Compound coarse grain instant food and preparation method thereof

A technology for compounding grains and miscellaneous grains, which is applied in the fields of food preparation, food science, and application to achieve the effects of improving health-care functional properties, improving nutritional value and functionality, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

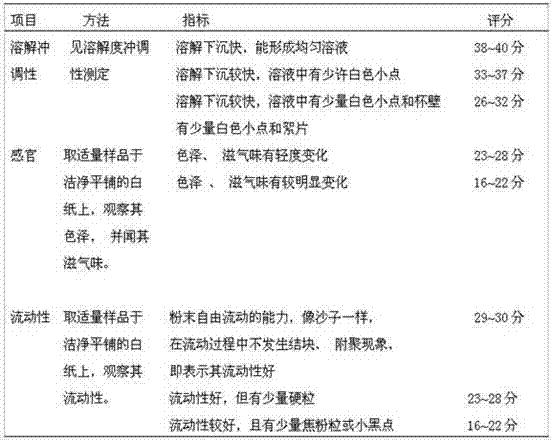

Image

Examples

Embodiment 1

[0036] A kind of instant compound cereal cereals, the raw material used comprises the following components by weight ratio:

[0037] 28 parts of white rice flour, 21 parts of corn flour, 14 parts of black bean flour, 10.5 parts of oat flour, 9.5 parts of buckwheat flour, 5.25 parts of barley grass powder, and 4.75 parts of barley malt powder.

[0038] Preparation:

[0039] (1) Remove impurities from the raw materials, mix them, and pulverize them at low temperature to obtain fine powder. The pulverization temperature is 10°C, and the pulverization particle size is 80-120 mesh;

[0040] (2) Mix the fine powder and distilled water at a weight ratio of 1:8, add 4g of complex enzyme per kg of fine powder, enzymatically hydrolyze at 55°C and pH 5.5 for 4 hours, and centrifuge at a speed of 3000r / min. Centrifuge for 10 minutes, filter, then inactivate the filtrate at 90°C for 3 minutes, and cool down;

[0041] (3) Concentrate the filtrate in vacuum at 60°C and a vacuum degree of 0...

Embodiment 2

[0047] A kind of instant compound cereal cereals, the raw material used comprises the following components by weight ratio:

[0048] 32 parts of white rice flour, 19 parts of corn flour, 16 parts of mung bean flour, 9.5 parts of oat flour, 10.5 parts of buckwheat flour, 4.75 parts of wheat grass powder, 5.25 parts of barley malt powder, 2 parts of apple powder, 2 parts of vegetable powder, 5 parts of Jerusalem artichoke powder 3 parts and flavoring agent honey.

[0049] Preparation:

[0050] (1) Mix the raw materials and pulverize at low temperature to obtain fine powder, the pulverization temperature is 15°C, and the pulverization particle size is 80-120 mesh;

[0051](2) Mix the fine powder and distilled water at a weight ratio of 1:12, add 8 g of compound enzyme per kg of fine powder, enzymolyze at 55°C and pH 5.5 for 5 hours, and centrifuge at a speed of 3000r / min. Centrifuge for 10 minutes, filter, then inactivate the filtrate at 90°C for 3 minutes, and cool down;

[0...

Embodiment 3

[0058] A kind of instant compound cereal cereals, the raw material used comprises the following components by weight ratio:

[0059] 30 parts of white rice flour, 20 parts of corn flour, 15 parts of soybean flour, 10 parts of oat flour, 5 parts of buckwheat flour, 5 parts of wheatgrass flour, 5 parts of barley malt powder, 8 parts of citrus powder, 5 parts of Jerusalem artichoke powder and flavoring agent honey 5 servings.

[0060] Preparation:

[0061] (1) Mix the raw materials and pulverize at low temperature to obtain fine powder, the pulverization temperature is 12°C, and the pulverization particle size is 80-120 mesh;

[0062] (2) Mix fine powder and distilled water at a weight ratio of 1:10, add compound enzyme at a rate of 6 g per kg of fine powder, enzymatically hydrolyze at 55°C and pH 5.5 for 6 hours, and centrifuge at a speed of 3000r / min. Centrifuge for 10 minutes, filter, then inactivate the filtrate at 90°C for 3 minutes, and cool down;

[0063] (3) Concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com