Special-shaped hole machining device and method

A processing device and special-shaped hole technology, applied in the field of sheet metal parts processing, can solve the problems of high processing tool requirements, poor processing accuracy, difficult clamping, etc., and achieve the effects of low electrode wear rate, convenient operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

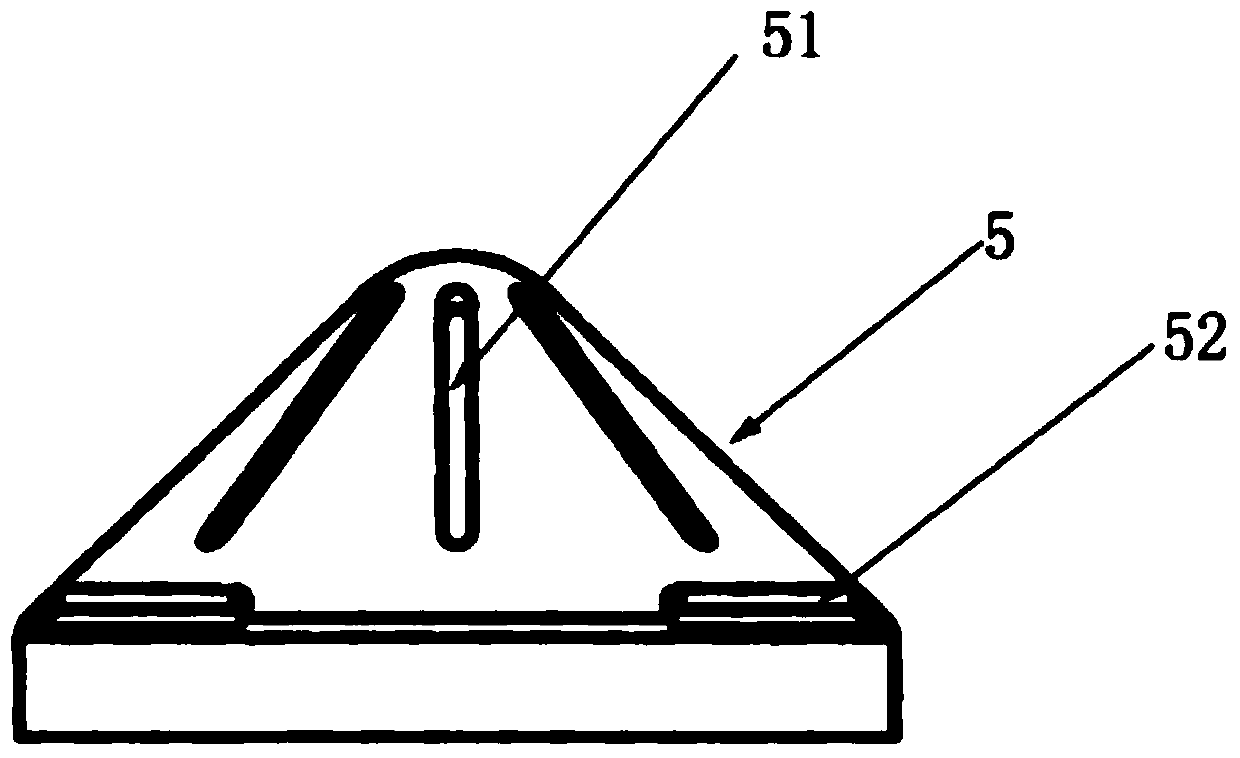

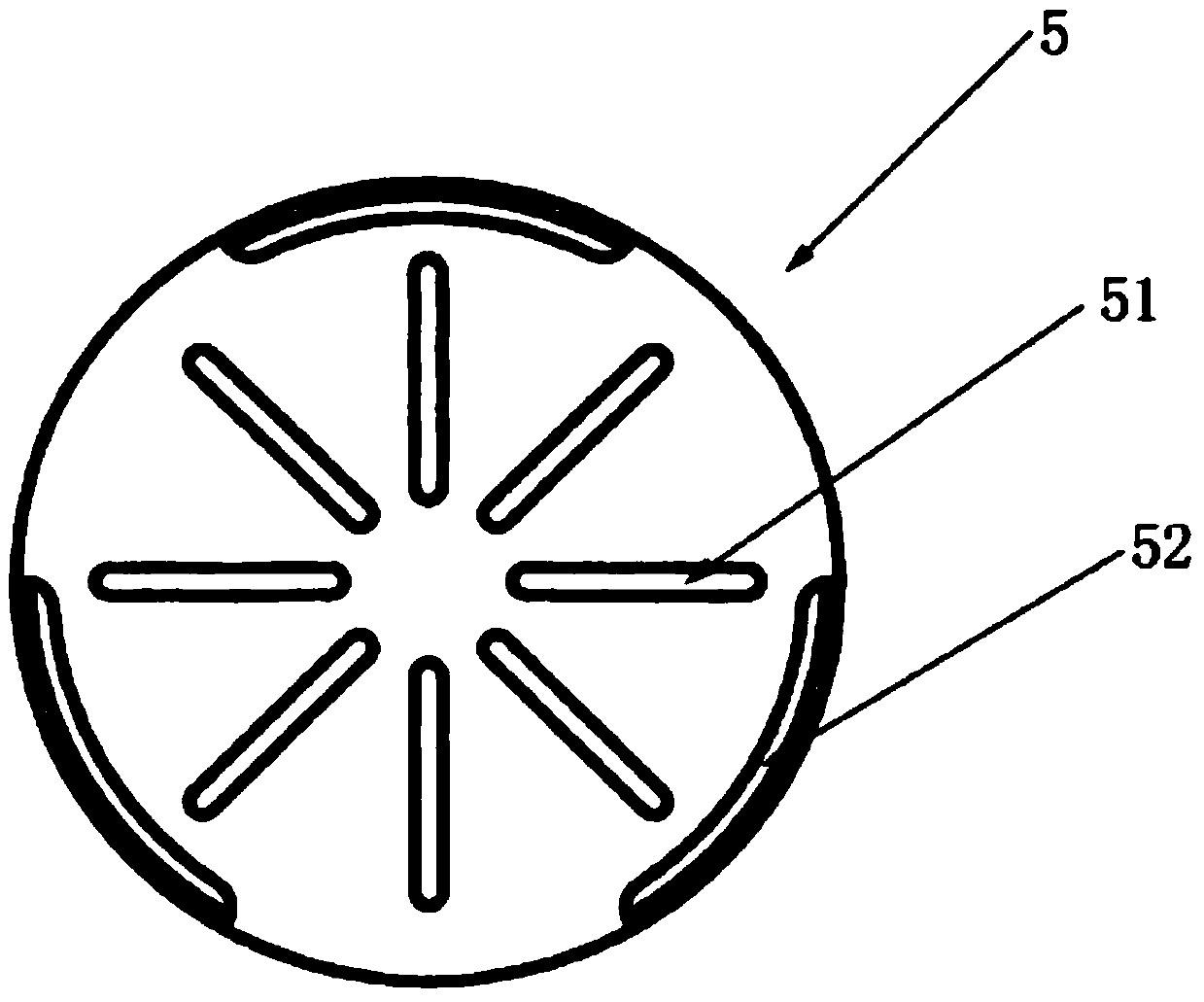

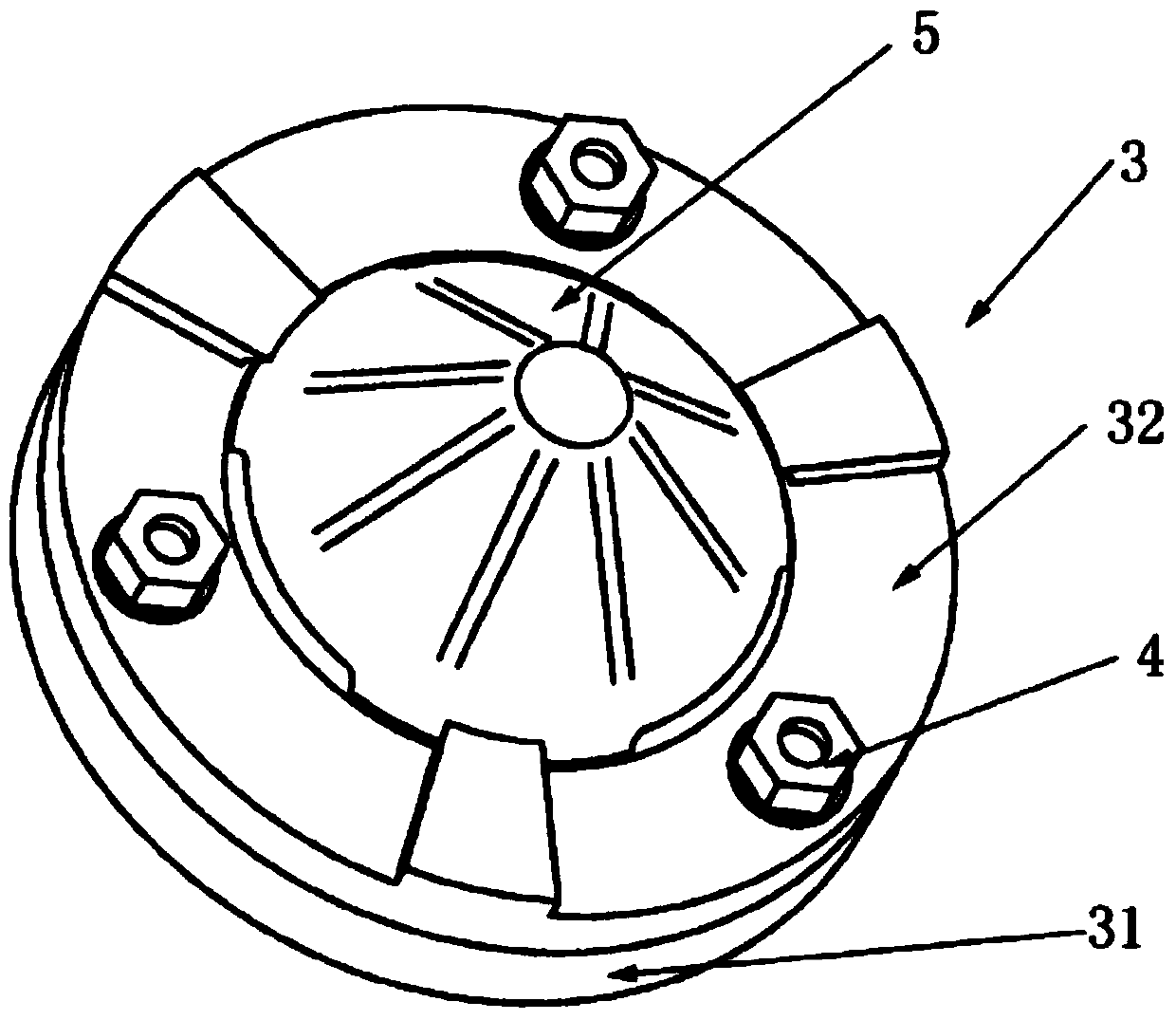

[0030] Such as Figure 1-7 As shown, a special-shaped hole processing device is used for processing special-shaped holes on tapered sheet metal parts 5, including an electrode mechanism and a clamping mechanism 3. Corresponding electrode positioning holes, the electrodes corresponding to the special-shaped holes are arranged in the electrode positioning holes, and the central axis of the electrode positioning seat is provided with a connecting rod. The clamping mechanism 3 includes a carcass 31 and an annular pressure plate 32, and several matching screw holes are provided on the carcass 31 and the annular pressure plate 32. The conical sheet metal part 5 is placed between the carcass 31 and the annular pressure plate 32, and passes through The bolt 4 fastens and connects the carcass 31 , the conical sheet metal part 5 and the annular pressure plate 32 . Such as Figure 1-2 As shown, there are two kinds of special-shaped holes on the tapered sheet metal part 5, special-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com