Curved surface tool path contour error compensation method based tool location point correction

A contour error and compensation method technology, which is applied in the direction of instruments, computer control, simulators, etc., can solve the defects of the contour error reduction method, the reduced applicability of highly integrated CNC machine tools, and the inability to estimate the contour error of large-curvature machining trajectories, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

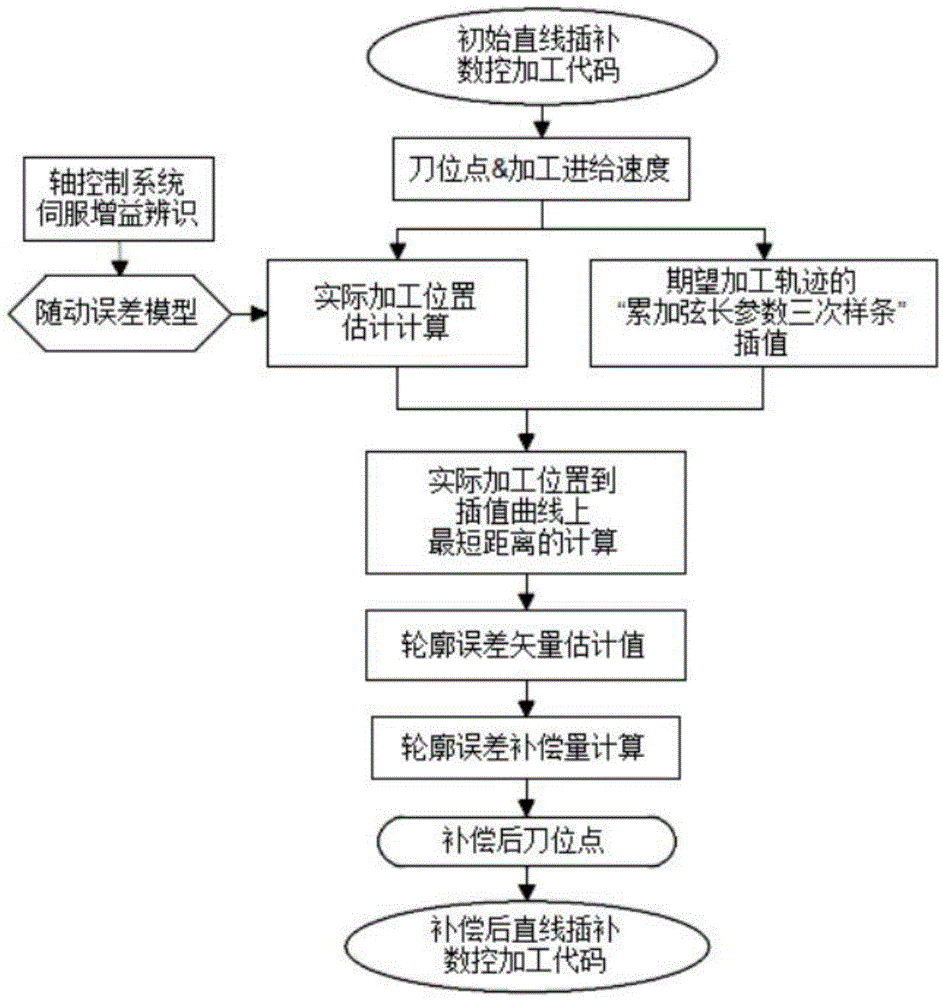

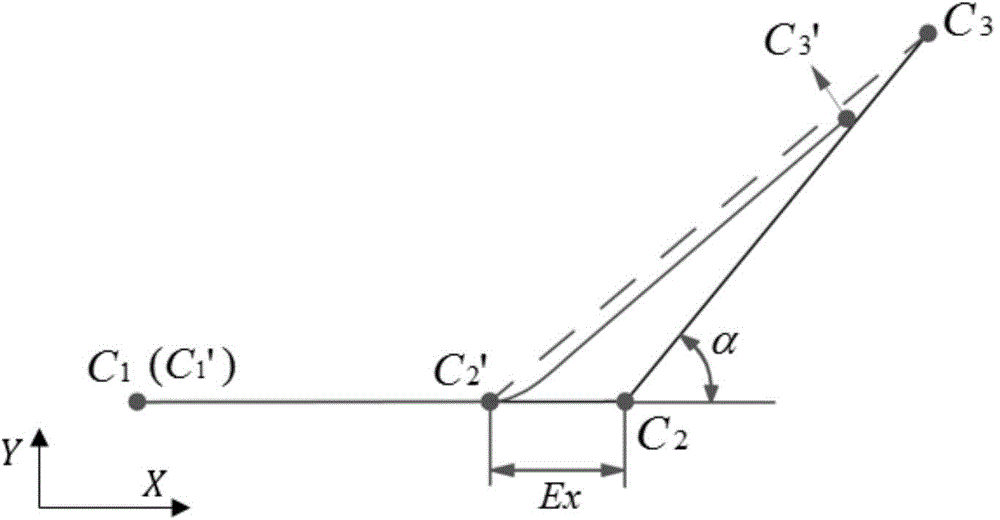

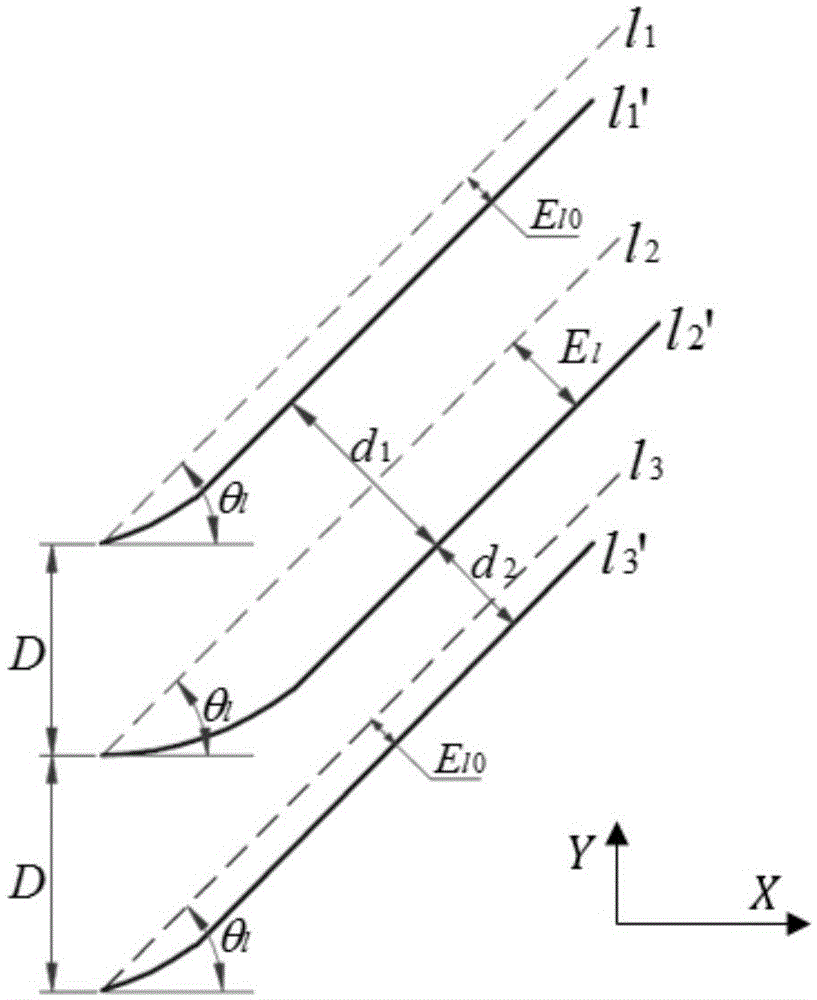

[0083] The specific implementation manner of the present invention will be described in detail in conjunction with the accompanying drawings and technical solutions.

[0084] In order to ensure the processing requirements of complex curved surface parts with high contour accuracy, the processing efficiency is low, which cannot meet the large demand for high contour precision complex curved surface parts in the rapid development of aerospace, energy and power and other fields. Machining with high feed rate is one of the important means to improve the machining efficiency of complex curved surface parts with high contour accuracy. However, in the "continuous path" operation mode of CNC machining, due to the limitation of the dynamic characteristics of the CNC machine tool, when the machining feed rate is high, the contour error of the machining trajectory curve of the CNC machine tool tool increases significantly, which in turn leads to a decrease in the contour accuracy of compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com