Food grade additive-free acne-removal nourishing mung bean mask and green production method thereof

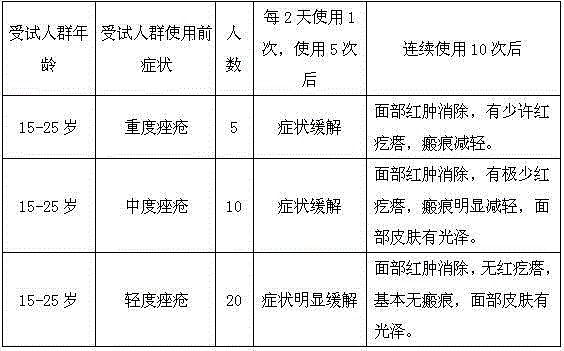

An additive-free, food-grade technology, applied in cosmetics, food science, pharmaceutical formulations, etc., can solve problems such as adverse reactions, and achieve the effect of reducing acne, lightening acne scars, and beautifying facial skin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Made from the following raw materials and steps in parts by weight:

[0033] 15 parts of mung bean, 1 part of tremella, 1 part of pearl, 1 part of pine pollen, 1 part of dried lily, 1 part of dried honeysuckle, 1 part of dried rose, 0.3 part of lemon slice, 0.1 part of dried tangerine peel;

[0034] (1) Continuous activation and crushing of mung beans

[0035] Take the ripe mung bean seeds of the year and screen them to remove impurities, spray and wash them with cold water at 8°C, put them into a vortex scalding tank and scald them in 80°C water for 5 seconds for the first activation, then quickly remove them and put them into 29°C water for aerobic reciprocating oscillation soaking 9h for the second activation treatment, the oscillation frequency is 30r / min, the amount of air introduced into the water is 1L / h, then the running water is sprayed and cleaned, the surface water is drained, and the third activation is carried out at 40°C and 5min microwave oscillation pro...

Embodiment 2

[0046] Made from the following raw materials and steps in parts by weight:

[0047] 25 parts of mung bean, 3 parts of white fungus, 3 parts of pearl, 3 parts of pine pollen, 2 parts of dried lily, 2 parts of dried honeysuckle, 2 parts of dried rose, 1.2 parts of lemon slice, 0.5 part of dried tangerine peel;

[0048] (1) Continuous activation and crushing of mung beans

[0049] Take the ripe mung bean seeds of the year and screen to remove impurities, spray and wash them with cold water at 15°C, put them into a vortex scalding tank, soak them in 90°C water for 3 seconds for the first activation, then quickly remove them and put them into 35°C water for aerobic reciprocating oscillation soaking 5h for the second activation treatment, the oscillation frequency is 80r / min, the amount of air introduced into the water is 3L / h, then the running water is sprayed and cleaned, the surface water is drained, and the third activation is carried out at 45°C and 3min microwave oscillation ...

Embodiment 3

[0060] Made from the following raw materials and steps in parts by weight:

[0061] 20 parts of mung bean, 2 parts of tremella, 2 parts of pearl, 2 parts of pine pollen, 1.5 parts of dried lily, 1.5 parts of dried honeysuckle, 1.5 parts of dried rose, 0.8 part of lemon slice, 0.3 part of dried tangerine peel;

[0062] (1) Continuous activation and crushing of mung beans

[0063] Take the mature mung bean grains of the year and screen to remove impurities, spray and wash them with cold water at 11°C, put them into a vortex scalding tank, soak them in 85°C water for 4 seconds for the first activation, then quickly remove them and put them into 32°C water for aerobic reciprocating oscillation soaking 7h for the second activation treatment, the oscillation frequency is 55r / min, the amount of air introduced into the water is 2L / h, then the running water is sprayed and cleaned, the surface water is drained, and the third activation is carried out at 42.5°C and 4min microwave oscilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com