Patents

Literature

430 results about "Oatmeal Powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Colloidal oatmeal, whole oats milled to a fine powder, with anti-pruritic activity. Oatmeal powder, especially when added to a warm bath, is used to provide temporary relief of itching and irritation caused by insect bites, eczema, sun burns, reactions to poisonous plants and various other skin rashes and allergies.

Compound mixed grain nourishing food and producing method thereof

InactiveCN101223900AFull of nutritionRich foodDough treatmentBakery productsBiotechnologyPolygonum fagopyrum

The invention relates to a compound coarse cereal nutrition food and a production method thereof. The compound coarse cereal nutrition food can overcome the problems of single variety, insufficient nutrition and poor eating effect of the current coarse cereal food so as to meet different demands of people on coarse cereal foods. The technical proposal to solve the problems is that the food is produced by 4-6 portions of wheat flour, 4-6 portions of purple rice flour, 8-12 portions of rye flour, 7-11 portions of barley flour, 7-11 portions of oat flour, 7-11 portions of buckwheat flour, 8-12 portions of corn flour, 8-12 portions of millet flour, 4-6 portions of sorghum powder, 4-6 portions of pearl barley powder, 2.5-3.5 portions of soybean flour, 1.5-2.5 portions of black soybean powder, 1.5-2.5 portions of pea meal, 0.8-1.2 portions of black sesame seed powder, 1.5-2.5 portions of black rice flour, 7-11 portions of rice flour, 3-5 portions of sweet potato dry powder and water by weight. 3-5 portions of mung bean powder can be added if the food is eaten in spring, summer and autumn. The food has scientific composing prescription, rich nutrition and good taste and is convenient for eating, conducive to the health of people and a great creation of food deep processing, thus having great economic and social benefits.

Owner:单良才

Salty salicornia europaea egg tart and preparation method thereof

InactiveCN102669244ADisadvantages of changing the taste of heavy additives that are too greasy and too sweetImprove blood acidificationDough treatmentBakery productsBiotechnologyAnimal science

The invention relates to salty salicornia europaea egg tart and a preparation method thereof. In the tart wrapper, the weight ratio of salicornia europaea meal, rye meal, oat meal, wheat germ meal, natural cream, vegetable oil to clean water is 1: 18: 3: 2: 12.5: 0.25: (5-7.5); and in the aqueous tart, the weight ratio of the salicornia europaea meal, Chinese yam meal, egg white to fresh milk is 2: 1: 24: 36. The preparation method for the salty salicornia europaea egg tart comprises the following steps of: preparing the tart wrapper and the aqueous tart, shaping and baking. The preparation method for the egg tart is easy to master; and salicornia europaea containing amino acids, trace elements and vitamins which are necessary for human body is added in the raw materials, and the egg tartdoes not contain any chemical additive and is fully natural healthy food.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

Compound coarse grain instant food and preparation method thereof

ActiveCN102389084ARetain nutrientsImprove digestion and absorption rateFood preparationBiotechnologyNutritive values

The invention relates to the technical field of instant foods and particularly relates to a compound coarse grain instant food. The ingredients of the food include rice flour, core flour, bean flour, oat flour, buckwheat flour, wheat spout flour and barley malt flour. The preparation method comprises the steps as follows: grinding at a low temperature, hydrolyzing with compound enzymes, concentrating under vacuum, pre-freezing, freeze-drying, and grinding. The low-temperature grinding procedure can retain various nutrients in coarse grains to the greatest extent. The compound enzyme enzymolysis procedure can hydrolyze certain insoluble functional active components to form soluble components, so as to increase digestion and absorption rate of nutrients in vivo. The low-temperature vacuum concentration procedure and the freeze-drying procedure can prevent loss of nutrients and functional active components to the greatest extent during the process, so as to increase the nutritional valueand health-care function of the product and improve the product quality. Therefore, the product has the characteristics of being convenient to eat and good in instant solubility and preparing property.

Owner:JINAN HUALU FOOD

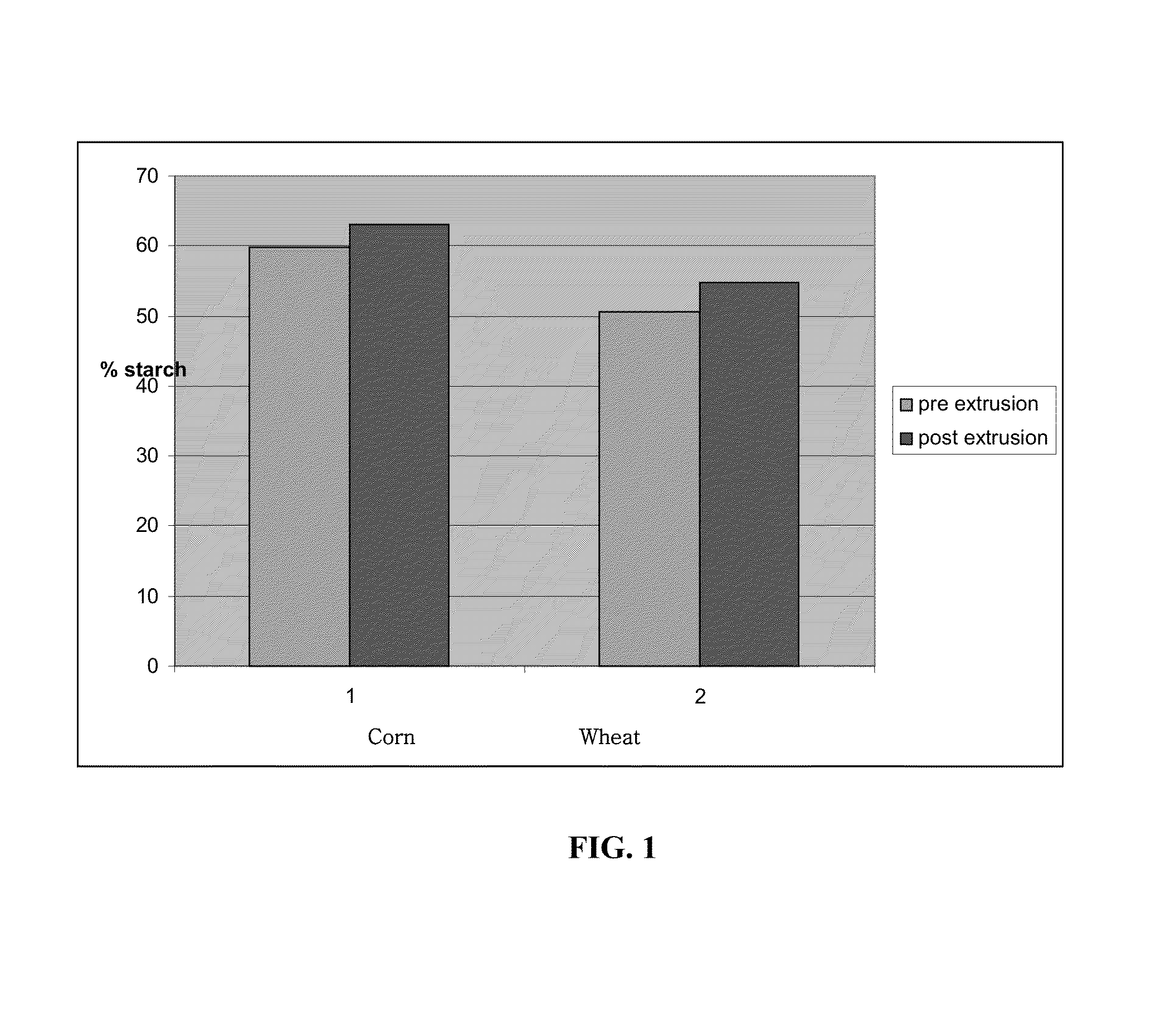

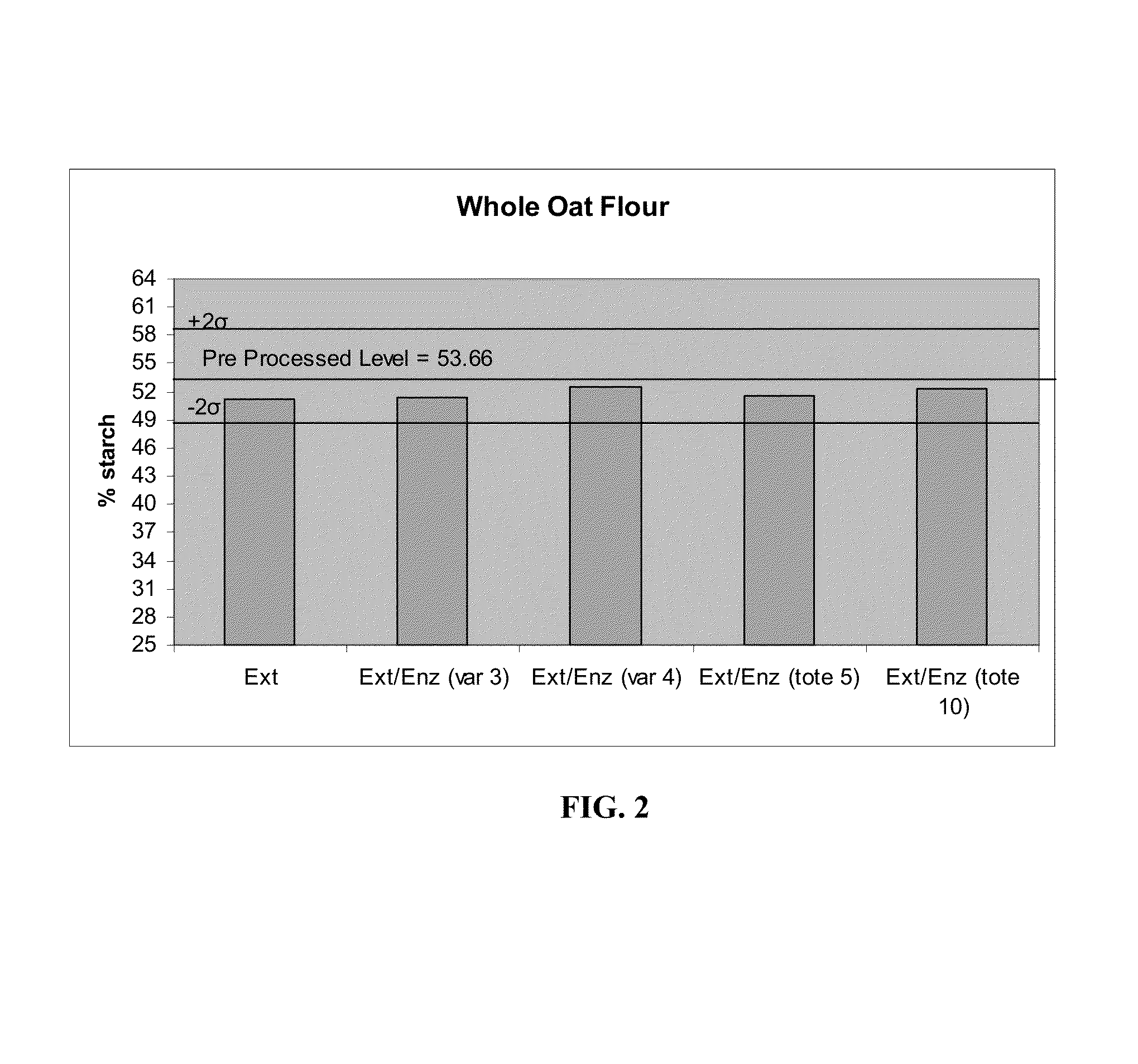

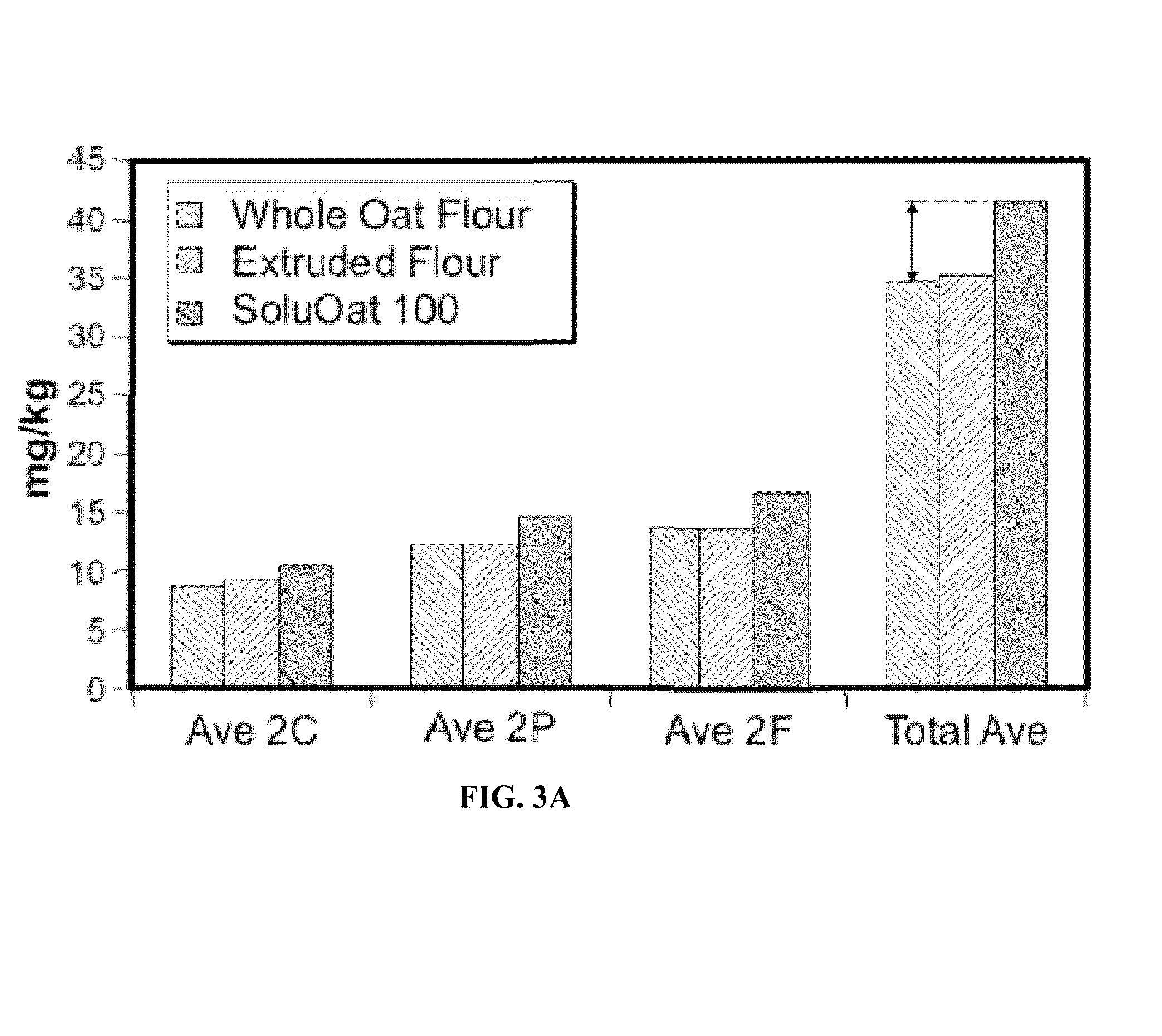

Method of Preparing Highly Dispersible Whole Grain Flour with an Increased Avenanthramide Content

ActiveUS20130209610A1Increased avenanthramide contentMaintain integrityWort preparationMetabolism disorderWhole grainsAvenanthramide

A method of preparing a highly dispersible whole grain oat flour by hydrolyzing, milling and agglomerating grain flour to arrive at a whole grain oat flour having an increased avenanthramide content compared to native oat flour.

Owner:THE QUAKER OATS CO

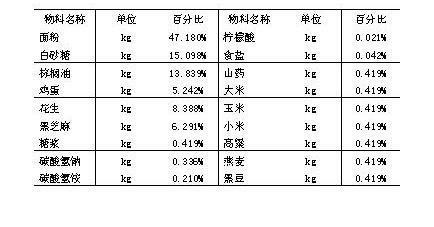

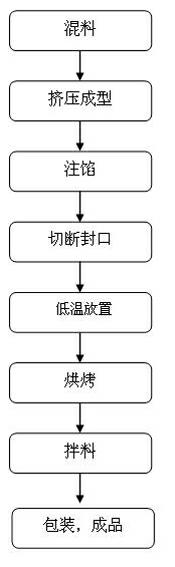

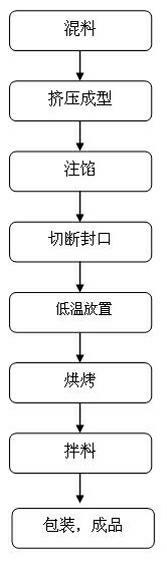

Cereal nutrient biscuit and preparation method thereof

InactiveCN101779690AAnti agingReasonable nutritionDough treatmentBakery productsBiotechnologySodium bicarbonate

The invention relates to a leisure food, namely a cereal nutrient biscuit and a preparation method thereof, belonging to the technical filed of food processing, which is composed of flour, white sugar, edible vegetable oil, black sesame seed, broken peanut, black soy milk powder, yam flour, rice powder, millet powder, corn powder, sorghum powder, oatmeal, fresh hen eggs, salt, sodium bicarbonate, ammonium bicarbonate and citric acid. The preparation method is as follows: evenly mixing the raw materials and stirring into paste; rolling the paste into the shape of biscuit and then baking; spraying palm oil on the surface of biscuits; cooling at room temperature; detecting the biscuits by a metal detector, removing biscuits containing metal chips or metal particles; picking out damaged biscuits; and packaging and warehousing the biscuits. In the invention, multiple grains such as sesame, peanuts and black beans are added to ensure more reasonable nutrition, no fumet is added to let the biscuits keep natural fragrance of rice; and the biscuit has the advantages of rich nutrition, multiple disease prevention, beautifying and body building, prolonging life, thin and crisp mouth feeling and the like, thus is a convenient leisure food suitable for people at all ages.

Owner:WEIHAI DONGWANG FOOD

Rice fruit and preparing method thereof

The invention discloses a rice fruit. The formula of the rice fruit comprises the following components in parts by weight: 20-25 parts of rice, 15-20 parts of sticky rice, 15-20 parts of white granulated sugar, 1-2 parts of modified starch, 1-2 parts of wheat flour, 1-2 parts of corn flour, 1-2 parts of sorghum flour, 1-2 parts of red bean flour, 1-2 parts of oat flour, 1-2 parts of soybean flour, 1-2 parts of sesame flour and 0.5-1.5 parts of red chilli powder. The invention also discloses a preparing method of the rice fruit. The rice fruit disclosed by the invention is unique in taste, crispy and sweet; and the fillings are soft and have long aftertaste. The preparing method of the rice fruit is suitable for industrial production.

Owner:SUZHOU KOUSHUIWA FOOD

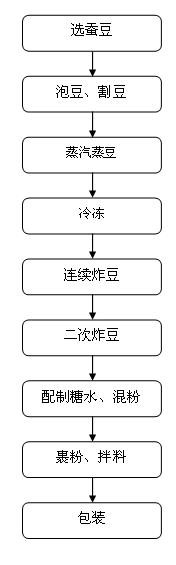

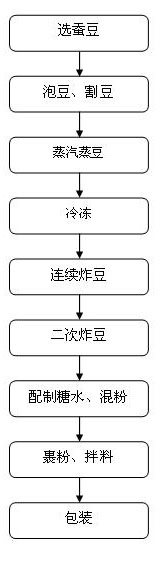

Deep-fried broad beans and preparation method thereof

The invention discloses deep-fried broad beans, the formula of which comprises 25-35 portions of broad beans, 20-25 portions of soft sugar, 5-10 portions of modified starch, 5-10 portions of wheat flour, 2-5 portions of corn flour, 2-5 portions of sorghum flour, 2-5 portions of ormosia flour, 2-5 portions of oat flour, 0.5-1.5 portion of cayenne powder, and 0.5-1.5 portion of powder. The powder consists of pepper powder, star anise powder, common fennel powder, salt powder, white granulated sugar and sodium glutamate which are mixed together and have a ratio of 1:1:1:1:1:1. The invention also discloses a preparation method for the deep-fried broad beans, which is simple and easy to operate, is suitable for industrialized production and promotes the development of the deep-fried broad beans.

Owner:SUZHOU KOUSHUIWA FOOD

Nutritious energy bar and the method of producing the same

InactiveCN101061868AIncrease energy densityPromote growth and developmentFood preparationFructoseSoybean Lecithin

The invention discloses a nutritious energy rod and its preparing process, wherein the rod is prepared from malt sugar 5-20%, levulose 5-20%, glucose 10-42%, oat powder 3-15%, soybean polypeptide 3-16%, fish protein small peptide 2-12%, fish bone meal 1-5%, cocoa powder 2-10%, onion 3-15%, sea-tangle 2-8%, vitamin 0. 3-3%, microelements 0. 1-2%, amino acid 0. 5-5%, taurine 0. 1-2%, choline 0. 05-1%, soybean lecithin 2-8%, DHA fish oil 3-12% and edible gelatin 1-8%.

Owner:RONGCHENG TAIXIANG FOOD

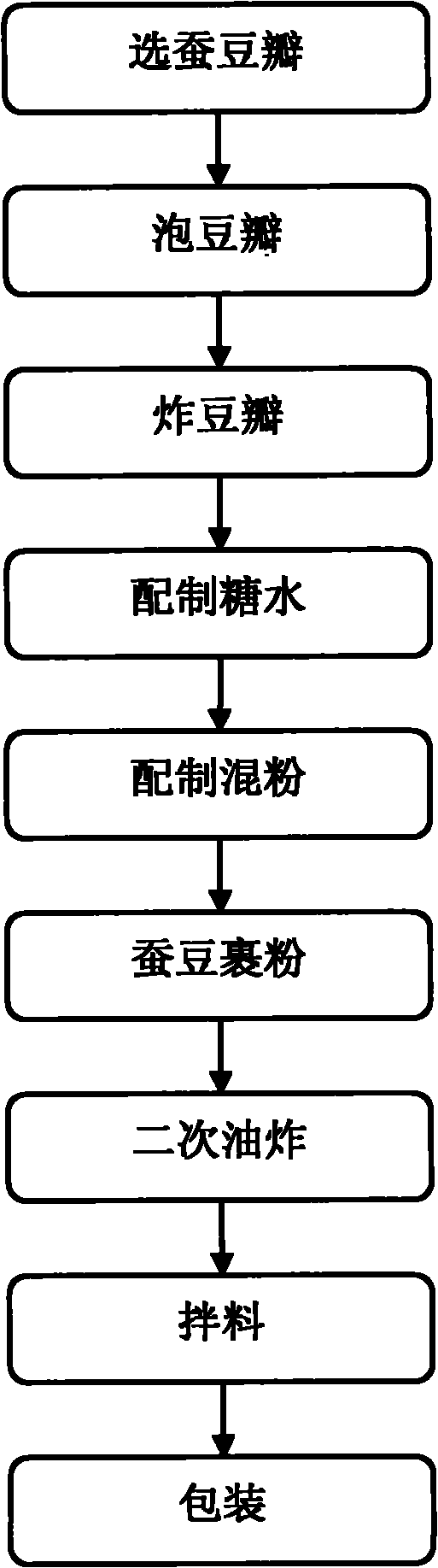

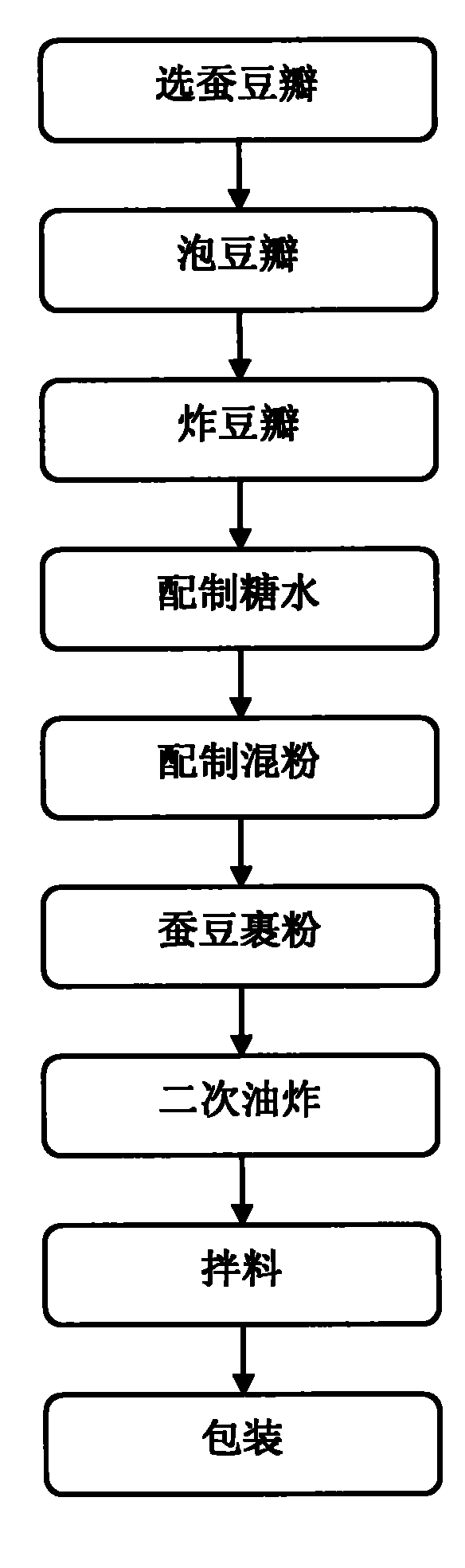

Coated broad bean and manufacturing method thereof

The invention discloses a coated broad bean which comprises the following formula: 25-35 portions of broad bean petal, 20-25 portions of soft sugar, 5-10 portions of modified starch, 5-10 portions of wheat flour, 2-5 portions of corn flour, 2-5 portions of sorghum flour, 2-5 portions of red bean flour, 2-5 portions of oat flour and 0.5-1.5 portions of paprika. The invention also discloses a manufacturing method of the coated broad bean. The coated broad bean has unique taste, is crispy and sweet and has high quality, low price and convenient carrying; and the manufacturing method has the advantage of simple operation, and is applicable to industrialized production.

Owner:SUZHOU KOUSHUIWA FOOD

Preparation method of pre-enzymatic oat powder and application of preparation method

ActiveCN102845677AImprove processing application performanceReduce energy costsFood preparationBiotechnologyAmylase

The invention relates to a preparation method of pre-enzymatic oat powder. The method comprises the following steps of: uniformly mixing amylase with water to mix with coarse oat power, then carrying out extrusion on the obtained mixture and drying, and finally milling the mixture to be fine powders. According to the preparation method provided by the invention, with the combination of extrusion and enzymolysis, not only the oat is aged but also the starch is enzymolysed, so that the processing application property of oat powder is greatly enhanced. In addition, according to the preparation method provided by the invention, the complex drying processes such as spraying drying or drum drying are not in need after the enzymolysis of the oat powder is carried out, so that the processing energy consumption and the processing cost are greatly reduced; compared with the prior processing technique, the preparation method provided by the invention is more energy-saving and more environment-friendly, and the cost is lower.

Owner:BEIJING SHUOFANG SCI & TECH DEV CO LTD

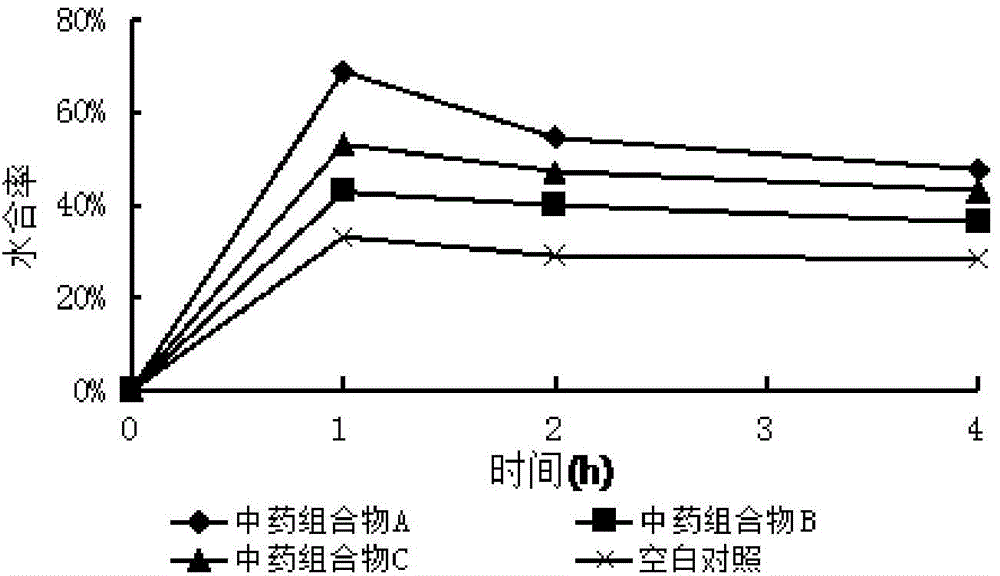

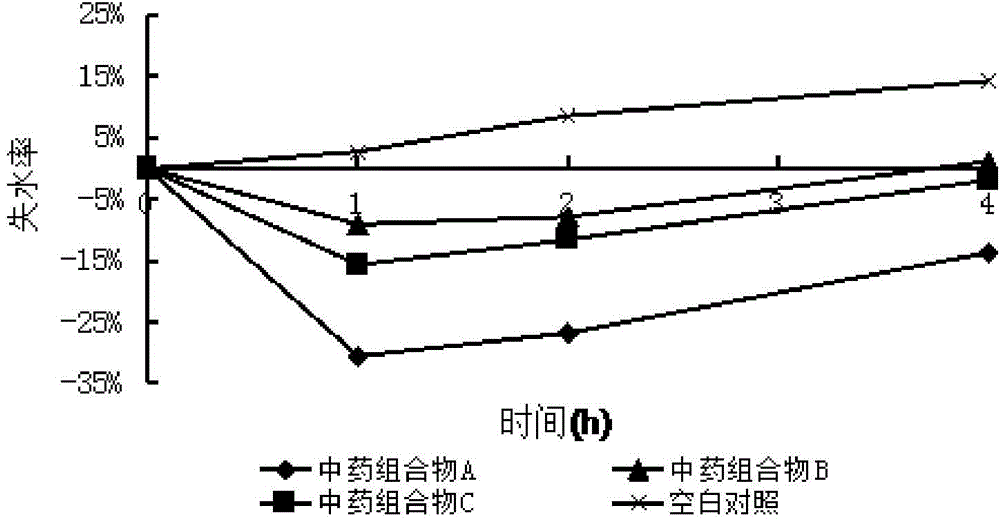

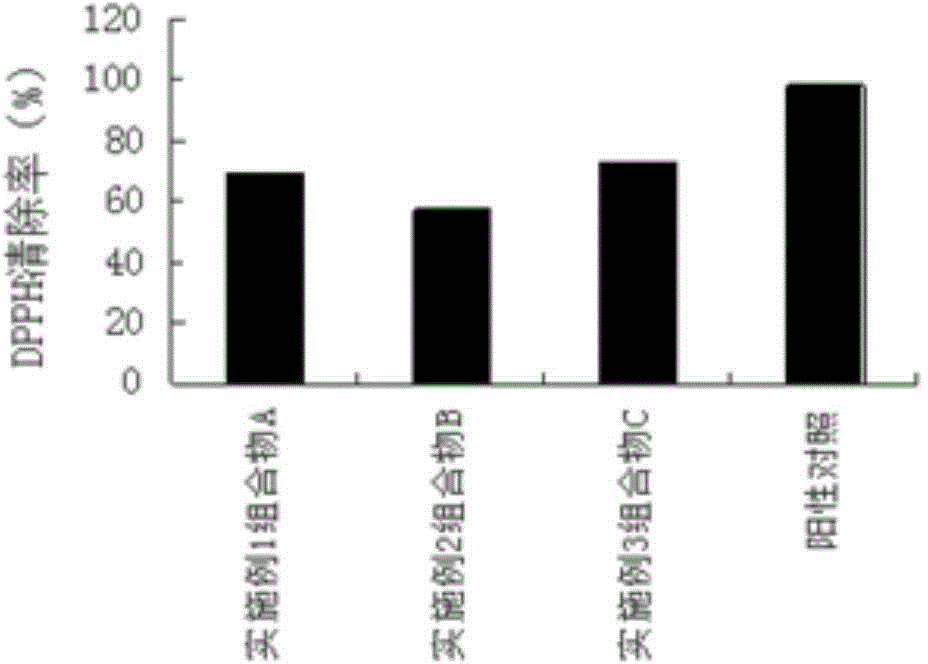

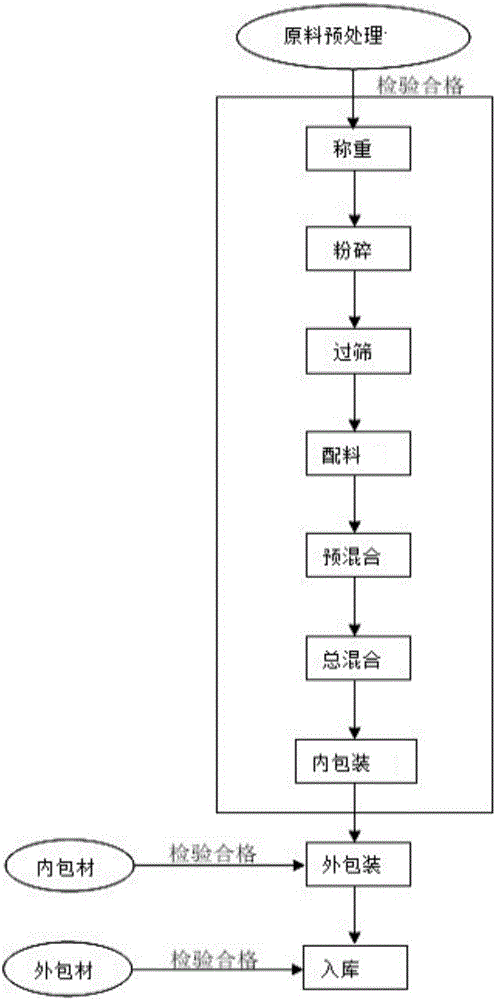

Plant composition with moisturizing, anti-wrinkle and irritability-relieving effect and preparation method thereof

InactiveCN104414895AAnti agingAchieve moisturizing effectCosmetic preparationsToilet preparationsBiotechnologyOatmeal Powder

A moisturizing, anti-wrinkle, and anti-allergic traditional Chinese medicine composition, and a preparation method thereof. Active components of the traditional Chinese medicine composition are water extracts of Dendrobium nobile, Viola tricolor, Ophiopogon japonicas, Tremella fuciformis, and an oat material. The oat material is oat grains, oat powder, or oat bran. A mass ratio of the Dendrobium nobile, Viola tricolor, Ophiopogon japonicas, Tremella fuciformis, and oat in the composition is 5-15: 2-10: 2-10: 1-5: 1-5, and is preferably 12: 6: 3: 2: 2. The composition of the Dendrobium nobile, Viola tricolor, Ophiopogon japonicas, oat material, and Tremella fuciformis is extracted and for external use. By retaining water, maintaining normal physiological functions of aquaporins, and other means, the composition not only achieves a moisturizing effect, but also achieves skin aging resisting, anti-allergic, and anti-crack efficacies.

Owner:INFINITUS (CHINA) CO LTD

Purple sweet potato biscuits and preparation method thereof

The invention provides purple sweet potato biscuits, comprising the following components: 15-25 parts of cake flour, 90-120 parts of oat kernel flour, 40-60 parts of purple sweet potato mud, 15-25 parts of sugar, 35-45 parts of butter, 45-55 parts of egg liquid and suitable water. The purple sweet potato biscuits provided in the invention have the following advantages: 1, the biscuits preserve the nutrition of the purple sweet potato and have rich nutrition; 2, the biscuits can be preserved for a long time and not easy to go bad; 3, the food formed in a biscuit manner can be produced in scales and can be widely circulated, so the nutrition utilization for the purple sweet potato is promoted.

Owner:NANTONG GOLDEN LAND GREEN FOOD

Meal replacement powder with effects of detoxifying and reducing weight and preparation method thereof

InactiveCN106617112AEnsure balanceReduce and suppress productionFood scienceMeal replacementFat bodies

The invention discloses meal replacement powder with effects of detoxifying and reducing weight. The meal replacement powder is prepared from the following components in parts by weight: 20 to 30 parts of fructo-oligosaccharide, 18 to 25 parts of soybean isolate protein powder, 15 to 25 parts of wheat flour, 20 to 30 parts of pumpkin powder, 8 to 15 parts of orange fruit powder, 8 to 15 parts of plantago ovate powder, 5 to 10 parts of chia seeds, 8 to 15 parts of lemon fruit powder, 0.5 to 2 parts of oat powder, 5 to 10 parts of konjaku flour, 0.05 to 0.5 part of xylooligosaccharide, and 0.05 to 0.1 part of sucralose. The invention also provides a preparation method for the meal replacement powder. According to the meal replacement powder, the balanced nutrition in a weight reducing process is ensured; the hunger sense is reduced; an easy-fat body can be improved by matching the meal replacement powder with dinner for a long time.

Owner:黄通县

Oat instant noodle and preparing method thereof

The invention relates to an oat instant noodle with homogenous function on medicine and food and a preparation method thereof: firstly, by weight percentage, 60-90 percent of oat flour and 10-40 percent of soybean flour are mixed, which are blended with water, which is 50-70 percent of total weight of the oat flour and the soybean flour; the oat flour and the soybean flour mixed with water are added with commissariat and squeezed and drawn once into long-wired dry noodle by a shaping mill with the temperature being controlled at 170-220 DEG C and the pressure under 1-2Mpa; the product only needs to be dipped in boiling water for minutes or cooked in boiling water for a while and can be eaten. The noodle can be cooked and preserved easily and conveniently, feels smooth and sticky and is a food with low carbohydrates, high protein and high energy; eating the noodle constantly can increase the ingestion of dietary fiber and has the function of moistening the intestines, defecation, eliminating toxicants and beauty maintenance; vitamin E, linolenic acid, Cu, Zn, Se, Mg, etc., in the noodle are anti-aging, whiten skin, induce sleep, with the obvious lipid-lowering and weight losing function.

Owner:黑河农耕大健康食品有限公司

High-fiber high-protein noodles for diabetics and people needing to control body weight

ActiveCN104431770ASave energyLower protein contentVitamin food ingredientsFood ingredient functionsBiotechnologyLow glucose

The invention relates to high-fiber high-protein noodles for diabetics and people needing to control body weight. The high-fiber high-protein noodles are made from the following raw materials in parts by weight: 0-10 parts of tartary buckwheat flour, 0-20 parts of oat flour, 18-70 parts of wheat flour, 0-15 parts of whole wheat flour, 2-15 parts of puerarin powder, 0-6 parts of Chinese yam flour, 0-8 parts of ultra-fine black rice flour, 5-15 parts of wheat protein, 0-10 parts of soybean protein, 0-10 parts of whey protein, 0-10 parts of dietary fiber and 0-0.55 part of vitamins and microelements. The noodles can ensure that the diabetics and overweight people fully ingest protein, dietary fiber and vitamin B to maintain normal nutrient requirements under the condition of controlling energy intake, and is popular food which has low energy, high fiber, high protein and low glycemic index and can be eaten as staple food.

Owner:蒋博

Broomcorn-oat-buckwheat coarse cereal bread

InactiveCN104322620AFull shapeNormal sizeDough treatmentBakery productsBiotechnologyPolygonum fagopyrum

The invention discloses broomcorn-oat-buckwheat coarse cereal bread. The product is made from 160 to 180 parts of high-quality wheat flour, 20 to 30 parts of broomcorn flour, 30 to 40 parts of oat flour, 20 to 30 parts of buckwheat flour, 20 to 30 parts of white granulated sugar, 6 parts of bread improver, 5 parts of yeast, 12 parts of milk powder, 30 parts of butter, 100 parts of water and 1.5 parts of salt by baking according to a 'secondary agitation and two-step fermentation' process. The bread product is light brown, the shape is full, the surface is smooth, the volume is normal, and the phenomena of cracks and deformation do not exist; the internal structure is shaped like uniform sponge, and is fine, soft and elastic; the broomcorn-oat-buckwheat coarse cereal bread has the light fragrance of coarse cereals, and does not have pungent smell, and the palatability of the product is good. The broomcorn-oat-buckwheat coarse cereal bread has the following advantages: firstly, after the coarse cereals, such as broomcorn, oat and buckwheat, are added, the nutrition of the product is increased, and the product has the effects of oxidation resistance, aging resistance, blood fat reduction and blood pressure decrease; secondly, after the coarse cereals are added into the material, the rheological property and nutritional properties of the bread are changed.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

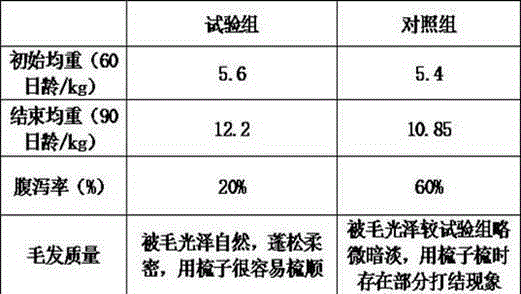

Healthcare agent for pet puppies

InactiveCN105230987AMake up for nutritional imbalancesIncrease nutritionAnimal feeding stuffBiotechnologyVitamin C

The invention discloses a healthcare agent for pet puppies. The healthcare agent for pet puppies comprises the following ingredients in parts by mass: 5-10 parts of egg micro-capsule powder, 5-15 parts of hydrolyzed wheat protein, 0.5-1.5 parts of vitamin A, 3-10 parts of glucose, 2-5 parts of chicken liver powder, 0.3-1 part of vitamin D3, 15-25 parts of puffed oat flour, 15-25 parts of puffed corn flour, 5-8 parts of vitamin C and 30-50 parts of skimmed milk powder. The healthcare agent for pet puppies of the invention is capable of supplementing nutrients required puppy growth and development, increasing pet appetite, reinforcing body immunity, preventing and treating intestinal inflammation, improving pet physique as well as improving hair quality. The healthcare agent for pet puppies is obvious in effect, safe and free of toxic and side effects.

Owner:山东贝瑞康生物科技有限公司

Sea-tangle soda biscuit and production method thereof

InactiveCN103053654AUniform surface cracksGolden colorDough treatmentBakery productsBiotechnologyWeight gaining

The invention relates to a sea-tangle soda biscuit and a production method thereof and solves the problems of elevated blood pressure, aggravated edema and easiness weight gaining of the traditional soda biscuit. The sea-tangle soda biscuit comprises fishy smell eliminated sea-tangle flour, wheat flour, pat flour, white granulated sugar, milk powder, bicarb, ammonium bicarbonate and active dry yeast. The production method of sea-tangle soda biscuit comprises the following processes of preparation of fishy smell eliminated sea-tangle flour, raw materials processing, a first process of making paste, a first fermentation, a second process of making paste, a second fermentation, a rolling process, a forming process, a baking process, a cooling process and a packaging process and then the sea-tangle soda biscuit is obtained. Sea-tangle flour and oat flour are added to the raw materials to improve the nutritive value of soda biscuit and the prepared soda biscuit becomes a lodine supplementation, blood fat reducing, blood pressure reducing, fat absorbing prevention and diabetic prevention health food. The production method of the sea-tangle biscuit has the advantages of being simple in production technology, reasonable in working procedure and short in production cycle.

Owner:SHANDONG HOMEY AQUATIC DEV +1

Rich milk-tea flavored flowery health tea and preparation method thereof

InactiveCN104247805AFull of nutritionRich in nutrientsPre-extraction tea treatmentZiziphus jujubaOsmanthus

The invention discloses rich milk-tea flavored flowery health tea. The rich milk-tea flavored flowery health tea is prepared from the following raw materials in parts by weight: 2-4 parts of jujube peel, 3-5 parts of osmanthus, 3-5 parts of apple blossoms, 7-9 parts of black tea juice, 2-4 parts of orange peel, 1-3 parts of spinach root, 1-3 parts of chestnut leaves, 5-7 parts of eggplant dices, 7-8 parts of broccoli, 7-9 parts of green olives, 4-6 parts of milk-tea powder, 6-7 parts of oat flour, 3-5 parts of pomegranate seeds, 5-7 parts of peanut red peel, 3-5 parts of rice wine, 4-6 parts of barley, 9-11 parts of kiwi fruits, 4-6 parts of honey lyophilized powder, 13-14 parts of nutrition adding liquid and a proper amount of water. The health tea disclosed by the invention has the raw materials of the osmanthus, apple blossoms, spinach root and green olives, eggplants, peanut red peel and the like, thereby containing rich nutrition, cellulose, vitamins and minerals, and has the efficacies of enriching the blood and improving eyesight and high medicinal value, thereby being beneficial to health after long-term drinking.

Owner:叶青芝

Blood-sugar-reducing health-care noodles and preparation method thereof

InactiveCN102805296AImprove immunityHas hypoglycemic functionFood preparationBiotechnologyPolygonum fagopyrum

The invention discloses blood-sugar-reducing health-care noodles, which are prepared from the following raw material components by weight: 20 to 30kg of flour, 20 to 30kg of buckwheat, 10 to 15kg of oat kernel flour, 10 to 15kg of Chinese yam powder, 10 to 15kg of mulberry juice (calculating the weight of fresh mulberry) and 4 to 6kg of Chinese herbal medicine. The preparation method comprises the following steps of: crushing the Chinese herbal medicine, performing water extraction to obtain extract liquid, mixing water, the extract liquid and the mulberry juice in a ratio to obtain mixed liquid, mixing the mixed liquid and other powdery substances, and preparing the noodles by the conventional method. The health-care noodles have an effect of reducing blood sugar, contain comprehensive nutrition, are good in mouthfeel, can be used as staple food of patients suffering from hyperglycemia and can be eaten for a long time.

Owner:ANHUI SIHAI FOOD

Dandelion blood sugar lowering health noodles and preparation method thereof

InactiveCN103976365AOvercome the problem of bad taste and inconvenient eatingGreat tasteNatural extract food ingredientsFood ingredient functionsFiberWheat germ

The present invention discloses dandelion blood sugar lowering health noodles, which are prepared from the following raw materials by weight: 40-50 parts of wheat powder, 80-90 parts of buckwheat powder, 8-10 parts of mung bean powder, 8-10 parts of oat powder, 20-30 parts of defatted wheat germ, 6-10 parts of wheat dietary fiber powder, 0.1-0.5 part of glyceryl monostearate, 8-10 parts of L-lysine hydrochloride, 8-10 parts of walnut powder, 5-8 parts of black sesame powder, 30-40 parts of dandelion powder, 20-30 parts of choerospondias axillaris powder, and 1-2 parts of a nutritional additive. According to the present invention, the dandelion blood sugar lowering health flour has natural wheat aroma, is rich in dietary fibers and a variety of nutrition elements, and has complete nutrition; the problems that the wheat dietary fibers and the buckwheat powder contained in the existing blood sugar lowering health noodles do not have good taste and the eating is not convenient are overcome; and the blood sugar lowering health noodles have characteristics of lubricating taste and convenient eating, and are especially for long-term consumption of high blood sugar patients.

Owner:ANHUI YULONG NOODLES FOOD

Health care agent for old dogs

InactiveCN105410347AEnhance digestion and absorptionReduce pleat spacingAnimal feeding stuffAccessory food factorsBiotechnologyDisease

The invention discloses a health-care agent for old dogs. The health care agent for old dogs consists of the following components in parts by weight: 5-10 parts of egg microcapsule powder, 0.3-1 part of a yucca extract, 5-15 parts of wheat hydrolyzed protein, 0.5-1.5 parts of astragalus membranaceus polysaccharide, 1-2 parts of probiotics, 15-25 parts of puffing oat flour, 10-20 parts of puffing corn flour, 0.5-1.5 parts of vitamin C, 30-40 parts of nonfat dry milk powder, 2-5 parts of chicken liver powder, 3-5 parts of glucose, 2-4 parts of xylooligosaccharide and 3-5 parts of sodium butyrate. According to the health care products disclosed by the invention, the digestion function of intestinal tracts of the old dogs can be improved, the utilization of nutrient substances can be improved, diseases of intestinal tracts can be prevented and treated, the immunity of organisms can be enhanced, and halitosis and the fetor of excrement can be reduced; the health care products are notable in effects, safe and free from toxic and side effects.

Owner:山东贝瑞康生物科技有限公司

Caramel and oatmeal cookie and preparation method thereof

The invention discloses a caramel and oatmeal cookie and a preparation method thereof. The caramel and oatmeal cookie comprises the following raw materials in parts by weight: 100 to 160 parts of wheat flour, 40 to 60 parts of oatmeal powder, 30 to 40 parts of purple sweet potato, 8 to 12 parts of maple sugar, 8 to 12 parts of vegetable oil, 10 to 20 parts of egg, 20 to 30 parts of honey, 1 to 2 parts of vanillin, 3 to 5 parts of table salt, and 30 to 50 parts of water. According to the caramel and oatmeal cookie, the cookie with a new taste is added for the cookie food and applied to people loving the taste of oat and depending on the oatmeal health; the cookie has rich taste of caramel and is the first choice of snack of people loving the taste of caramel.

Owner:刘韶娜

Nutrient flour product of giant salamander and grains and production method thereof

InactiveCN103283799AInhibitionRich in nutritional valueDough treatmentBakery productsBiotechnologyPolygonum fagopyrum

The invention relates to a nutrient flour product of giant salamander and grains and a production method thereof. Raw materials include, by weight: 2-20 parts of bone and meat meal of the giant salamander, 65-80 parts of wheat flour, 5-20 parts of grain powders and 5-15 parts of nutrition powders. The grain powders are made of one or more of buckwheat powder, oat powder, sweet potato powder, rye powder and sesame powder. The nutrition powders are made of one or more of black peach powder, yam powder, arrowroot powder and konjac powder. The bone and meat meal of the giant salamander is made of one or more of meat powder of the giant salamander, bone powder of the giant salamander and viscera powder of the giant salamander. The nutrient flour product can be noodles, breads or biscuits. Nutrient ingredients of the flour product of the giant salamander are comprehensive, a health-preserving function of the product is enhanced, absorption by human bodies is benefited, and the nutrient flour product has advantages of increasing appetite, improving physical fitness, improving intelligence, promoting growth and development, preventing cancers and cardiovascular diseases and the like.

Owner:张家界金鲵生物工程股份有限公司

Multi-grain cornflake and making method thereof

InactiveCN104000118APrevent type 2 diabetesPrevent obesityFood ingredient functionsFood preparationBiotechnologySucrose

Owner:SICHUAN JIAHE FOOD CO LTD

Gut purging powder capable of shaping intestine-like model

The invention discloses a gut purging powder capable of shaping intestine-like model, which is mixed by the following raw materials: wheat grass powder, composite plant enzymes, apple fiber, vitamin C, Spirulina, blue-green algae, citric acid, fructo-oligosaccharide, barley flour, wheat flour, broccoli powder, oatmeal powder, spinach powder, cabbage powder, celery powder, green alga powder, red alga powder, apple powder, pineapple powder, garnetberry powder, cranberry powder, pomegranate powder, honey peach powder, orange powder, corn starch, fructo-oligosaccharide, sorbitol, maltodextrin, glucose, natural cranberry acid, natural cranberry essence, honey peach essence, orange essence, fish albumen powder, and wheat starch. The gut purging powder of the invention shapes the stubborn feces into intestine-like model, so that one can defecate easily without consuming energy of the abdomen, and the shape of stubborn feces defecated has a similarity over 95% to the shape of intestine.

Owner:赫康贸易(上海)有限公司

Health-care food for diabetics

InactiveCN103371364ARestore secretionSuitable for long-term consumptionFood preparationBiotechnologyPolygonum fagopyrum

The invention relates to a health-care food for diabetics in the field of health-care foods. According to the technical scheme, the health-care food comprises the following components: 5-10 parts of pumpkin powder, 3-8 parts of corn meal, 2-4 parts of spirulina, 3-8 parts of soybean meal, 2-4 parts of ground seshocked, 4-8 parts of oat powder, 4-8 parts of yam flour, 3-5 parts of ganoderma lucidum powder, 3-5 parts of tuchahoe powder, 3-5 parts of pig pancreas, 2-4 parts of mulberry leaves, 4-8 parts of malt flour, 1-3 parts of puerarin powder, 3-5 parts of sorghum flour and 3-5 parts of buckwheat powder. The health-care food has the effects of combining reasonably, strengthening healthy energy, invigorating spleen-stomach and replenishing qi, reducing blood sugar, enhancing immunity and restoring insulin secretion, and is suitable for the diabetics for long-time eating and quick in curative effect.

Owner:李国庆

Tartary buckwheat bud and seedling composite nutritional powder and production process thereof

InactiveCN106343368AImprove germination rateIncrease contentFood ingredient functionsDiseaseAdditive ingredient

The invention provides a tartary buckwheat bud and seedling composite nutritional powder and a production process thereof. The tartary buckwheat bud and seedling composite nutritional powder contains 5-20% of oat flour, 50-70% of tartary buckwheat bud and seedling powder, 5-15% of mung bean powder, 10-20% of lotus leaf powder, 4-10% of white granulated sugar powder, and 4-10% of skim milk powder. Compared with the prior art, the method disclosed by the invention adopts multiple physical methods for induction treatment, which can improve the germination rate of tartary buckwheat seeds and significantly increase the content of active ingredients such as total flavonoids and GABA in tartary buckwheat seeds, buds and seedlings, and significantly enhances the antioxidant capacity, and the harvested buds and seedlings are processed and compounded into the tartary buckwheat bud and seedling composite nutritional powder rich in a variety of functional nutrients. The tartary buckwheat bud and seedling composite nutritional powder is not only rich in vitamins, minerals and other nutrients, but also rich in isoflavones, GABA and other physiological active ingredients, has high antioxidant capacity, and has the effects of reducing blood lipid, resisting oxidation, improving cell nutrition, enhancing body constitution, improving body immunity, and preventing diseases.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Health preserving meal flavouring milk and preparation method thereof

ActiveCN101180992APromote digestion and absorptionProduction status is stableMilk preparationCow milkOatmeal Powder

The invention relates to a flavoring milk and a preparation method thereof, in particular to a health diet flavoring milk and a preparation method thereof, pertaining to the dairy food technical field. The health diet flavoring milk of the invention comprises: 700 to 900 Kg of milk, 30 to 100Kg of white granulated sugar, 10 to 50 Kg of expansion coarse rice powder, 0.1 to 1 Kg of fragrant lactenin, 0.1 to 2 Kg of oatmeal powder, 1 to 10 Kg of soy protein isolate and 1 to 8 Kg of stabilizing agent. The method of the invention has the advantages that production state is stable, and sterilizing cow milk beverage is endowed with a brown rice taste.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

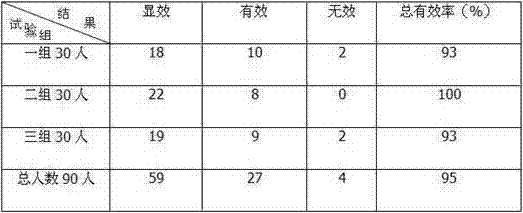

Enzyme dietary fiber and preparation technology thereof

InactiveCN106954856APrevent constipationSolve constipationYeast food ingredientsLactobacillusSide effectPolydextrose

The invention relates to enzyme dietary fiber and a preparation technology thereof. The enzyme dietary fiber comprises the following raw materials in parts by weight: 30-50 parts of enzyme powder, 1.5-3 parts of fructo-oligosaccharides, 10-15 parts of polydextrose, 15-25 parts of galacto-oligosaccharides, 5-8 parts of oat flour, and 6-10 parts of herba portulacae powder. The preparation technology of the enzyme dietary fiber comprises the following steps of: taking the raw materials and carrying out mixing, adding auxiliary materials, preparing the mixture into desired dosage forms, and carrying out sterilization so as to obtain the enzyme dietary fiber. Enzymes prepared by a special technology is adopted as the main raw material of the enzyme dietary fiber, other raw materials are matched, and related processes are combined so as to fundamentally solve constipation and gastrointestinal dysfunction; moreover, the enzyme dietary fiber is safe, free of any toxic and side effects, and free of drug dependence. Effective rate of the enzyme dietary fiber is up to 95% or higher.

Owner:河南佳禾康生物食品科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com