Rice fruit and preparing method thereof

A production method and technology of rice crackers, which are applied in the directions of food preparation, application, food science, etc., can solve the problems of rice cracker varieties, single taste, restricting the development of rice crackers, etc., and achieve rich taste, prevention and treatment of cardiovascular and cerebrovascular diseases, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A rice cracker with a slightly spicy taste, its formula is as follows: rice: 20kg; glutinous rice: 16 kg; white sugar: 15 kg; modified starch: 1 kg; wheat flour: 1.8 kg; corn flour: 1.6 kg; sorghum flour: 1 kg; red bean powder: 1 kg; oat powder: 1.9 kg; soybean powder: 2 kg; sesame powder: 2 kg; chili powder: 0.5 kg.

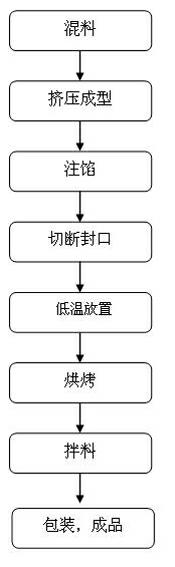

[0023] The concrete steps of the preparation method of above-mentioned rice crackers are as follows:

[0024] (a) Mixing: Do the ingredients according to the above formula, and then put the prepared ingredients into the mixer and stir evenly;

[0025] (b) Extrusion molding: the uniformly stirred material is sent to an extrusion molding machine to extrude rice husks with a preliminary shape of rice husks;

[0026] (c) Filling: squeeze the filling into the rice shell; the formula of the filling is as follows, water: white sugar: peanut oil: cream is 0.8:0.9:0.1:1.5.

[0027] (d) Cutting and sealing: use a cutter to cut and seal the rice husk to make raw r...

Embodiment 2

[0032] A kind of spicy rice cracker, the formula of the rice cracker is as follows: northeast high-quality rice: 23kg; glutinous rice: 20 kg; white granulated sugar: 17 kg; modified starch: 1.7kg; wheat flour: 2 kg; corn flour: 2 kg; sorghum flour : 1.3 kg; red bean powder: 1.4 kg; oat flour: 2 kg; soybean powder: 1kg; sesame powder: 1.8kg; chili powder: 1.2 parts; fried peanut powder 2kg;

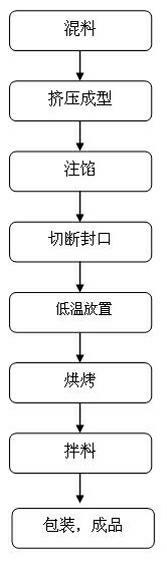

[0033] The concrete steps of the preparation method of above-mentioned rice crackers are as follows:

[0034] (a) Mixing: Do the ingredients according to the above formula, and then put the prepared ingredients into the mixer and stir evenly;

[0035] (b) Extrusion molding: the uniformly stirred material is sent to an extrusion molding machine to extrude rice husks with a preliminary shape of rice husks;

[0036] (c) filling: extruding the filling into the rice shell; the formula of the filling is as follows, water: white sugar: soybean oil: bean paste is 1.1: 1: 0.2: 1.55;

[0037] (d) ...

Embodiment 3

[0042] A kind of crispy and spicy rice cracker, the formula is as follows: northeast high-quality rice: 25 kg; glutinous rice: 15 kg; white sugar: 20 kg; modified starch: 2 kg; wheat flour: 1 kg; corn flour: 1 kg; sorghum flour: 2 kg; Red bean powder: 2 kg; oat flour: 2 kg; soybean powder: 1.9 kg; sesame powder: 1 kg; chili powder: 1.5 kg; walnut kernel powder: 1.6 kg.

[0043] The concrete steps of the preparation method of above-mentioned rice crackers are as follows:

[0044] (a) Mixing: Do the ingredients according to the above formula, and then put the prepared ingredients into the mixer and stir evenly;

[0045] (b) Extrusion molding: the uniformly stirred material is sent to an extrusion molding machine to extrude rice husks with a preliminary shape of rice husks;

[0046] (c) Filling: squeeze the filling into the rice shell; the formula of the filling is as follows, water: white sugar: rapeseed oil: peanut butter is 1:0.9:0.3:1.5;

[0047] (d) Cutting and sealing: us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com