Microwave-combined electric field-assisted method for production of quickly-frozen convenient rice and refrigeration unit

An electric field-assisted, instant rice technology, applied in food preparation, food preservation, food science, etc., can solve problems affecting food quality, uneven distribution, and different ice crystal sizes, so as to achieve good taste and quality, expand the scope of requirements, Effect with high sensory evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

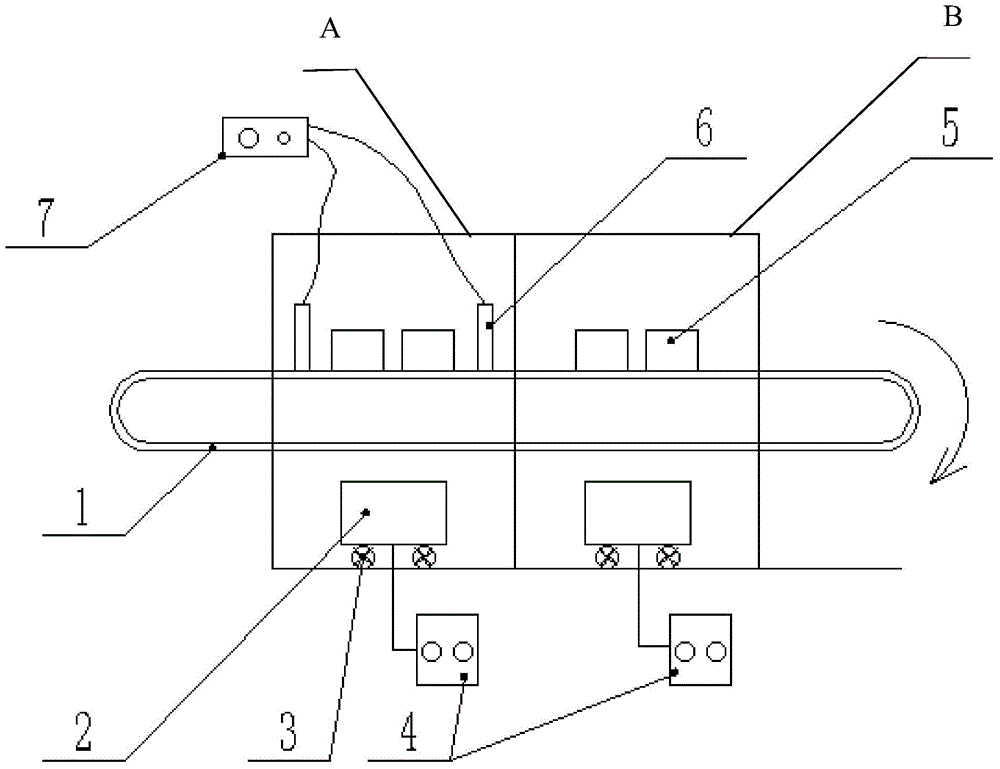

[0051] The freezing device used in this embodiment is as figure 1 As shown, it includes a conveyor belt 1, an electric field-assisted freezing chamber A, and a non-electric field freezing chamber B; during operation, the rice sample 5 is sequentially sent into the electric field-assisted freezing chamber A and the non-electric field freezing chamber B for freezing by the conveyor belt.

[0052]The electric field assisted freezing chamber A is provided with a semiconductor refrigeration sheet 2 and two opposite electrode plates 6; the non-electric field freezing chamber B is provided with a semiconductor refrigeration sheet 2; the semiconductor refrigeration sheet 2 is provided with a fan 3; The sheet 2 is connected with a semiconductor power control box 4 ; the electrode plate 6 is connected with an electrode power control box 7 .

[0053] The method for making quick-frozen instant rice assisted by microwave combined with electric field of the present embodiment comprises the ...

Embodiment 2

[0055] The microwave-assisted method of making quick-frozen instant rice of the present embodiment comprises the following steps: choosing Guobaoqiao rice (moisture content is 17.5%, amylose content 16.80%) is raw material, takes by weighing 2kg rice, after conventional elutriation, place Add 3 L of tap water at 42°C to the sample box of the microwave oven, cover the sample box and soak at a constant temperature for 25 minutes; after soaking, carry out microwave cooking, give 850W microwave treatment for 20 minutes, pause for 10 minutes, give 550W microwave treatment for 10 minutes, and stop heating for 10 minutes , take it out and place it at room temperature; spread it out and cool it to room temperature with cold air, it takes about 25 minutes; use 16*24cm aluminum foil packaging bag, carry out vacuum packaging at 0.1MPa, each bag is 200g; place it in a cold storage at 1-2°C Pre-cooling to 1-2°C takes about 1.5 hours; turn on the conveyor belt, transfer the pre-cooled rice t...

Embodiment 3

[0057] The microwave-assisted method of making quick-frozen instant rice of the present embodiment comprises the following steps: Wufangzhai glutinous rice (moisture content is 24.5%, amylose content is 0.40%) is raw material, takes by weighing 2.5kg rice, after conventional elutriation, Place in the sample box of a microwave oven, add 2.5L tap water at 35°C, cover the sample box, and soak at a constant temperature for 20 minutes; after soaking, carry out microwave cooking, give 700W microwave treatment for 13 minutes, pause for 8 minutes, give 500W microwave treatment for 13 minutes, and stop heating After 8 minutes, take it out and place it at room temperature; spread it out and cool it down to room temperature, it will take about 30 minutes; use 20*20cm aluminum foil bags, vacuum pack at 0.1MPa, each bag contains 300g; store at 1-2°C It takes about 2 hours to pre-cool in the cold storage to 1-2°C; turn on the conveyor belt, and transfer the pre-cooled rice to the electric fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com