Poly-generation process for pyrolyzing solid thermal carrier via low-rank coal vibration bed

A solid heat carrier and low-rank coal technology, which is applied in solid fuel, petroleum industry, tar processing, etc., can solve the problem that the low-rank coal pyrolysis process has not formed an industrial scale, so as to increase the operating cost of the process and save the operating cost , high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings, but not as a limitation of the present invention.

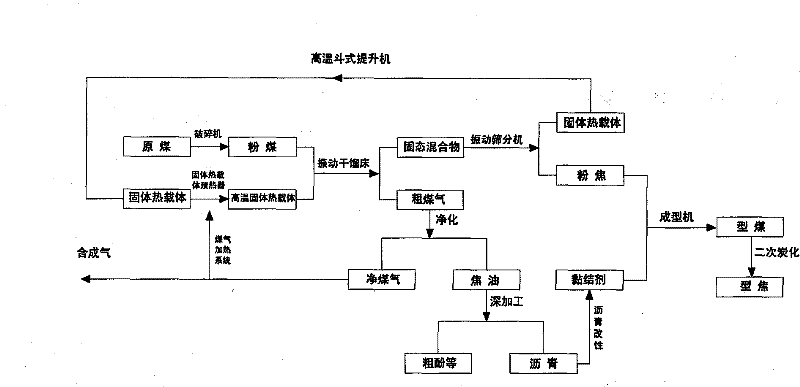

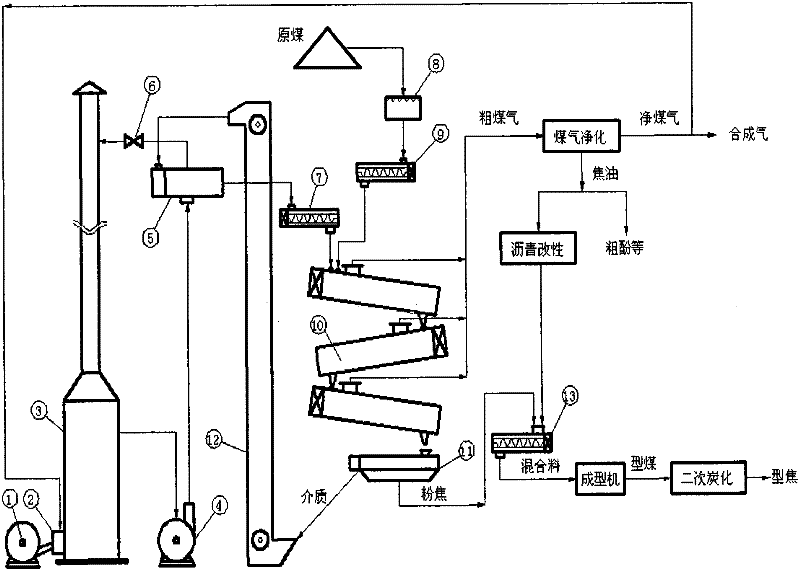

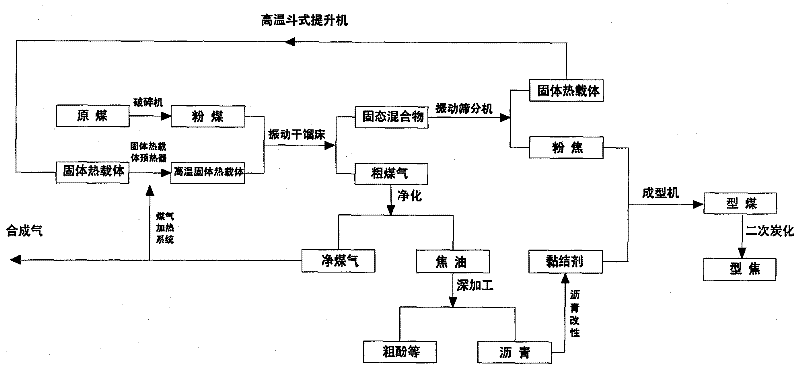

[0025] figure 1 , figure 2 Shown: the raw coal is crushed to a particle size of 3-6mm by a crusher (8), sent to the pulverized coal inlet of the vibrating carbonization bed (10) through a pulverized coal screw conveyor (9), and is preheated by a solid heat carrier at the same time The high-temperature solid heat carrier heated by the system is transported to the solid heat carrier inlet of the vibrating dry distillation bed (10) through the high-temperature screw conveyor (7). The high-temperature solid heat carrier and pulverized coal are mixed rapidly on the bed of the vibrating retort bed (10), and the high-temperature solid heat carrier transfers heat to the pulverized coal, so that a large amount of volatile matter in the pulverized coal is separated out, and the crude gas produced is passed through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com