T-shaped adjustable clamp of linear cutting machine

A technology of cutting machine tools and fixtures, which is applied in the direction of manufacturing tools, electric processing equipment, metal processing equipment, etc., can solve the problems of lower processing efficiency, frequent replacement, long calibration time, etc., and achieve the effects of ensuring accuracy, preventing shaking, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

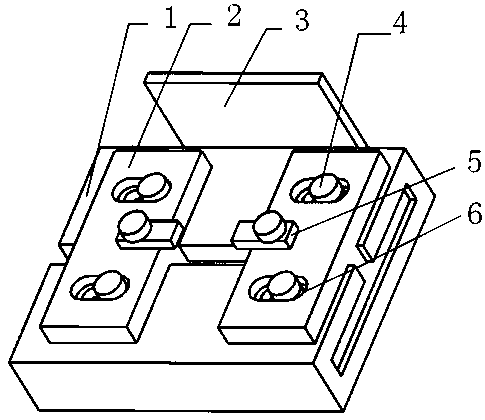

[0007] exist figure 1 Among them, 1. Guide rail with T-shaped groove 2, clamp block 3, clamp body 4, compression bolt 5, compression piece 6, gasket. The invention can be used for the clamping of workpieces processed on electric discharge wire cutting machine tools. The fixture includes a fixture block, a guide rail with a T-shaped slot, a compression bolt, a spacer, and a compression piece. The gasket is placed in the groove of the fixture block to prevent the compression bolt from destroying the precision of the guide rail with the T-shaped groove after long-term use. The tightening bolt can be placed on the gasket and rotated up and down, so that the fixture block can move back and forth. The upper side of the fixture block can be equipped with different shapes of pressing pieces according to the shape of the workpiece, and the surface of the fixture body perpendicular to the direction of the guide rail can also prevent the workpiece from tilting.

[0008] When in use, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com