Waste gas purification environmental protection equipment

A kind of environmental protection equipment and exhaust gas purification technology, which is applied in the direction of gas treatment, chemical instruments and methods, combined devices, etc., can solve the problems of exhaust gas emission not up to standard, poor purification effect, etc., and achieve environmental protection in industrial production, reduce impurities, and ensure safe use of equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

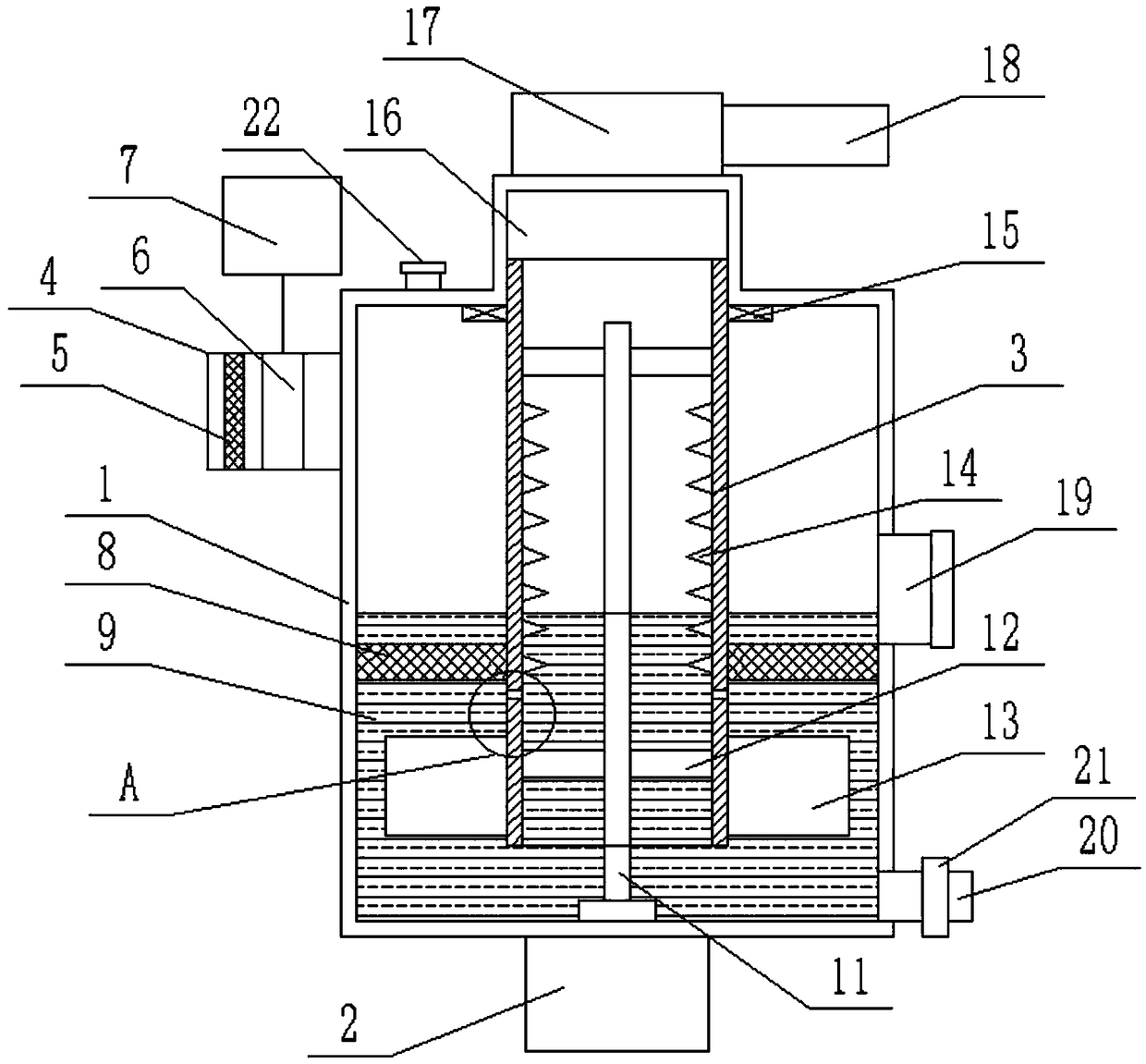

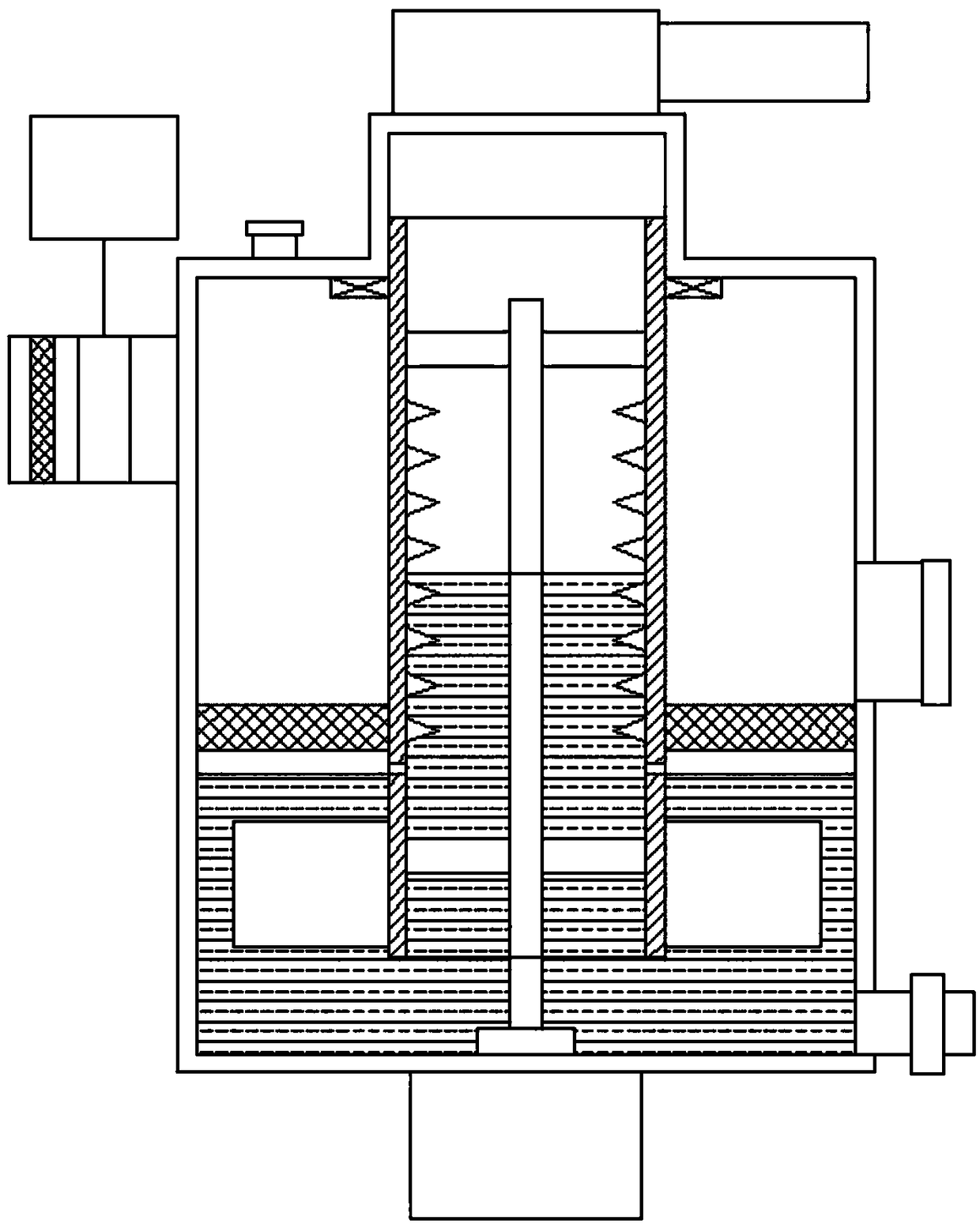

[0017] Please refer to the figure. In the embodiment of the present invention, an environmental protection device for purifying exhaust gas includes a housing 1, a motor 2, a rotating drum 3, and an air inlet pipe 4; the air inlet pipe 4 is connected to the upper end of the side wall of the housing 1, and Exhaust gas is fed into the casing 1 through the air inlet pipe 4, and a protective net 5 and an air pump 6 are installed in the air inlet pipe 4, and the protective net 5 plays a protective role to prevent large light debris from entering with the wind , The exhaust gas in the air inlet pipe 4 is sent into the housing 1 through the air pump 6 to pressurize the housing 1.

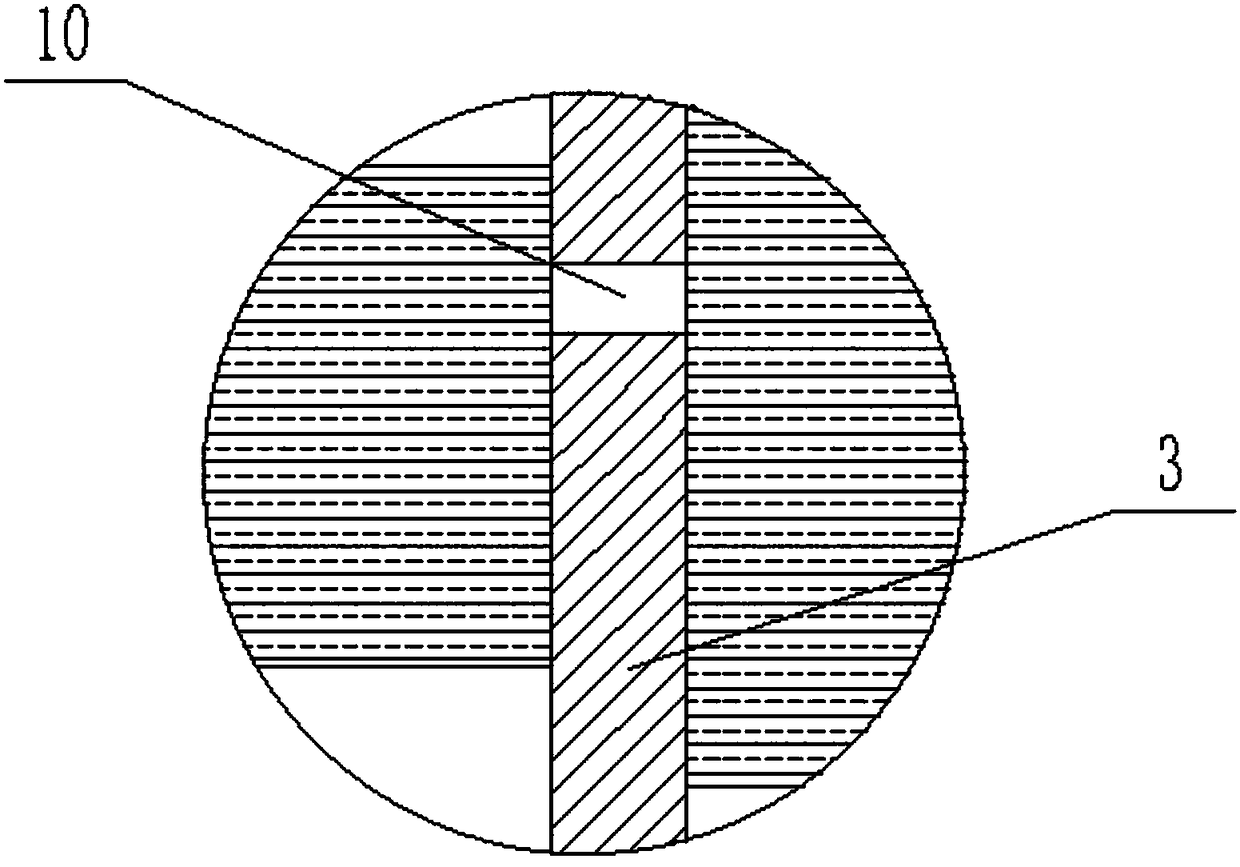

[0018] The motor 2 is fixedly installed at the bottom of the housing 1, the output shaft of the motor 2 extends vertically upward into the housing 1, and a vertical rotating shaft 11 is fixedly connected to the upper end of the output shaft of the motor 2. The vertical rotating drum 3, the rotating shaft 11 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com