Improved bioreactor

A bioreactor and reactor technology, applied in the field of water treatment, can solve the problems of poor treatment effect, easy blockage of the reactor, low oxygenation efficiency, etc., and achieve enhanced relative operation, improved oxygenation efficiency, and reliable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

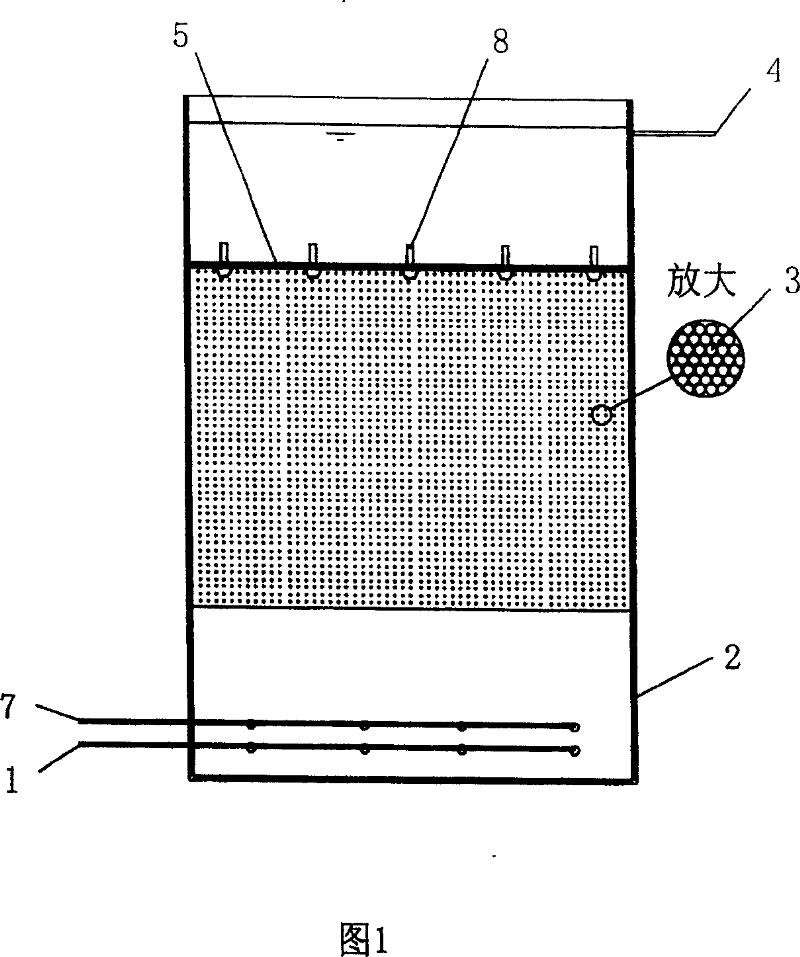

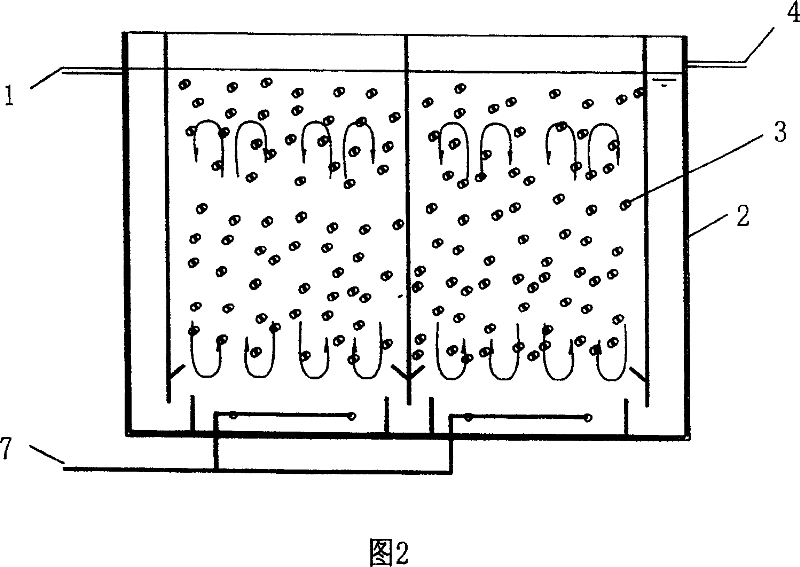

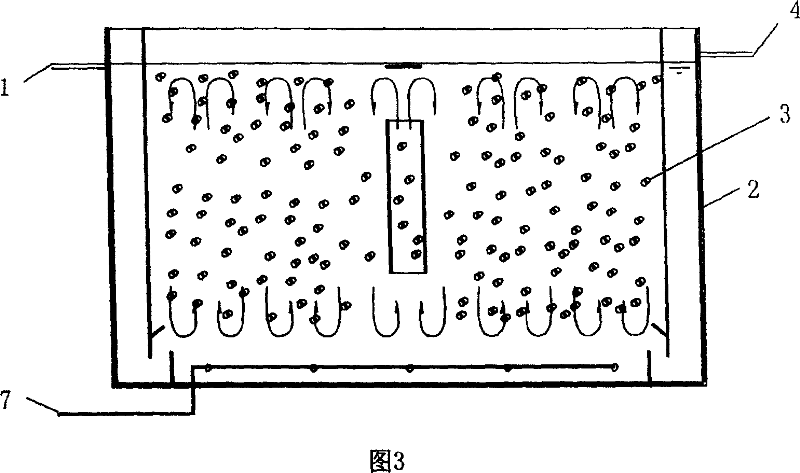

[0029] Embodiment: referring to Fig. 4, 5, the hollow tubular packing 3 (the size is 300,000-300,000 per cubic meter) that specific gravity 0.9, porosity 85%, axial direction and radial ratio are 0.9~1.1 are filled in reaction vessel 2. 450,000 grains), the filling amount of filler accounts for 65-80% of the effective volume of the reactor, and there is a porous filler baffle 5 at 100-200 mm below the water surface on the top of the reactor, with a pore diameter of 5-10 mm, a water outlet 4 at the top, and a water outlet 4 at the bottom. There are oxygen supply aeration system 7 and fluidized aeration system 6, and water inlet pipe 1. Microporous aerators are used for oxygen supply and aeration, and the air supply volume of each aerator is 0.2 to 0.6 cubic meters per hour, and the installation density is 25 to 49 per square meter; the fluidized aeration uses macroporous aerators, The air supply volume of each aerator is 2.0-6.0 cubic meters per hour, and the installation densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com