Patents

Literature

122results about How to "Does not affect processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

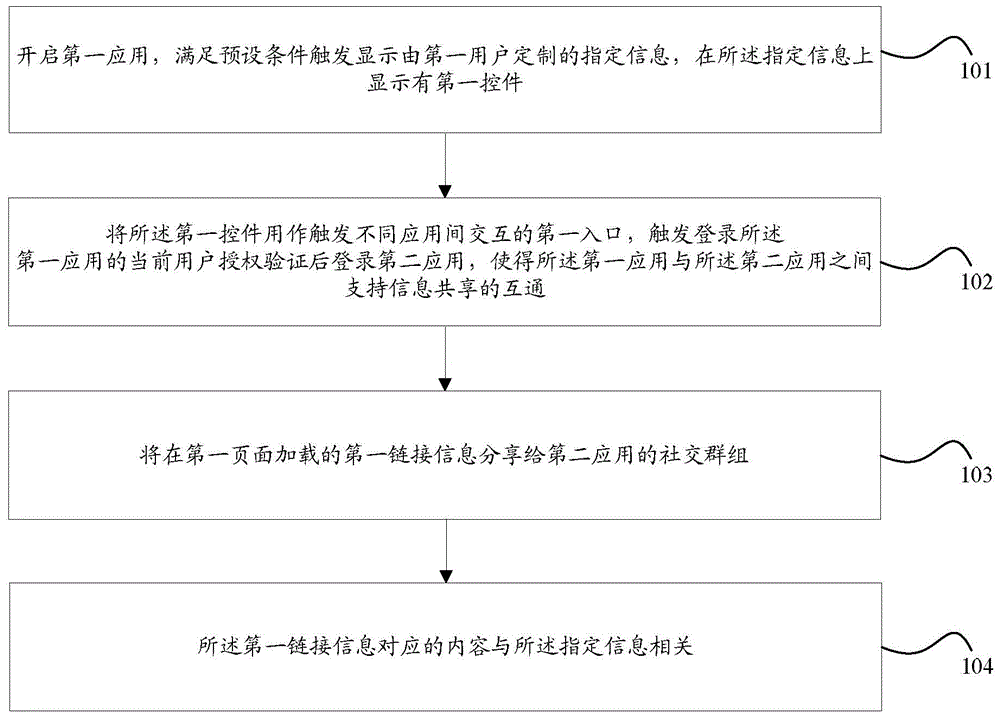

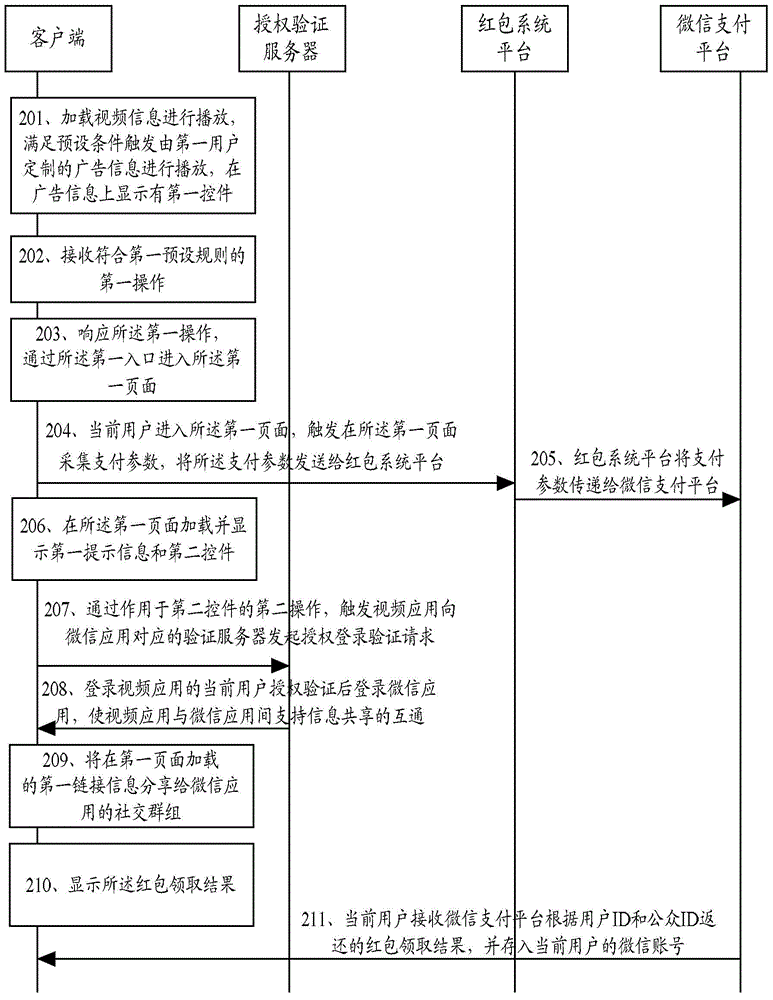

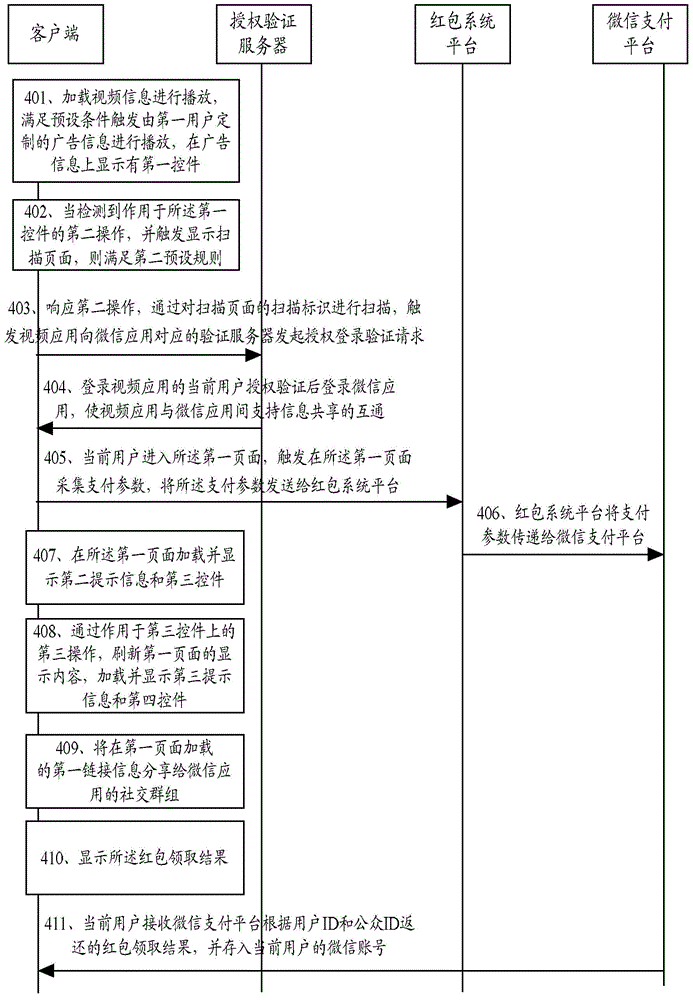

Information processing method and client side

ActiveCN104615335ADoes not affect processing efficiencyIncrease storage spaceInterprogram communicationPayment architectureInformation processingInformation sharing

The invention discloses an information processing method and a client side. The information processing method includes: opening a first application, triggering and displaying designated information customized by a first user if preset conditions are met, and displaying a first control on the designated information; taking the first control as a first entrance triggering interaction of different applications, and logging in a second application after triggering to log in current user authorization verification of the first application so as to enable supportive information between the first application and the second application to be shared mutually; sharing first link information uploaded in the first page to a social group of the second application; content corresponding to the first link information is relevant to the designated information.

Owner:TENCENT TECH (BEIJING) CO LTD

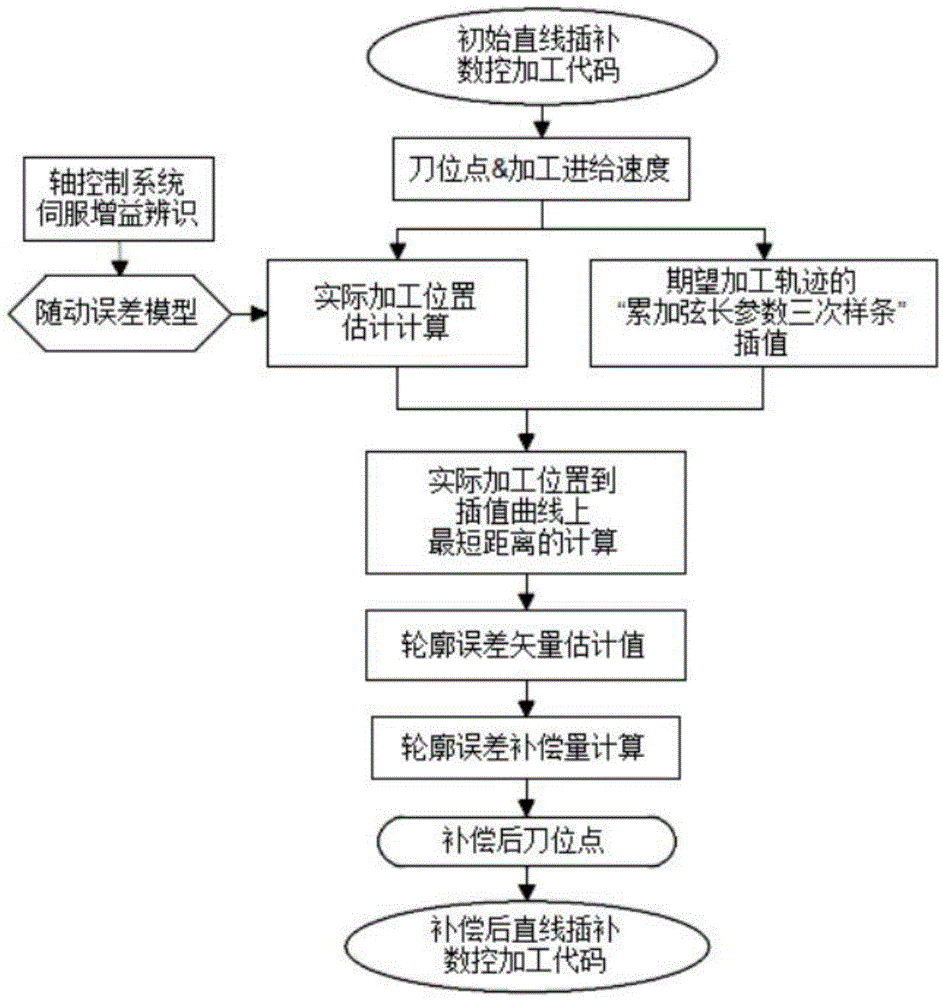

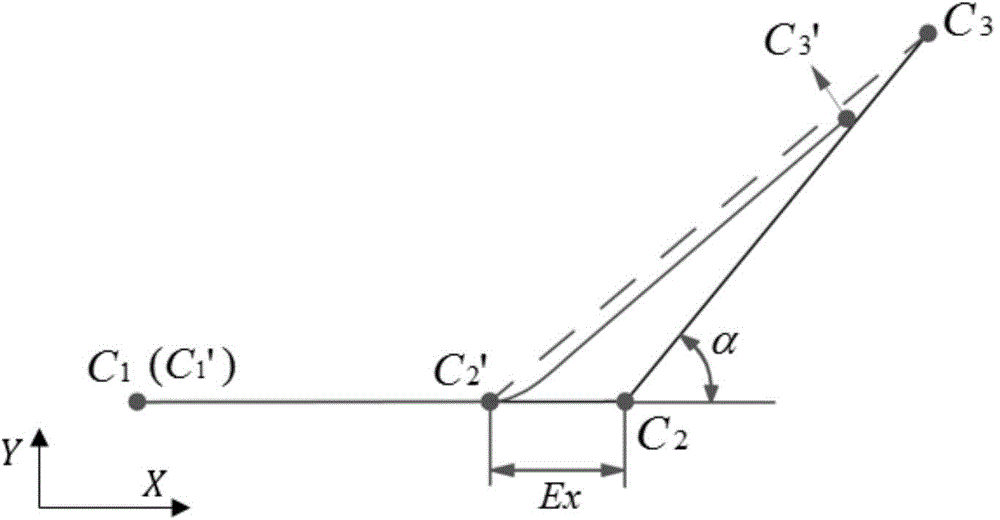

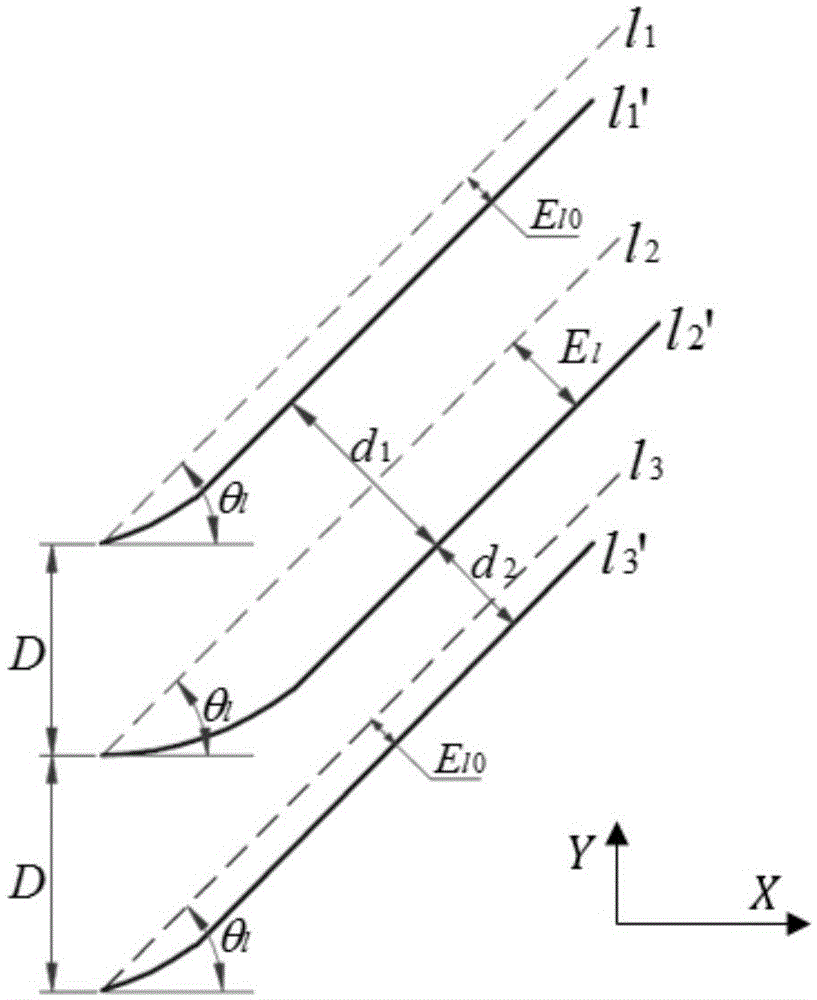

Curved surface tool path contour error compensation method based tool location point correction

ActiveCN104615083AHigh precisionCalculation stableProgramme controlComputer controlEstimation methodsControl system

The invention belongs to the field of numerical control machine tool dynamic error compensation and relates to a novel contour error estimation method, particularly to a curved surface tool path contour error compensation method based tool location point correction. The method comprises, on the basis of identifying the servo gain of a machining feed shaft control system, estimating practical machining points off line according to a following error model and linear interpolation machining codes; estimating contour error vectors according to a method similar to accumulated chord length parametric cubic spline of ideal tool paths; computing the contour error compensation according to the components of the contour error vectors on every axis to obtain compensated tool location points and further to generate linear interpolation numerical control machining codes for practical machining. The curved surface tool path contour error compensation method based tool location point correction can improve the dynamic precision of a numerical control machine tool and is high in precision, stable in computation, free from online measurement, easy to implement and wide in application range.

Owner:DALIAN UNIV OF TECH

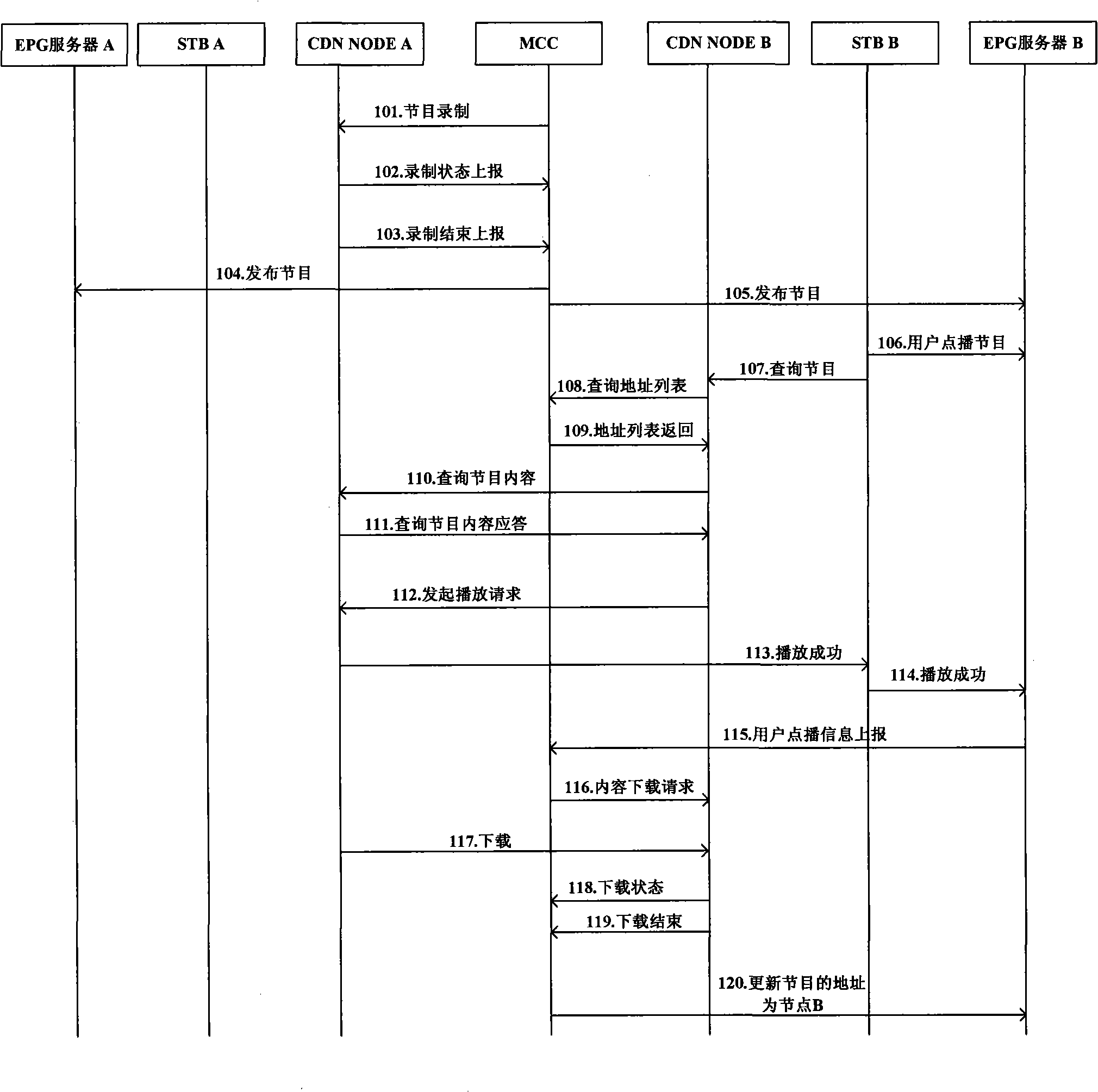

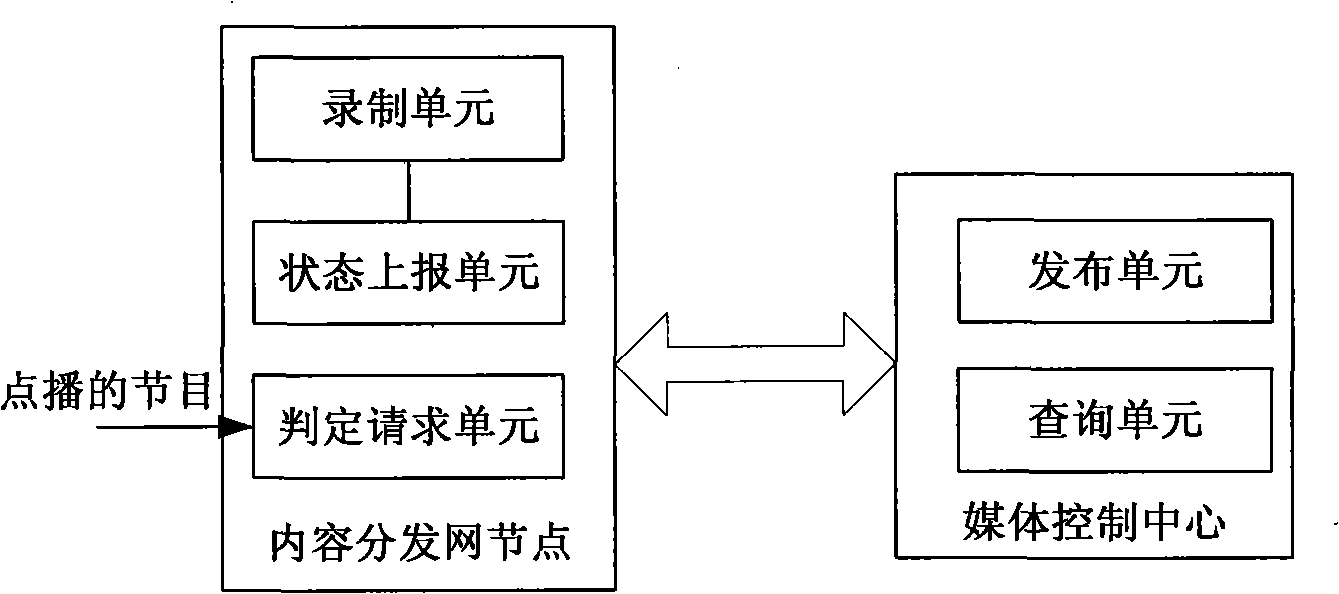

Method and system realizing content dynamically publishing based on hotness of user's demand

InactiveCN101291425ADoes not affect access latencySave storage spaceTwo-way working systemsTransmissionMedia controlsContent distribution

The invention discloses a method and a system for realizing dynamic publication of content according to VOD (Video-On-Demand) heat degree of users, wherein the method comprises the following steps that: a plurality of nodes of a content distribution network respectively record and store programs in a specified time period according to preset strategy, and display the recorded programs to all users; when a program ordered by some user is not at the present node, the node where the program is stored actually is acquired through inquiry, and VOD is carried out through the node actually storing the program. The system comprises a plurality of nodes of the content distribution network and a media control center. Through the method and the system of the invention, identical content does not need to be recorded at all content distribution nodes; a download command is initiated only if the number of access users exceeds a threshold value. On the one hand, the storage space of the system is greatly saved, and on the other hand, the load of the system is balanced without affecting the access time delay of users and the processing efficiency of the system.

Owner:ZTE CORP

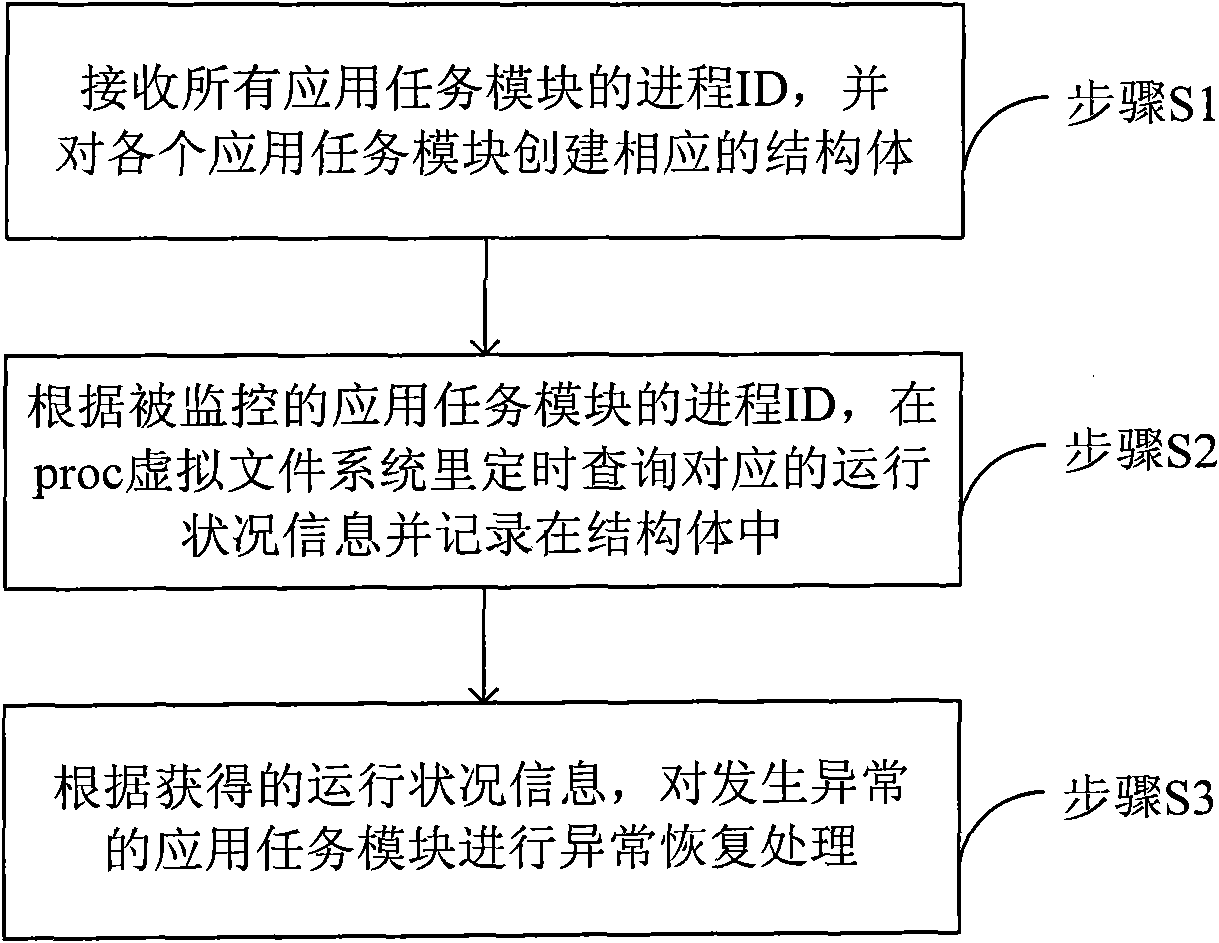

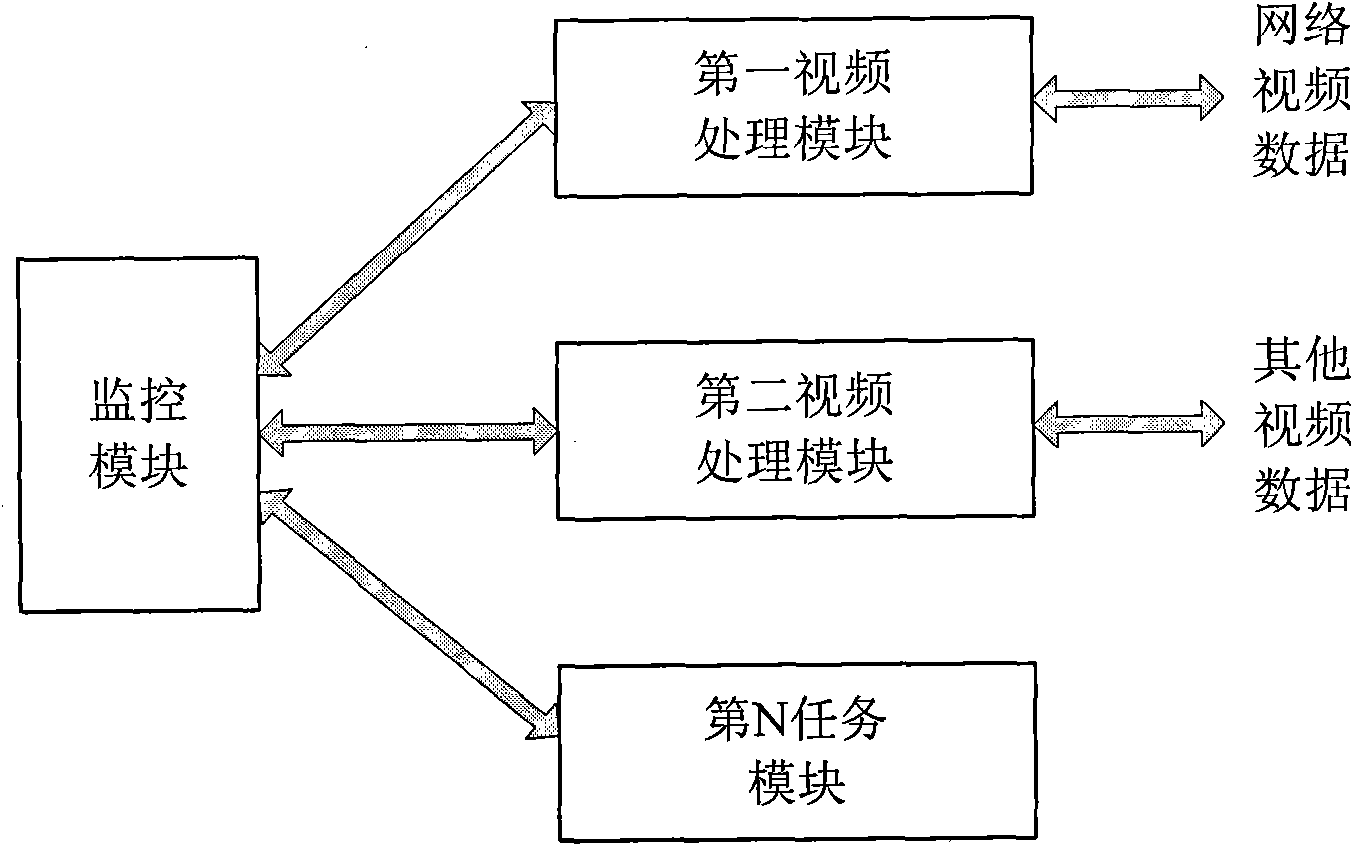

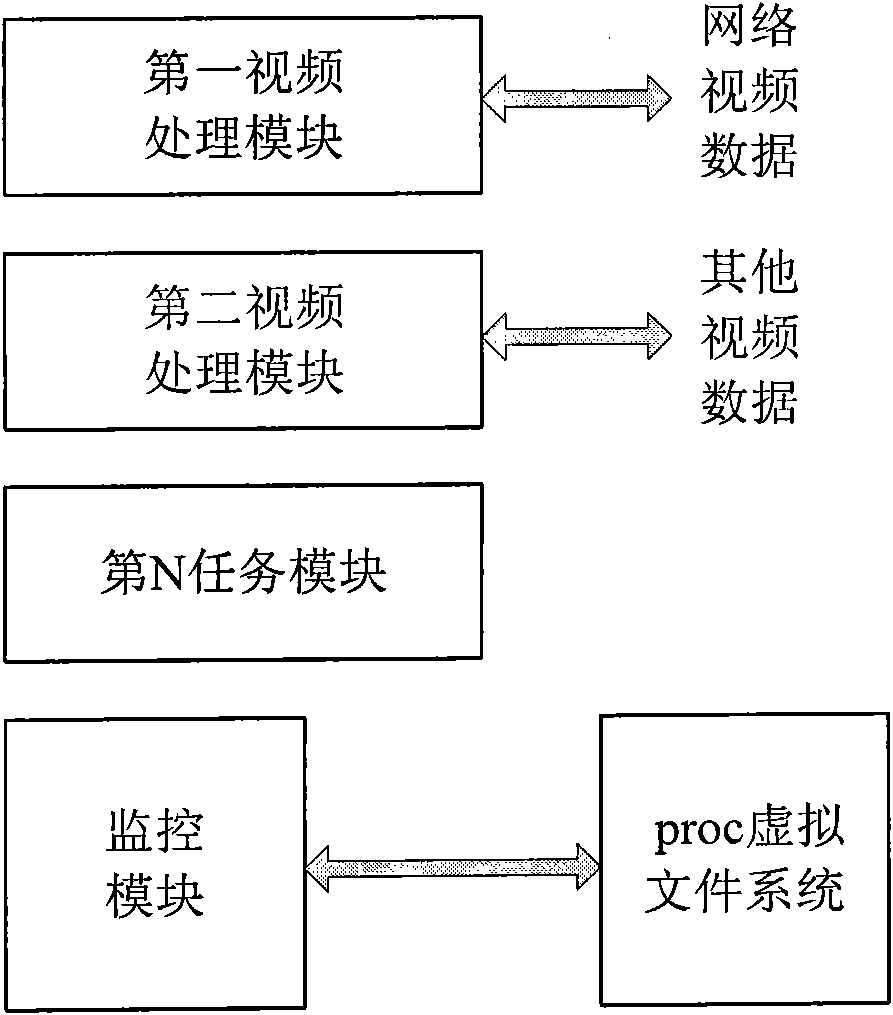

Method and system for multi-task monitoring process of videos

InactiveCN101674465ADoes not affect processing efficiencyLower latencyProgram initiation/switchingClosed circuit television systemsVirtual file systemFile system

The invention relates to the field of multi-task monitoring and provides a method for the multi-task monitoring process of videos. The method comprises the following steps: receiving the process IDs of all the application task modules and creating a corresponding structural body for each application task module, wherein, the structural body is used for recording the information on the process running state of the application task module; inquiring the corresponding information on the running state regularly in a proc virtual file system according to the process IDs of the monitored applicationtask modules, and recording the information on the running state thereof in the structural body; and detecting exceptions, and handling the exceptions of the application task module. Meanwhile, the invention further provides a system for the multi-task monitoring process of videos. The system comprises a parent process, a monitoring module, a plurality of application task modules and the proc virtual file system. The invention can monitor the application task modules and handle the exceptions without influencing the data processing efficiency of the video; moreover, the invention can reduce the picture delay.

Owner:NANTONG BEICHEN MACHINERY EQUIP MFGCO

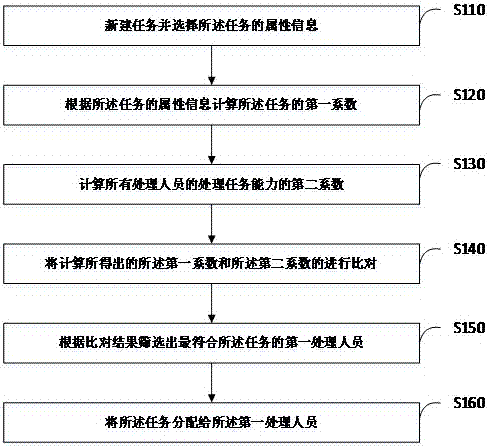

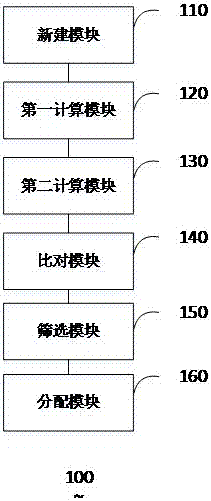

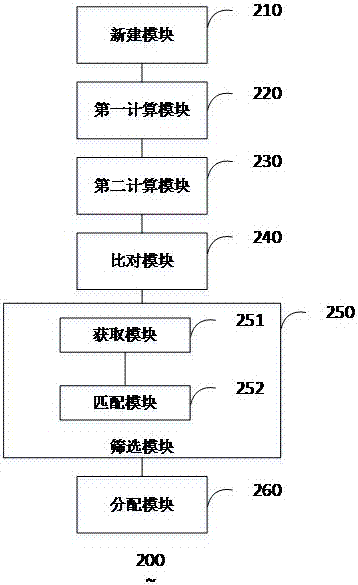

Work task automatic distribution method and system

PendingCN107301485ATimely response to tasksTimely responseResourcesDistribution systemDistribution method

The invention provides a work task automatic distribution method. The work task automatic distribution method comprises steps of establishing a new task and choosing attribute information of the task, calculating a first coefficient of the task according to the attribute information of the task, calculating a second coefficient of task processing capabilities of all processing staff, comparing the first coefficient with the second coefficient, screening out the first processing staff which are most suitable for the task, and distributing the task to the first processing staff. The invention also provides a working task automatic distribution system. The work task automatic distribution method and system guarantee that the task is distributed to the most suitable processing staff according to the task attribute information and processing capability of the processing staff and guarantee that task processing efficiency is not affected when the task is responded.

Owner:SHENZHEN WADE INNVOATION INFORMATION CO LTD

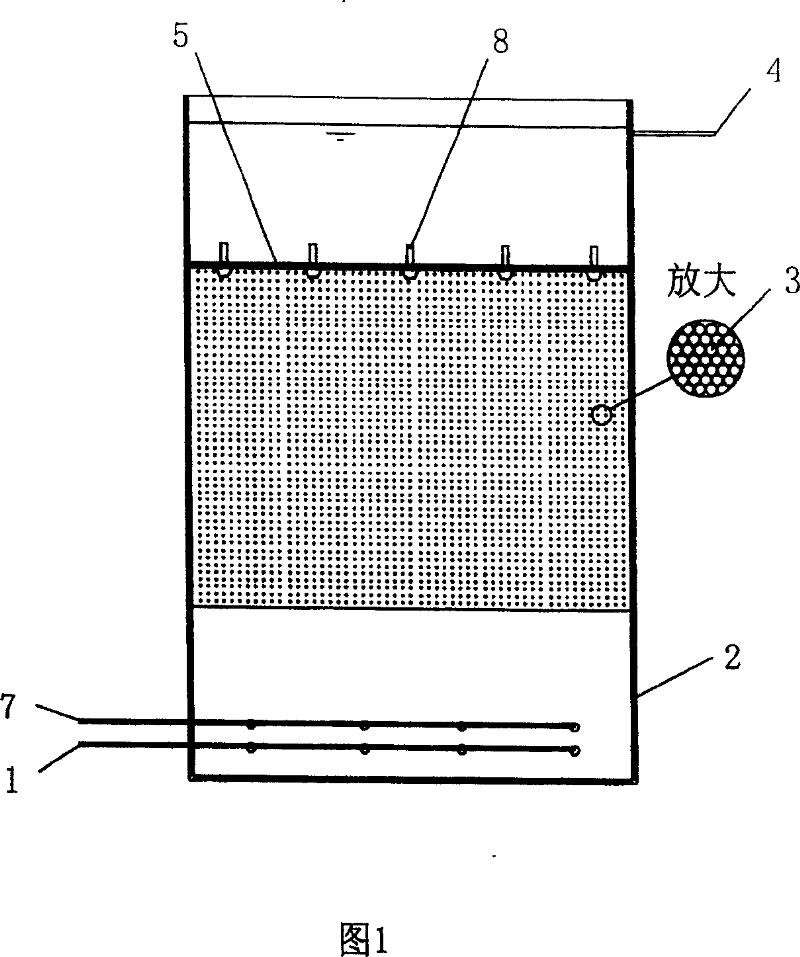

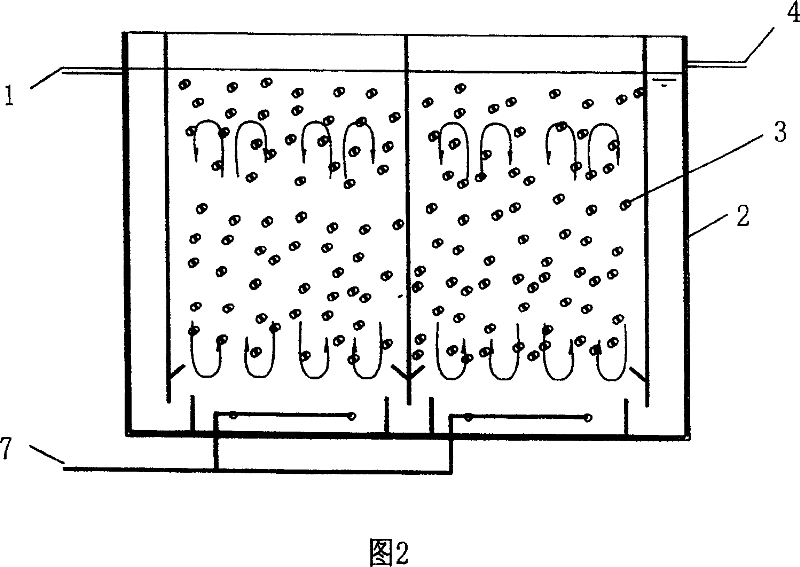

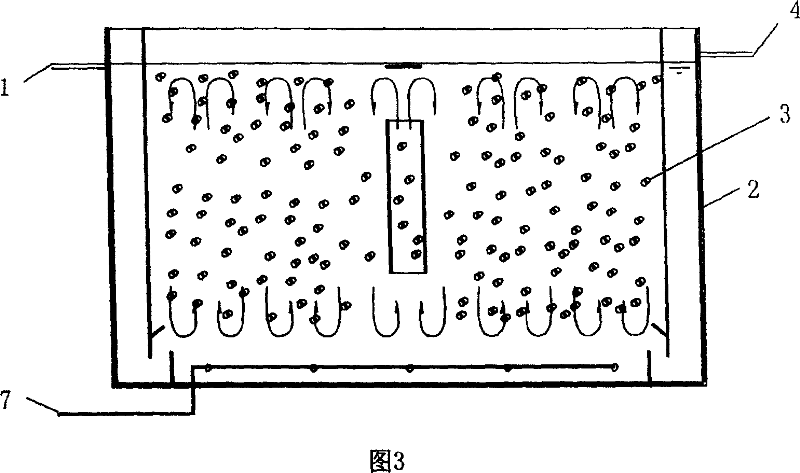

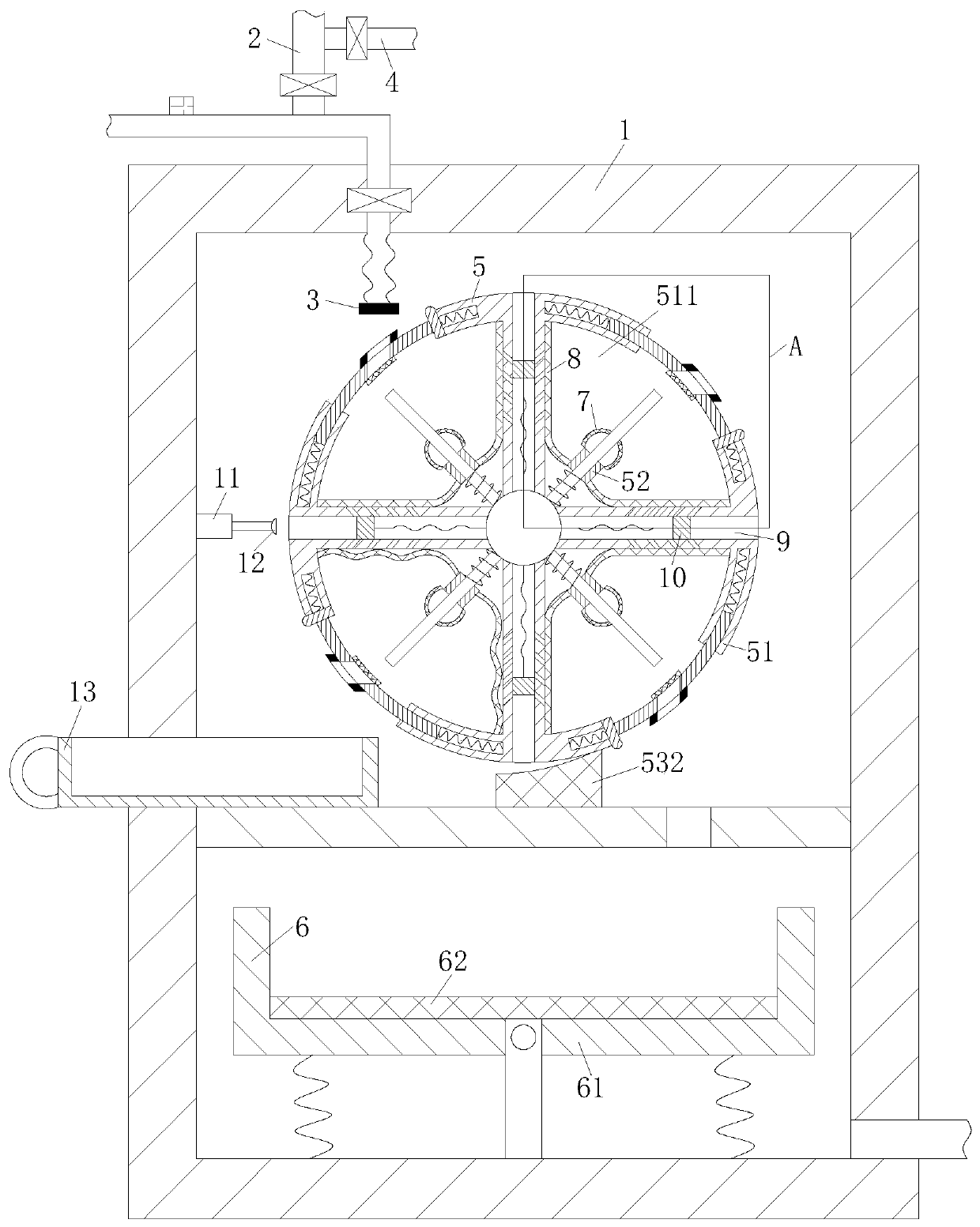

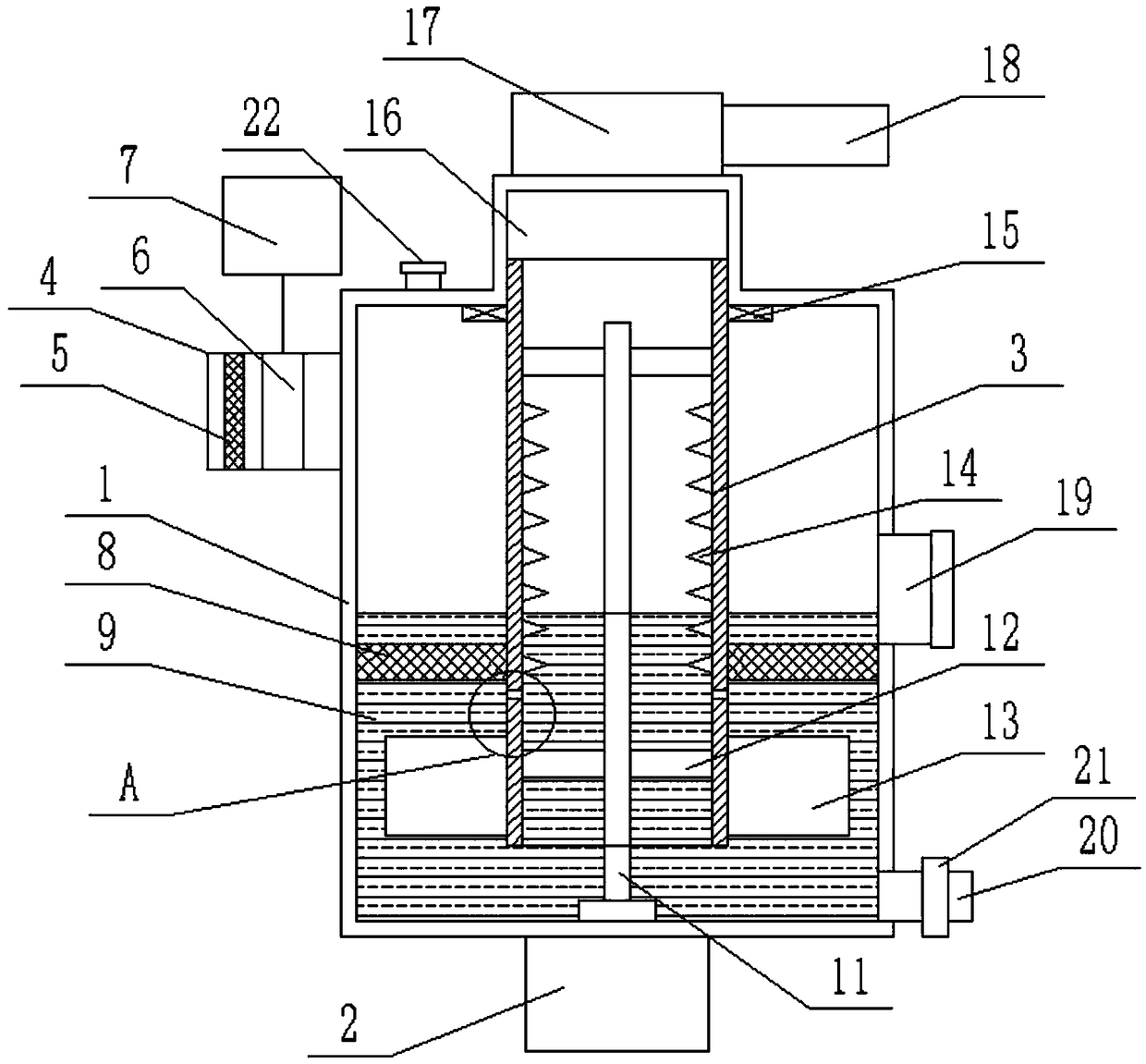

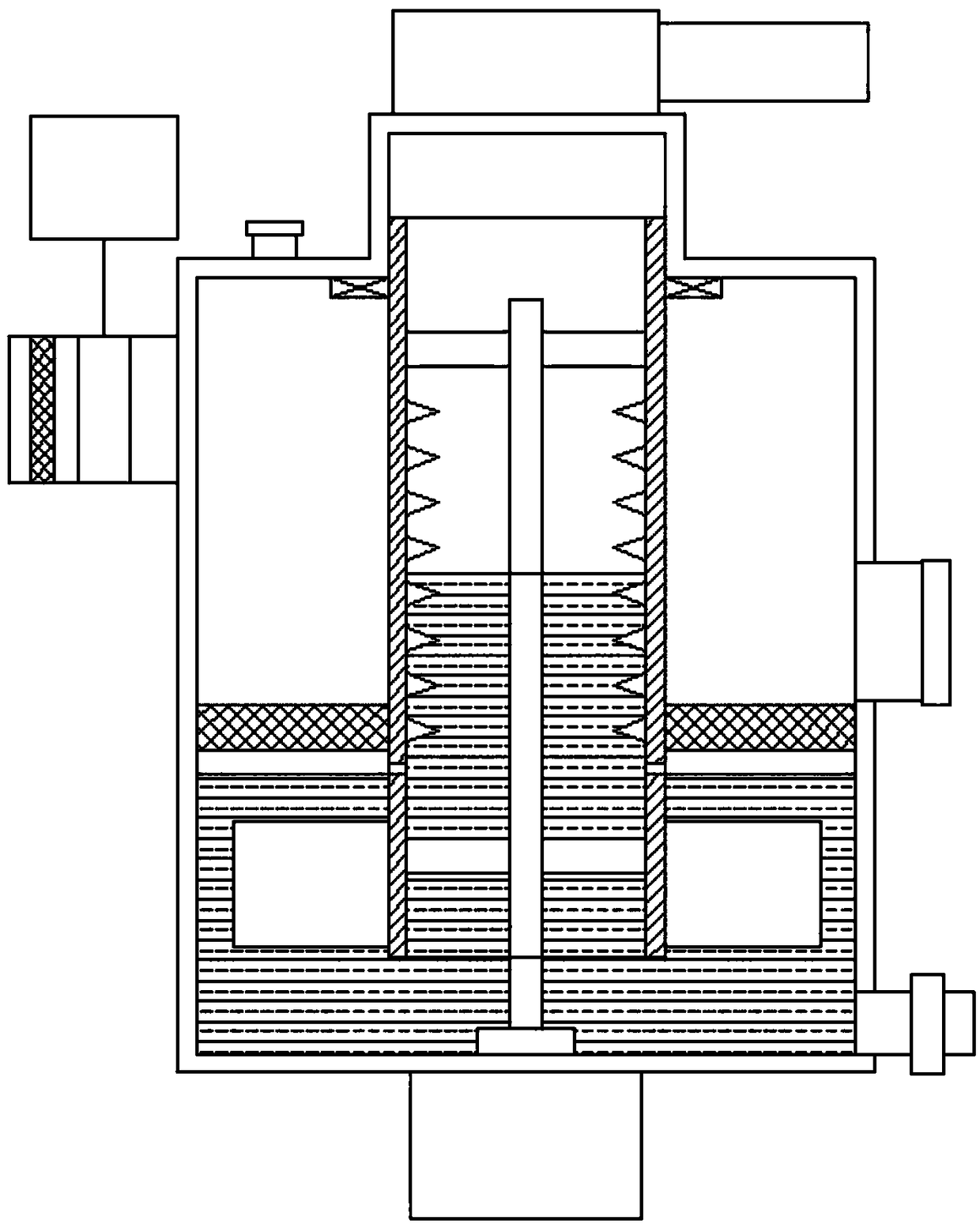

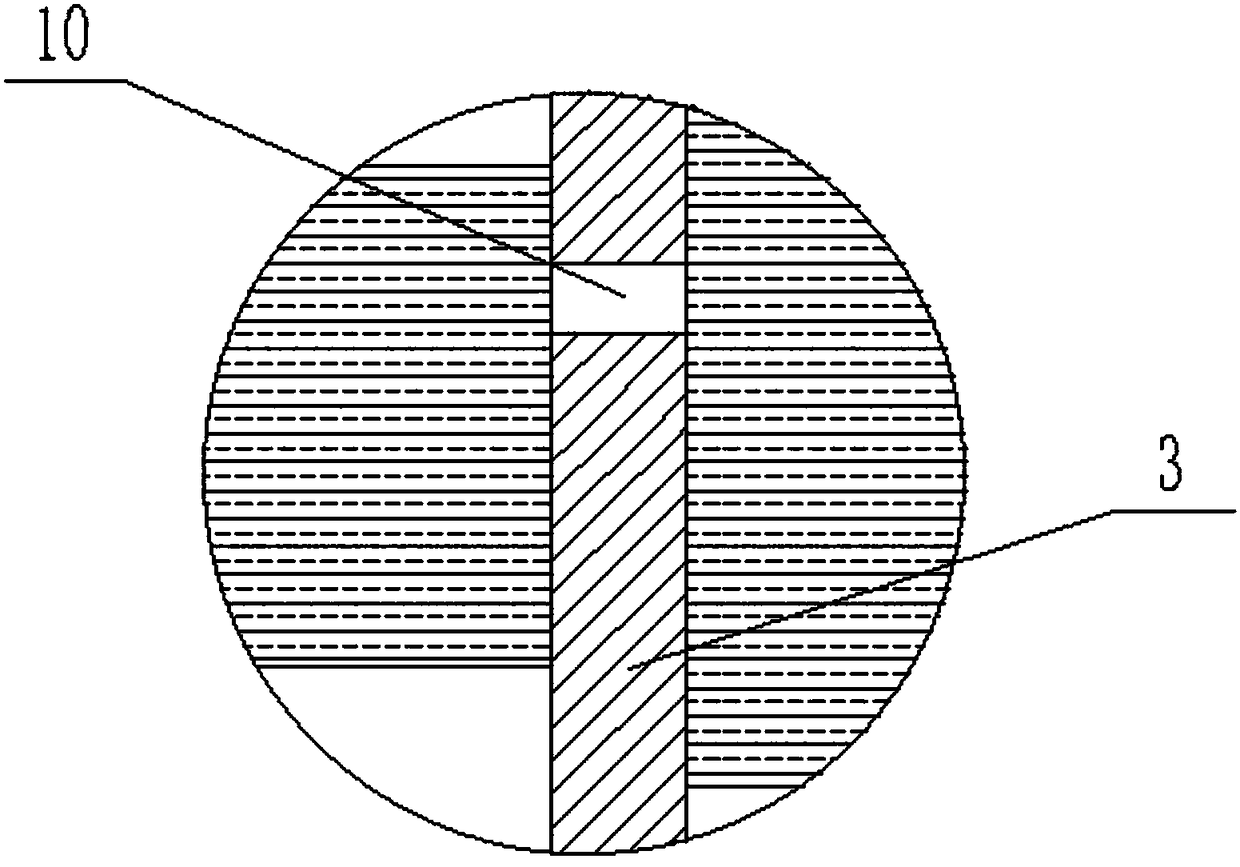

Improved bioreactor

ActiveCN100337936CHigh oxygenation efficiencyExtended pathTreatment using aerobic processesSustainable biological treatmentVoid ratioEffective volume

The present invention relates to the field of water treatment, especially an aerobic biological treatment bioreactor which contains large particle easy-fluidization filling having a specific density of 0.7-0.95, and a void ratio of >=50%, the loading amount of the filling is 50-90% of the reactor's effective volume, and the aeration apparatus includes separate oxygen supply aeration device and fluidization aeration device.

Owner:PENYAO ENVIRONMENTAL PROTECTION

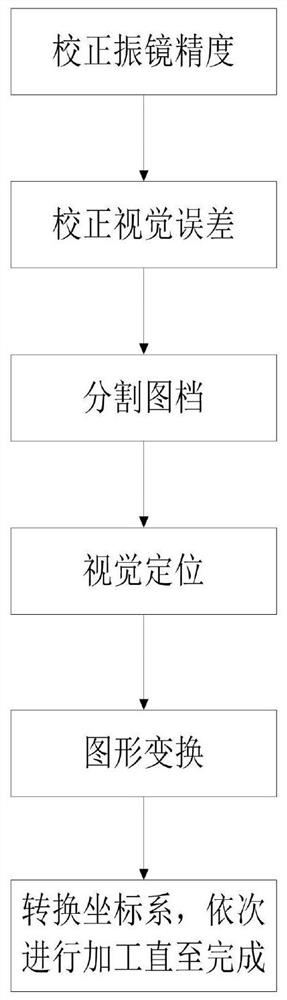

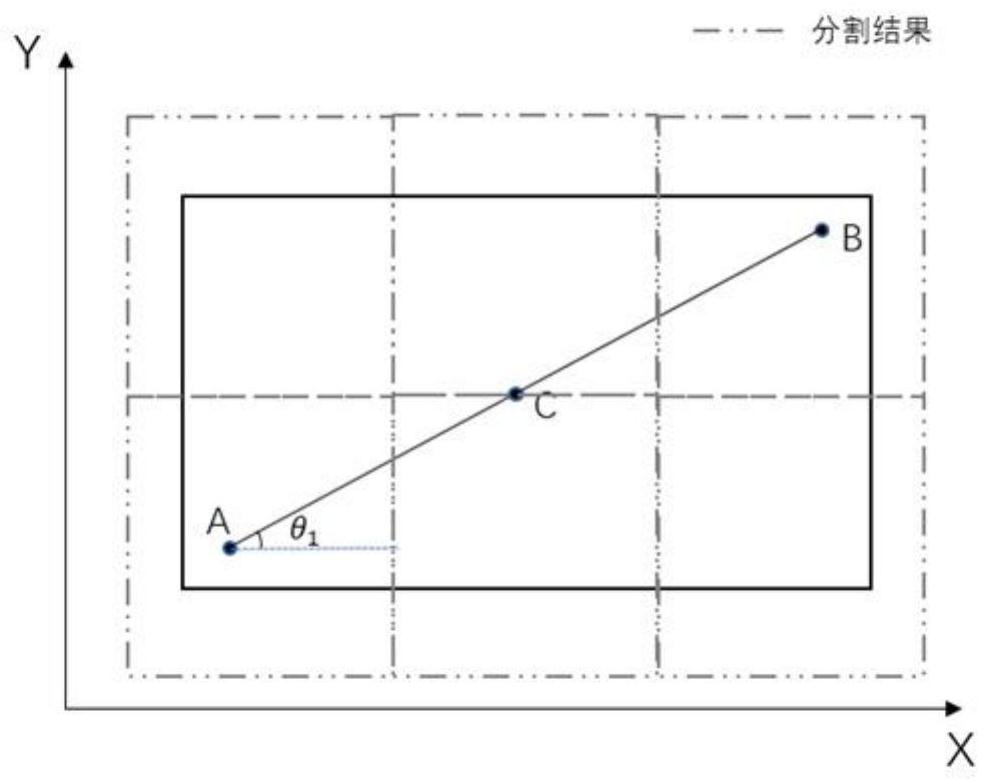

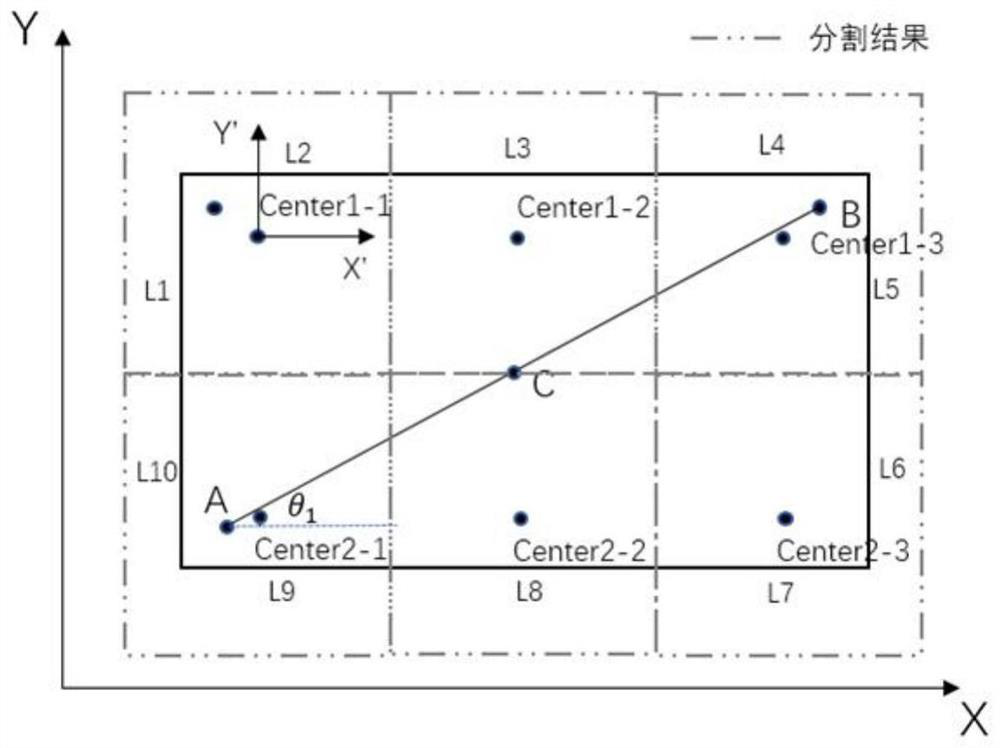

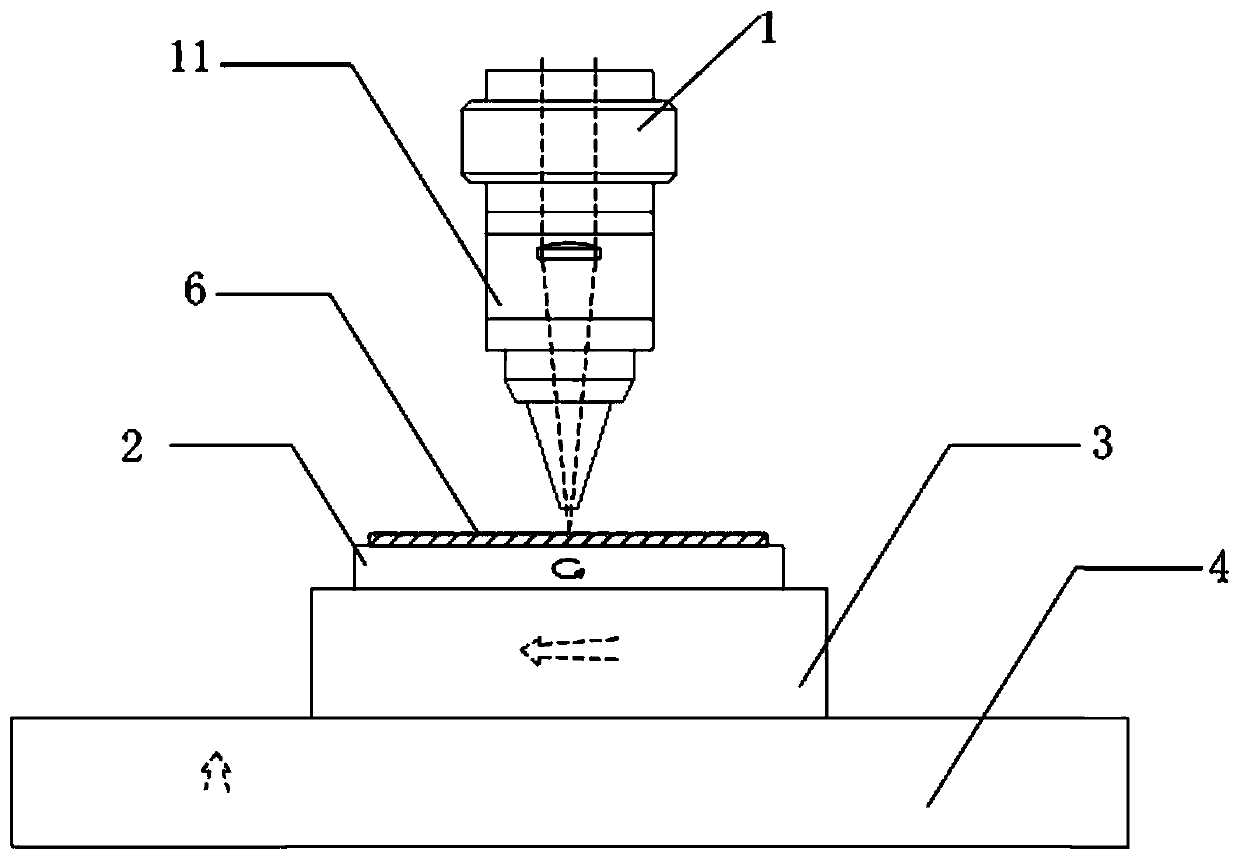

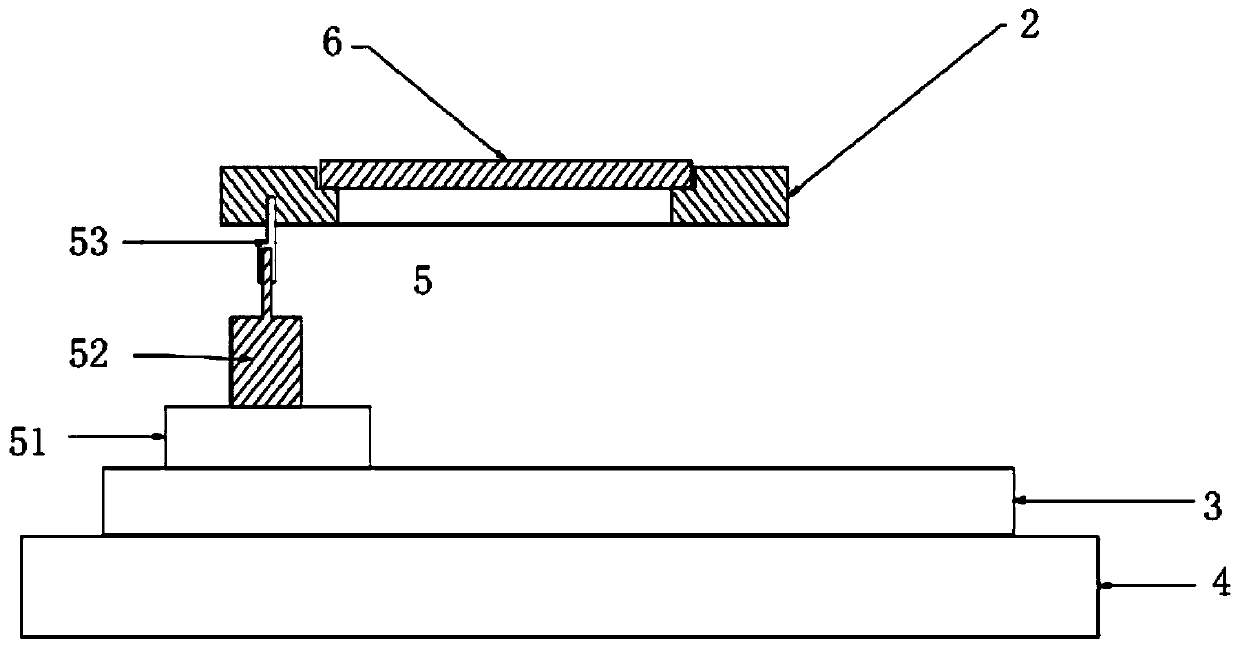

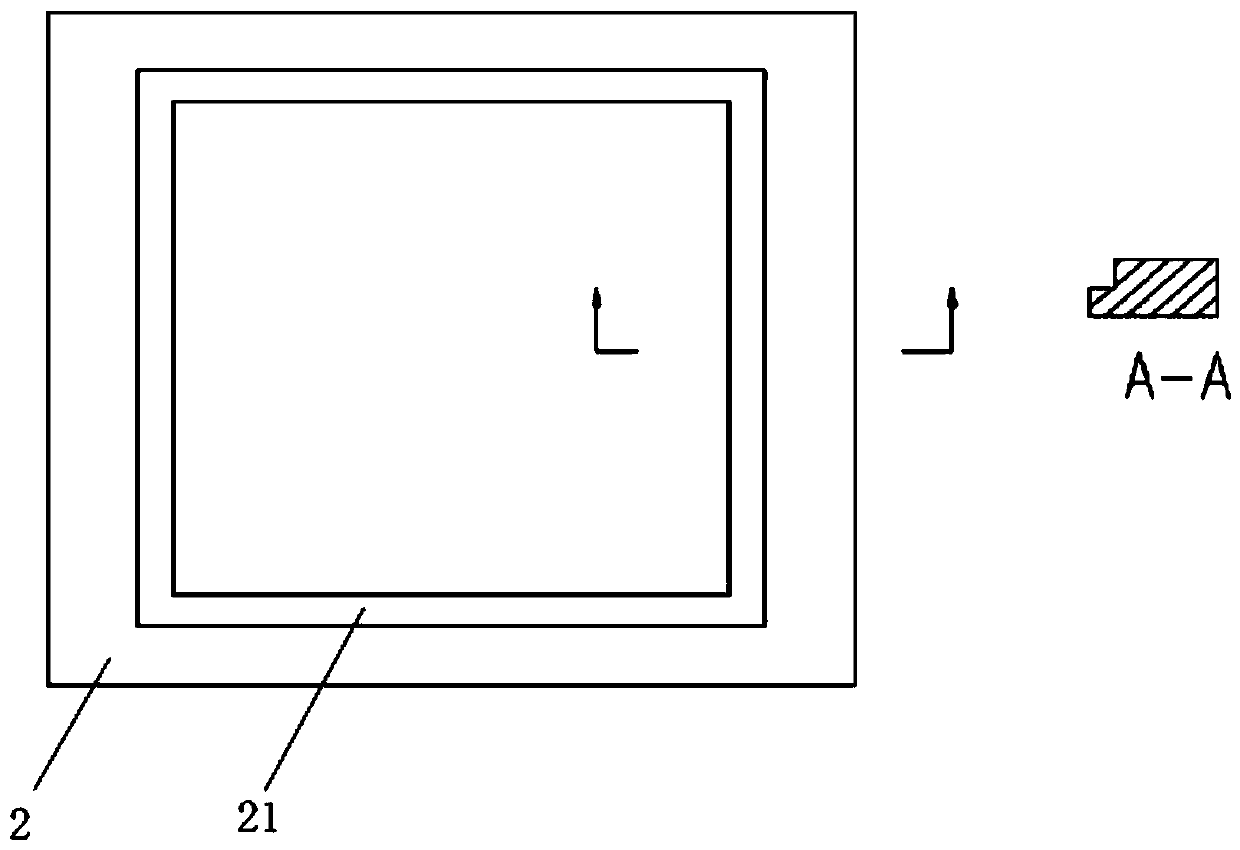

Visual positioning method based on side-axis visual structural galvanometer puzzle processing

ActiveCN111992911AImprove stitching accuracyImprove processing efficiencyUsing optical meansLaser beam welding apparatusGraphicsGalvanometer

The invention discloses a visual positioning method based on side-axis visual structural galvanometer puzzle processing. Firstly, the precision of a galvanometer is corrected, a galvanometer correction file is generated, and a visual error is corrected through a galvanometer correction file; drawing segmentation is then performed, the path required for each block to be processed after segmentationis calculated before processing, and only direction offset and angle rotating need to be performed in the processing process; visual positioning is then performed, and a reference point coordinate and a corresponding offset rotating amount are found; graphic transformation is conducted based on a reference point and offset rotating amount, points on a motion platform coordinate system are converted into coordinate values under a galvanometer coordinate system, and the coordinate values are directly sent to a galvanometer system for processing during processing; and a motion control platform is moved to the coordinate position of the center point under a platform coordinate system, coordinate values of feature points of processing path line segments to the galvanometer system for processing, and other blocks are sequentially processed after processing of the current block is completed until processing of all the blocks is completed.

Owner:WUHAN HGLASER ENG CO LTD

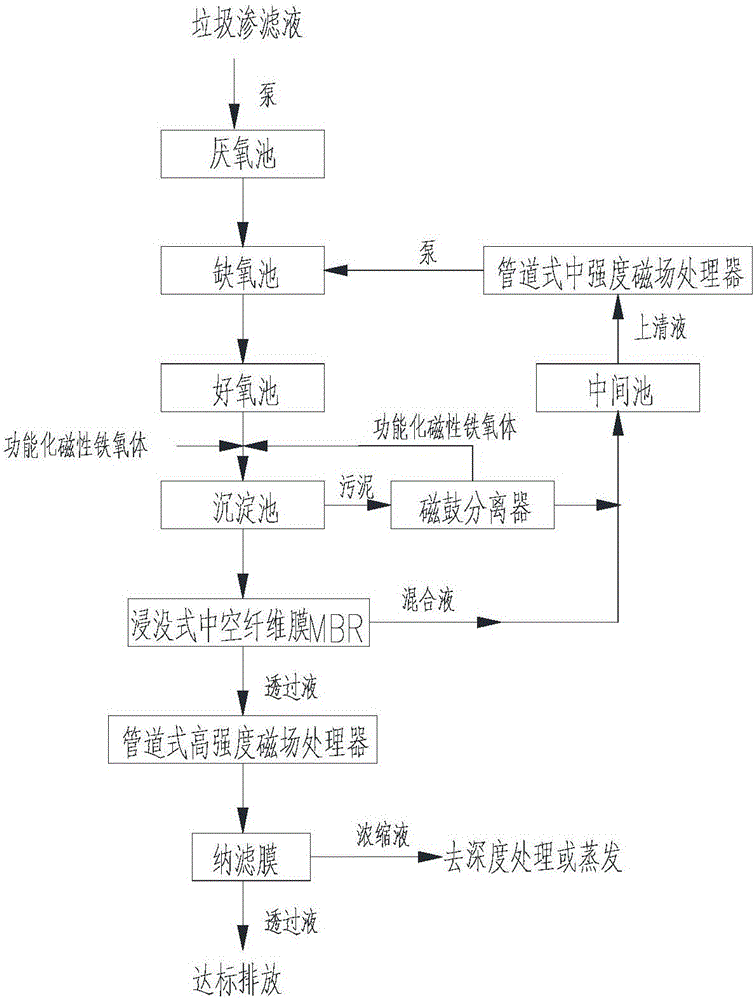

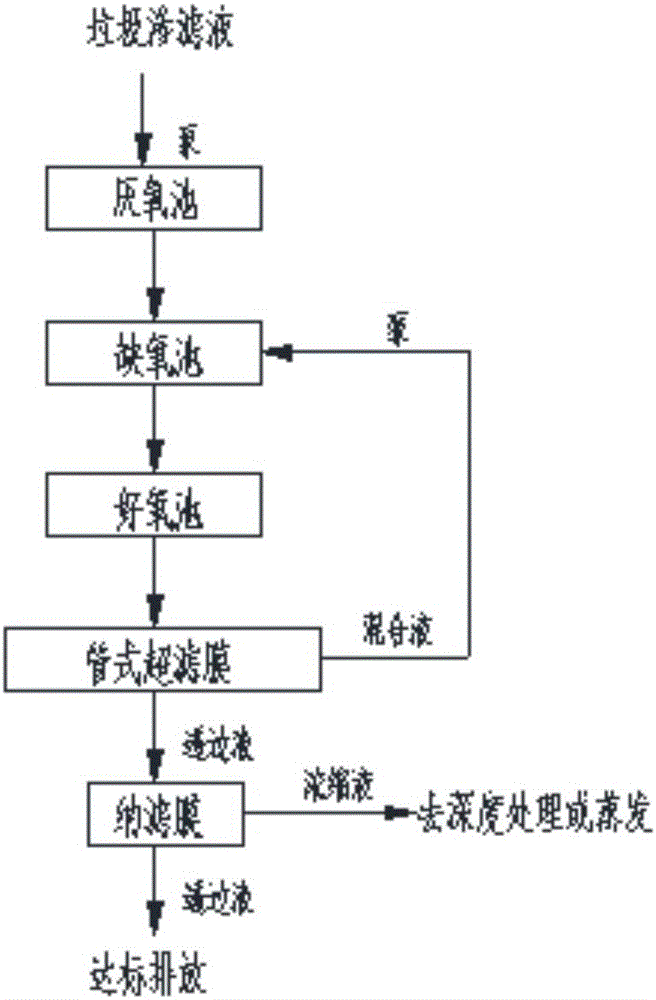

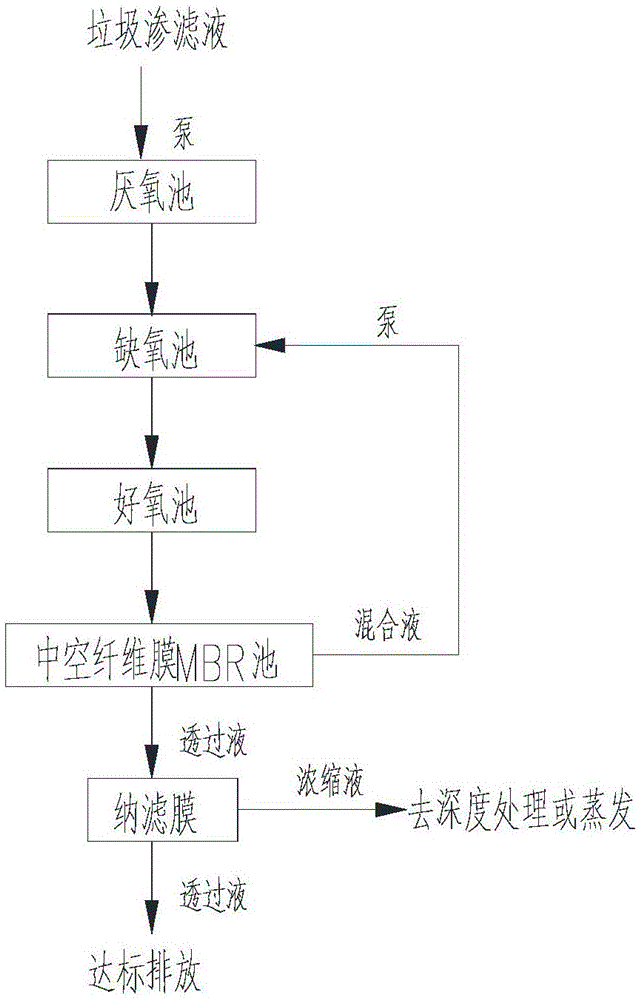

Landfill leachate multi-membrane treatment process

ActiveCN106219752AReduce concentrationEffective solid-liquid separationWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment bu osmosis/dialysisReverse osmosisSlurry

The invention discloses a landfill leachate multi-membrane treatment process. Landfill leachate is pumped into an anaerobic tank, an anoxic tank and an aerobic tank in sequence for treatment, functional magnetic ferrite is put into effluent of the aerobic tank, and the effluent enters a sedimentation tank for solid-liquid separation; supernatant obtained from the sedimentation tank enters an immersed membrane reactor for secondary solid-liquid separation; sludge obtained from the sedimentation tank enters a magnetic drum separator for separation, and slurry containing the magnetic ferrite and returned sludge are obtained, wherein the slurry containing the magnetic ferrite flows back to enter the water outlet portion of the aerobic tank, and the returned sludge enters a middle tank; immersed membrane reactor permeate enters a tubular high-intensity magnetic field processor for magnetizing sterilization and then enters a nanofiltration or reverse osmosis system to be treated, and the treated immersed membrane reactor permeate is discharged up to standard; immersed membrane reactor concentrated mixed liquid is mixed with the returned sludge through the middle tank, and the supernatant is pressurized through a water pump and subjected to magnetic activation through a tubular medium-intensity magnetic field processor and then flows back to enter the anoxic tank.

Owner:江苏环保产业技术研究院股份公司

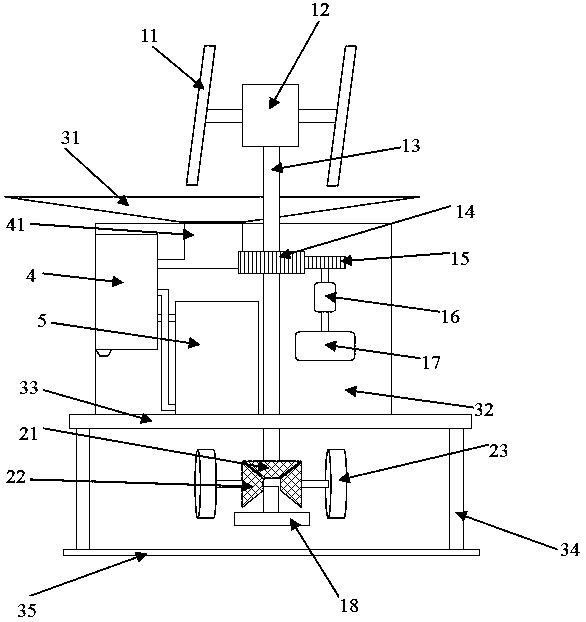

Vertical-axis offshore wind generator device

ActiveCN108488033ASave energyTurn harm into benefitGeneral water supply conservationTreatment involving filtrationElectricityEngineering

The invention relates to a vertical-axis offshore wind generator device which comprises a wind power generation component, a hydroelectric generation component, a support frame component, a rainwatertreatment room I and a rainwater treatment room II. The hydroelectric generation component is arranged at the bottom of the offshore wind generator device, and generated energy is supplemented throughwave energy of ocean tides. As the wave energy is converted into electrical energy, the shaking damage on the offshore wind generator device of the tides is greatly relieved, and therefore the service life of the wind generator is prolonged as a whole. Due to the arrangement of the rainwater treatment rooms, rainwater on the sea is collected and treated. Therefore, the rainwater on the sea is utilized, and the overall energy utilization is greatly improved.

Owner:中广核如东海上风力发电有限公司

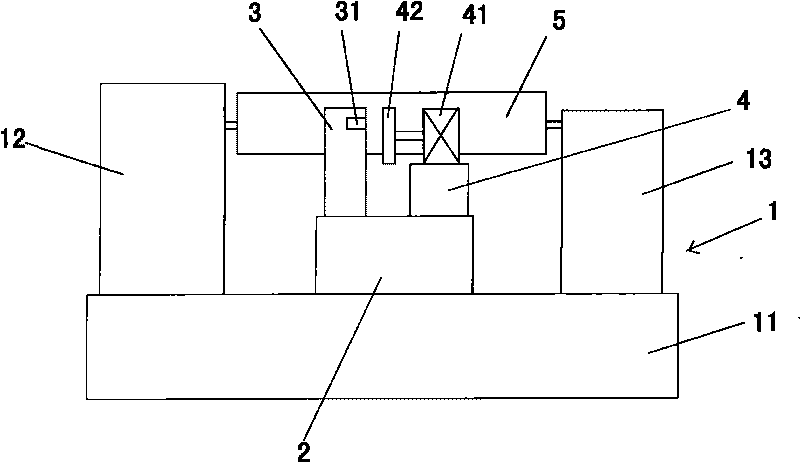

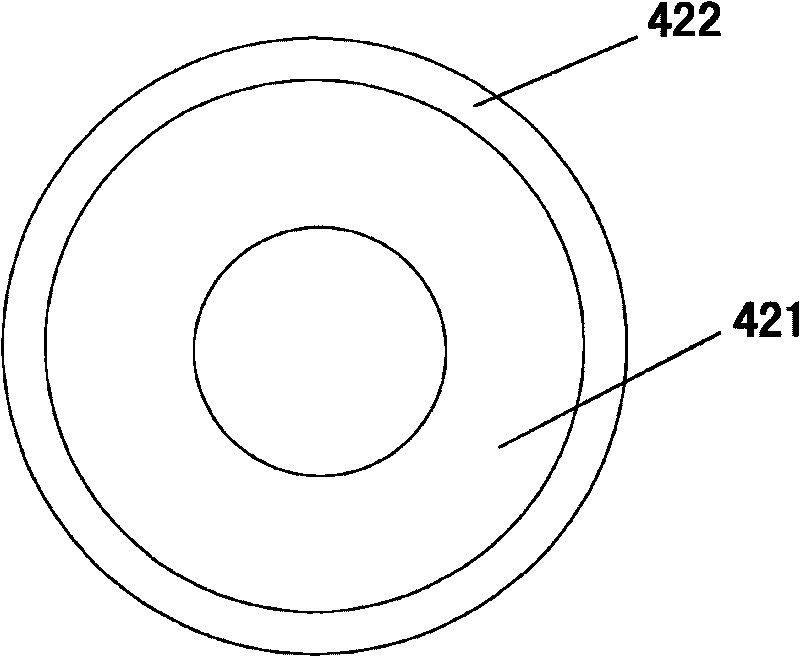

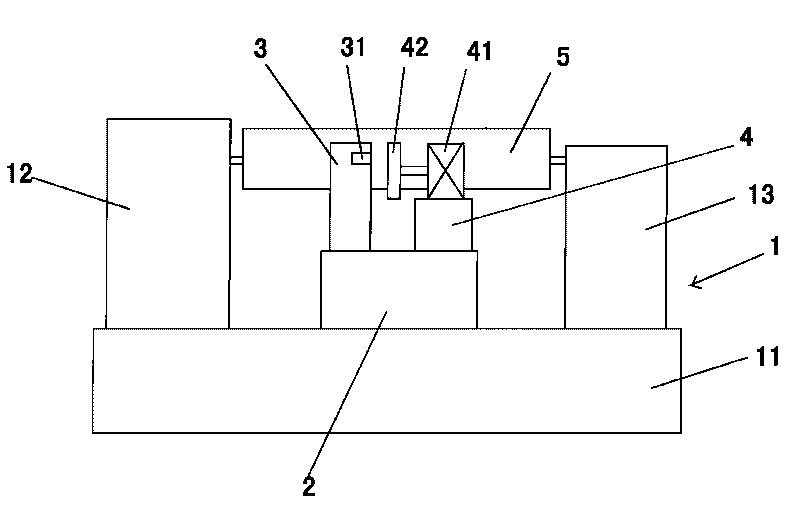

Improved high-precision numerical control machine

InactiveCN101745805AImprove processing efficiencyLow costOther manufacturing equipments/toolsLarge fixed membersNumerical controlEngineering

The invention provides an improved high-precision numerical control machine comprising a high-precision numerically controlled lathe. The body of the lathe is provided with a movable slide carriage; the slide carriage is provided with a tool holder and a grinding and polishing machining mechanism in parallel; a tool is installed on the tool holder; the grinding and polishing machining mechanism comprises a motor installed on the slide carriage as well as a grinding and polishing head installed on the principal axis of the motor; and the grinding and polishing head is composed of an abrasive wheel and an abrasive belt ring sheathed on a grinding wheel. The improved high-precision numerical control machine of the invention combines the grinding and polishing function of the abrasive belt and the lathe and realizes that lathing and grinding and polishing treatment are simultaneously carried out, so that the improved high-precision numerical control machine has the common advantages of the lathe and the grinder.

Owner:上海运申制版模具有限公司

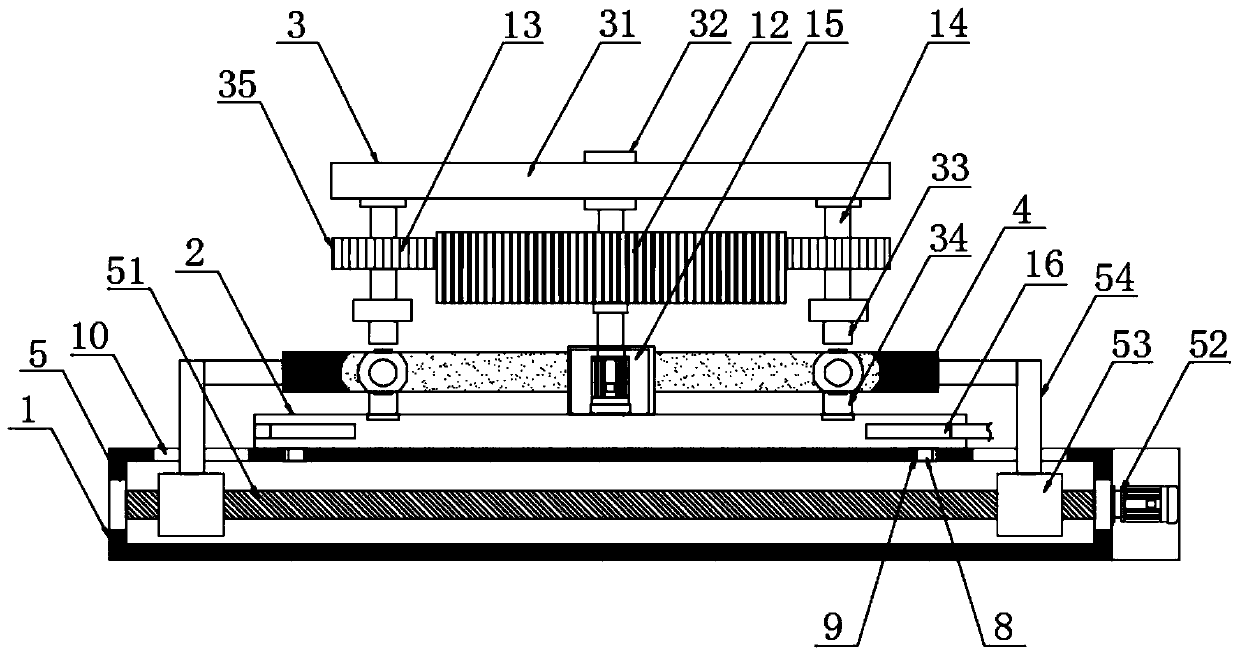

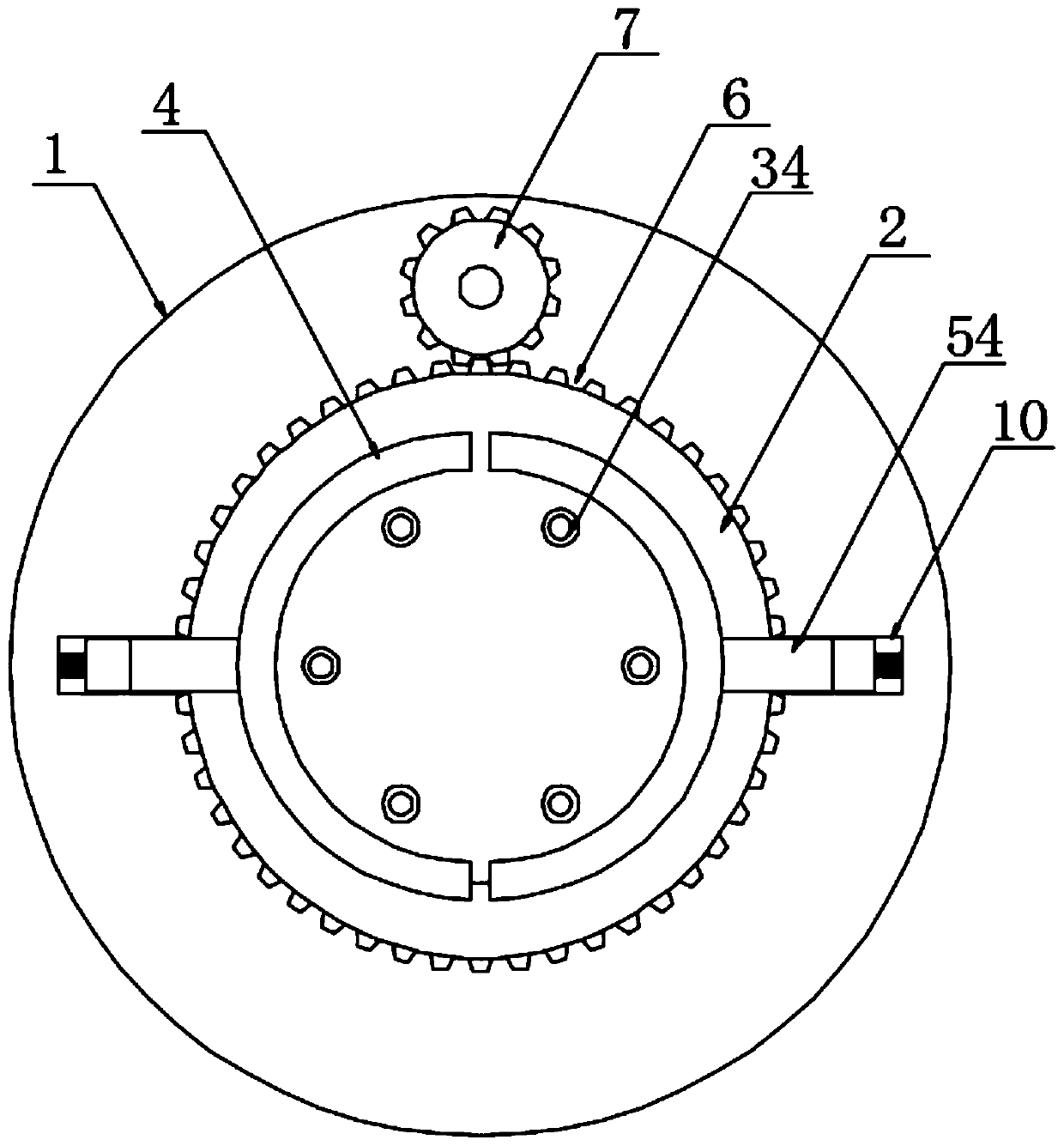

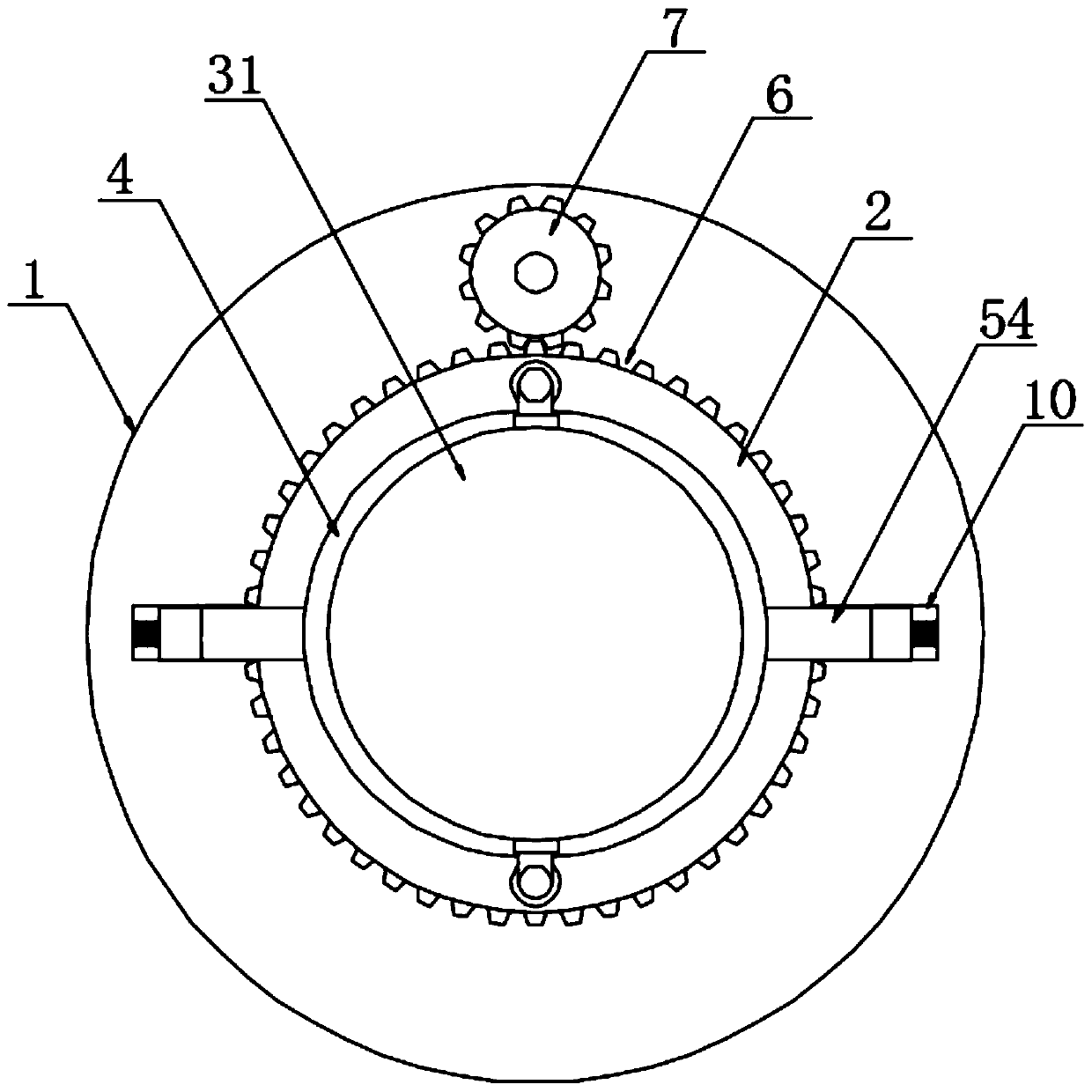

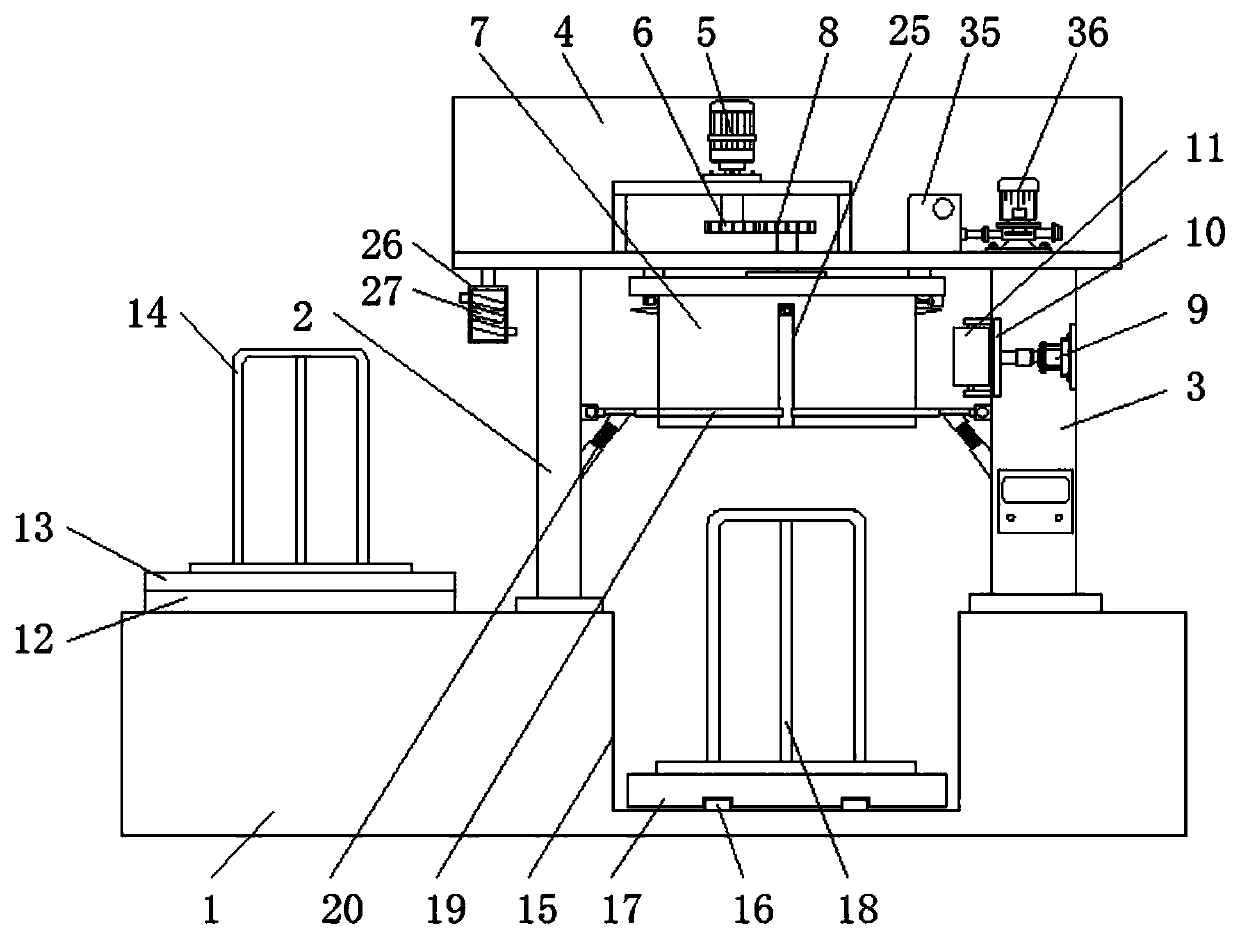

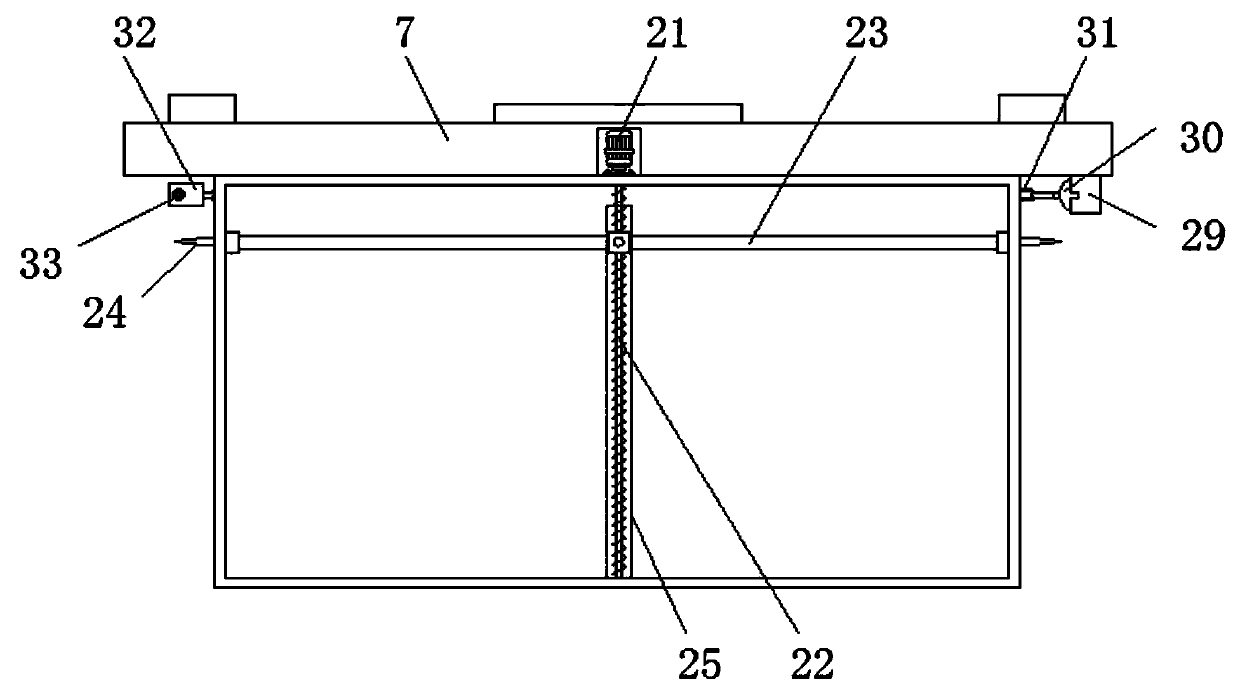

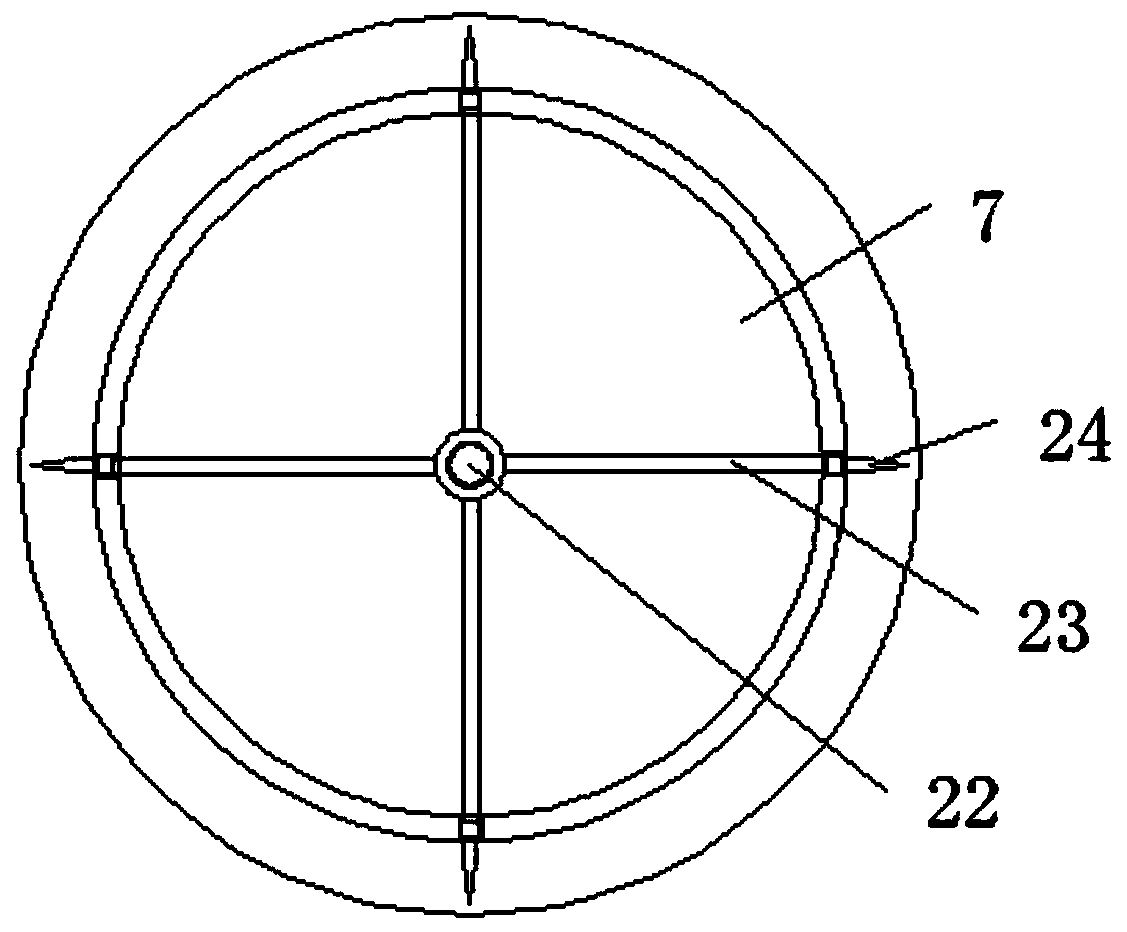

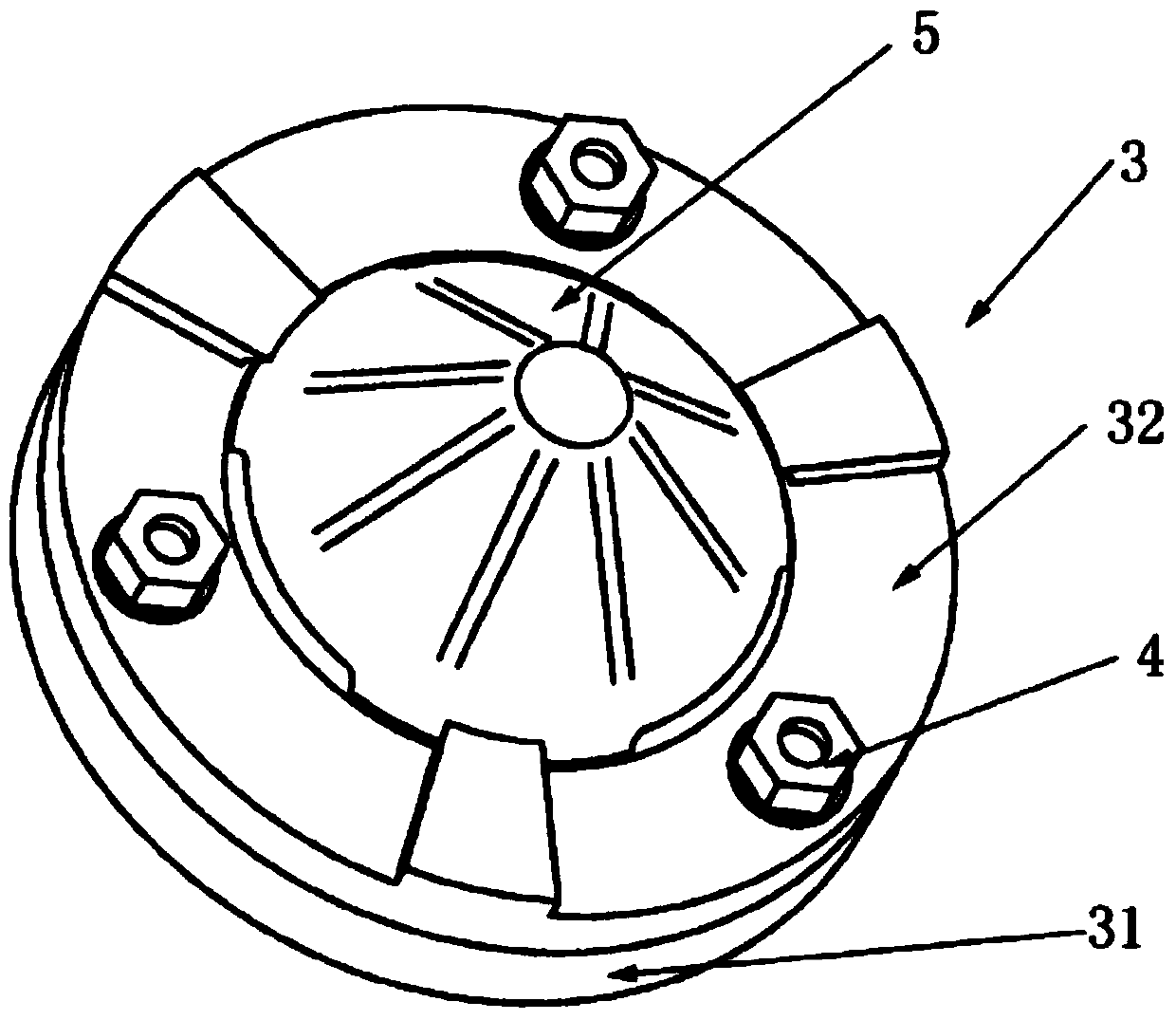

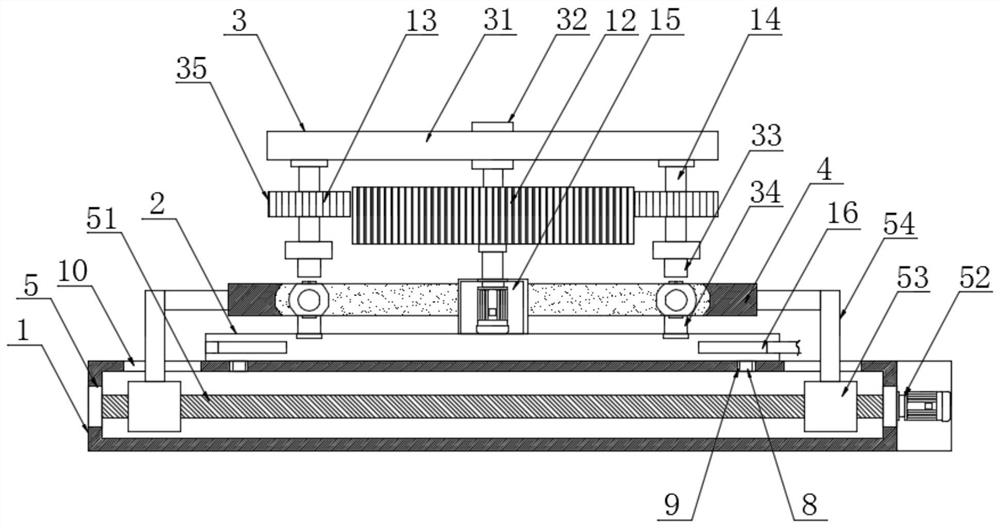

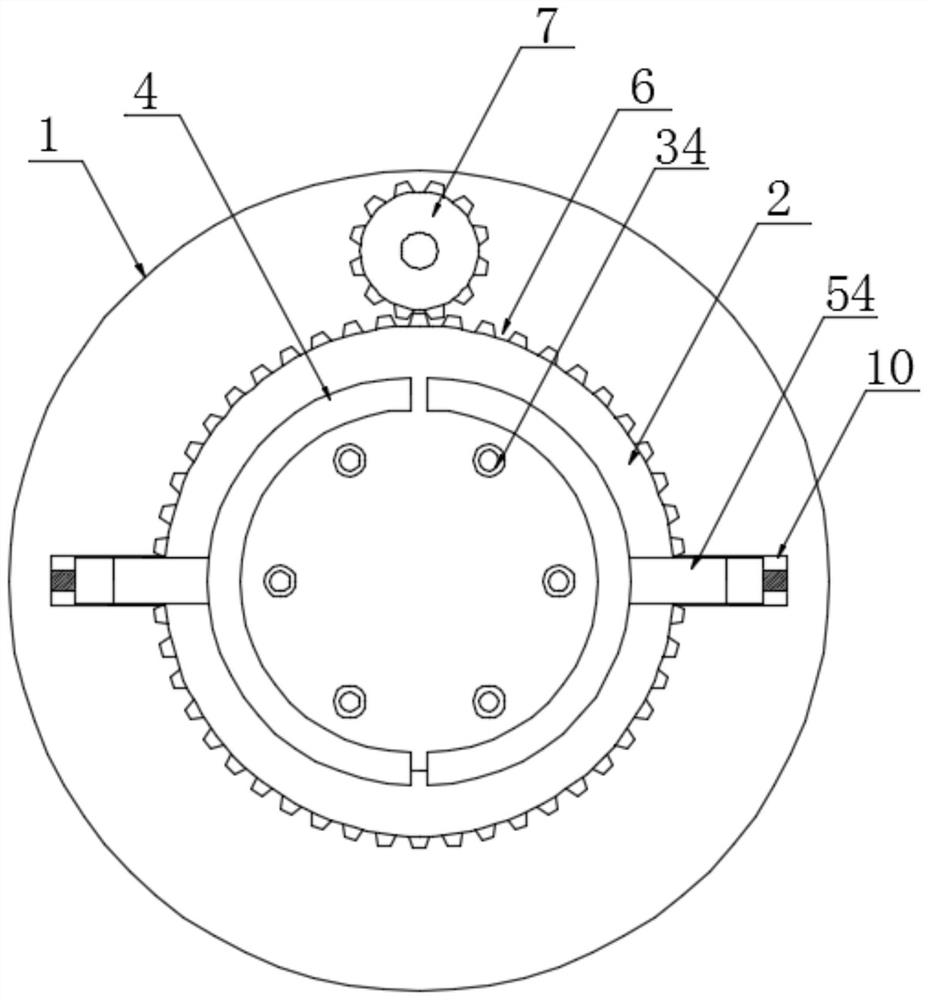

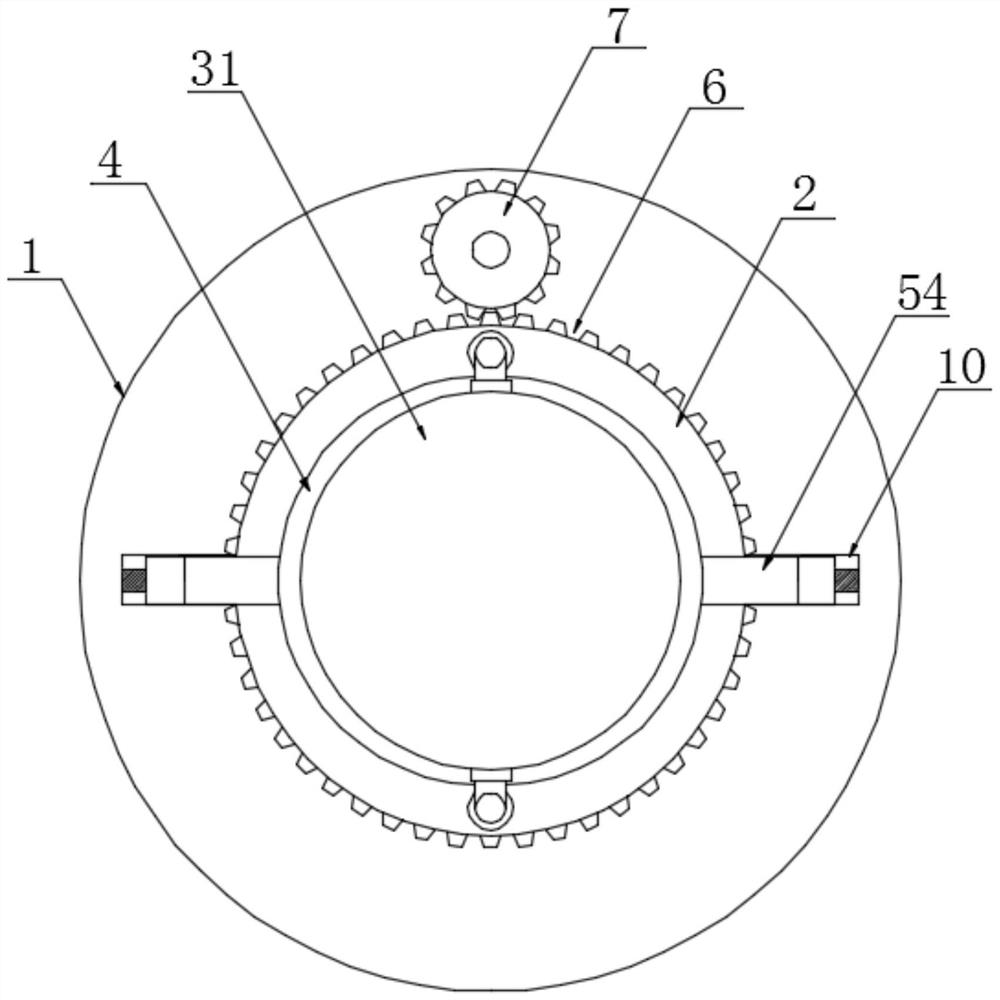

Spherical surface grinding device for ball valve cores

ActiveCN111113198AImprove work efficiencyEasy to useGrinding drivesSpherical surface grinding machinesRotary stageGear wheel

The invention discloses a spherical surface grinding device for ball valve cores and particularly relates to the field of ball valve element machining. The spherical surface grinding device for the ball valve cores comprises a worktable, a rotating table is arranged at the top of the worktable, a multi-ball-core clamping mechanism is arranged at the top of the rotating table, outer grinding platesare arranged on the two sides of the multi-ball-core clamping mechanism respectively, the two outer grinding plates are driven through a reciprocating mechanism to do reciprocating linear movement and are used for grinding the spherical surfaces of ball cores fixed by the multi-ball-core clamping mechanism, tooth grooves are formed in the outer wall of the rotating table, and a driving gear engaged with the tooth grooves is arranged on the rear side of the rotating table. The spherical surface grinding device can grind multiple ball cores at the same time, and the working efficiency is greatly improved; besides, when the contact faces of the outer grinding plates and the ball cores are worn, position offset replacement of multiple ball core clamps can be achieved simply by driving the rotating table through the driving gear, and the grinding faces of the outer grinding plates and the ball cores are replaced; and the grinding device is very convenient to use, adjustment is quick, and the machining efficiency and the precision of the ball cores are not influenced.

Owner:顶红科技发展(浙江)有限公司

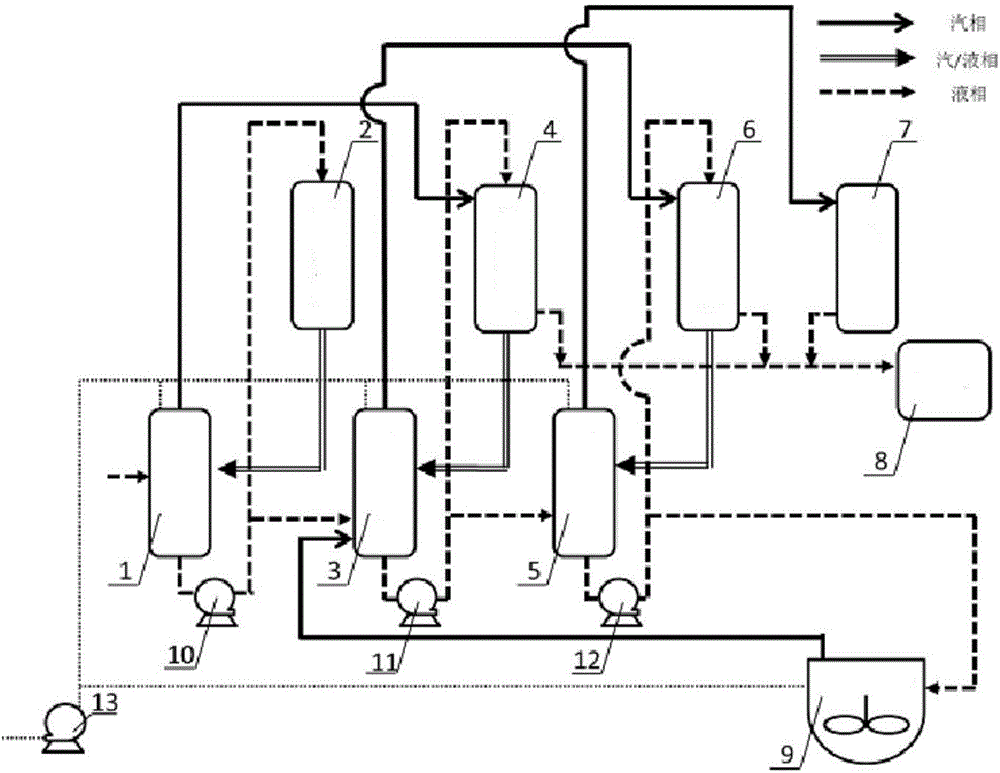

Solid-liquid separation process for combining multiple-effect evaporation and agitated evaporation

ActiveCN104548634AReduced energy consumption for solid-liquid separationImprove transportation convenienceMultiple-effect evaporationSeparation processSolubility

A solid-liquid separation process, comprising the following steps: A. concentrating an aqueous solution or a mixed solution in water-organic solvents containing soluble solids at a low concentration to give a medium-concentrated mixed solution; B. discharging the medium-concentrated mixed solution into a stirring evaporation kettle (9), and further concentrating same by evaporation to give a high-concentrated mixed solution; and C. controlling the solid content of the high-concentrated mixed solution to ensure that same is discharged out of the stirring evaporation kettle (9) in the liquid form; returning the vapour generated in step B to the multi-effect evaporation system and heating the liquid while the vapour phase is condensing, such that the heat is recovered and the recovery of the solution is ensured. The high-concentrated mixed solution discharged in the liquid form in step C is cooled and solidified.

Owner:NANTONG CELLULOSE FIBERS CO LTD

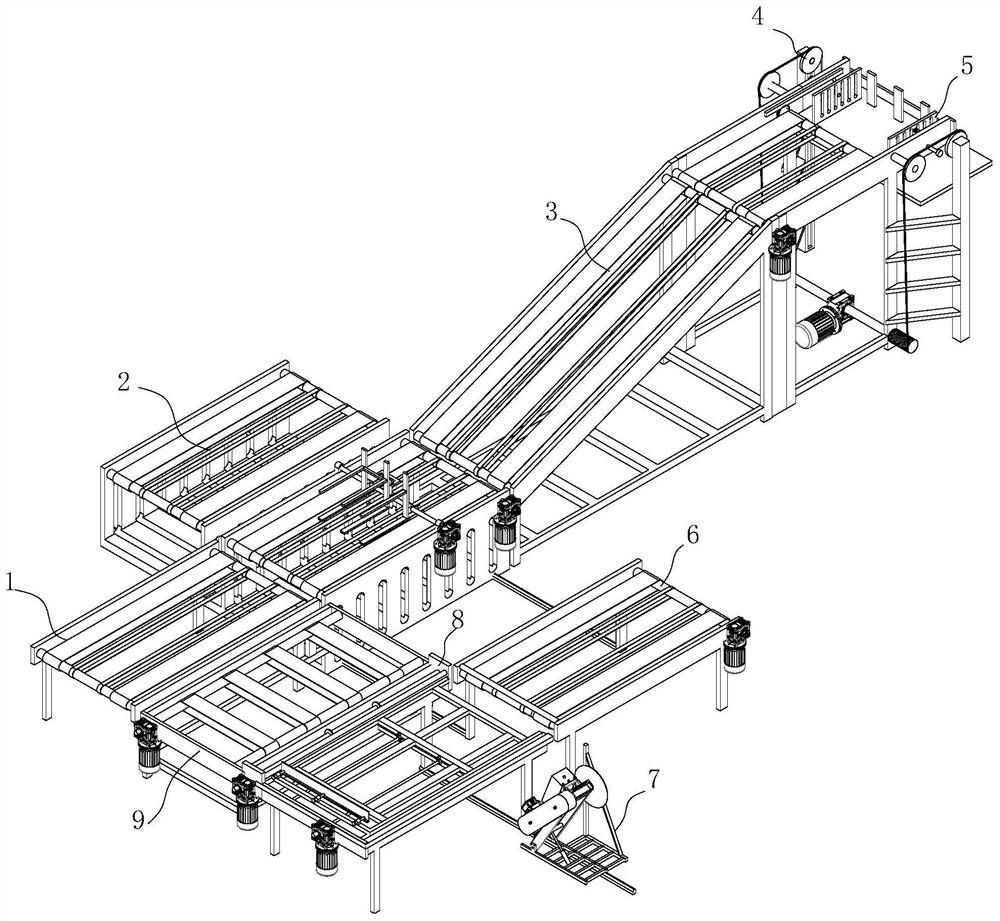

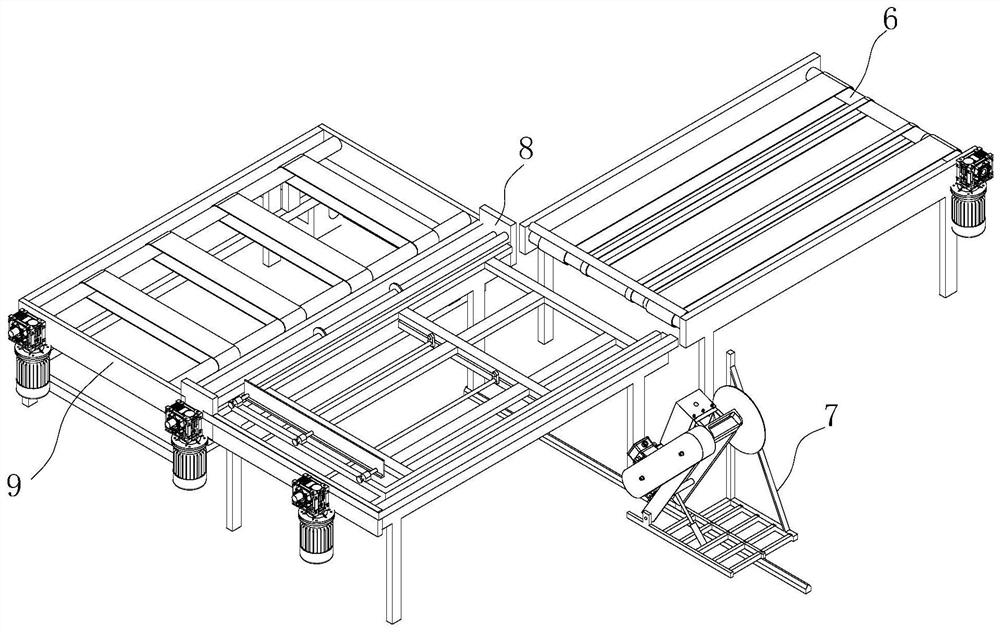

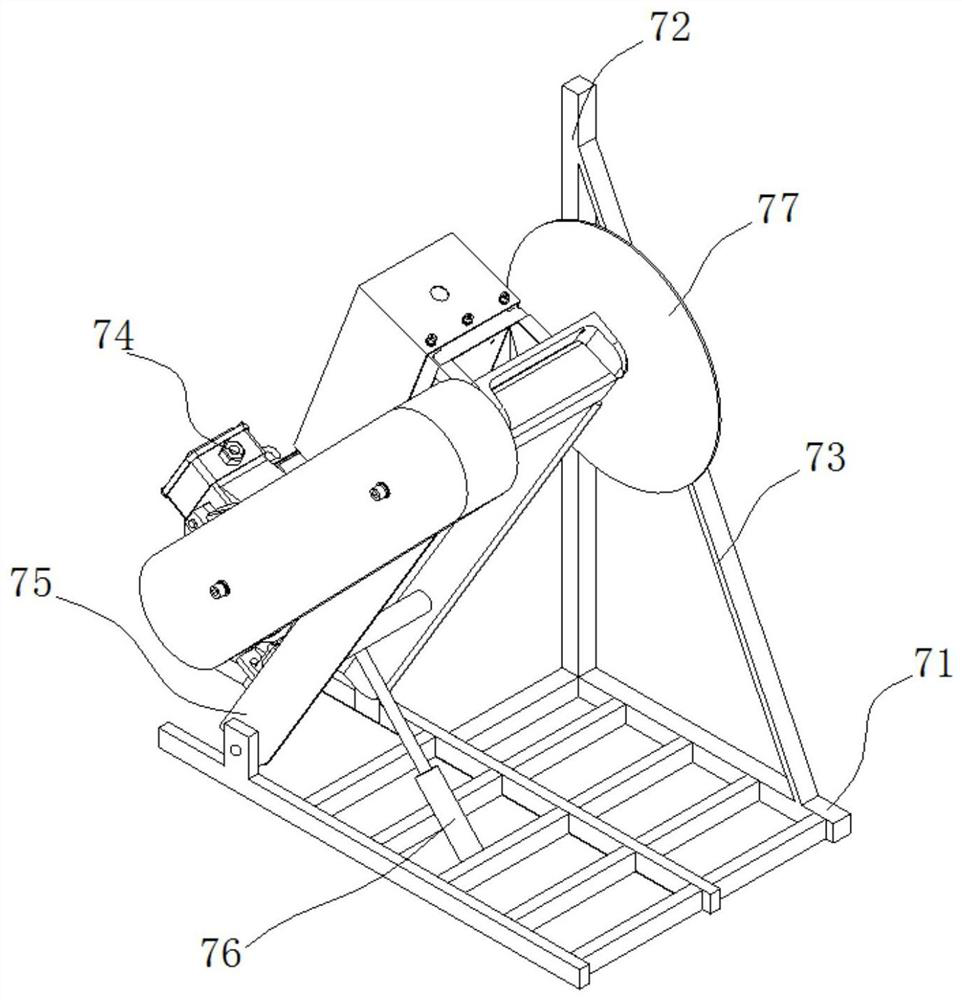

Paperboard processing line

InactiveCN111807107AImprove cutting efficiencyFunctionalOverturning articlesPile receiversPaperboardStructural engineering

The invention provides a paperboard processing line. A paperboard cutting device is used for cutting a strip-shaped paperboard into paperboard blocks and stacking the paperboard blocks into a plurality of stacks; a paperboard stacking device comprises a conveying device and a stacking mechanism; the conveying device comprises a trolley, two fourth conveying mechanisms and an overturning mechanism,the trolley can move in the longitudinal direction, the two fourth conveying mechanisms are distributed at an interval in the longitudinal direction and used for receiving the paperboard blocks separated from a third conveying mechanism, and the overturning mechanism is used for overturning the paperboard stacks on one of the fourth conveying mechanisms by 180 degrees; a fifth conveying mechanismis used for receiving the paperboard blocks separated from the fourth conveying mechanism; and the stacking mechanism is used for stacking the paperboard stacks separated from the fifth conveying mechanism. According to the paperboard processing line, paperboards are stacked forwards and reversely alternately stack by stack instead of piece by piece, so that the stacking efficiency is greatly improved; and the automation degree of the processing line is high without manual guarding in the process, so that the labor cost is reduced while the labor intensity is reduced.

Owner:朱蓉

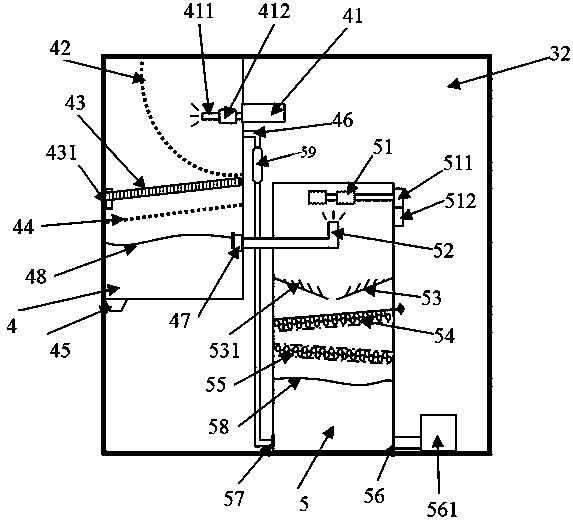

Intelligent purification device for nickel plating wastewater

ActiveCN109704486AProcessing time does not affectImprove processing efficiencyWater contaminantsMultistage water/sewage treatmentWater qualityFresh water

The invention belongs to the technical field of wastewater treatment, and particularly relates to an intelligent purification device for nickel plating wastewater. The intelligent purification devicecomprises a box body and a controller; the controller is used for controlling the device to operate automatically, and the controller is fixedly arranged on the side wall of the box body; a water inlet pipe is arranged at the top of the box body, a water outlet pipe is arranged at the bottom of the box body, and a waste water treatment module is arranged in the box body; the water inlet pipe is provided with a detection module, a sulfuric acid lead-in pipe is connected to the water inlet pipe, and a first magnet is arranged at an end of the water inlet pipe; the detection module is used for detecting whether the pH value of wastewater in the water inlet pipe meets the requirements; the sulfuric acid leading-in pipe is connected with a fresh water leading-in pipe; and the wastewater treatment module is used for purifying the wastewater. The intelligent purification device is simple in structure, and operation is convenient; the wastewater can be continuously purified through cooperationof the wastewater treatment module and a purification unit, and treatment efficiency is not affected while sufficient treatment time of the wastewater is ensured; and through two-time purification, the wastewater is completely purified, and water pollution is avoided.

Owner:ZHAOQING UNIV

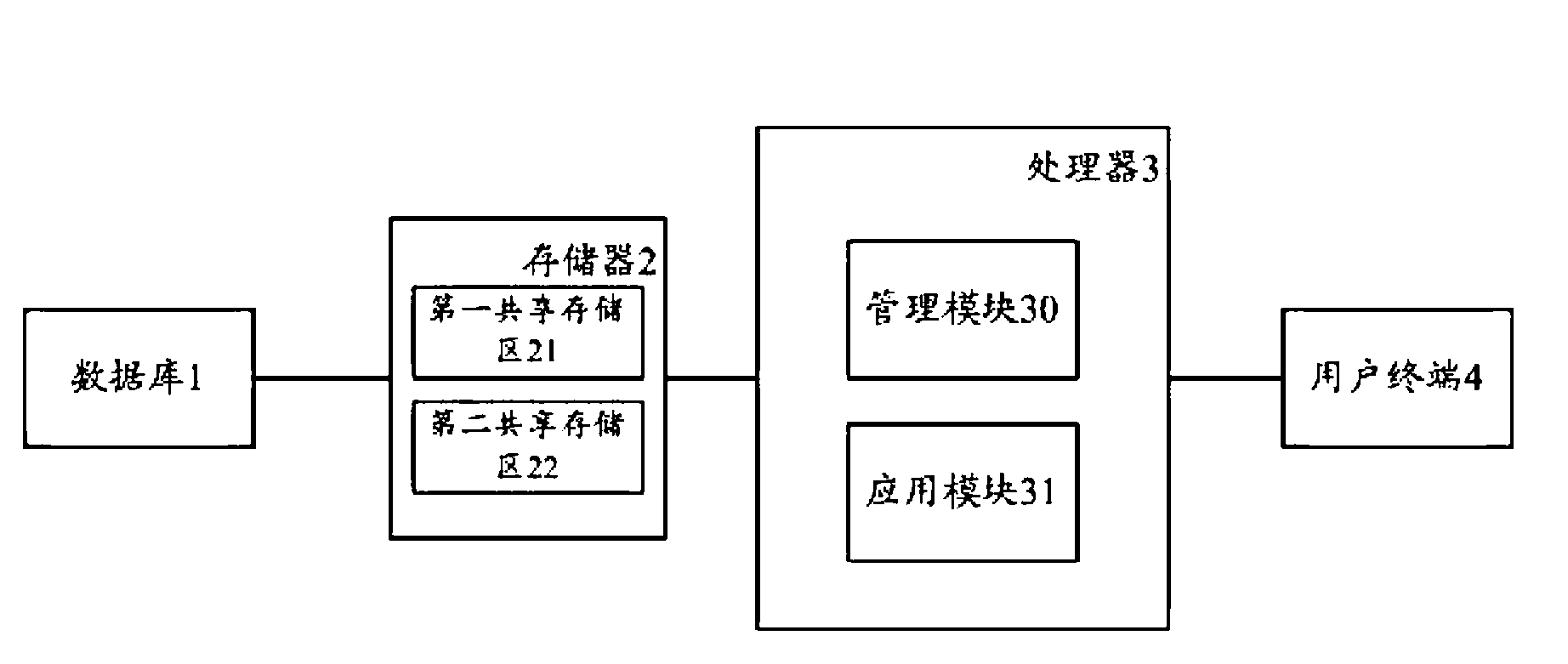

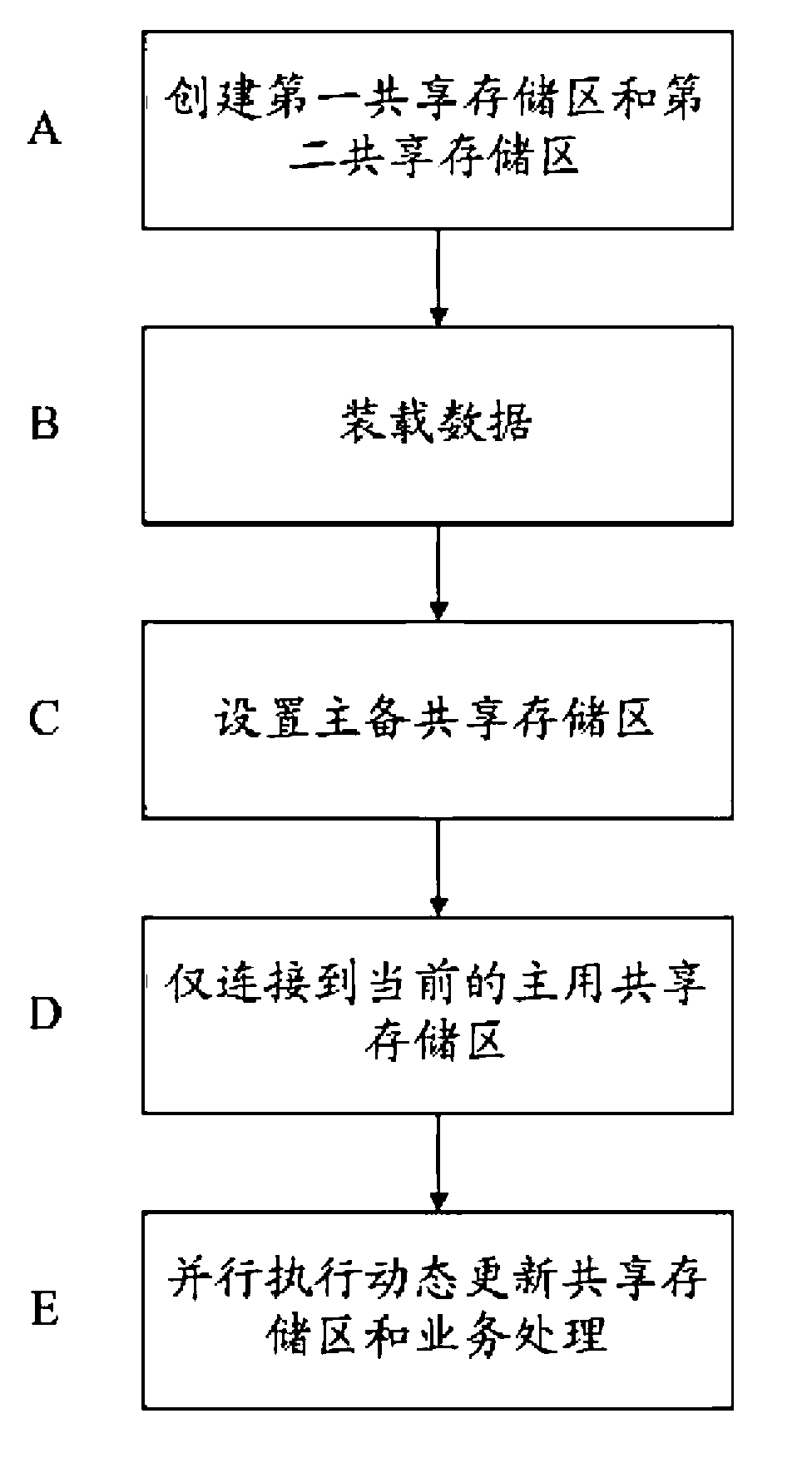

Service processing method and service processing system

InactiveCN103176909AGuaranteed normal processingUnlimited accessMemory adressing/allocation/relocationOperating systemTreatment system

The invention provides a service processing method and a service processing system. The service processing method comprises the steps of A, establishing a first sharing storage area and a second sharing storage area; B, loading data in a data base into a data area of the first sharing storage area and a data area of the second sharing storage area; C, setting the state zone bits of the first sharing storage area and the second sharing storage area, enabling one of the sharing storage areas to be a main sharing storage area, and enabling the other one to be a standby sharing storage area; D, accessing to a current main sharing storage area; and E, carrying out parallel execution on updating of the sharing storage areas and service processing, wherein the first sharing storage area and the second sharing storage area comprise respective head areas and data areas, the head areas comprise capacities and the state zone bits of the sharing storage areas, and a configuration file comprises key valves and capacities of the first sharing storage area and the second sharing storage area. The service processing method and the service processing system can be operated for 7*24 hours.

Owner:CHINA UNIONPAY

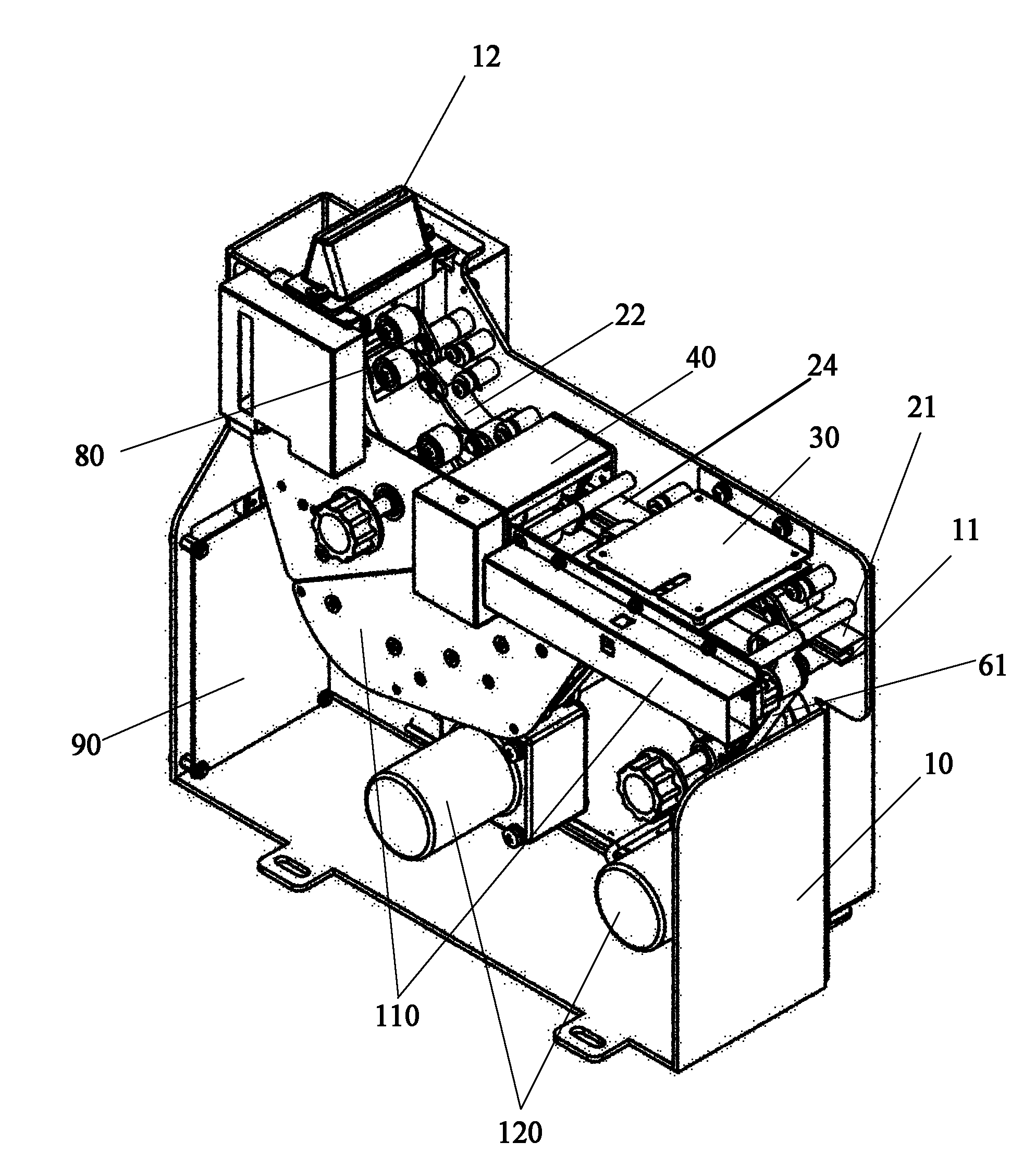

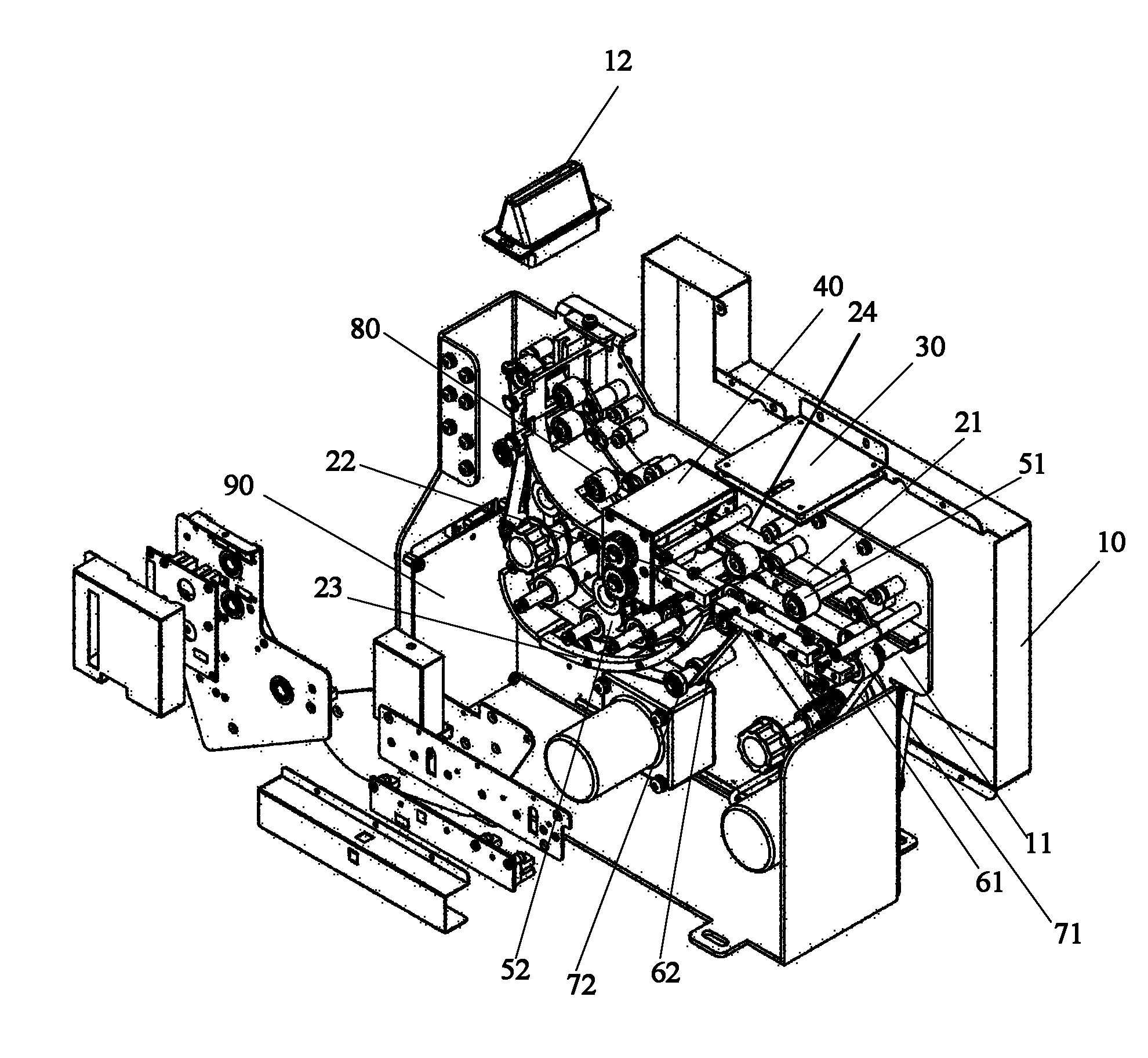

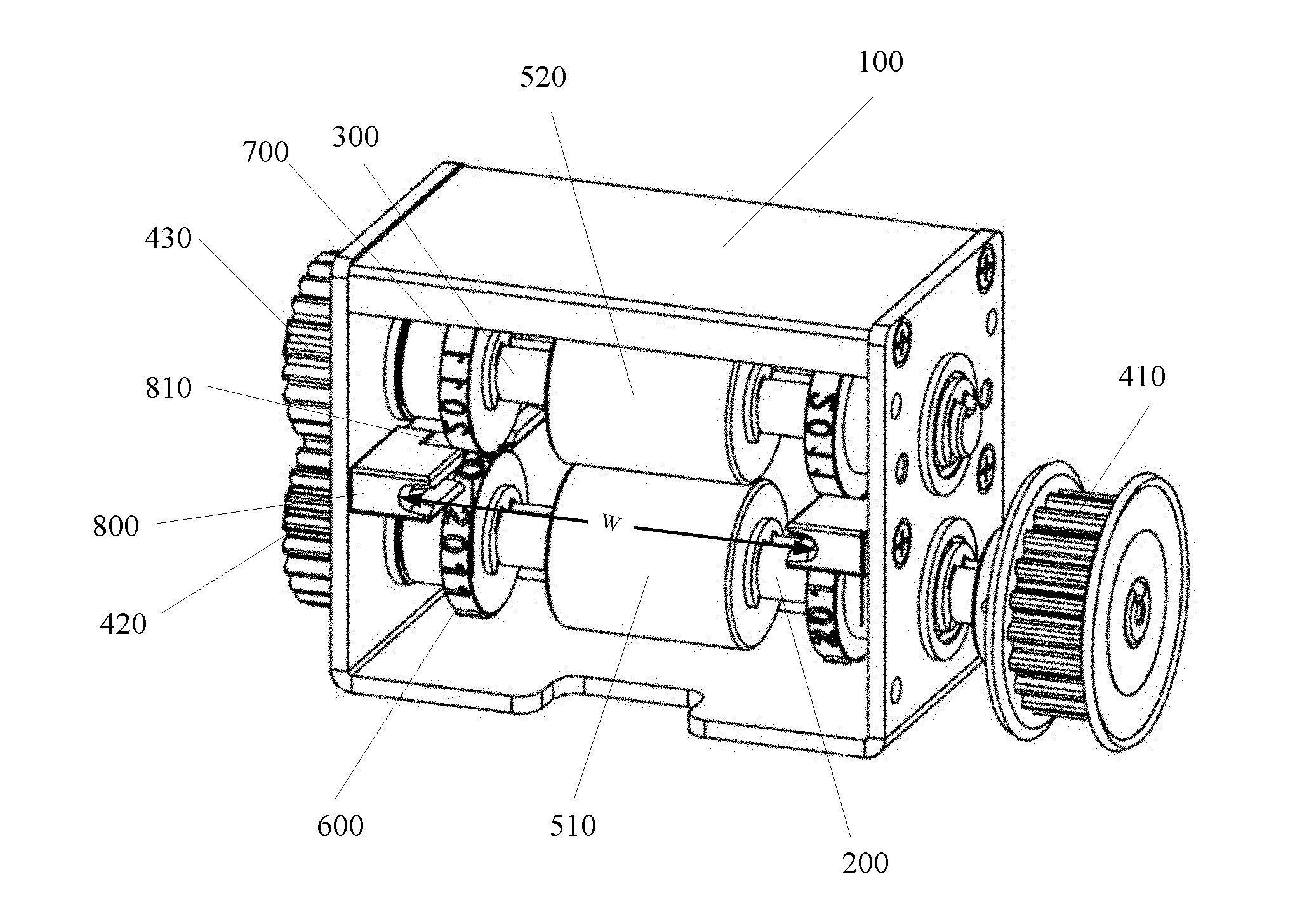

Automatic ticket feeding and discharging mechanism

ActiveCN102486874ADoes not affect processing efficiencySolve processing problemsMachines for printing and issuing ticketsComputer scienceSynchronizing

The invention discloses an automatic ticket feeding and discharging mechanism which is provided with two paths, wherein one path is used for processing a card ticket which reaches a use limit so as to imprint the card ticket; a visual reading characteristic showing that the card ticket is used is formed on the surface of the card ticket; the other path is used for processing a card ticket which does not reach the use limit, therefore, under the condition of not influencing the card ticket processing efficiency, the problem of processing different ticket types can be better solved; the two paths are formed by three ticket guide slots of which one ends are collected; the collecting end of the three ticket guide slots is provided with an overturning plate; a first ticket guide slot path is provided with a reading-writing antenna, a plurality of first pressure rollers and a first synchronous belt; a second ticket guide slot path is provided with an imprinting device and a plurality of pinch rollers; a third ticket guide slot path is provided with a plurality of second pressure rollers and a second synchronous belt; the first synchronous belt is driven by a first synchronizing wheel; the second synchronous belt is driven by a second synchronizing wheel; and a control plate controls the pinch rollers, the overturning plate, the second pressure rollers and the second synchronizing wheel to rotate according to the signal of the reading-writing antenna.

Owner:SHANGHAI HUAHONG JITONG SMART SYST

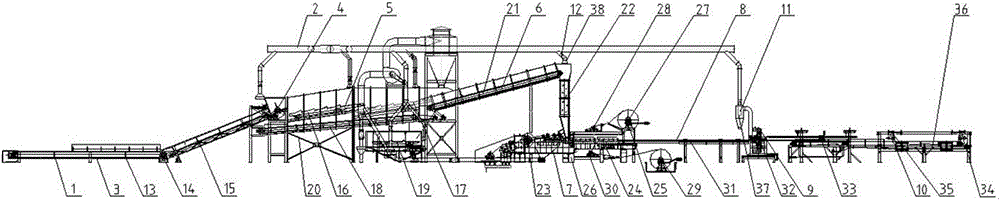

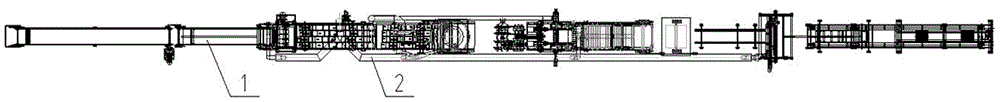

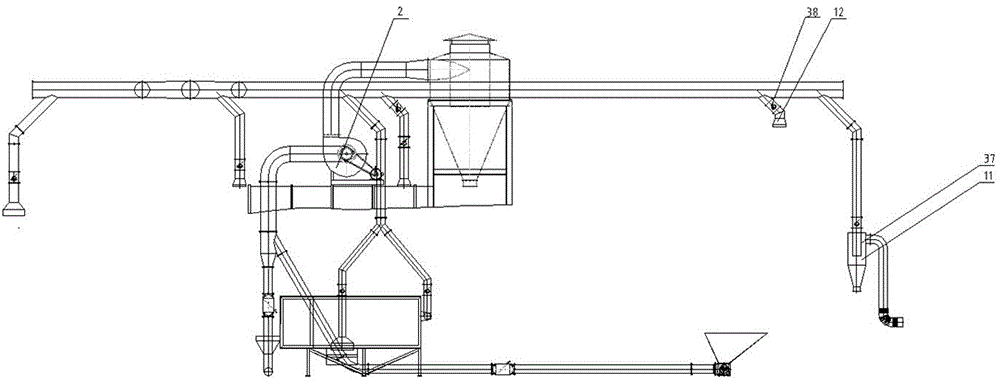

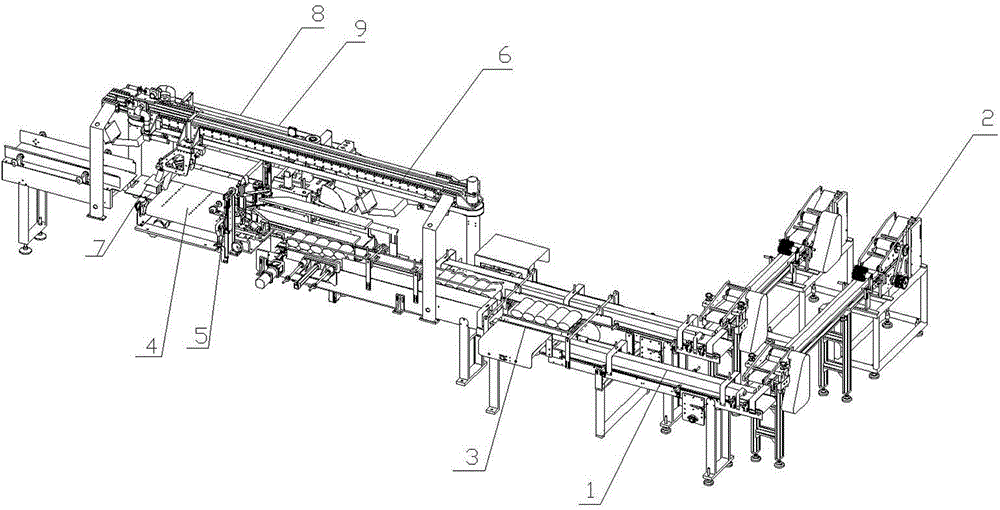

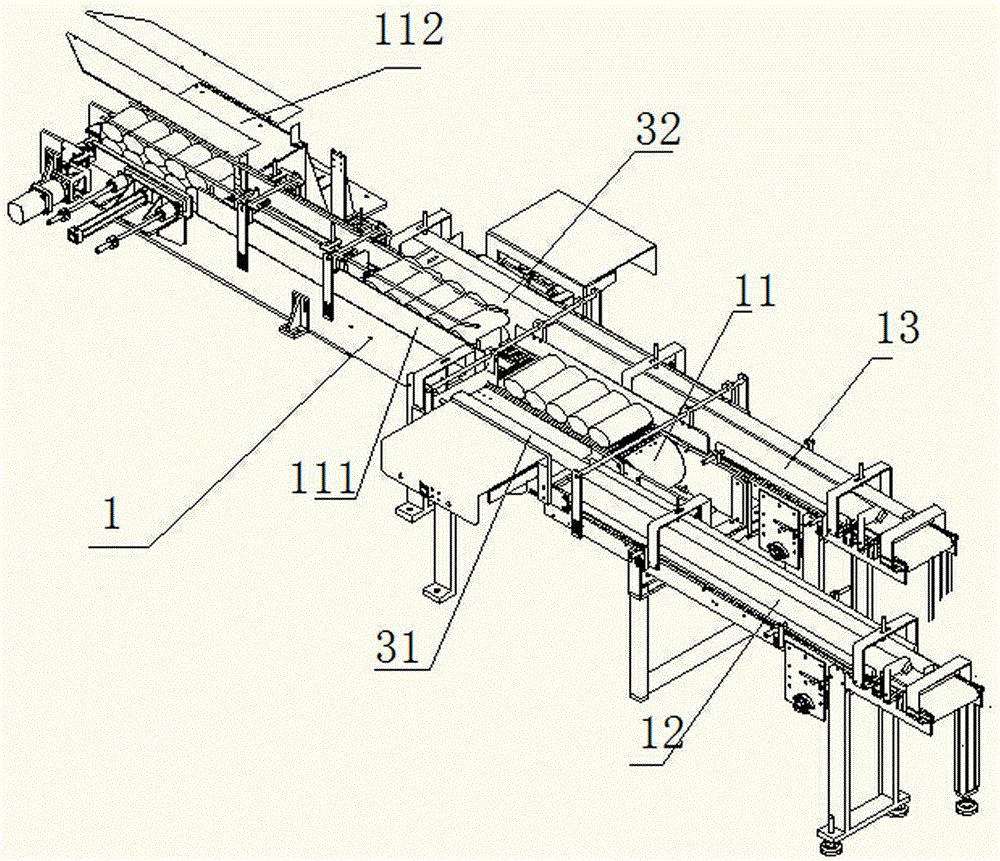

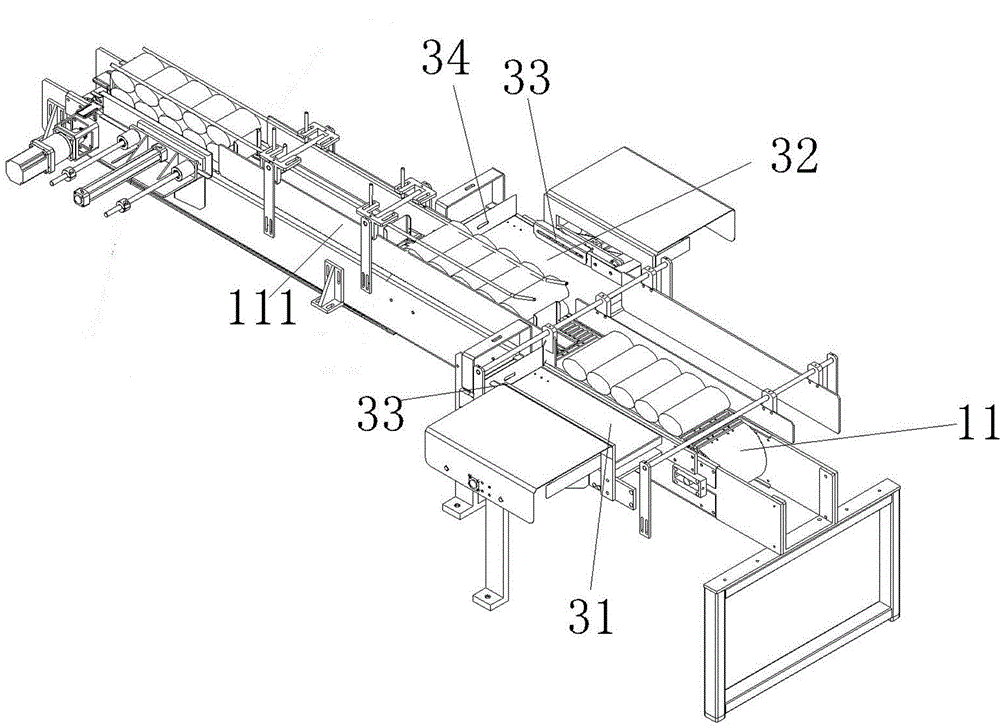

Straw plate producing and processing system

ActiveCN106003280AEquipment collocation is reasonableGood continuityLamination ancillary operationsLaminationRice strawProcess engineering

A straw plate producing and processing system comprises a main production system and a material recycling and dust removing system. The material recycling and dust removing system is arranged at the upper end of the main production system. The main production system is composed of a straw supplying and feeding module, an unbundling module, a stepping separation module, a straw conveying module, a forming module, a conveying module, a cut-off module and an end sealing module. The material recycling and dust removing system is composed of a material recycling module and a dust removing module. The straw supplying and feeding module, the unbundling module, the stepping separation module, the straw conveying module, the forming module, the conveying module, the cut-off module and the end sealing module are sequentially connected from left to right. The material recycling module is connected with the dust removing module. The straw plate producing and processing system is reasonable in overall system device matching, good in continuity and high in transfer efficiency; and in the production process, no auxiliary materials need to be added, straw plates are completely formed by processing straw, and the high-quality, high-strength and purely-natural straw plates can be produced.

Owner:高唐融知融智科技服务有限公司

Wire drawing machine for fastening part machining

The invention discloses a wire drawing machine for fastening part machining. The machine involves a ground, wherein the top of the ground is fixedly connected with a first supporting column and a second supporting seat through bolts, the first supporting column is located on one side of the second supporting seat, the top of the first supporting column and the top of the second supporting seat areprovided with a machine body, the interior of the machine body is fixedly connected with a driving motor through bolts, and one end of the driving motor is rotationally connected with a driving gearthrough a rotating shaft. According to the wire drawing machine for fastening part machining, a wire bunching barrel on one side of a bearing roller can be used for providing binding force for a wirebefore wire drawing, a spiral pipe is used for tensioning a cable, the cable is ensured to be in the tensioned state, the wire is ensured to be stably conveyed in the wire drawing process of a wire drawing machine, the problem that coiling of the wire is loose and not tight is avoided, the quality of wire drawing of the wire drawing machine is improved, the coiled wire can be scraped off from thebearing roller through a vertically-lifting inserting rod, automatic discharging is realized, and the trouble of manual discharging is reduced.

Owner:嘉兴金凌五金科技股份有限公司

Flat roll packaging machine

ActiveCN104129529AGuarantee the quality of materialsIncrease productivityPackagingEngineeringPackaging machine

The invention discloses a flat roll packaging machine, and relates to the field of tissue packaging machines. The flat roll packaging machine comprises conveying devices, a film conveying device, a bag opening and supporting device, a package pushing device and a negative pressure forming device and further comprises flattening devices and a laminating device. The conveying devices comprise the first conveying device, the second conveying device and the third conveying device. The laminating device comprises a first pushing platform and a second pushing platform, the first pushing platform and the second pushing platform are provided with pushing air cylinders respectively, and the first pushing platform and the second pushing platform are arranged on the two sides of the first conveying device respectively. According to the flat roll packaging machine, flattening is conducted on a paper roll twice, the paper roll is flattened and formedcompletely, the situations of jumping and warping can be avoided, automatic laminating processing can be achieved, laminating packaging is completed automatically, and packaging operation is completed efficiently.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

Ceramic laser perforating device

PendingCN110605488AQuality improvementImprove drilling efficiencyLaser beam welding apparatusLaser processingLaser cutting

The invention relates to the technical field of laser processing equipment, in particular to a laser perforating device. The laser perforating device comprises a laser cutting portion, a control device and a workbench, and further comprises an X-axis movement mechanism, a Y-axis movement mechanism, a workbench and a rotary vibration mechanism. The rotary vibration mechanism is provided with an accommodating portion, when a ceramic material is cut, the ceramic material to be processed is placed in the accommodating portion, the control device controls the X-axis movement mechanism and the Y-axis movement mechanism to move, the coordinates of the center of the site of a hole perforated in the ceramic material to be processed are positioned, then the control device controls the rotary vibration mechanism to carry out rotary vibration to draw a circle, and the control device controls the laser cutting portion to emit a laser beam to complete perforation of the ceramic material to be process. By arrangement of the rotary vibration mechanism, for perforation of a through hole with the aperture greater than 0.07 mm, the perforation quality can be improved by a circle-drawing cutting mode,and the perforation efficiency is high.

Owner:DONGGUAN INST OF OPTO ELECTRONICS PEKING UNIV

Waste gas purification environmental protection equipment

InactiveCN108295626AImprove purification effectLess impuritiesCombination devicesGas treatmentInternal pressureEngineering

The invention discloses waste gas purification environmental protection equipment. The equipment comprises a shell, a motor, a rotation cylinder and an air inlet pipe; a protection mesh and an air pump are arranged in the air inlet pipe; a vertical rotation shaft is fixedly connected to the upper end of an output shaft of the motor, the vertical rotation cylinder sleeves the outer side of the rotation shaft, and a horizontal purification layer is fixed to the middle in the shell; the shell is filled with purification liquid, multiple stirring thorns are fixedly arranged on the inner wall of the rotation cylinder, multiple through holes in a same horizontal surface are formed in the portion, corresponding to the side wall of the rotation cylinder, below the purification layer, and a pulse controller is arranged on the air pump. According to the waste gas purification environmental protection equipment, the internal pressure is increased through the arranged air pump, waste gas is pressed into water, the waste gas is quickly in contact with purified liquid through stirring, and the effect of purifying the liquid is improved; by connecting the air pump of the pulse controller, the internal air pressure is intermittently reduced, the internal liquid flows and is in contact with the waste gas conveniently, the pressure is changed, and the treatment efficiency is not influenced.

Owner:沈漪澜

Special-shaped hole machining device and method

The invention discloses a special-shaped hole machining device used for machining special-shaped holes in a conical sheet metal part. The special-shaped hole machining device comprises an electrode mechanism and a clamping mechanism, the electrode mechanism comprises an electrode positioning seat which is provided with a plurality of electrode positioning holes corresponding to the special-shaped holes, electrodes are arranged in the electrode positioning holes, and a connecting rod is arranged on the spindle of the electrode positioning seat; the clamping mechanism comprises a tire body and an annular pressure plate, a plurality of mutually-matched screw holes are arranged in the tire body and the annular pressure plate, the conical metal part is arranged between the tire body and the annular pressure plate, and the tire body, the conical metal part and the annular pressure plate are fixedly connected through bolts. The invention further discloses a special-shaped hole machining method utilizing the special-shaped hole machining device to have the special-shaped holes in the conical metal part machined. By the special-shaped hole machining device and the special-shaped hole machining method, operation is facilitated, accuracy requirements on shape and position of the special-shaped holes in the part are guaranteed, machining cost is lowered, and production efficiency is improved.

Owner:SHENYANG AIRCRAFT CORP

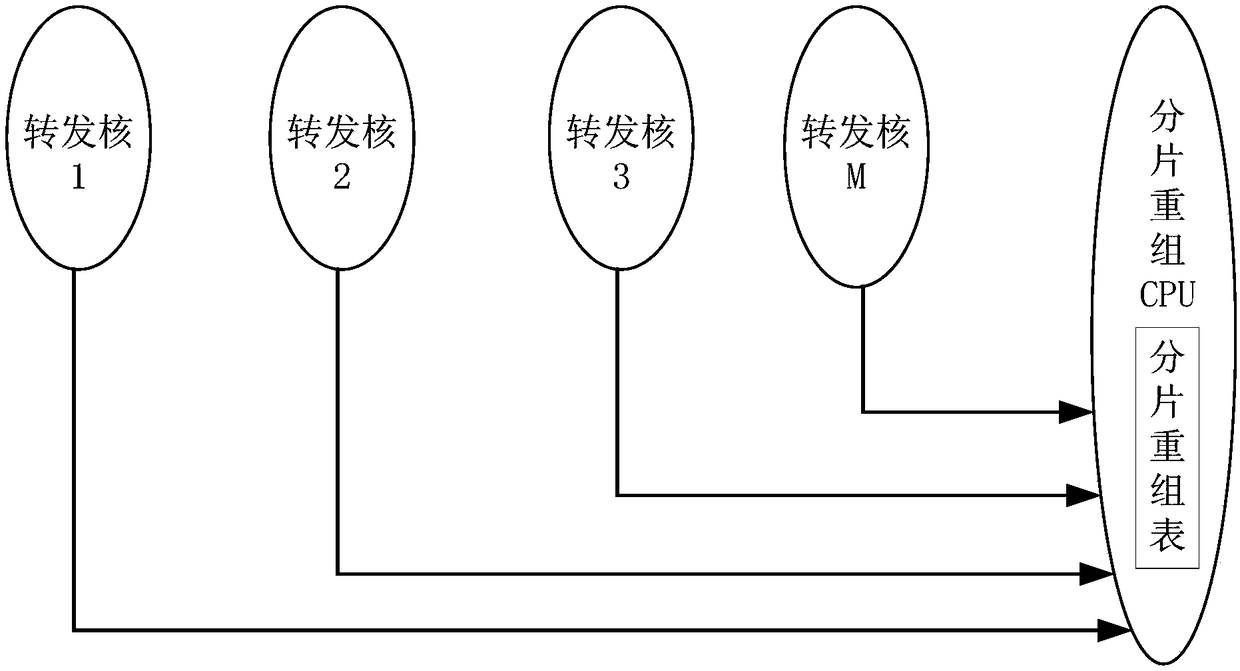

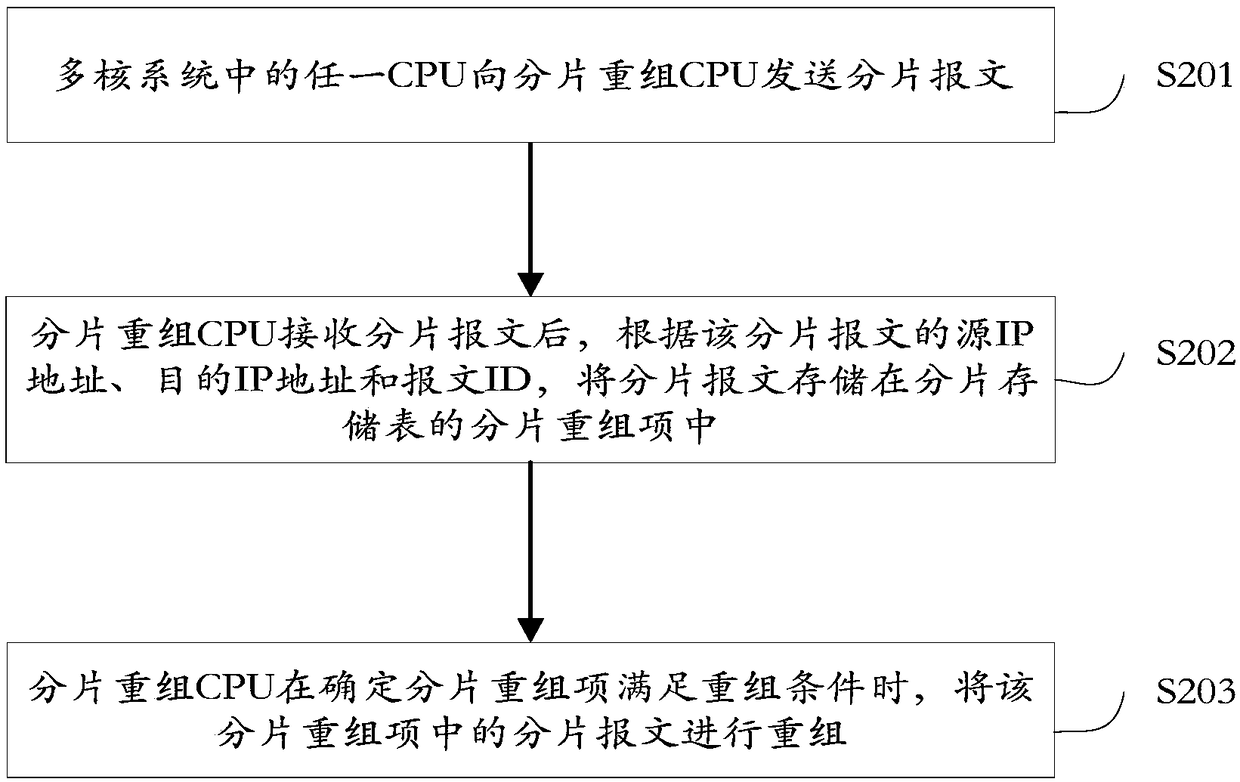

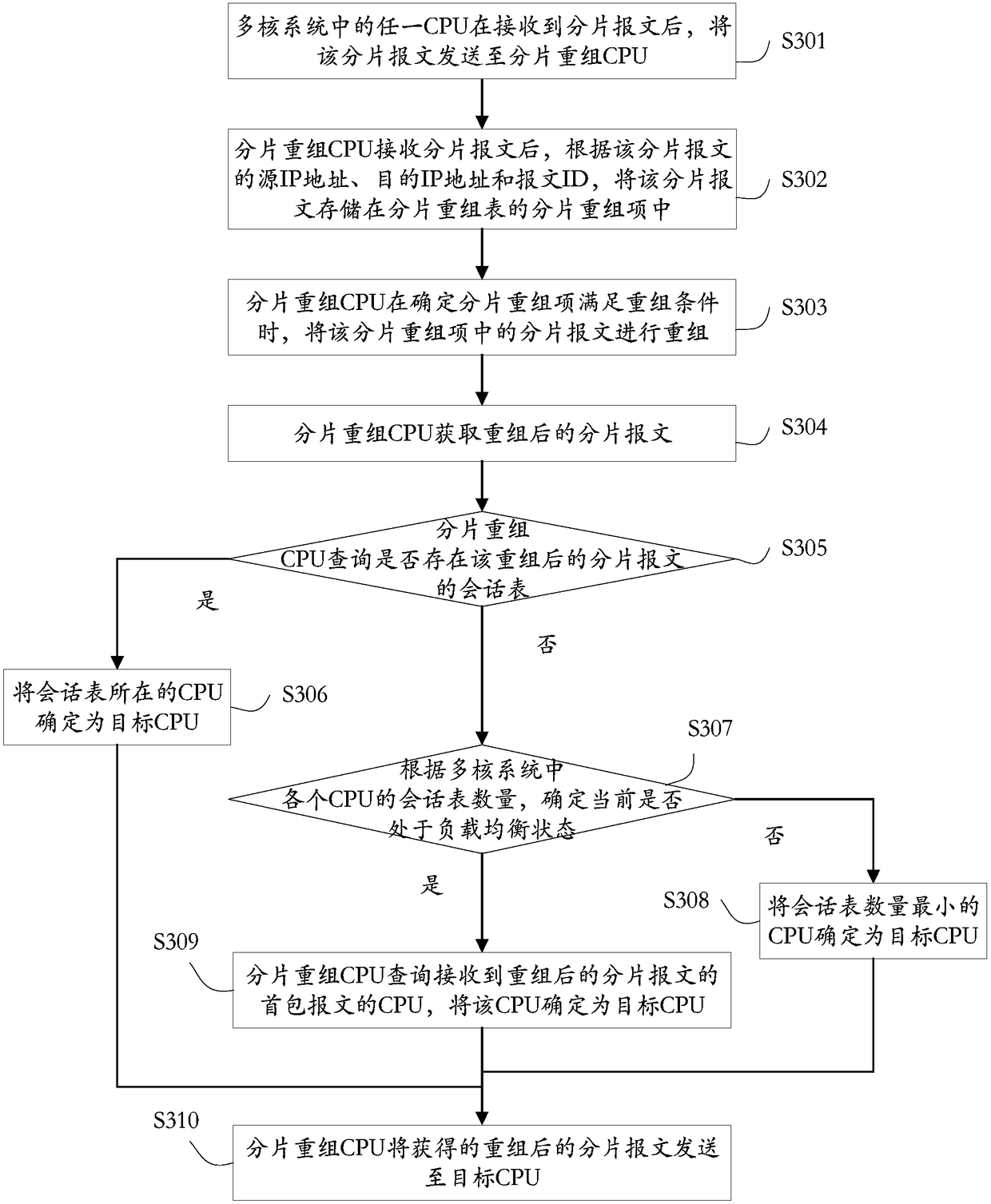

Fragment recombination method, device and equipment in multi-core system

PendingCN109286577ADoes not affect processing efficiencyNo multi-core resource contention issuesData switching networksIp addressCore system

The invention discloses a fragment recombination method, device and equipment in a multi-core system. The method is characterized in that the multi-core system includes a fragment recombination CPU provided with a fragment recombination table; and the fragment recombination table includes fragment recombination items. The method comprises: after the fragment recombination CPU receives fragment messages sent by all CPUs in the multi-core system, the fragment messages are stored in the fragment recombination items in the fragment recombination table according to source IP addresses, destinationIP addresses, and message IDs of the fragment messages; and when the fragment recombination CPU determines that the fragment recombination items meet a recombination condition, the fragment messages in the fragment recombination items are recombined. According to the invention, the independent fragment recombination CPU is used for recombining the fragment messages of all CPUs and the fragment recombination table is set to be resources only available to the fragment recombination CPU, so that a phenomenon of multi-core resource competition caused by too many fragment messages is avoided and thus the processing efficiency of the fragment recombination is protected.

Owner:NEUSOFT CORP

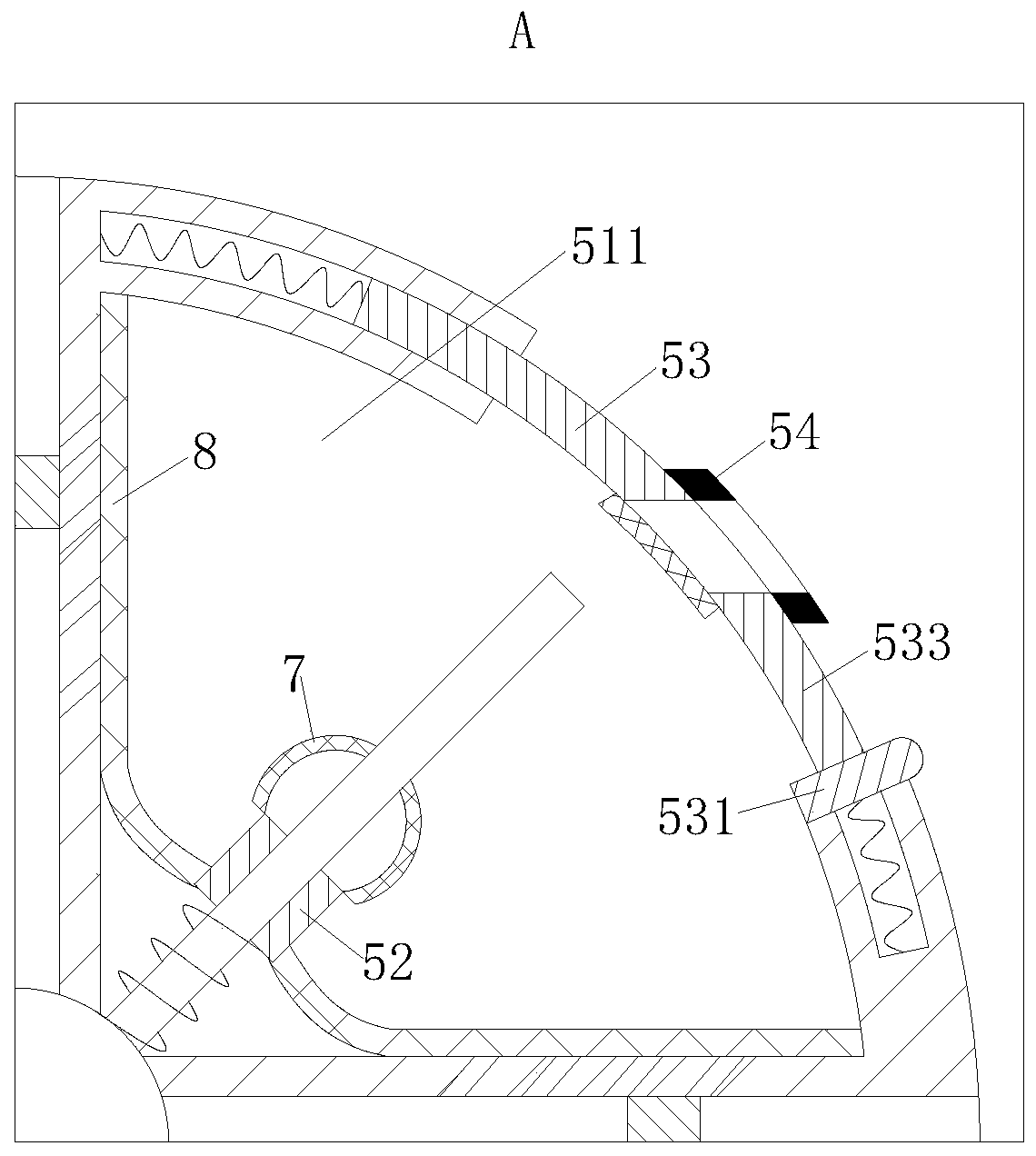

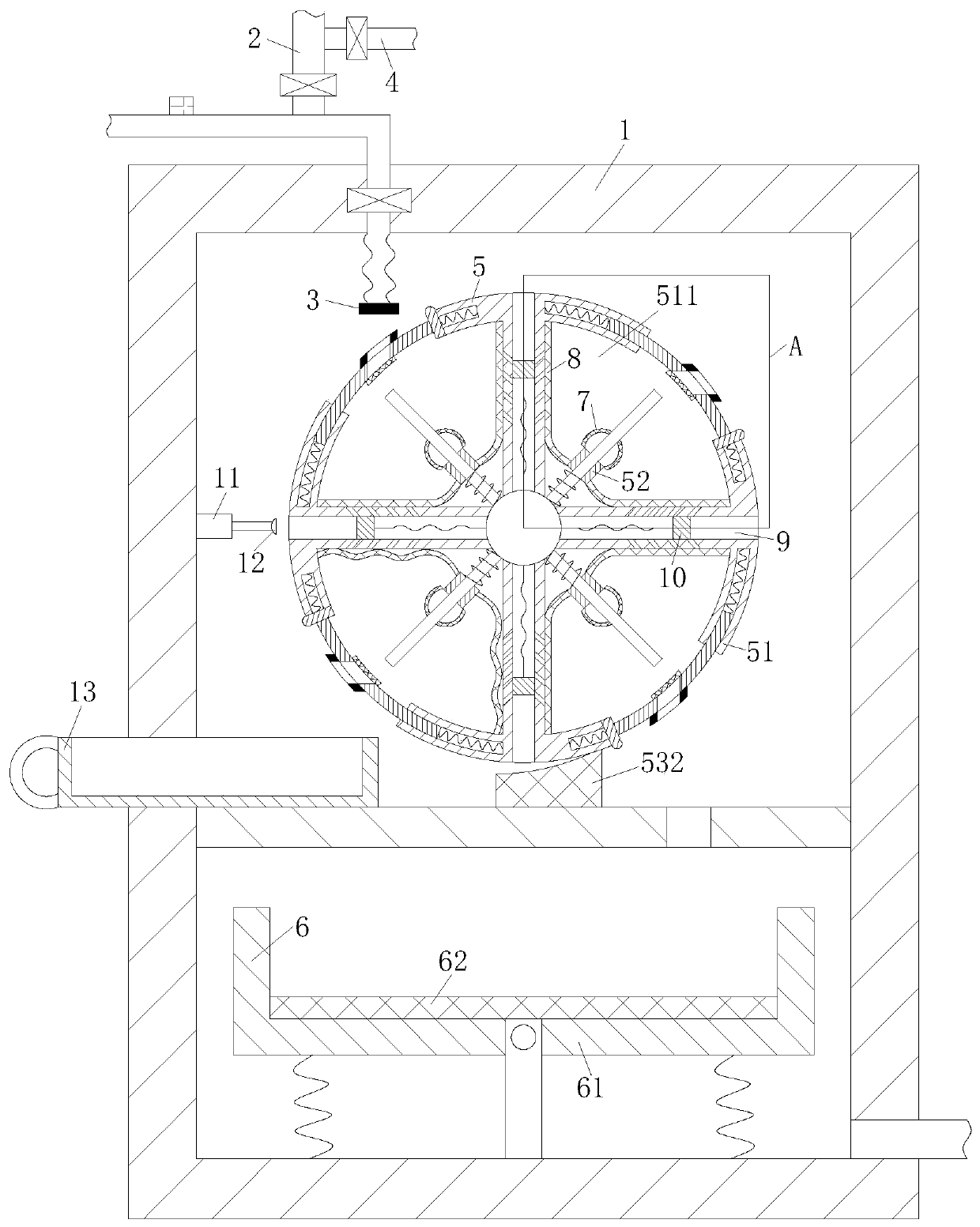

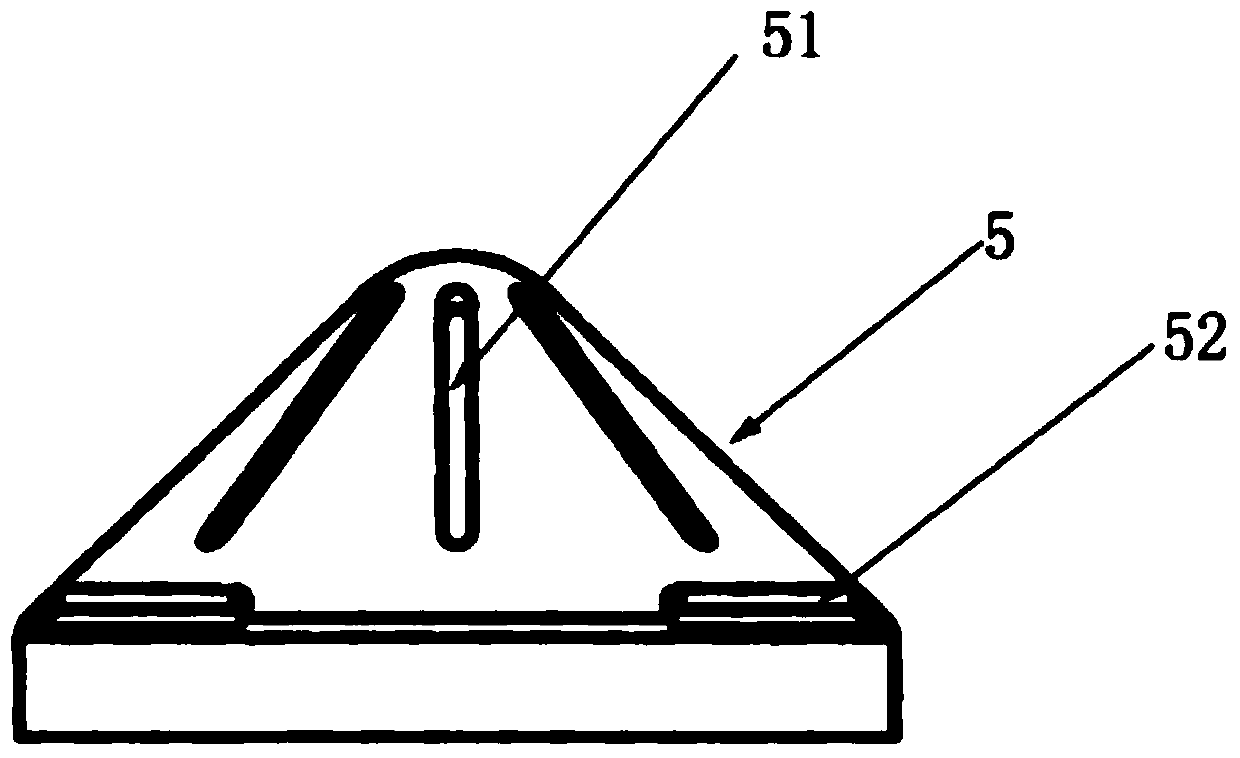

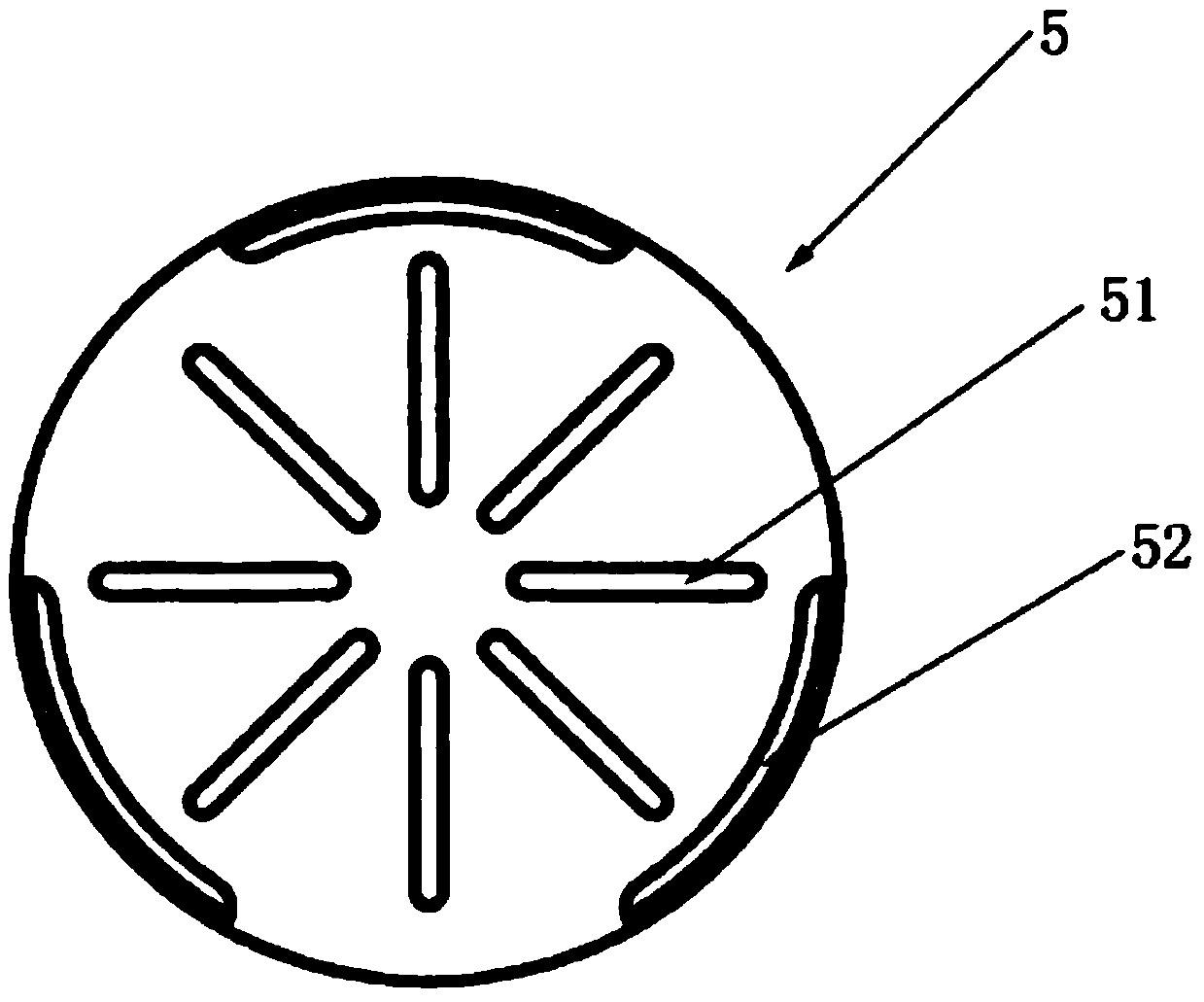

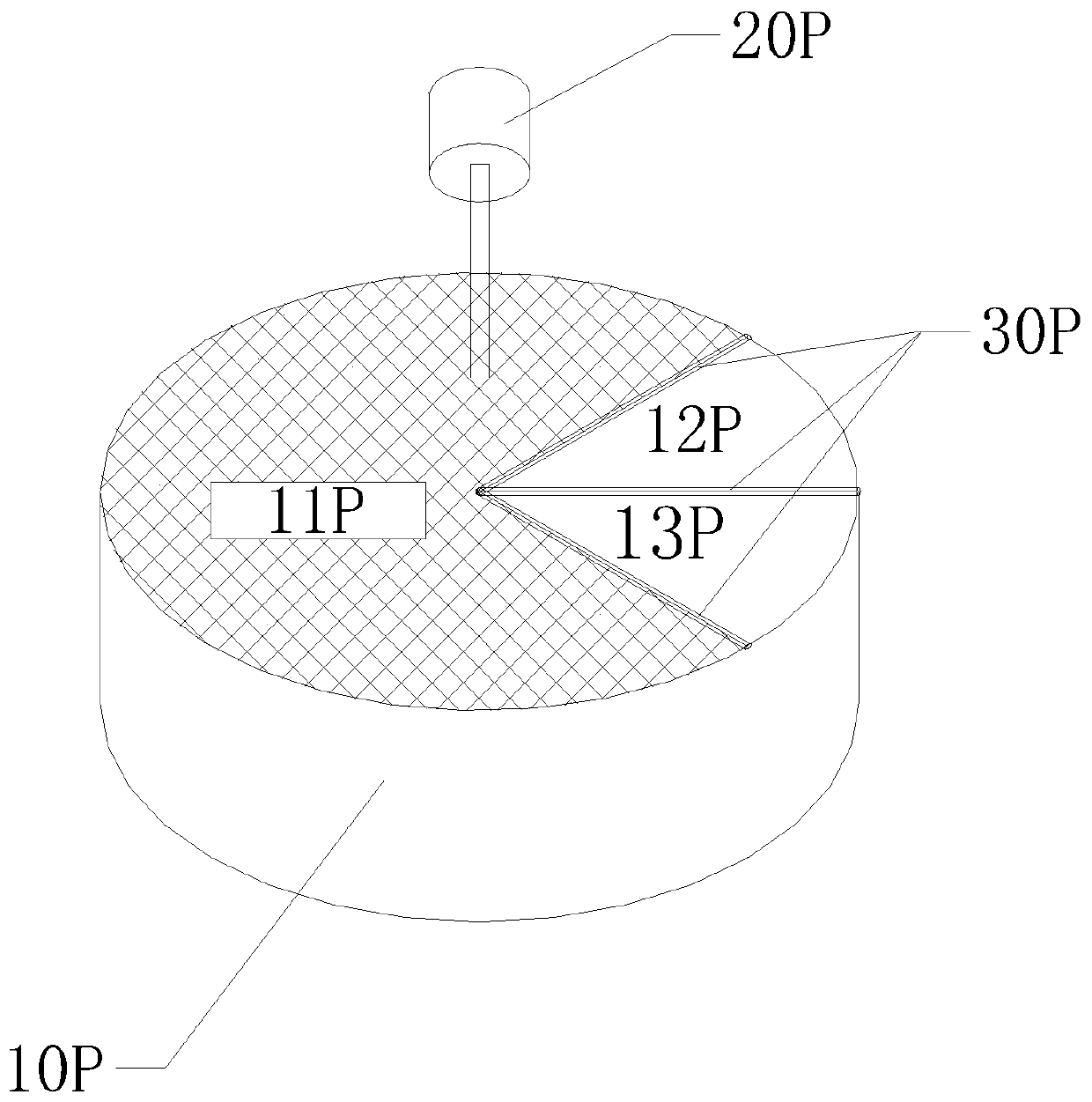

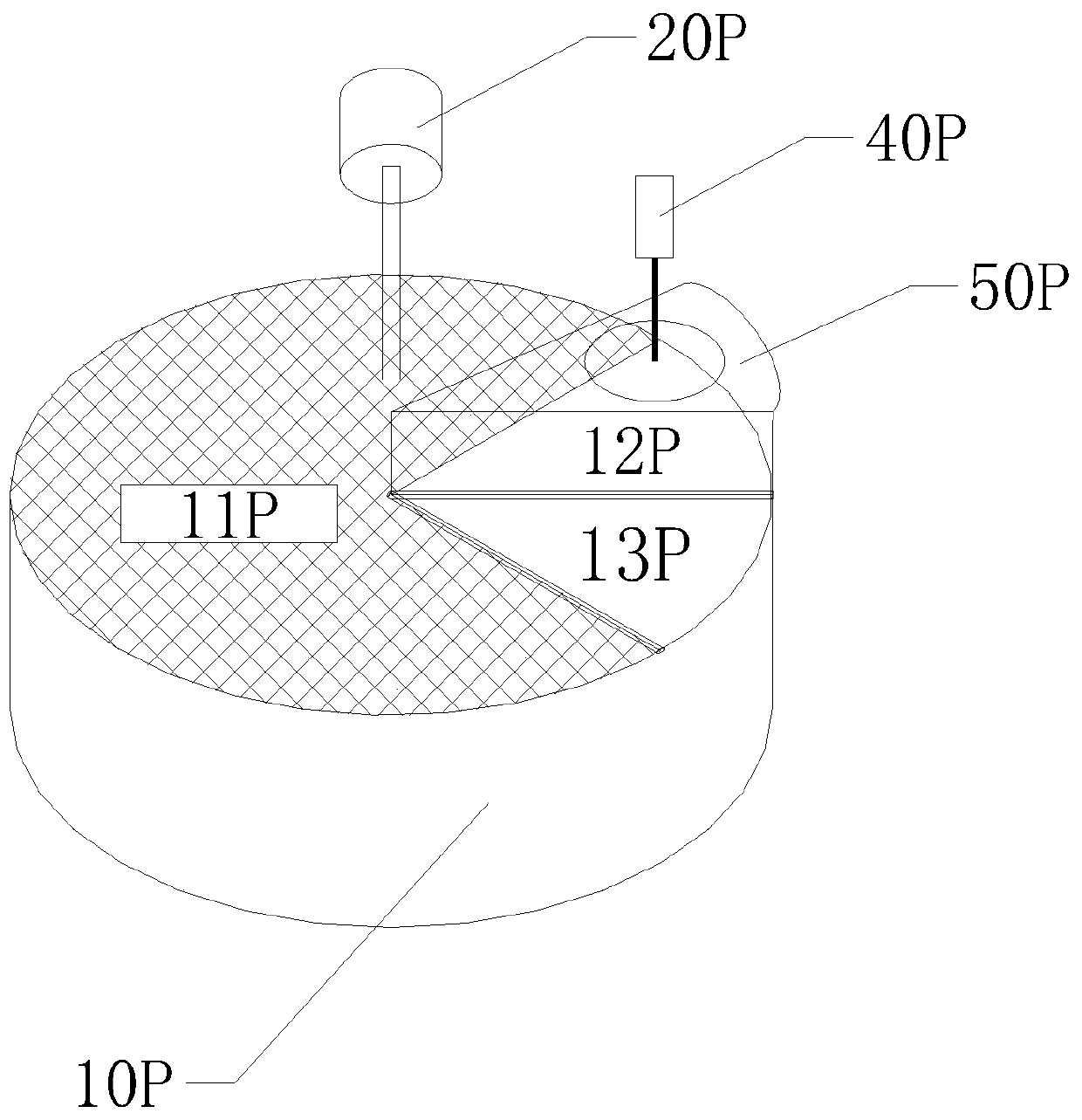

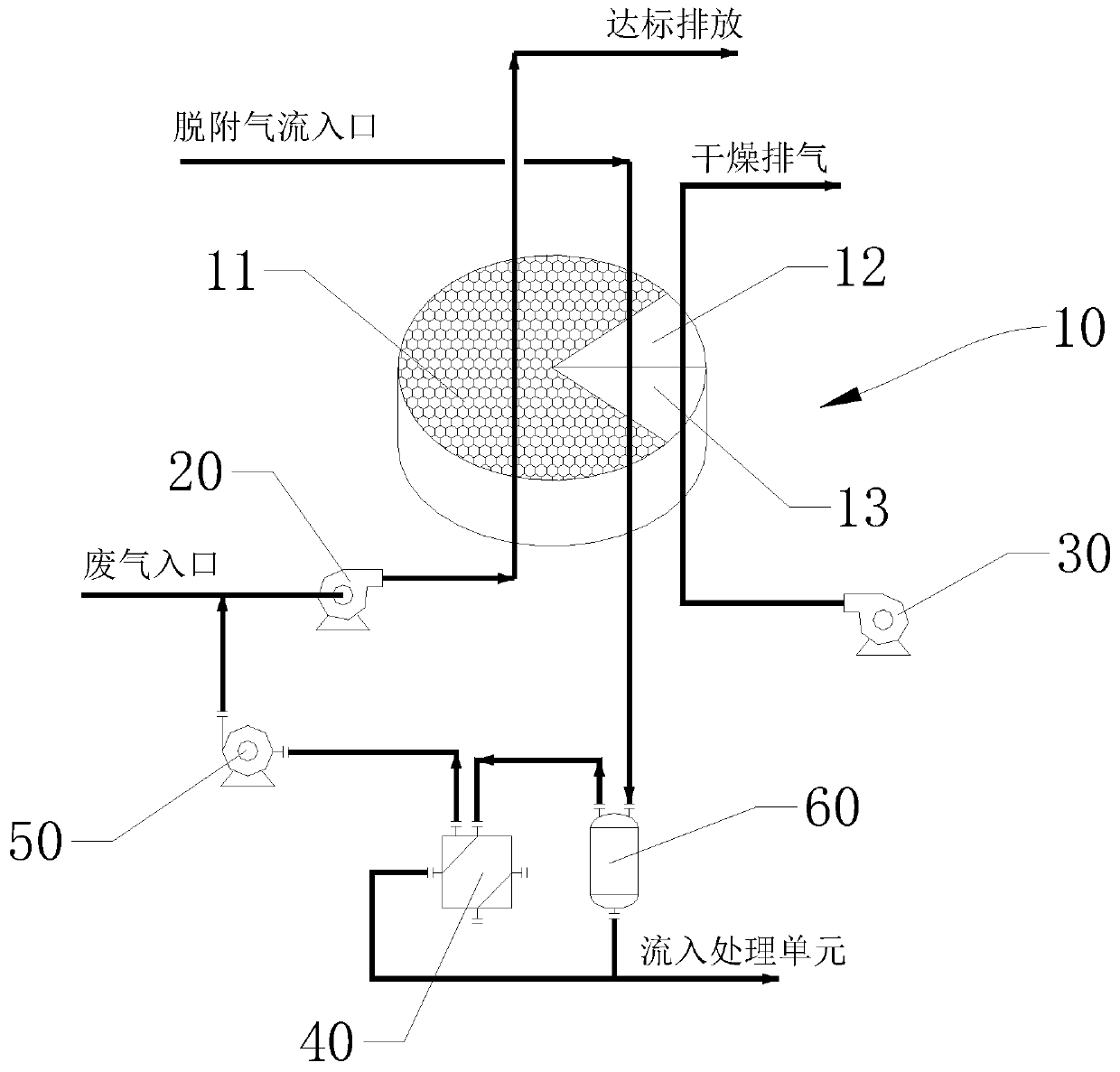

Anti-leakage rotary adsorber unit

PendingCN111249858ALow costDoes not affect processing efficiencyGas treatmentDispersed particle separationEngineeringMechanical engineering

The invention provides an anti-leakage rotary adsorber unit. The anti-leakage rotary adsorber unit comprises a rotary adsorber, an air inlet fan, a drying fan, a heat exchanger and a suction device. The heat exchanger communicates with the desorption area of the rotary adsorber, and airflow for desorption passes through the desorption area and then enters the heat exchanger for cooling. One end ofthe suction device communicates with the heat exchanger through a pipeline, and the other end of the suction device communicates with the air inlet fan through a pipeline. Under the action of the suction device, negative pressure is formed in a pipeline between the desorption area and the suction device, airflow sequentially enters the heat exchanger and the suction device after penetrating through a bed layer in the desorption area and cannot drift away towards the adjacent adsorption area and an adjacent drying and cooling area, and cooled non-condensable gas in the heat exchanger can alsobe sucked into the air inlet fan and enters the adsorption area for adsorption again. Therefore, problems in sealing performance of the desorption area are solved, expensive sealing materials with good abrasion resistance are not needed, sealing treatment cost is low, continuous rotating operation can be achieved, and waste gas treatment efficiency cannot be affected.

Owner:杭州楚环科技股份有限公司

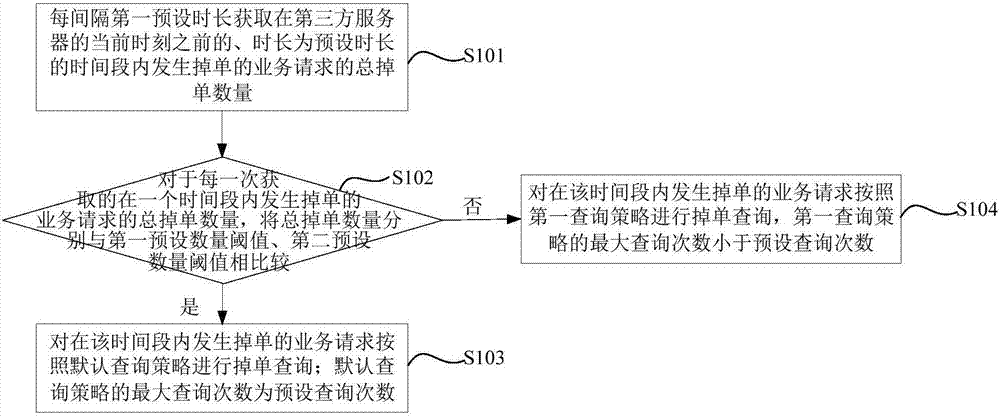

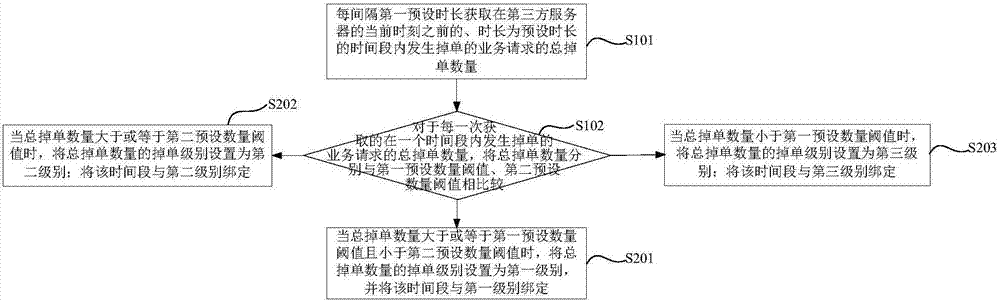

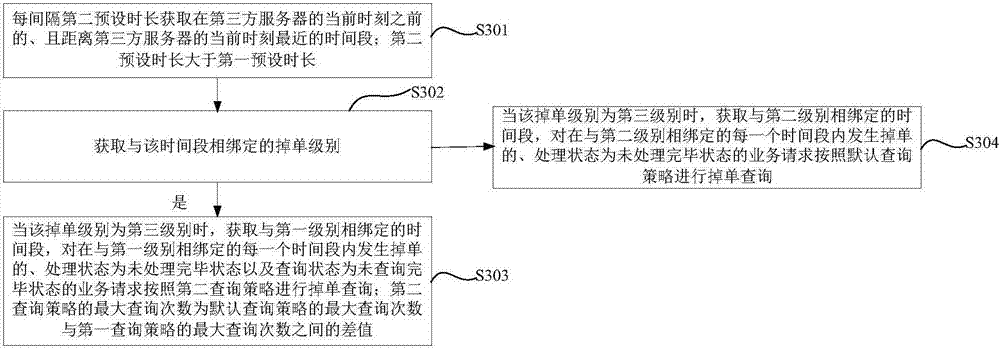

Information processing method and device

ActiveCN107230048AReduce system pressureDoes not affect processing efficiencyPayments involving neutral partyThird partyInformation processing

The embodiment of the invention provides an information processing method and device. The method comprises the steps that the total amount of dropped orders of business requests with dropped orders in a time period of preset duration before the current time of a third party server is acquired at the interval of first preset duration; for the total amount of dropped orders acquired every time, whether the total number of dropped orders is less than a first preset number threshold is determined; if the total number of dropped orders is less than the first preset number threshold, dropped order querying is carried out on business requests with dropped orders in the time period according to a default query policy; the maximum number of queries of the default query policy is the number of preset queries; if the total number of dropped orders is greater than or equal to the first preset number threshold and less than a second preset number threshold, dropped order querying is carried out on business requests with dropped orders in the time period according to a first query policy; and the maximum number of queries of the first query policy is less than the number of preset queries. According to the invention, the processing efficiency of business requests of a business server is not reduced, and vicious circle is avoided.

Owner:ADVANCED NEW TECH CO LTD

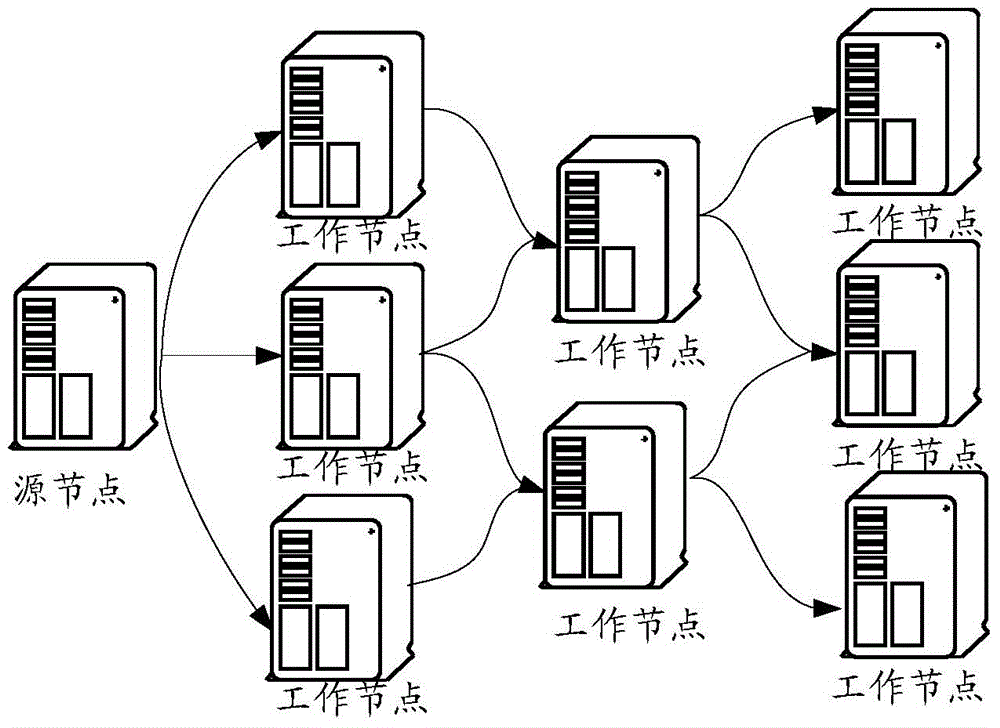

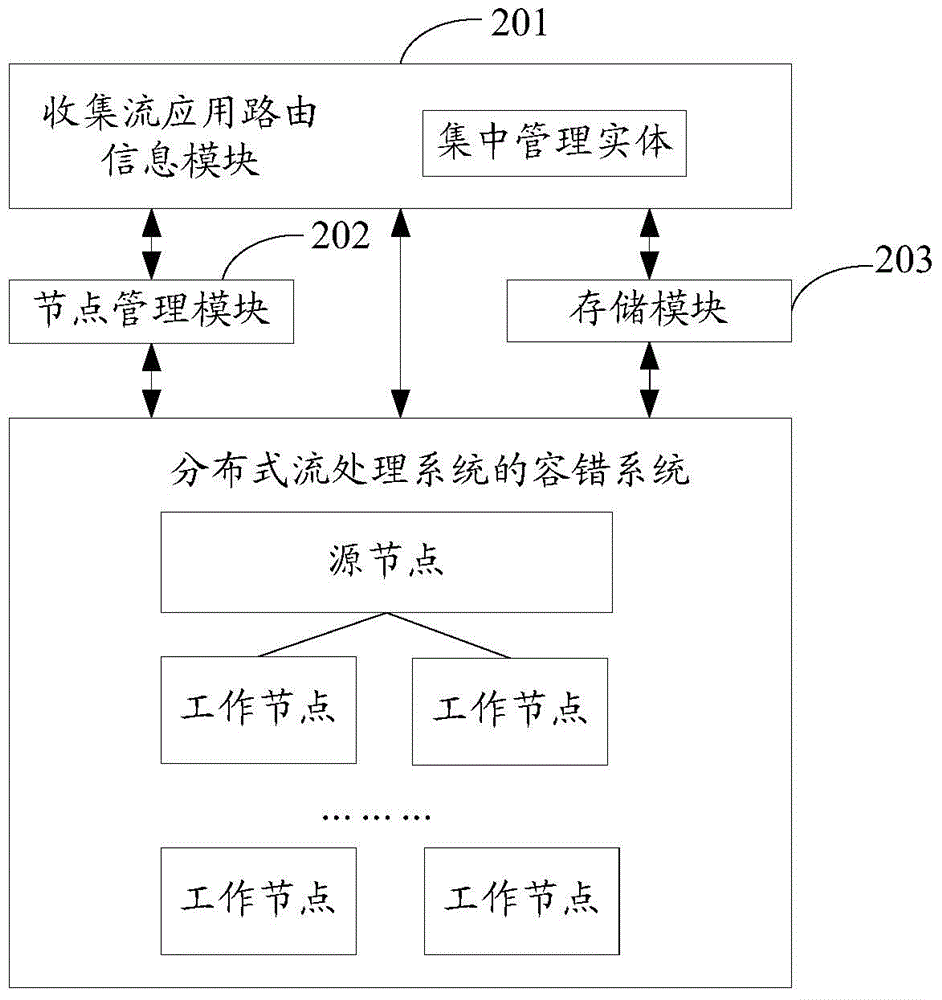

Distributed flow processing system fault tolerance method, nodes and system

ActiveCN104038364AImprove processing efficiencyDoes not affect processing efficiencyData switching networksReal-time computingSystem Fault Tolerance

Owner:HUAWEI TECH CO LTD

T-shaped adjustable clamp of linear cutting machine

InactiveCN110405297AFlexible clampingDoes not affect processing efficiencyElectrical-based machining electrodesElectrical-based auxillary apparatusWire cuttingEngineering

The invention provides a T-shaped adjustable clamp of a linear cutting machine, and relates to the field of clamps. The T-shaped adjustable clamp can be used for clamping the workpiece on an electricspark wire cutting machine. The clamp comprises clamp blocks, a guide rail with a T-shaped groove, a compression bolt, a gasket and a pressing piece, a transverse T-shaped groove matched with the shape of the lower part of the clamp block is machined in the guide rail, the clamp block is arranged in the T-shaped groove, the clamp block slides relative to the T-shaped groove, workpieces are fixed on the two sides, the pressing piece can be installed on the clamp block, and the compression bolt can rotate up and down relative to the two shoulders of the clamp blocks. Due to the fact that the sizes of the workpieces are different, the positions of the two clamp blocks are adjusted through the tightness of the compression bolts. Therefore, the clamp can be flexibly clamped along with the compression bolt, the machining efficiency is not affected, and the clamp is easy to machine.

Owner:HARBIN UNIV OF SCI & TECH

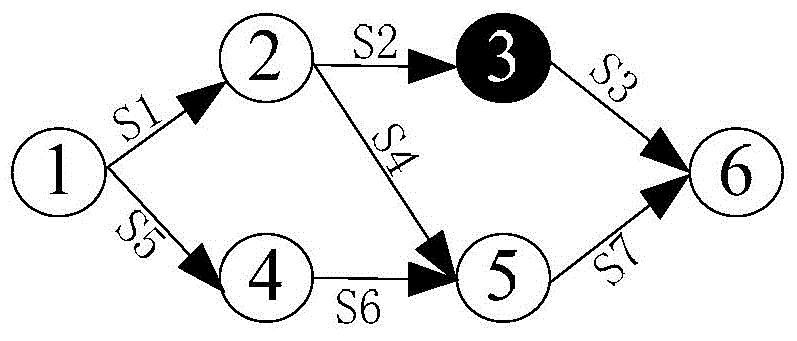

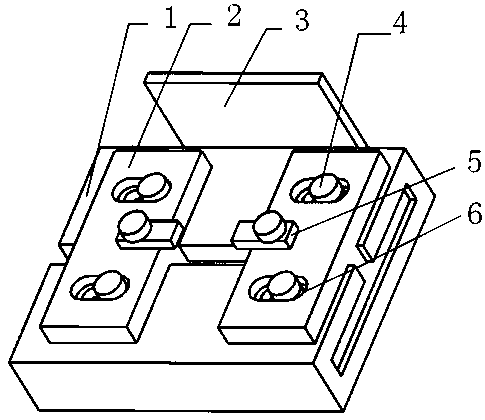

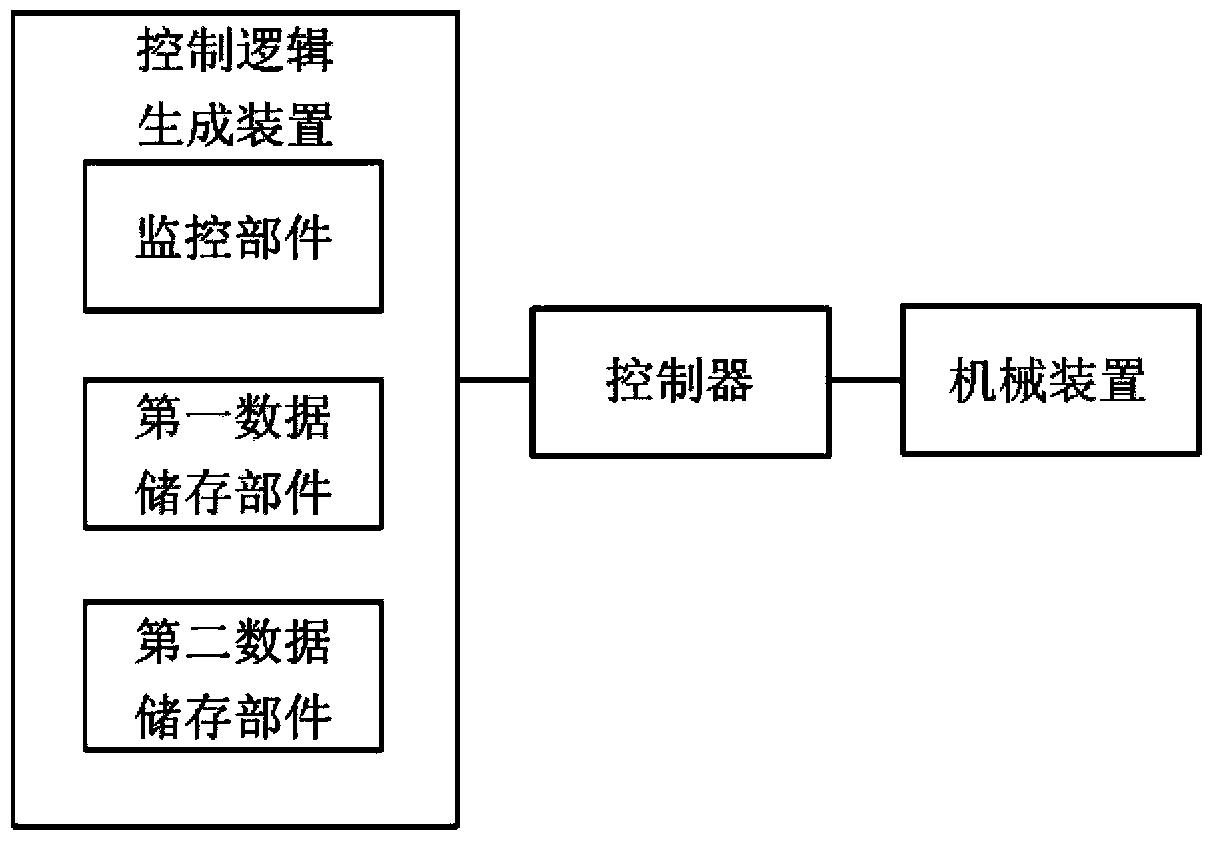

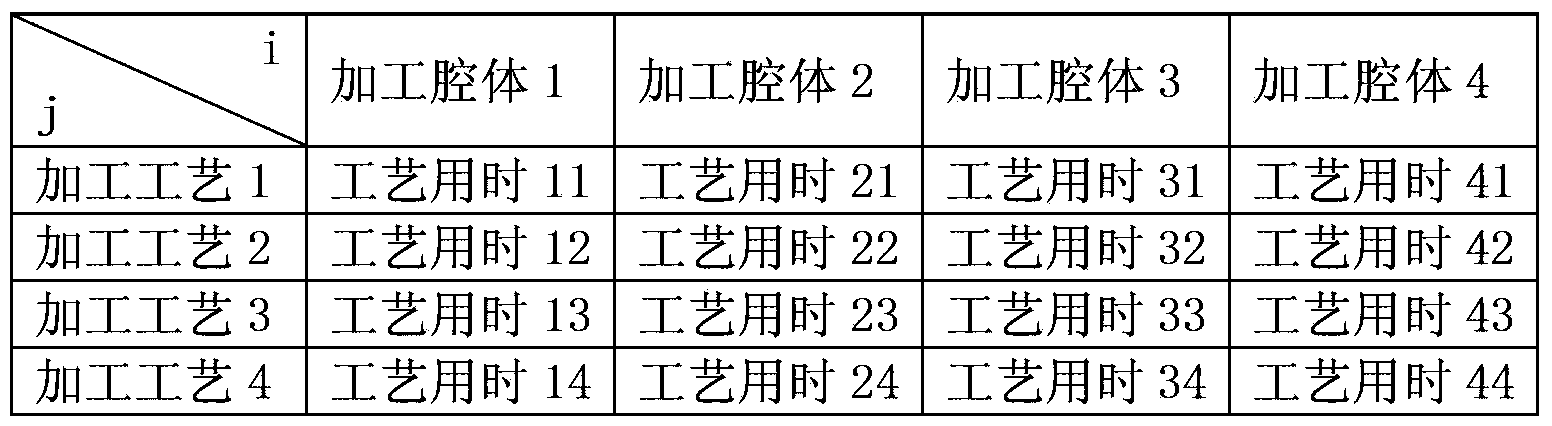

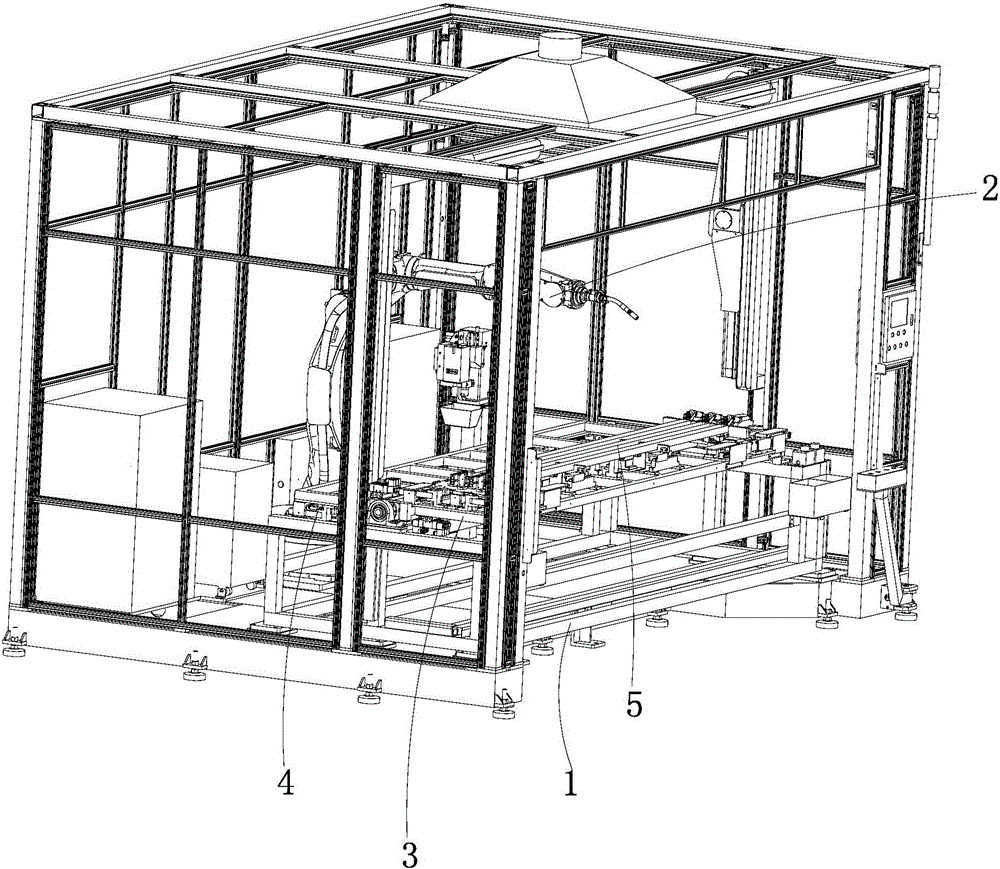

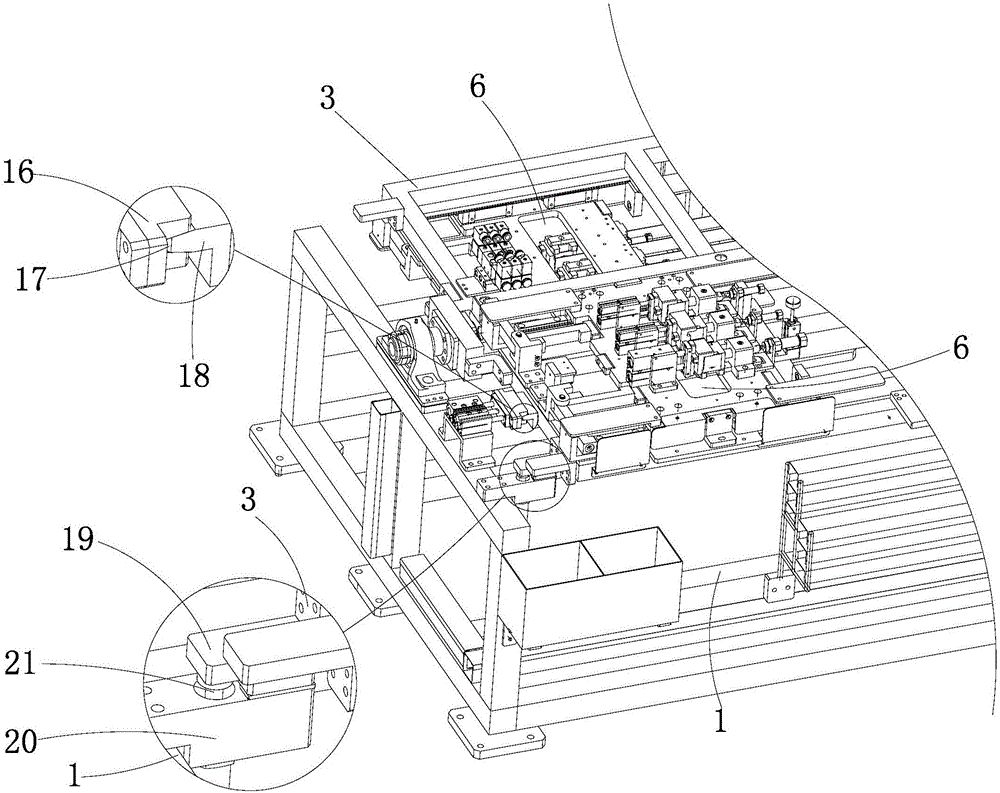

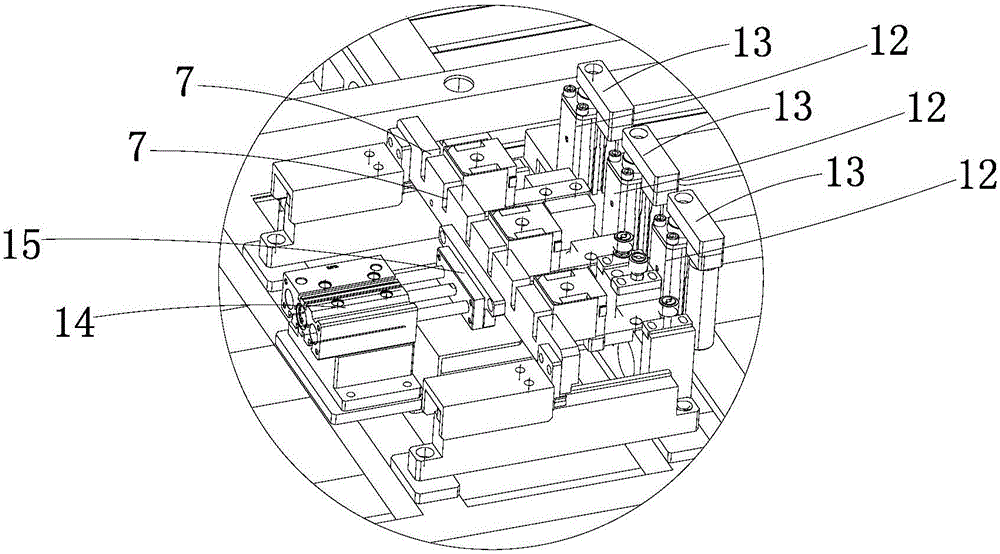

Control system and control method of robot

ActiveCN104162889ASolve the jamming of the robotic armSimple logic controlProgramme-controlled manipulatorPreconditionSemiconductor

The invention discloses a control system and a control method of a robot, and is applied to semiconductor manufacture equipment which is controlled by a block controller and provided with at least two processing cavities. The control system of the robot comprises a control logic generation device, a controller, and a mechanical device for loading and unloading processing base materials in the processing cavities; the control logic generation device is connected with the controller, and provides an instruction of controlling the mechanical device to the controller; and the controller is connected with the mechanical device, and is used for controlling the operation of the mechanical device. The control system of the robot has the following beneficial effects: the blockage problem of the robot in the prior art can be solved under the precondition of not influencing the processing efficiency of the semiconductor manufacture equipment; the hardware setting of the semiconductor manufacture equipment is not added; and the logic control is simpler.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Stand column welding device

ActiveCN106624540AContinuous welding operationDoes not affect processing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesSpin axisWelding

The invention relates to a stand column welding device. The current stand columns need to be clamped and fixed one by one and then welded by manpower, which is low in production efficiency. The stand column welding device comprises a rack and an operation arm used for welding arranged at one side of the rack, a roll-over stand is rotatably connected to the upper portion of the rack, the roll-over stand is provided with two sets of clamping structures arranged symmetrically on the basis of a roll-over stand spin axis, and the reciprocatingly rotary roll-over stand makes the two sets of clamping structures switch between a welding post cooperated with the operation arm and a feed replacing post of opening and closing the clamping structures. An original single set of clamping structure is improved into the reciprocatingly rotary roll-over stand, manpower welding is replaced by the operation arm used for welding, so that the welding efficiency is effectively improved, by utilizing the two sets of clamping structures on the roll-over stand to switch between the welding post and the feed replacing post, the two sets of clamping structures cooperate with the operation arm to work circularly and continuously, the continuous welding operation of the operation arm is ensured, and the processing efficiency cannot be influenced because feed on a clamping mechanism needs replacing.

Owner:宁波力隆盛世电器有限公司

A spherical grinding device for a ball core

ActiveCN111113198BImprove work efficiencyEasy to useGrinding drivesSpherical surface grinding machinesRotary stageGear wheel

The invention discloses a spherical surface grinding device for ball valve cores and particularly relates to the field of ball valve element machining. The spherical surface grinding device for the ball valve cores comprises a worktable, a rotating table is arranged at the top of the worktable, a multi-ball-core clamping mechanism is arranged at the top of the rotating table, outer grinding platesare arranged on the two sides of the multi-ball-core clamping mechanism respectively, the two outer grinding plates are driven through a reciprocating mechanism to do reciprocating linear movement and are used for grinding the spherical surfaces of ball cores fixed by the multi-ball-core clamping mechanism, tooth grooves are formed in the outer wall of the rotating table, and a driving gear engaged with the tooth grooves is arranged on the rear side of the rotating table. The spherical surface grinding device can grind multiple ball cores at the same time, and the working efficiency is greatly improved; besides, when the contact faces of the outer grinding plates and the ball cores are worn, position offset replacement of multiple ball core clamps can be achieved simply by driving the rotating table through the driving gear, and the grinding faces of the outer grinding plates and the ball cores are replaced; and the grinding device is very convenient to use, adjustment is quick, and the machining efficiency and the precision of the ball cores are not influenced.

Owner:顶红科技发展(浙江)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com