Microwave oven device for pyrolysis and pyrolysis method thereof

A microwave oven and pyrolysis technology, which is applied in household heating, household stove/stove, application, etc., can solve the problems of large microwave oven volume, uncontrollable reaction time, single power, etc., achieve uniform pyrolysis, facilitate collection, and ensure accurate sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

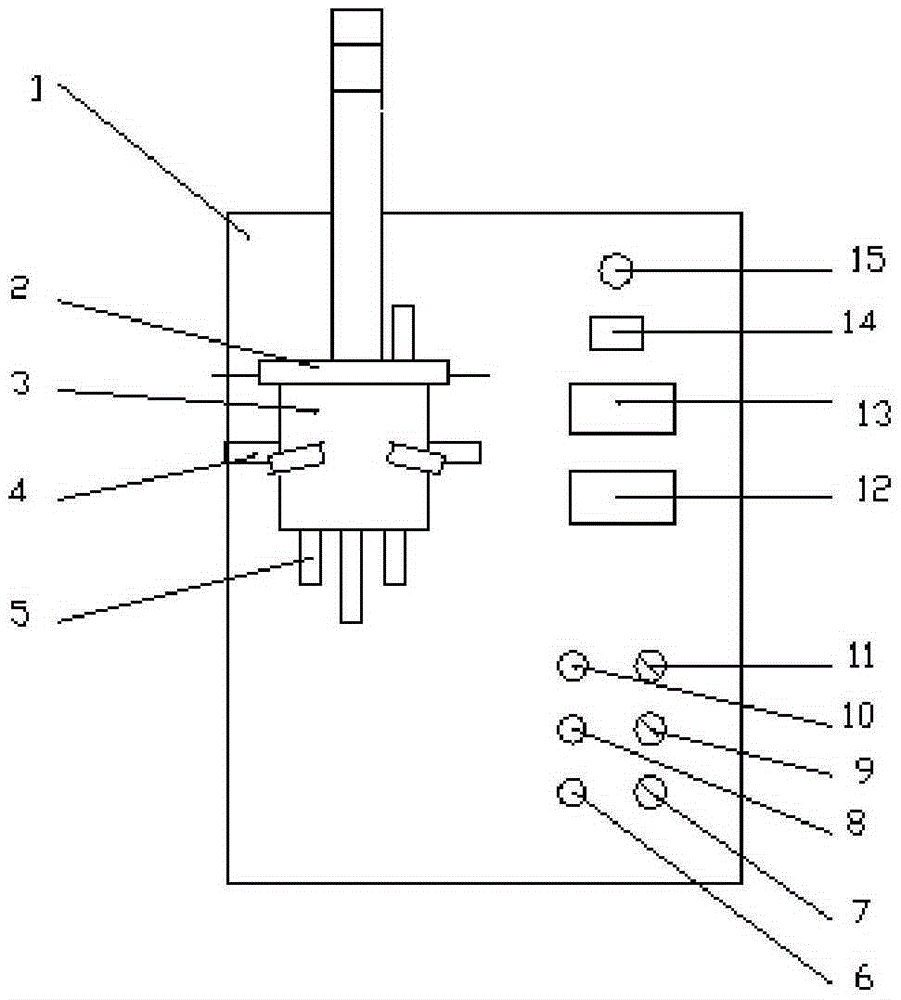

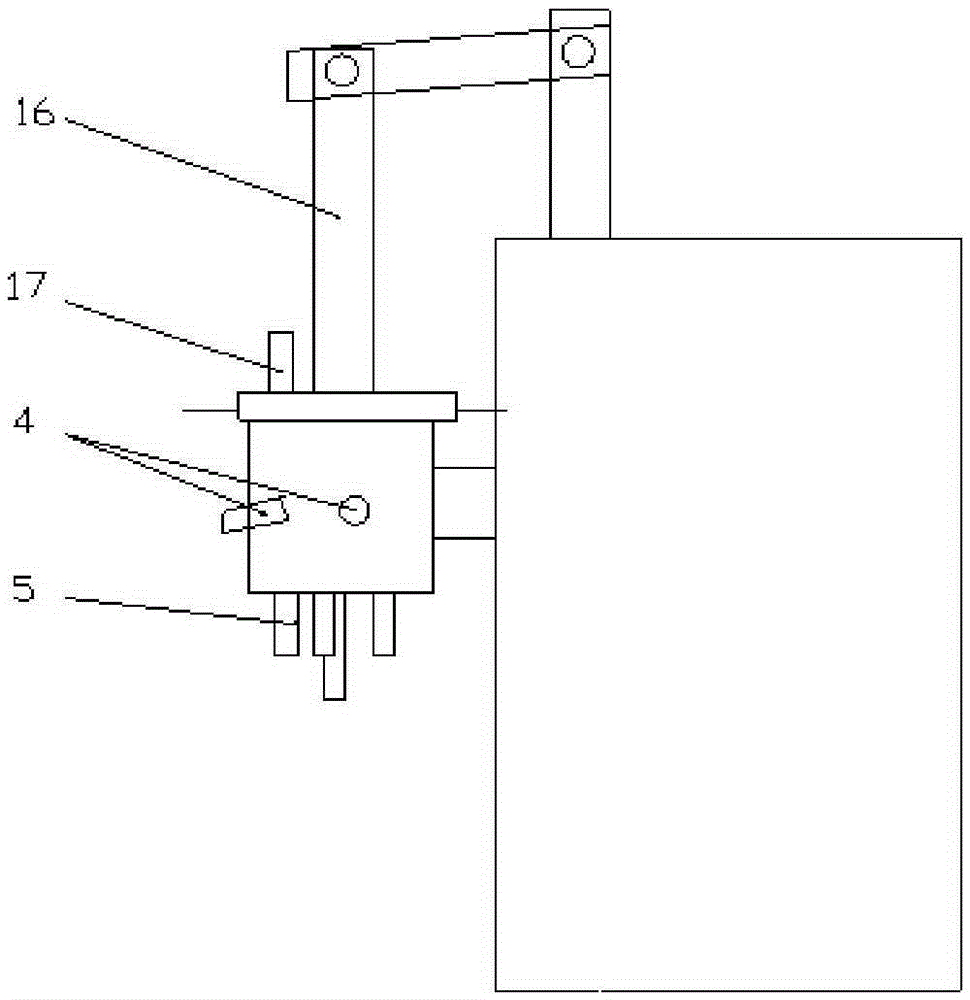

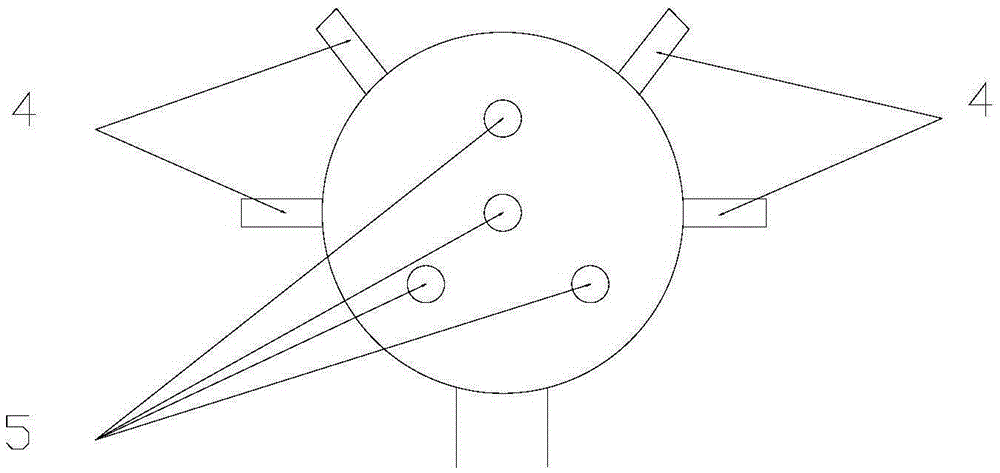

[0028] Such as Figures 1 to 4 shown. The microwave oven device used for pyrolysis of the present invention includes a microwave furnace body 1 and a reaction chamber 3 arranged outside the furnace body; the top of the reaction chamber 3 is provided with a closed end cover 2, and the surrounding walls of the reaction chamber 3 are distributed There are four side air inlets 4, the bottom of the reaction chamber 3 is provided with four bottom air inlets 5, and the peripheral wall of the reaction chamber 3 is provided with an electric heating device; body 1 connection.

[0029] An air outlet 17 , an infrared sensor 18 , a thermocouple 19 , a stirring rod 20 and a camera 21 are arranged on the closed end cap 2 .

[0030] The body of furnace 1 is provided with: stop key 6, stirring key 7, start key 8, electric heat key 9, power adjustment key 10, microwave key 11 and display, display is used for displaying thermocouple temperature 12, infrared temperature 13, Current 14 and Powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com