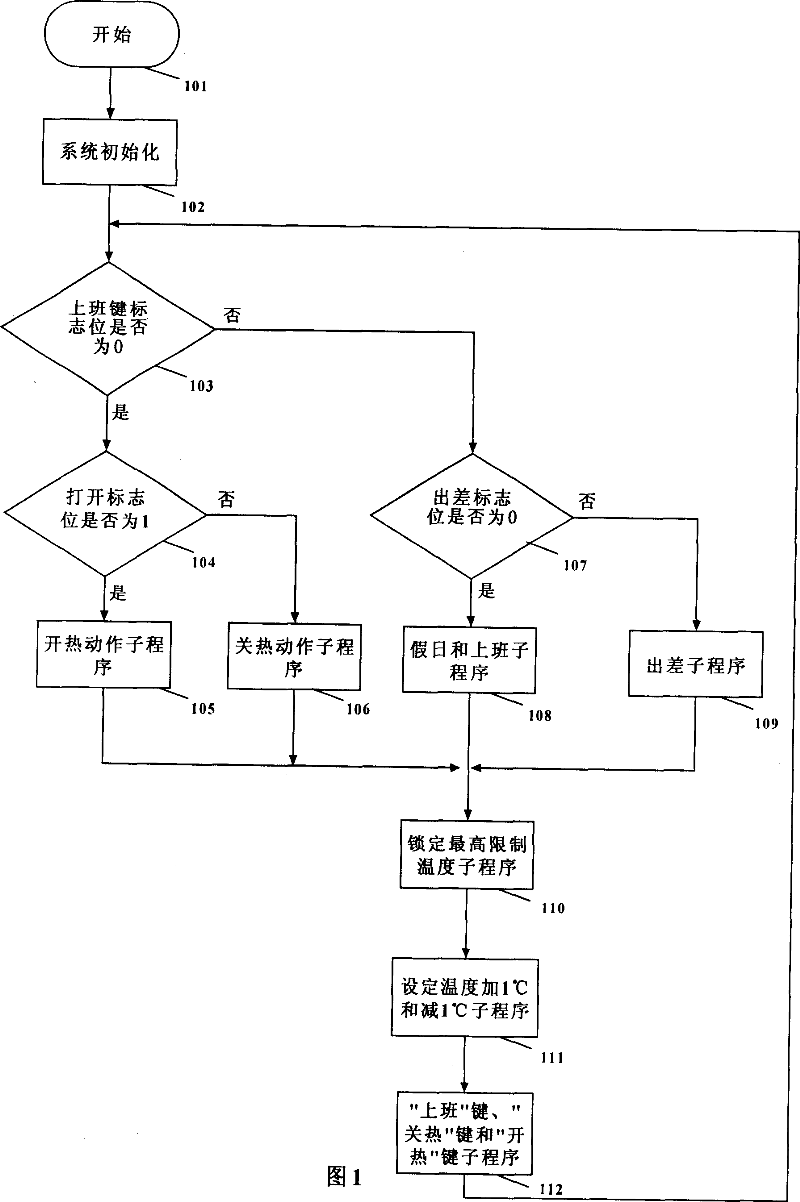

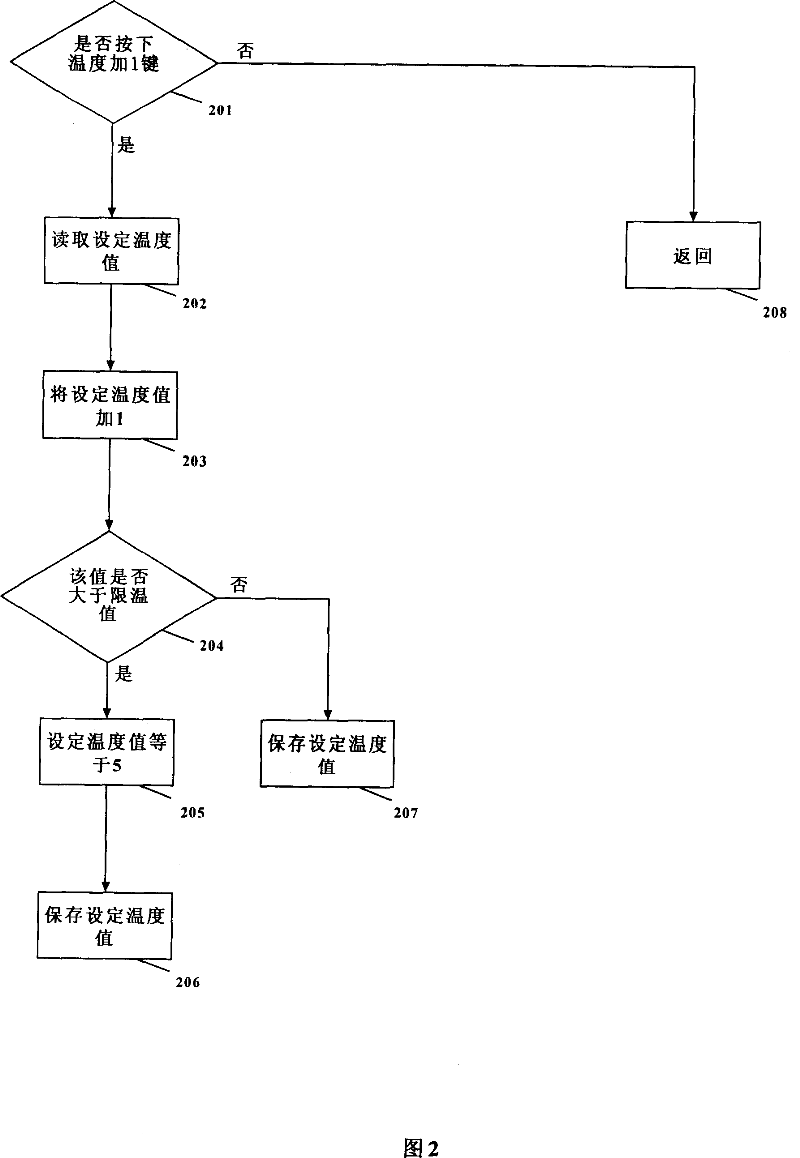

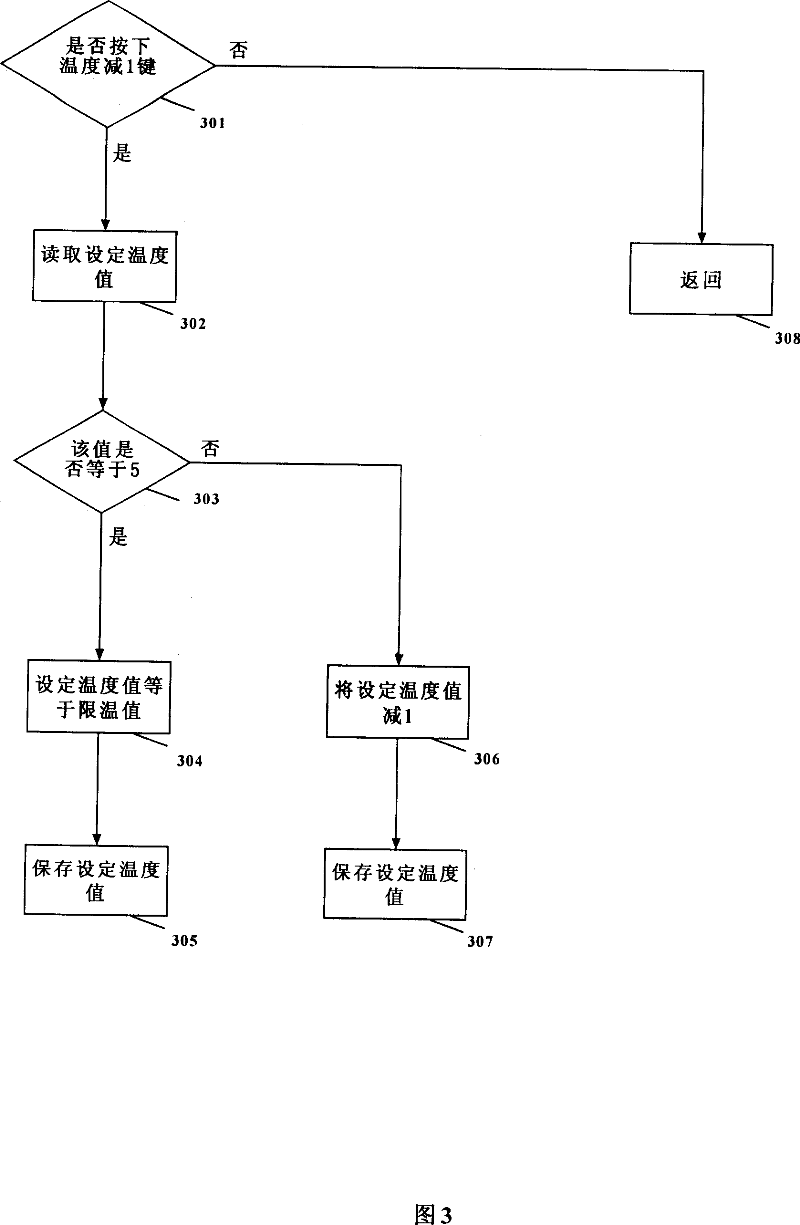

Residence heating energy-saving intelligent control method

InactiveCN101042573AGuaranteed comfortSave energyProgramme control in sequence/logic controllersInfraredResidence

This invention discloses one house heat save intelligent control method, which comprises single computer unit, sound output circuit, infrared receive circuit, permanent calendar unit, power execution structure, room temperature test circuit, outdoor infrared remote controller and lock temperature remoter, wherein, the software is set inside computer; the control chamber temperature is set as one; the press heat key and open key single computer controls the frozen temperature and set one; the work time temperature is controlled in frozen one and not wok time for set one; the room temperature is in open thermal status and the anti-frozen temperature close status has work time as anti-frozen temperature and other as set one.

Owner:纪义盛

A Freezing Method of High Gradient Heterogeneous Freezing Wall

The invention discloses a method for freezing a high-gradient heterogeneous freezing wall. The mixed freezing mode of "salt water + liquid nitrogen" is adopted, and a freezing pipe is arranged at the place where the soil around the shaft needs to be frozen, and a brine freezing pipe is arranged inside the freezing wall. , and a liquid nitrogen freezing tube is arranged on the periphery. The liquid nitrogen freezing tubes are arranged in one row, and the brine freezing tubes are arranged in at least one row, and each row is arranged in a circular shape. When there are two or more rows of brine freezing pipes, the diameter of the ring in the innermost row should ensure that the temperature of the well side during excavation is not higher than the ideal value that is conducive to the stability of the well side; the brine temperature setting of the brine freezing pipes should ensure that It can form a temperature field that gradually decreases from the inside to the outside. The temperature field formed by the freezing tube layout method of the present invention has obvious high gradient non-uniformity. Compared with conventional brine freezing, under the same load conditions, the thickness of the frozen wall formed by this pipe layout is small but has a higher bearing capacity, which will reduce the amount of frost heaving and thawing, and reduce the amount of engineering work for freezing holes , The freezing period is shortened.

Owner:TONGJI UNIV

Method and device for optimized freeze-drying of a pharmaceutical product

ActiveUS10809002B2Quality improvementImprove securityClosures with freeze-dryingDrying solid materials without heatFreeze-dryingProcess engineering

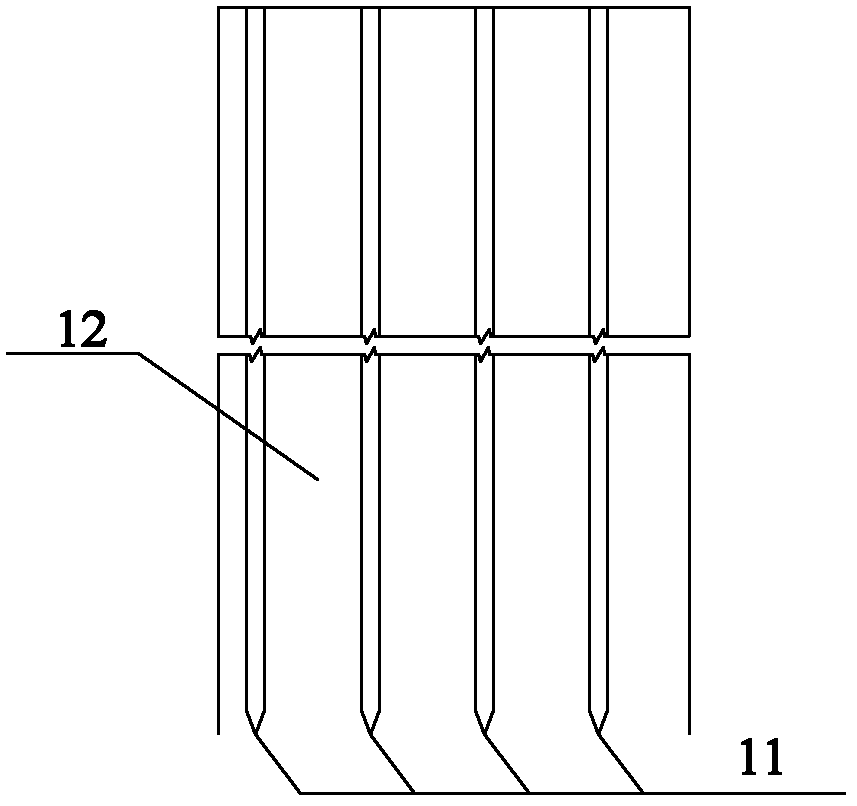

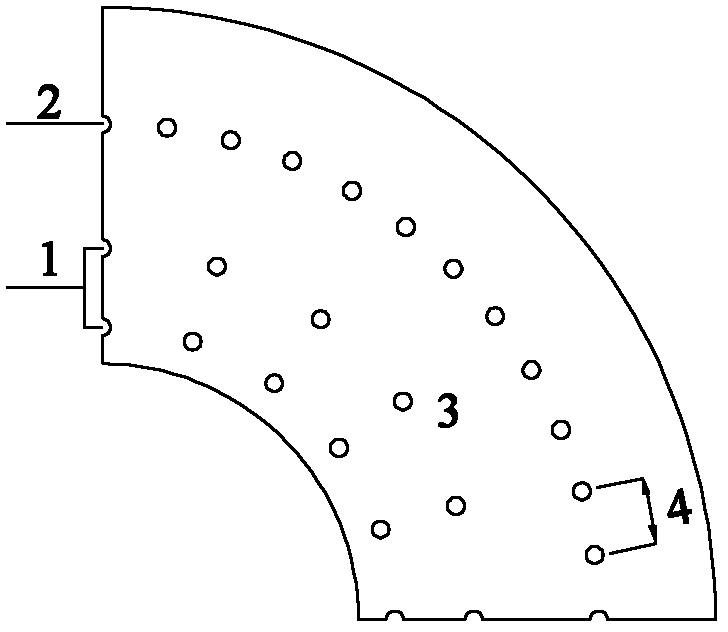

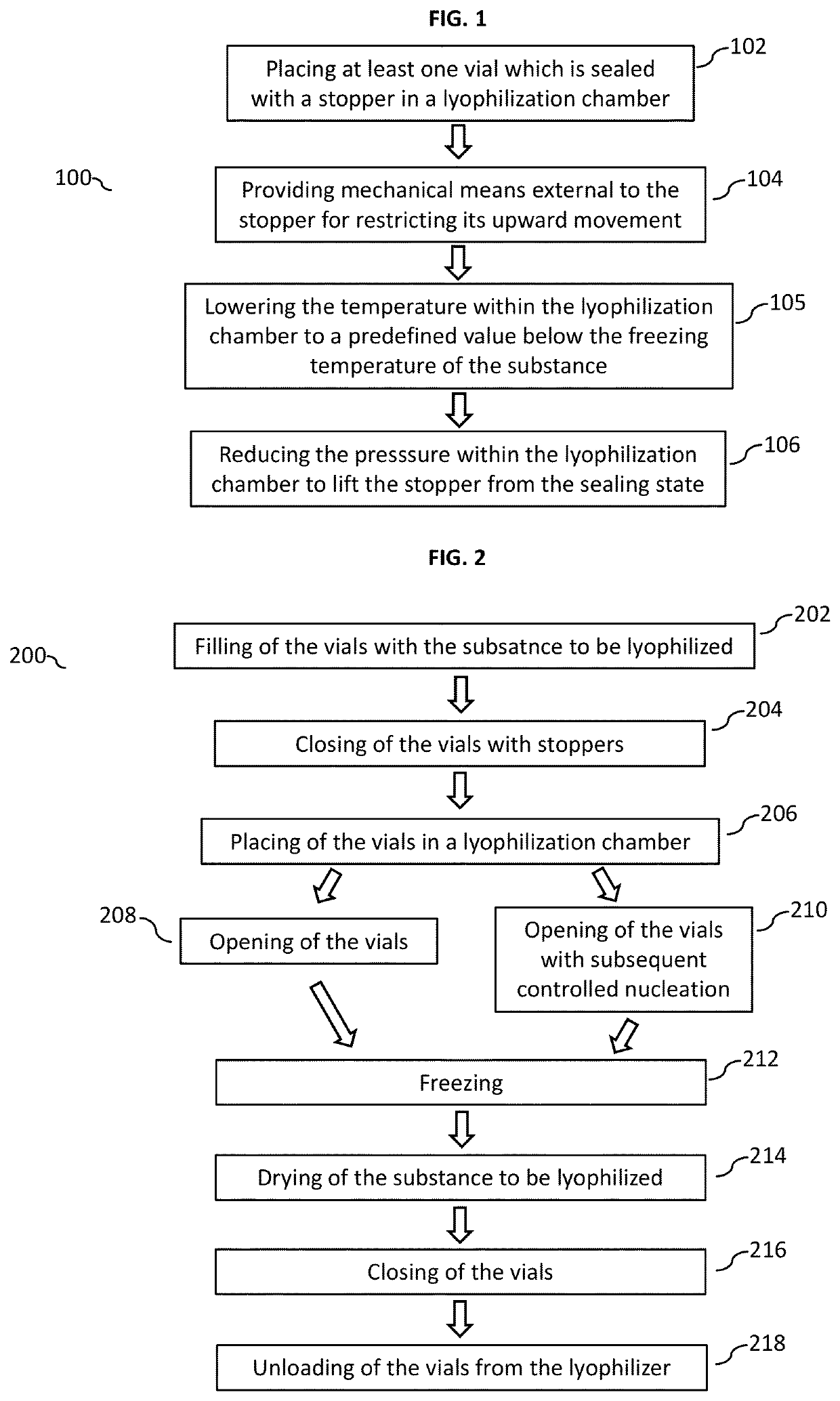

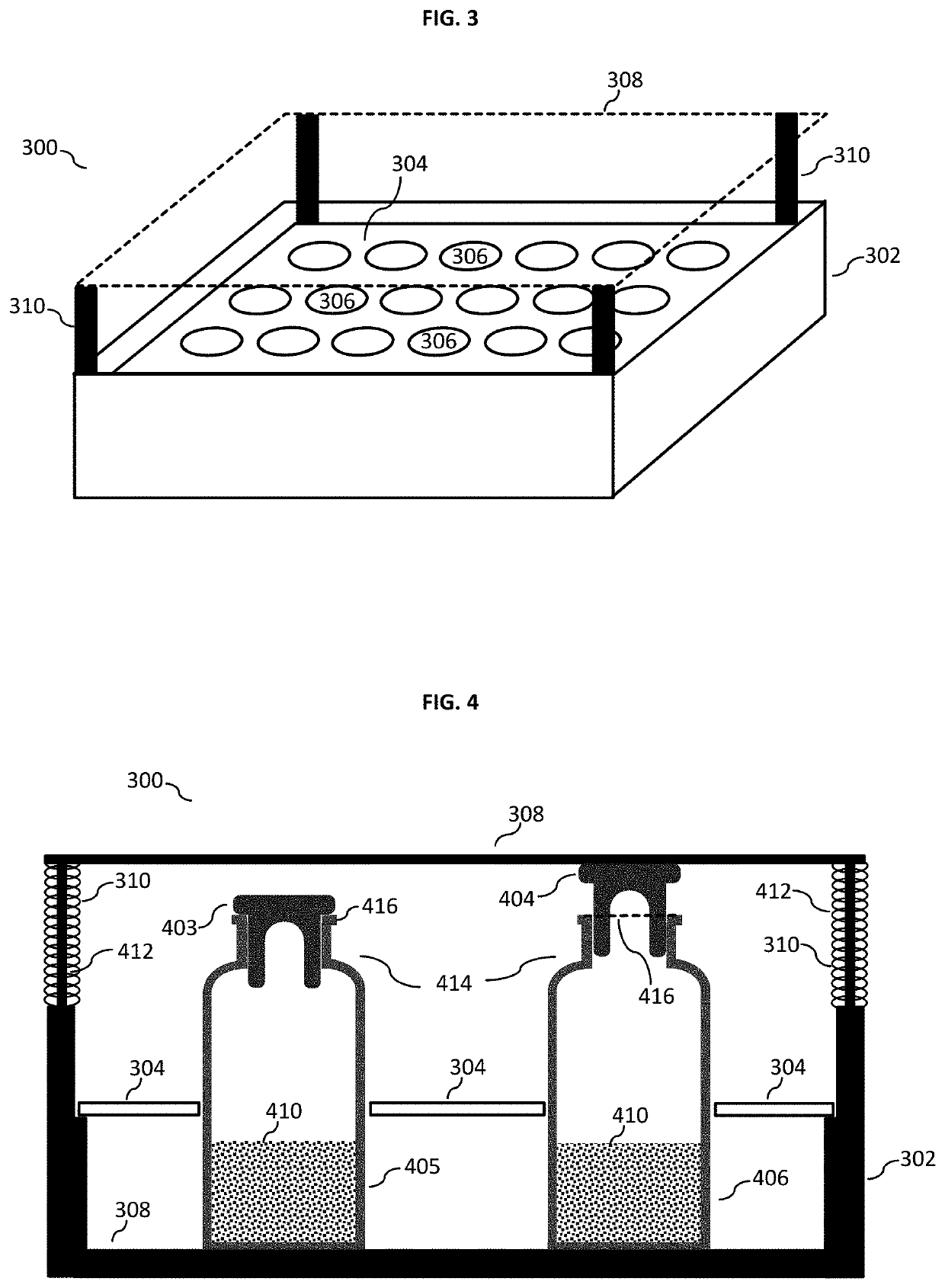

A method for lyophilizing a substance is provided which may include placing at least one vial containing the substance in a lyophilization chamber, the at least one vial having an opening in which a stopper is inserted in a closed state not allowing gas exchange between the interior and exterior of the vial; providing mechanical means external to the stopper and arranged at the opening for restricting an upward movement of the stopper; lowering the temperature within the lyophilization chamber to a predefined value below the freezing temperature of the substance and reducing the pressure within the lyophilization chamber to a predefined pressure at a predefined temperature, the predefined pressure being chosen such that the force exerted by it on the stopper lifts the stopper from the closed state to an exchange state in which the stopper is only partly inserted in the opening of the vial allowing gas exchange between the interior and exterior of the vial, wherein the lowering of the temperature within the lyophilization chamber to the predefined value is performed before reducing the pressure within the lyophilization chamber to the predefined pressure and wherein lifting the stopper from the closed state abruptly lowers the pressure within the at least one vial which initiates nucleation in the substance within that vial. In addition, mechanical means is provided which may be used in order to perform the method for lyophilizing a substance.

Owner:PROJECT PHARMA

Method of fully freezing ice and refrigerator using the same

InactiveUS7555909B2Improve ice qualityPreventing the ice from sticking togetherIce productionFluid circulation arrangementEngineeringRefrigerated temperature

A method of fully freezing ice in a refrigerator. The method includes setting a full-frozen temperature for determining whether ice is fully frozen, and a reference ambient temperature for re-adjusting the full-frozen temperature; supplying water to the ice-making tray to thereby perform ice-making; sensing ambient temperature; sensing temperature of the ice-making tray; re-adjusting the full-frozen temperature by comparing the sensed ambient temperature with the reference ambient temperature; and if the temperature of the ice-making tray reaches the re-adjusted full-frozen temperature, driving an ice-transfer motor to transfer full-frozen ice from the ice-making tray.Thus, not fully frozen ice is prevented from being transferred, to thereby improve ice quality and avoid sticking of ice, which may occur when not fully frozen ice is broken while being transferred. A refrigerator using such a method is also disclosed.

Owner:SAMSUNG ELECTRONICS CO LTD

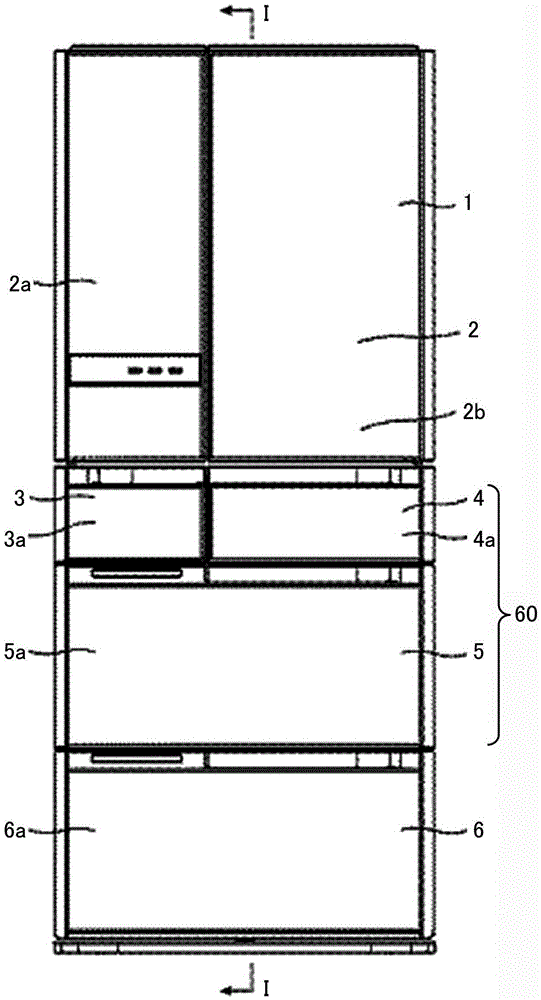

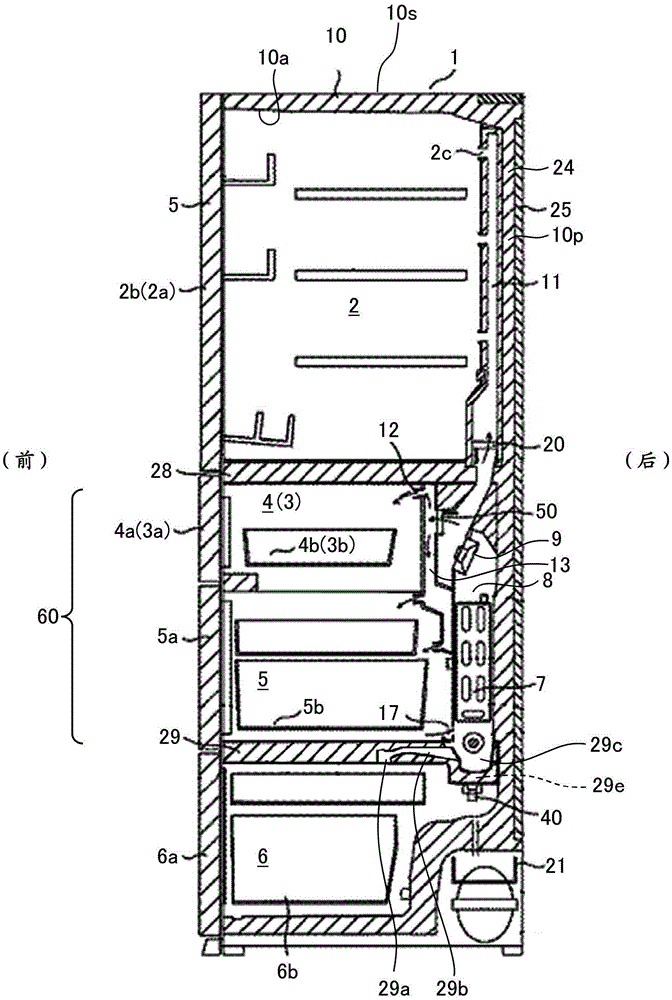

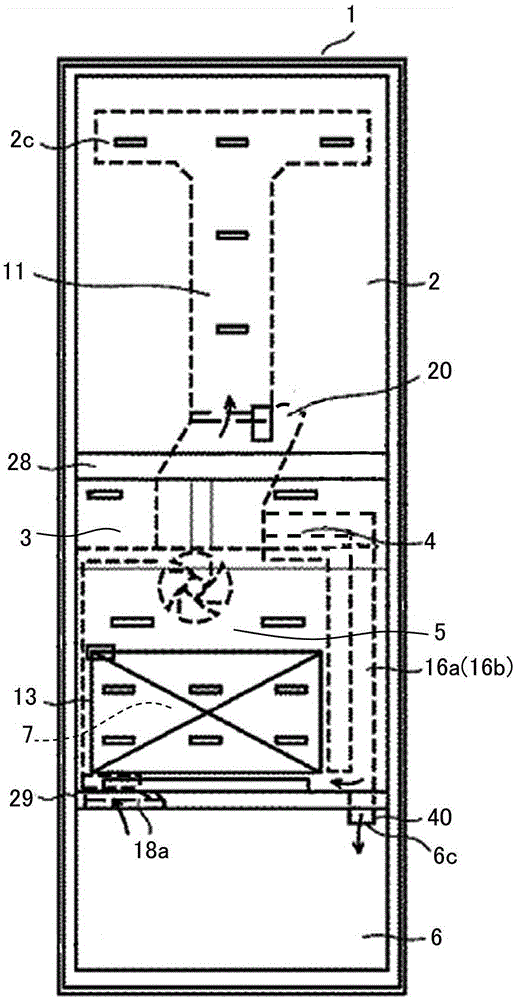

Refrigerator

ActiveCN106052248AIncrease volumeReduce power consumptionLighting and heating apparatusDomestic refrigeratorsRefrigerator carCold air

The present invention provides a refrigerator capable of reducing power consumption and having a heat-insulating partition wall capable of increasing the volume of the tank. The refrigerator according to the present invention is a refrigerator (1) for refrigerating or freezing an inner foodstuff by cold air generated by an evaporator (7). The refrigerator comprises an insulating case (10) (10) filled with foamed thermal insulating material (10p) between the outer box (10s) and the inner box (10u); a frozen temperature chamber(5) and a vegetable chamber (6) provided with an insulating case(10), and an insulating partition wall (29) provided with an insulating space (29d) thereof; an vaccum insulating material (32) configured inside the insulating wall (29). When viewed from the front, the lateral width of the vacuum insulating material (32) is larger than the lateral width of the evaporator (7); when viewed from the front or the above, a cool air returning port(29a) into which the cool air after cooling the vegetable compartment (6) is sucked is located on the projection surface of the vacuum heat insulating material (32).

Owner:日立グローバルライフソリューションズ株式会社

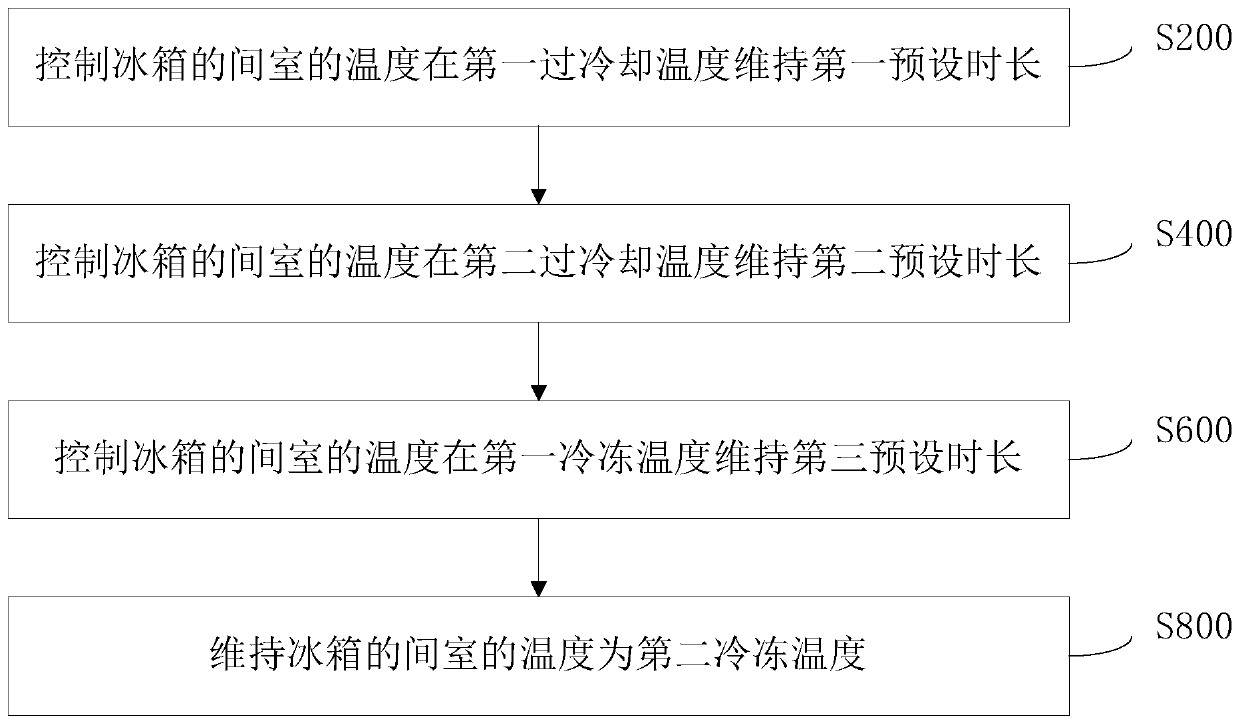

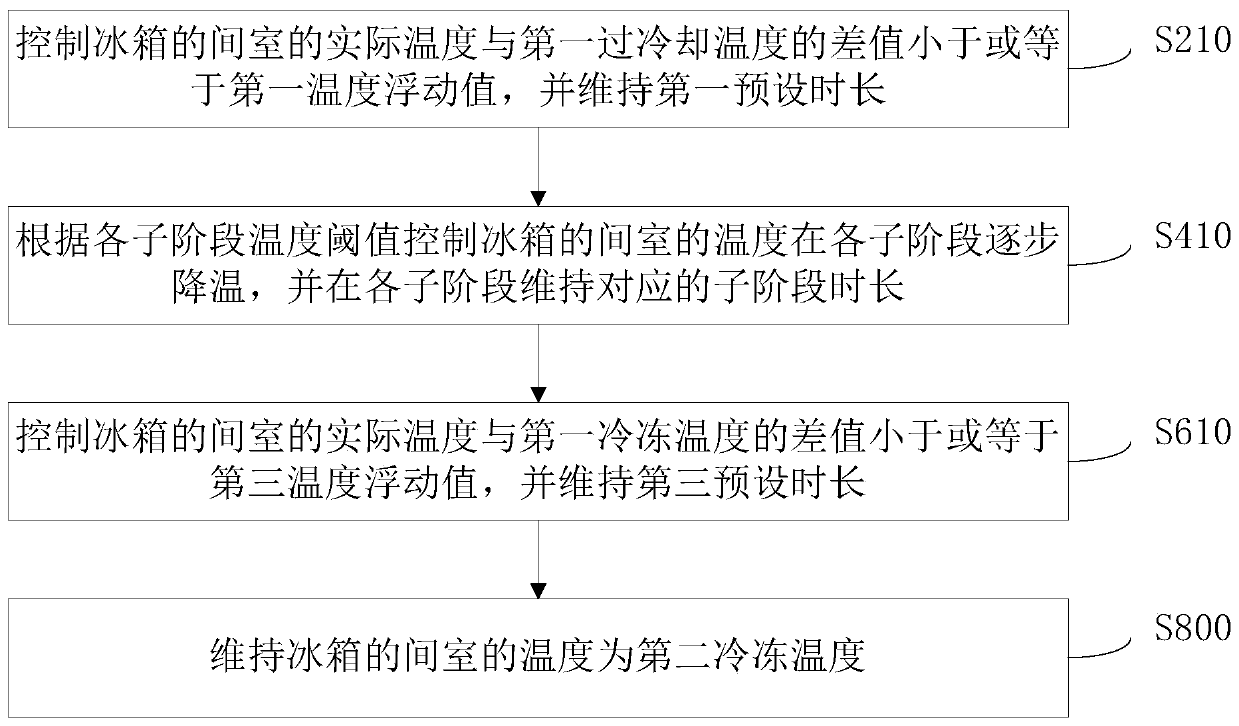

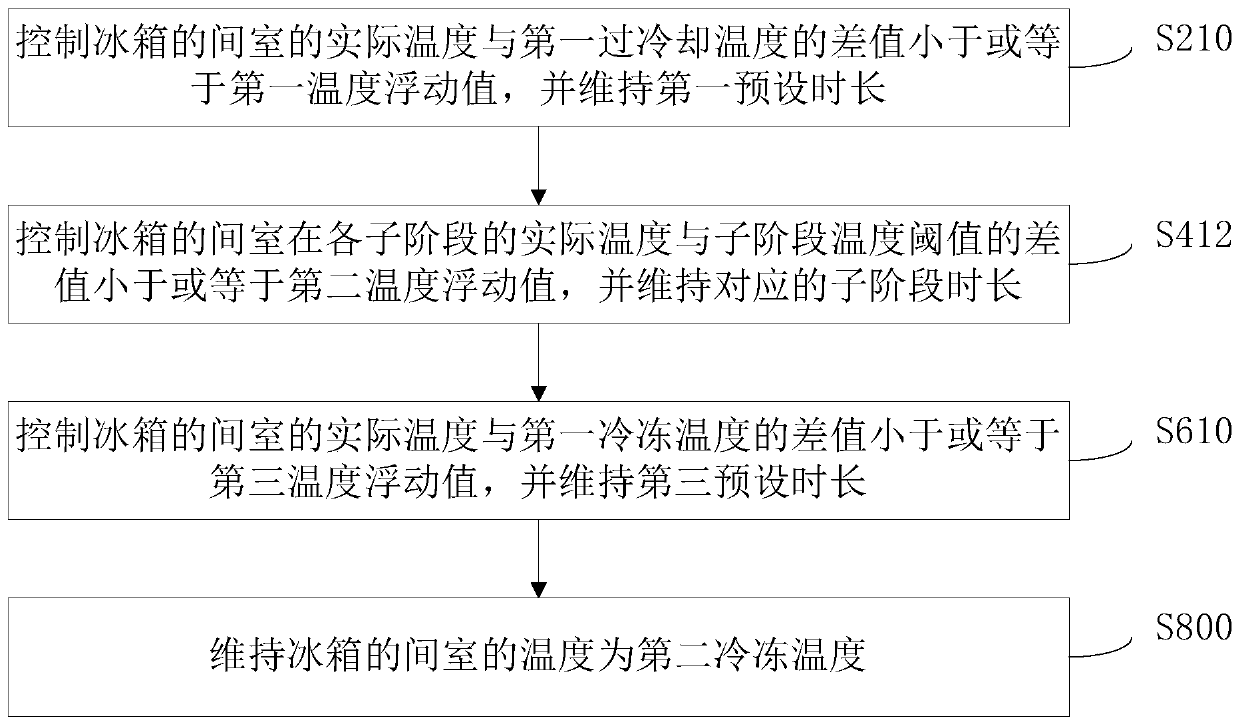

Food storage control method, device and equipment in refrigerator and refrigerator system

PendingCN110671889AImprove food storageProtect nutritionLighting and heating apparatusCooling fluid circulationCold airTemperature control

The invention relates to a food storage control method, device and equipment in a refrigerator and a refrigerator system. The method comprises the steps that the temperature of a compartment of the refrigerator is controlled at a first supercooling temperature for a first preset duration, the temperature of the compartment of the refrigerator is controlled at a second supercooling temperature fora second preset duration, the temperature of the compartment of the refrigerator is controlled at a first freezing temperature for a third preset duration, and the temperature of the compartment of the refrigerator is maintained at a second freezing temperature. It is ensured that food is in a supercooling state through temperature control and then frozen, so that damage to cells in the food is reduced; and finally, the temperature of the compartment of the refrigerator is maintained at the second freezing temperature higher than the first freezing temperature, and the food is conveniently cutafter being taken out on the premise of ensuring long-term storage of the food. In addition, through refrigeration of a refrigerant in a refrigerator evaporator, air blowing is not needed, adverse effects such as air drying and freezing burning caused by cold air on the food are avoided, the food quality is guaranteed, and the food storage effect of the refrigerator is improved.

Owner:HEFEI KINGHOME ELECTRICAL CO LTD +1

High pressure frozen sterilization process

ActiveUS20110059217A1Avoid mold growthPrevent growth yeastMilk preservationWort preparationHigh pressure freezingHigh pressure

Methods of sterilizing a temperature sensitive material, such as an acidified or non-acidified food product, pharmaceutical product or cosmetic product, are disclosed. The methods comprise freezing the temperature sensitive material to an initial temperature of less than or equal to −2° C. and then either (i) pressurizing the frozen temperature sensitive material to a first elevated pressure of at least 250 MPa for a predetermined first period of time of at least 3 minutes or (ii) pressurizing the frozen temperature sensitive material to a first elevated pressure of at least 250 MPa for a predetermined first period of time of at least 90 seconds, releasing the first elevated pressure for a predetermined pause period of time and then pressurizing the temperature sensitive material to a second elevated pressure of at least 250 MPa for a predetermined second period of time of at least 90 seconds.

Owner:TEXAS TECH UNIV SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com