Oat beverage and preparation method thereof

A technology for oats and beverages, applied in the field of vegetable protein beverage processing, can solve the problems of unfavorable processing, long-chain starch, etc., and achieve the effects of long production time, uniform tissue state, and pure flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

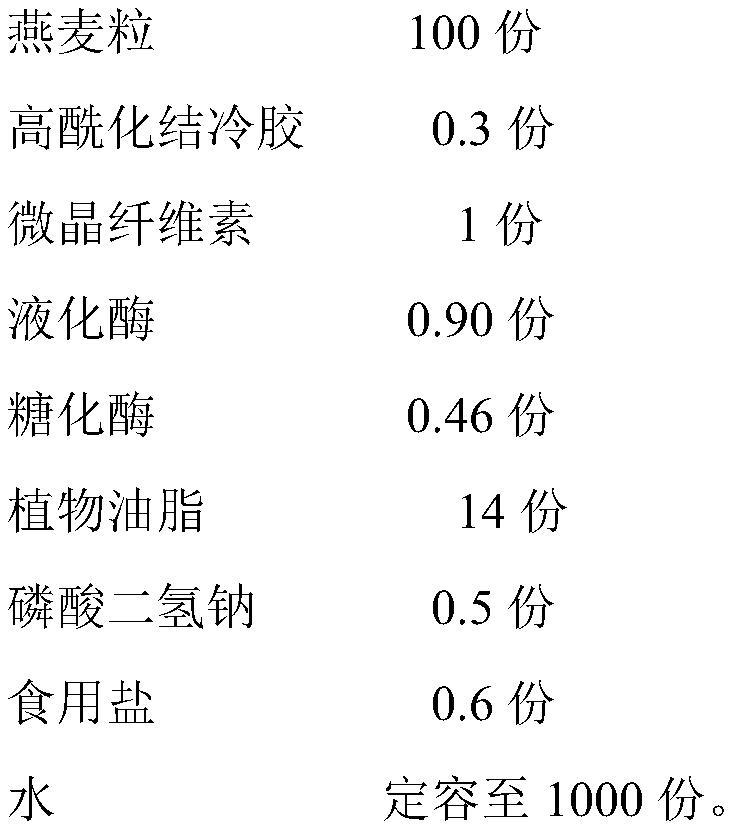

[0037] This embodiment provides an oatmeal drink, wherein, based on 1000 kg of finished product, the raw material composition of the oatmeal drink includes:

[0038]

[0039] The preparation method of the oat beverage of the present embodiment comprises the following specific steps:

[0040] 1. Oatmeal treatment: wash the fresh oatmeal with water, and drain the water;

[0041] 2. Cooking of oat grains: According to the ratio of oat grains: water = 1:6.5, make oat grain water, raise the temperature to 65-68°C, and cook for 15 minutes;

[0042] 3. Refining the oat grains; fully refine the oat grains, and use a three-stage grinding equipment for refining treatment. You can use edible baking soda to adjust the pH value of the oat pulp between 5.9-7.0;

[0043] 4. Enzymatic hydrolysis of oat pulp: raise the temperature of oat pulp to 70-75°C, when the viscosity of oat pulp reaches the maximum (at this time, the fluidity of oat pulp is poor, the heat exchange between the center ...

Embodiment 2

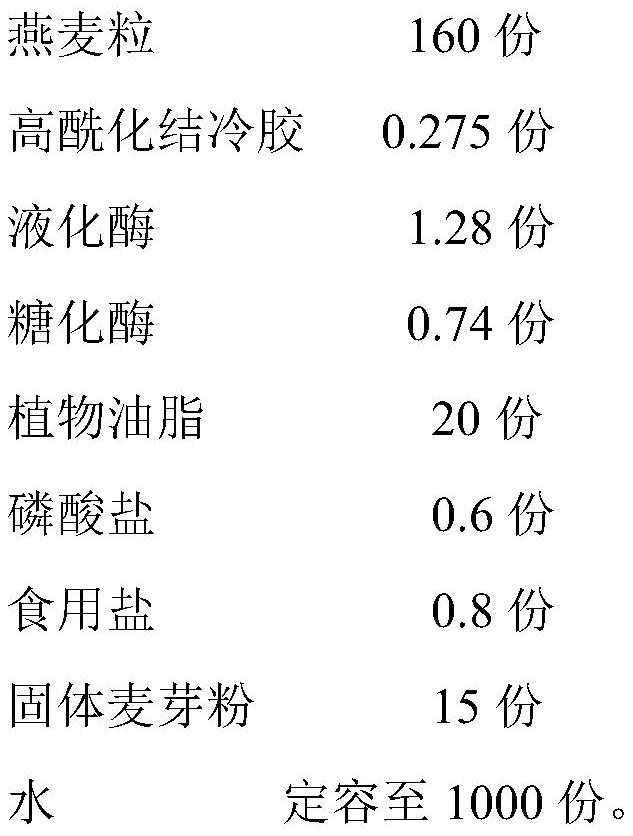

[0053] This embodiment provides an oatmeal drink, wherein, based on 1000 kg of finished product, the raw material composition of the oatmeal drink includes:

[0054]

[0055] The preparation method is the same as in Example 1.

Embodiment 3

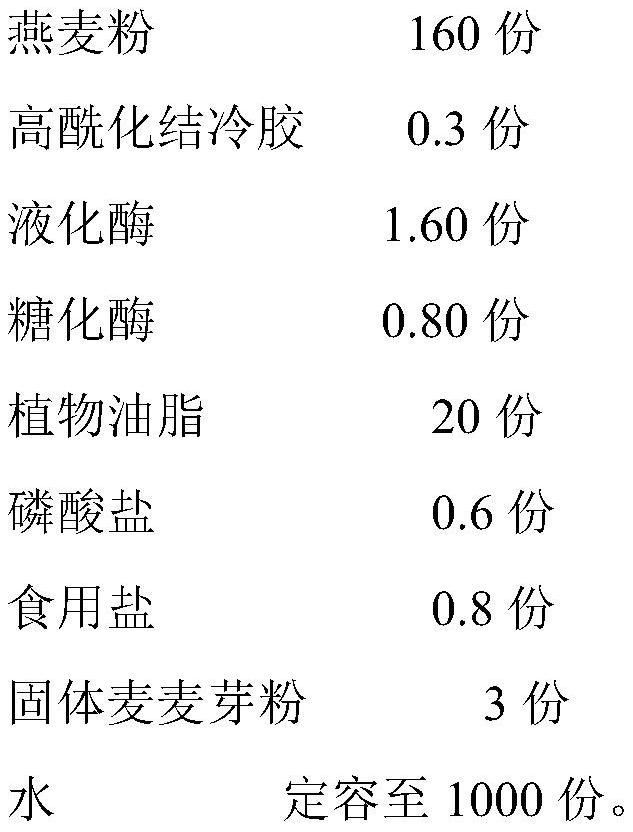

[0057] This embodiment provides an oatmeal drink, wherein, based on 1000 kg of finished product, the raw material composition of the oatmeal drink includes:

[0058]

[0059] The preparation method of the oat beverage of the present embodiment comprises the following specific steps:

[0060] 1. Hydration of oat flour: according to the concentration of 10-18%, the oat flour is hydrated with room temperature ingredient water to prepare oat pulp;

[0061] 2. Enzymatic hydrolysis of oat pulp: raise the temperature of oat pulp to 70-75°C, then when the temperature of oat pulp reaches 80°C, add liquefaction enzyme (medium temperature α-amylase) and hydrolyze for 15 minutes; cool the enzymatic solution to 60- At 65°C, add glucoamylase (glucoamylase) and hydrolyze for 30 minutes;

[0062] 3. Enzyme activity inactivation: raise the temperature of the enzymatic solution to 90-95°C for 15 minutes;

[0063] 4. Separation and deslagging: use turbine deslagging equipment to separate oa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com