Integrated sewage treatment device and method based on tidal aerated biological filter

A technology of biological aerated filter and sewage treatment equipment, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of high backwash intensity and large backwash water volume , High height of biological aerated filter, to achieve the effect of high effluent quality, small equipment size, and long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

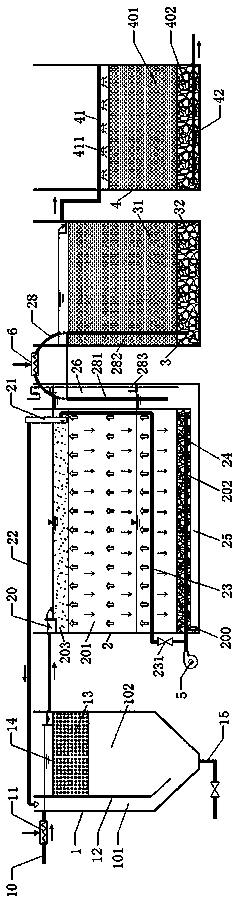

[0034] like figure 1 As shown, the integrated sewage treatment equipment based on the tidal aerated biological filter includes a sedimentation tank 1, a biological aerated filter 2, an anaerobic filter 3 and a breathing filter 4 connected in sequence through pipes. The upper part of the sedimentation tank 1 is provided with a water inlet pipe 10, and the water inlet pipe 10 is provided with a first pipeline mixer 11 for adding phosphorus removal chemicals. The interior of the sedimentation tank 1 is divided into a guide area 101 and a filter area 102 by a guide plate 12 , and the water inlet pipe 10 is communicated with the guide area 101 . The upper part of the filter area 102 is provided with a suspended filler layer 13, and the material of the suspended filler layer 13 is a foamed plastic with a particle size of 3-5 mm and a thickness of 50 cm. A fine mesh 14 is fixed above the suspended filler layer 13, and the aperture of the fine mesh is 2 mm. The lower part of the sed...

Embodiment 2

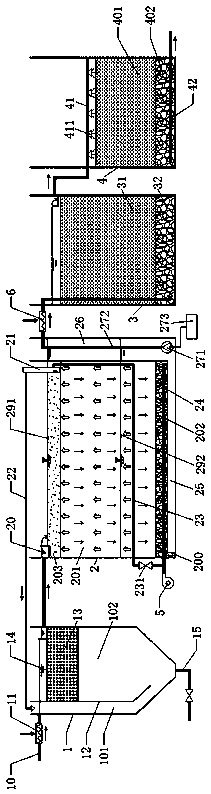

[0048] like figure 2 As shown, the difference between the present embodiment and the first embodiment is only that the tidal drainage device is a siphon 28, the siphon 28 is a stainless steel pipe, and the siphon 28 is composed of an interconnected water inlet siphon 281 and an outlet siphon 282, the highest of the siphon 28 is point is lower than the water level line of the biological aerated filter tank 2 maximum liquid level, the siphon pipe 28 is provided with a second pipeline mixer 6 for adding carbon source. The water inlet siphon water pipe 281 stretches into the bottom of the water collection well 26, and a certain height on the wall of the water collection well 26 is provided with a siphon breaking cup 283, and the end of the water outlet siphon water pipe 282 extends into the coarse aggregate filter layer 32 of the anaerobic filter tank 3 . The rest of the structure of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com