Additive-free food-grade mung bean anti-acne maintenance mask and green production method thereof

An additive-free, food-grade technology, applied in cosmetics, food science, pharmaceutical formulations, etc., can solve problems such as adverse reactions, achieve the effects of reducing acne, lightening acne scars, and beautifying facial skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

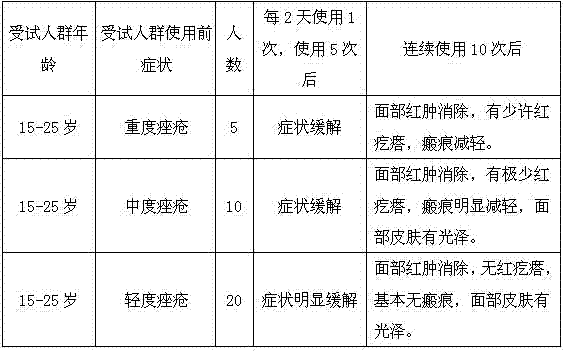

Image

Examples

Embodiment 1

[0032] Made from the following raw materials and steps in parts by weight:

[0033] 15 parts of mung bean, 1 part of tremella, 1 part of pearl, 1 part of pine pollen, 1 part of dried lily, 1 part of dried honeysuckle, 1 part of dried rose, 0.3 part of lemon slice, 0.1 part of dried tangerine peel;

[0034] (1) Continuous activation and crushing of mung beans

[0035] Take the ripe mung bean seeds of the year and screen them to remove impurities, spray and wash them with cold water at 8°C, put them into a vortex scalding tank and scald them in 80°C water for 5 seconds for the first activation, then quickly remove them and put them into 29°C water for aerobic reciprocating oscillation soaking 9h for the second activation treatment, the oscillation frequency is 30r / min, the amount of air introduced into the water is 1L / h, then the running water is sprayed and cleaned, the surface water is drained, and the third activation is carried out at 40°C and 5min microwave oscillation pro...

Embodiment 2

[0046] Made from the following raw materials and steps in parts by weight:

[0047] 25 parts of mung bean, 3 parts of white fungus, 3 parts of pearl, 3 parts of pine pollen, 2 parts of dried lily, 2 parts of dried honeysuckle, 2 parts of dried rose, 1.2 parts of lemon slice, 0.5 part of dried tangerine peel;

[0048] (1) Continuous activation and crushing of mung beans

[0049] Take the ripe mung bean seeds of the year and screen to remove impurities, spray and wash them with cold water at 15°C, put them into a vortex scalding tank, soak them in 90°C water for 3 seconds for the first activation, then quickly remove them and put them into 35°C water for aerobic reciprocating oscillation soaking 5h for the second activation treatment, the oscillation frequency is 80r / min, the amount of air introduced into the water is 3L / h, then the running water is sprayed and cleaned, the surface water is drained, and the third activation is carried out at 45°C and 3min microwave oscillation ...

Embodiment 3

[0060] Made from the following raw materials and steps in parts by weight:

[0061] 20 parts of mung bean, 2 parts of tremella, 2 parts of pearl, 2 parts of pine pollen, 1.5 parts of dried lily, 1.5 parts of dried honeysuckle, 1.5 parts of dried rose, 0.8 part of lemon slice, 0.3 part of dried tangerine peel;

[0062] (1) Continuous activation and crushing of mung beans

[0063] Take the mature mung bean grains of the year and screen to remove impurities, spray and wash them with cold water at 11°C, put them into a vortex scalding tank, soak them in 85°C water for 4 seconds for the first activation, then quickly remove them and put them into 32°C water for aerobic reciprocating oscillation soaking 7h for the second activation treatment, the oscillation frequency is 55r / min, the amount of air introduced into the water is 2L / h, then the running water is sprayed and cleaned, the surface water is drained, and the third activation is carried out at 42.5°C and 4min microwave oscilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com